Electroplating solution for nano-ZrO2 composite plating of Ni-P alloy and electroplating method

An electroplating solution and composite plating technology, applied in the field of nickel electroplating process, can solve the problems of weak corrosion resistance, low wear resistance, and low hardness of Ni-P alloy coating, so as to improve the hardness and wear resistance, improve the Corrosion resistance, passivation promotion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] (1) Preparation of nano-dispersion. DK417 nanometer ZrO produced by Beijing Deke Daojin Technology Co., Ltd. 2 . Add the fluorocarbon surfactant into the three-necked flask to dissolve and then stir with a mixer at low speed for several minutes. Then, after transferring to a large beaker and installing the GR-I shear disperser of Chengdu Xindu Yongtong Machinery Factory, add the nano-ZrO2 powder into the three-necked flask, and adjust the speed of the shear disperser to 300-500rpm. After the shear dispersion time is 5-10 minutes, the rotation speed is adjusted to 1500-2000 rpm, and the shear dispersion time is 10-15 minutes to obtain the nano slurry. The average particle size of the nano-dispersion was tested by a Mastersizer 2000 laser particle size analyzer from Malvern.

[0034] (2) Weigh the mass of other raw material components with an electronic balance according to the formula. Dissolve the component raw materials with appropriate amount of water, mix them ev...

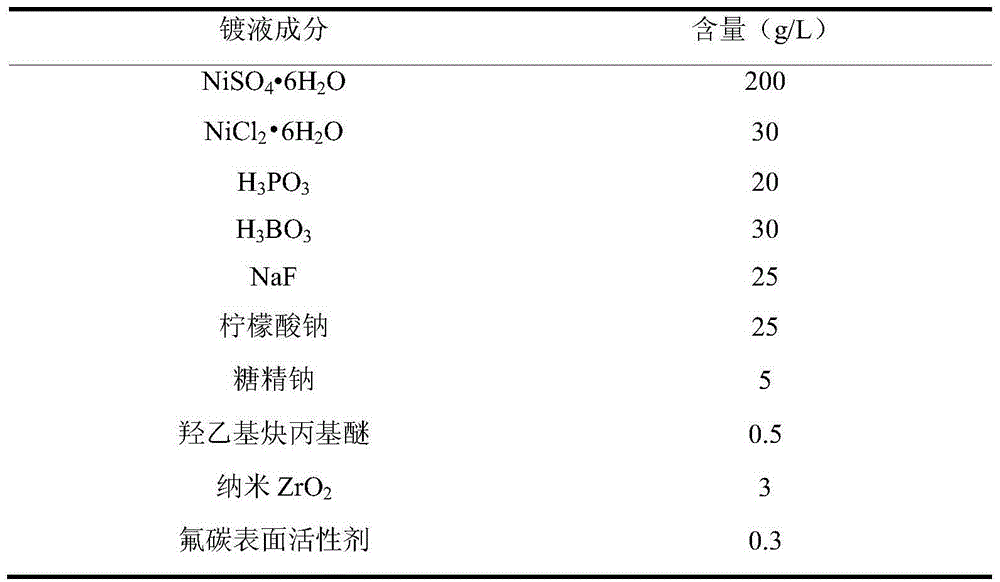

Embodiment 1

[0040] The formulation of the electroplating solution is as follows:

[0041]

[0042] In the nano-dispersion liquid preparation, the rotating speed of low-speed shear dispersion is 300rpm, and the time of low-speed shear dispersion is 5min; the rotational speed of high-speed shear dispersion is 1500rpm, and the time of high-speed shear dispersion is 10min; the ultrasonic dispersion power is 600W, The time of ultrasonic dispersion is 6min, and the average particle size of carbon nanometer in the prepared dispersion is 100nm; the plating process conditions: the pulse width of single pulse square wave current is 1ms, the duty ratio is 30%, and the average current density is 2A / dm 2 ; The pH is 2, the temperature is 50°C, and the electroplating time is 40min.

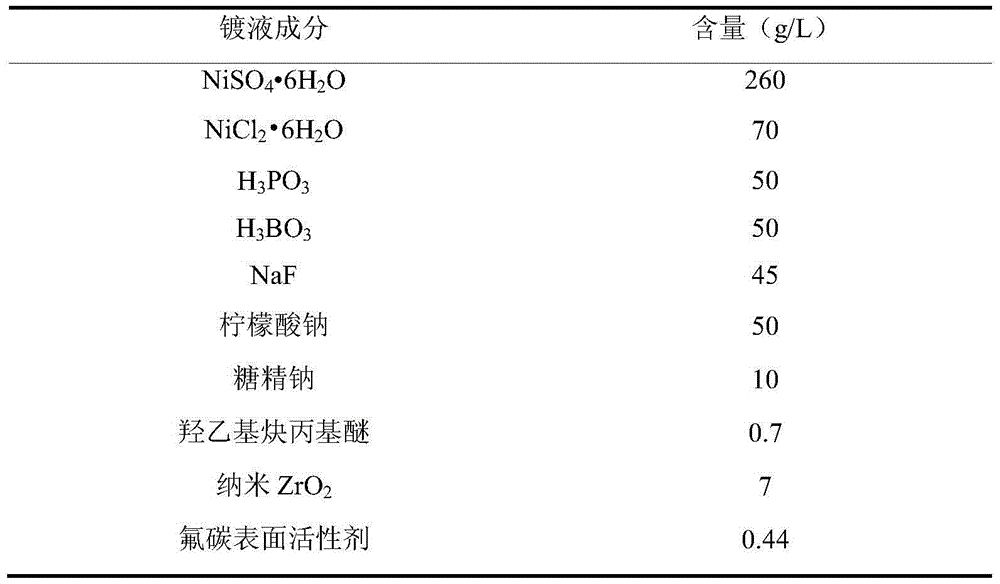

Embodiment 2

[0044] The formulation of the electroplating solution is as follows:

[0045]

[0046] In the nano-dispersion liquid preparation, the rotating speed of low-speed shear dispersion is 500rpm, and the time of low-speed shear dispersion is 10min; the rotational speed of high-speed shear dispersion is 2000rpm, and the time of high-speed shear dispersion is 15min; the ultrasonic dispersion power is 1000W, The ultrasonic dispersion time is 3 minutes, and the average particle size of carbon nanometers in the prepared dispersion is 110 nm. Plating process conditions: the pulse width of the single pulse square wave current is 1ms, the duty cycle is 25%, and the average current density is 3A / dm 2 ; The pH is 0.5, the temperature is 55°C, and the electroplating time is 35min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com