Method for welding specially-thick high-strength bridge steel plate

A welding method and bridge technology are applied in the welding of low-alloy high-strength steel extra-thick plates, and the welding of extra-thick and high-strength bridge steel plates, which can solve the problems of difficult control of welding deformation of extra-thick plates, low welding efficiency, and easy occurrence of cold cracks. , to avoid reheat embrittlement, improve welding efficiency, and avoid reheat cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

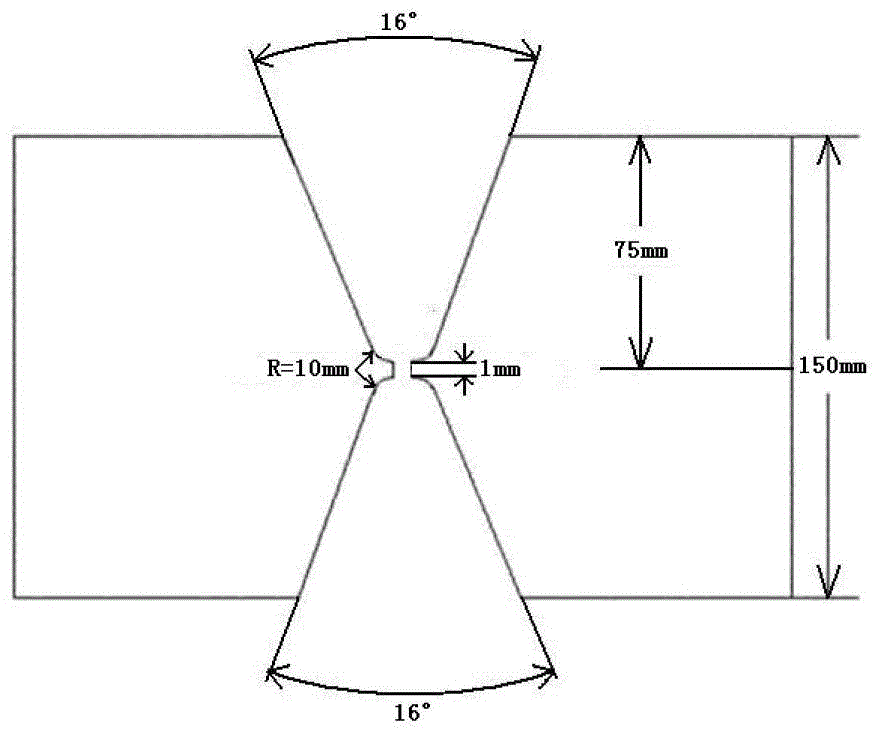

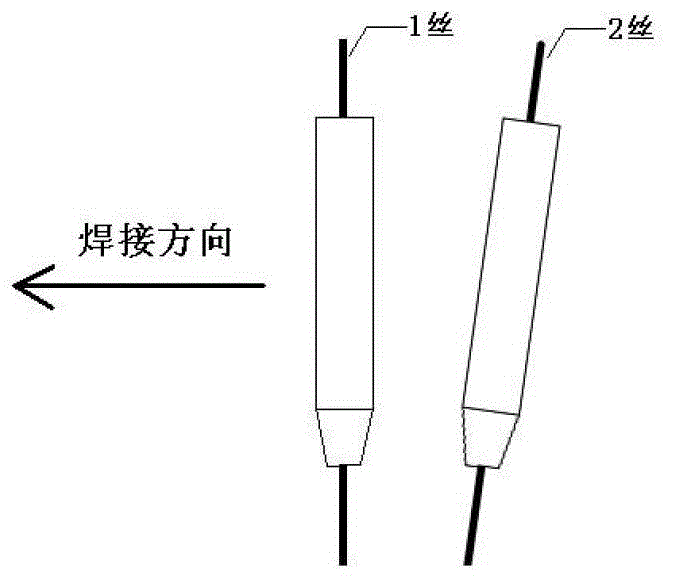

[0025] Base material: 100mm thick Q370qE bridge steel plate produced by hot rolling + normalizing process, yield strength 380MPa, tensile strength 530MPa, elongation 32%, impact energy 263J at -40°C at 1 / 4 thickness, 1 / 2 thickness The impact energy at -40°C is 233J, the thickness combination of welded steel plates is 100mm+100mm, and the size of the test plate is 600mm×220mm×100mm. figure 1 shown;

[0026] Welding materials: gas shielded welding wire diameter Φ1.2mm, mechanical properties of cladding metal: yield strength 525MPa, tensile strength 595MPa, elongation 27%, impact energy at -40°C 76J; submerged arc welding wire diameter Φ5mm, mechanical properties of cladding metal It is: yield strength 450MPa, tensile strength 560MPa, elongation 30%, impact energy at -40°C 125J.

[0027] Welding process: Before welding, use mechanical treatment to clean the groove surface to remove oil and rust; preheat 150 ° C before welding, and control the interlayer temperature at 150 ~ 200 ...

Embodiment 2

[0030] Base material: 150mm thick Q370qE bridge steel plate produced by hot rolling + normalizing process, yield strength 375MPa, tensile strength 520MPa, elongation 30%, impact energy 227J at -40°C at 1 / 4 of the plate thickness, 1 / 2 plate thickness The impact energy at -40°C is 207J, the thickness combination of welded steel plates is 150mm+150mm, and the size of the test plate is 600mm×220mm×100mm. figure 2 shown;

[0031] Welding materials: gas shielded welding wire diameter Φ1.2mm, mechanical properties of cladding metal: yield strength 525MPa, tensile strength 595MPa, elongation 27%, impact energy at -40°C 76J; submerged arc welding wire diameter Φ5mm, mechanical properties of cladding metal It is: yield strength 450MPa, tensile strength 560MPa, elongation 30%, impact energy at -40°C 125J.

[0032] Welding process: Before welding, use mechanical treatment to clean the groove surface to remove oil and rust; preheat 150°C before welding, and control the interlayer tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com