Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

204results about "Extrusion profiling tools" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

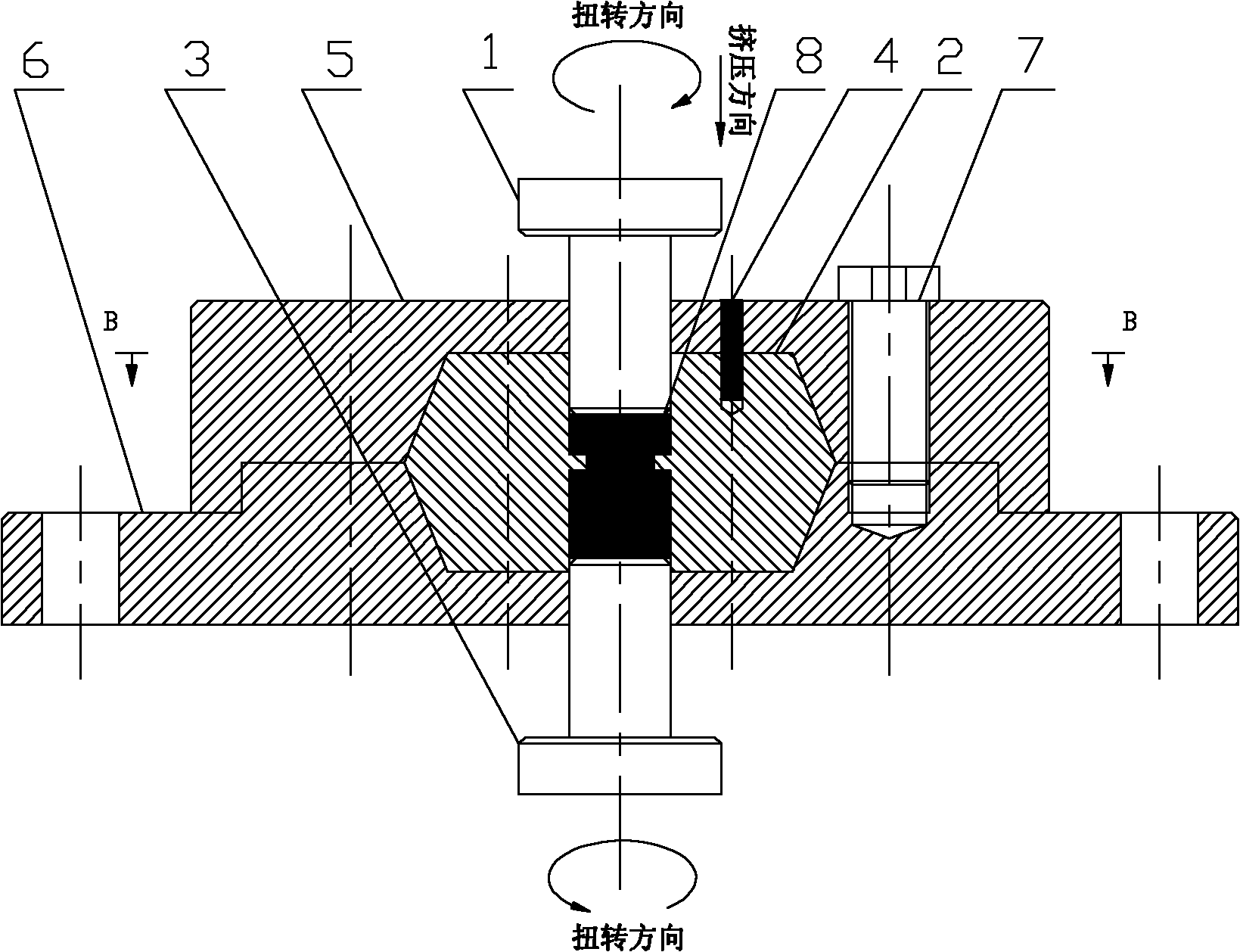

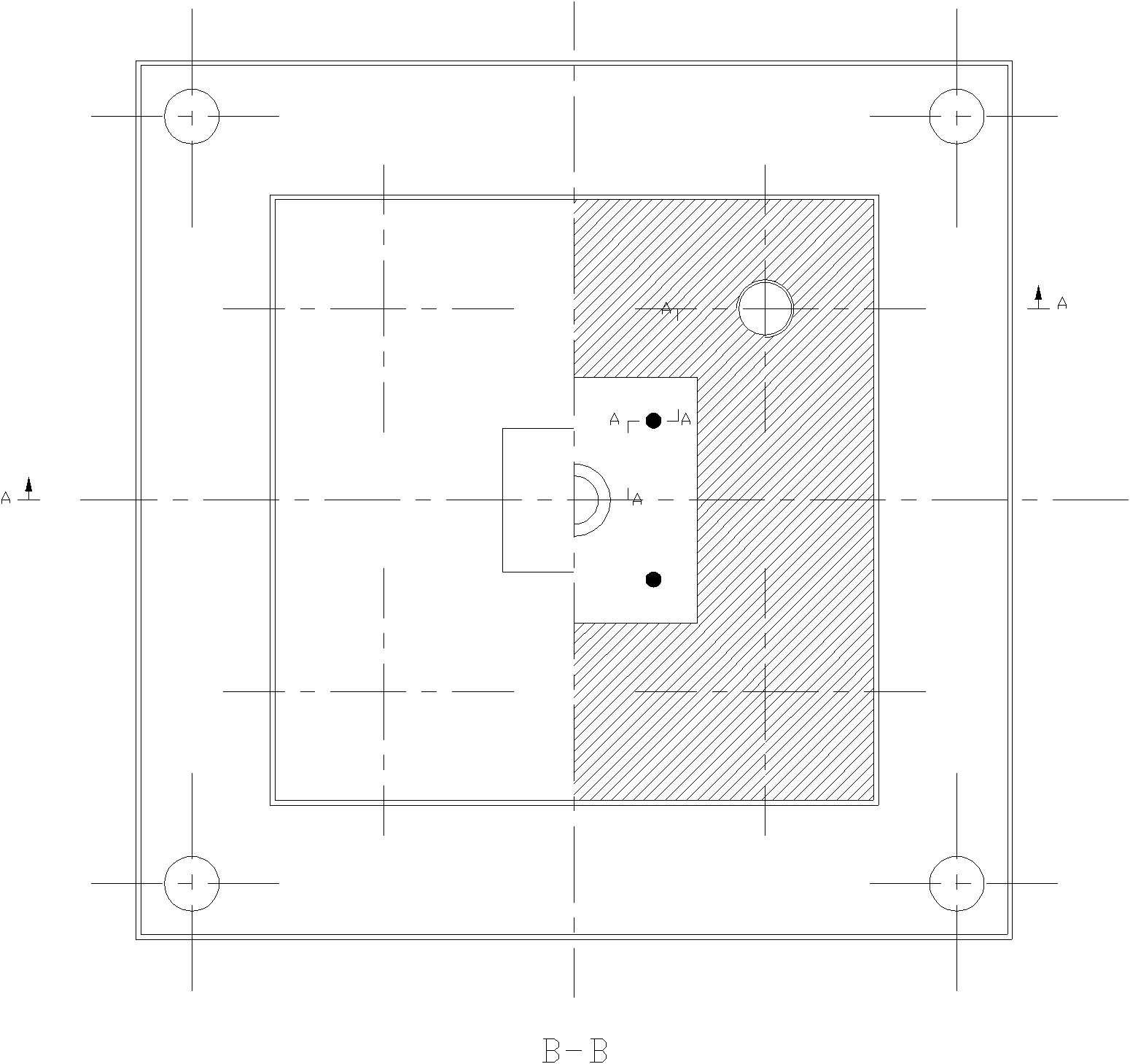

Torsion type reciprocating extrusion device and process method thereof

ActiveCN101966536AAddressing Smaller Size LimitationsImprove toughnessExtrusion profiling toolsExtrusion control devicesEngineeringUltra fine

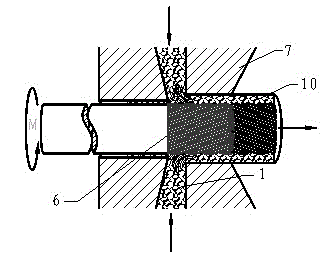

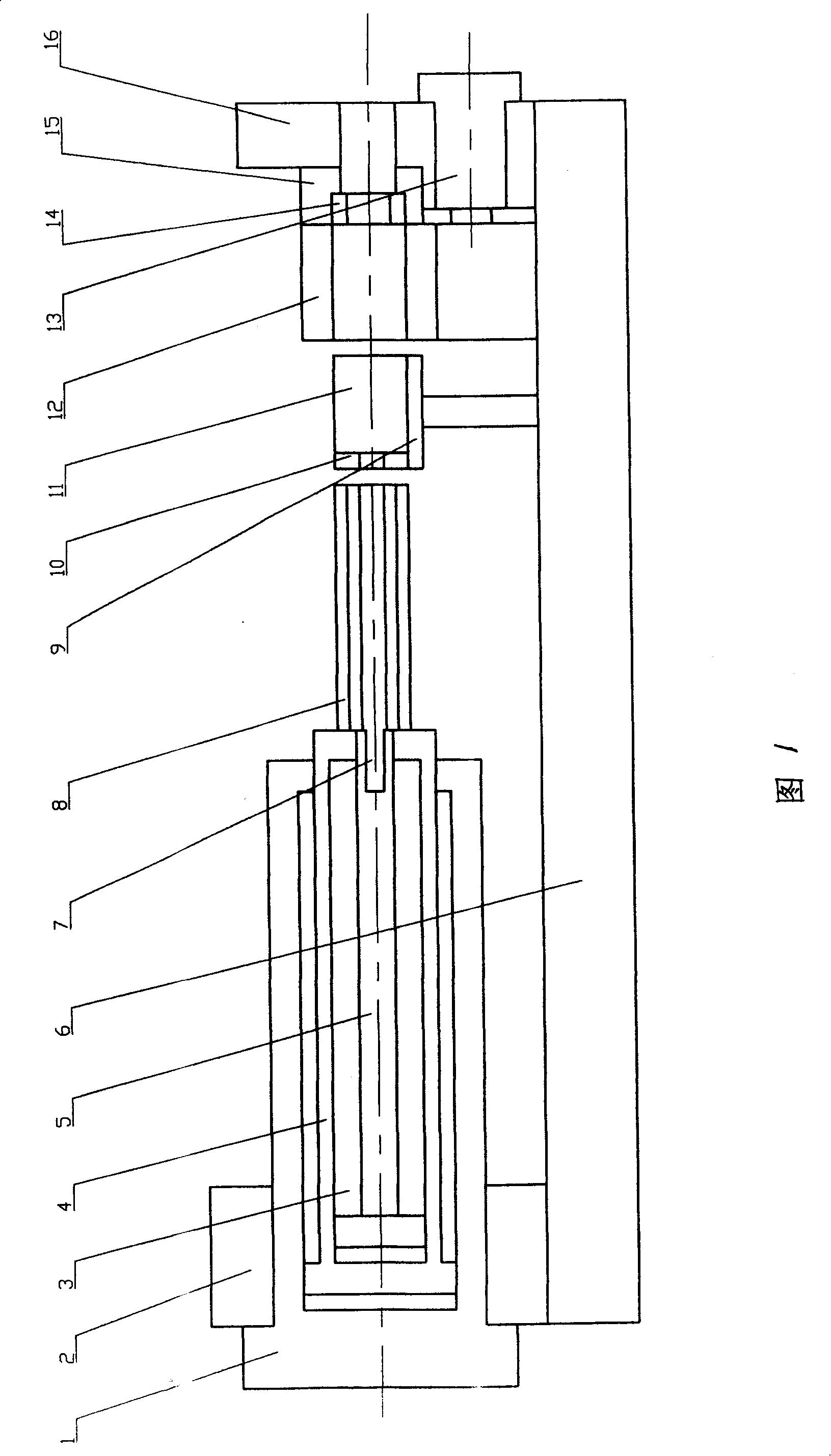

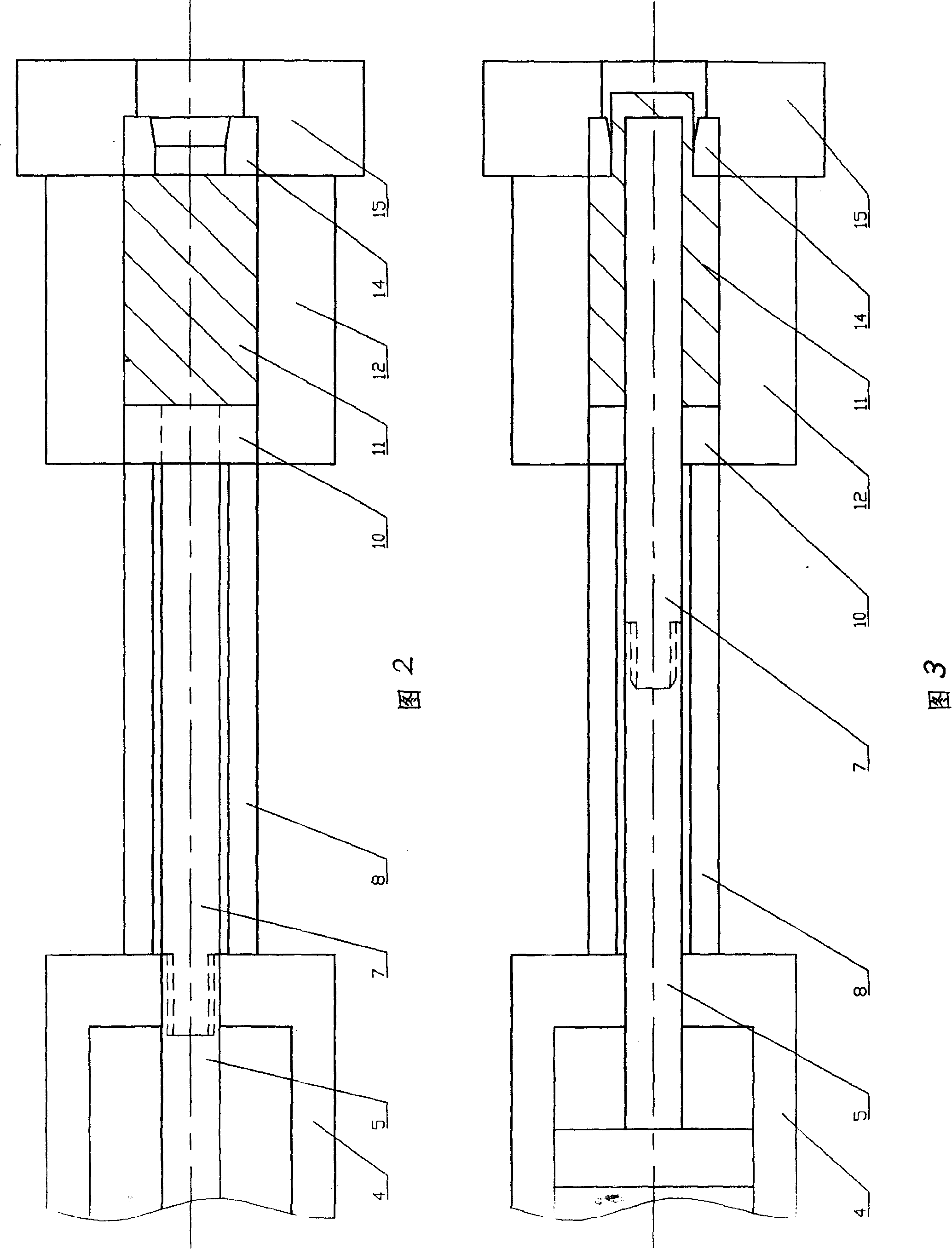

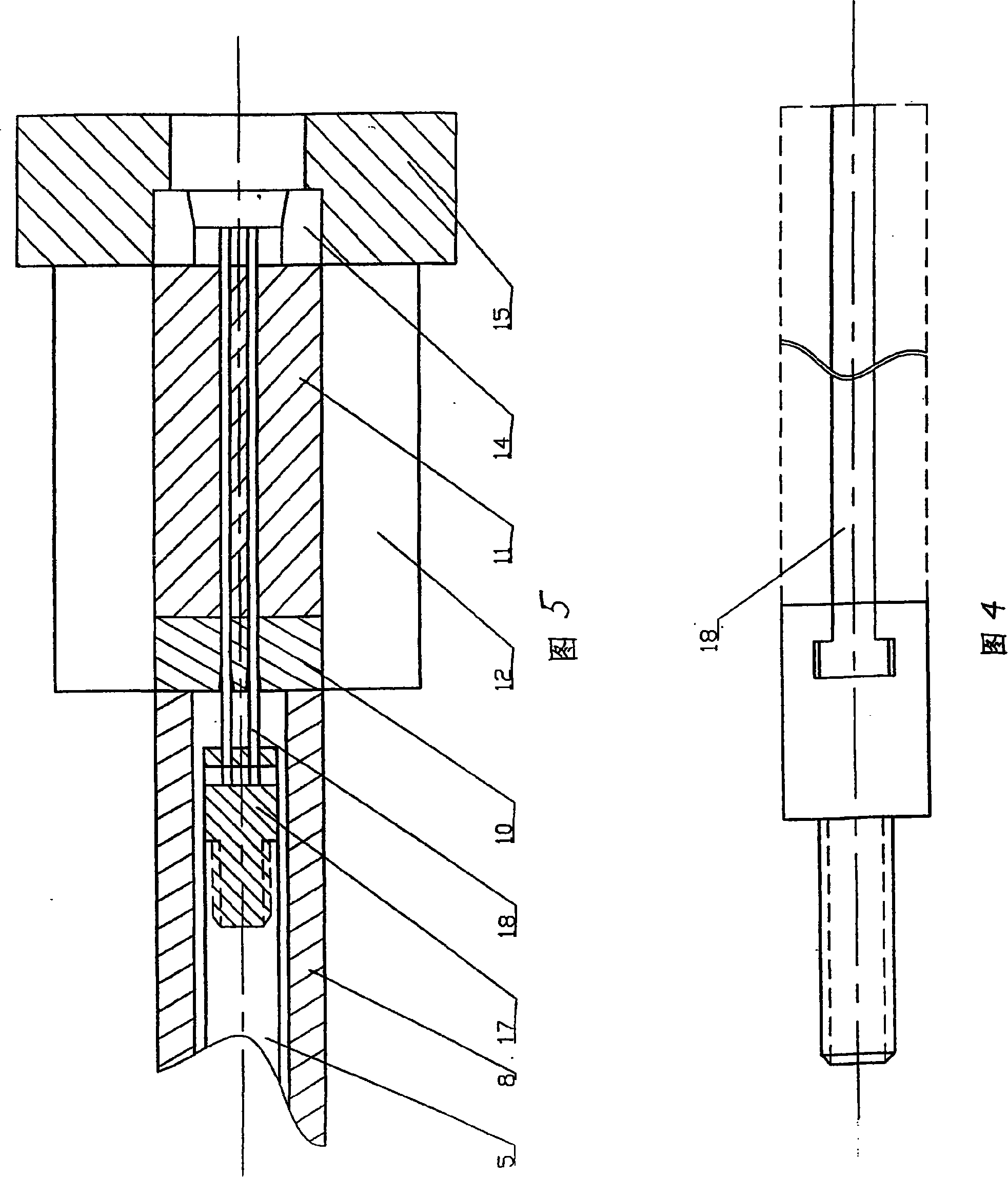

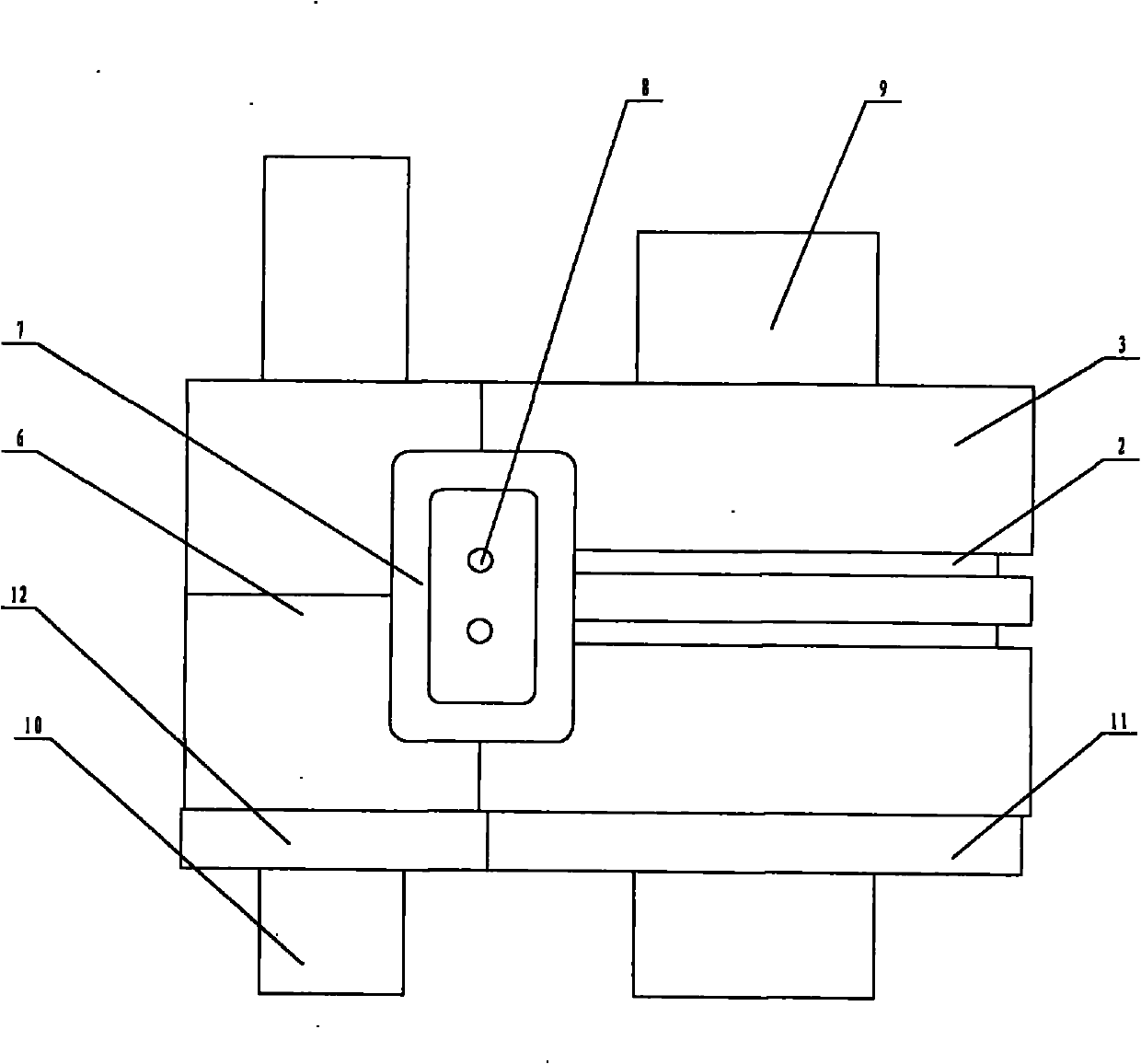

The invention discloses a torsion type reciprocating extrusion device and a process method thereof, belonging to the technical field of plastic formation. The device comprises a cavity die, a cavity die cover plate and a cavity die fixing plate, wherein the cavity die fixing plate is fixed on a work table, and the cavity die with a variable section spindle structure is arranged between the cavity die fixing plate and the cavity die cover plate. The process method makes materials generate the compound formation of reciprocating extrusion and torsion shearing so as to prepare ultra-fine grained materials with larger volume and uniform tissue.

Owner:SHANGHAI JIAO TONG UNIV

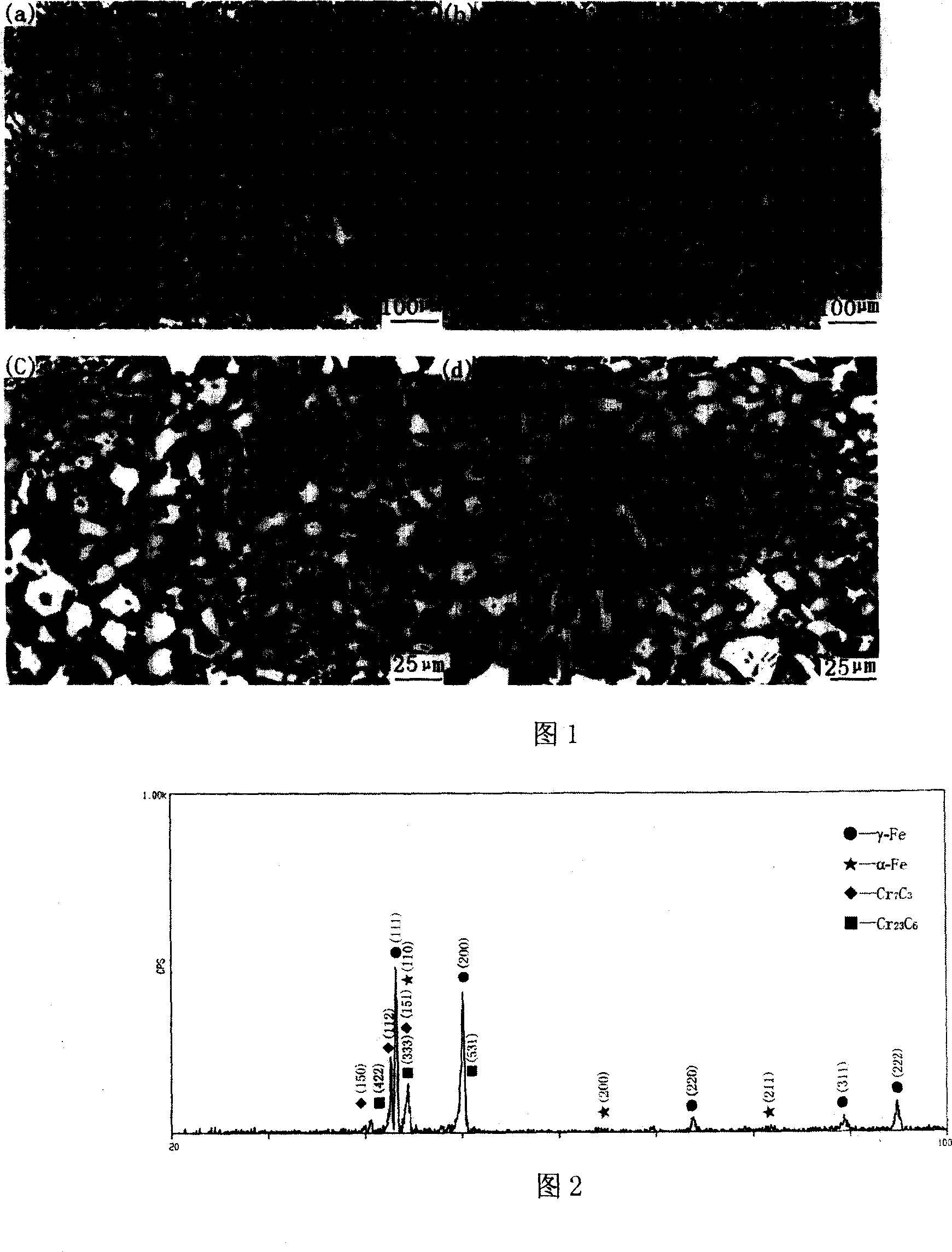

Rare earth multicomponent micro-alloying high-chromium cast iron and uses thereof

ActiveCN101012526AInhibition of germinationInhibition of scalabilityExtrusion profiling toolsRollsRare earthManganese

The invention discloses a polyvalent microalloying high-chromium cast-iron and usage of rare earth, which comprises the following parts: 1.0-3.5% carbon, 8.0-26.0% chromium, 0.5-4.5% nickel, 0.15-2.0% molybdenum, 0.5-2.0% copper, 0.05-2.0% aluminium, 0.03-0.3% vanadium, 0.005-0.20% rare earth, not more than 0.5% silicon, not more than 0.7% manganese, not more than 0.05% phosphor and ferric.

Owner:JINAN JIN PIN MAGNETIC MATERIALS & DIVECES

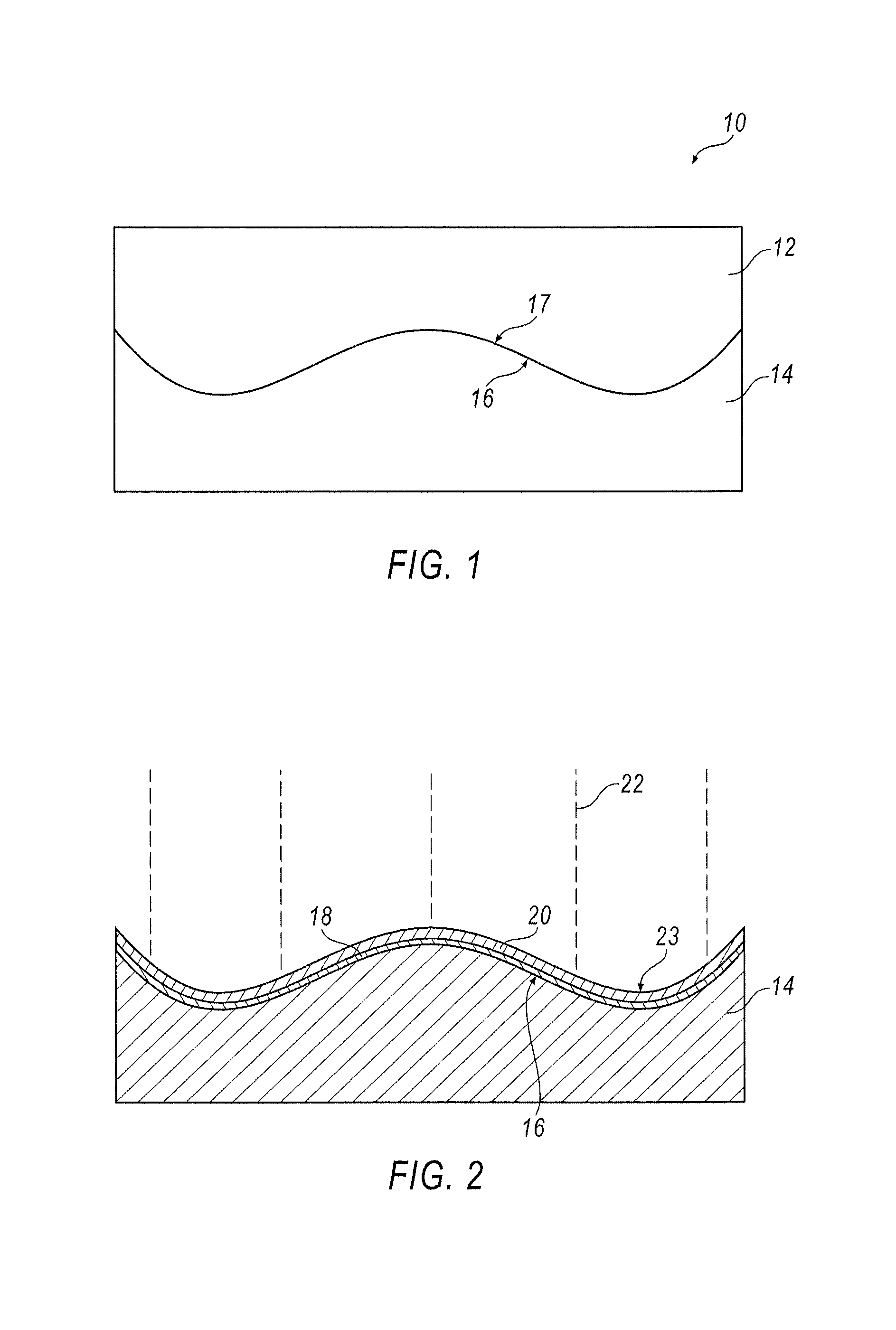

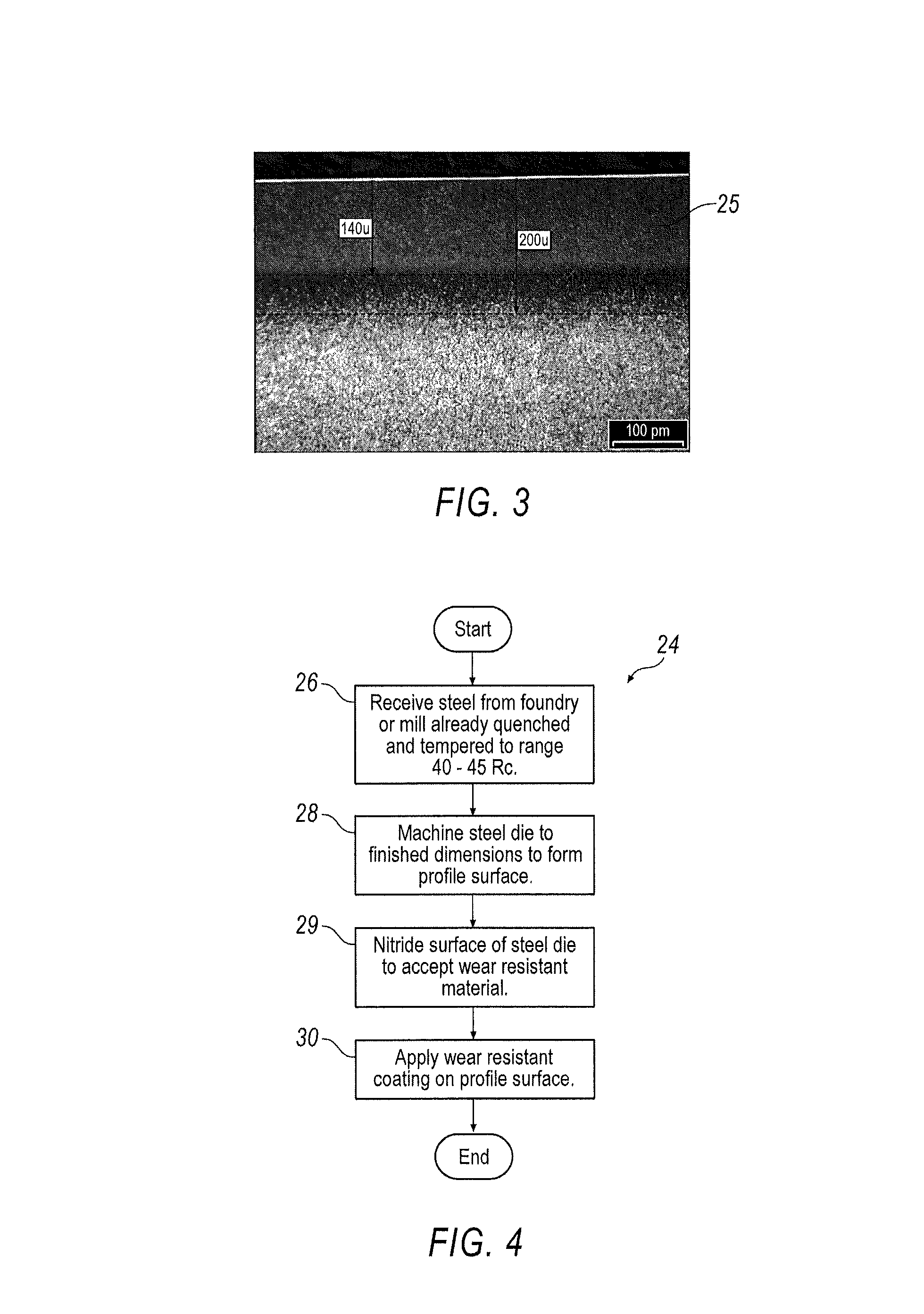

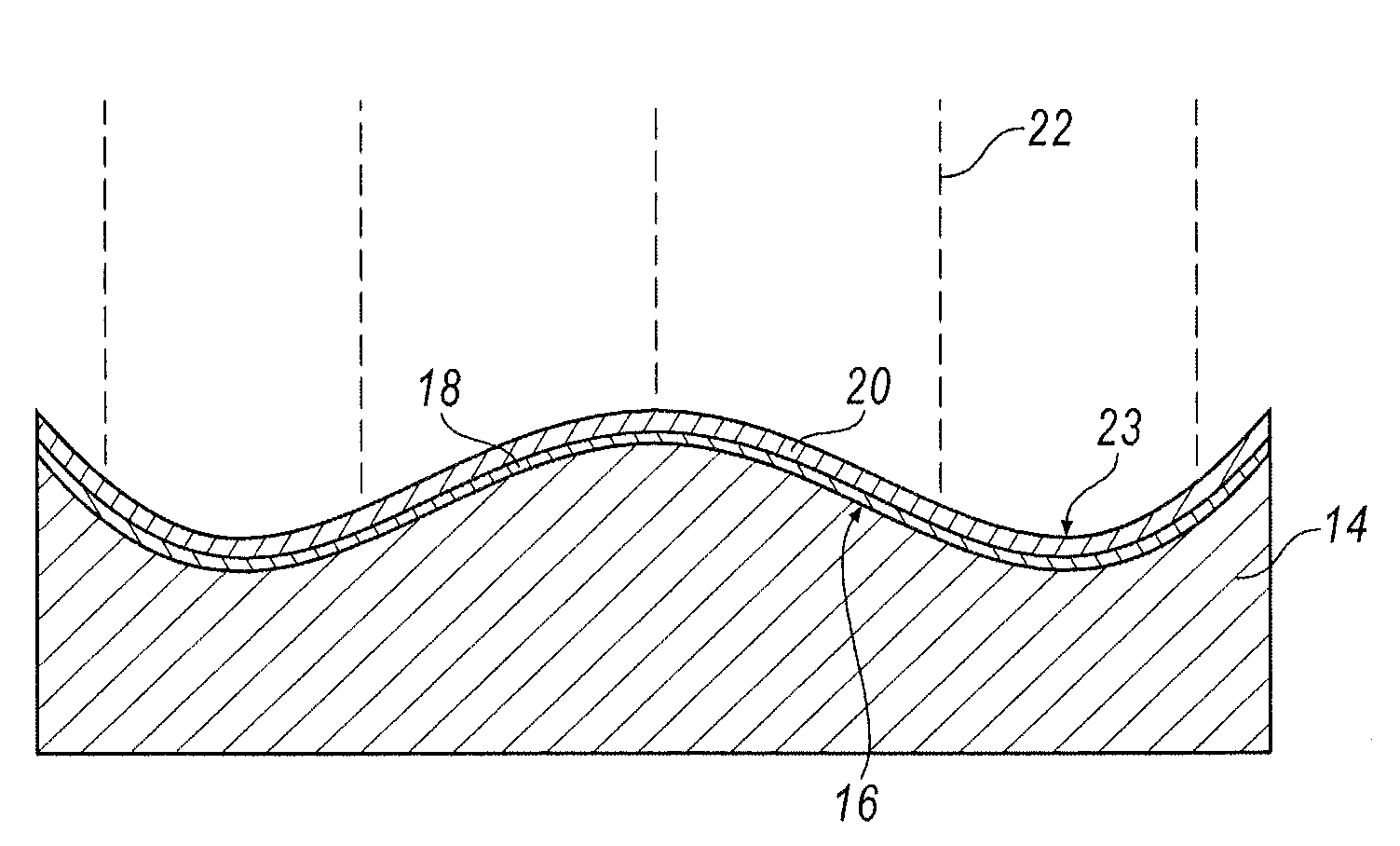

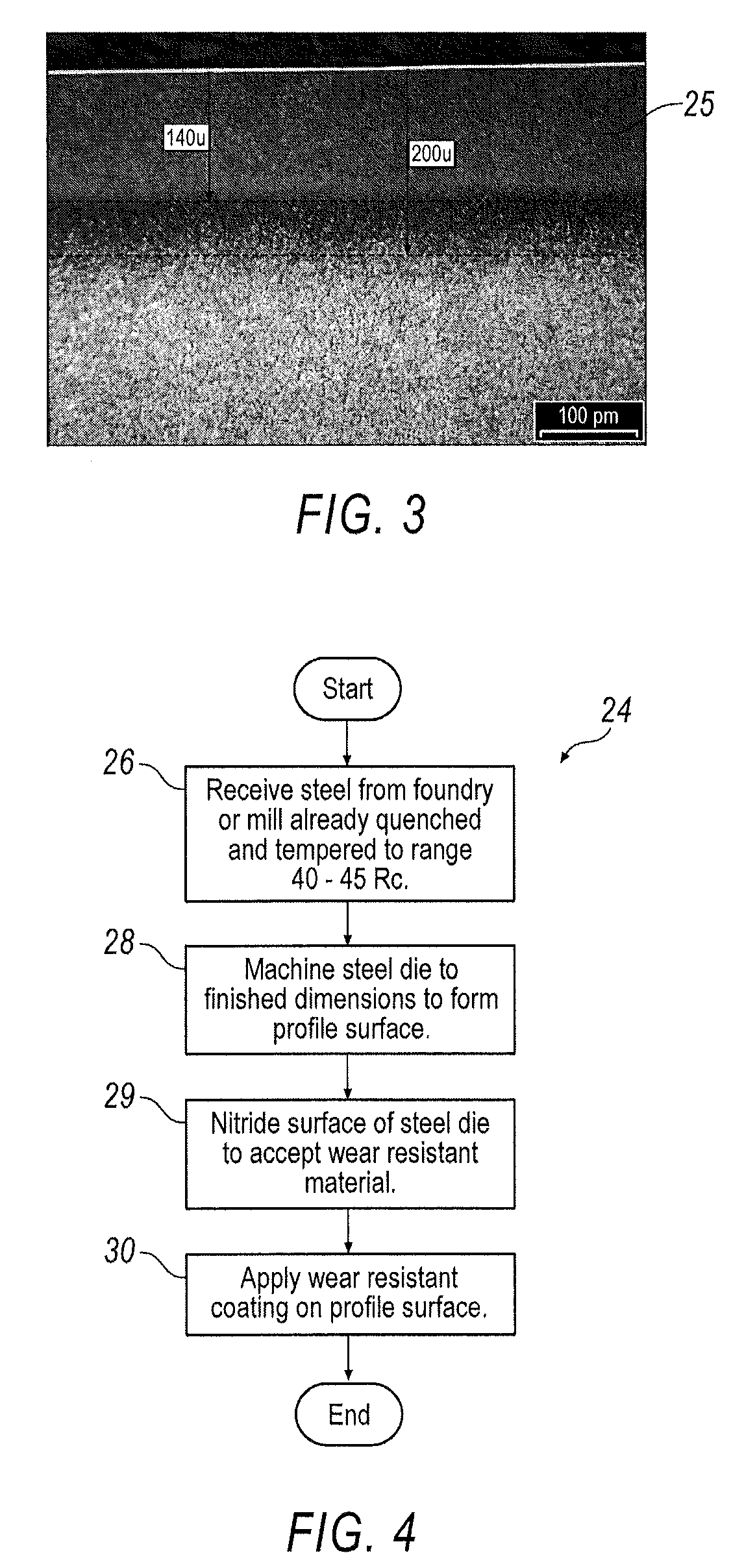

Wear resistant coated sheet metal die and method to manufacture a wear resistant coated sheet metal forming die

InactiveUS7587919B1Impart wear resistanceAvoid insufficient thicknessShaping toolsCutting toolsMetal formingGas phase

A method to manufacture a steel die having a Physical Vapor Deposition wear resistant coating on a profile surface and a steel die formed thereby is disclosed. The steel die is subjected to quenching and tempering to achieve a Rockwell hardness in the range of about 40-45 Rc and then subjected to machining to form a profile surface. The surface is then subjected to Physical Vapor Deposition of a wear resistant coating that may be multiple layers of CrN, AlCrN, TiCrN, TiN, TiCN or TiAlN, and preferably is alternating layers of TiN—TiCN—TiN. The coating is applied at a sufficient thickness to impart wear resistance to the steel die. The steel dies are useful in sheet metal stamping operations.

Owner:FORD MOTOR CO

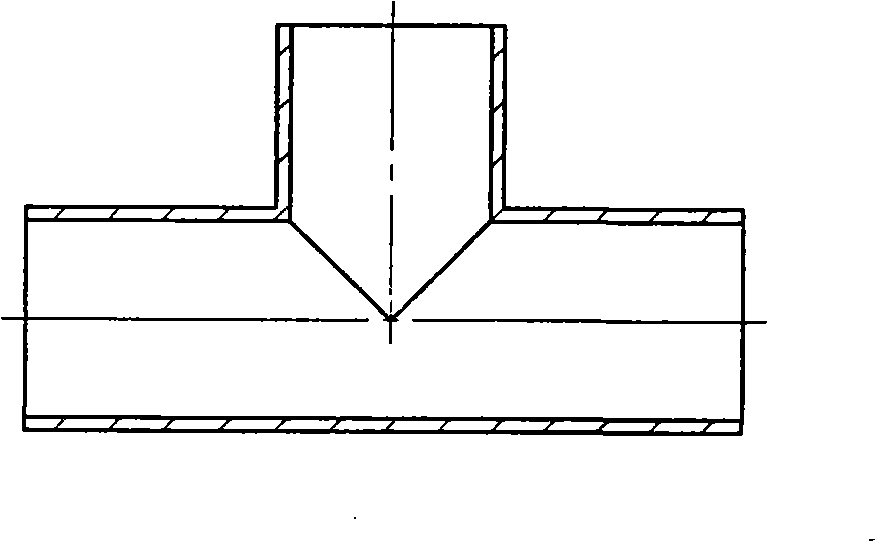

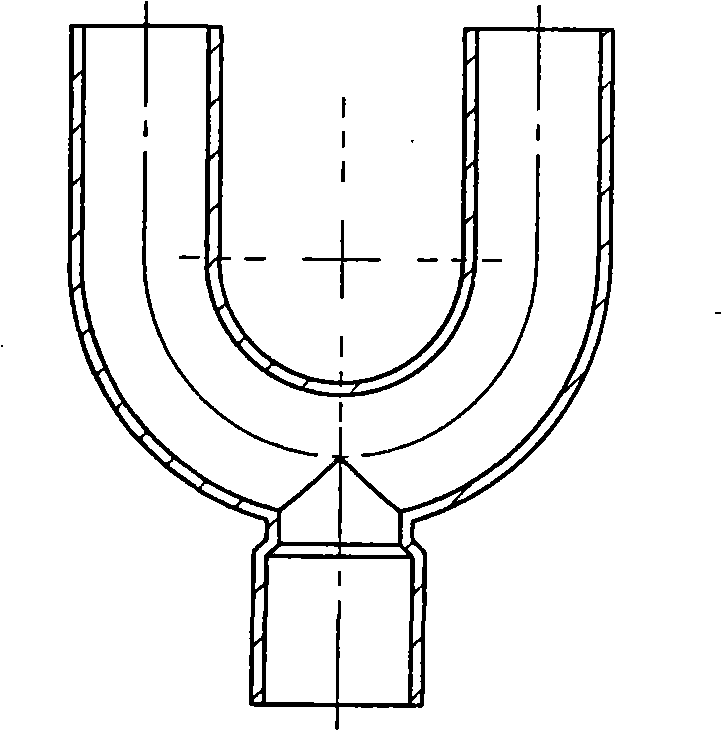

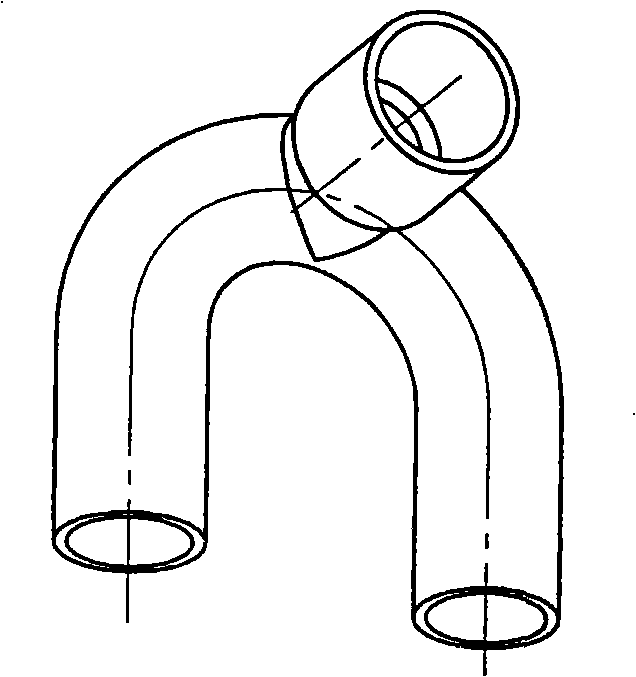

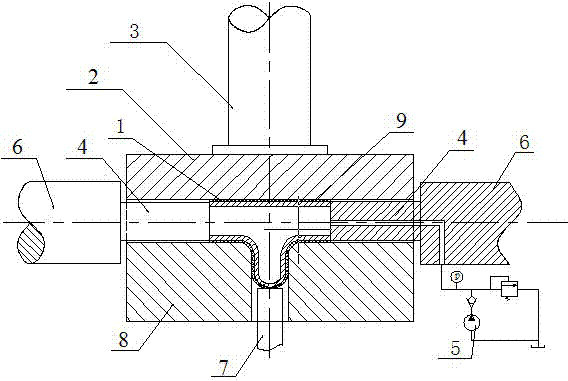

Nonmetal filling medium for producing piping branch junctions and technique for squeezing the piping branch junctions

InactiveCN101288881AShorten the lengthObvious technical advantagesExtrusion profiling toolsPlastic materialsCopper

The invention relates to a non-metal filling medium used for fabricating a three-way pipeline and a process for extruding the three-way pipeline. The filling medium is a non-metal power material which is uniformly mixed and consists of three powders: talcum powders H2Mg3(sio3)4, industrial salts NaCl and urease (NH4)2CO; the three powders are uniformly mixed respectively according to the mass proportion of 5-25%, 95-50% and 0-25%. The extrusion material range of the three-way pipeline of the invention is multiple high-plastic materials such as copper, iron, low carbon steel and cold extrusion stainless steel, etc.; therefore, the three-way pipeline can extrude and fabricate copper three-way pipeline, iron three-way pipeline, low carbon steel three-way pipeline and stainless steel three-way pipeline, etc. The non-metal filling medium and the process of the invention have obvious technical advantages of meeting the instruction requirement which is issued by European, Japan, etc. and contains that lead is not allowed to be added in the three-way pipeline production process, thereby completely avoiding the pollution of heavy metals such as lead, etc., having lower cost than the lead-pouring extrusion, having longer length and higher working efficiency than the oil (water) injection extrusion, and enlarging the ranging of extrusion material to the fields of multiple high-plastic material such as copper, iron, low carbon steel and stainless, etc.

Owner:佛山市南海飞鹏塑胶金属有限公司

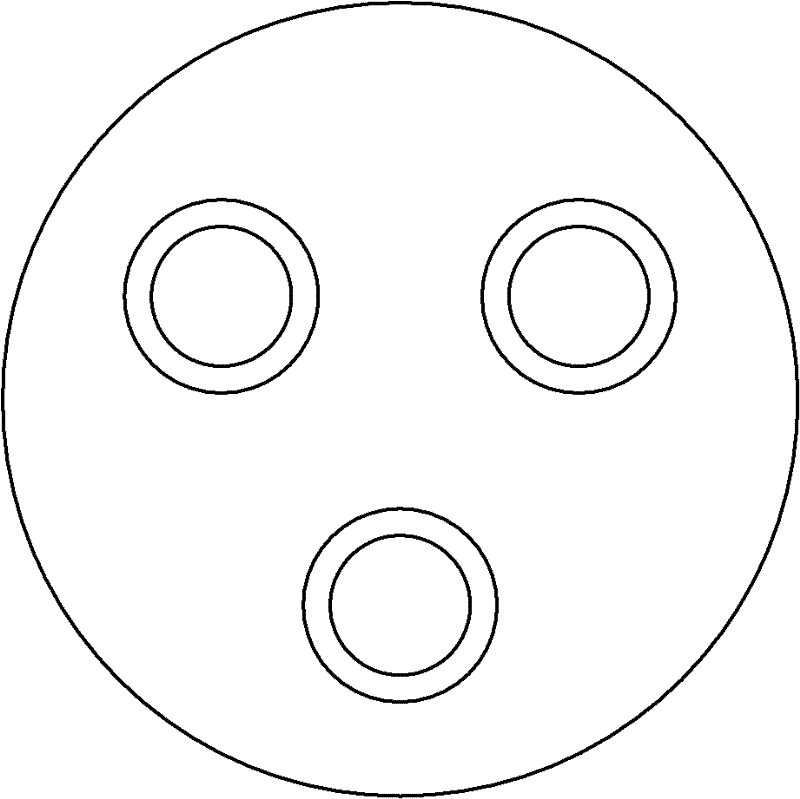

Method of manufacturing a catalyst

A method of manufacturing a catalyst, a catalyst precursor, or a catalyst support comprising: (a) mixing a refractory metal oxide or precursor thereof with a liquid to form a paste; (b) adding said paste to an extruder, the extruder having a die plate comprising one or more dies, each die having a plurality of apertures, the outlet of each aperture having a cross sectional area of 6 mm2 or less; (c) extruding the paste through the apertures to form catalyst support extrudates;wherein the inlet of the apertures has a greater cross sectional area than the outlet of said apertures; and wherein for at least one die the combined cross sectional area of all apertures at the inlet relative to the total cross sectional area of the die at the inlet is higher than 50%.

Owner:SHELL OIL CO

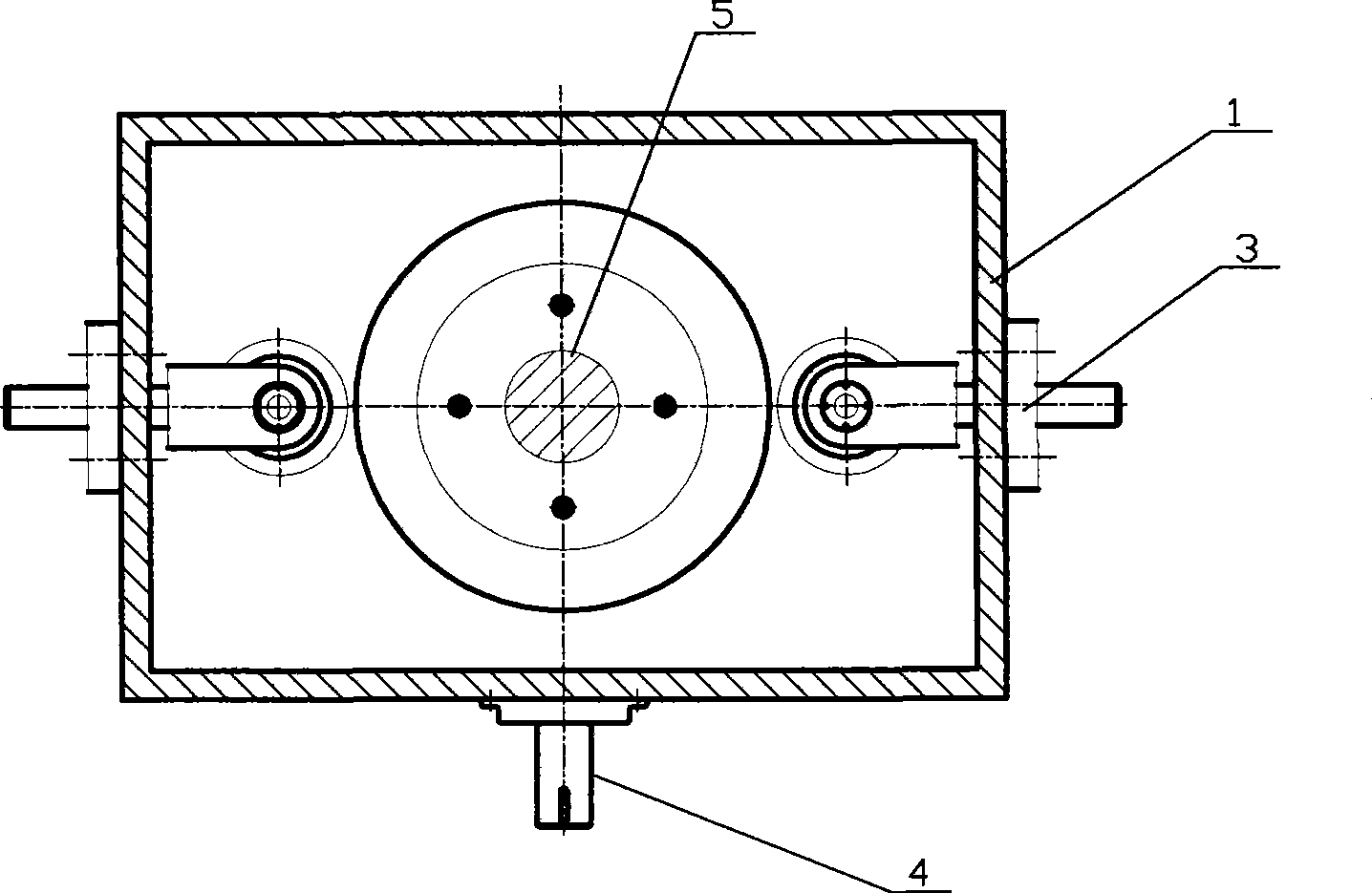

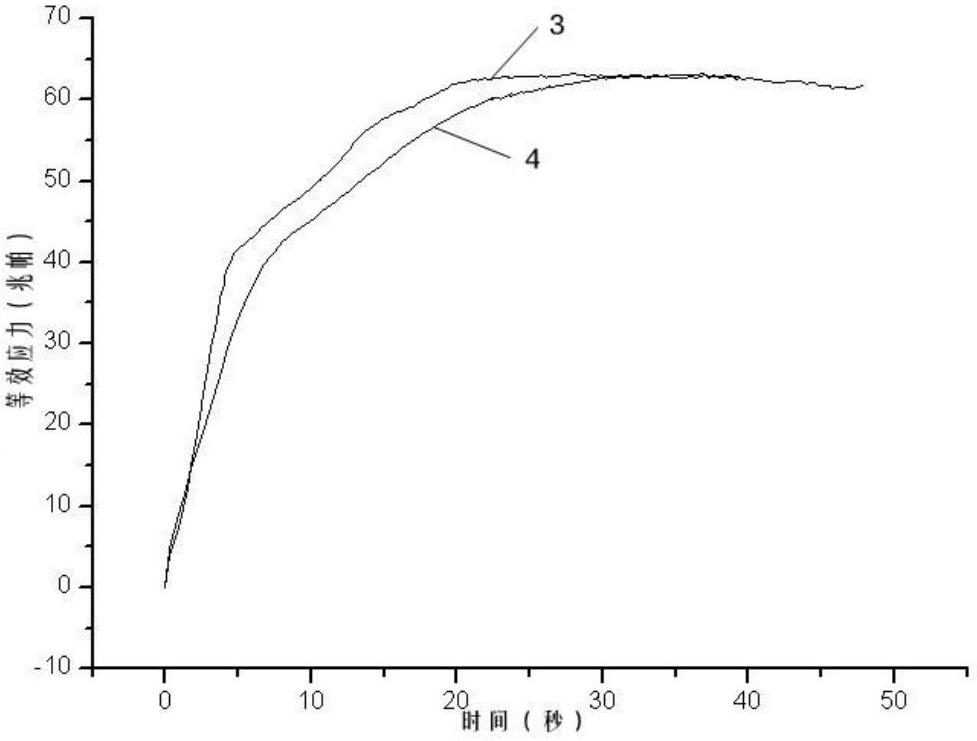

Squeezing-revolving shaping method of magnesium alloy wheel and device thereof

InactiveCN101480670ASubstantiveSolve difficult to shapeExtrusion profiling toolsFuel tankSurface pressure

The invention relates to a method and a device for spinning and forming a magnesium alloy wheel, adopting a cylinder-shaped prefabricated roughcast. The method is characterized in that the prefabricated roughcast is arranged on a core die, a flat surface pressure device is used for flaring the prefabricated roughcast by axially moving the prefabricated roughcast, then the prefabricated roughcast and the core die rotate together and the prefabricated roughcast is spun through the radical feeding movement of a rotating spinning roller having the same outline shape as the wheel along the prefabricated roughcast, so that the prefabricated roughcast is subjected to continuous partial plastic deformation along the radial direction, and finally a needed outline of the magnesium alloy wheel is formed. Furthermore, the device comprises a stand and a core die, wherein the stand is in a box shape and is a consistent temperature oil tank, and the box-shaped stand is internally provided with a spinning roller device, a core die rotating device, the flat surface pressure device and a tank cover. In addition, the invention solves the problems of the forming and the demoulding of a similar part of a wheel which is small at both ends and big in the middle, and has the advantages of consistent temperature extrusion, higher dimension precision of products, enhanced production efficiency, and the like.

Owner:ZHONGBEI UNIV

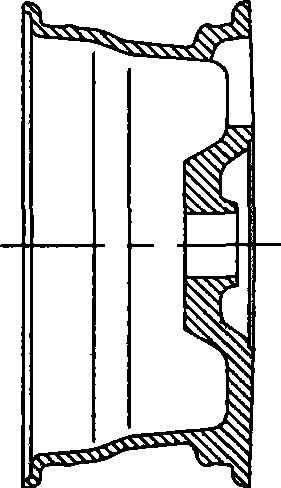

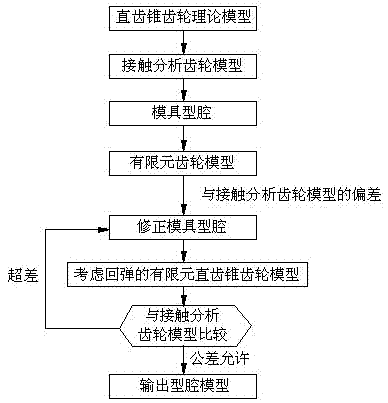

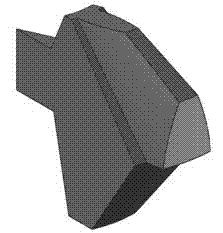

Control method for tooth shape size precision of cold forming straight bevel gear

InactiveCN102728646AGuaranteed dimensional accuracyIncrease contactShaping toolsExtrusion profiling toolsTheory modelCold formed

The present invention discloses a control method for tooth shape size precision of a cold forming straight bevel gear. The method comprises: 1) establishing a contact analysis gear model according to a gear theory model; 2) generating a mold cavity; 3) determining a finite element gear model after considering resilience; 4) comparing the finite element gear model with the contact analysis gear model to obtain model deviation; 5) correcting the mold cavity, and carrying out finite element calculation to obtain a new finite element straight bevel gear model; 6) comparing the finite element straight bevel gear model with the contact analysis of gear model, carrying out outputting if the size precision requirement is met, otherwise determining the deviation between the finite element straight bevel gear model and the contact analysis of gear model; and 7) repeated performing the steps of 5) and 6) until the size precision requirement is met. According to the present invention, the size of the cold forming mold cavity of the straight bevel gear is determined after the shape correcting, the material and the mold of the tooth shape after resilience are considered, such that the tooth shape size precision of the straight bevel gear is ensured, and it is ensured that excellent contact and transmission effects of the straight bevel gear after cold forming can be directly met without mechanical processing.

Owner:CHONGQING UNIV OF TECH

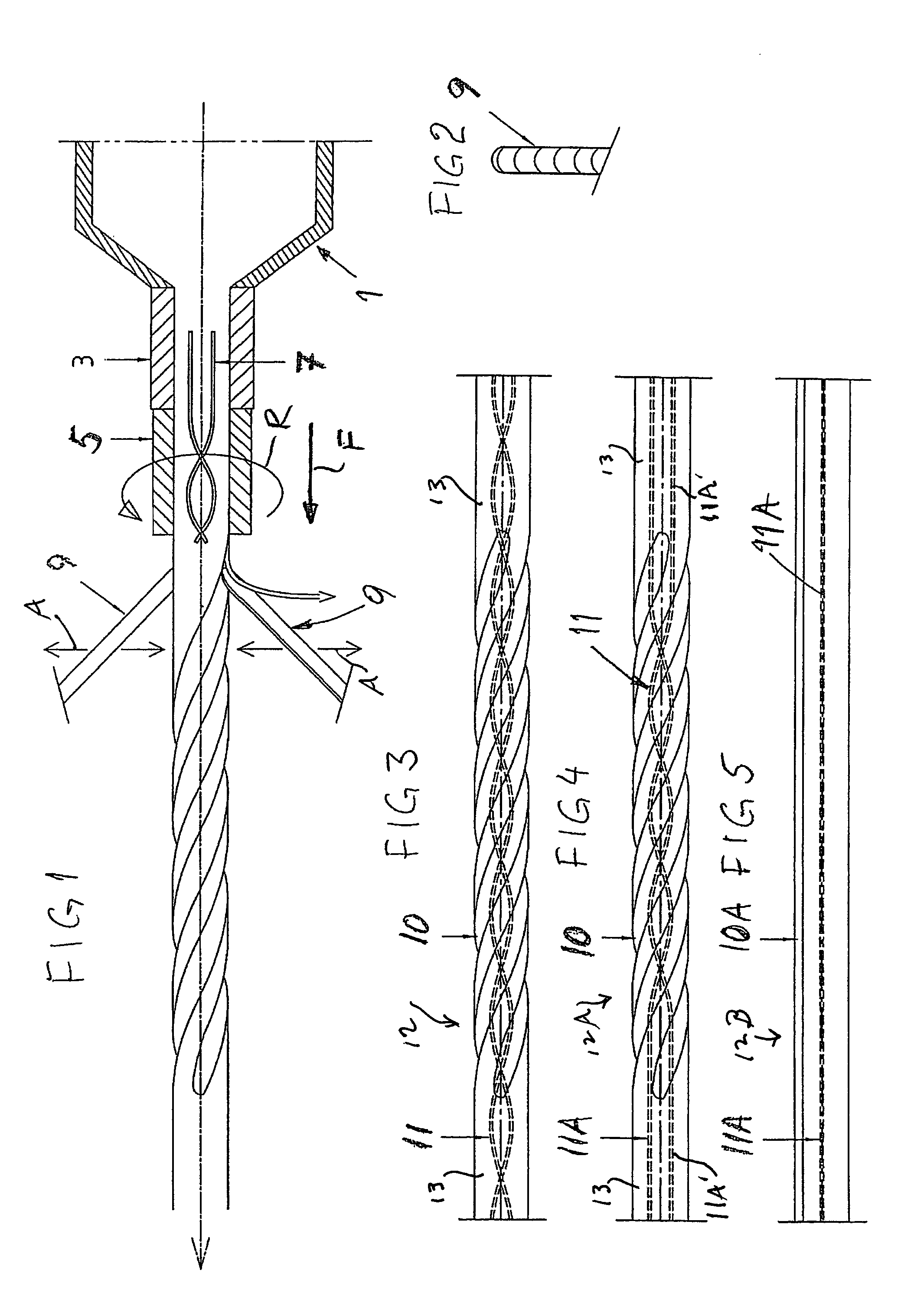

Method and apparatus for making a rotary tool for chip removing machining

A method for manufacturing a rotary tool for chip removing machining with at least one chip flute that extends in the longitudinal direction of the tool. The method involves preparing a mixture of a cemented carbide, cermet or ceramics powder and a carrier, such as a polymer, and placing the mixture in an extruding machine. The mixture is extruded in a feed direction by means of a die to form the diameter of the mixture body. The mixture body passes against a chisel which forms a chip flute in the outer periphery of the mixture body by chip-removing machining. When the chisel is displaced away from the mixture body, a non-fluted shaft portion is formed. By rotating the mixture body while contacted by the chisel, a helical chip flute can be formed. Alternatively, the body could be twisted after a straight flute has been formed, whereupon the flute becomes helical.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

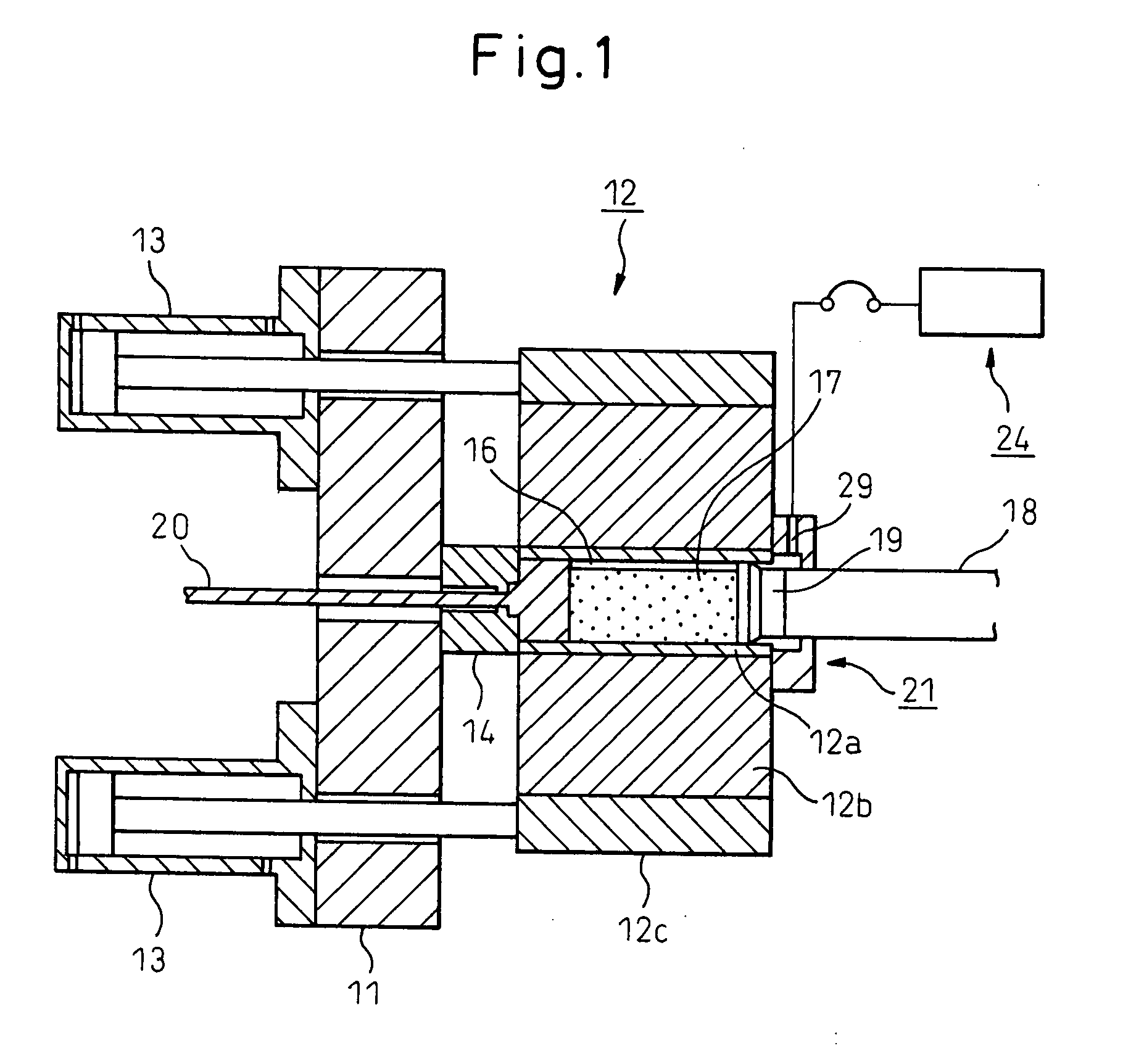

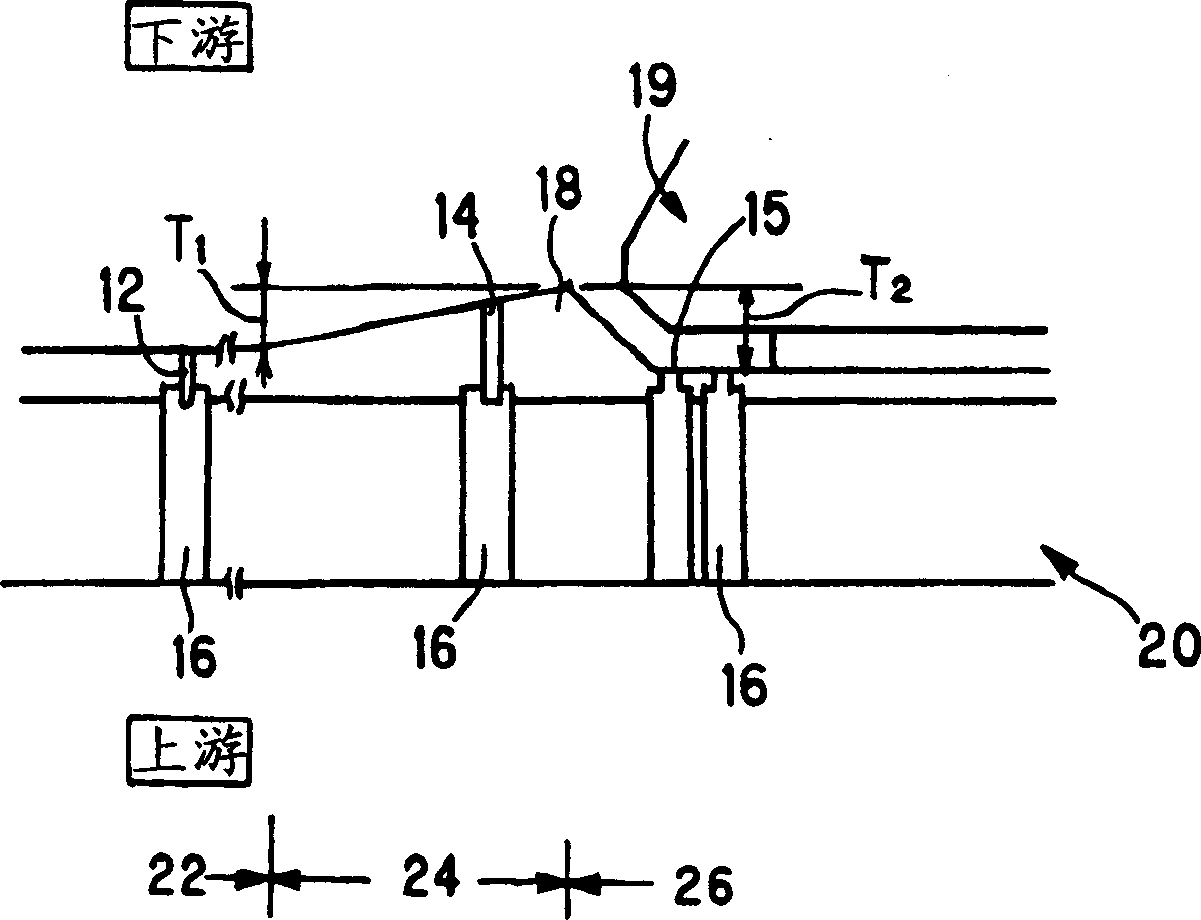

Extrusion molding method and apparatus of extrusion press

InactiveUS20070227221A1Stable container accuracyImprove accuracyExtrusion profiling toolsExtrusion containersEngineeringMechanical engineering

An extrusion molding method of an extrusion press includes a first step of loading a billet, the outer surface of which is subjected to a barking treatment, into a container, and extruding the billet in such a manner as to leave a predetermined length, a second step of loading a next billet into the container, additionally extruding the preceding billet with the succeeding billet in such a manner as to leave a predetermined length of the succeeding billet; and a third step of loading a next billet into the container and additionally extruding the preceding billet with the succeeding billet in such a manner as to leave a predetermined discard length of the succeeding billet and stopping extrusion. By way of these steps, the container does not move while maintaining contact with a die, and the billet is continuously extruded by leftover and additional extrusion.

Owner:UBE MASCH CORP LTD

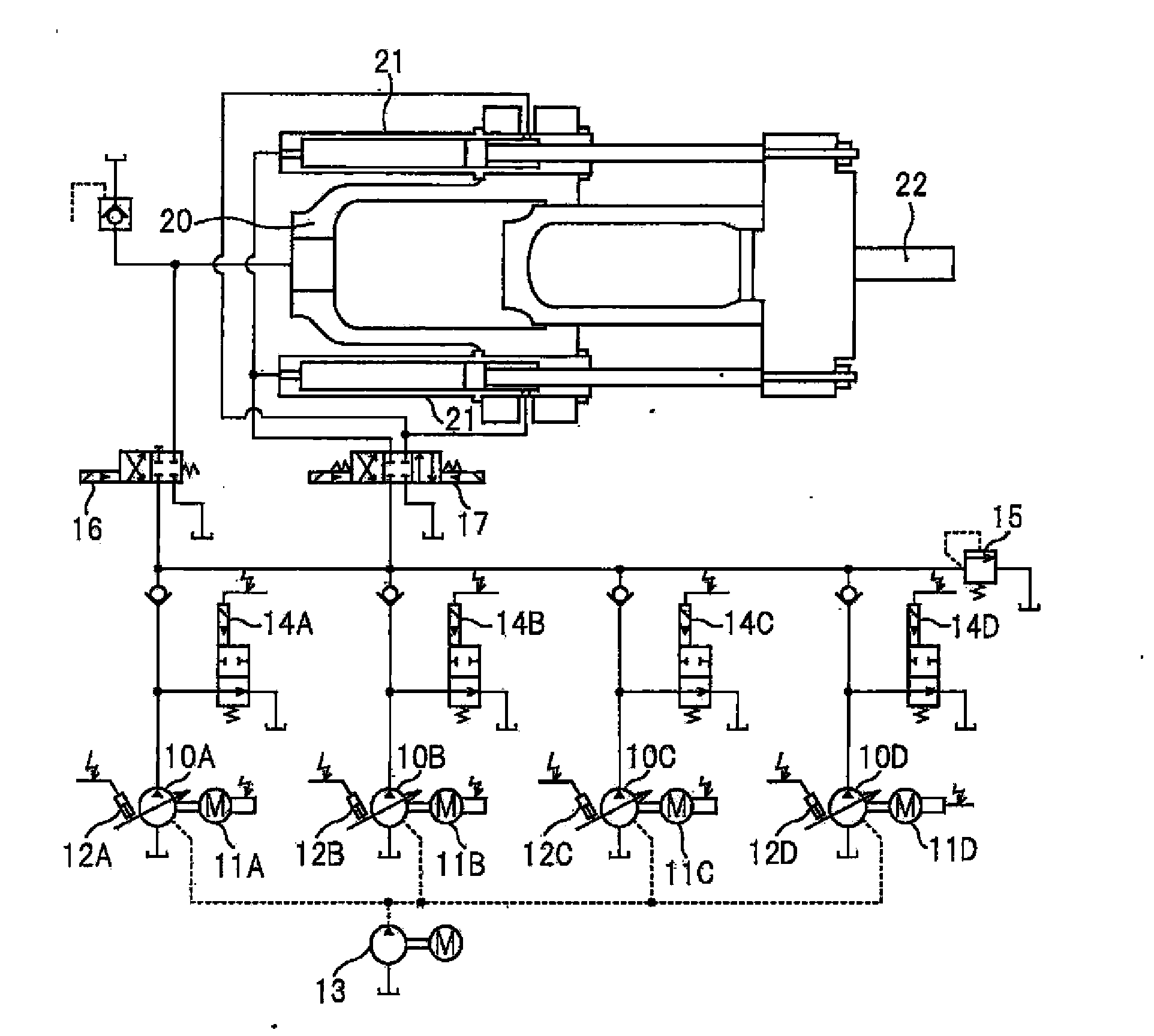

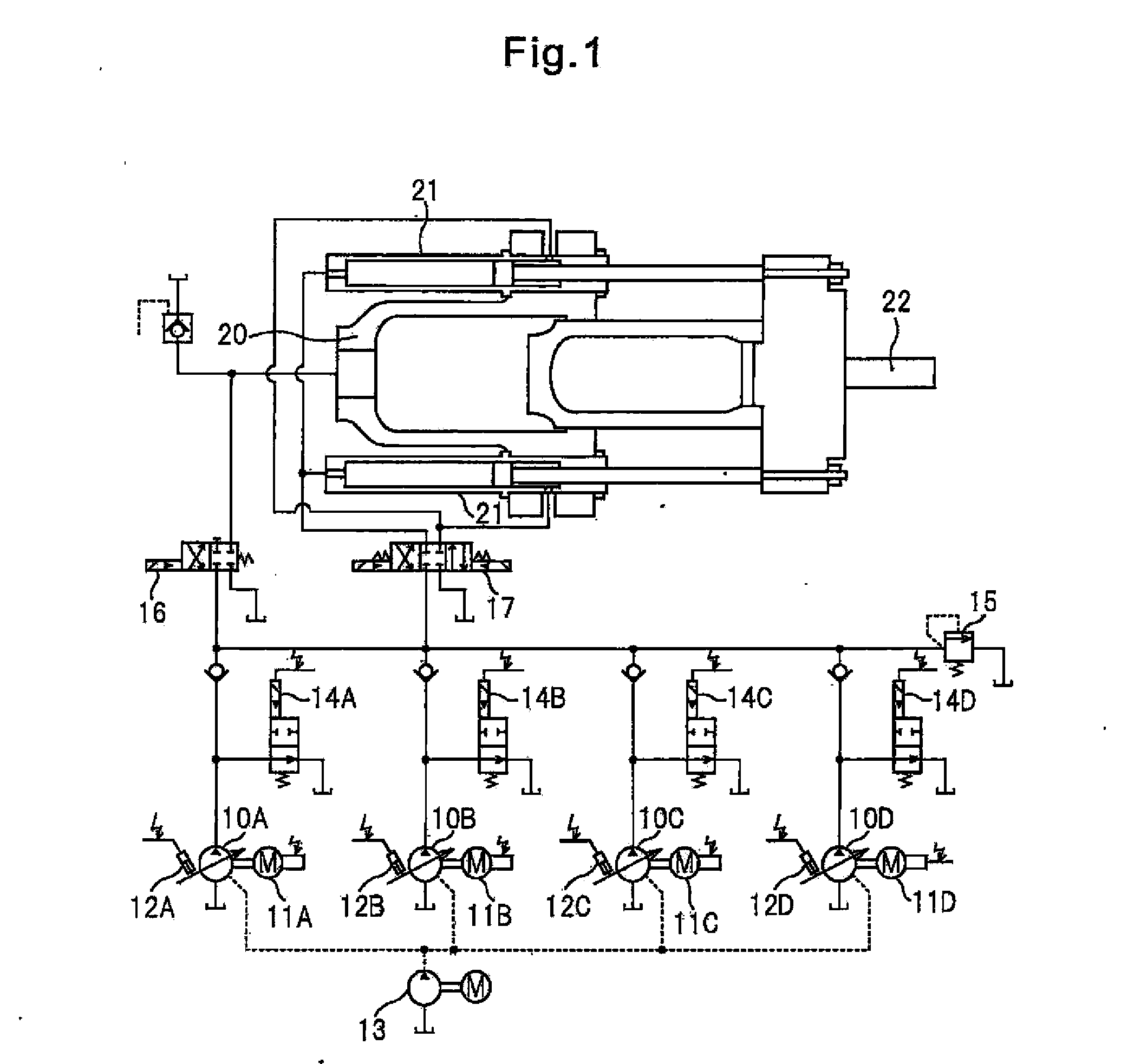

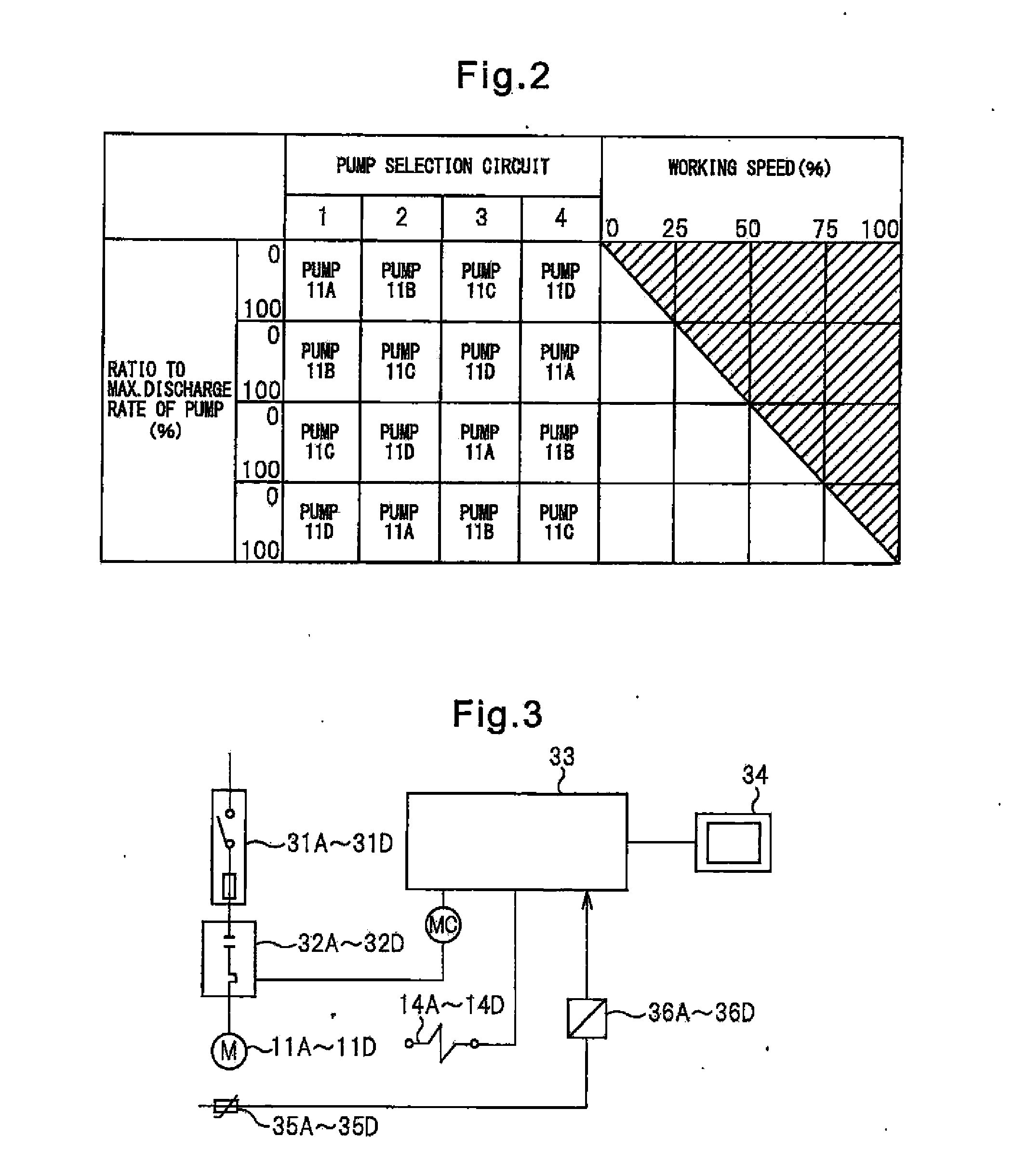

Extrusion press

InactiveUS20140096581A1Suitable operational managementReduce power wasteExtrusion profiling toolsElectric motor controlHydraulic cylinderThermal fatigue

The present invention provides an extrusion press which eliminates unevenness of dynamic and thermal fatigue degrees of the hydraulic devices which form the hydraulic circuit in the extrusion press, the electric Motors which drive the hydraulic pump, the control devices, etc., which makes the dynamic and thermal fatigue degrees and remaining service lives of the component devices even, and which is excellent in energy saving effect.An extrusion press which has a plurality of variable capacity type hydraulic pumps connected to it in parallel for supplying working oil to hydraulic cylinders of the extrusion press, uses a preset working speed as the basis to find the required discharge rate of the hydraulic pumps, and selectively controls the drive operations of the hydraulic pumps, wherein the order of selection of the hydraulic pumps which are selectively controlled in drive operation is controlled by a program which progressively advances when a predetermined number of molding cycles are completed.

Owner:UBE MASCH CORP LTD

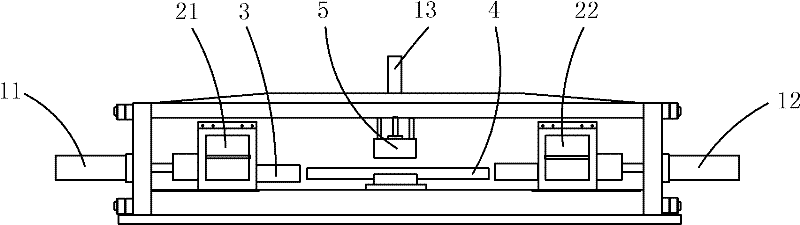

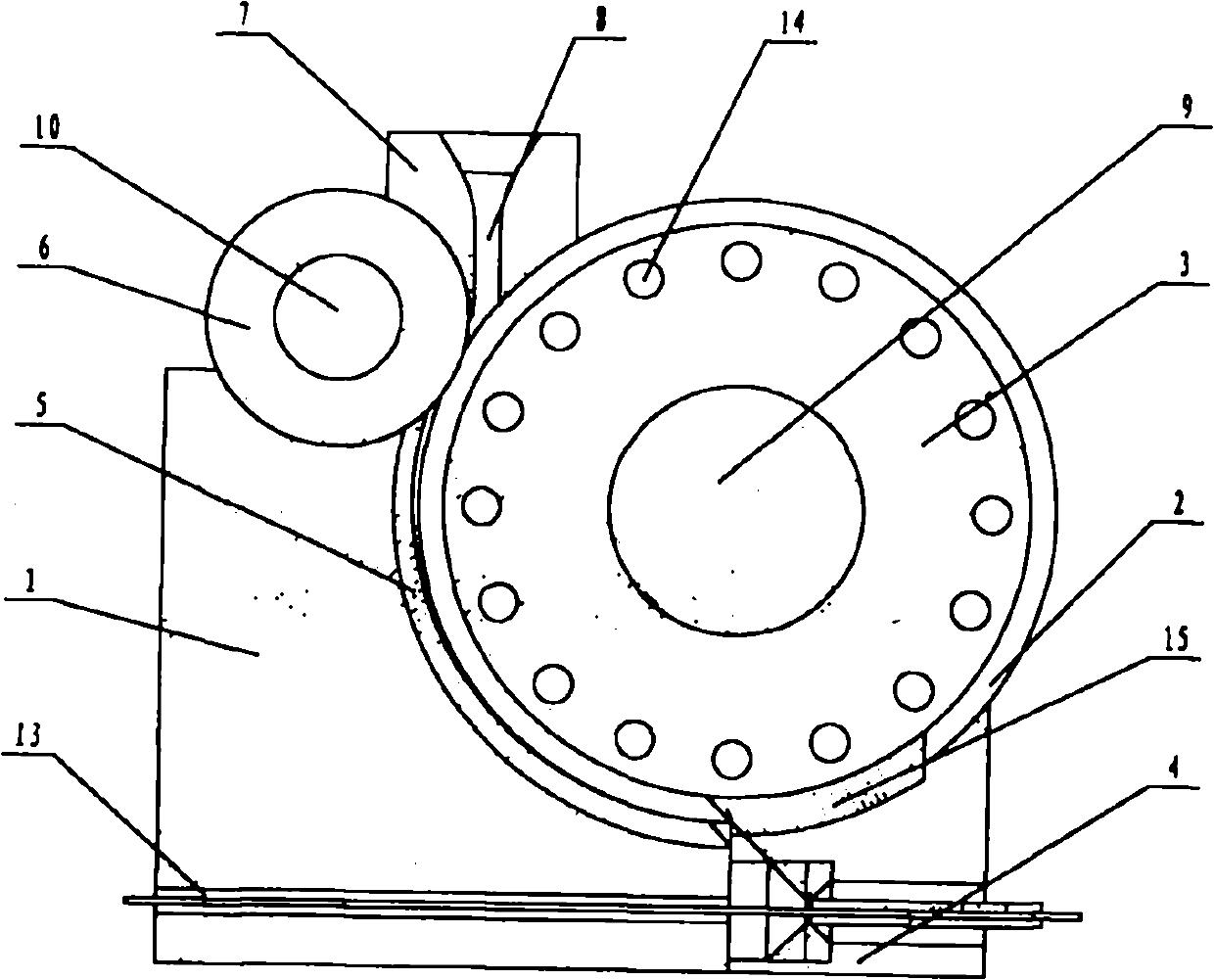

Semitrailer integral axle tube extrusion moulding equipment and method

InactiveCN102172658AIncrease productivityReduce manufacturing costExtrusion profiling toolsIntermediate frequencyPulp and paper industry

The invention relates to semitrailer integral axle tube extrusion moulding equipment, comprising a hydraulic machine and an intermediate frequency heating furnace, wherein the two ends of the rack of the hydraulic machine are respectively provided with a first slide seat and a second slide seat, the first slide seat is connected with a first cylinder of the hydraulic machine, the second slide seat is connected with a second cylinder of the hydraulic machine, and the first and second slide seats are provided with mould replacing wheel discs; and the top of the rack of the hydraulic machine is also provided with a clamping device for an axle tube. The axle tube extrusion moulding equipment provided by the invention has high production efficiency and has the advantages of high product processing accuracy, good integral mechanical property and stable product quality compared with the traditional hot spinning process. A steel pipe blank is directly moulded at axle heads at the two ends in an extruding way by virtue of the hydraulic machine, and various welding defects existing in subsection moulding are avoided, thus the bearing capacity of a car axle is greatly improved.

Owner:GUANGDONG FUWA HEAVY IND

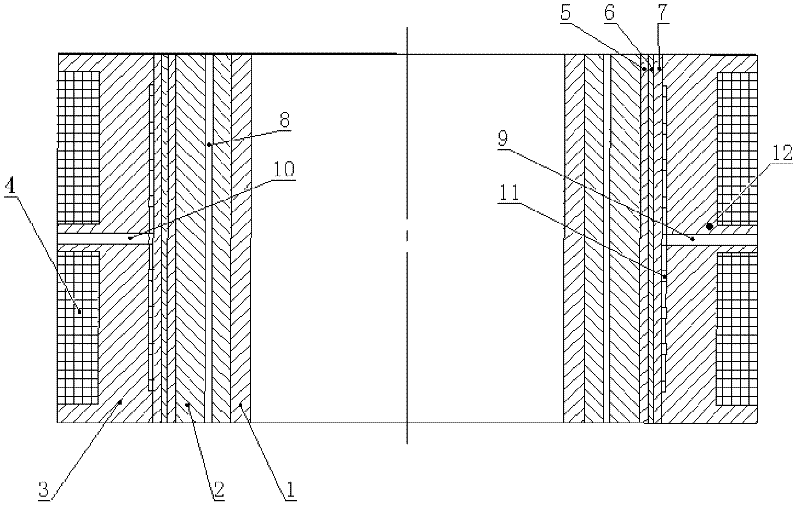

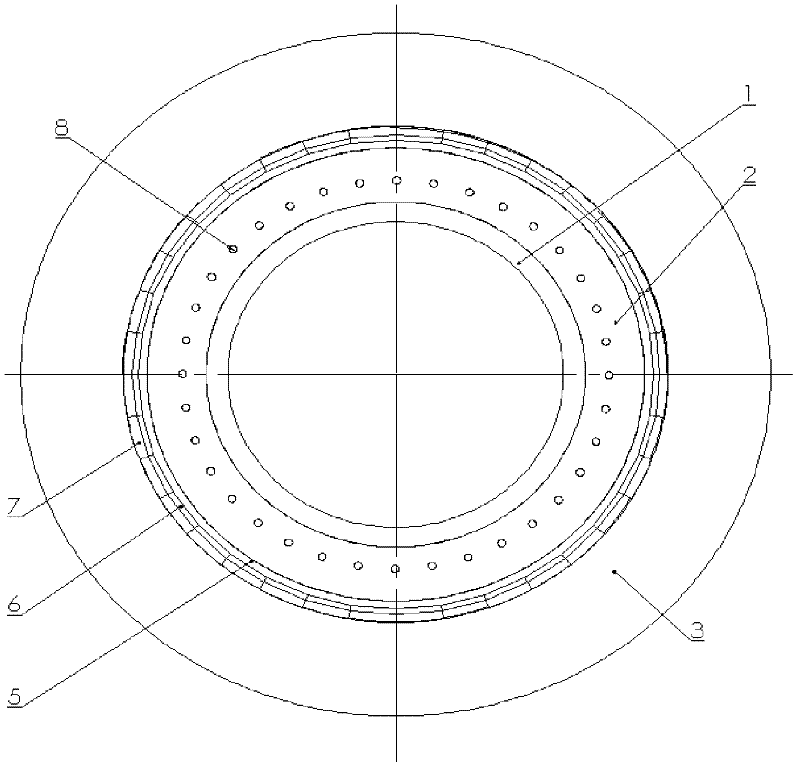

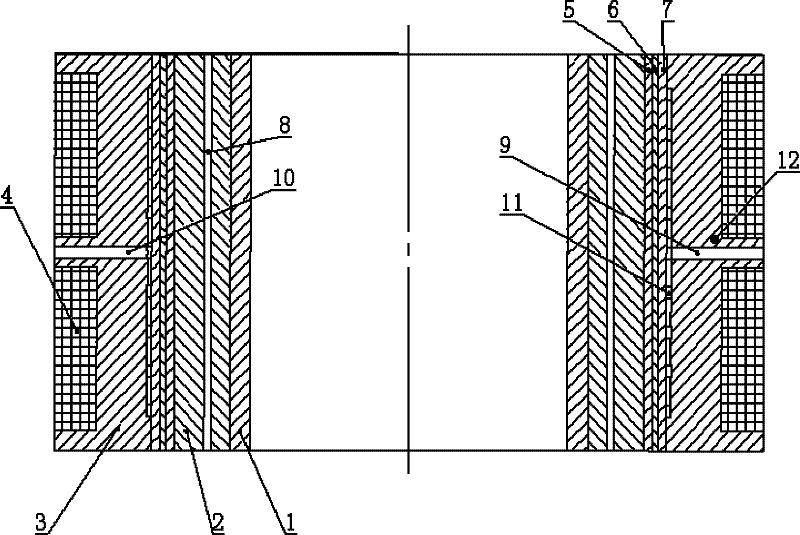

Machining method of aluminum profile hot extrusion mold

InactiveCN108435818AShorten the processing cycleIncrease productivityExtrusion profiling toolsElectrical-based auxillary apparatusCooling effectThermal treatment

The invention discloses a machining method of an aluminum profile hot extrusion mold, and relates to the technical field of mold production. The machining method of the aluminum profile hot extrusionmold comprises the steps of: (1) pretreatment: comprising cutting, turning, roughening and drilling in sequence to finish machining of the shape of a mold, a flow separation hole, a process hole, a pin hole, a screw hole and a positioning hole to obtain a mold blank; (2) heat treatment; (3) plane grinding and milling; (4) finish machining; (5) linear cutting; (6) carving; (7) electrospark machining; (8) polishing; (9) tool polishing; (10) polishing; (11) finish turning; and (12) obtaining of a finished product. The machining method of the aluminum profile hot extrusion mold greatly improves the problem of bad cooling effect in the mold production process, and indirectly improves the working efficiency.

Owner:佛山市顺德区惠联模具科技有限公司

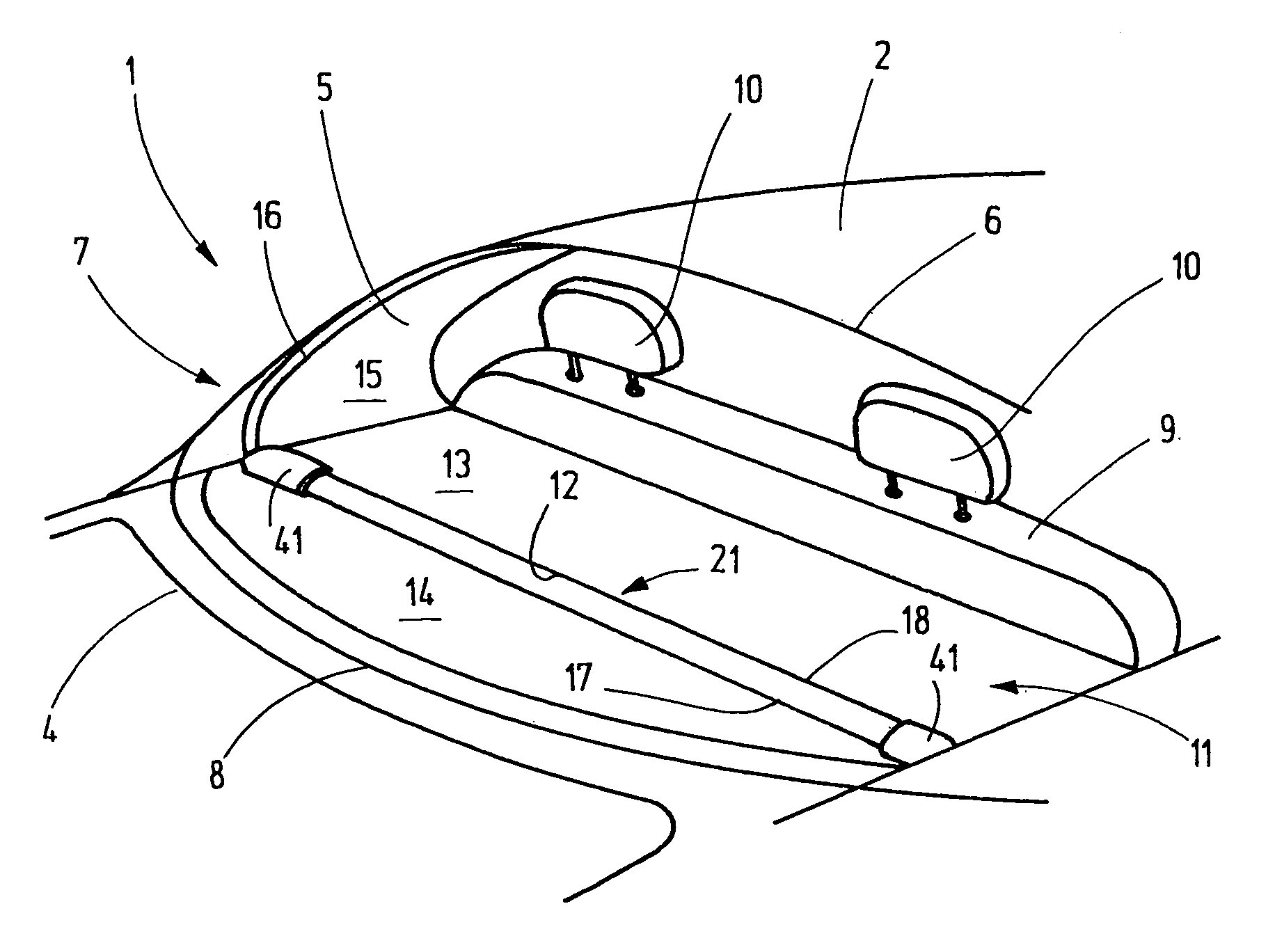

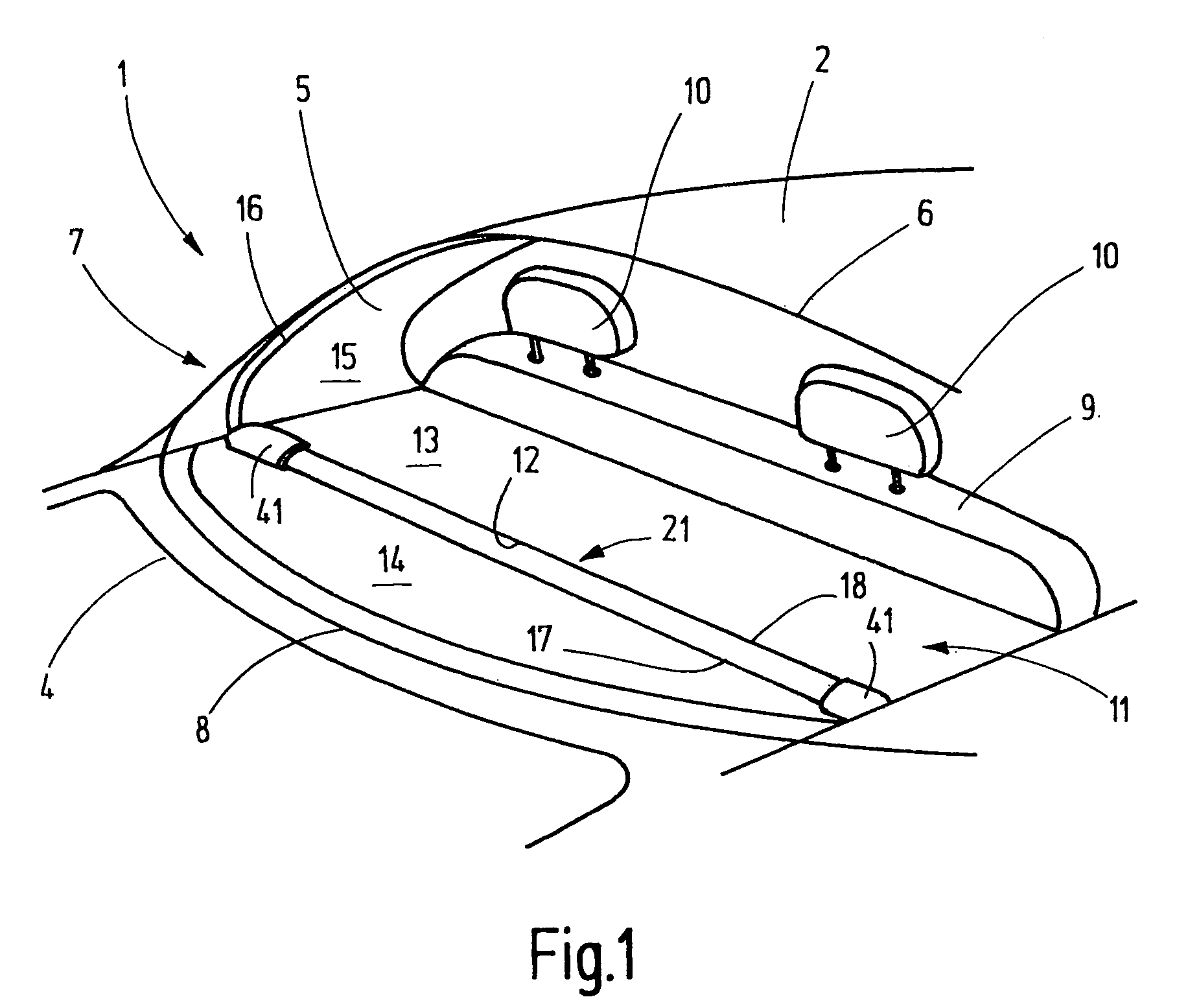

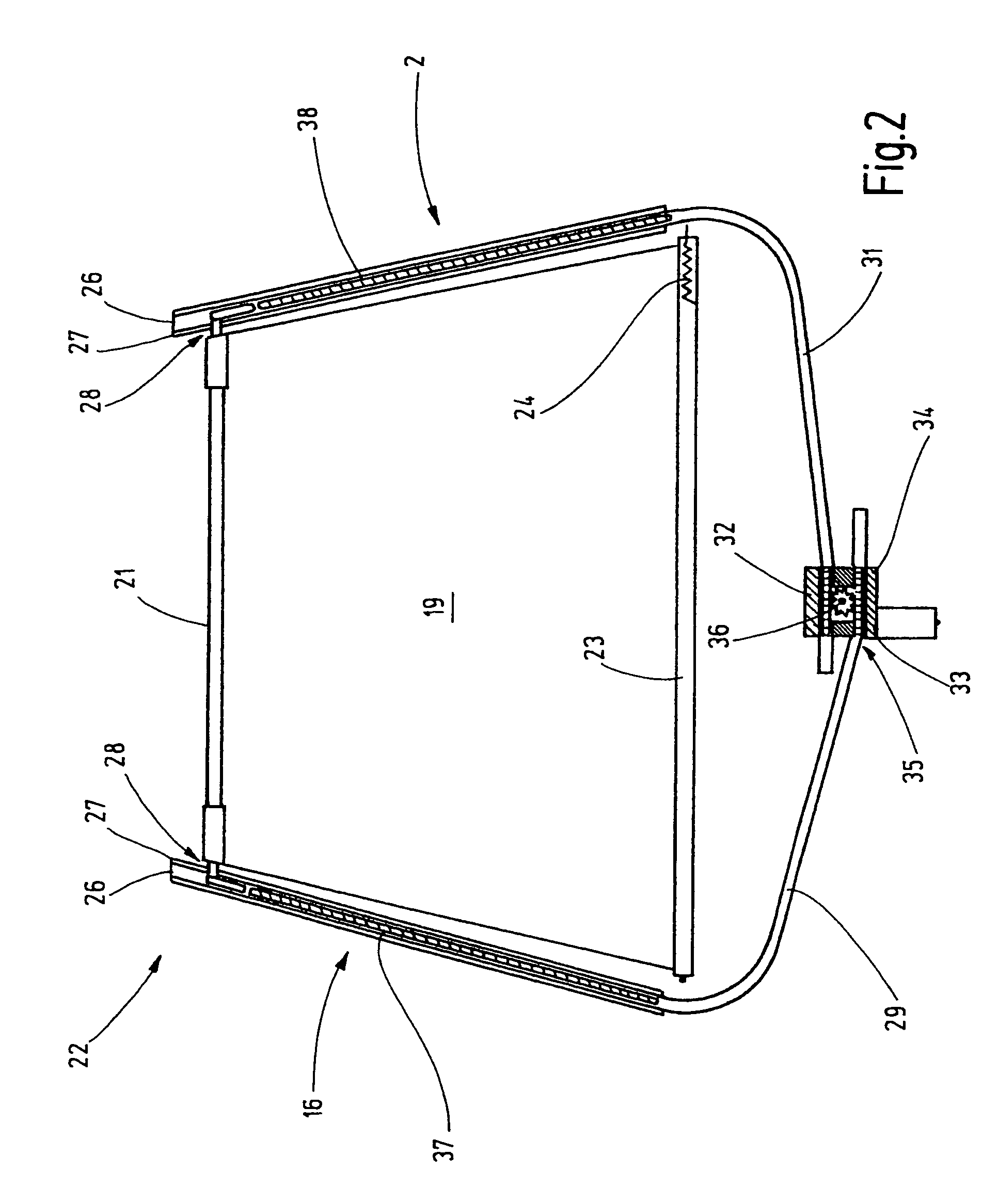

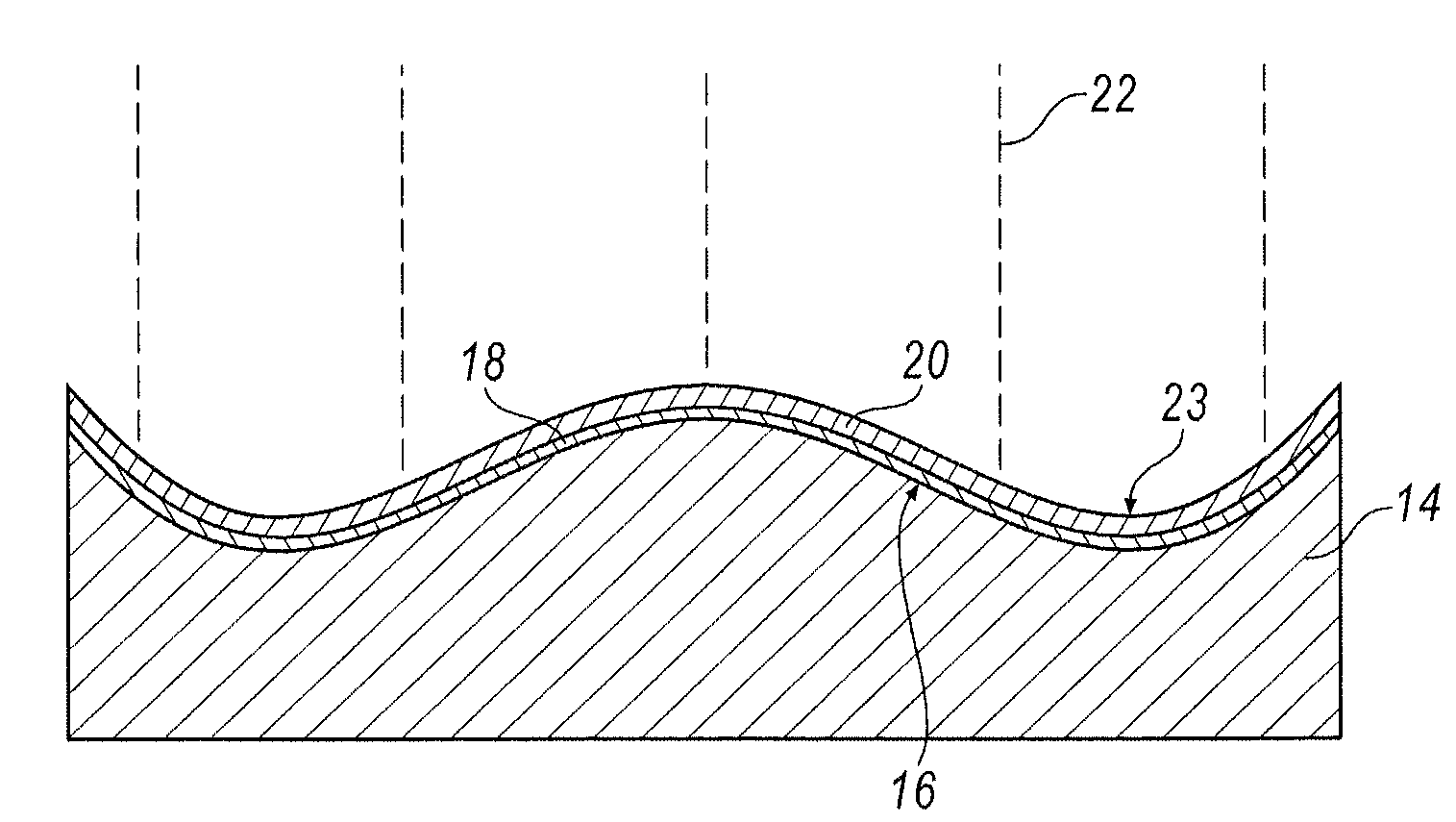

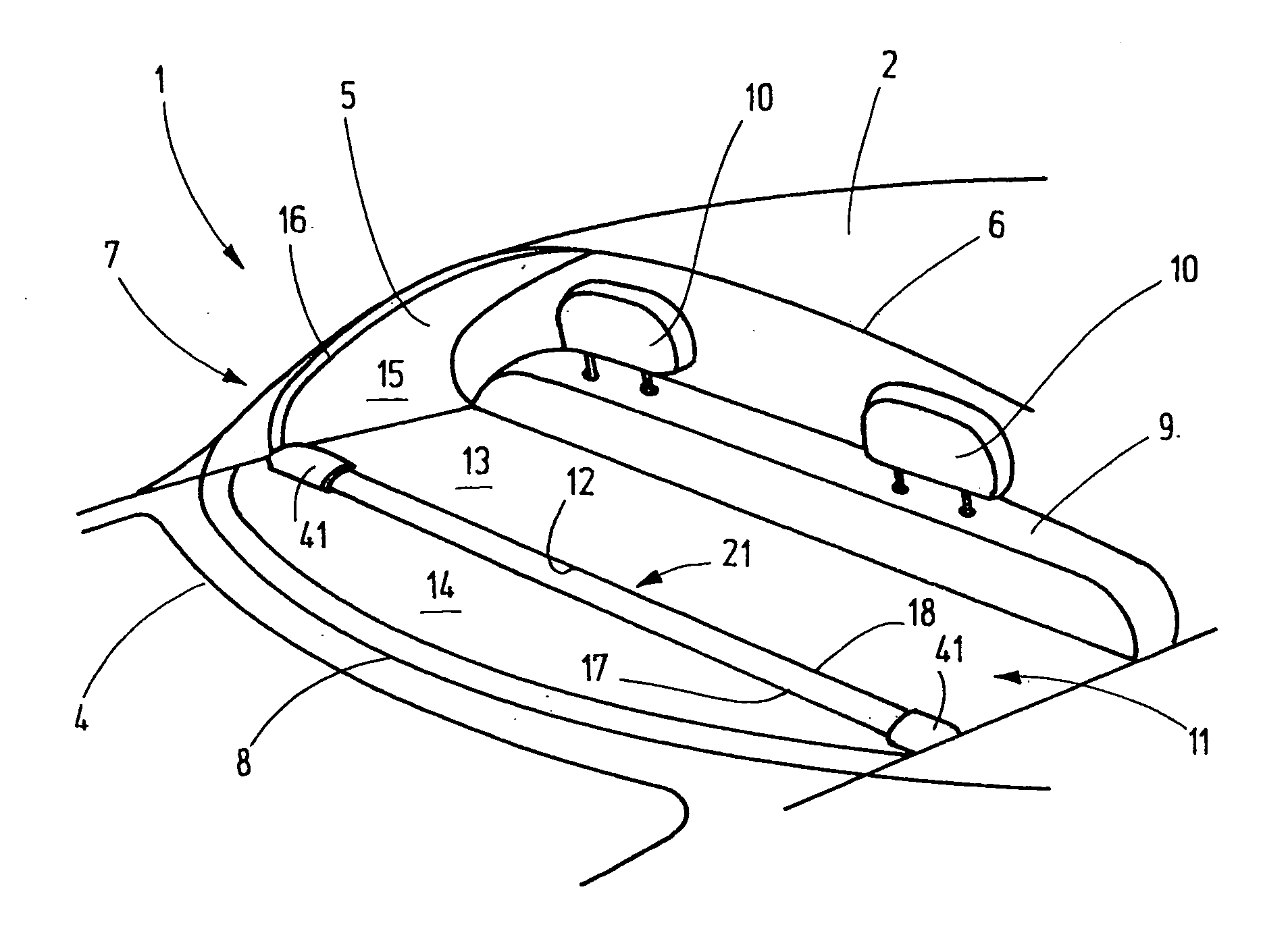

Rear window roller blind with complete split coverage by the pull-out element

A rear-window roller blind assembly for motor vehicles in which the roller blind is movable out of a pull-out slit to an extended position through movement of a pull-out element on a free edge thereof. The pull-out element includes a center piece and relatively movable end pieces shaped so that when the pull-out element is in a retracted position the pull-out slit is covered over its entire length by the pull-out element.

Owner:BOS

Extruded material of aluminum alloy for structural members of automobile body and method of manufacturing the same

There is disclosed an aluminum alloy extruded material for structural members of automotive bodies, which is composed of an aluminum alloy containing more than 2.6 wt % but 4.0 wt % or less of Si and more than 0.3 wt % but 1.5 wt % or less of Mg, further, (i) containing Mn, Zn, Cu, and Fe each in a given amount, or (ii) containing Zn, Cu, and Fe each in a given amount and containing at least one selected from among Mn, Cr, Zr, and V in a given amount, and the balance being made of Al and unavoidable impurities, which material has a given conductivity and a given melting start temperature. There is also disclosed a method for producing the extruded material, in which after an aluminum alloy ingot of the above composition is subjected to a homogenizing treatment at given conditions, it is cooled, heated again, and subjected to hot extrusion at given conditions. The extruded material is excellent in spot weldability and surface treatment property, such as the chemical conversion property and degreasing property, and it has high mechanical strength and ductility, and is excellent in impact absorbability and / or bendability.

Owner:FURUKAWA SKY ALUMINUM CORP +1

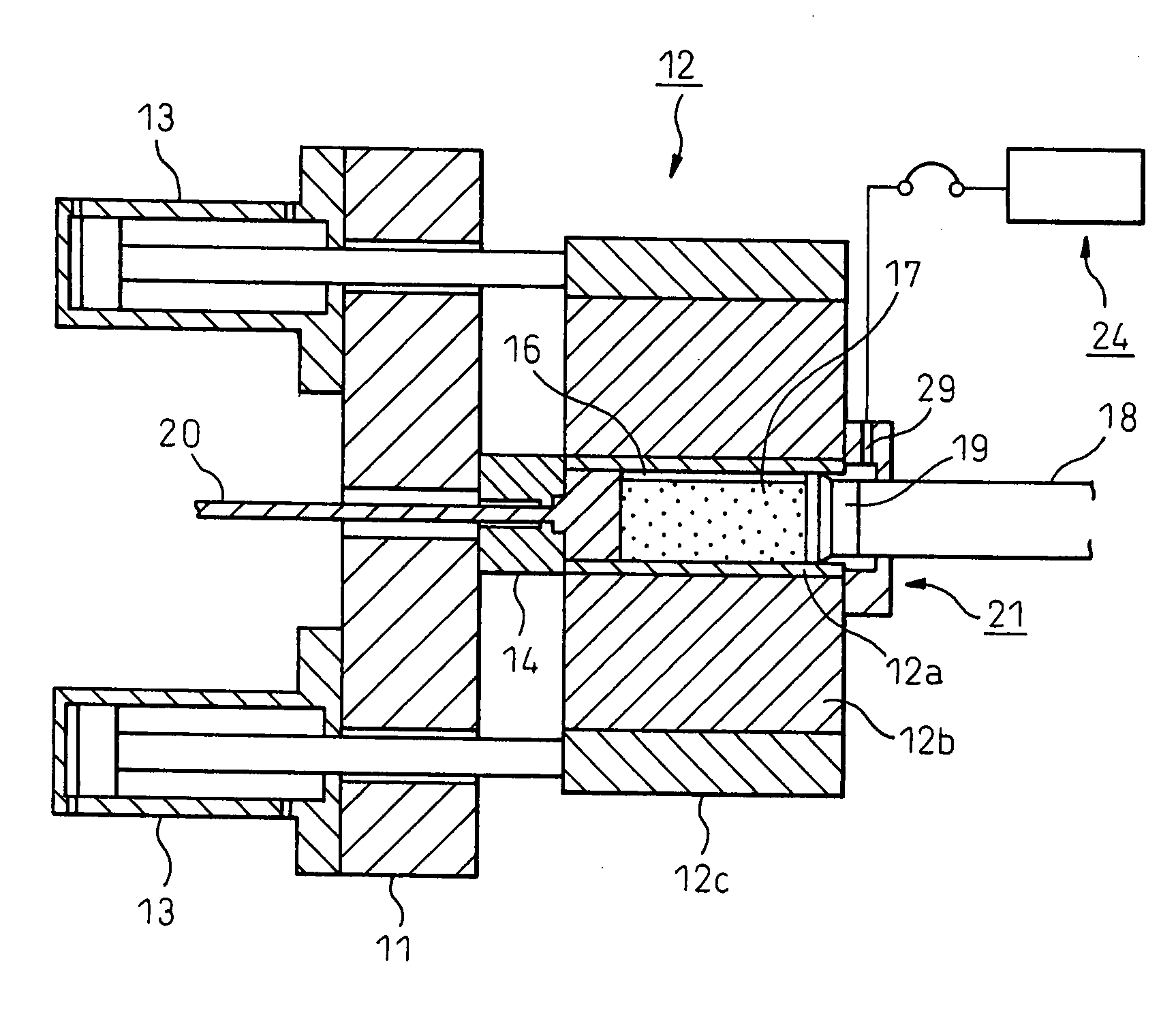

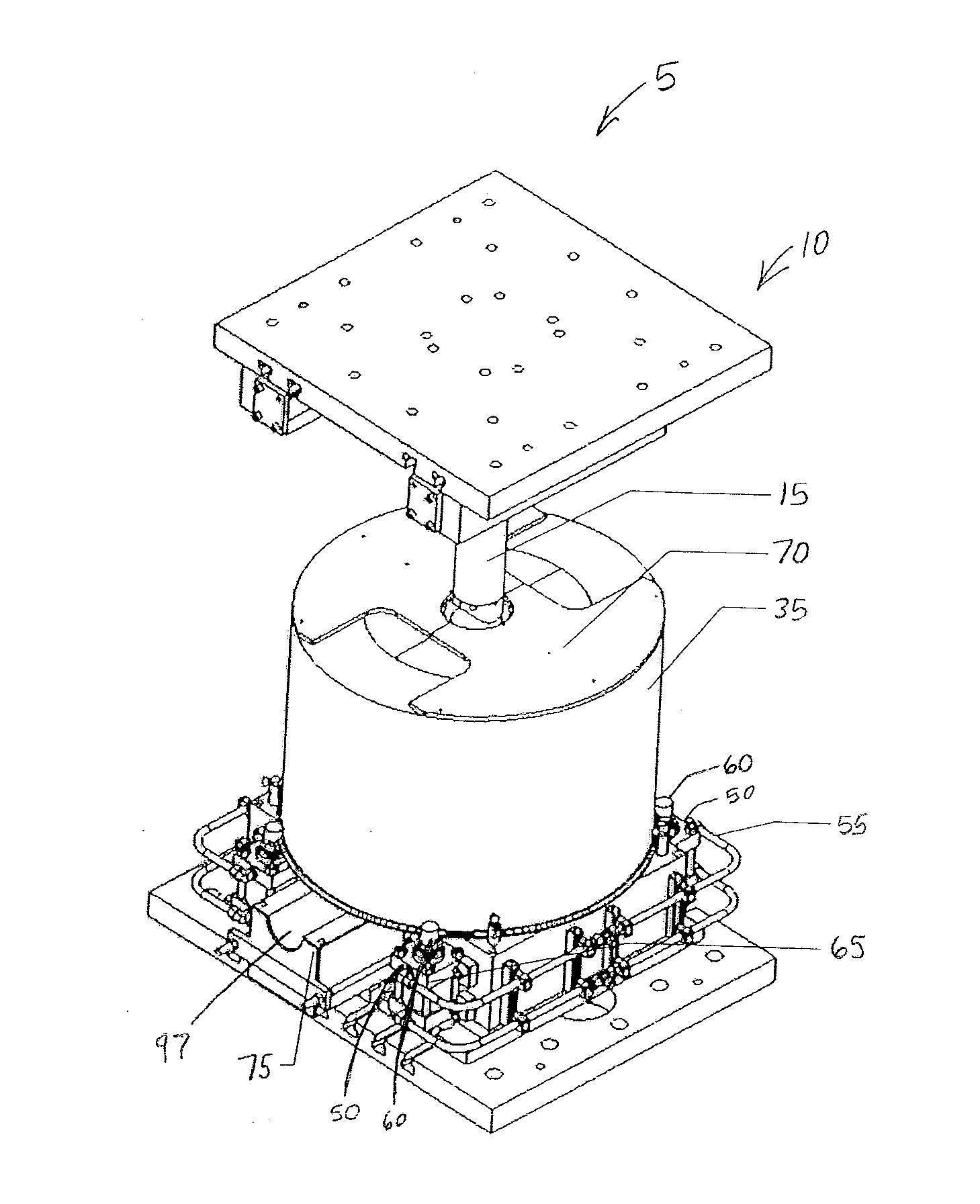

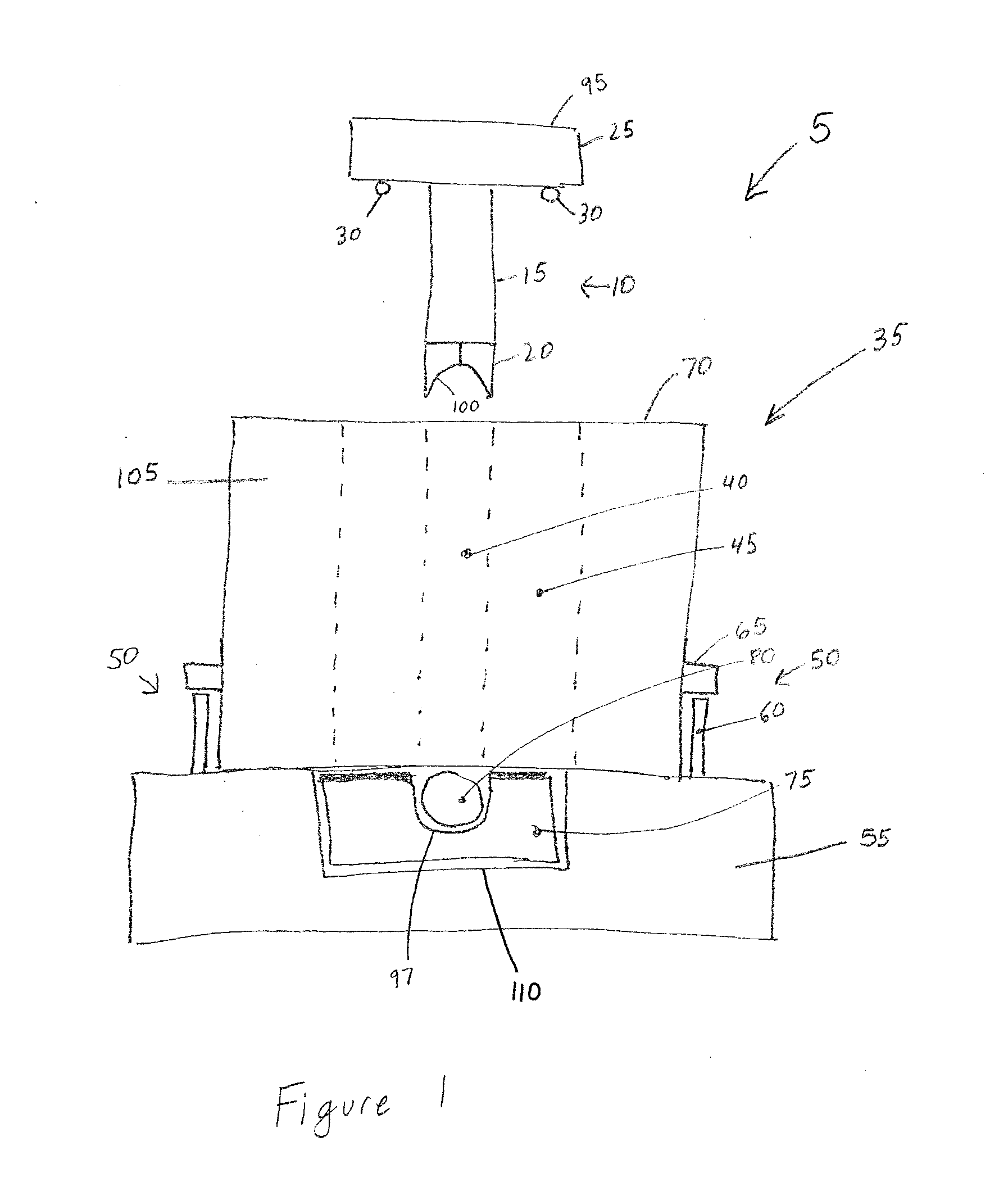

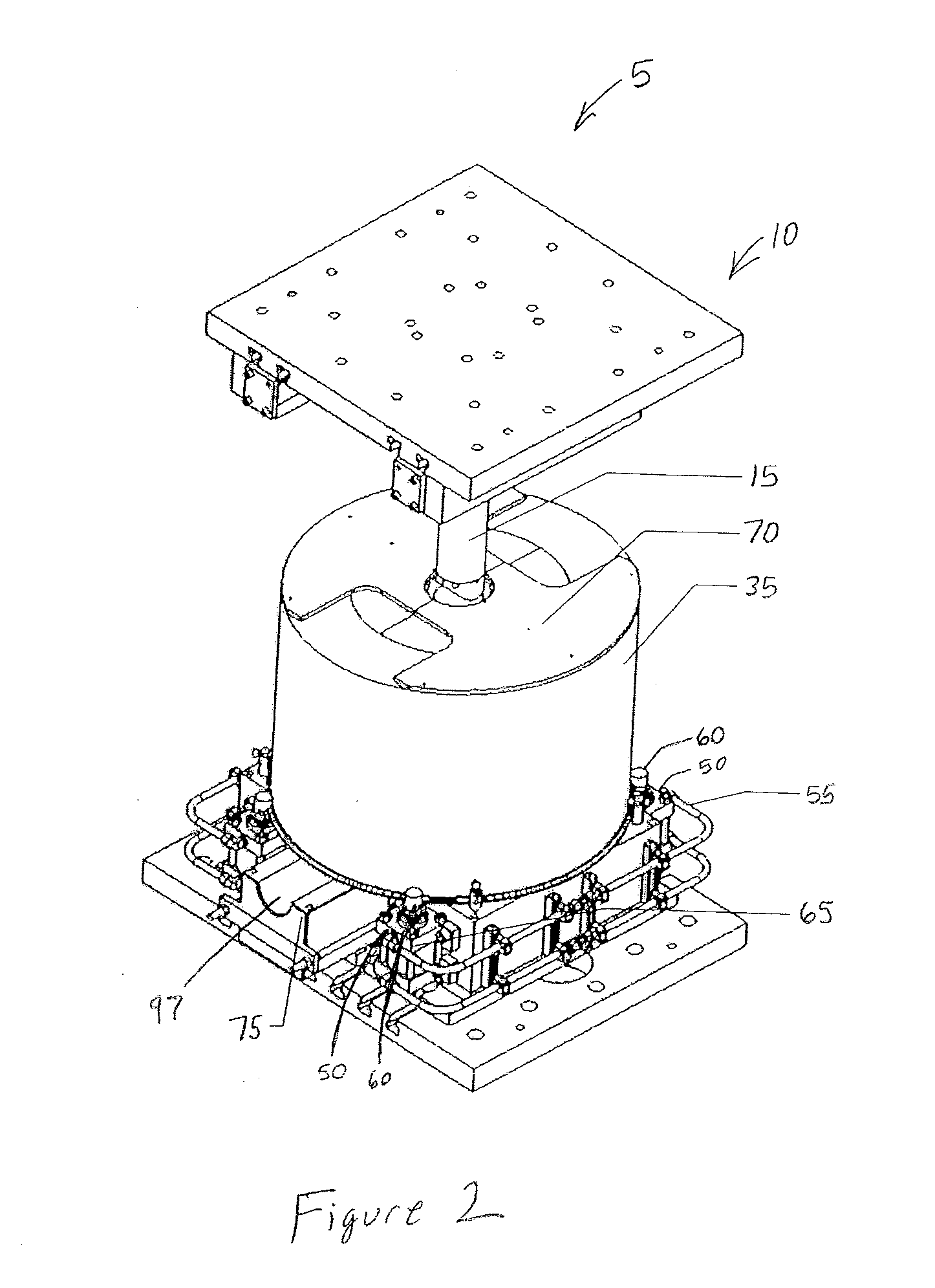

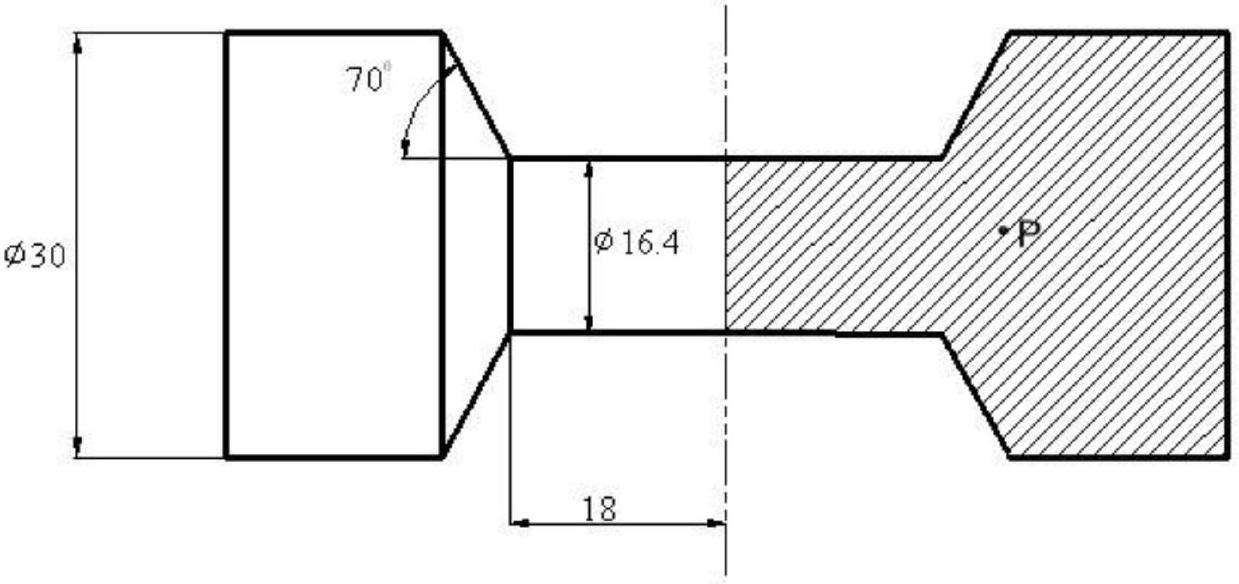

Apparatus for Deformation of Solid Sections

ActiveUS20130276501A1Extrusion profiling toolsAuxillary shaping apparatusInlet channelEqual channel angular extrusion

An equal channel angular extrusion tool comprising a punch assembly, a die set assembly, a base assembly, and a bottom slider assembly. The punch assembly comprises a punch, a punch nose, and a punch trolley. The die set assembly comprises an inlet channel and a removable core. The base assembly comprises a lifting mechanism which further comprises a die lift cylinder and a hold down ram. The bottom slider assembly comprises an ejection ram. The tool also includes a billet. The billet may be disposed in the bottom slider assembly. Severe plastic deformation is applied to the billet in the bottom slider assembly.

Owner:SHEAR FORM

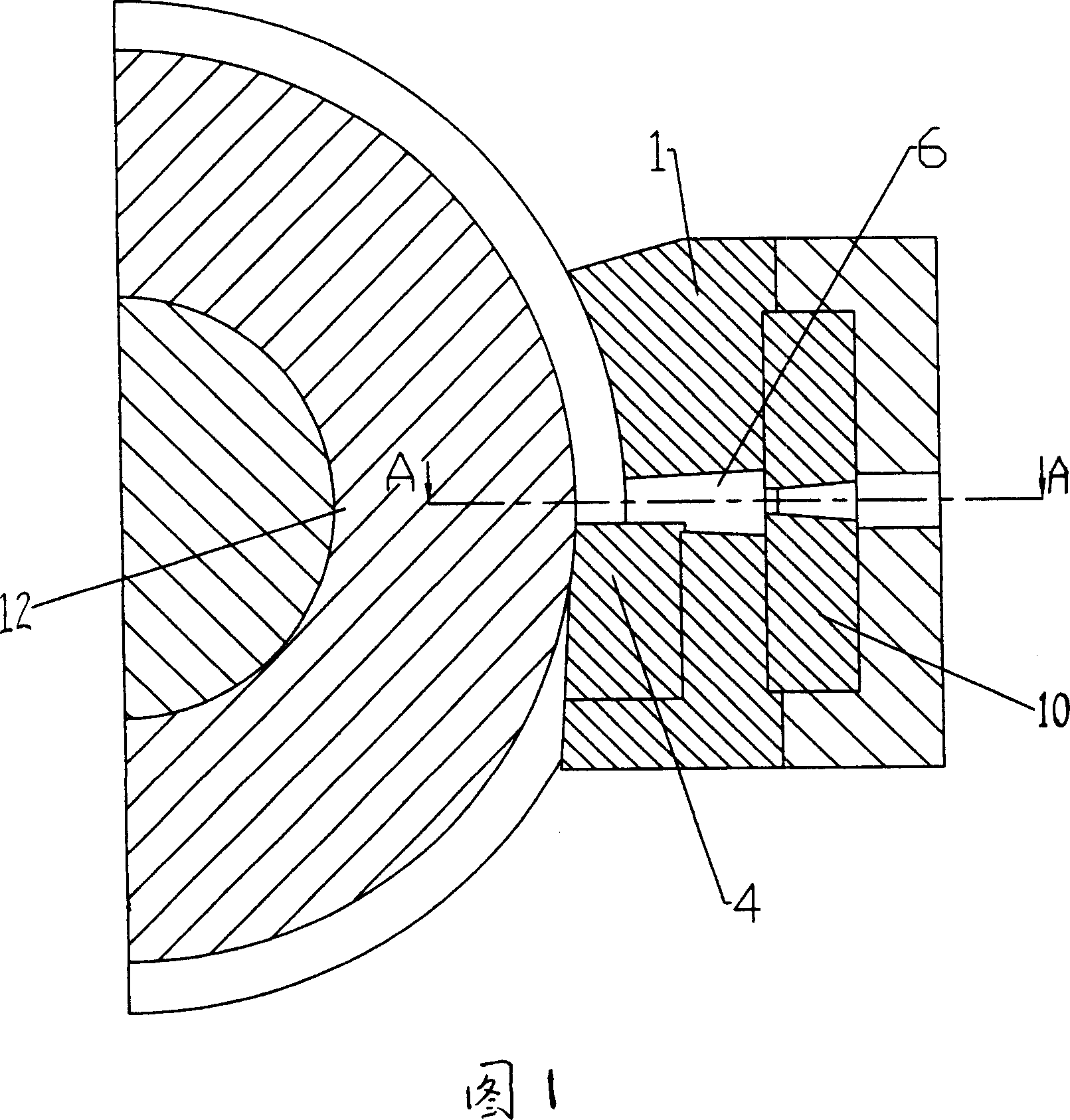

Combined continuous extruder cavity

ActiveCN1943893AEasy loadingReduce the overall heightExtrusion profiling toolsSurface plateLoad bearing

The present invention relates to shaped section extruding apparatus, and is especially one kind of combined continuous extruder cavity. The cavity consists of panel including sealing plane and feeding port, bottom plate, material stoppers as independent parts embedded to the cavity, and mold. The cavity in the combined structure with embedded material stoppers may have material stoppers of different material for greatly raised load bearing capacity and may have the damaged material stopper replaced without need of replacing the whole cavity. The cavity bottom plate is so designed that mold may be installed, and this can lower the height of the cavity obviously and saving material for the cavity.

Owner:大连康丰科技有限公司

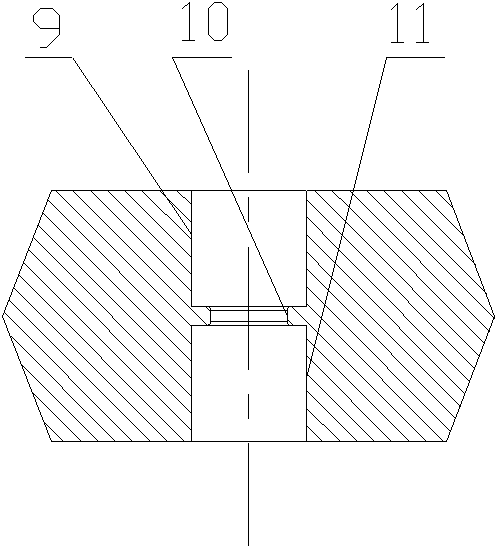

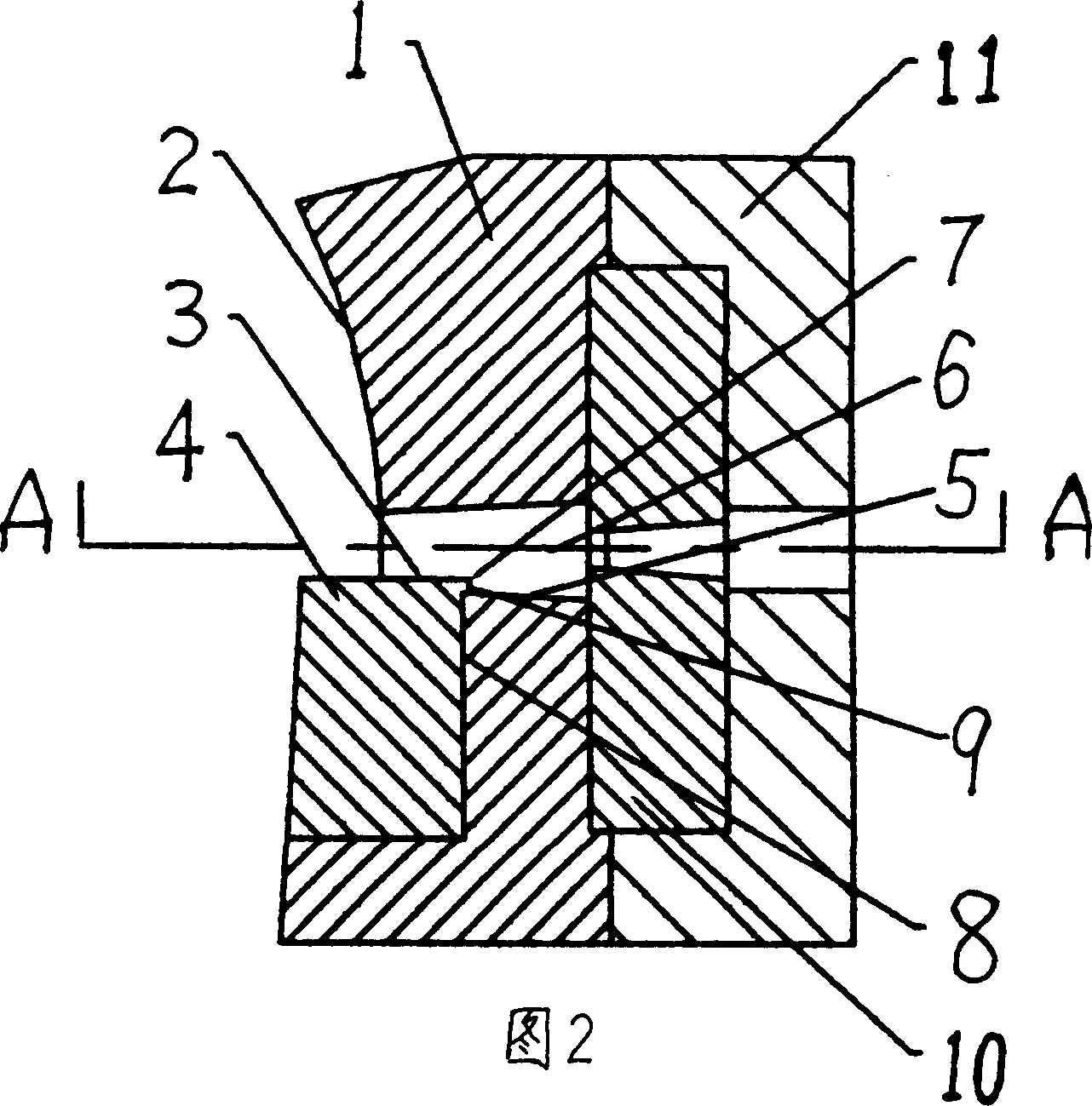

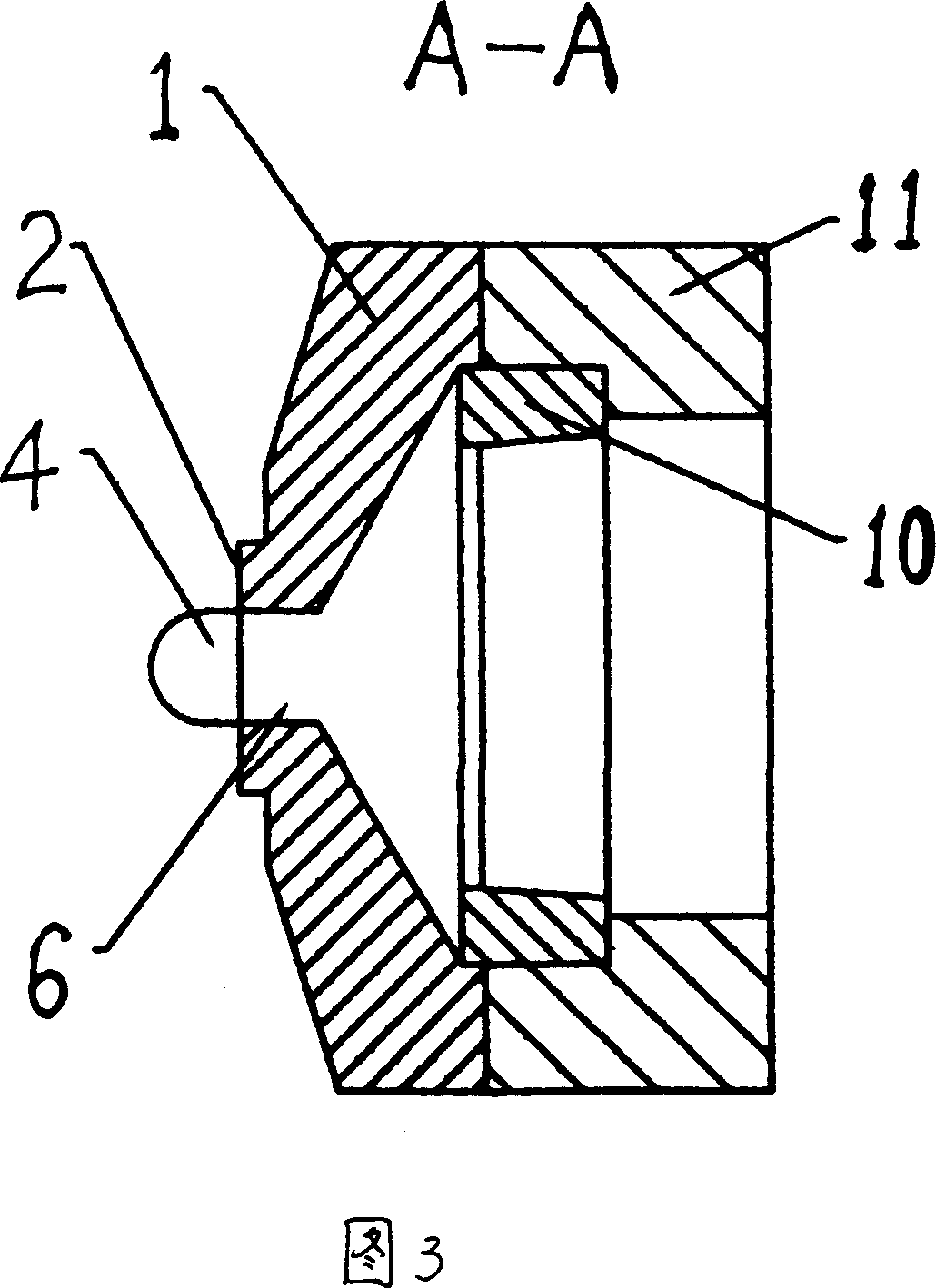

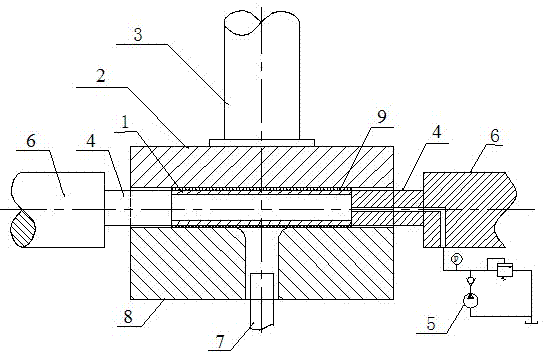

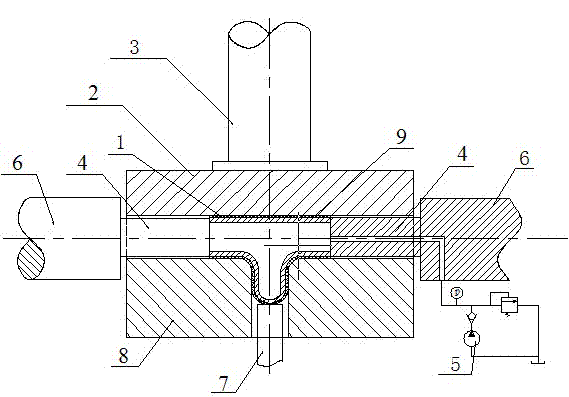

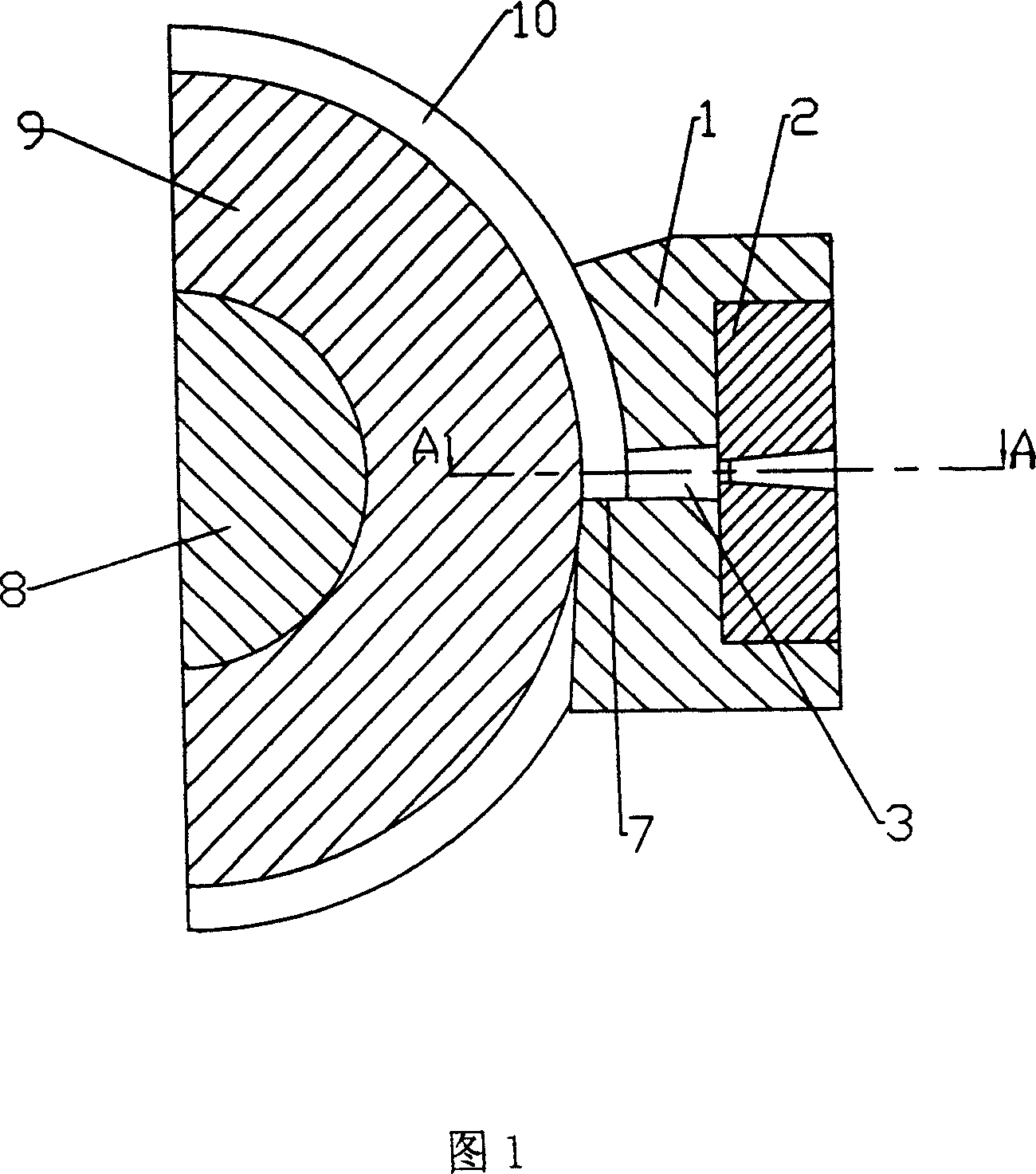

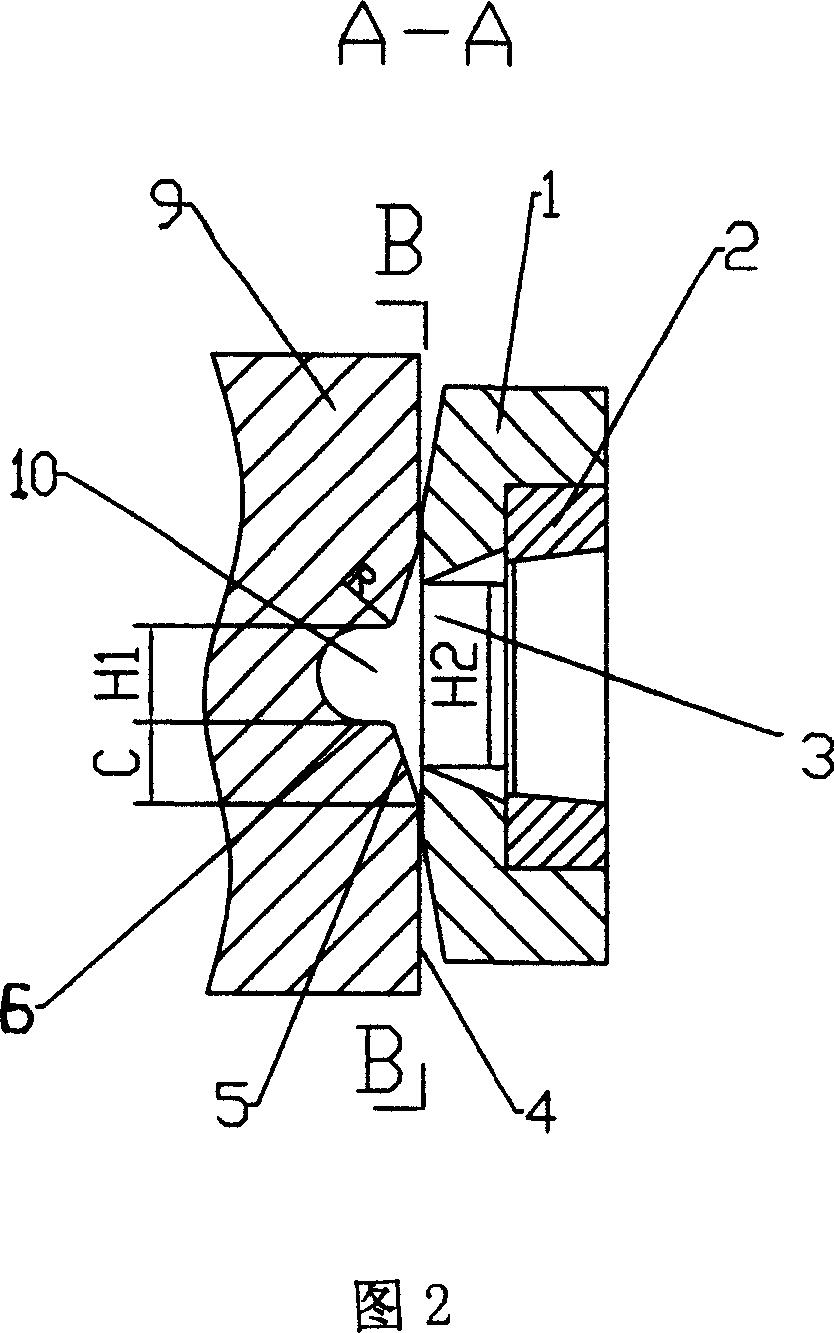

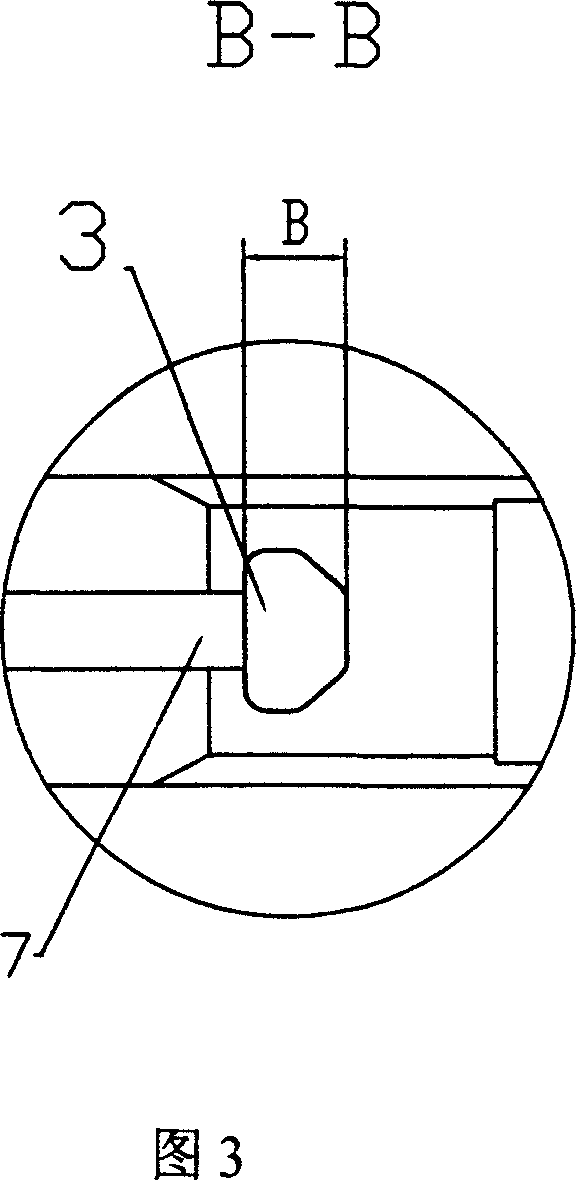

Method for extruding and forming stainless steel three-way joint

InactiveCN102240700AEasy to cleanImprove processing qualityExtrusion profiling toolsSolution treatmentEmulsion

The invention discloses a method for extruding and forming a stainless steel three-way joint, comprising the following steps of: 1), preparing a stainless steel tube billet (1), surface of which is wrapped by a layer of plastic film (9); 2), extruding and forming the stainless steel tube billet (1) so as to obtain a semi-finished product of the three-way joint, wherein a liquid filling medium in a liquid filling system in a tube is emulsion formed by modulating emulsified oil and water; and 3), performing solid solution treatment, surface grinding and groove processing of the semi-finished product of the three-way joint. According to the method for extruding and forming the stainless steel three-way joint disclosed by the invention, the emulsion is ingeniously used as the liquid filling medium; energy-saving and environmental protection requests can be satisfied; the three-way joint extruded and formed by the invention is cleaned easily; the emulsion of the liquid filling medium in the tube can be recycled; stainless steel metal tee joints and the environment cannot be polluted; furthermore, a layer of plastic film is ingeniously wrapped on the stainless steel tube billet in advance; the surface of the formed three-way joint can be effectively prevented from generating defects; and the processing quality of the three-way joint is obviously improved.

Owner:江苏兴洋管业股份有限公司

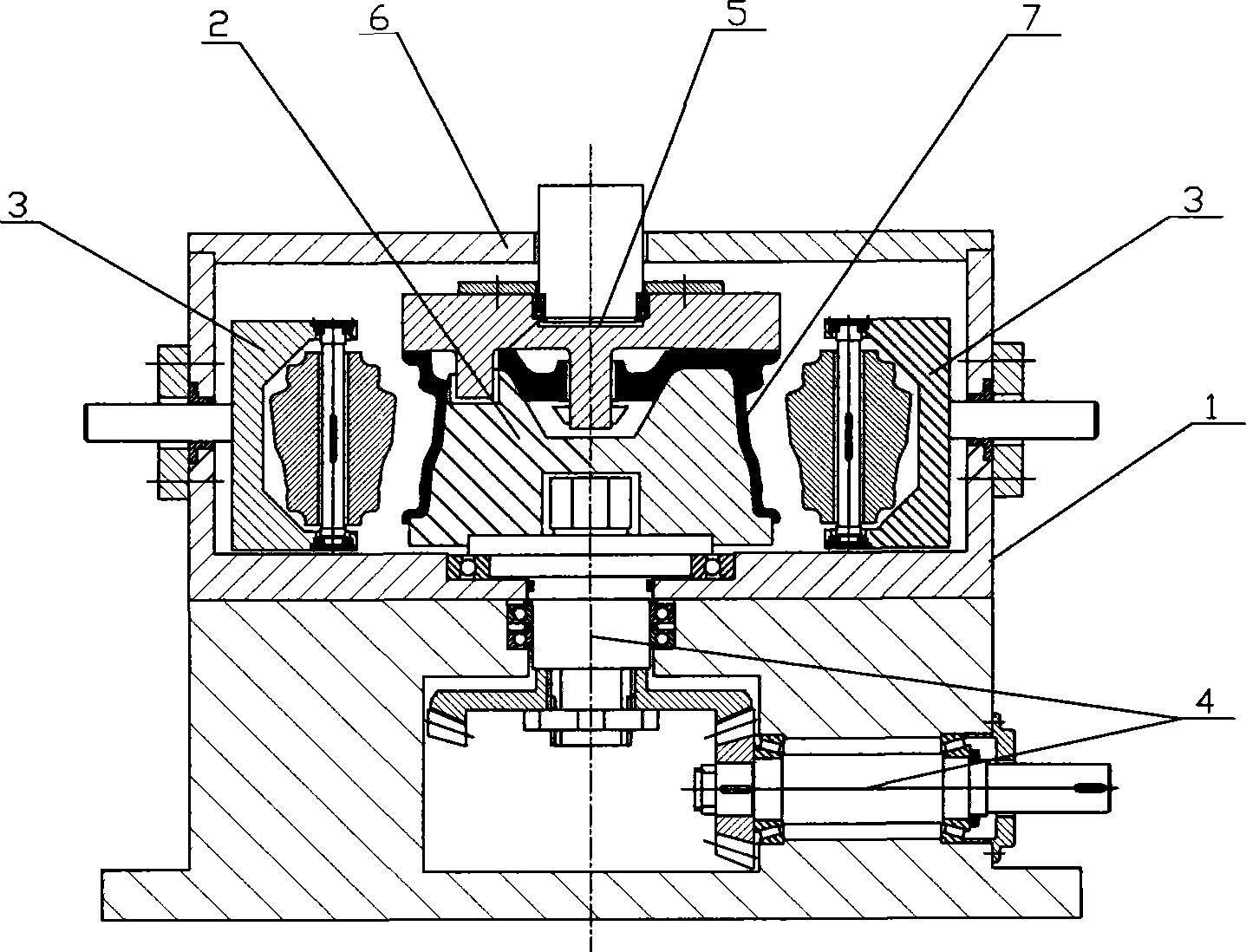

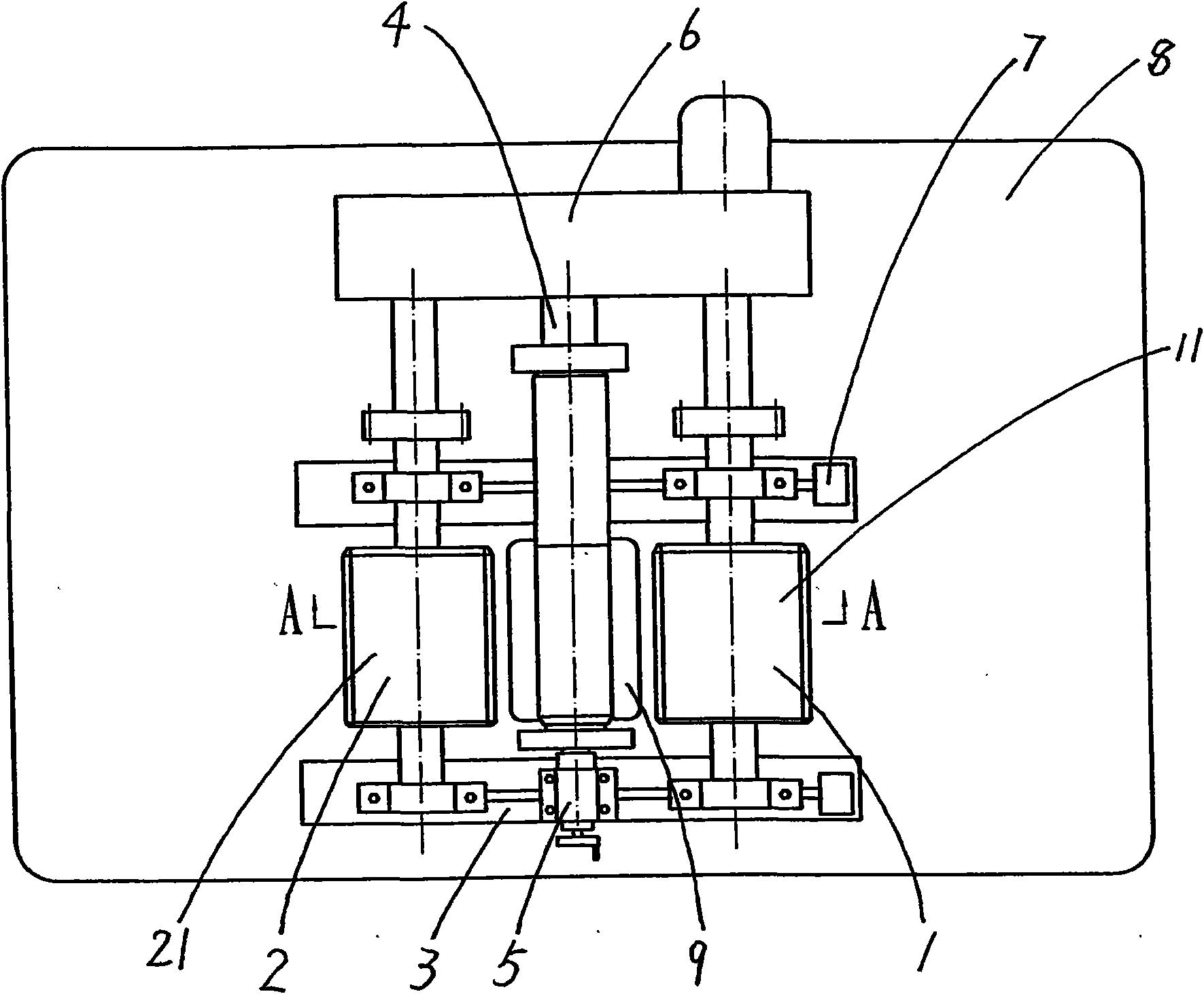

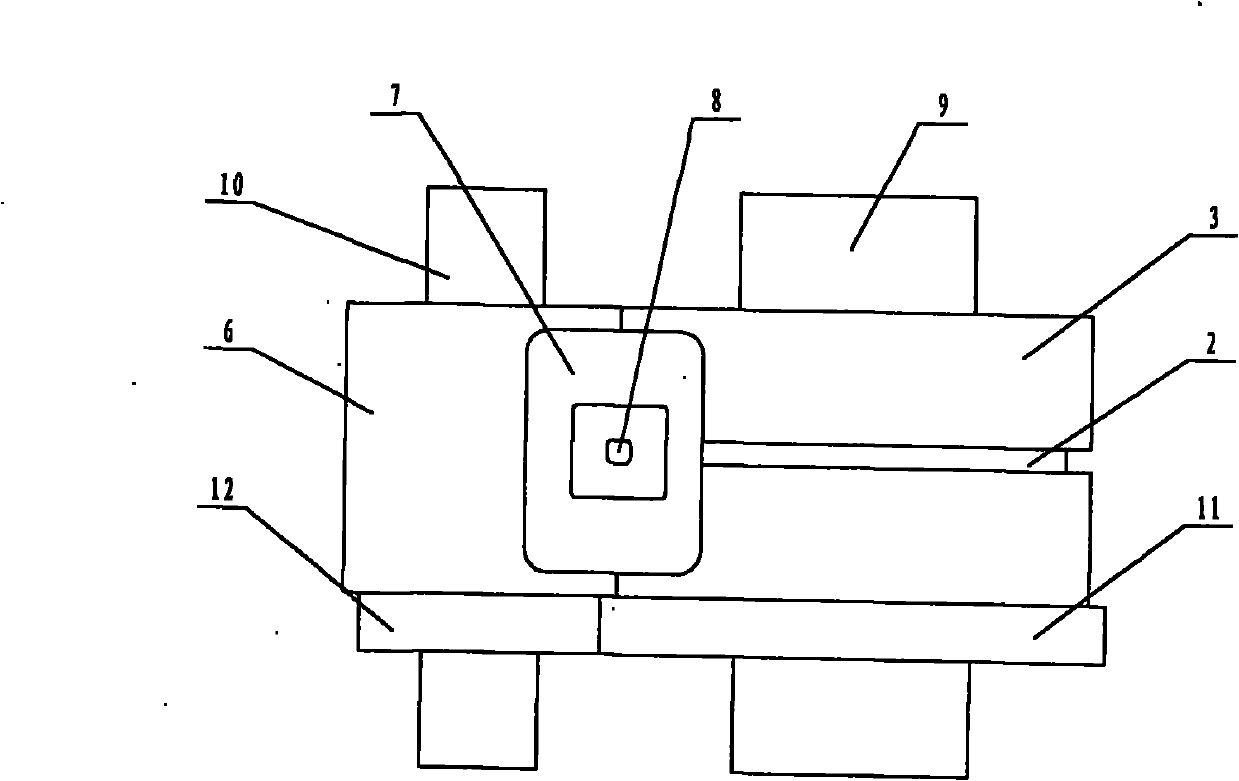

Method for processing camshaft spline of automotive brake and device therefor

ActiveCN101767117AImprove surface densityQuality improvementExtrusion profiling toolsPulp and paper industryVolumetric Mass Density

The invention relates to a method for processing a camshaft spline of an automotive brake and a device therefor. The device comprises a squeeze roller I, a squeeze roller II, a squeeze roller base, a limit device, an adjusting device, a driving mechanism, a squeeze roller position adjusting mechanism, a frame and a wear-resisting bearing, wherein the squeeze roller base is provided with the limit device and the adjusting device and is also provided with the squeeze roller position adjusting mechanism; the squeeze roller I and the squeeze roller II are connected with the driving mechanism; and the squeeze roller base, the driving mechanism and the wear-resisting bearing are arranged on the frame. By adopting the two squeeze rollers for rolling, the tooth shape of the processed spline is consistent, and the surface density degree after processing is obviously strengthened, thereby greatly improving the quality of the processed product. As the blank is preheated before extrusion processing, the extrusion is carried out under certain temperature, so that the extrusion is easy, and the performance of the processed product is reliable. The extrusion process is adopted for processing, so as to improve the working efficiency greatly.

Owner:JIANGSU CASHIDA TRANSMISSION TECH CO LTD

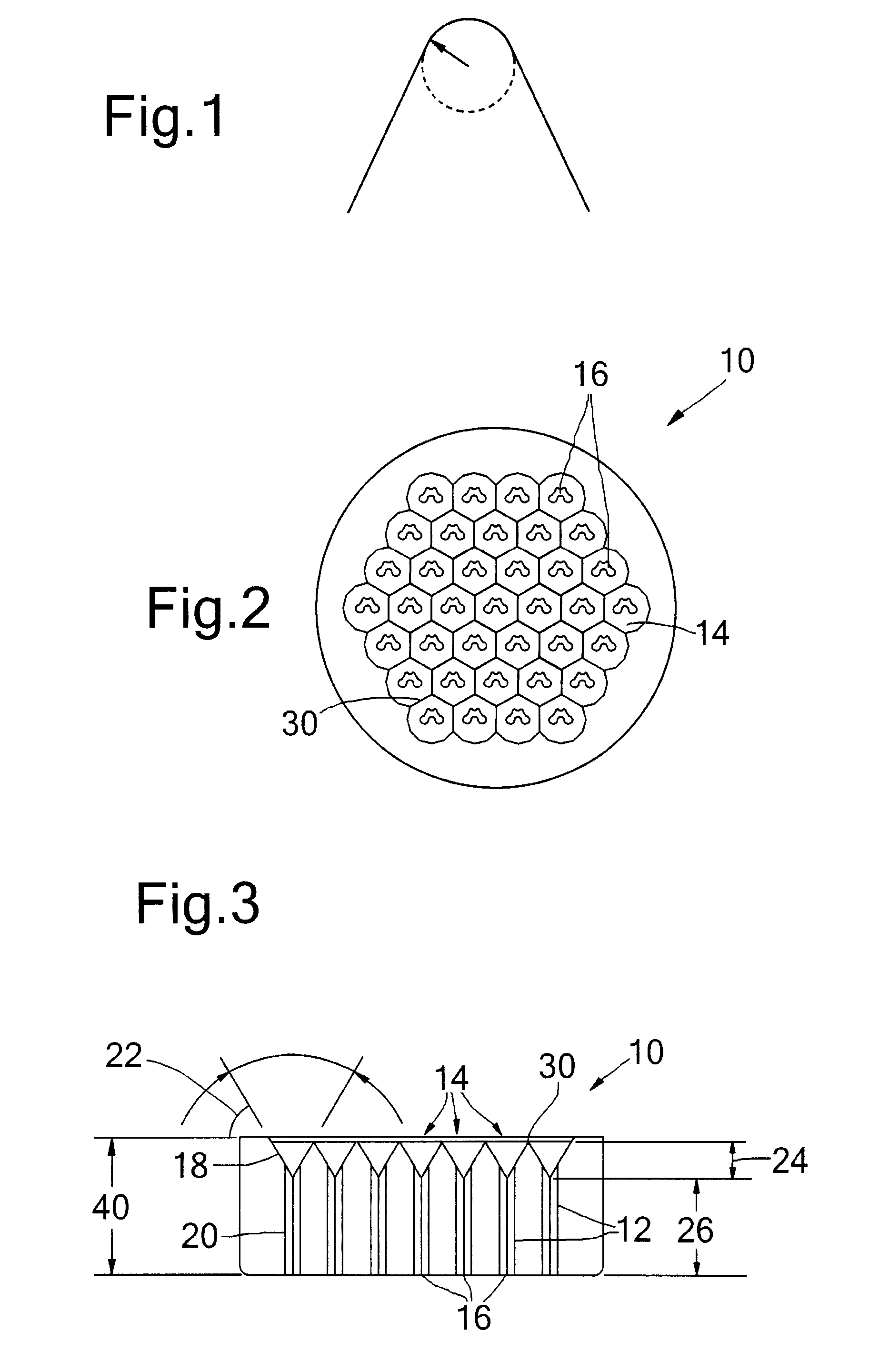

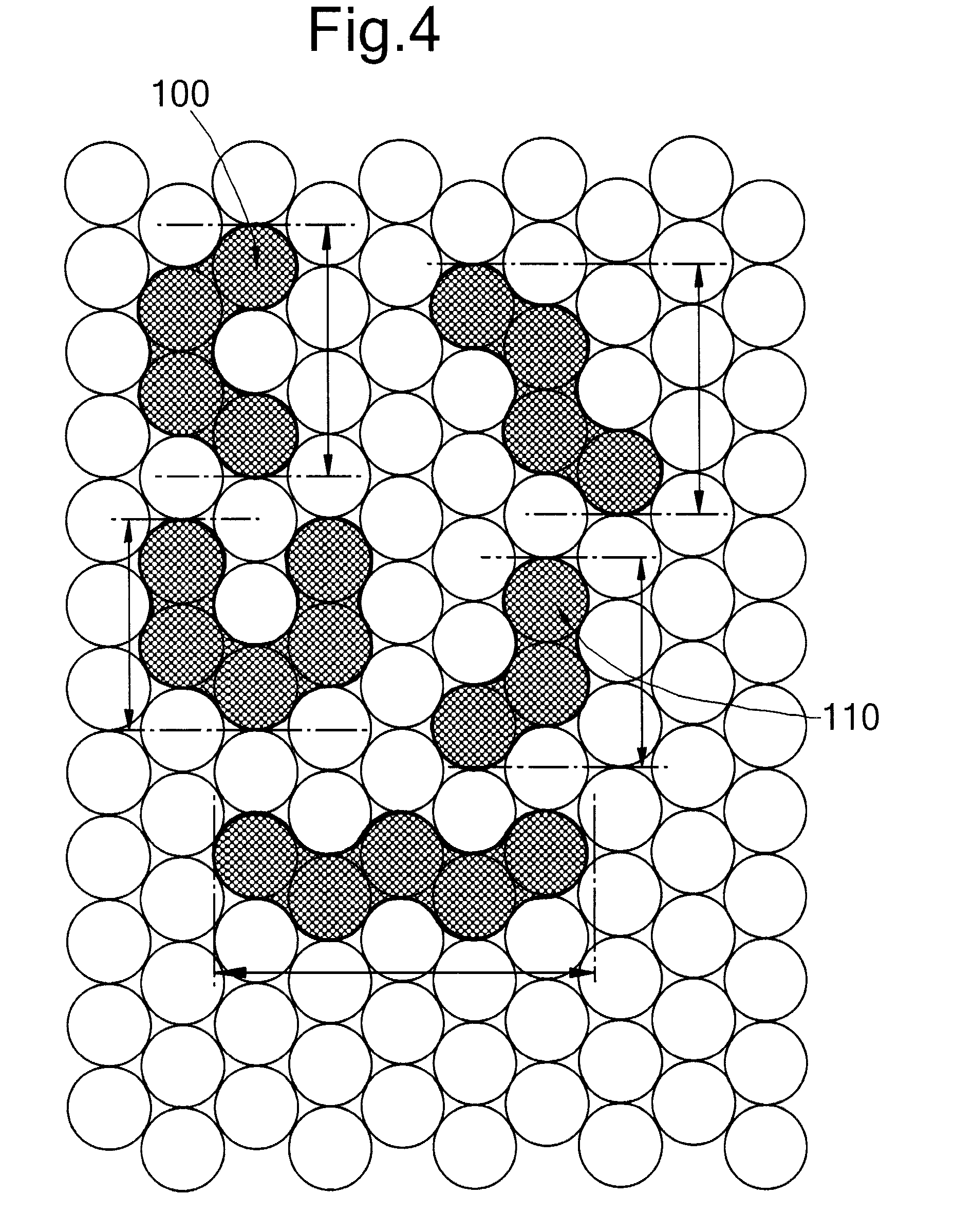

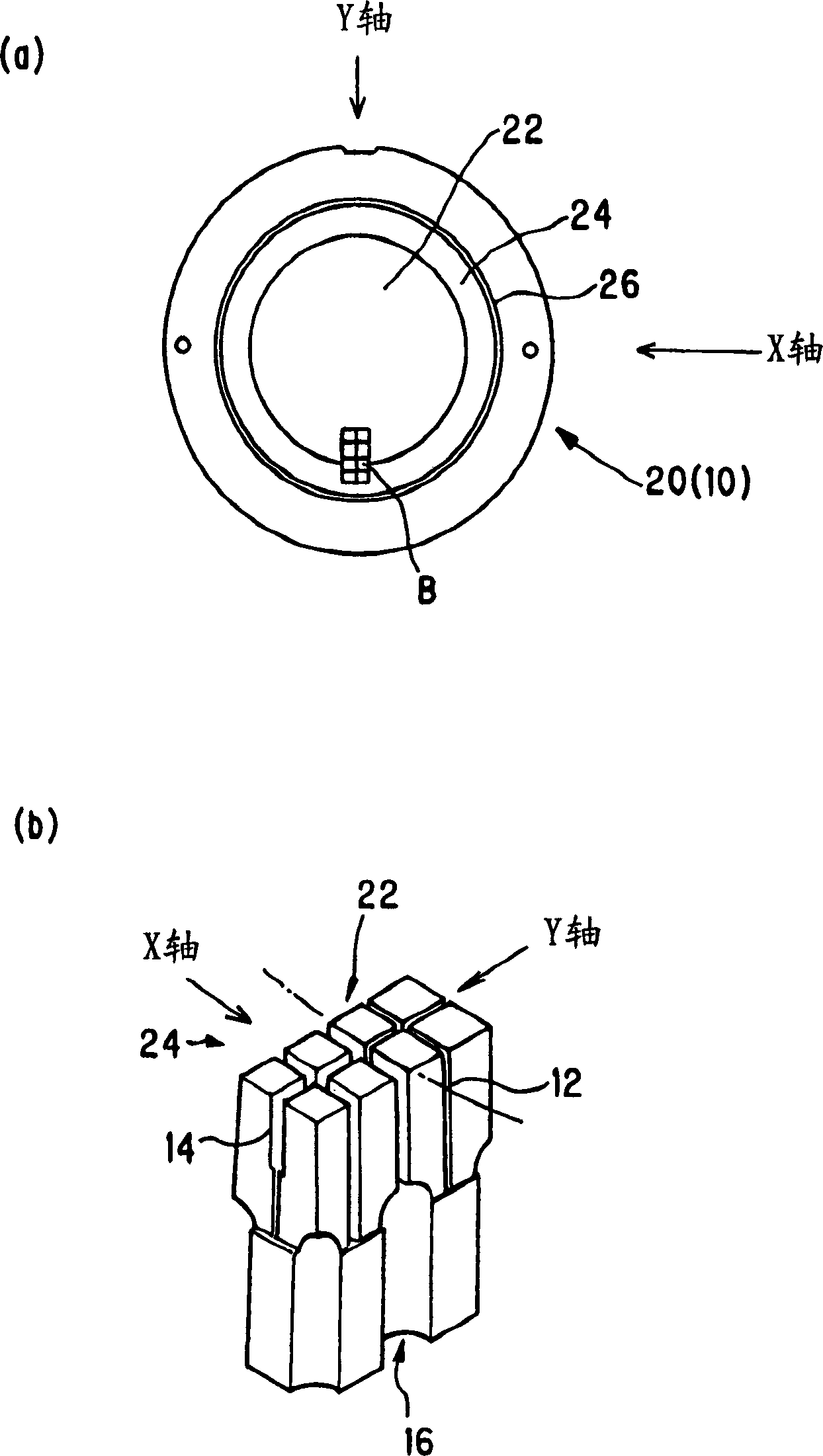

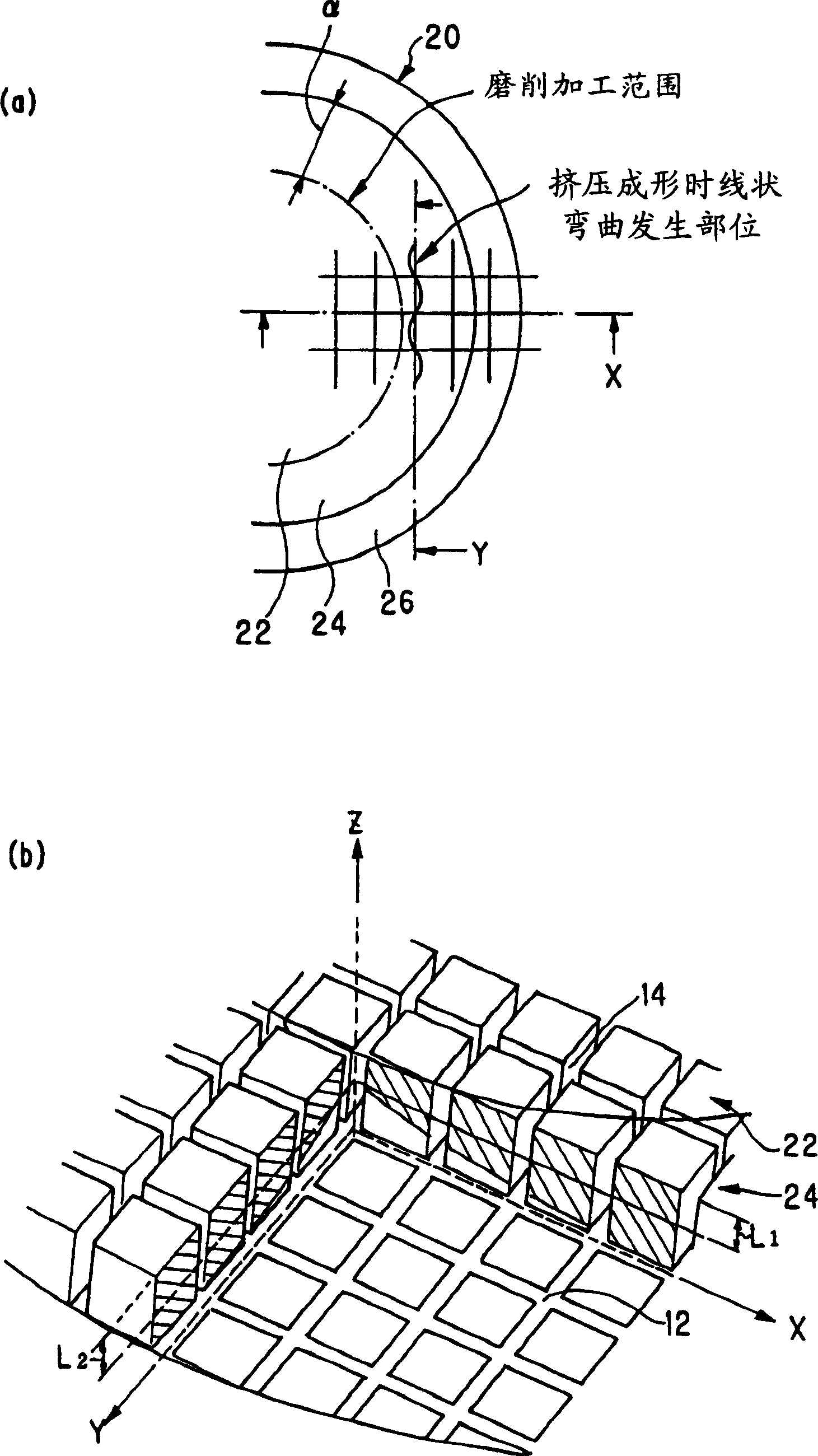

Honeycomb-shape mouthpiece forextruding for mation and production method thereof

InactiveCN1404935AIncrease productivityPrevent getting caught in bad graphicsExtrusion profiling toolsCeramic extrusion diesSurface roughnessVolumetric Mass Density

Owner:NGK INSULATORS LTD

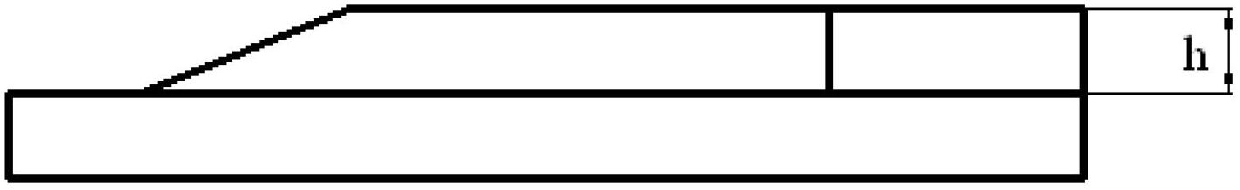

Designing method for cross wedge rolling mould of conical surface stepped shaft part

InactiveCN102688908ASimplify the design processSimplify the manufacturing processExtrusion profiling toolsStructural engineeringDesign methods

The invention discloses a designing method for a cross wedge rolling mould of a conical surface stepped shaft part. The designing method comprises the following steps of: 1, designing a structure of the cross wedge rolling mould, wherein the cross wedge rolling mould consists of four parts, namely a wedge section with the length being L, a first widening section with the length being L1, a second widening section with the length being L2 and a shaping section with the length being L3, and the four parts are connected integrally on a template; and the first widening section, the second widening section and the shaping section have the same thickness, and the thickness is equal to a wedge top height (h) of the wedging section; 2, designing the wedging section with the length being L, wherein L=hcot(alpha)cot(beta), h=r1-r0+delta; 3, designing the first widening section with the length being L1, wherein L1=ecot(beta); 4, designing the second widening section with the length being L2, wherein L2=(L1-e)cot(beta); and 5, designing the shaping section with the length being L3.

Owner:JILIN UNIV

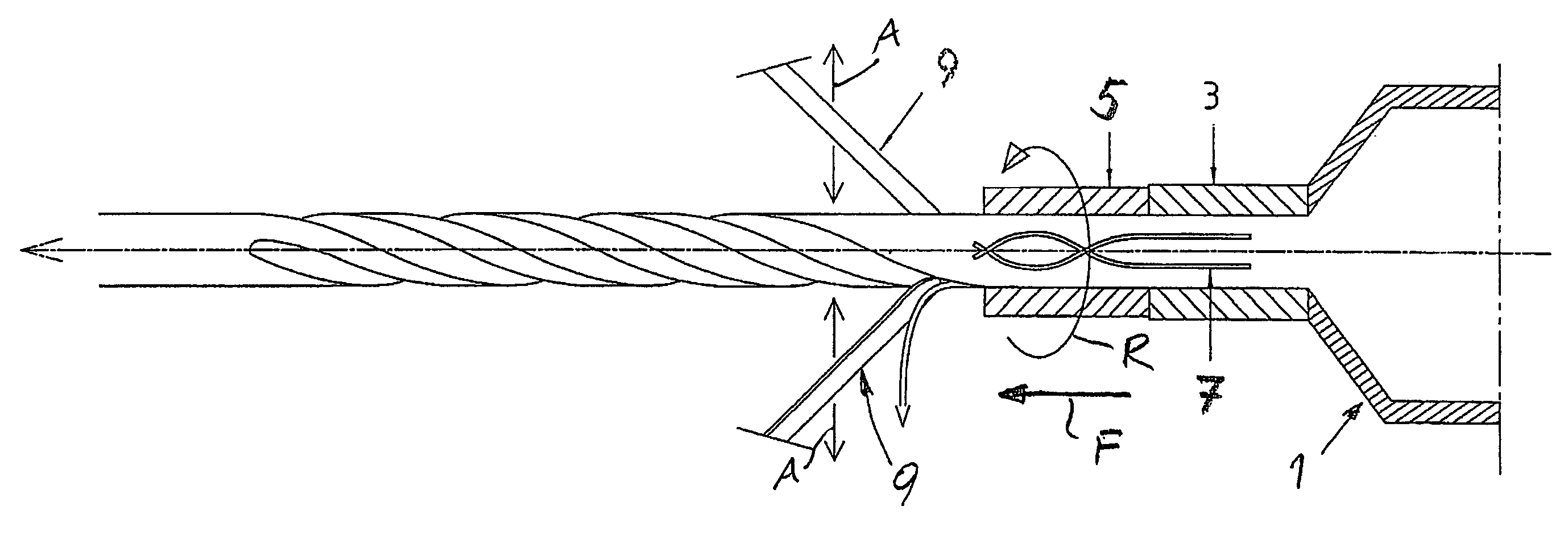

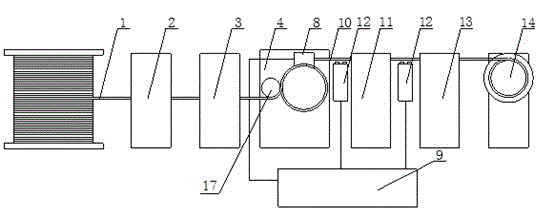

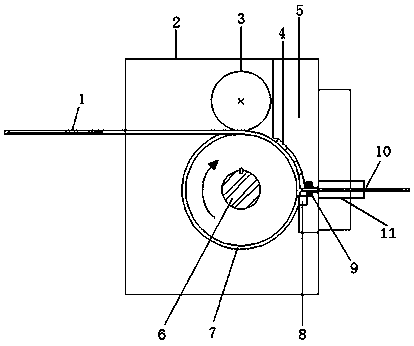

Rifled tube extruding method

The invention provides a rifled tube extruding method and belongs to the technical field of continuous extrusion. A metal rod is sent into a die cavity of a tangential continuous extruding machine and enters the die cavity (shown as the arrow in the abstract figure) from a feeding port formed by an extruding wheel groove and a pinch roller to fill a toothed slot of a threaded core mark, a rifled tube in thread mesh with the threaded core mark is welded to drive subsequent continuous feeding and wrap the threaded core mark along with rotation of the pinch roller, a driving device drives the threaded core mark to move circularly, the rifled tube moves axially along the threaded core mark, the movement trail after the axial movement of the rifled tube and the circular movement of the threaded core mark are overlapped forms a helical toothed groove spatially, and a thread is formed on the inner surface of the rifled tube, so that the rifled tube is obtained. Using the method and equipment used with the method can produce products of rifled tubes made of various metal alloys, wherein the rifled tubes include aluminum rifled tubes with special tooth shapes, such as aluminum rifled tubes with high and low teeth and sawtoothed aluminum rifled tubes. Further, the rifled tube extruding method is simple in operation, high in automation level and easy for organization of massive production.

Owner:KUNMING UNIV OF SCI & TECH +1

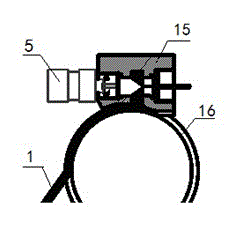

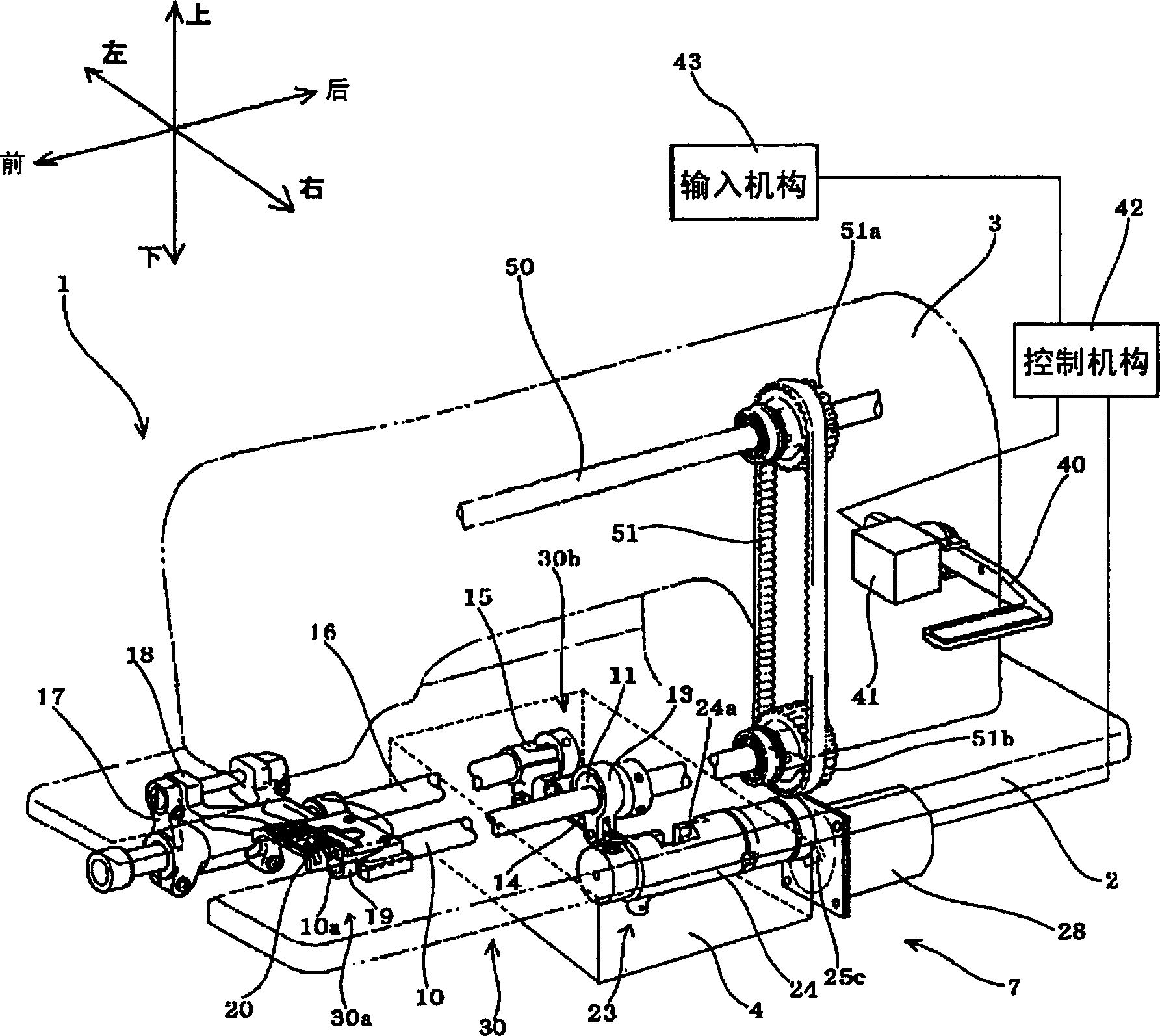

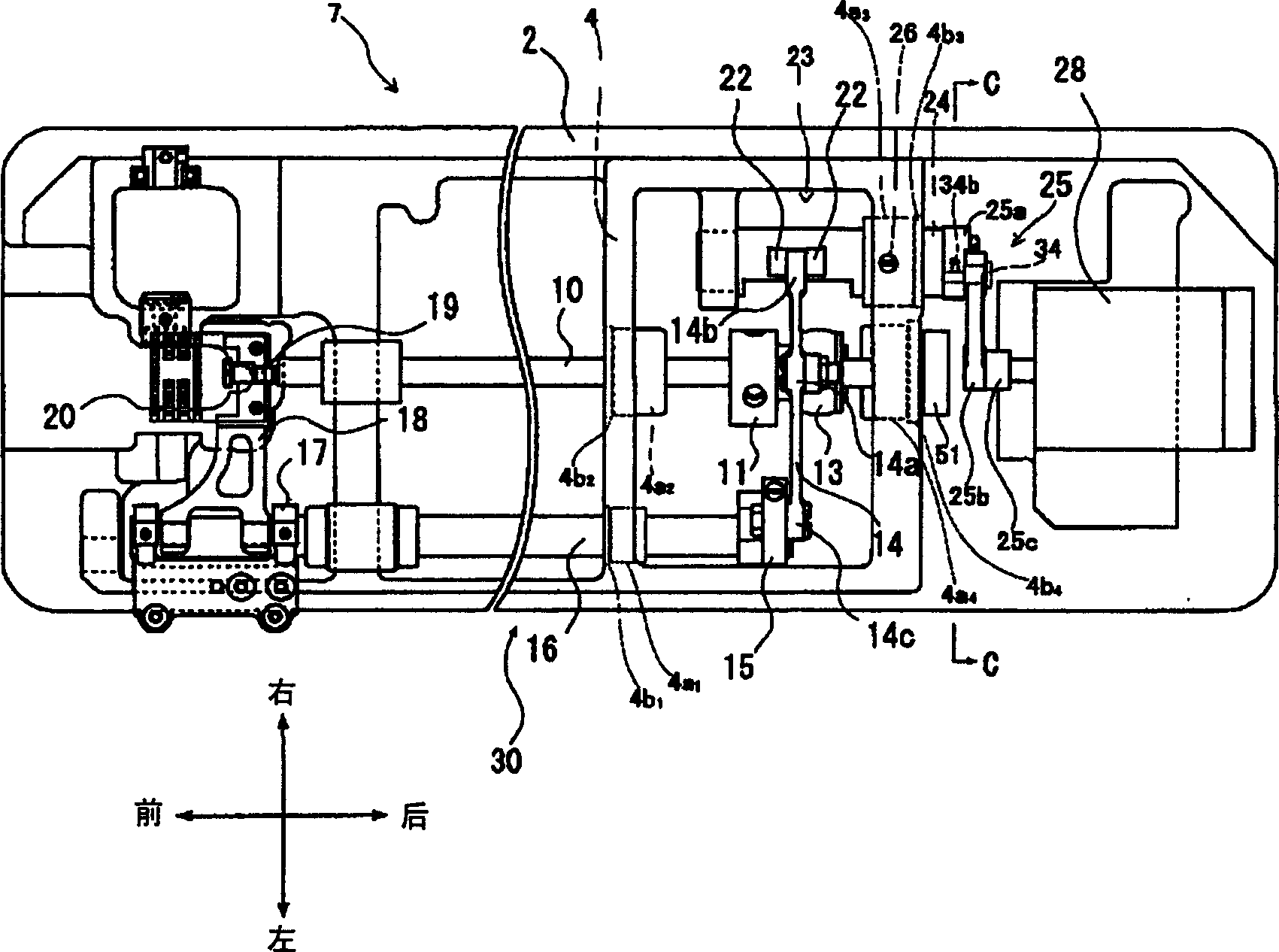

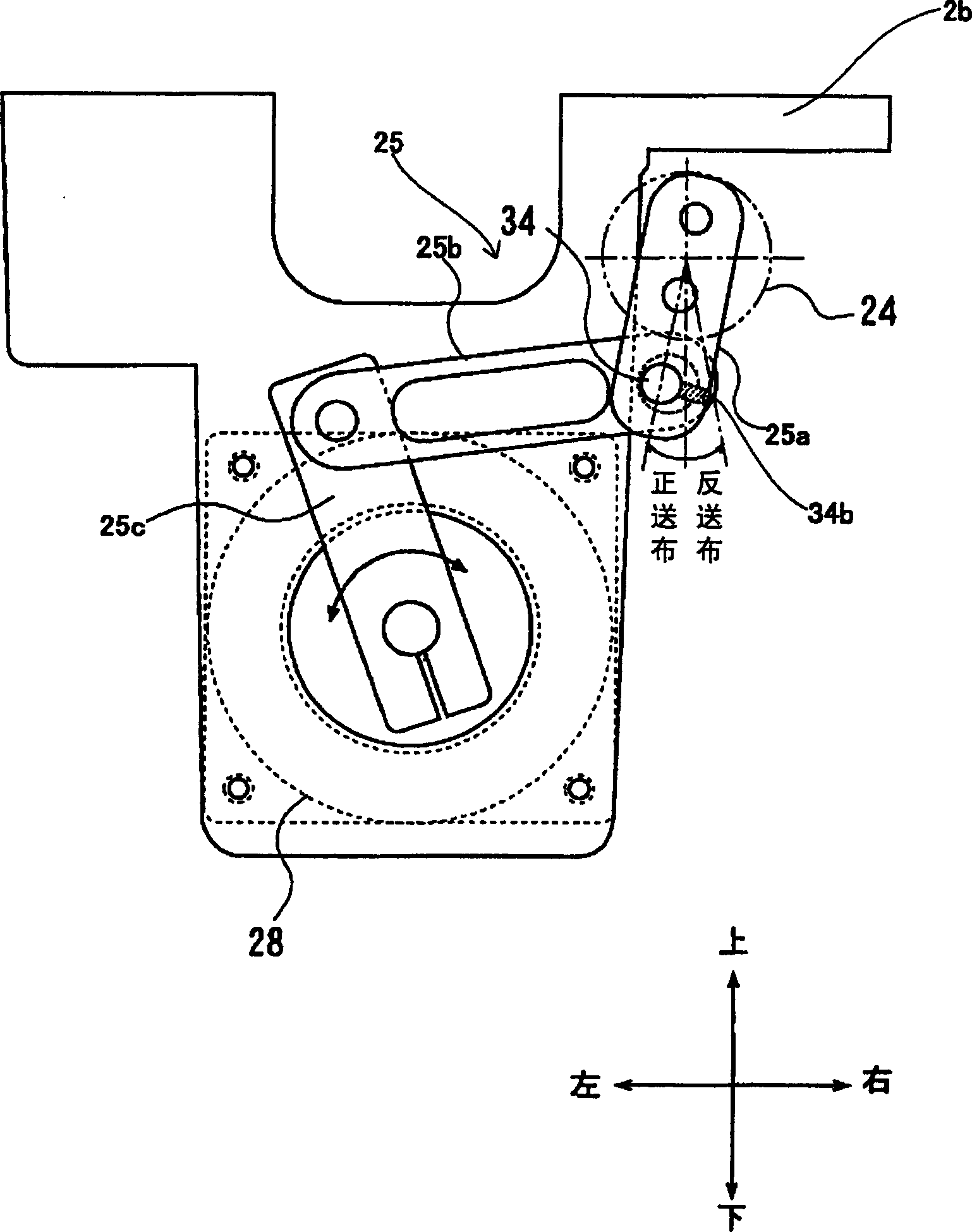

Cloth feeding mechanism of sewing machine

A horizontal feed mechanism 30b and a feed distance change means 23 of a cloth feeder 7 is provided in a closed lubricating chamber 4 separated from the outside. A pulse motor (a drive means) 28 actuating the feed distance change means 23 to change the feed distance is connected to a feed adjusting body 24 of the feed distance change means 23 via a link mechanism 25 and is fixed to the lower part of a sewing machine bed 2 outside the lubricating chamber 4. To provide a feeder capable of quietly changing an accurate feed distance even in a high-speed sewing time.

Owner:JUKI CORP

Wear resistant coated sheet metal die and method to manufacture a wear resistant coated sheet metal forming die

InactiveUS20090241632A1Increased longevityHigh hardnessShaping toolsCutting toolsMetal formingWear resistant

A method to manufacture a steel die having a Physical Vapor Deposition wear resistant coating on a profile surface and a steel die formed thereby is disclosed. The steel die is subjected to quenching and tempering to achieve a Rockwell hardness in the range of about 40-45 Rc and then subjected to machining to form a profile surface. The surface is then subjected to Physical Vapor Deposition of a wear resistant coating that may be multiple layers of CrN, AlCrN, TiCrN, TiN, TiCN or TiAlN, and preferably is alternating layers of TiN—TiCN—TiN. The coating is applied at a sufficient thickness to impart wear resistance to the steel die. The steel dies are useful in sheet metal stamping operations.

Owner:FORD MOTOR CO

Prestressed wire winding recipient

ActiveCN102389906AImprove fatigue lifeEnsure safetyExtrusion profiling toolsStress distributionThermal insulation

A prestressed wire winding recipient can be applied to hot metal extruding technology, and particularly can be applied to the hot extrusion of seamless steel tubes with large caliber and thick walls. The recipient comprises an inner liner, a middle liner, a thermal insulation layer, an outer liner and a steel wire layer, wherein a hearing rod hole is arranged in the middle liner, and a heating element is arranged in the hole and is used for preheating the recipient; the thermal insulation layer is arranged between the middle liner and the outer liner, consists of an inner protective plate od the thermal insulation layer, a thermal insulation material and an outer protective plate of the thermal insulation layer, and is used for preventing heat from being transmitted to the outer liner and the steel wire layer from the inner liner and the middle liner which are in high temperature; an annular cooling groove is arranged on the inner surface of the outer liner and is used for cooling the outer liner by leading cooling media in; and the temperature near a contact interface between the steel wire layer and the outer liner is detected in real time by a temperature sensor. As the middle liner is provided with a preheating hole to preheat the recipient, a preheating temperature field which is more uniform on the radial and circumference directions can be obtained by the recipient, and the reasonable stress distribution in the recipient can be realized, so that the fatigue life of the recipient can be prolonged greatly.

Owner:TSINGHUA UNIV +1

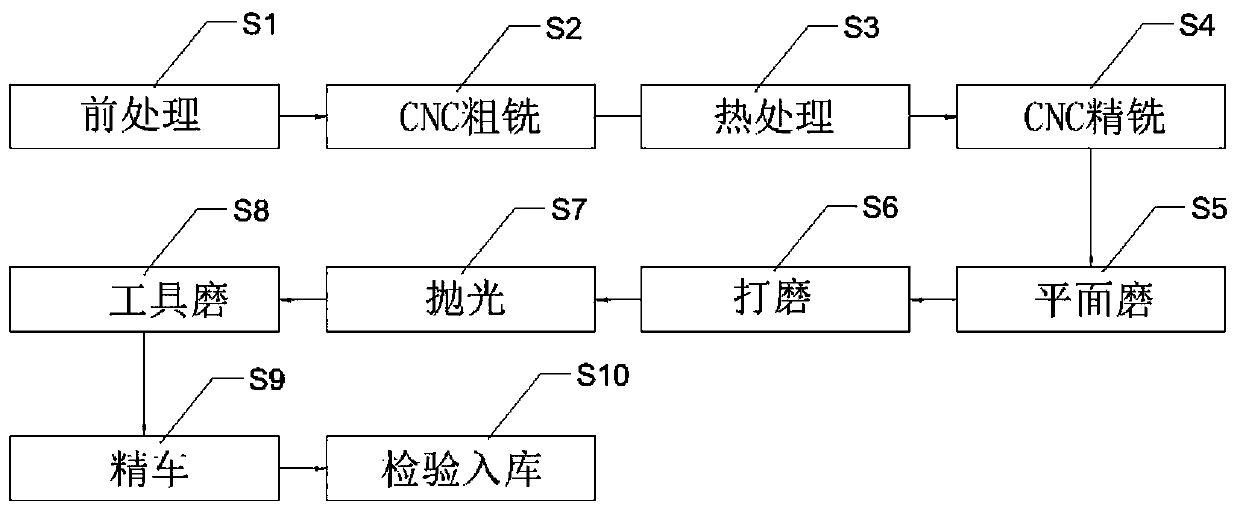

Machining method of extrusion die

InactiveCN110842047AShorten the production cycleIncrease productivityExtrusion profiling toolsRough surfaceSurface grinding

The invention discloses a machining method of an extrusion die. The machining method includes the following steps of S1, pre-treatment, S2, CNC rough milling including rough milling of an upper die and rough milling of a lower die, S3, heat treatment, S4, CNC finish milling including finish milling of the upper die and finish milling of the lower die, S5, surface grinding, S6, grinding adopting asand paper to grind the rough surface of a flow dividing hole to be smooth for reducing the action of the friction force between the flow dividing hole and an aluminum rod during extrusion of aluminumprofiles, S7, polishing, S8, tool grinding, S9, fine turning and S10, inspection and storage. According to the machining method, the production cycle of the extrusion die is greatly shortened, and the processing efficiency is improved.

Owner:苏州华泰模具制造有限公司

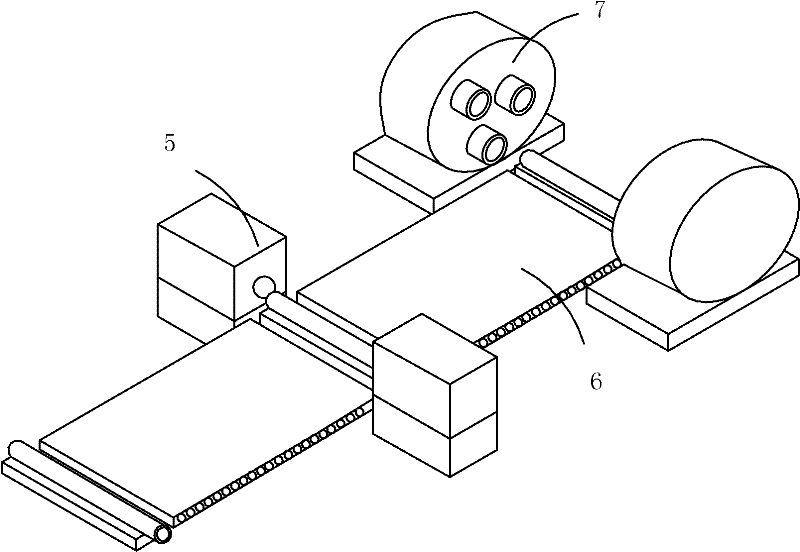

Technique for extrusion pressing copper stephanoporate sectional material with follow-up composite needle

The invention discloses a process that a copper section bar with multi holes is extruded by a servo-actuated combined needle and a device of the process. A conventional double-acting forward extruder is used to extrude the copper section bar with double holes, the servo-actuated combined needle is arranged on a support of a hole forming needle, a combined needle stand is connected with the support of the hole forming needle, the front end flat surface of the combined needle stand is provided with a T-shaped slot, two core rods with T-shaped heads are arranged in the T-shaped slot, the length of the combined needle is equal to the length of an original hole forming needle, a guiding hole whose diameter is 0.7mm bigger than the diameter of a core rod is opened on a position which is on an extruding pat and corresponded with the combined needle, and two holes whose bore diameters are 2mm bigger than the diameter of the core rod are pre-traversed on a copper blank ingot. The copper blank ingot and the extruding pat are propelled into an extruding cylinder through an extruding shaft, the support of the hole forming needle is propelled forwards, the servo-actuated combined needle is propelled forwards, and a double-core rod is traversed through the guiding hole of the extruding pat, entered into a hole of the copper blank ingot, and entered forwards a position which exceeds a sizing belt of an extruding die for10mm. The double-core rod and an outer die are formed together into a deformed space, the copper blank ingot is extruded by the extruding shaft to propel forwards, the servo-actuated combined needle is propelled forwards in servo-actuation, the copper blank ingot is passed through a space which is formed by the outer die and the double-core rod, and the section bar with the double holes is extruded out.

Owner:上海飞驰铜铝材有限公司 +2

Continuous casting-rolling and extrusion molding device of Al-Mg-Cu alloy and composite materials

InactiveCN101905241AEasy to formGuarantee the balance of extrusion forceExtrusion profiling toolsMetal rolling arrangementsDrive shaftAlloy

The invention relates to a continuous casting-rolling and extrusion molding device of Al-Mg-Cu alloy and composite materials, solving the problem that the traditional machining and molding device of Al-Mg alloy and the composite materials has lower performance of section bars due to the structural imperfection. A driven shaft is arranged on a stand, a casting roller is arranged on the driven shaft, the roller surface at the lower part of the casting roller is in transitional fit with the upper surfaces of a squeezing seat and a groove sealing block, a crystallizer is arranged above the casting roller and an extruding roller, a crystallizing hole is arranged on the crystallizer, the lower end of the crystallizing hole is positioned above the contact part between the casting roller and the extruding roller, the lower surface of the crystallizer is in transitional fit with the roller surfaces of the casting roller and the extruding roller, and a rotatable driving mechanism is respectively arranged on a driving shaft and the driven shaft. The invention greatly improves the performance of the section bars by additionally arranging the casting roller and the crystallizer, ensures that the section bars are possible to be made to meet the requirements for high-precision thin walls with ultra thinness and ultra length and simultaneously has the advantages of simple structure, convenient operation and low cost.

Owner:山西奥铭科技有限公司

Continuous extruding machine for tin brass welding wires and production process based on same

InactiveCN107755444AImprove energy savingReduce pollutionExtrusion profiling toolsDrive shaftEngineering

The invention discloses a continuous extruding machine for tin brass welding wires. The continuous extruding machine comprises a machine body, a driven extrusion wheel, an extrusion shoe, a driving extrusion wheel, a material blocking block and an extrusion die; a driving shaft is arranged in the machine body, the driving extrusion wheel is fixedly arranged on the driving shaft, the driven extrusion wheel is rotationally installed in the machine body through a rotating shaft, a first extrusion groove is formed in the circumference of the driving extrusion wheel, and a second extrusion groove is formed in the circumference of the driven extrusion wheel; and the extrusion shoe is installed in the machine body, an arc-shaped inclined face is arranged on the side face, facing the driving extrusion wheel, of the extrusion shoe, groove sealing blocks are arranged on the arc-shaped inclined face, the groove sealing blocks is matched with the first extrusion groove of the driving extrusion wheel to form a second extrusion cavity, the material blocking blocks ar efixedly arranged on the arc-shaped inclined surface of the extrusion shoe and are located at the bottom part of the second extrusion cavity, and the bottom part of the second extrusion cavity is closed. The invention further discloses a production process based on the same. According to the continuous extruding machine for thetin brass welding wires and the production process based on the same, energy is saved, and production efficiency is improved.

Owner:湖南德润有色焊材科技股份有限公司

Continuously squeezing method and apparatus for expanding extrusion

InactiveCN1927493AExtended service lifeIncrease speedExtrusion profiling toolsGroove widthNonferrous metal

The invention relates to a method for compressing metal. Wherein, in the groove of compressing wheel or at the material inlet of chamber, the blank is extended to be 10mm wider than the groove width of compressing wheel; then feeding the blank into material inlet, to be compressed via mould into needed product. The invention has simple process, to obtain better shape when compressing color metal wire or round rod, and obtain accurate size, to reduce the pressure and temperature of mould. And it can improve the rotation speed of compressing wheel and improve the yield.

Owner:大连康丰科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com