Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

145results about How to "Easy to form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silica-coated quantum dots and preparation method thereof

InactiveCN107474821AEasy to formImprove quantum efficiencyLuminescent compositionsQuantum dotSilica coating

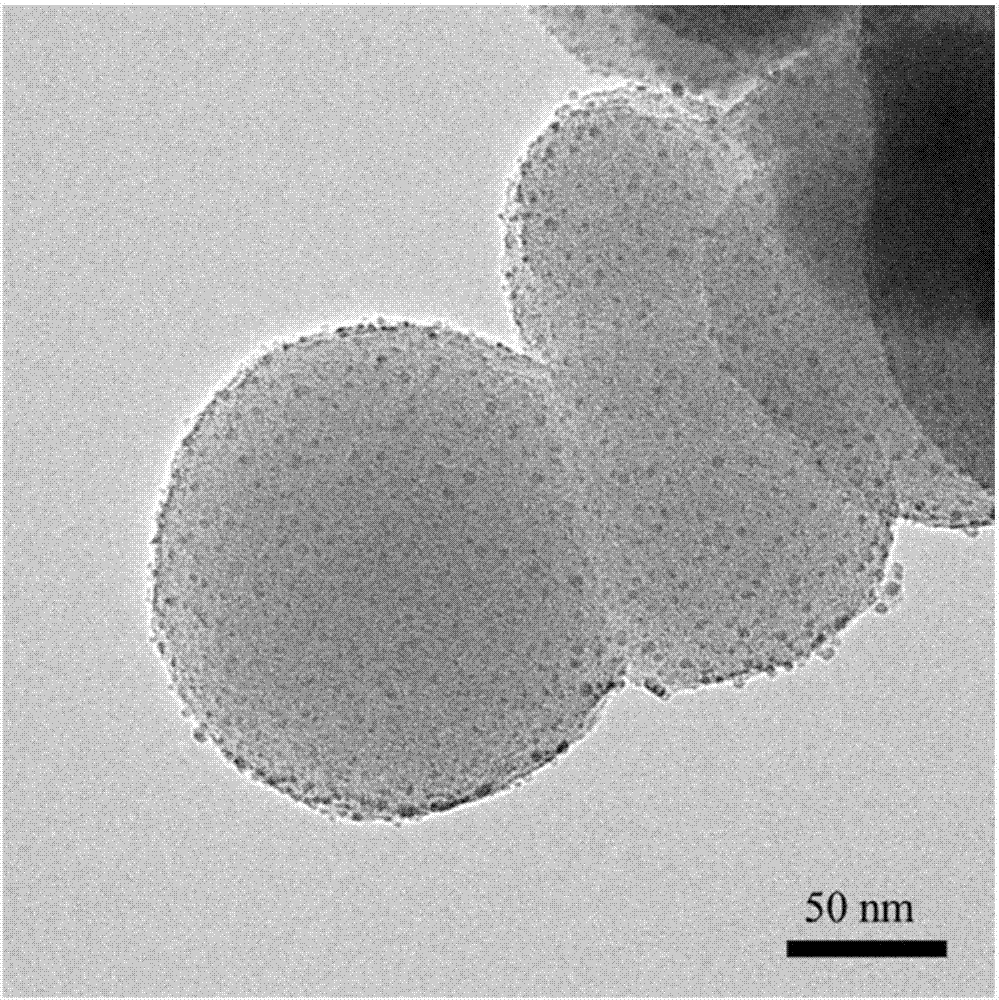

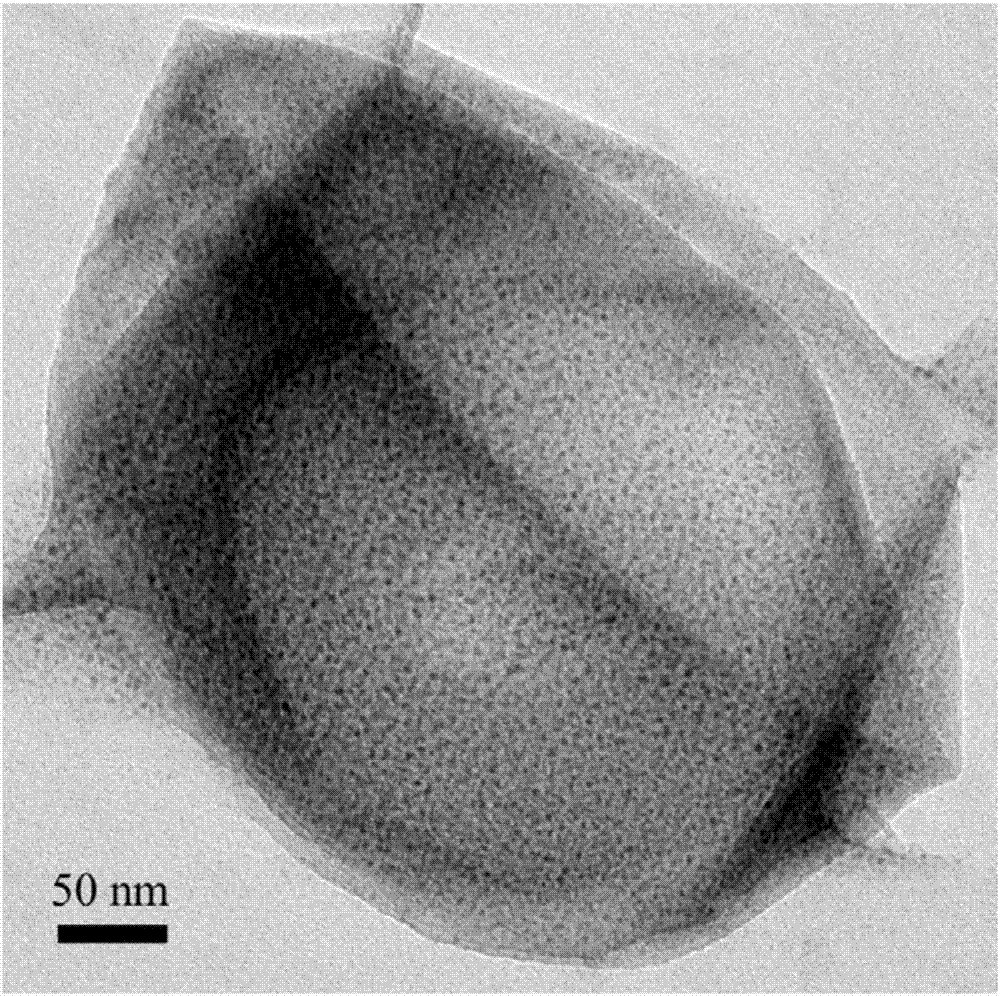

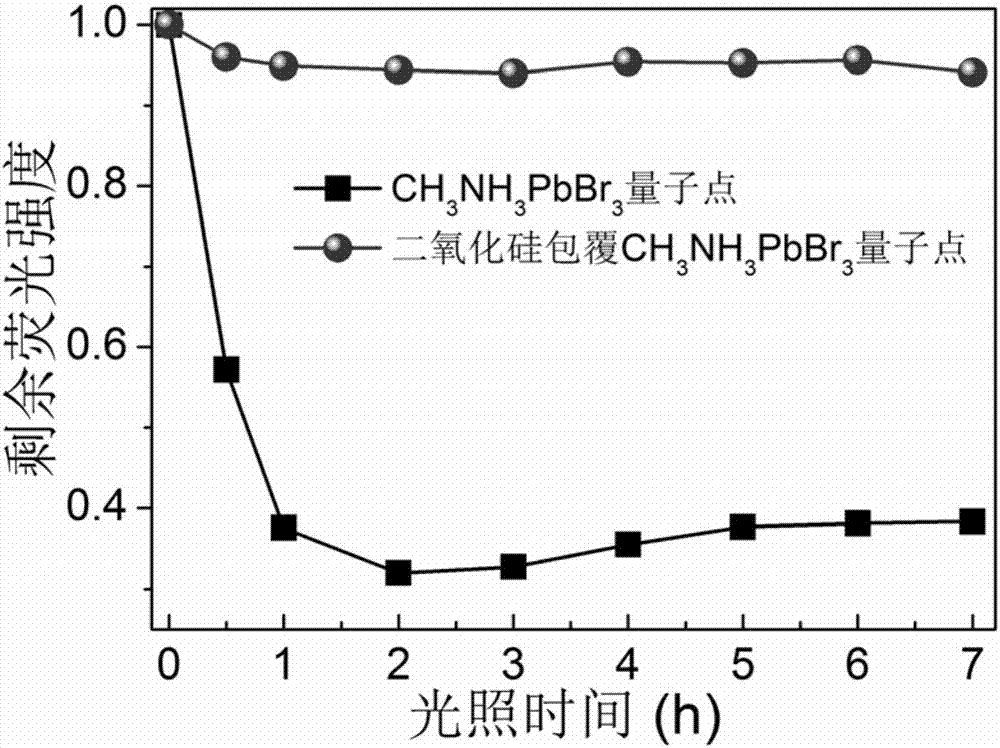

The invention relates to silica-coated quantum dots and a preparation method thereof. Silica employs a silanization agent as a raw material, the raw material is added into an anhydrous organic solvent containing quantum dots, and a reaction is carried out in order to prepare silica-coated quantum dots, wherein the mass ratio of the silanization agent to the quantum dots is 0.1-10:1. During preparation, a certain amount of the silanization agent is added into the anhydrous organic solvent containing quantum dots; under a sealing or opening condition and at a certain temperature, a continuous stirring is carried out for a period of time in order to obtain a silica-coated quantum dots sample; the anhydrous organic solvent is an analytically pure organic solvent or a totally anhydrous organic solvent, and the silanization agent is used for carrying out a hydrolysis reaction depending on the organic solvent or residual moisture in air in order to obtain a silica coating. The preparation method is simple, water, ammonia, sulfydryl and other catalysts are not needed for introduction, initial fluorescence efficiency of quantum dots are not weakened, and the silica-coated quantum dots nano-material has very high quantum efficiency and stability.

Owner:SHANGHAI JIAO TONG UNIV

Ag/TiO2/graphene nanometer composite photocatalyst and preparation method thereof

InactiveCN102688755AEasy to formReagent savingMetal/metal-oxides/metal-hydroxide catalystsIonPhotocatalysis

The invention discloses an Ag / TiO2 / graphene nanometer composite photocatalyst and a preparation method thereof, belonging to the field of new materials. The Ag / TiO2 / graphene nanometer composite photocatalyst is prepared by assembling metal silver, nanometer titanium dioxide (P25) powder onto a two-dimensional lamellate graphene carrier material by using a photocatalytic oxidation-reduction method, using the two-dimensional lamellate graphene as the carrier material, the silver nitrate as the silver source and the nanometer titanium dioxide as the photocatalysis material, initiating the nanometer titanium dioxide to generate photoproduction electron and photoproduction hole by stimulating sunlight, capturing the photoproduction hole by a sacrifice agent, and restoring the silver ion and the graphite oxide to be metal Ag and graphene by the photoproduction electron. The invention has simple preparation method and low cost in reagent, is beneficial to large-scale preparation, and provides an environment-friendly method for preparing graphene load composite photocatalyst through the restoration of the graphite oxide.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

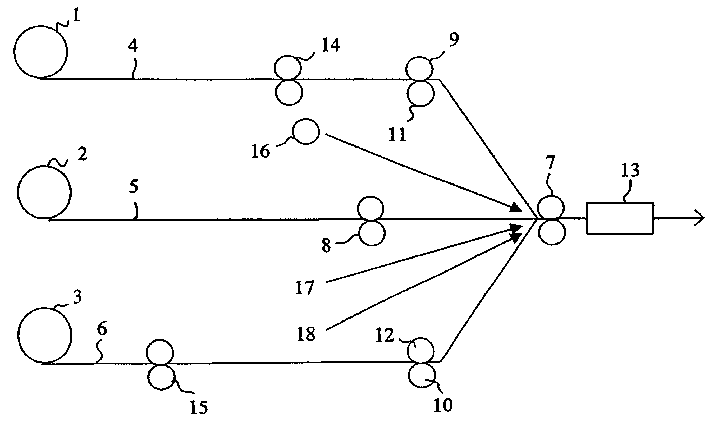

Method and apparatus for producing board and a board product

InactiveCN1469802AHigh cost-effectiveness ratioHigh strengthMechanical working/deformationPaper/cardboard layered productsFiberCardboard

A method is disclosed for producing a multilayer paperboard product, as well as an assembly suited for implementing the method and a paperboard manufactured according to the method, whereby the paperboard is made from at least two, advantageously three layers (4, 5, 6) bonded to each other by gluing, and the material of the middle layer (5) is subjected to mechanical working in a dry state (8) so as to deform the material prior to gluing through pressing thereon desired pattern that is raised from the surface of the material (5). The layers (4, 5, 6) are bonded to each other in a single step (7). The method is capable of providing a strong paperboard that uses less fiber than prior-art paperboards of equal thickness and strength.

Owner:AVENIRA

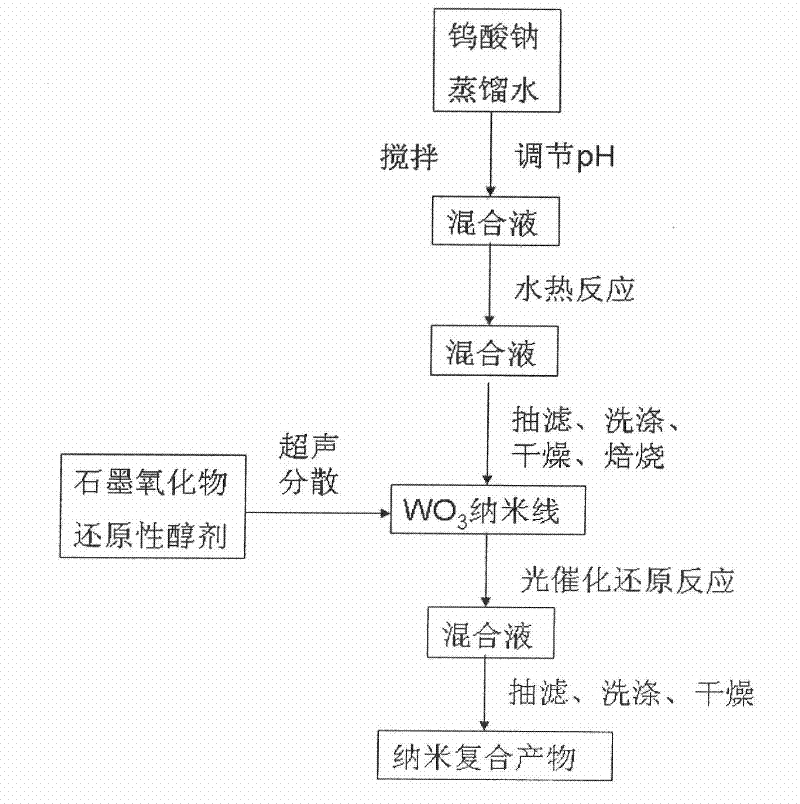

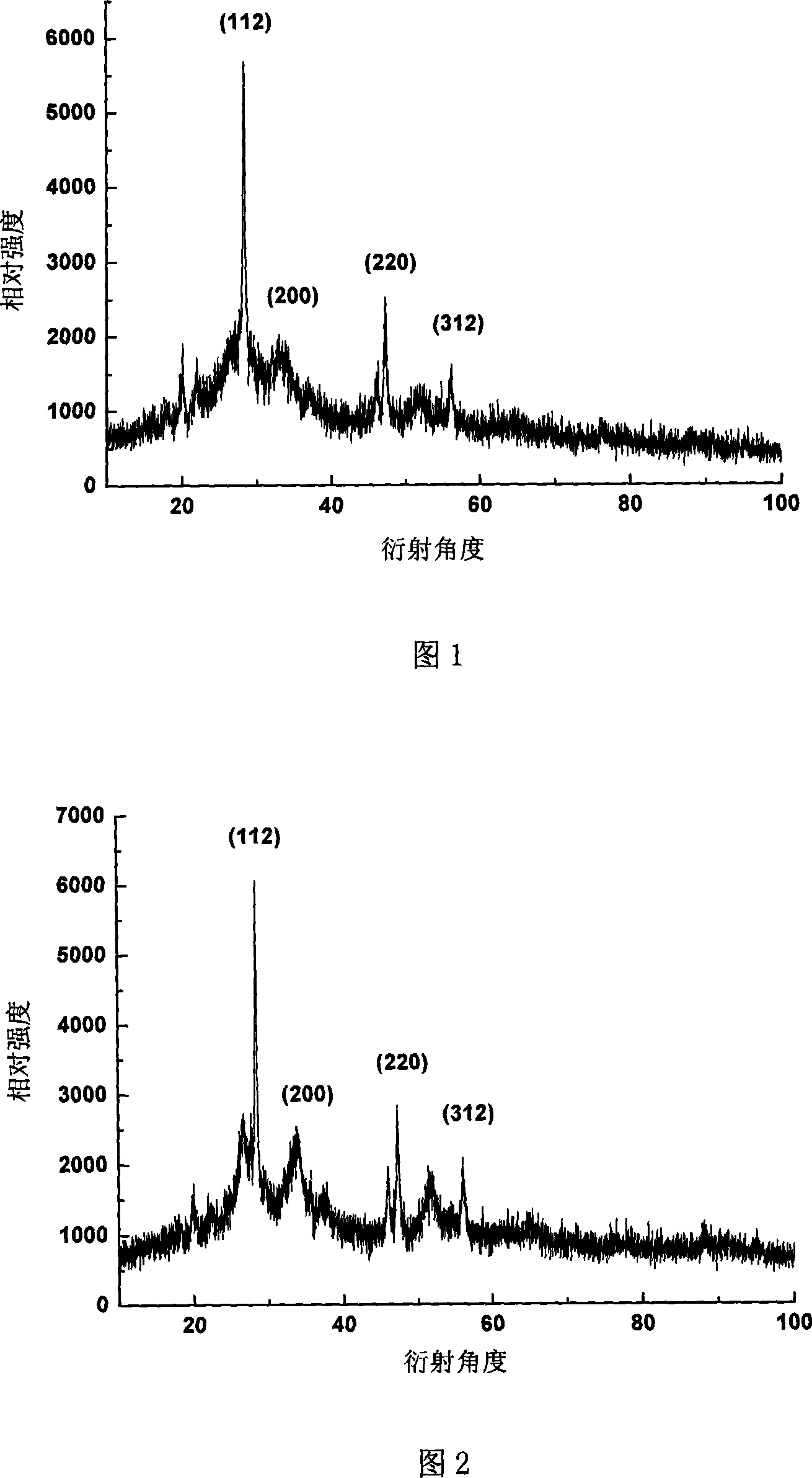

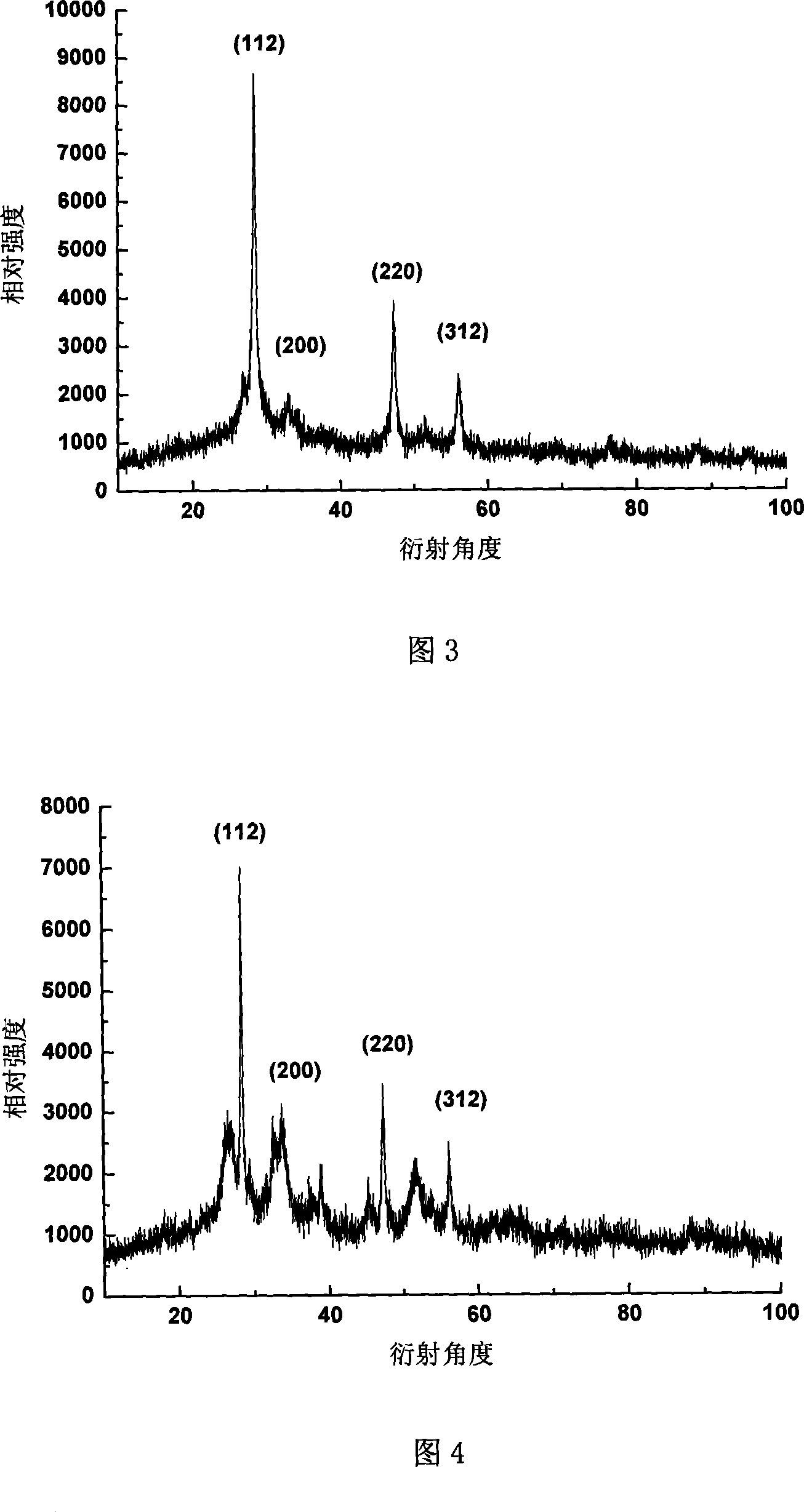

Graphene load tungsten trioxide (WO3) nanowire composite material and preparation method thereof

InactiveCN102531063AEasy to formReagent savingTungsten oxides/hydroxidesGrapheneCvd grapheneComposite structure

The invention discloses a graphene load tungsten trioxide (WO3) nanowire composite material and a preparation method thereof, which belong to the field of new materials. The nano composite material has a one-dimensional composite structure and a two-dimensional nano composite structure, the diameter of a WO3 nanowire is 10-30 nanometers, the length of the WO3 nanowire is 50-600 nanometers, and the WO3 nanowire penetrates through or is distributed on the inner layer or the surface of a layer-shaped grapheme main material. The preparation method comprises utilizing a two-dimensional grapheme as an auxiliary material and sodium tungstate as a tungsten source, generating the WO3 nanowire through a hydrothermal synthesis method, then mixing the WO3 nanowire with graphite oxide dispersing solution, and then obtaining the graphene load WO3 nanowire composite material by means of photocatalytic reduction. The preparation process is simple, reagents are cheap, large-scale preparation is facilitated, and simultaneously an environment-friendly preparation method is provided for reduction of graphite oxide and formation of the nano composite material.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

Process for preparing Cu2ZnSnS4 semiconductor thin film solar cell

InactiveCN101026198AAvoid loss of elementsEasy to formFinal product manufactureSemiconductor devicesNitrogen gasChemical measurement

This invention relates to a technology for preparing Cu2ZnSnS4 semiconductor film solar cells, which mixes grains of Cu, Zn and Sn in the chemical measured ratio Cu : Zn : Sn=1.6-1.7 : 1 : 1 to press it to a cylindrical pressed shape in the diameter of 10mm and height of 15mm to be packaged in a quartz tube in the vacuum degree of 10-4-10-3pa to form an alloy ingot by inducing melt, then manufactures a brittle alloy thin strip of 15-30mum thick and 5-8mm wide by a strip-throwing technology, then mixes the strip with sulfur powder to be milled for 48-96 h to form black slurry to be coated on a Mo matrix or a glass matrix then to be dried and heated in H2 or N2 atmosphere, which can avoid loss of elements and guarantee strict chemical measurement ratio.

Owner:UNIV OF SCI & TECH BEIJING

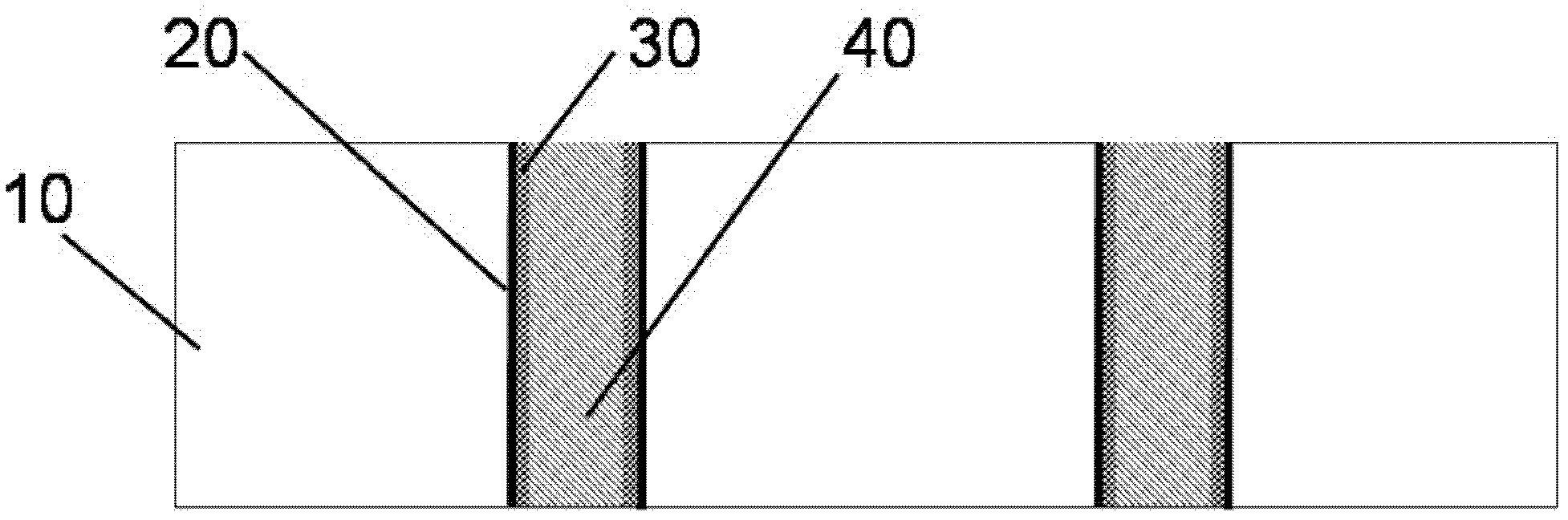

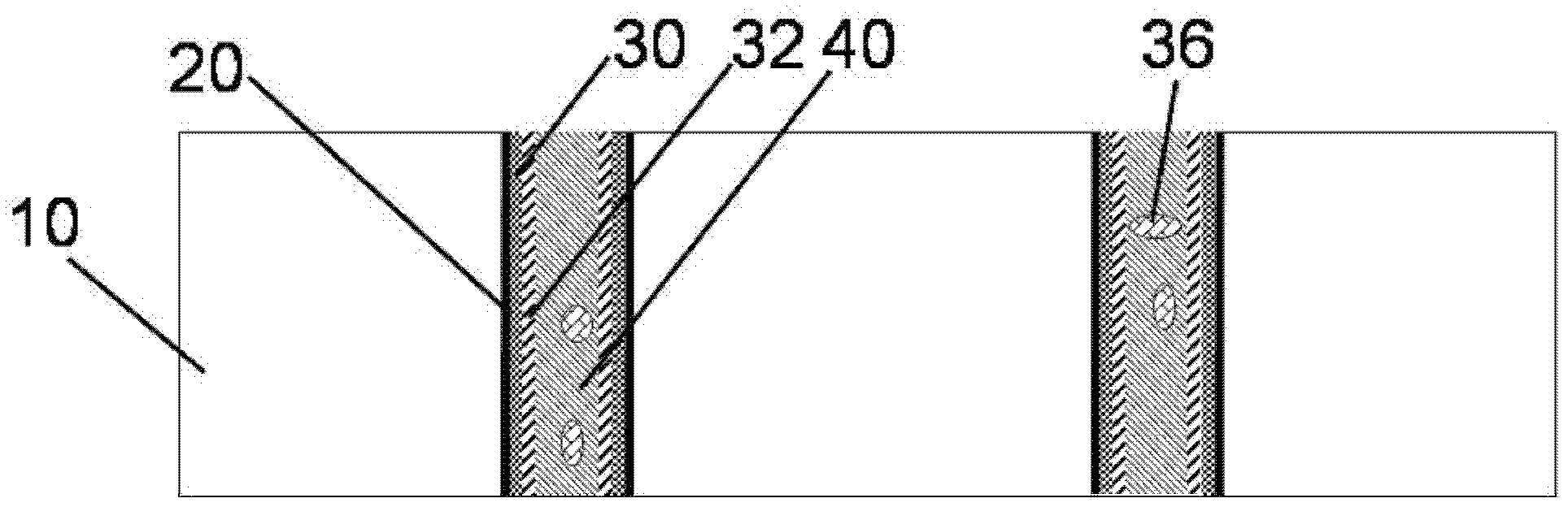

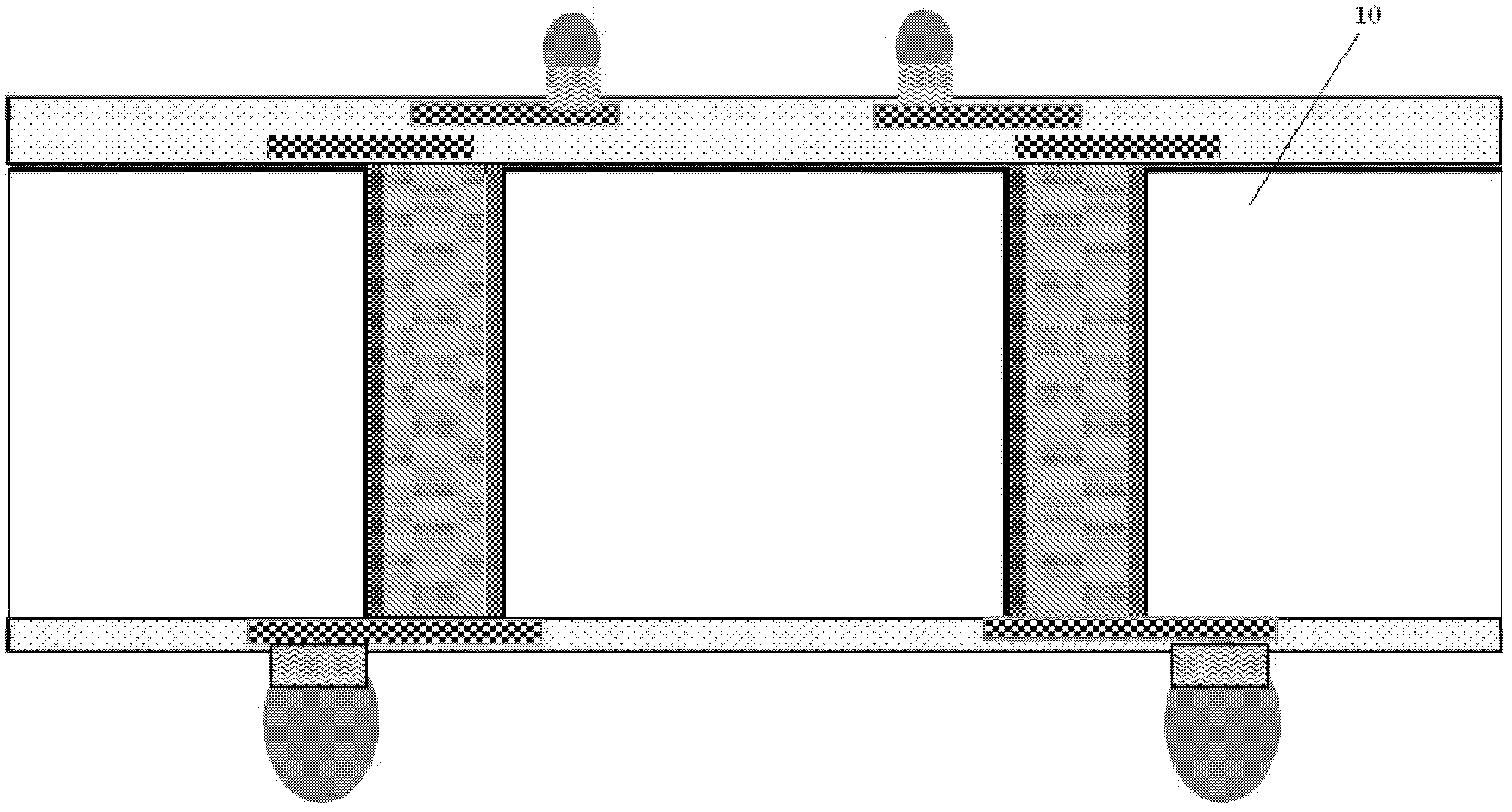

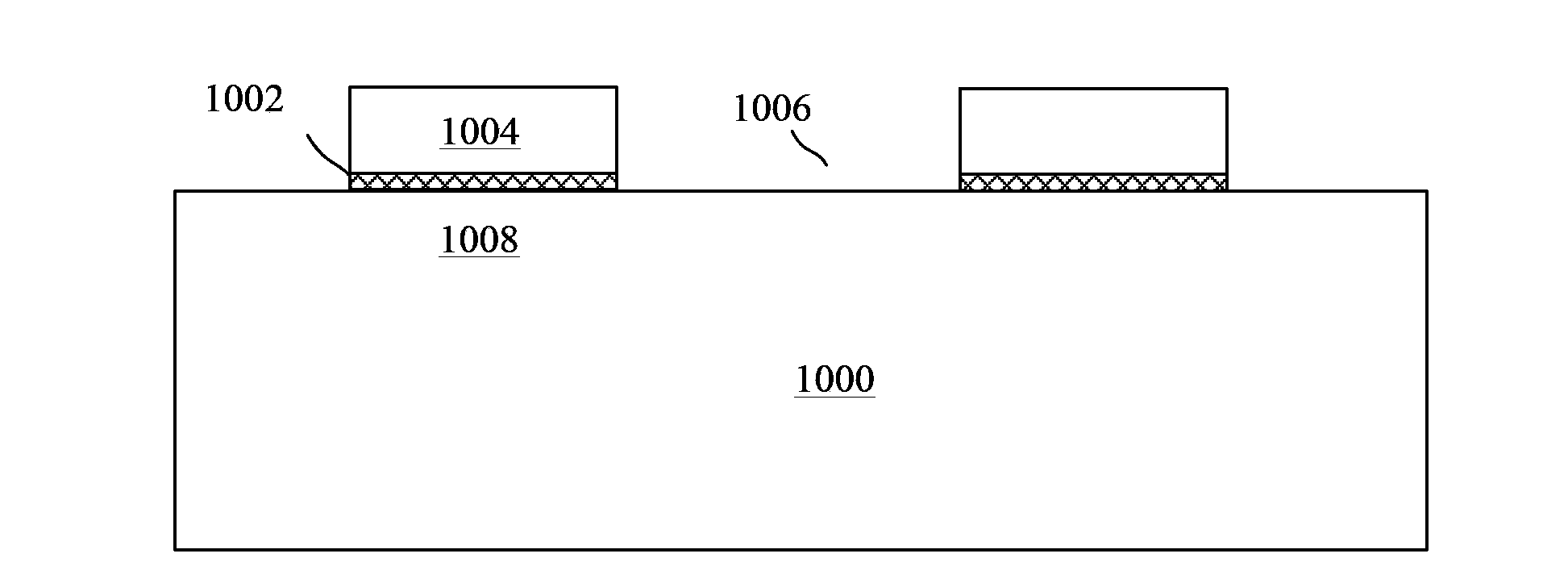

Intermetallic compound filled vertical through-hole interconnecting structure for three-dimensional package and preparation method thereof

ActiveCN102569251AEasy to formReduce process complexitySemiconductor/solid-state device detailsSolid-state devicesIntermetallicProcess complexity

The invention relates to an intermetallic compound filled vertical through-hole interconnecting structure for three-dimensional package and a preparation method thereof. The vertical through-hole interconnecting structure comprises a substrate, wherein at least one through hole which vertically penetrates through the substrate is formed in the substrate; an insulating layer grows on the inner wall of the through hole; an intermetallic compound layer is filled in the through hole of the grown insulating layer; and an adhesion layer is arranged between the intermetallic compound layer and the insulating layer. At least one through hole which vertically penetrates through the substrate is formed in the substrate; the insulating layer grows on the inner wall of the through hole; the intermetallic compound layer is filled in the through hole; the adhesion layer is arranged between the intermetallic compound layer and the insulating layer; by the intermetallic compound layer, electric connection required in three-dimensional stacking can be finished, the vertical through-hole interconnecting structure is convenient to form and manufacture, and process complexity and manufacturing cost are reduced; and therefore, the vertical interconnecting structure can be manufactured on an integrated circuit, an adapter plate can be manufactured on a passive substrate, the yield is improved, and the vertical through-hole interconnecting structure is safe and reliable.

Owner:NAT CENT FOR ADVANCED PACKAGING

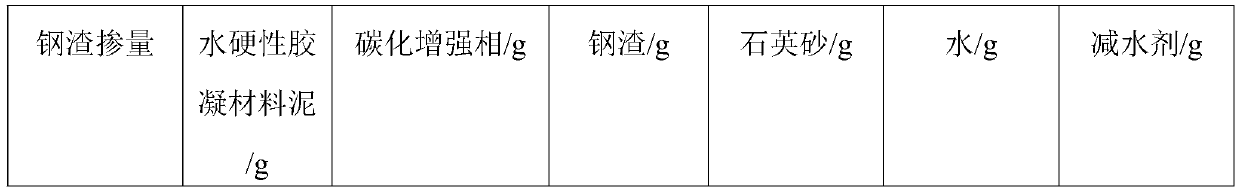

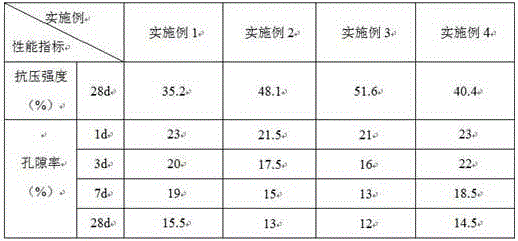

Preparation method of high-performance carbonized reinforced concrete

ActiveCN110818356AHigh strengthGive full play to the carbonization activityCeramic shaping apparatusCompressive resistanceReinforced concrete

The invention discloses a preparation method of high-performance carbonized reinforced concrete, and the method comprises the following steps: mixing steel slag, a hydraulic cementing material, a carbonized reinforced phase and quartz sand, adding water and a water reducing agent, stirring, and carrying out casting molding on the stirred slurry; sealing and maintaining the molded product for 12-24hours, removing a mold, and carrying out drying pretreatment; and putting the dried product into a carbonization kettle with a CO2 atmosphere and an air pressure of 0.1-0.5 MPa, and carrying out carbonization maintenance for 12-24 hours to obtain a steel slag product. The high-performance carbonized reinforced concrete prepared by the invention has excellent working performance; the hydrated andcarbonized synergistic effect of the hydraulic cementing material and the steel slag is fully utilized, the compressive strength can reach 100 MPa within a short time, meanwhile, the utilization rateof the steel slag is remarkably increased, a large amount of CO2 can be solidified and stored, huge environmental benefits are achieved, development of green building materials is facilitated, and a sustainable development road is achieved.

Owner:WUHAN UNIV OF TECH

Method for preparing laser sintering rapid prototyping type silicon carbide ceramics

ActiveCN106083061AImprove performanceEasy to formAdditive manufacturing apparatusSelective laser sinteringBoron nitride

The invention relates to a method for preparing laser sintering rapid prototyping type silicon carbide ceramics. The method comprises the steps of 1, preparing laser sintering rapid prototyping type silicon carbide ceramic powder; 2, making the laser sintering rapid prototyping type silicon carbide ceramic powder into a rough blank with the 3D printing technique based on selective laser sintering; 3, burying the rough blank in mixed powder formed by silica powder and boron nitride powder for reactive sintering in a vacuum environment, so that a sintering blank is obtained; 4, soaking the sintering blank in an alkaline solution to remove redundant metallic silicon on the surface of the sintering blank, so that the laser sintering rapid prototyping type silicon carbide ceramics are obtained. Compared with the prior art, the method has the advantages that a die is not needed, the process is simple, conditions are easy to control, and silicon carbide parts in various shapes can be manufactured. The method has unique advantages in small-lot special part manufacturing.

Owner:ZHEJIANG LIGHT TOUGH COMPOSITE MATERIALS

Cyclic utilization method and apparatus of lead dioxide from storage cells

InactiveCN1805208AEasy to obtainLow costWaste accumulators reclaimingBattery recyclingLead dioxideAir volume

The invention relates to a cycle utilization method and relative device of accumulator lead dioxide. It comprises: drying the anode plate in the temperature of 80-100Deg. C; when the water content is less than 10wt%, taking out anode plate and separating the plate grid with lead pastern; milling the lead pastern on the milling breaker into PbO2 powder; controlling the wind content of wind nozzle of positive fan and passive fan to form micro passive pressure in the milling breaker; collecting the PbO2 powder into powder collector; adding lead powder which is 4.5-5.0wt% of collected PbO2 powder. The invention can utilize the waste accumulator electrode plate which can improve the initial capacity and improve the cycle service life of accumulator.

Owner:赵恒祥

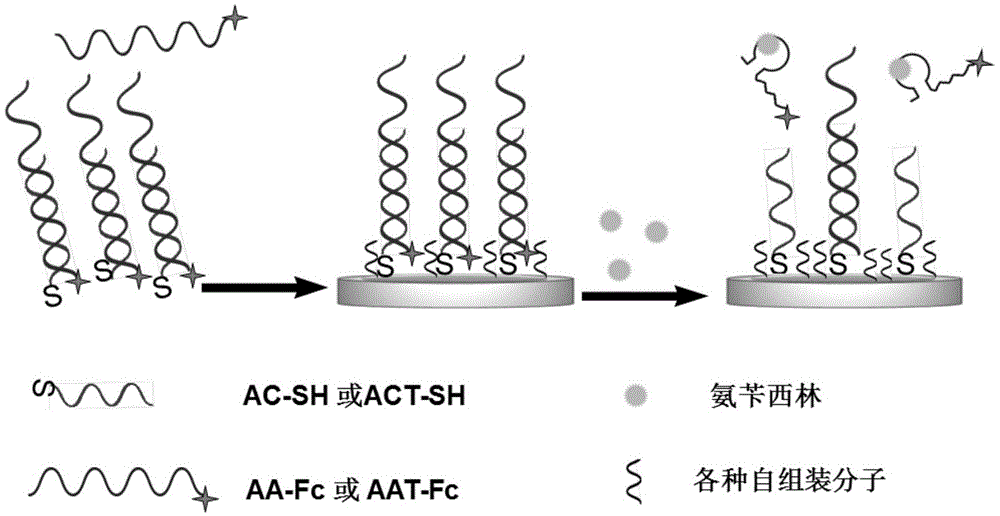

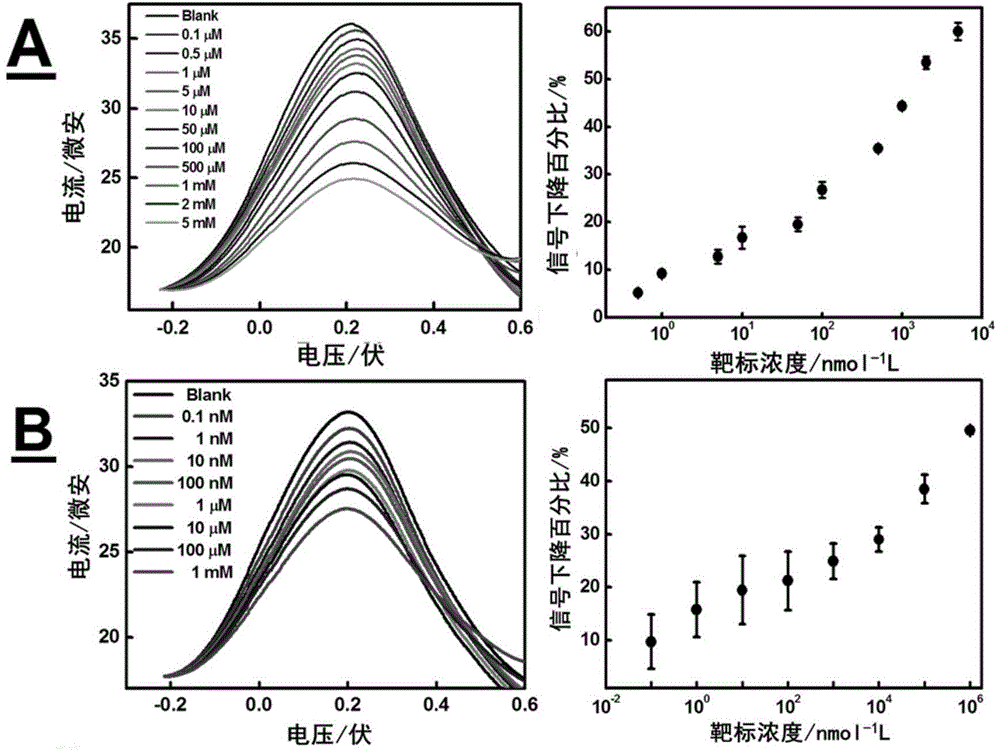

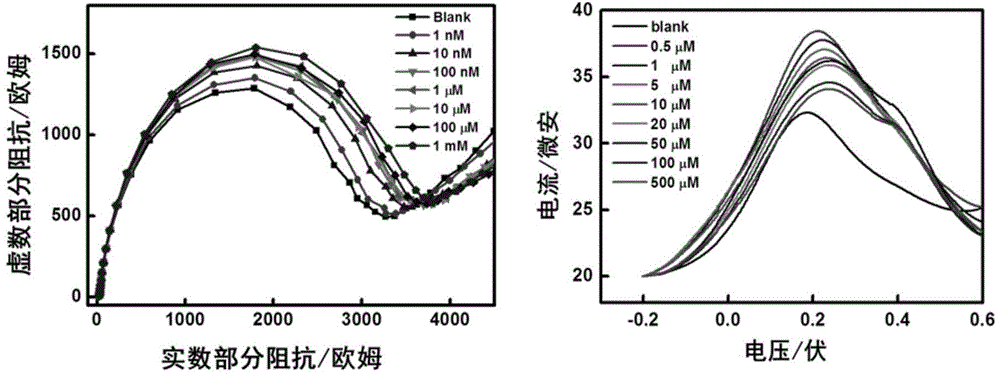

Forming method of ampicillin and sulfadimethoxine electrochemical sensor self-assembled passivation layer, and electrochemical sensor thereof

ActiveCN104914151ASimple designImprove general performanceMaterial electrochemical variablesElectrochemical gas sensorAmpicillin

The invention relates to a forming method of a self-assembled passivation layer of a signal probe chain substitution-based aptamer electrochemical sensor (SD-EAB) for detecting ampicillin and sulfadimethoxine, and an electrochemical sensor thereof. A preparation method of ampicillin SD-EAB comprises the following steps: hybridizing a capture probe with the terminal modified by a mercapto group with a ferrocene labeled aptamer signal probe complementing with the capture probe, fixing the obtained hybridized probe on a gold electrode through self-assembling and closing the electrode by using OEG6-OMe as a self-assembled passivation layer molecule. The steps of a preparation method of sulfadimethoxine SD-EAB are similar to above steps. The problem of unable detection of ampicillin and sulfadimethoxine of MCH self-assembled passivation layers commonly used in SD-EAB in the prior art is solved in the invention.

Owner:CAPITAL NORMAL UNIVERSITY +1

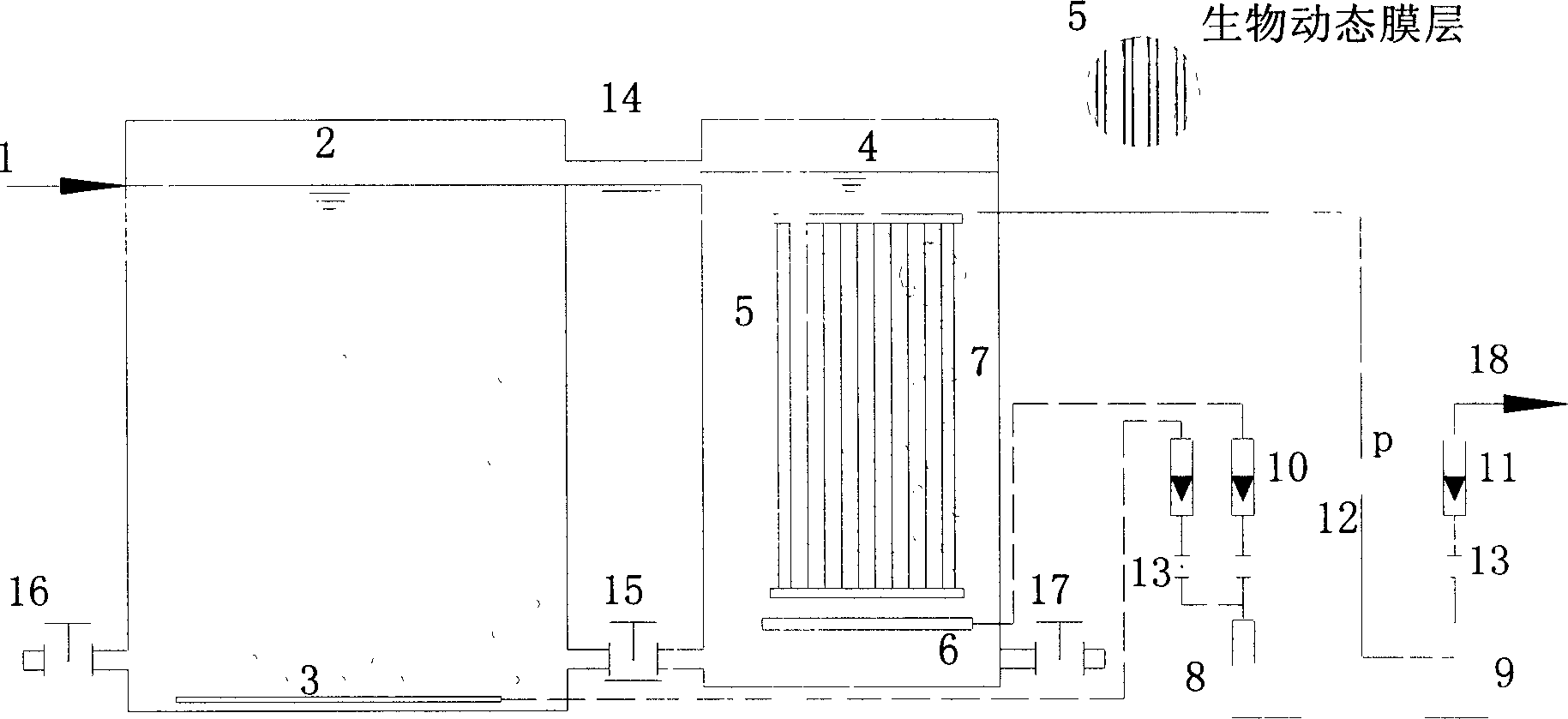

Split-type tube type dynamic membrane bioreactor

InactiveCN1785841AEasy to formRealize online cleaningTreatment using aerobic processesSustainable biological treatmentAeration systemAutomatic control

The present invention relates to a body-separated tubular dynamic membrane biological reactor. It mainly is formed from biological unit, aeration system, membrane unit, suction system and automatic control system. Said invention also provides the working principle of said biological reactor.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

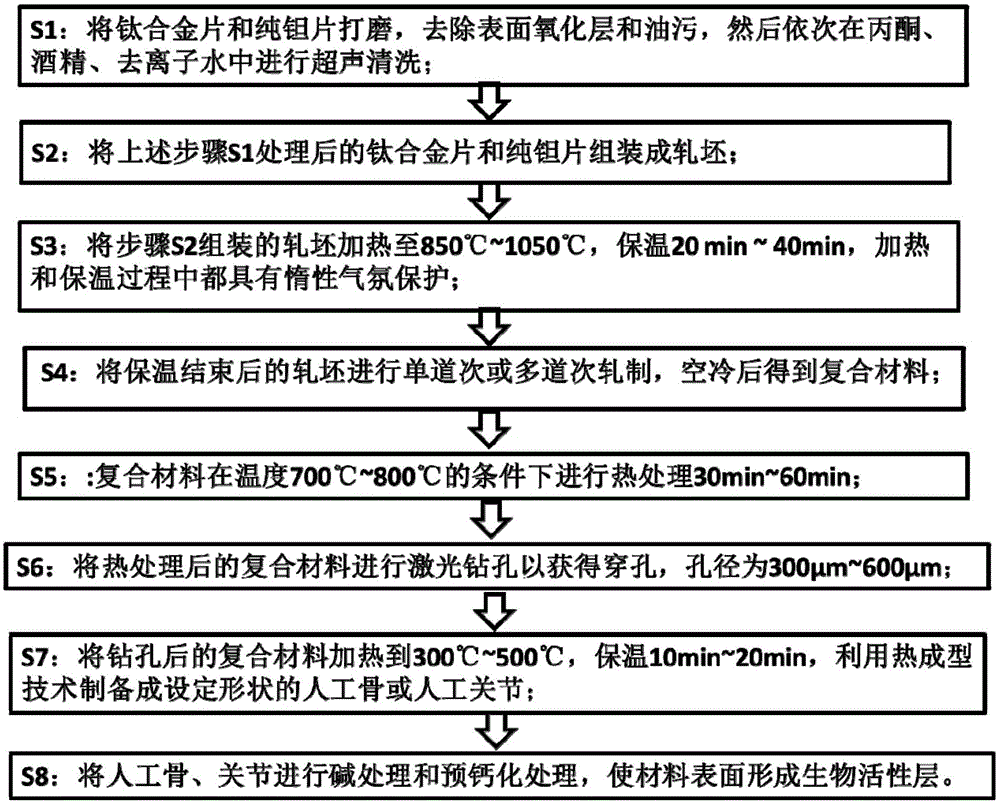

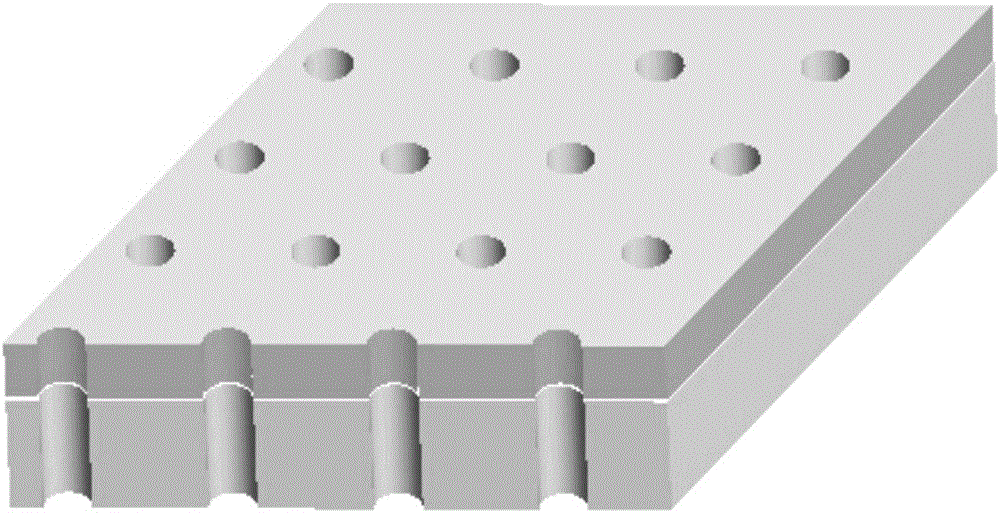

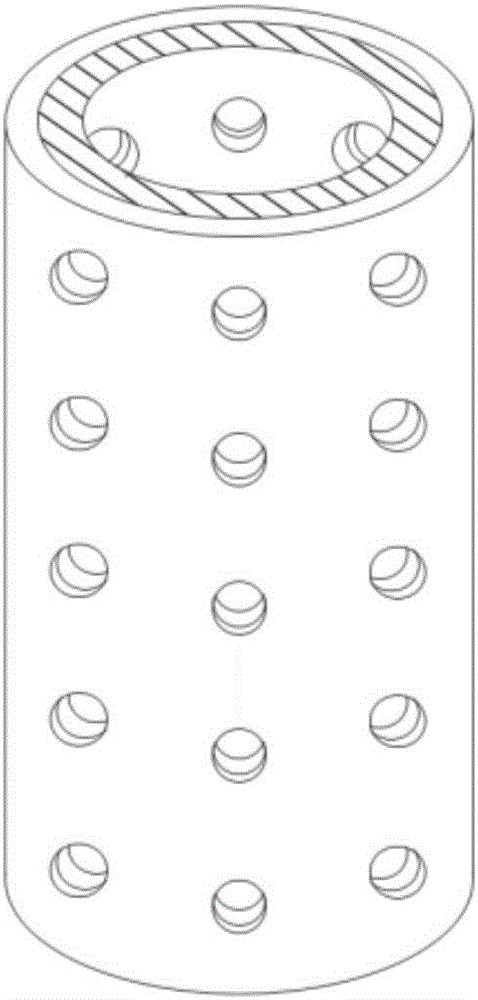

Method for preparing medical porous titanium-tantalum artificial bone and artificial joint, and products thereof

ActiveCN106693069AGuaranteed bonding qualityReliable workmanshipPharmaceutical delivery mechanismTissue regenerationBiocompatibility TestingArtificial bone

The invention discloses a method for preparing porous titanium-tantalum artificial bone and joint and products thereof, and belongs to the field of biological materials. The method comprises the following steps: S1, grinding to-be-bonded surfaces of a titanium alloy sheet and a tantalum sheet, and performing ultrasonic washing sequentially with acetone, alcohol and deionized water; S2, fitting the titanium alloy sheet and the tantalum sheet, heating to 850-1050 DEG C, insulating for 20-40 minutes, pressurizing to perform plastic deformation, and air-cooling to room temperature to form metallurgic bonding between the two materials; S3, quickly preparing pores having a pore size of 300-600mu m in a compound plate by utilizing a solid laser; S4, preparing various artificial bones and joints from the titanium-tantalum compound plate by utilizing a thermal forming technology; and S5, performing alkali and pre-calcifying treatment to improve the biocompatibility of the compound material. Compared with a traditional explosive compound method, the hot-rolling compound method is safer, controllable, convenient and firm in bonding. The product has relatively high biocompatibility.

Owner:HUAZHONG UNIV OF SCI & TECH

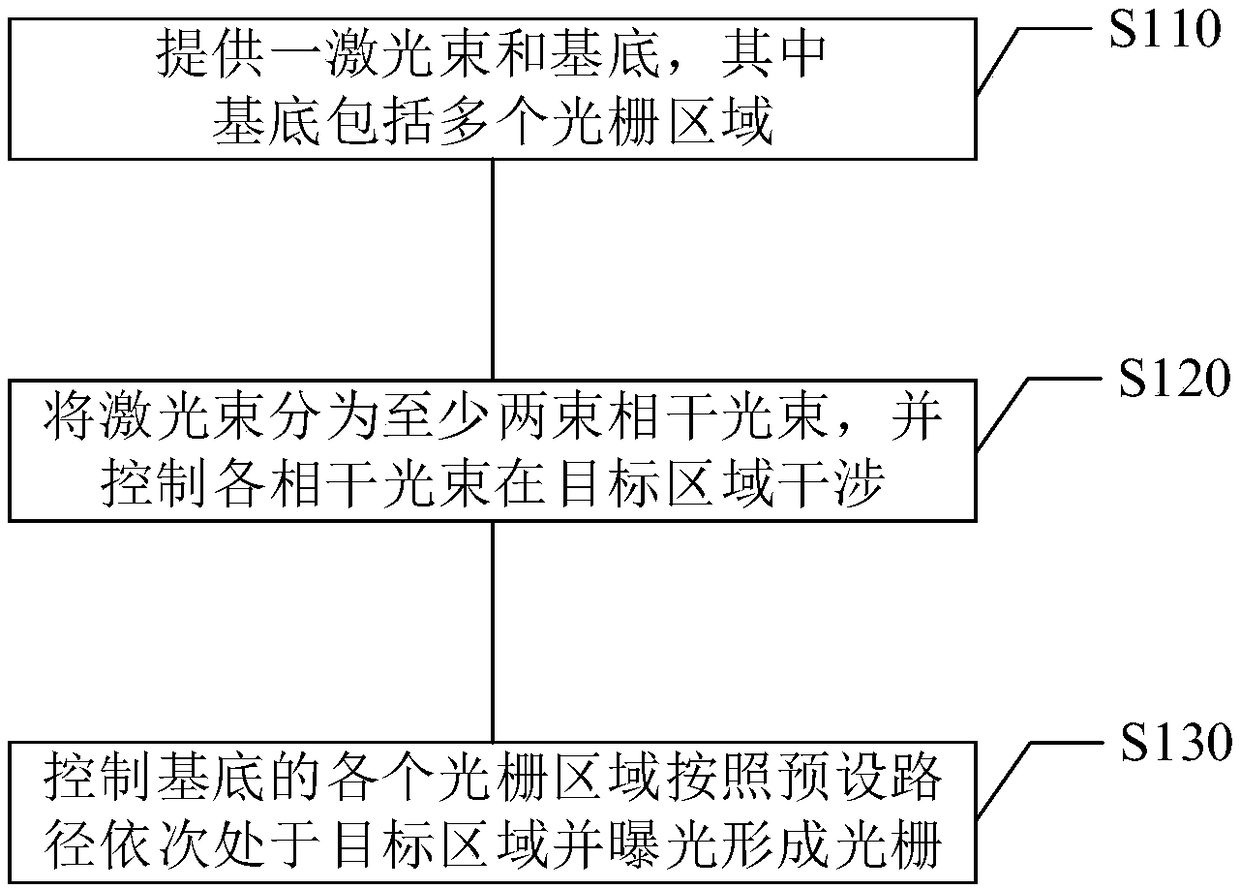

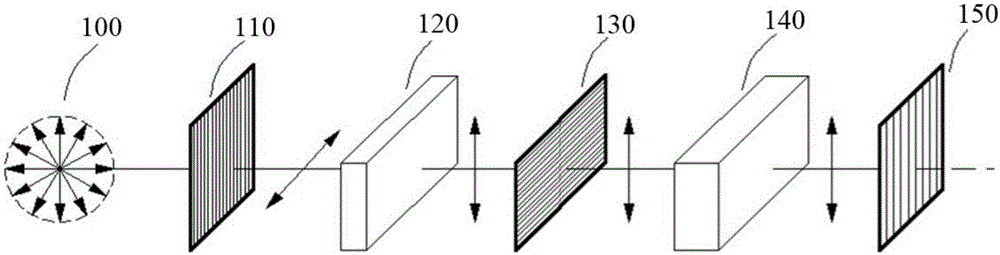

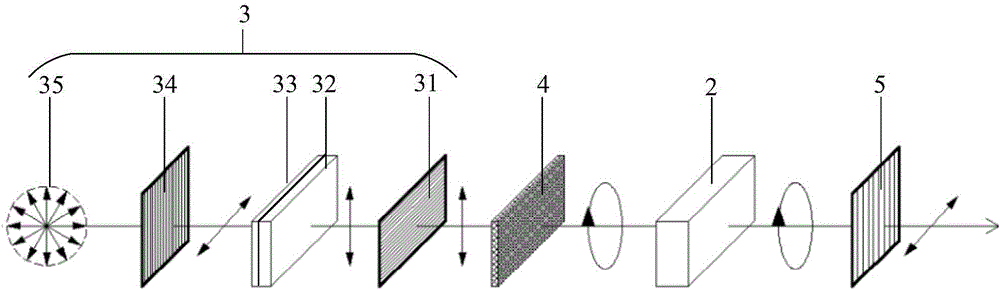

Preparation system and preparation method of grating structure

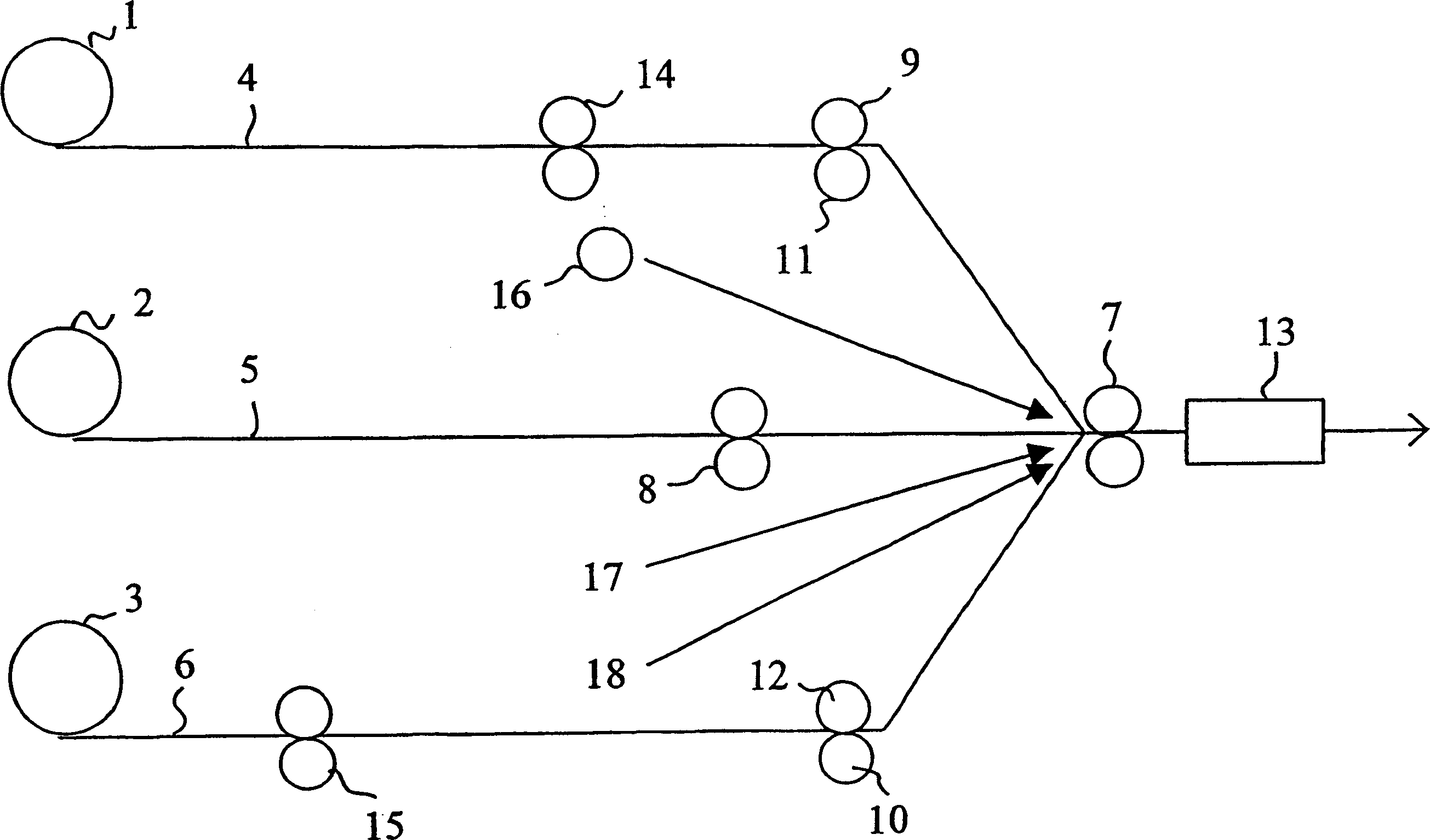

The invention provides a preparation system and a preparation method of a grating structure, which belong to the technical field of gratings. The grating structure comprises a plurality of grating regions which are mutually isolated on a substrate. The preparation system of the grating structure comprises a laser device, an optical path system and a sample stage, wherein the laser device is for providing a laser beam; the optical path system is used for dividing the laser beam into at least two coherent light beams, and controlling the coherent light beams to interfere in a target region; andthe sample stage is used for fixing and moving the substrate, such that the grating regions of the substrate are sequentially positioned in the target region according to a preset path and expose to form a grating. The preparation system and the preparation method of the grating structure can prepare the grating structure quickly and precisely.

Owner:BOE TECH GRP CO LTD

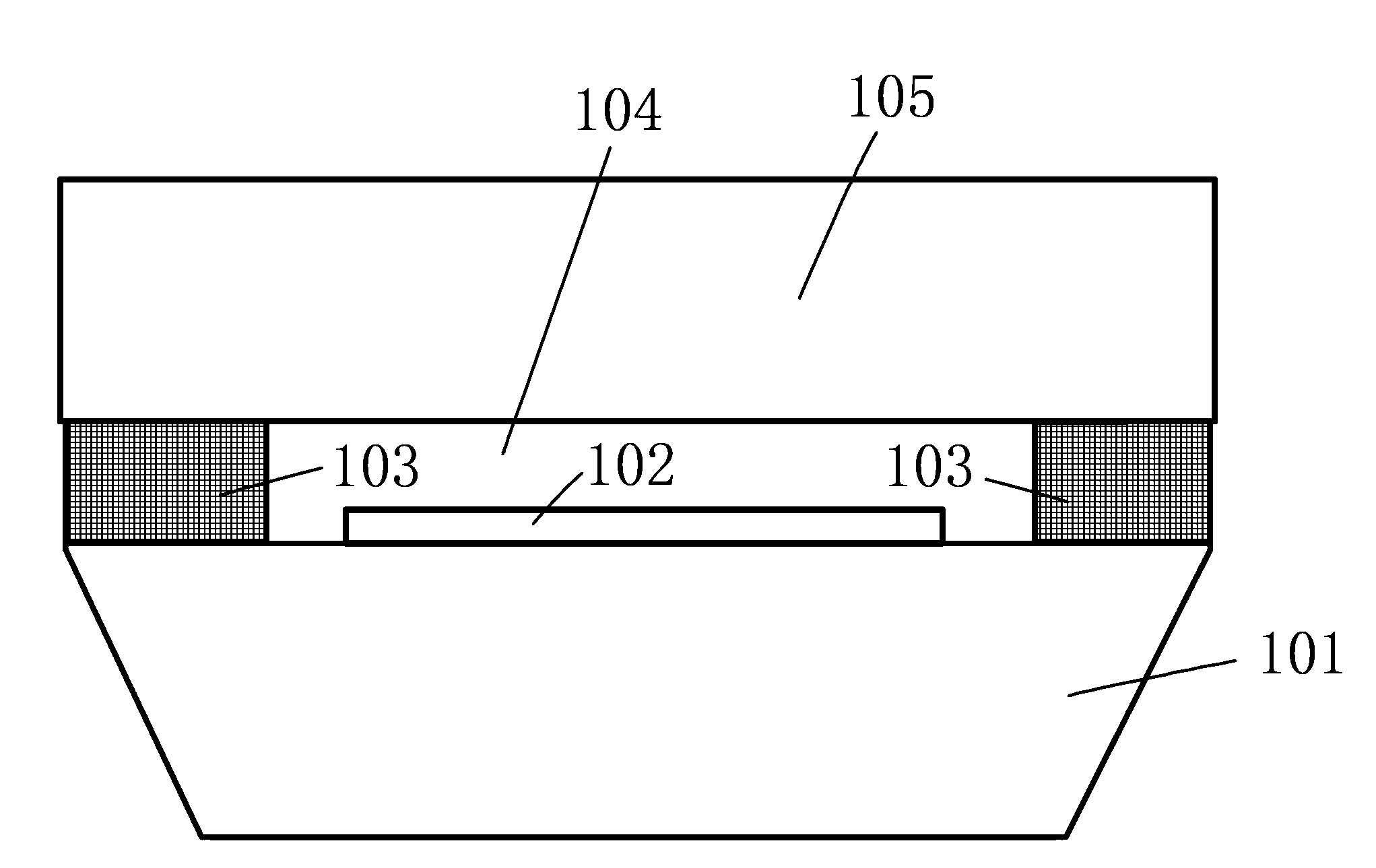

Mixed substrate encapsulation method and mixed substrate encapsulation structure for semiconductor device

ActiveCN103178023AReduce usageHigh mechanical strengthSemiconductor/solid-state device detailsSolid-state devicesOptical glassUltimate tensile strength

The invention provides a mixed substrate encapsulation method and a mixed substrate encapsulation structure for a semiconductor device. A mixed substrate is used for encapsulating the semiconductor device and comprises a support frame and a transparent substrate. The support frame comprises a frame bottom and a frame wall which are connected with each other, wherein the frame bottom is provided with a first through hole, the frame wall is provided with a second through hole, the area of the first through hole is smaller than that of the second through hole, and the first through hole is communicated with the second through hole. The transparent substrate is located in the second through hole and fixed on the upper surface of the frame bottom or the side of the frame wall. A first micropore is arranged between the transparent substrate and the frame bottom. A second micropore is arranged between the transparent substrate and the frame wall. The first micropore is communicated with the second micropore. The strength of the mixed substrate is much higher than that of a large optical glass, so that yield and efficiency of the mixed substrate encapsulation structure and the mixed substrate encapsulation method are increased while cost is reduced.

Owner:GALAXYCORE SHANGHAI

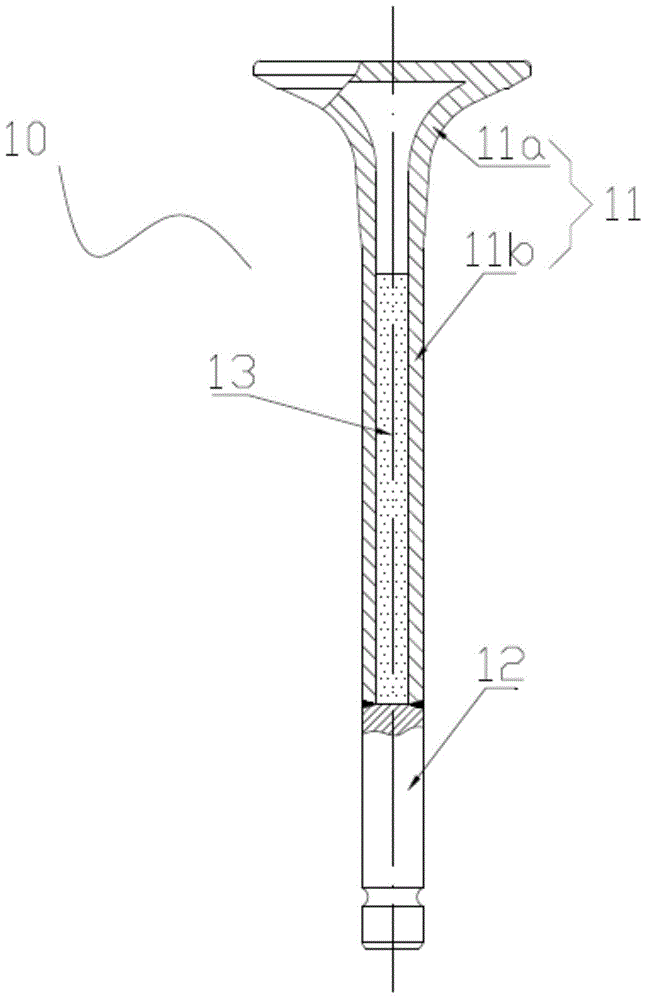

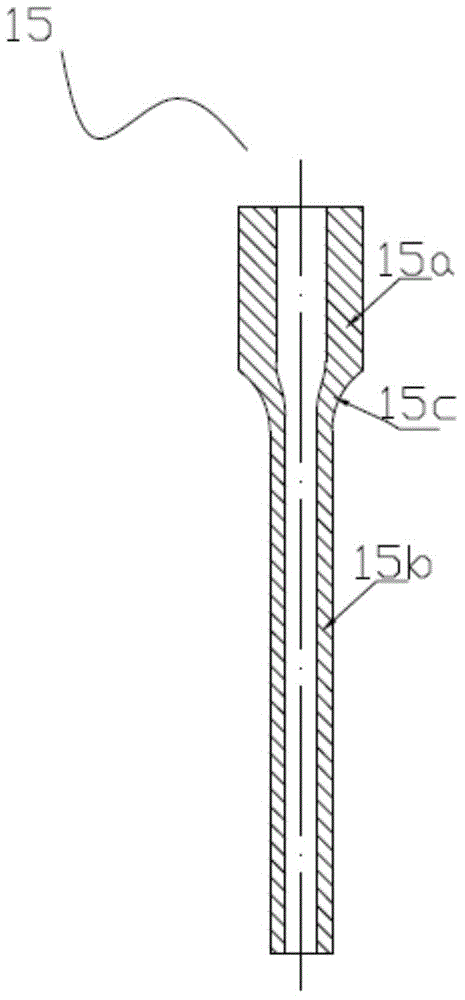

Novel hollow sodium-filled valve

ActiveCN104791040AIncrease the amount of sodiumImprove cooling effectMachines/enginesLift valveFriction weldingEngineering

The invention discloses a novel hollow sodium-filled valve. The novel hollow sodium-filled valve comprises a valve shell and a solid rod part. The forming method of the valve shell comprises the steps that cross wedge rolling is performed on a steel pipe material for preforming; friction welding sealing is performed on the head of a preformed billet; afterwards, a die forging forming technology is performed, so the valve shell is integrally formed. The valve shell comprises a flared hollow disc part and a hollow rod part which are integrally formed. One end of the hollow rod part is welded to the solid rod part through friction welding, and the diameter of the cross section of the solid rod part is equal to the outer diameter of the cross section of the hollow rod part. The disc end face of the hollow disc part is airtight, and an inner cavity is defined by the disc end face of the hollow disc part, the hollow rod part and the solid rod part and is filled with sodium. The novel hollow sodium-filled valve is convenient to form, capable of saving materials and good in heat dissipation performance.

Owner:HUAI JI DENG YUE VALVE CO LTD

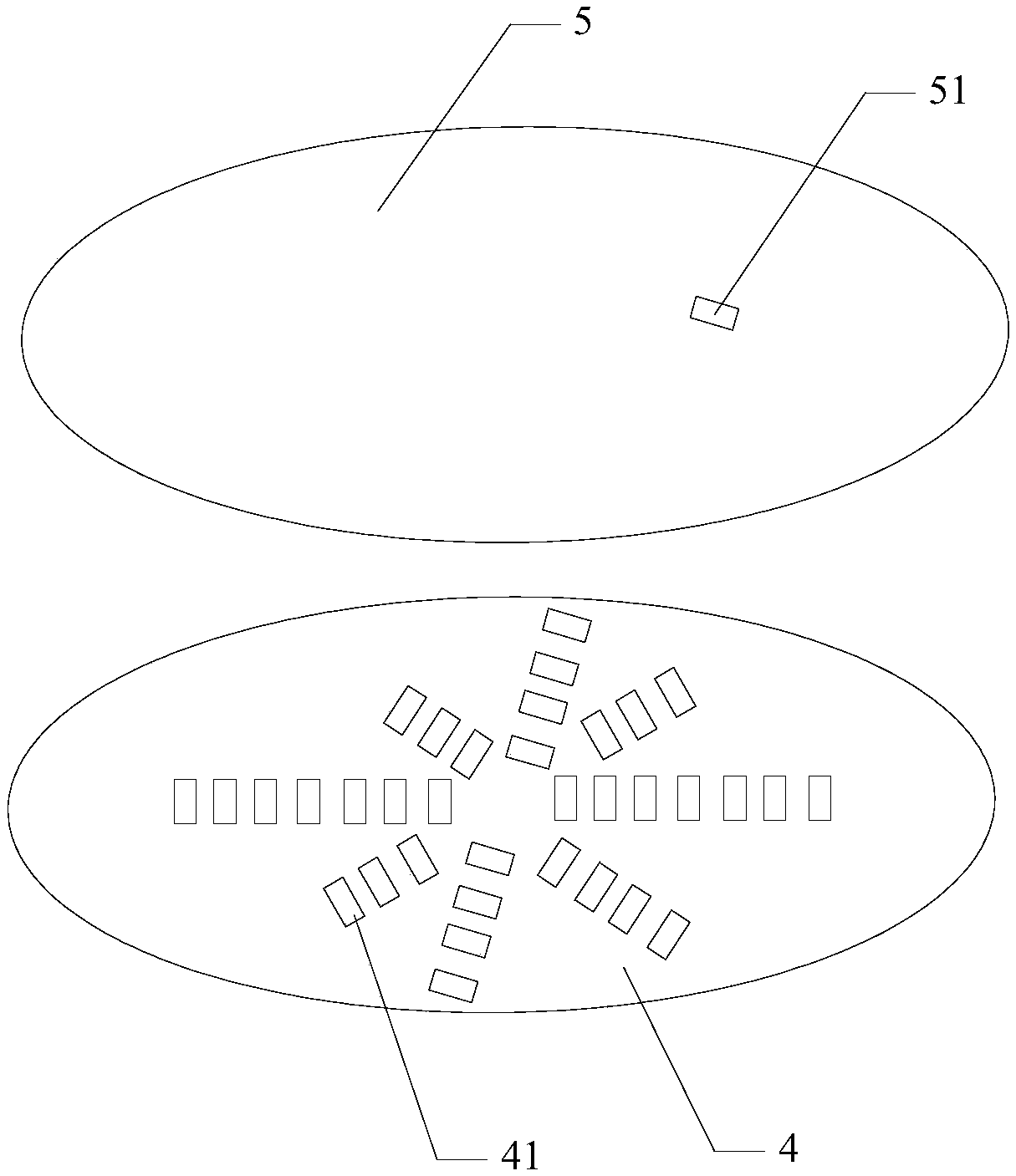

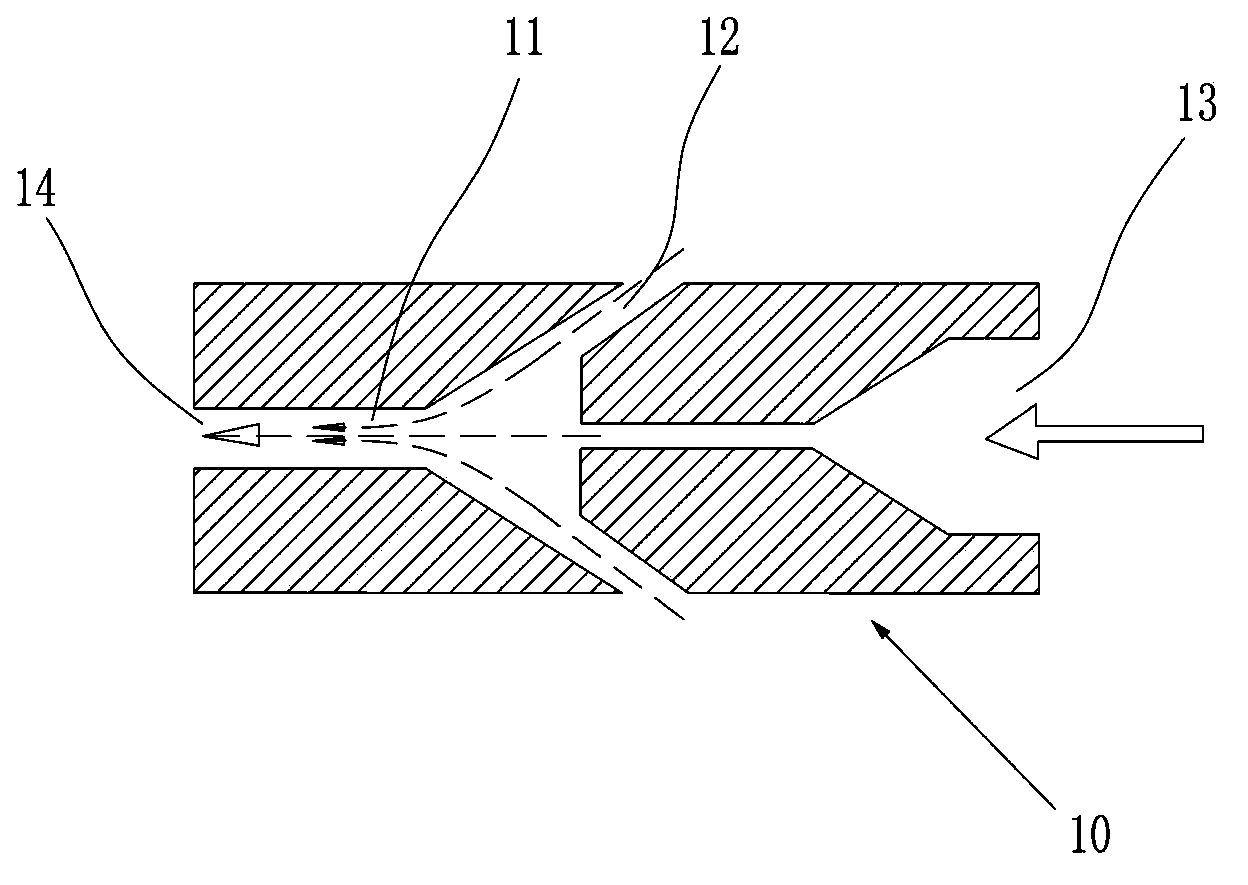

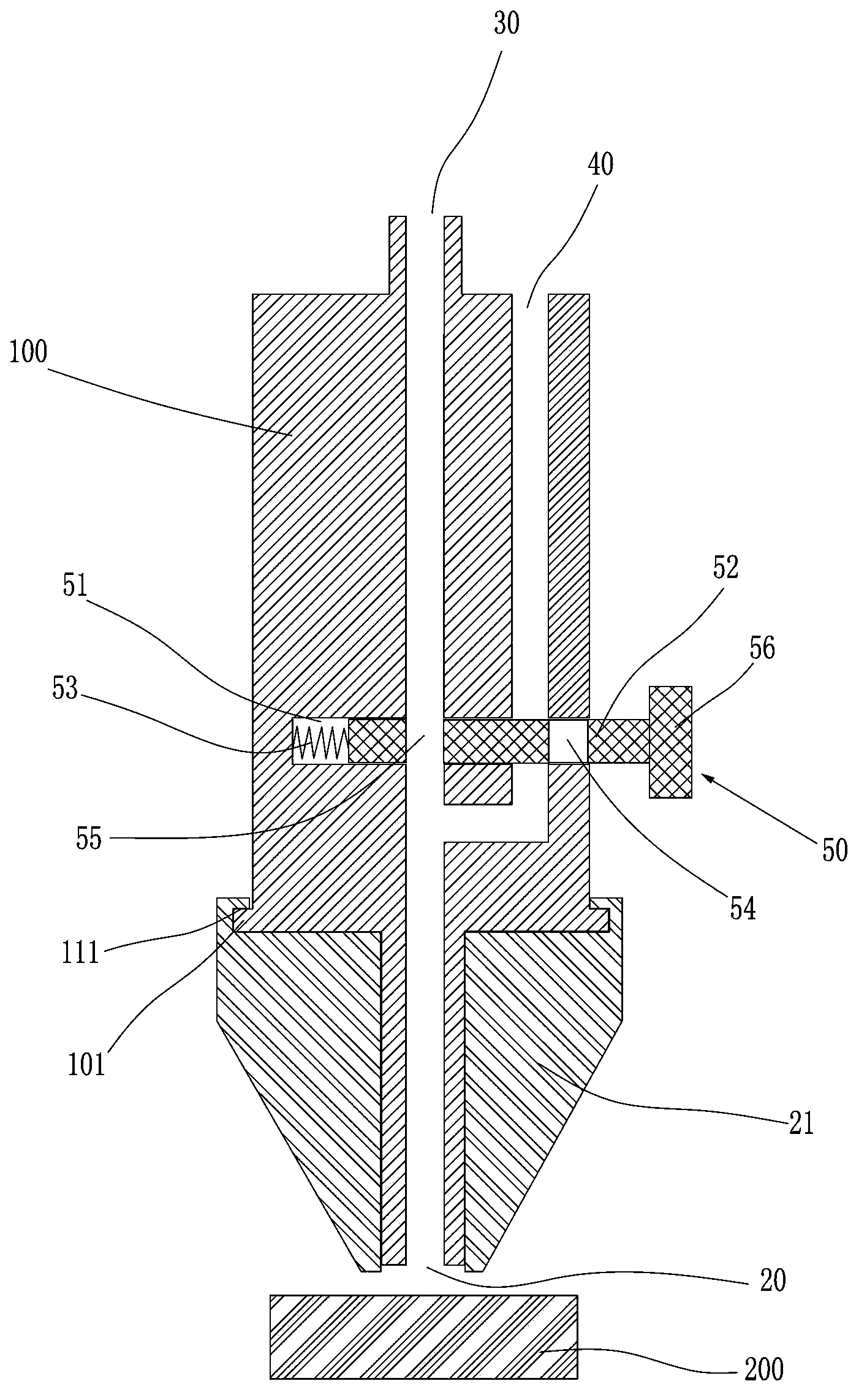

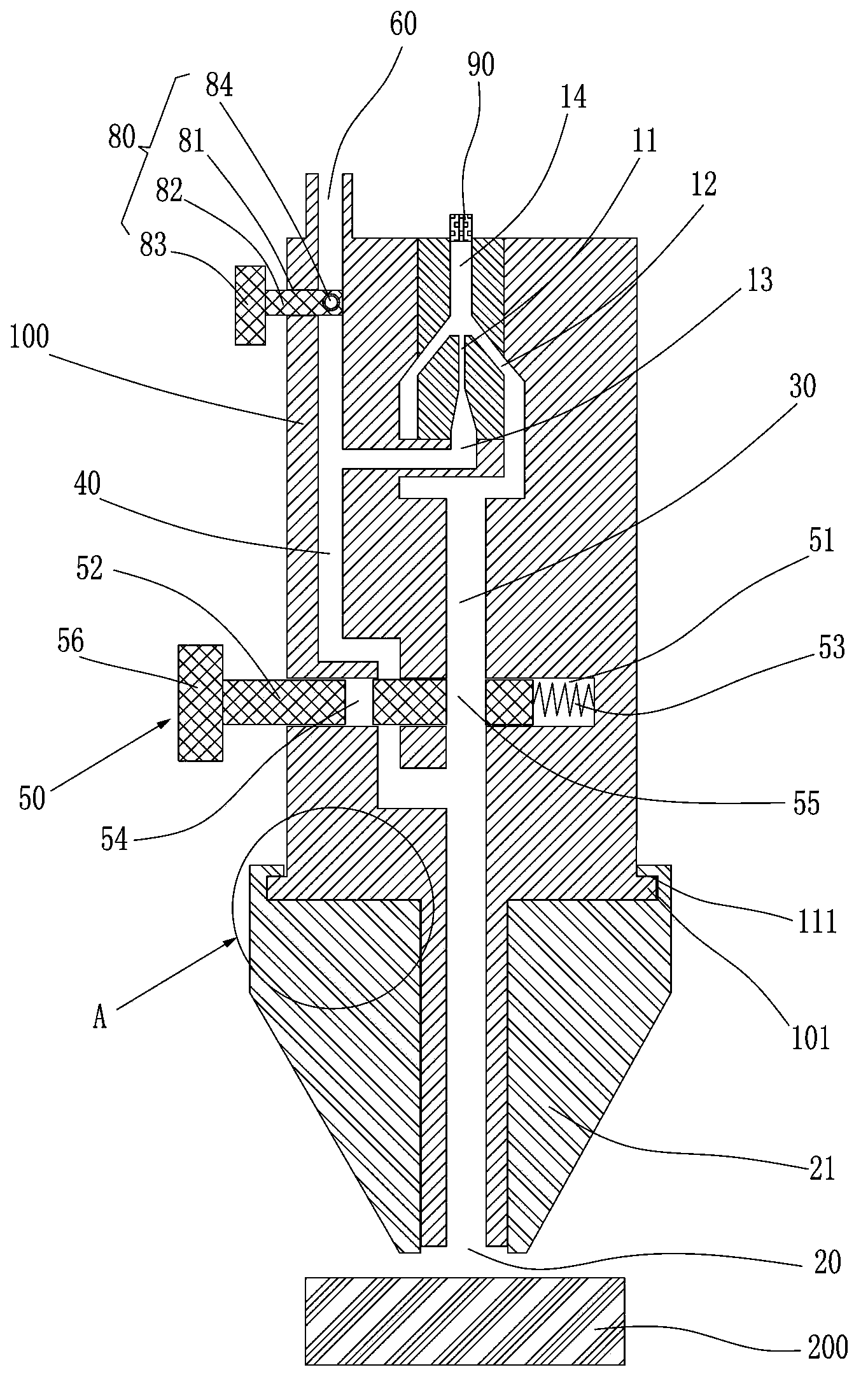

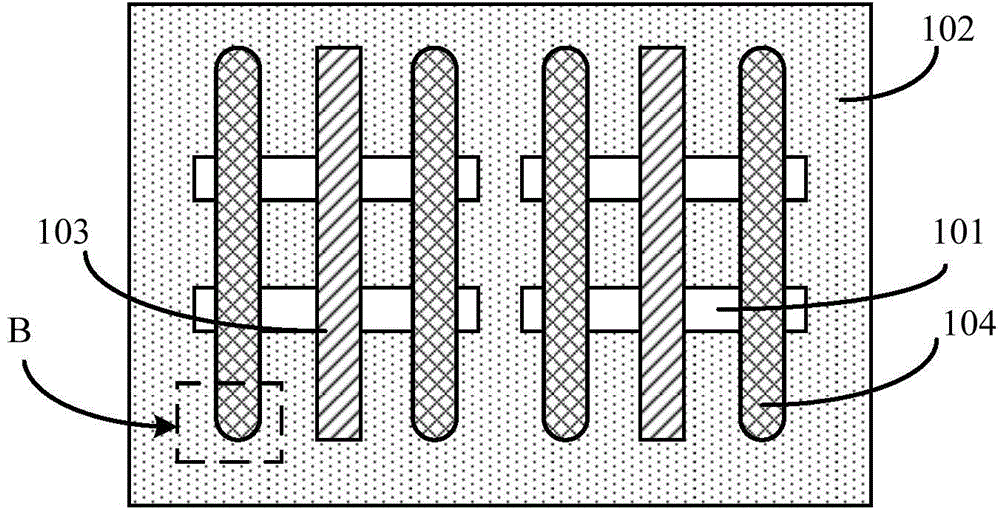

Negative pressure generator and material taking and placing device thereof

ActiveCN103771131APrecise Positioning Made EasyEasy to formManual conveyance devicesConveyor partsEngineeringHigh pressure

An embodiment of the invention discloses a negative pressure generator. The negative pressure generator comprises a high-pressure air channel and a negative pressure channel, wherein the high-pressure air channel is communicated with an external high-pressure air flow conveying device, and the negative pressure channel is arranged on at least one side of the high-pressure air channel and communicated with the high-pressure air channel. An embodiment of the invention simultaneously further discloses a material taking and placing device. The material taking and placing device comprises the negative pressure generator, a negative pressure pipe, exhaust pipes and a first control switch, wherein one end of the negative pressure pipe is communicated with the negative pressure channel of the negative pressure generator, the exhaust pipes are arranged on one side of the negative pressure pipe at intervals side by side, one end of every exhaust pipe is communicated with the negative pressure pipe, and the first control switch controls the negative pressure pipe and the exhaust pipes to be in reverse on-off states. A suction nozzle for adsorbing materials is formed at the other end of the negative pressure pipe. The material taking and placing device is simple in structure, simple and convenient and rapid to operate and safe to use and can effectively improve operation quality, improve operation efficiency and reduce production cost.

Owner:SHENNAN CIRCUITS

Method for forming semiconductor device

ActiveCN104979199ASmall sizeHigh densitySemiconductor/solid-state device manufacturingSemiconductor devicesInterconnectionEngineering

A method for forming a semiconductor device comprises a step of providing a substrate whose surface has gate structures, wherein two sides of each gate structure has an interconnection region respectively, portions, in the interconnection regions, of the substrate have source regions and drain regions positioned at two sides of the corresponding gate structure respectively, and surfaces of the substrate and the gate structures have a first dielectric layer; a step of forming a barrier opening on the surface of the first dielectric layer, wherein the pattern of the barrier opening at least penetrates one interconnection region; a step of forming a barrier layer in the barrier opening; a step of forming a first patterned layer on the first dielectric layer and the surface of the barrier layer, wherein the first patterned layer exposes the positions of the interconnection regions; a step of taking the first patterned layer and the barrier layer as mask layers, and etching the first dielectric layer until the surface of the substrate in the interconnection regions is exposed, so as to form source-drain grooves; a step of forming gate through holes in the first dielectric layer for exposing tops of the gate structures; and a step of forming source-drain conductive structures in the source-drain grooves and forming gate plugs in the gate through holes. The formed semiconductor device is good in appearance and has improved performances.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Polarized display device and mobile terminal

PendingCN106405925ASimple structureEasy to implementTelephone set constructionsNon-linear opticsDisplay deviceComputer terminal

Owner:HUAQIN TECH CO LTD

Concrete curb prepared from ardealite-based hydraulic composite cementing material and preparation method of concrete curb

The invention belongs to the technical field of building materials and particularly relates to concrete curb prepared from an ardealite-based hydraulic composite cementing material and a preparation method of the concrete curb. The concrete curb is prepared from blast furnace slag, ardealite, cement, limestone, anhydrite, Na2SO4, a water reducing agent, metakaolin, CaF2, stone and sand. Physical and mechanical properties and durability of common plastic concrete can be improved, quick and convenient forming is realized, natural resources and maintenance and replacement costs are saved, and environmental pollution is reduced. The concrete curb is applicable to the fields of highway engineering and the like.

Owner:TONGJI UNIV

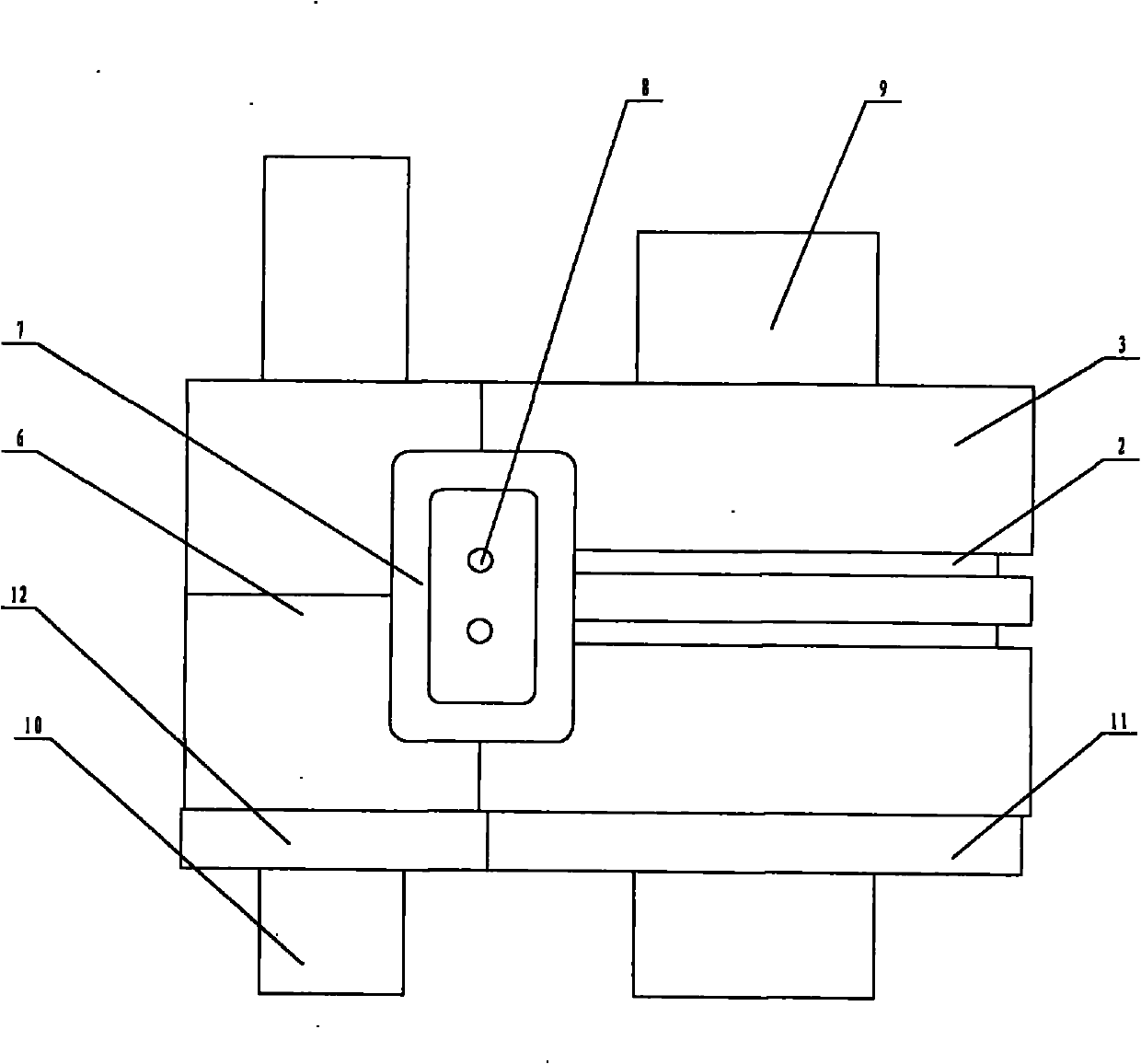

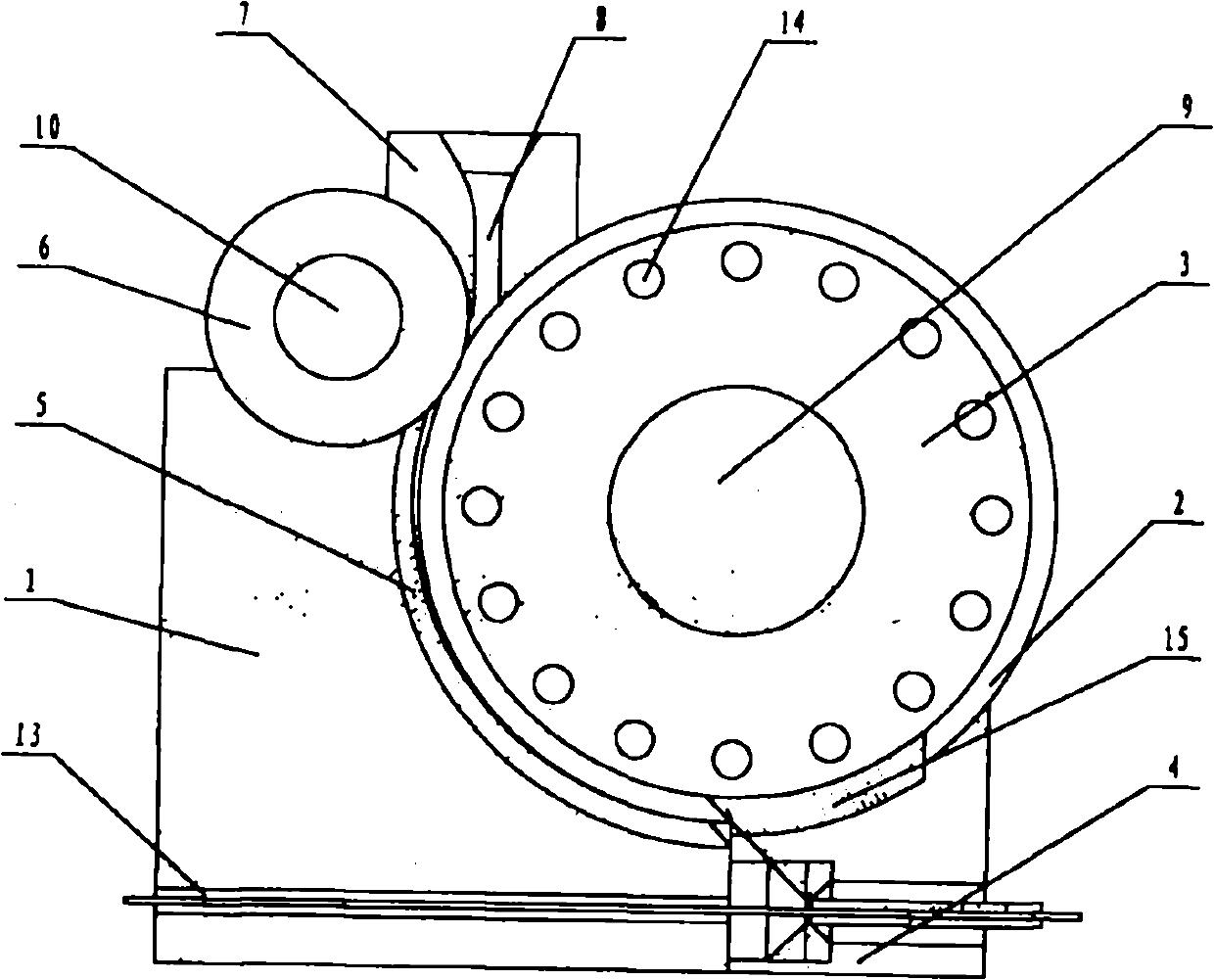

Continuous casting-rolling and extrusion molding device of Al-Mg-Cu alloy and composite materials

InactiveCN101905241AEasy to formGuarantee the balance of extrusion forceExtrusion profiling toolsMetal rolling arrangementsDrive shaftAlloy

The invention relates to a continuous casting-rolling and extrusion molding device of Al-Mg-Cu alloy and composite materials, solving the problem that the traditional machining and molding device of Al-Mg alloy and the composite materials has lower performance of section bars due to the structural imperfection. A driven shaft is arranged on a stand, a casting roller is arranged on the driven shaft, the roller surface at the lower part of the casting roller is in transitional fit with the upper surfaces of a squeezing seat and a groove sealing block, a crystallizer is arranged above the casting roller and an extruding roller, a crystallizing hole is arranged on the crystallizer, the lower end of the crystallizing hole is positioned above the contact part between the casting roller and the extruding roller, the lower surface of the crystallizer is in transitional fit with the roller surfaces of the casting roller and the extruding roller, and a rotatable driving mechanism is respectively arranged on a driving shaft and the driven shaft. The invention greatly improves the performance of the section bars by additionally arranging the casting roller and the crystallizer, ensures that the section bars are possible to be made to meet the requirements for high-precision thin walls with ultra thinness and ultra length and simultaneously has the advantages of simple structure, convenient operation and low cost.

Owner:山西奥铭科技有限公司

Excimer lamp

InactiveCN101847564AEasy to formEasy lighting portGas discharge lamp detailsAuxiliary electrodeExcimer lamp

Provided is an excimer lamp, an integral electrode is formed at the end of a pair of light transmission electrodes, a starting auxiliary electrode is formed at the inner surface of the discharging container, a reflection film is formed at the inner surface at one non-light output side of the discharging container, a daylight opening for light monitoring is formed at the end of the reflection film, characterized in that a branch-shaped electrode extending along the pipe shaft is formed on the integral electrode, one part of starting auxiliary electrode is overlapped with the branch-shaped electrode, thus the excimer lamp is discharged on the surface from the starting auxiliary electrode to the integral electrode with on influence on the daylight opening, and can correctly perform the light monitoring.

Owner:USHIO DENKI KK

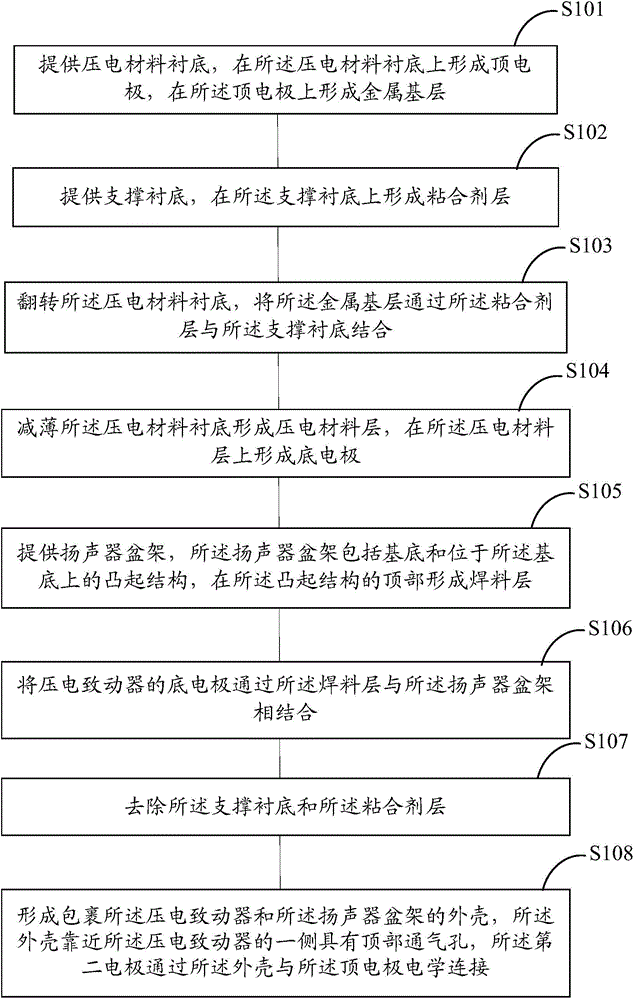

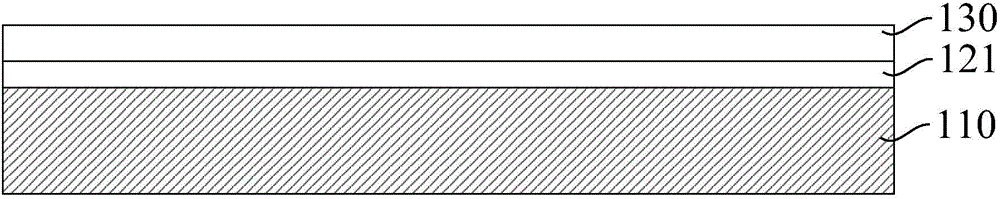

Piezoelectric loudspeaker and method for forming same

ActiveCN104811881AEasy to formReduce manufacturing costPiezoelectric/electrostrictive transducersPiezoelectric actuatorsEngineering

The invention provides a piezoelectric loudspeaker and a method for forming the same. The method for forming the piezoelectric loudspeaker includes providing piezoelectric actuators; providing loudspeaker frames; forming welding flux layers on the tops of protruded structures; combining bottom electrodes of the piezoelectric actuators with the loudspeaker frames by the welding flux layers. The piezoelectric actuators comprise piezoelectric material layers, the bottom electrodes and top electrodes. The loudspeaker frames comprise substrates and the protruded structures positioned on the substrates. The piezoelectric loudspeaker and the method for forming the piezoelectric loudspeaker have the advantages of simple process and low cost.

Owner:WEIFANG GOERTEK MICROELECTRONICS CO LTD

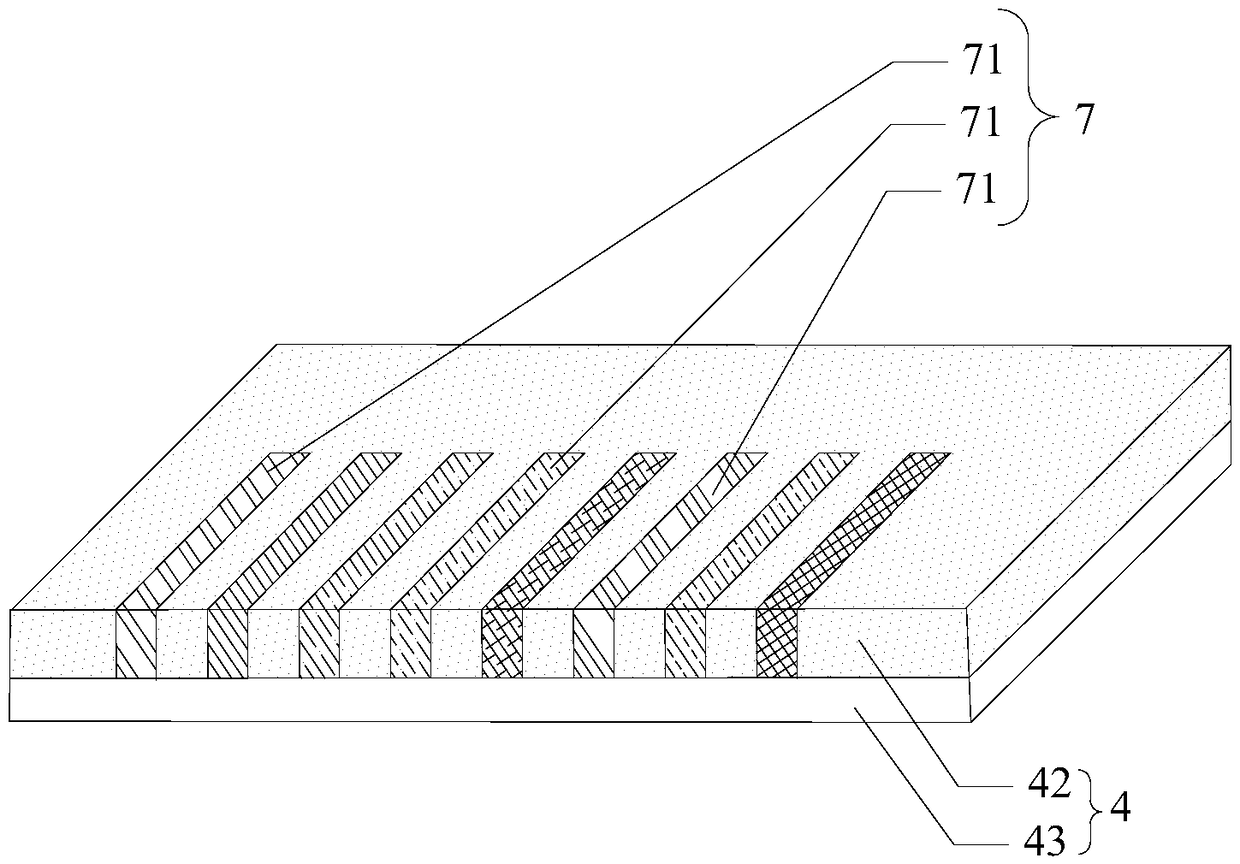

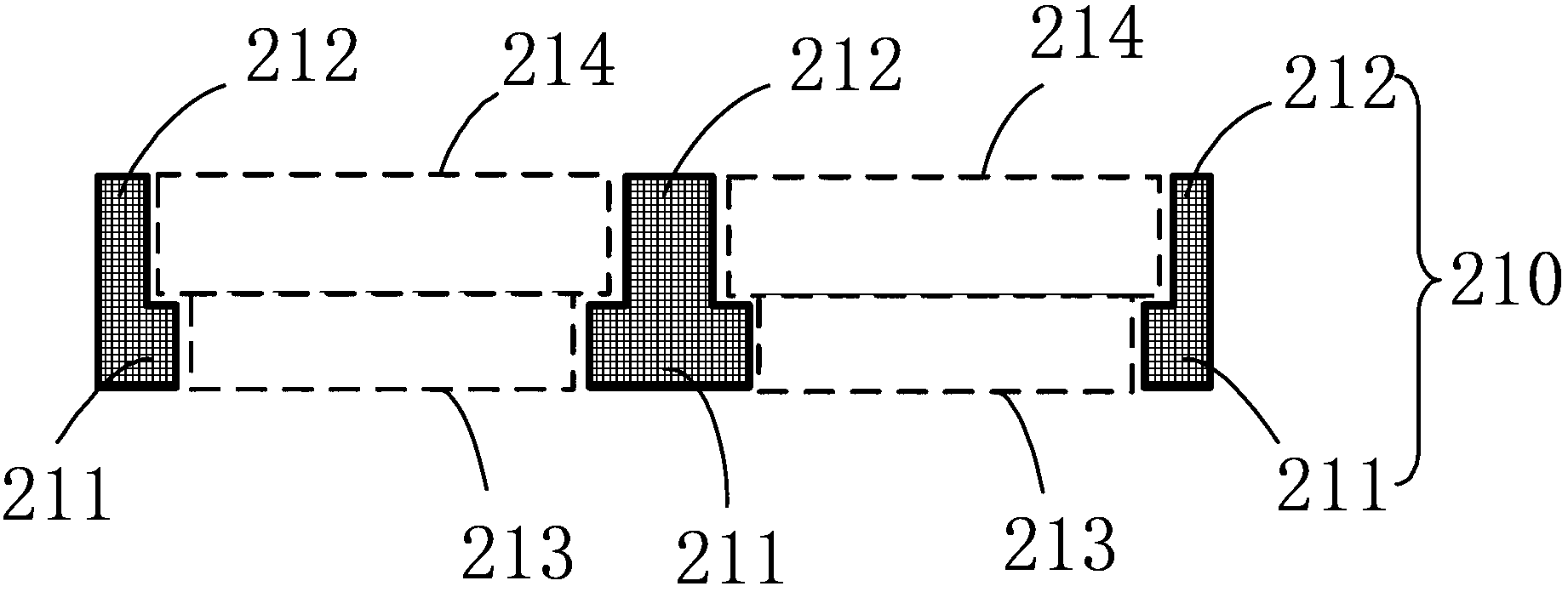

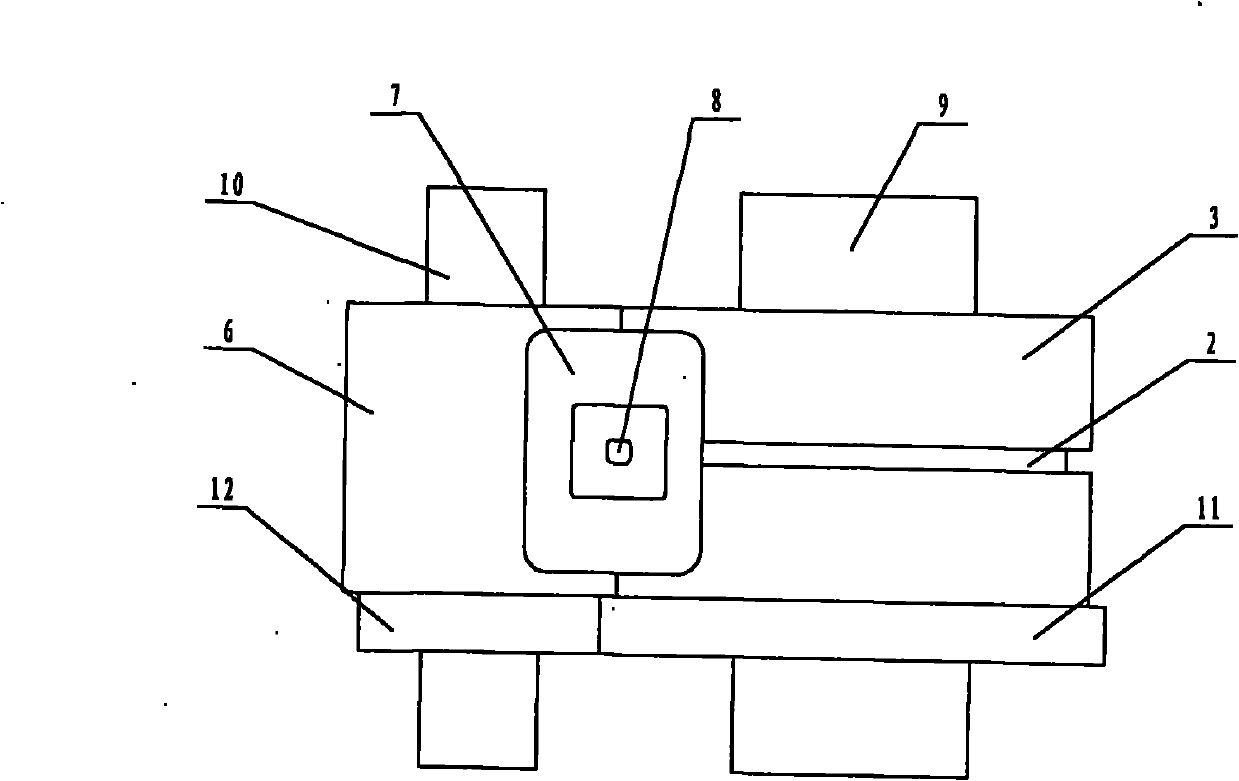

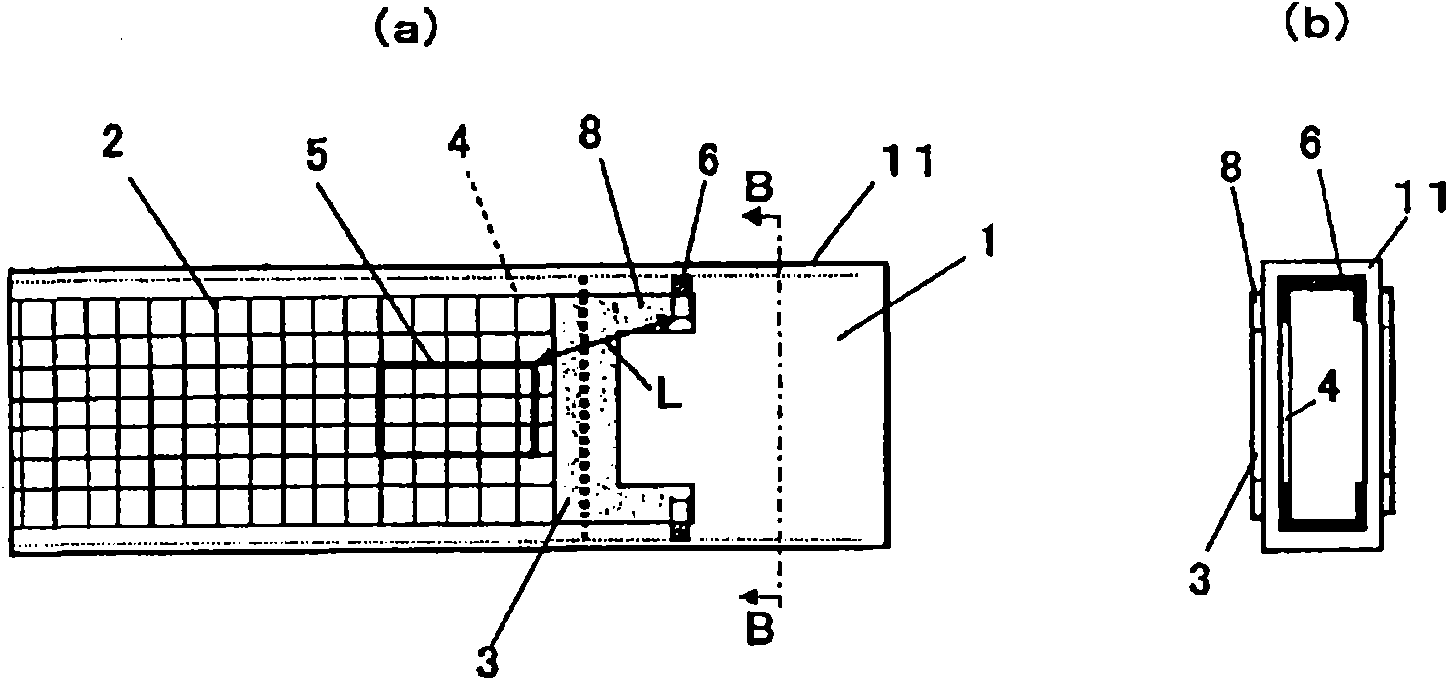

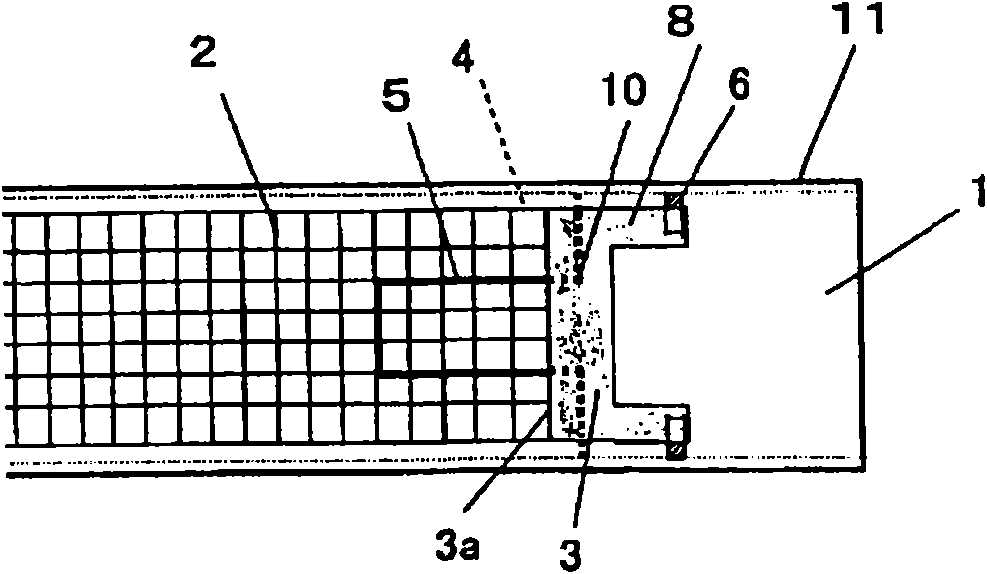

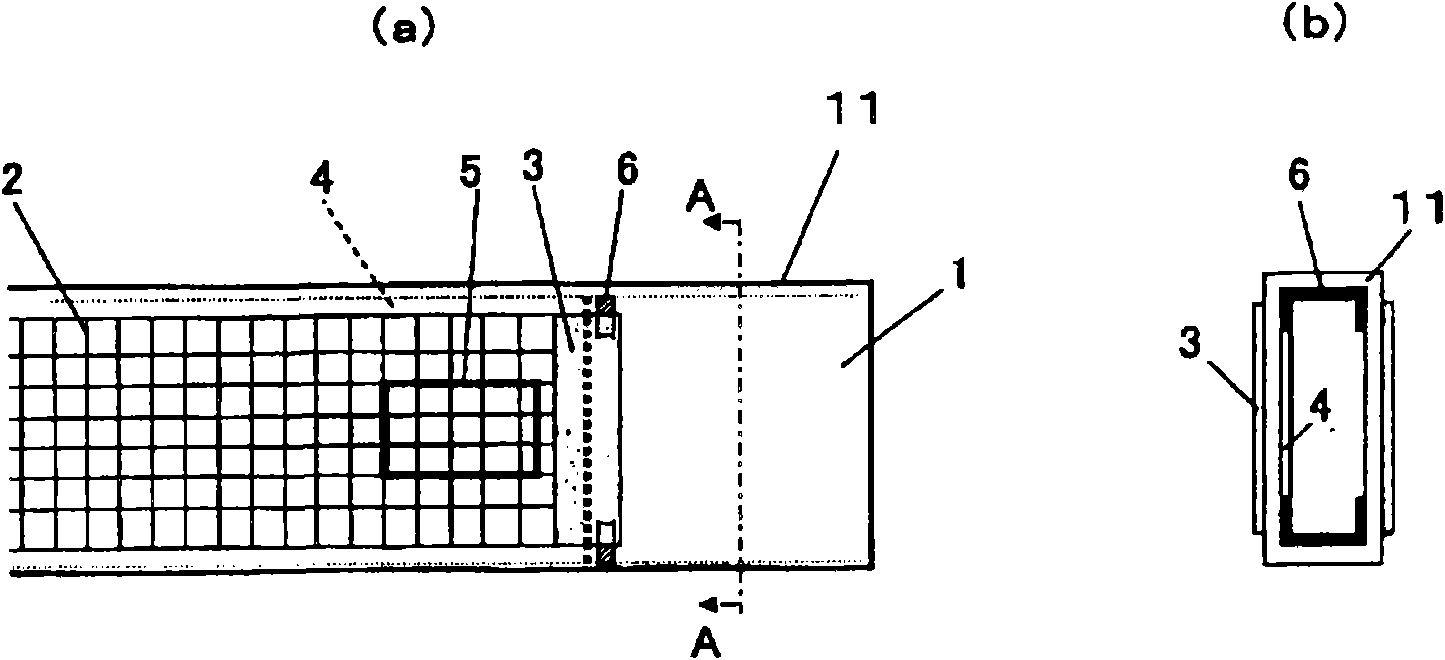

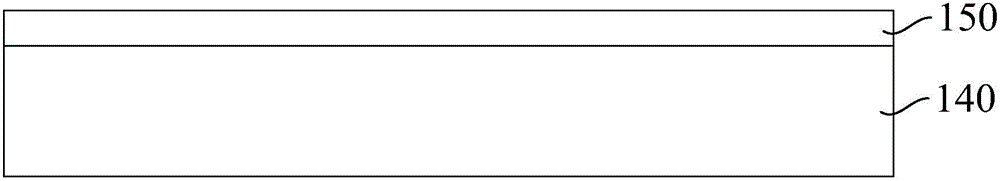

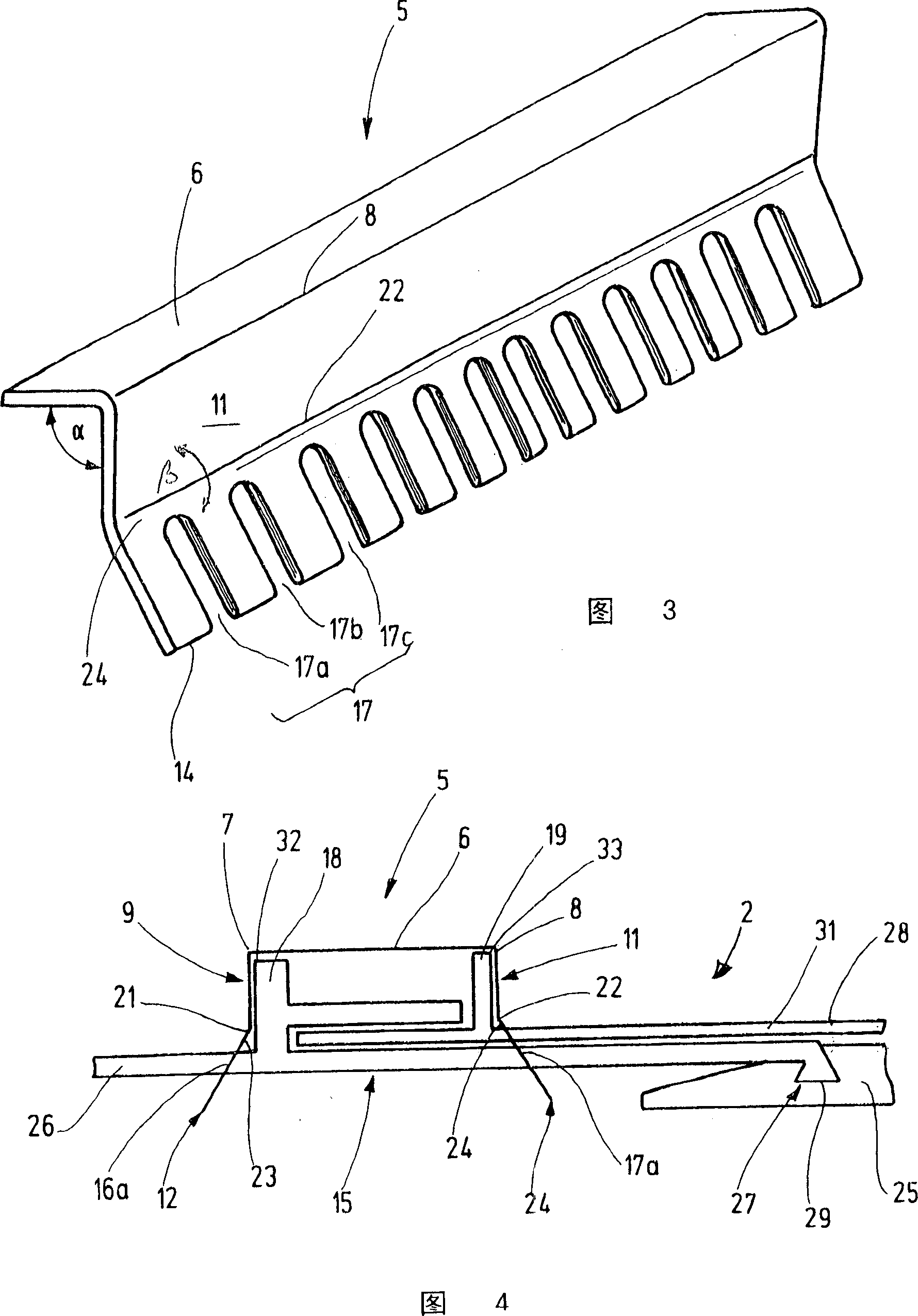

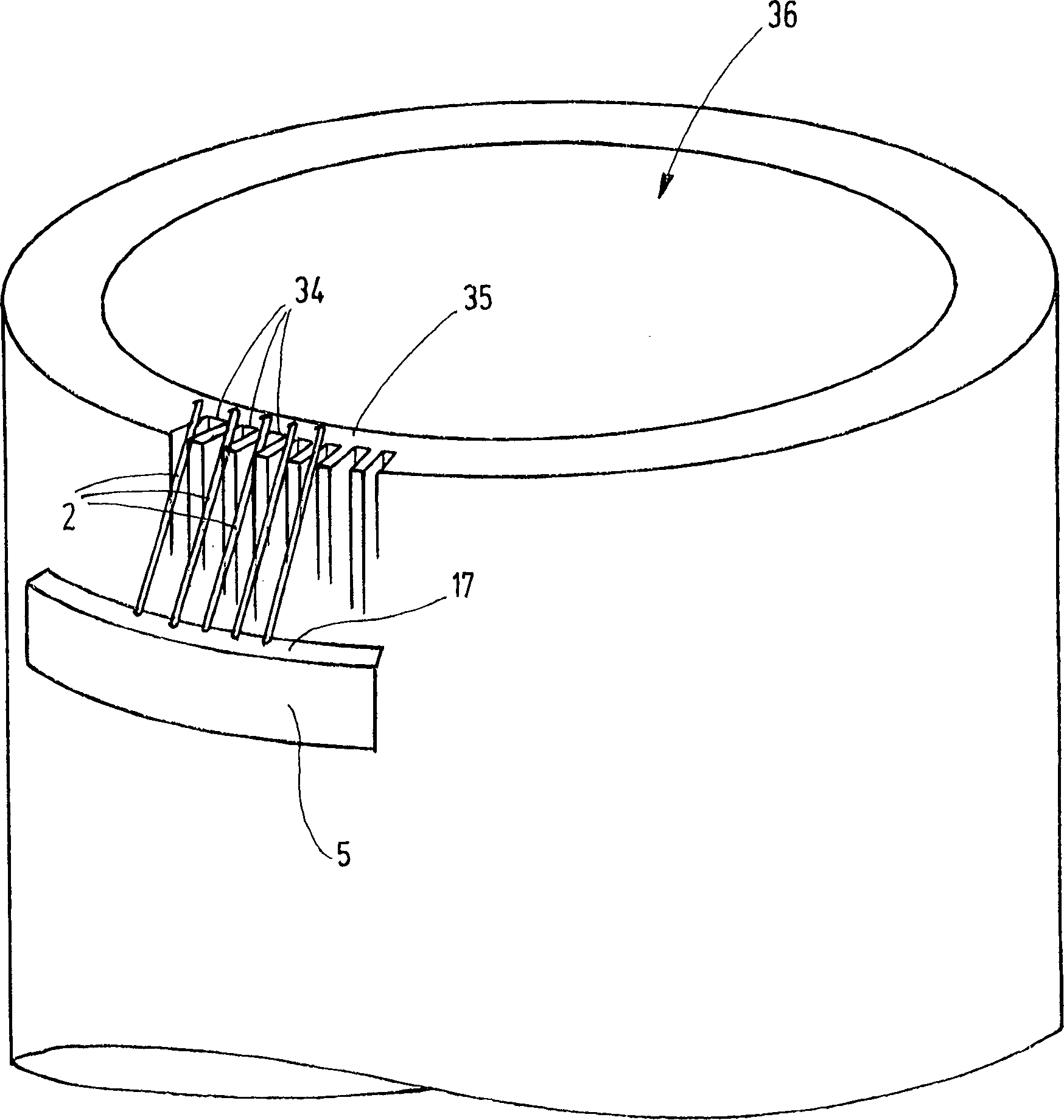

Tool carriage for composite needle and transferring component

ActiveCN1495112AEasy to formReduce shipping weightWeft knittingCharge manipulationTool holderEngineering

For keeping knitting tools (2) in readiness and mounting them on knitting machines or other loop-forming machines, a tool holder (4) is provided, which is formed by or contains a transport rail (5). The transport rail (5) has two clamping legs (9, 11), which are parallel to one another and are provided with regularly distributed slots (16, 17). The slots firmly clamp inserted knitting tools by frictional engagement. With the knitting tools (2), the transport rail (5) forms a manipulable unit, in which when it is freely handled, the knitting tools (2) do not fall out of the transport rail (5). The pitch of the transport rail preferably matches the pitch of a needle bed of a machine to be equipped. The equipping of the machine is done by placing the transport rail on the needle bed or attaching it to it and pressing the knitting tools away, in a direction approximately perpendicular to the back portion (6) of the transport rail (5), out of their frictionally engaged mounting into their needle channel. Multi-part knitting tools are thus securely held together in every stage.

Owner:GROZ BECKERT KG

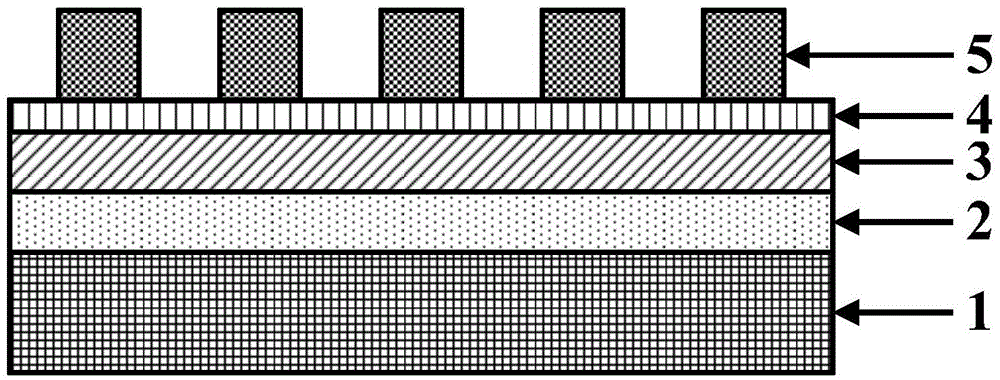

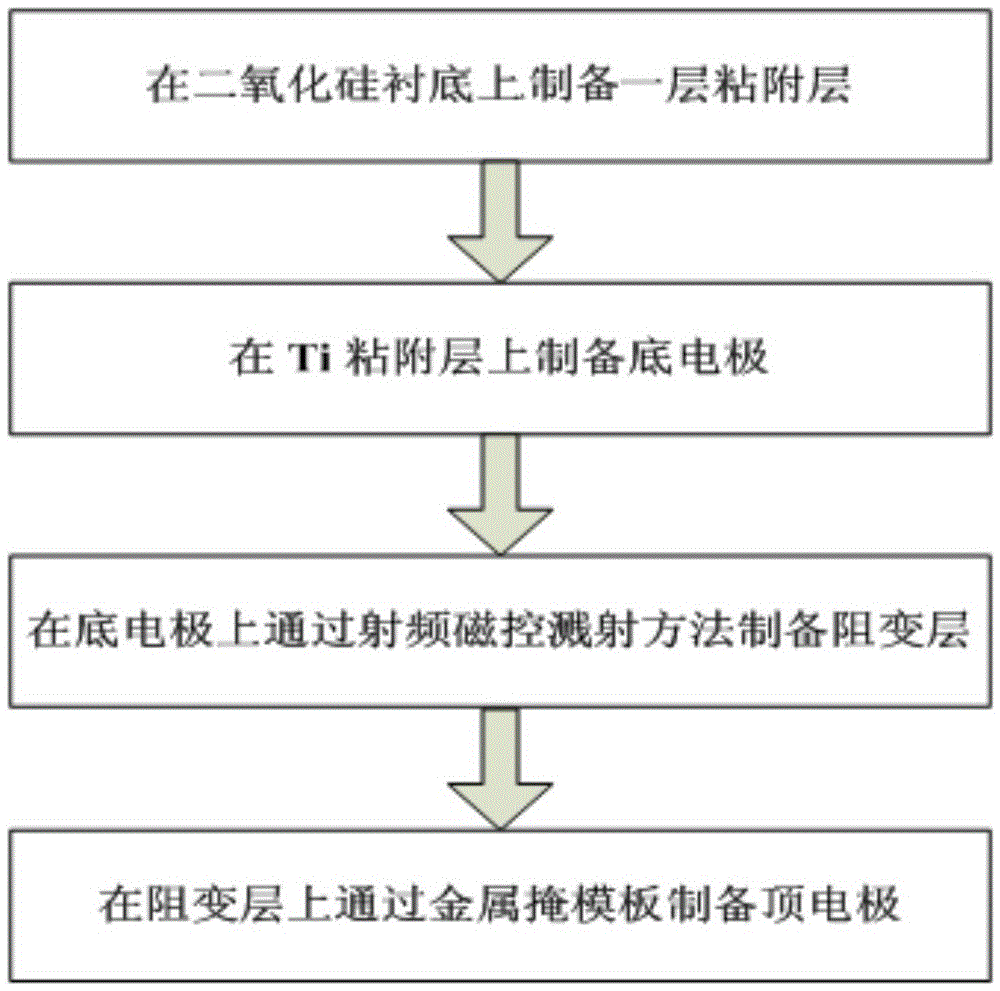

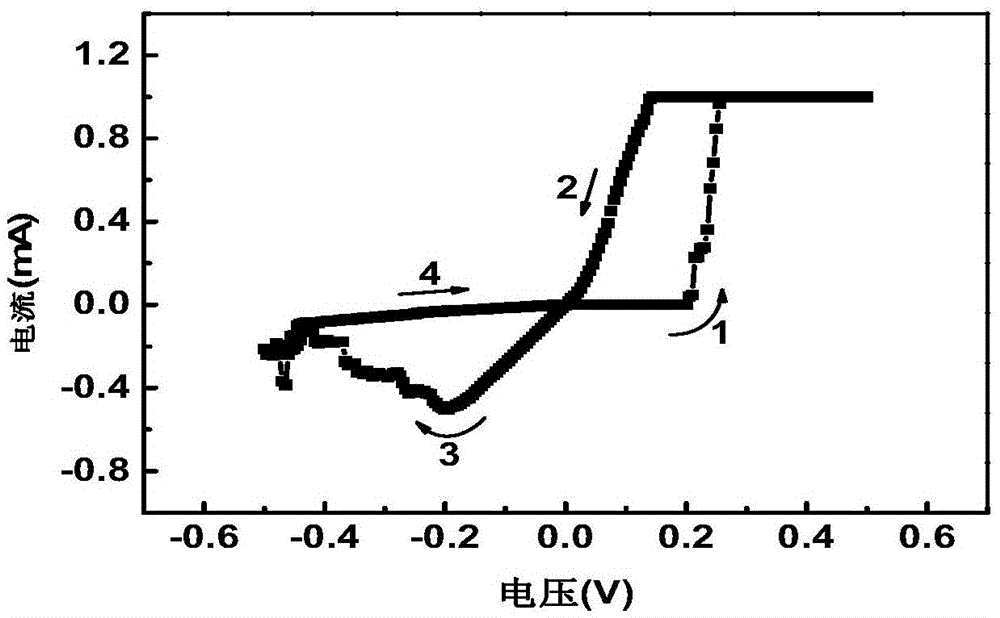

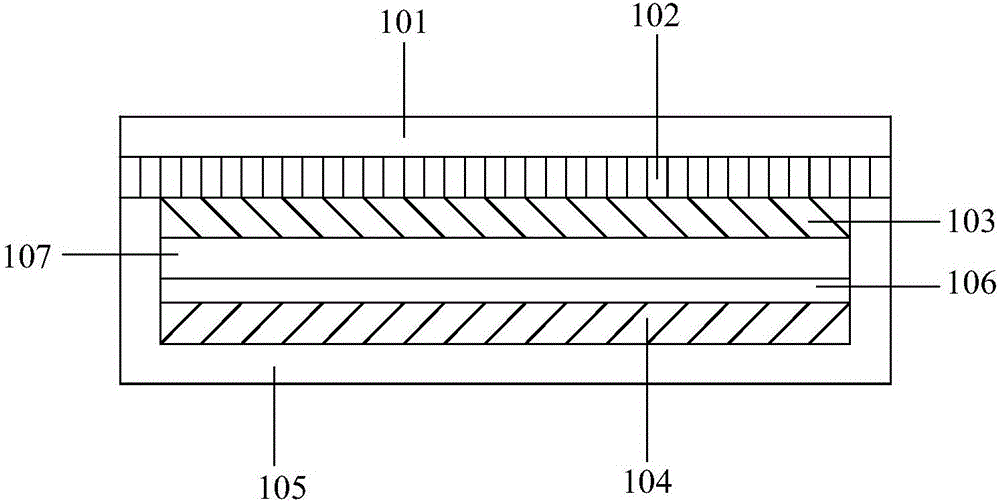

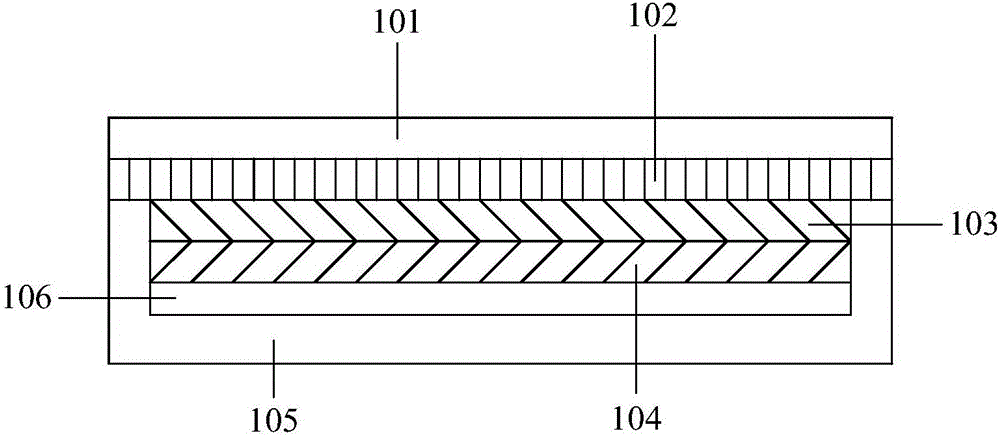

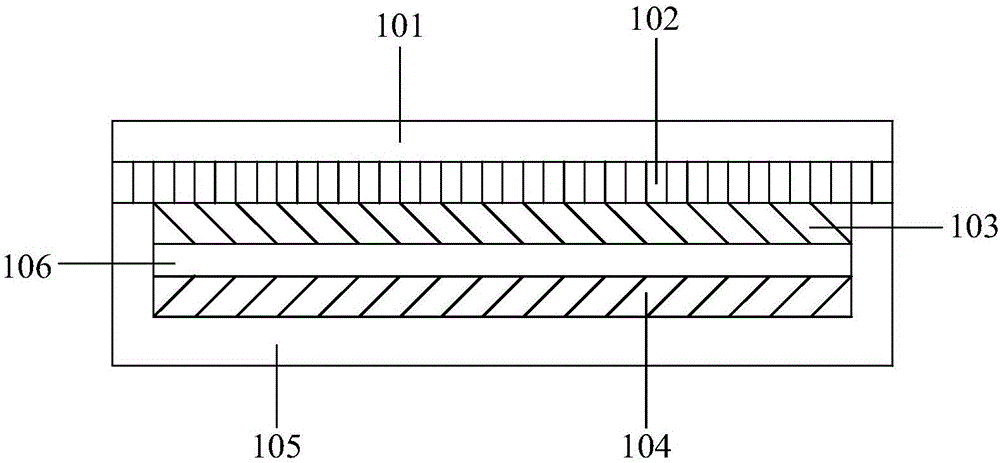

Silicon oxide thin film based low power consumption resistive random access memory and preparation method therefor

InactiveCN105552220ALow powerReduce power consumptionElectrical apparatusStatic random-access memoryRadio frequency magnetron sputtering

The invention discloses a silicon oxide thin film based low power consumption resistive random access memory. The low power consumption resistive random access memory comprises a substrate, a Ti adhesion layer, a bottom electrode, a resistance variable layer and a top electrode that are overlaid in sequence; the resistance variable layer is the silicon oxide thin film with a loose structure; the preparation method for the resistive random access memory comprises the following steps of preparing the Ti adhesion layer on the substrate; preparing a Pt bottom electrode on the Ti adhesion layer; and preparing the silicon oxide thin film resistance variable layer on the Pt bottom electrode through a radio frequency magnetron sputtering method, wherein the process conditions of the radio frequency magnetron sputtering are as follows: a silicon oxide target is taken as the sputtering target material; the cavity pressure is less than 5*10<-6>Torr; the sputtering temperature, sputtering pressure, sputtering power, argon flow and volume fraction of oxygen are properly controlled; and preparing a point-like metal Ag thin film on the resistance variable layer through a direct current magnetron sputtering method on the resistance variable layer to be used as the top electrode to obtain the resistive random access memory. The resistive random access memory has the advantages of low preparation temperature, and low operating voltage.

Owner:NAT UNIV OF DEFENSE TECH

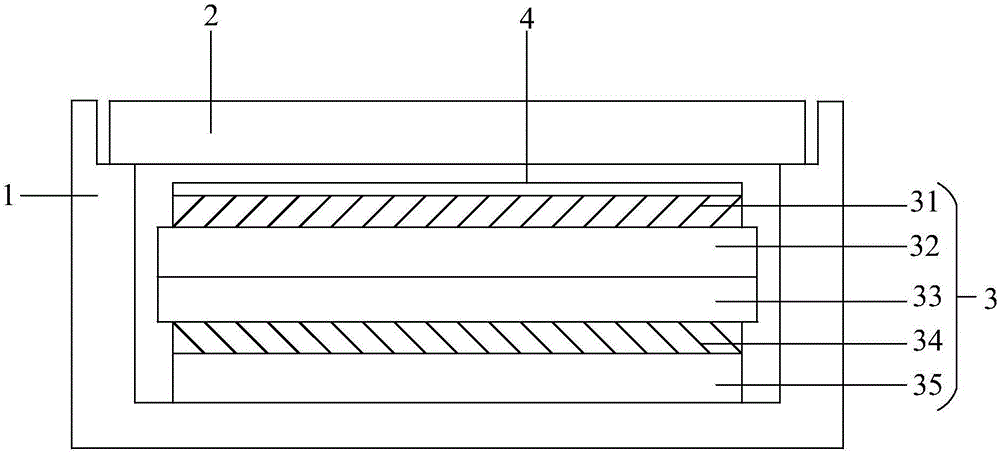

Pressure induction touch control display and electronic equipment

PendingCN106775104AReduce assembly errorsAvoid Structural Design ConstraintsNon-linear opticsInput/output processes for data processingCapacitanceBatch production

The embodiment of the invention relates to the technical field of computer input equipment, and discloses a pressure induction touch control display and electronic equipment. In the embodiment of the invention, the pressure induction touch control display comprises a frame body, a display module and a capacitance pressure induction layer; the capacitance pressure induction layer is internally embedded in the display module; the frame body comprises a metal bottom wall and a side wall connected to the metal bottom wall; the display module is fixed at the inner surface of the side wall, and an insulating buffer layer is arranged between the display module and the metal bottom wall. The invention further discloses the electronic equipment. According to the pressure induction touch control display and the electronic equipment, the capacitance pressure induction layer is internally embedded in the display module, thus the assembly error of a whole machine is lowered, the structure stability is good, the stability and the reliability of the whole machine are improved, and the pressure induction touch control display is suitable for batch production.

Owner:HUAQIN TECH CO LTD

New type automobile gasoline tank and forming method thereof

The invention relates to a new type automobile gasoline tank and a forming method thereof. the new type automobile gasoline tank comprises an upper part of the gasoline tank and a lower part of the gasoline tank which are connected in a butting manner, wherein the upper part of the gasoline tank is provided with an oil inlet; the upper part of the gasoline tank and the lower part of the gasoline tank are made of a glass fiber reinforced plastic material; a joint adopts a glass fiber reinforced plastic hand lay-up process, and adopts 400g / m<2> of glass fiber woven roving to perform hand lay-up connection in a sealing manner. The forming method comprises the following steps that (1) an upper die of the gasoline tank and a lower die of the gasoline tank are sprayed with gel coat for curing; (2) a layer of 1100g / m<2> of combination mat and a layer of 1080g / m<2> of sandwich felt are respectively laid at the interiors of the upper die of the gasoline tank and the lower die of the gasoline tank in sequence after the gel coat is cured; (3) UPR (unsaturated polyester resin) is introduced into the combination mat and the sandwich felt by utilizing a vacuum bag molding process; (4) demoulding is respectively performed after curing to obtain split upper part of the gasoline tank and the lower part of the gasoline tank; (5) the upper part of the gasoline tank and the lower part of the gasoline tank are connected in a butting manner, and are connected in a sealing manner by adopting the 400g / m<2> of glass fiber woven roving through the hand lay-up process; (6) burrs polishing are performed.

Owner:EULIKIND TIANJIN TECH

Isoplanar field oxidation isolation structure and forming method thereof

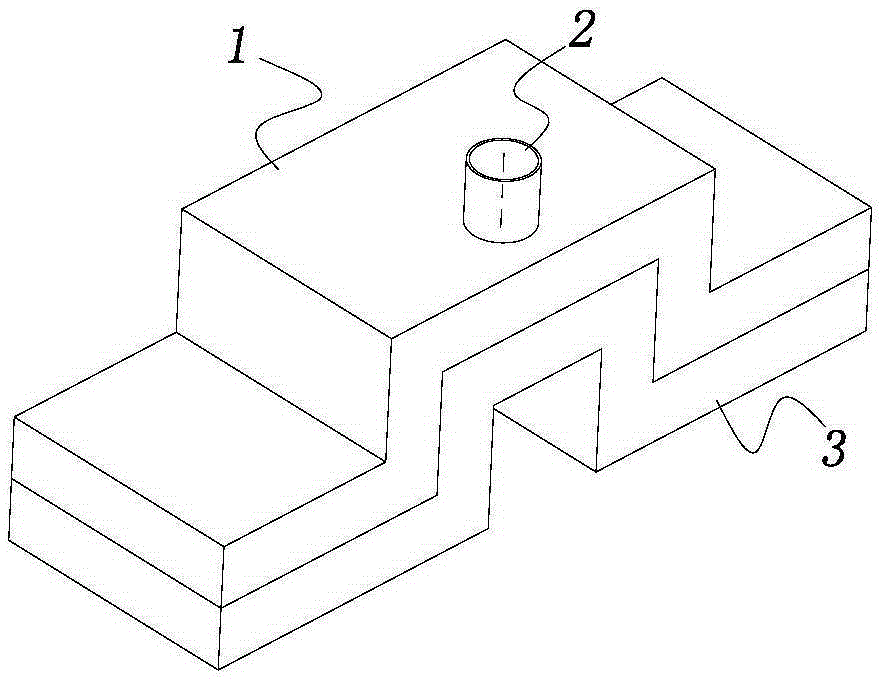

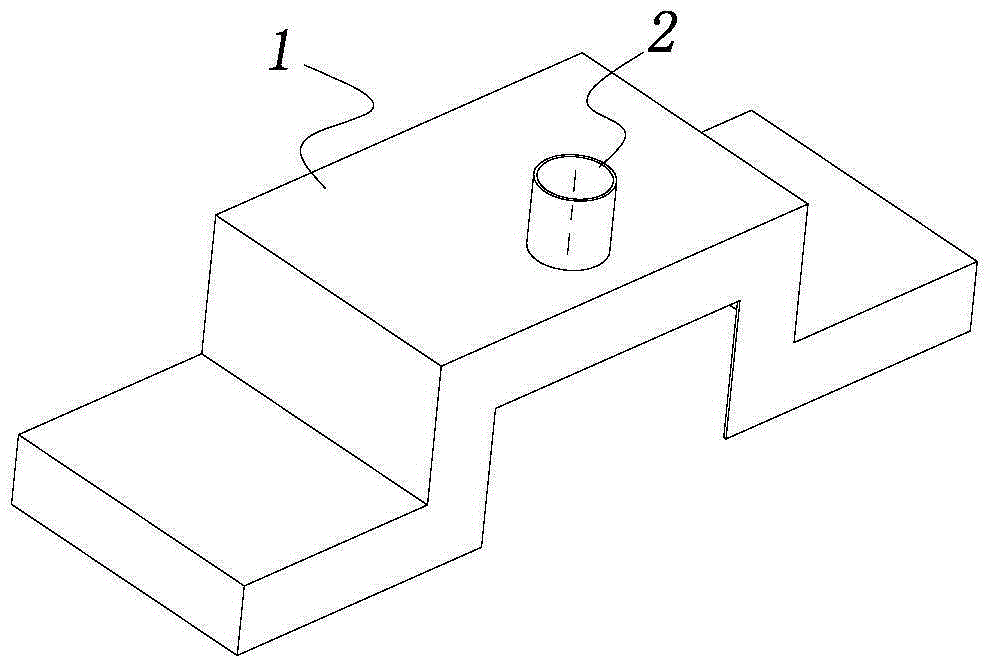

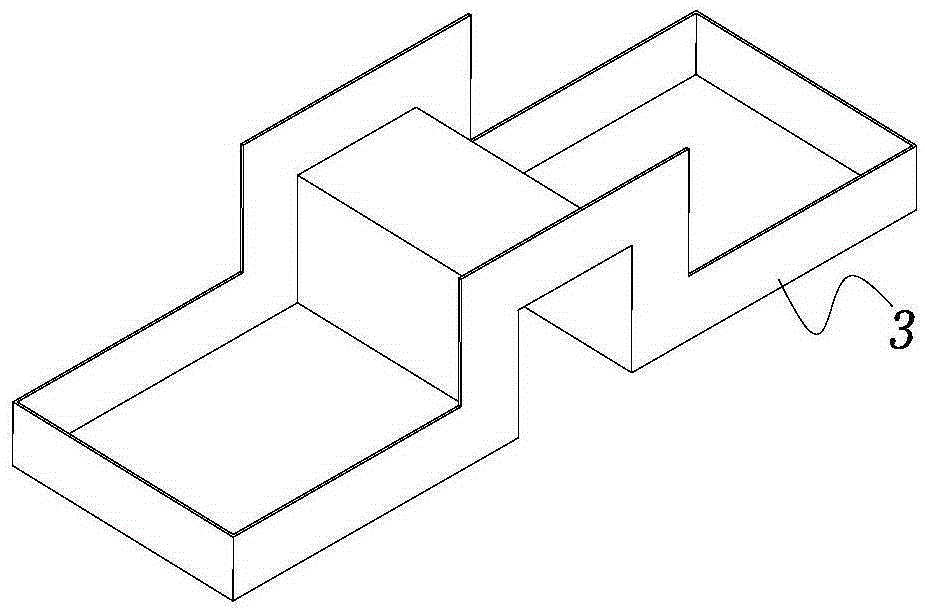

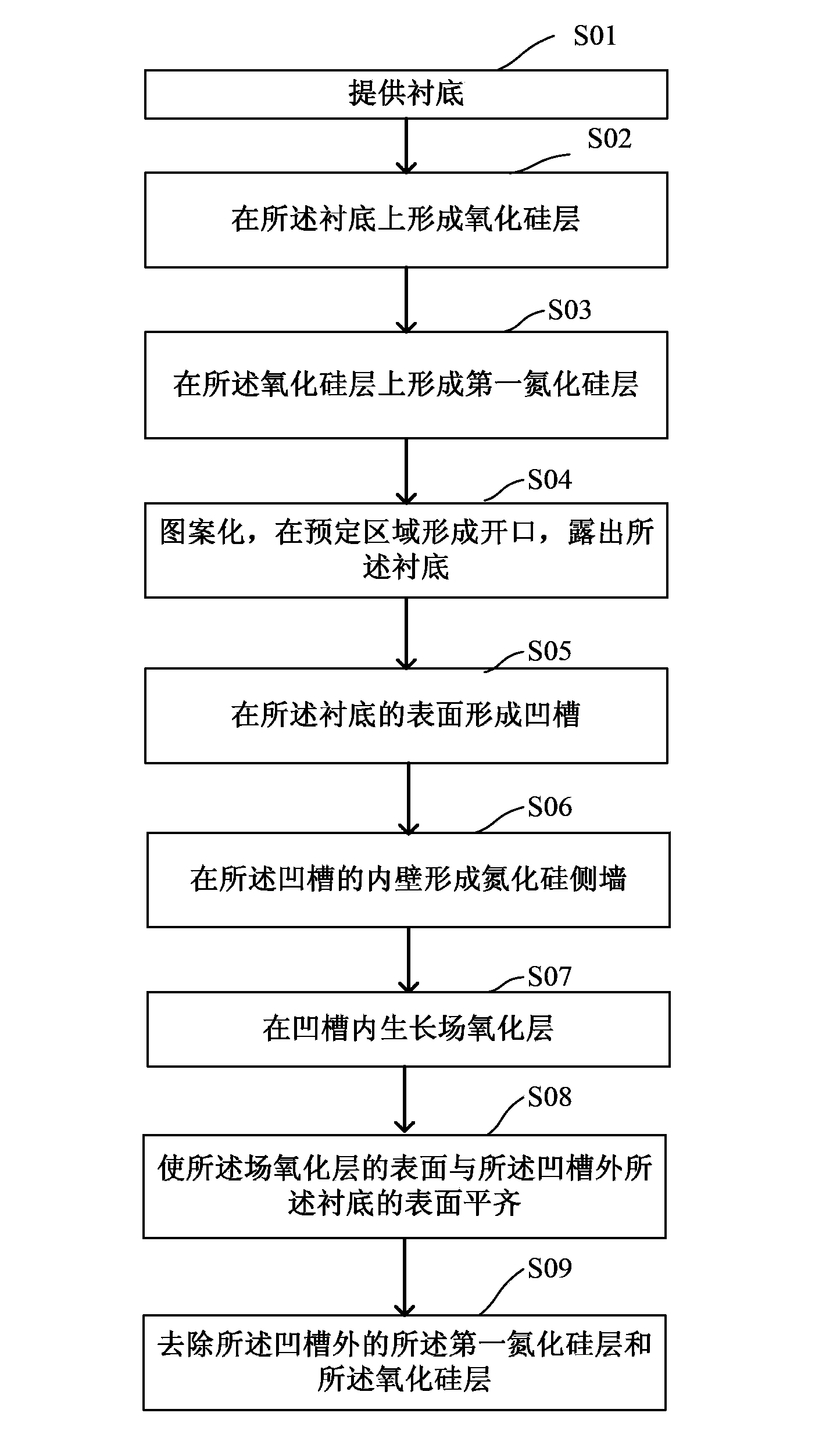

ActiveCN103855072APrevent lateral oxidationEasy to formSemiconductor/solid-state device manufacturingSilicon oxideOptoelectronics

Provided are an isoplanar field oxidation isolation structure and a forming method thereof. The method comprises the steps of providing a substrate, forming a silicon oxide layer on the substrate, forming a first silicon nitride layer on the silicon oxide layer, carrying out patterning, forming slots in preset areas to expose the substrate, removing the substrate parts in the slots to form grooves, forming silicon nitride side walls on the inner walls of the grooves, growing field oxide layers in the grooves, enabling the surfaces of the field oxide layers to be flushed with the surface of the substrate outside the grooves, and removing the first silicon nitride layer and the silicon oxide layer outside the grooves. According to the forming method of the isoplanar field oxidation isolation structure, the isoplanar field oxidation isolation structure can be obtained, meanwhile, the silicon nitride side walls are formed on the inner walls of the grooves, transverse peroxidation can be prevented, and the area of an active area is maintained the same.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

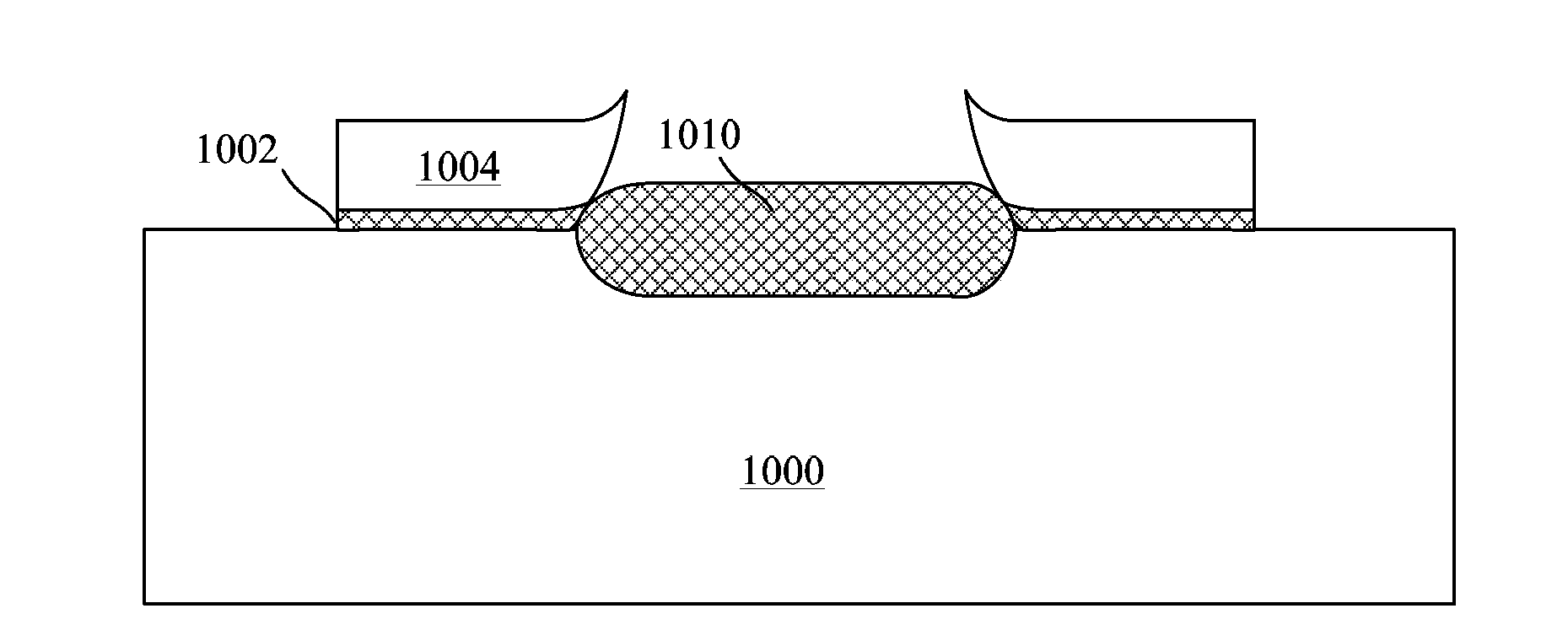

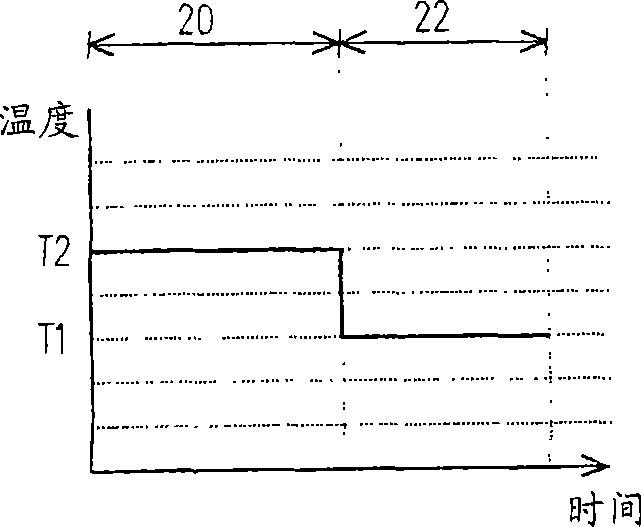

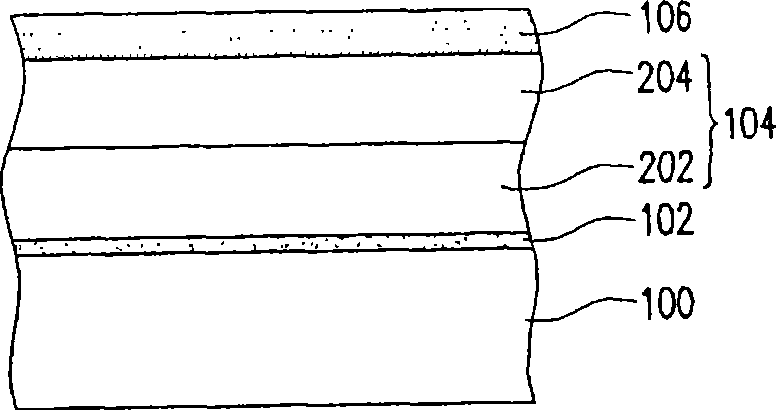

Dielectric layer of ultra-low dielectric constant and forming method thereof

ActiveCN101393865AReduce tensile stressGood electrical performance and reliabilitySemiconductor/solid-state device detailsSolid-state devicesLow-k dielectricOptoelectronics

The invention relates to a method for forming an ultra-low dielectric constant dielectric layer. The method is characterized in that the reaction of a dielectric substratum added for deposition is triggered by the regulation of temperature-varying program or pressure-varying program in the process of deposition so as to allow the ultra-low dielectric constant dielectric layer, which is porous, multi-layered and provided with a density gradient, to be formed on the barrier layer of the substratum.

Owner:UNITED MICROELECTRONICS CORP

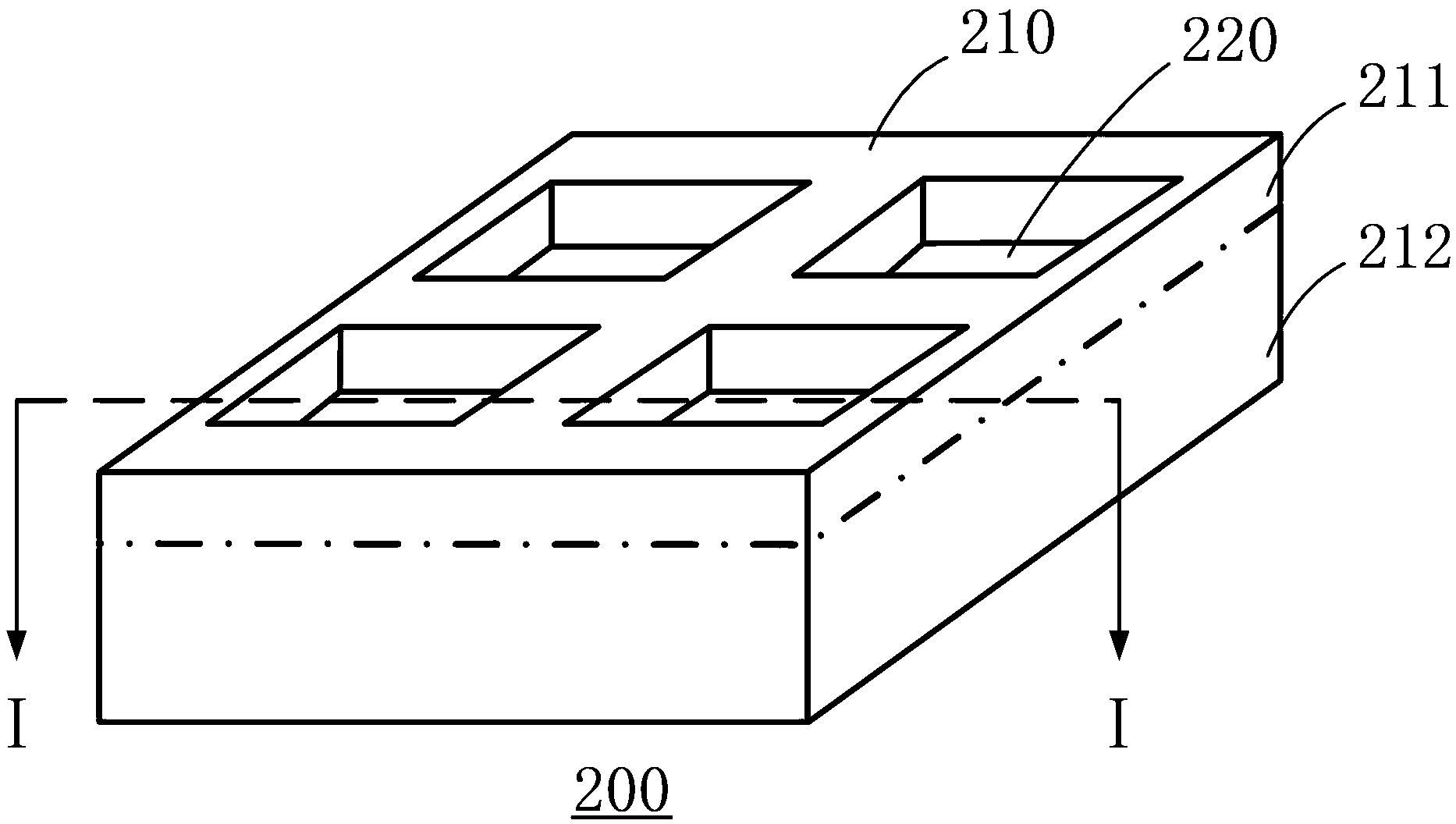

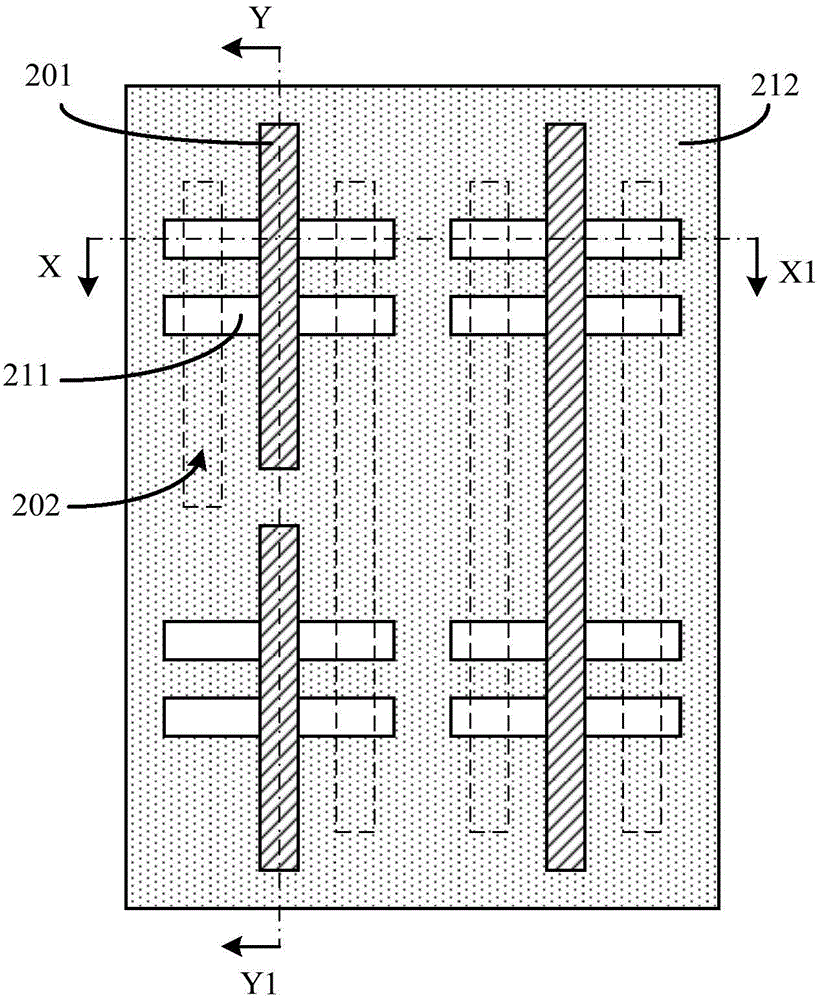

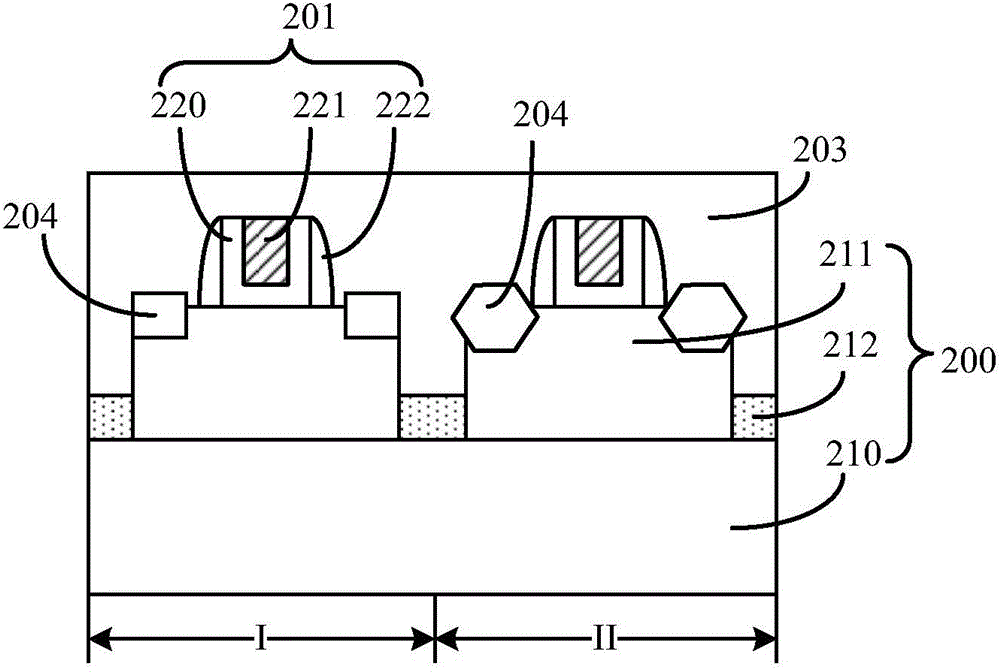

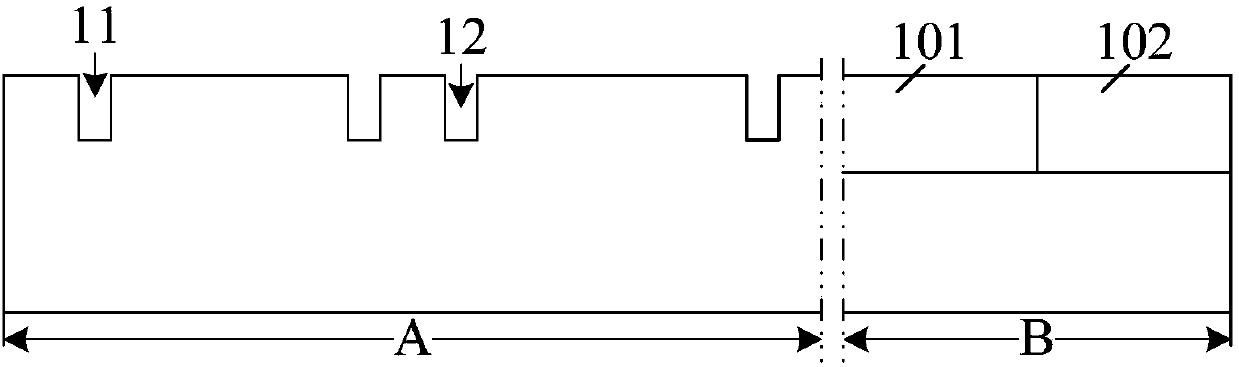

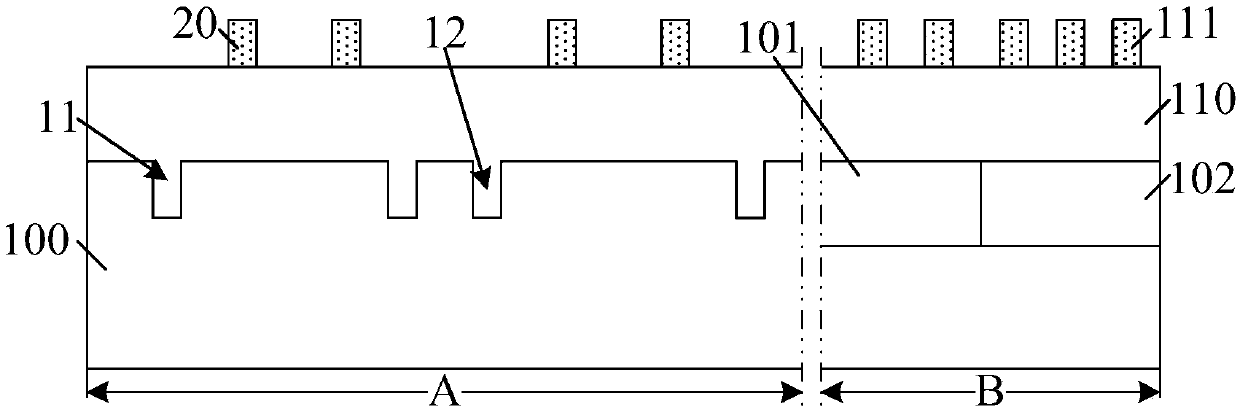

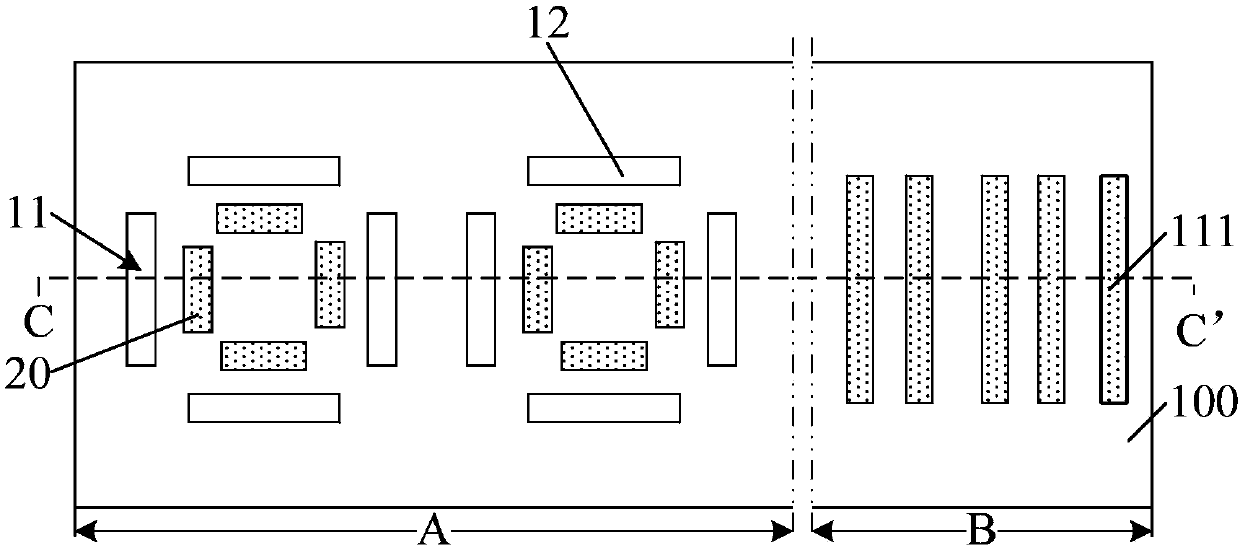

Semiconductor structure and forming method thereof

ActiveCN110034097AEasy to formSimplifies alignment,Semiconductor/solid-state device detailsSolid-state devicesSemiconductor structureEngineering

The invention discloses a semiconductor structure and a forming method thereof. The method comprises the following steps: forming a first device structure and a second device structure in a device region, and forming a mark structure in the mark region, wherein the mark region has a first rotating center, the mark region comprises a plurality of mark parts, each marking part comprises a first branch part and a second branch part, and the first branch parts are used for marking a first device, and the second branch parts are used for marking a second device structure; and forming a first graphical layer on the device region, and forming a test mark on the mark region. The forming method can improve the performance of the formed semiconductor structure.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

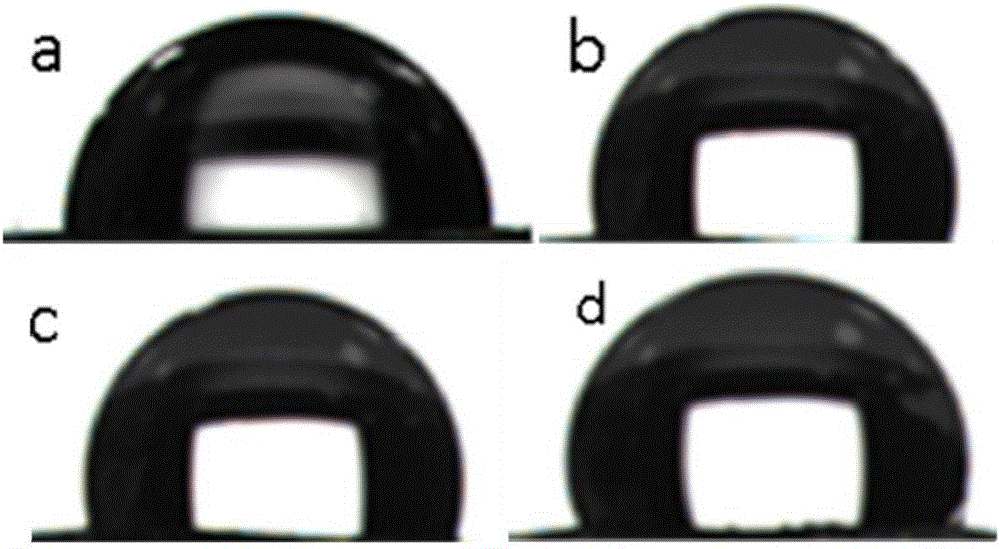

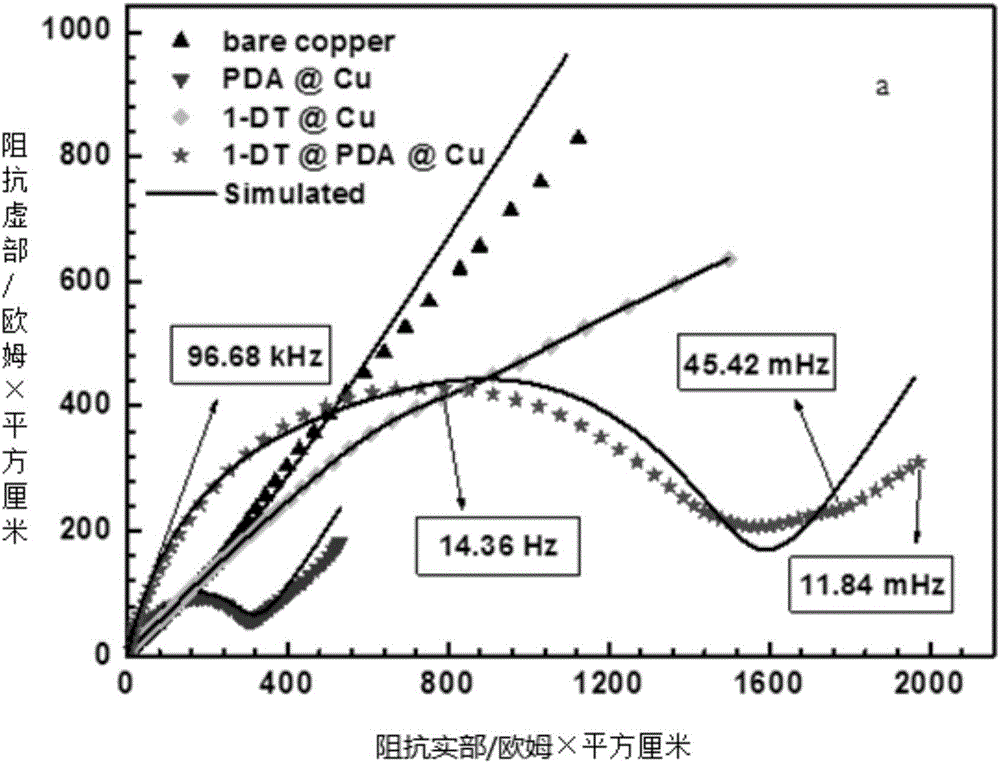

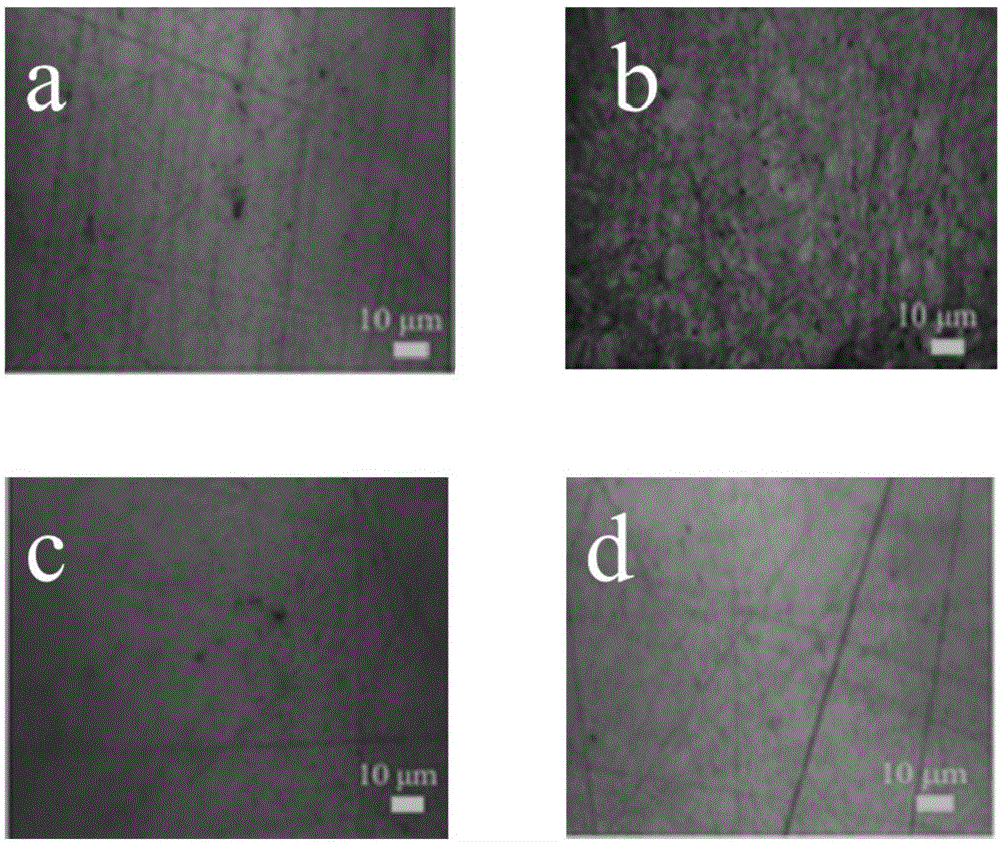

Preparation method for corrosion-resistant hydrophobic film on metal surface

InactiveCN106367753AReduce lossesHigh corrosion inhibition efficiencyMetallic material coating processesCopperPre treatment

The invention relates to a preparation method for a corrosion-resistant hydrophobic film on a metal surface. The preparation method comprises the following steps: (1) placing a pretreated metal electrode into a tris(hydroxymethyl)aminomethane buffer solution of dopamine (PDA), soaking the metal electrode and then taking the metal electrode out for cleaning; and (2) then hermetically soaking the metal electrode in a dodecylthiol (1-DT) solution so as to form the corrosion-resistant hydrophobic film on the surface of the metal electrode. Compared with the prior art, the invention has the advantages that in virtue of the viscosity of PDA and the hydrophobicity of 1-DT, PDA and 1-DT act on the surfaces of metals like copper through self-polymerization and self-assembling to inhibit corrosion of the surfaces; and the preparation method for the hydrophobic film is simple, time-saving, environment-friendlier, etc.

Owner:SHANGHAI NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com