Silica-coated quantum dots and preparation method thereof

A technology of silica and quantum dots, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of quantum dot fluorescence efficiency reduction, surface defect quenching fluorescence efficiency, etc., and achieve good photostability and chemical stability, The formation method is simple and the effect of high quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Silica-coated methylamino lead bromide (CH 3 NH 3 PbBr 3) preparation of quantum dots

[0031] Add a certain amount of methyl orthosilicate to 20mL containing CH 3 NH 3 PbBr 3 Quantum dots were analyzed in pure toluene colloidal solution. Among them, CH 3 NH 3 PbBr 3 The concentration of quantum dots is 0.64mg / mL, the added methyl orthosilicate and CH 3 NH 3 PbBr 3 The mass ratio of quantum dots is 1.7:1. The quantum dot colloid solution obtained above was introduced into a flask sealed with a rubber stopper, and stirred at 25 °C for 12 and 36 hours, respectively, to obtain silica-coated CH 3 NH 3 PbBr 3 Quantum dot nanoparticles.

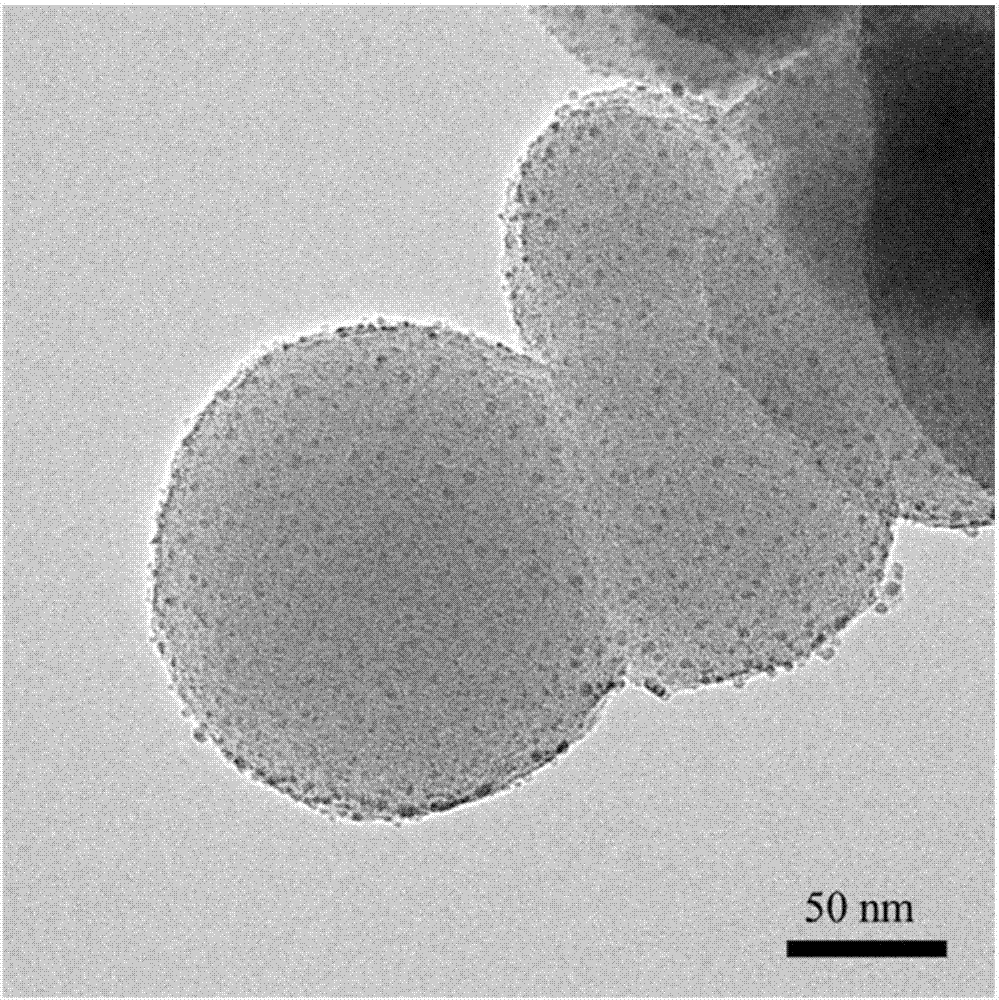

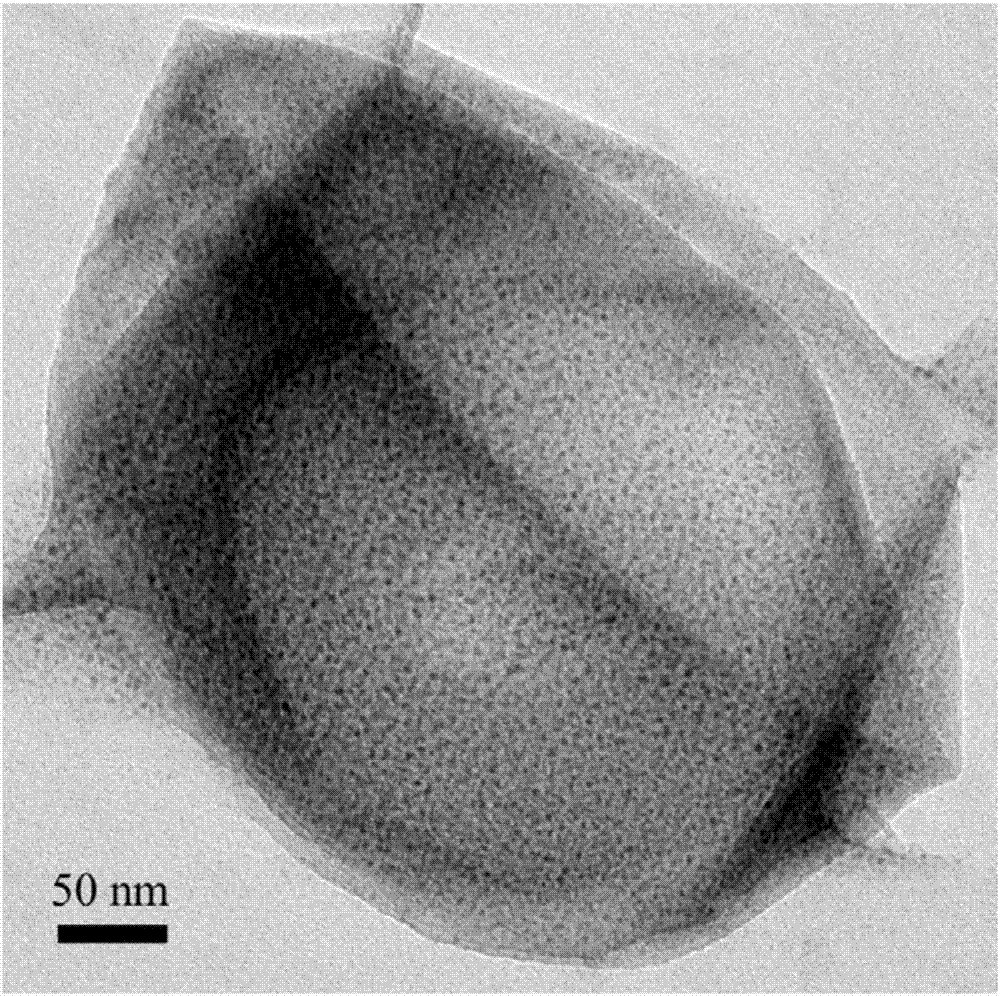

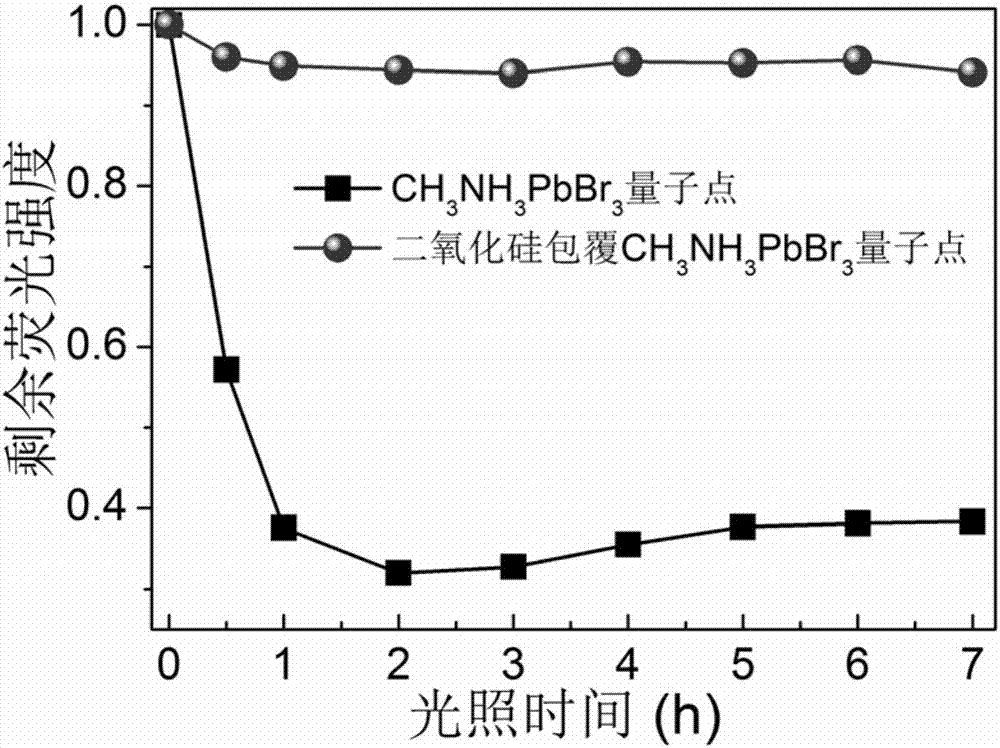

[0032] Silica-coated CH obtained by stirring for 12 hours 3 NH 3 PbBr 3 The TEM morphology of quantum dots is as follows: figure 1 As shown, many CH 3 NH 3 PbBr 3 The quantum dots have been coated with silica and embedded in large silica spheres (approximately 150nm in diameter). When the stirring time is extended to 3...

Embodiment 2

[0035] Preparation of SiO2-coated Cadmium Selenide / ZnS (CdSe / ZnS) Quantum Dots

[0036] A certain amount of methyl orthosilicate was added to 50 mL of completely anhydrous toluene colloidal solution containing CdSe / ZnS quantum dots. Wherein, the concentration of CdSe / ZnS quantum dots is 300 mg / mL, and the mass ratio of added tetraethyl orthosilicate to CdSe / ZnS quantum dots is 10:1. The quantum dot colloid solution obtained above was introduced into an open flask, and stirred at 25°C for 500 hours respectively to obtain CdSe / ZnS quantum dot nanoparticles wrapped in silicon dioxide.

[0037] The pure CdSe / ZnS quantum dot colloid solution and the silica-wrapped CdSe / ZnS quantum dot sample were vacuum-filled at 50°C for 1 hour to obtain pure CdSe / ZnS quantum dot powder and silica-wrapped CdSe / ZnS quantum dots. Dot powder. Take a certain mass of these two powders to adjust to the same absorbance and place them on the Ocean Optics spectrometer (LS-450) for photostability testing....

Embodiment 3

[0039] Preparation of SiO2-coated Cadmium Selenide / Cadmium Sulfide (CdSe / CdS) Quantum Dots

[0040] Equal moles of ethyl orthosilicate and N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane were added to 30 mL of analytical grade n-hexane colloidal solution containing CdSe / CdS quantum dots. Wherein, the concentration of CdSe / CdS quantum dots is 50 mg / mL, and the mass ratio of the added silylating agent to CdSe / CdS quantum dots is 4:1. The quantum dot colloid solution obtained above was introduced into a polytetrafluoroethylene hydrothermal reaction kettle, and kept at 180° C. for 2 hours to obtain CdSe / CdS quantum dot nanoparticles wrapped in silica.

[0041] Vacuumize the pure CdSe / CdS quantum dot colloid solution and the silica-wrapped CdSe / CdS quantum dot sample at 50°C for 30 minutes to obtain pure CdSe / CdS quantum dot powder and silica-wrapped CdSe / CdS quantum dots. Dot powder. Take a certain mass of these two powders and adjust them to have the same absorbance and place th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com