Cyclic utilization method and apparatus of lead dioxide from storage cells

A technology of lead dioxide and battery, applied in battery recycling, recycling technology, recycling by waste collectors, etc., can solve the problems of increased pollution, high cost, and increased capital costs, and achieve low facility investment, low cost, and high production capacity big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Remove the scrap battery plate, carefully separate the positive plate from the negative plate, dry the positive plate at 90°C, take out the positive plate when the moisture content is less than 10wt%, and manually knock off the lead paste on the plate to make The grid is separated from the lead paste, and when the lead dioxide powder is collected, it is pulverized with a roller mill, and the particle size is passed through a 300-mesh sieve, and the 5wt% of the lead powder amount is added in the lead powder when mixing the paste.

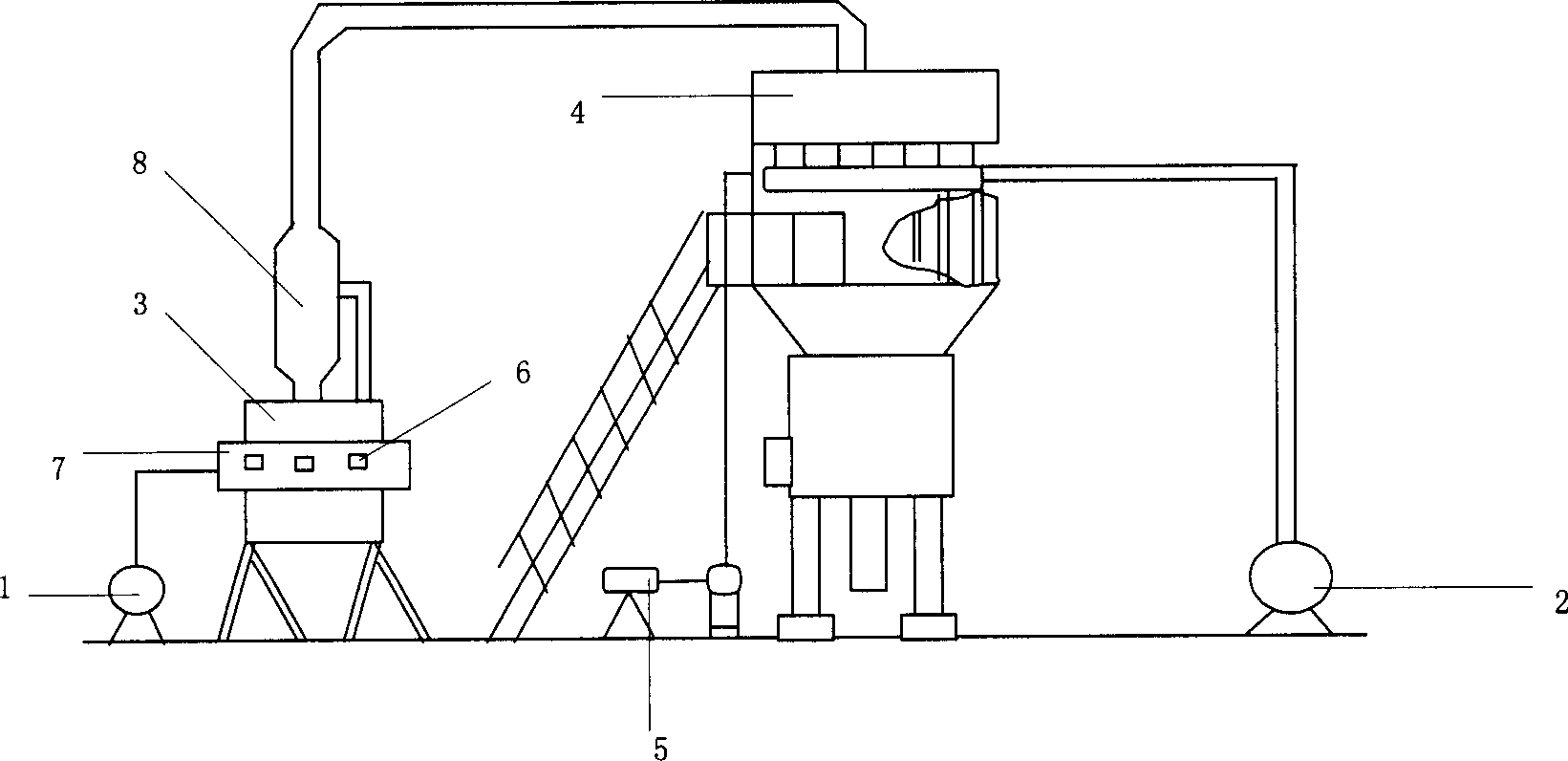

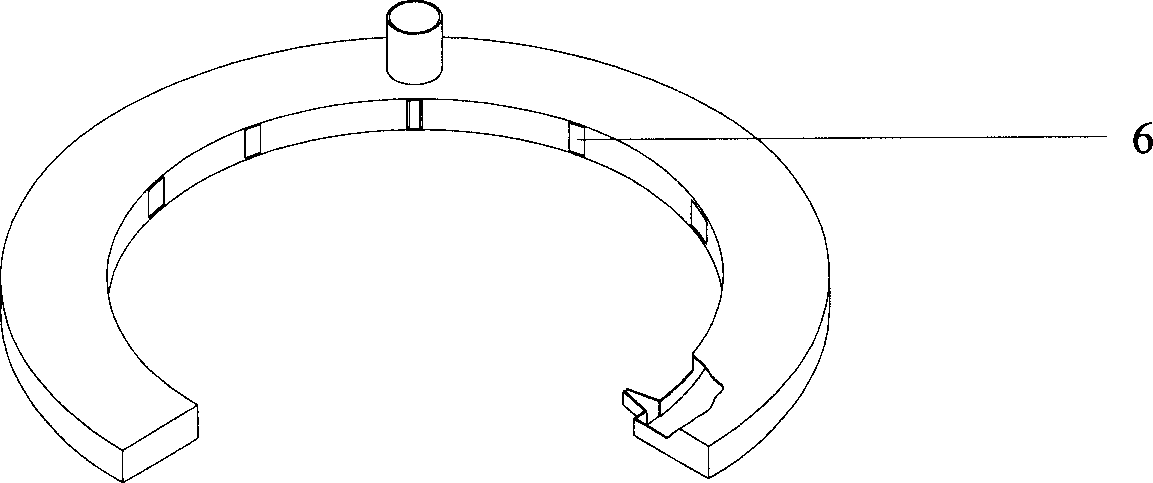

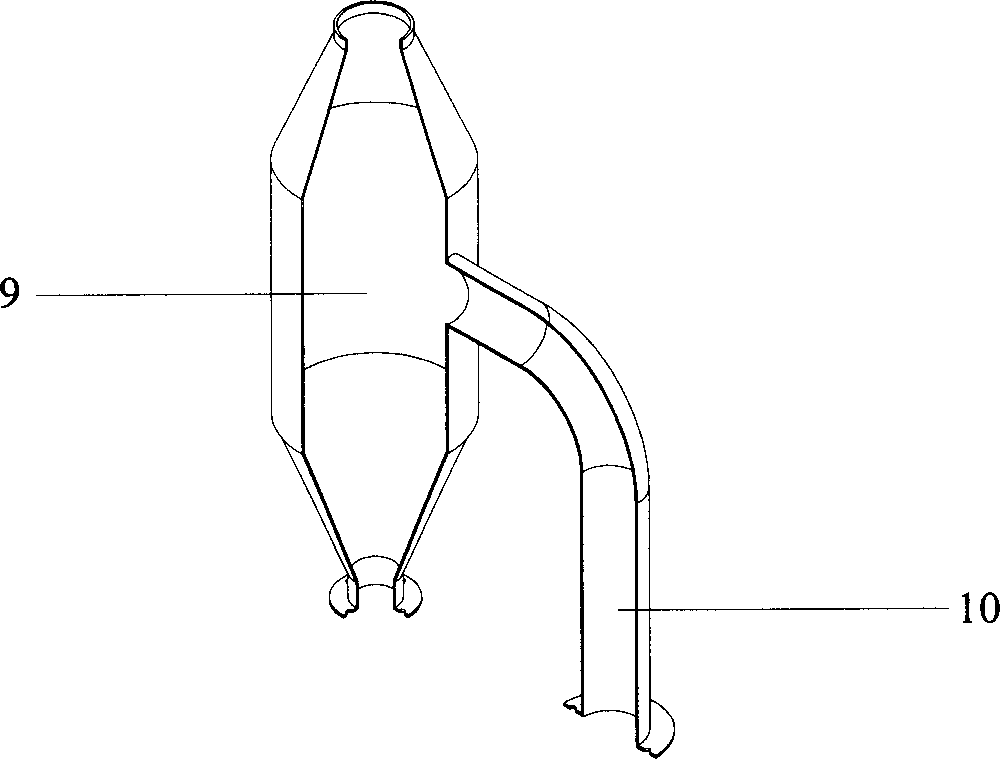

[0033] Such as figure 1 As shown, the device is composed of a positive pressure fan 1, a negative pressure fan 2, a roller mill 3, a powder collector 4, an air compressor 5, an air nozzle 6 and a separator 8. The positive pressure fan 1 is directly connected with the roller mill 3, and the negative pressure fan communicates with the roller mill 3 through the powder collector 4, the pipeline and the separator 8. An air compressor 5 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com