Process for preparing Cu2ZnSnS4 semiconductor thin film solar cell

A solar cell and semiconductor technology, applied in semiconductor devices, sustainable manufacturing/processing, circuits, etc., can solve problems such as complex processes, and achieve the effects of easy formation, simple operation and use, and avoiding the loss of elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

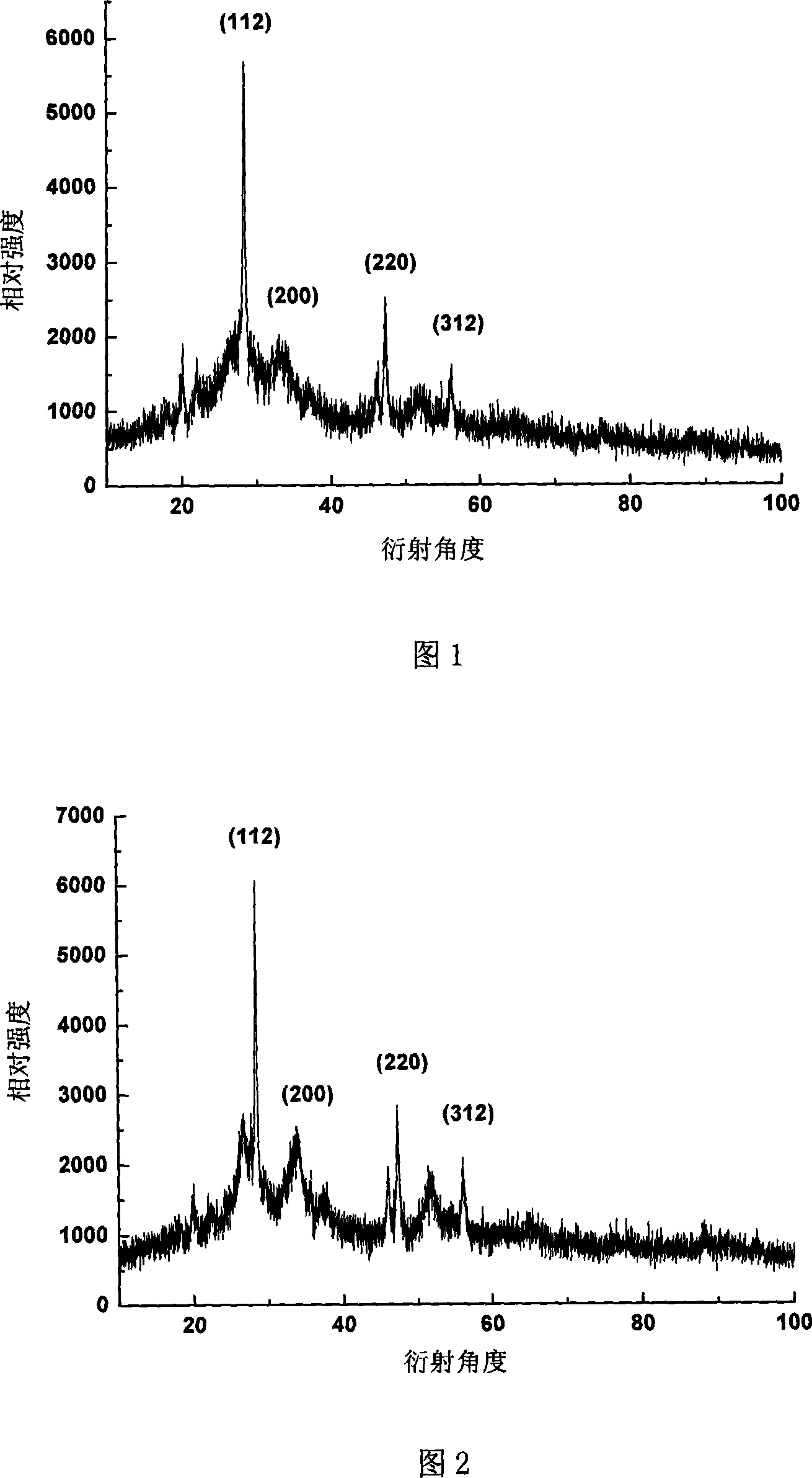

[0021] Example 1: Cu 2 ZnSnS 4 N of the absorbing layer 2 Atmosphere (350°C) preparation

[0022] (1) Place the molybdenum sheet (or conductive glass) coated with the slurry in a resistance furnace and pass N 2 Exclude air for fifteen minutes, then preheat at 50°C for ten minutes.

[0023] (2) Raise the temperature to 200°C at a rate of 10°C / min, and keep it warm for one hour.

[0024] (3) Heat up from 200°C to 350°C at a rate of 2°C / min, keep warm for two hours, then cool to room temperature with the furnace and take out to obtain a blue-black absorption layer.

example 2

[0025] Example 2: Cu 2 ZnSnS 4 N of the absorbing layer 2 Atmosphere (400°C) preparation

[0026] (1) Place the molybdenum sheet (or conductive glass) coated with the slurry in a resistance furnace and pass N 2 Exclude the air for fifteen minutes, then preheat at 50°C for ten minutes.

[0027] (2) Raise the temperature to 200°C at a rate of 10°C / min, and keep it warm for one hour.

[0028] (3) Heat up from 200°C to 400°C at a rate of 2°C / min, keep warm for two hours, then cool to room temperature with the furnace and take out to obtain a blue-black absorption layer.

example 3

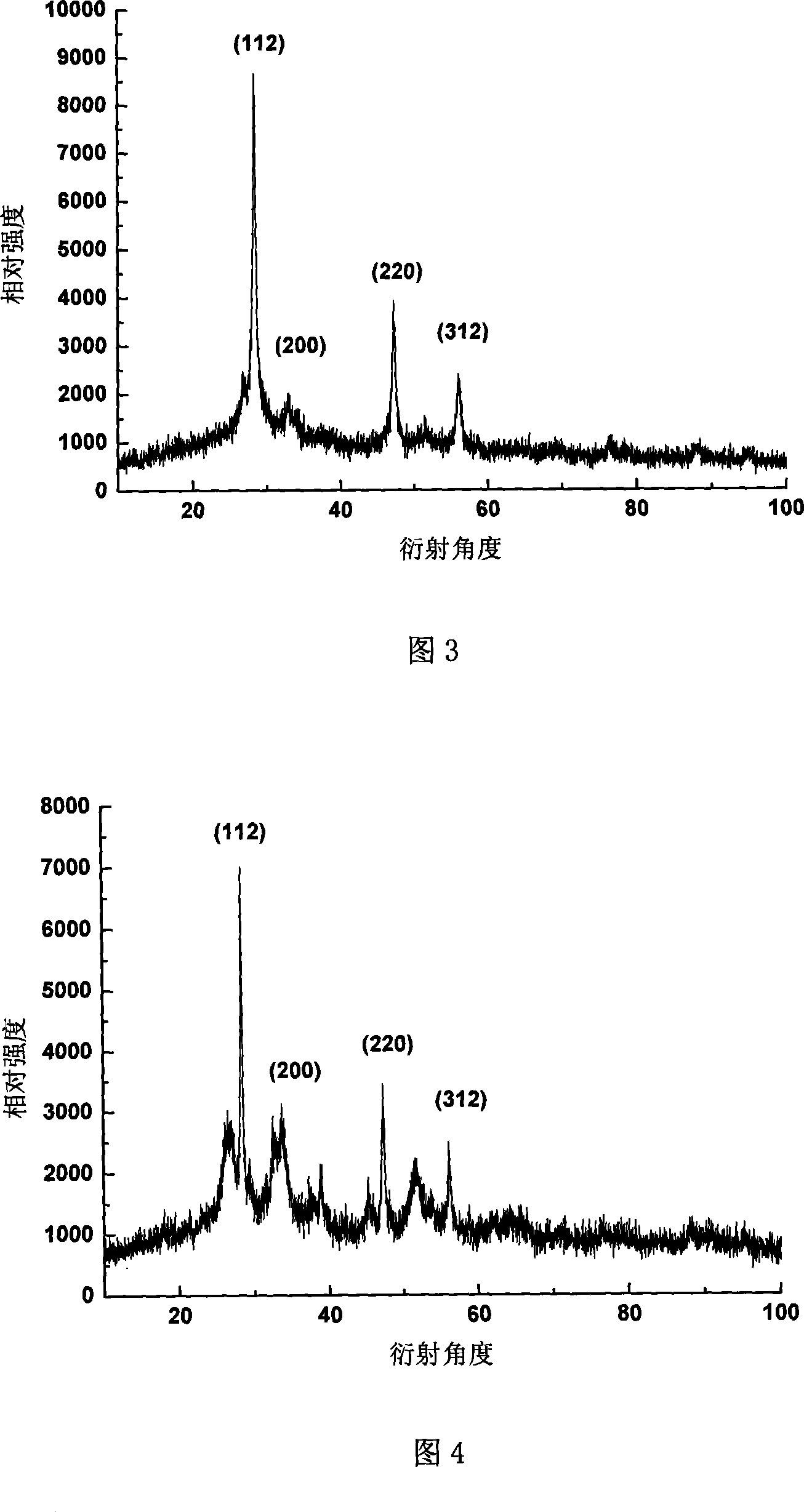

[0029] Example 3: Cu 2 ZnSnS 4 H of the absorbing layer 2 Atmosphere (350°C) preparation

[0030] (1) Place the molybdenum sheet (or conductive glass) coated with the slurry in a resistance furnace and pass through H 2 Exclude the air, check the purity three times, and then preheat at 50°C for ten minutes.

[0031] (2) Raise the temperature to 200°C at a rate of 10°C / min, and keep it warm for one hour.

[0032] (3) Heat up from 200°C to 350°C at a rate of 2°C / min, keep warm for two hours, then cool to room temperature with the furnace and take out to obtain a blue-black absorption layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com