Concrete curb prepared from ardealite-based hydraulic composite cementing material and preparation method of concrete curb

A technology of composite cementitious material and phosphogypsum, applied in the field of building materials, can solve problems such as unsuitability for use, and achieve the effects of saving natural resources, excellent mechanical properties and durability, and quick and convenient molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

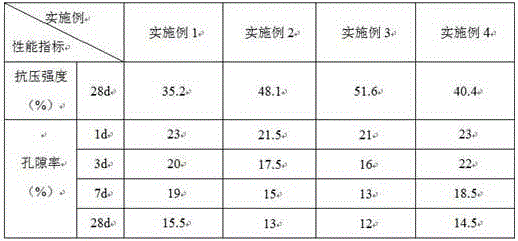

[0047] Example 1, a concrete curb prepared by using phosphogypsum-based hydraulic composite cementitious material, according to S95 blast furnace slag powder 100, phosphogypsum 25, cement 5, limestone 2.2, anhydrous gypsum 3.5, Na 2 SO 4 1.5, water reducer 1.89, metakaolin 1.1, CaF 2 0.01, the mass ratio of gravel 448, sand 186 is weighed and then mechanically stirred and mixed evenly. Add tap water accounting for 6% of the total weight of raw materials, mechanically stir for 3 minutes, pour into a special mold, and mechanically vibrate for 2 minutes, at 50 o Steam curing at C temperature for 20 hours, demoulding to get the desired product. The performance test results are shown in Table 1.

Embodiment 2

[0048] Example 2, a concrete curb prepared by using phosphogypsum-based hydraulic composite cementitious material, according to S95 blast furnace slag powder 100, phosphogypsum 27.4, cement 6, limestone 2.7, anhydrous gypsum 4, Na 2 SO 4 2.5, water reducer 1.91, metakaolin 1.5, CaF 2 0.02, the mass ratio of gravel 454, sand 189 is weighed and then mechanically stirred and mixed evenly. Add tap water accounting for 8% of the total weight of the raw materials, mechanically stir for 4 minutes, pour into a special mold, and mechanically vibrate for 5 minutes. o Steam curing at C temperature for 25 hours, demoulding to get the desired product. The performance test results are shown in Table 1.

Embodiment 3

[0049] Example 3, a concrete curb prepared by using phosphogypsum-based hydraulic composite cementitious material, according to S105 blast furnace slag powder 100, phosphogypsum 41.6, cement 9, limestone 3.9, anhydrous gypsum 8, Na 2 SO 4 3.2, water reducing agent 2.26, metakaolin 2.1, CaF 2 The mass ratio of 0.04, stone 537, and sand 223 was weighed and then mechanically stirred and mixed evenly. Add tap water accounting for 7% of the total weight of raw materials, mechanically stir for 5 minutes, pour into a special mold, and mechanically vibrate for 4 minutes, at 70 o Steam curing at C temperature for 20 hours, demoulding to get the desired product. The performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com