Graphene load tungsten trioxide (WO3) nanowire composite material and preparation method thereof

A technology of composite materials and nanowires, applied in the field of graphene-loaded WO3 nanowire composite materials and its preparation, to achieve the effects of cheap reagents, simple formation process, and large-scale preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

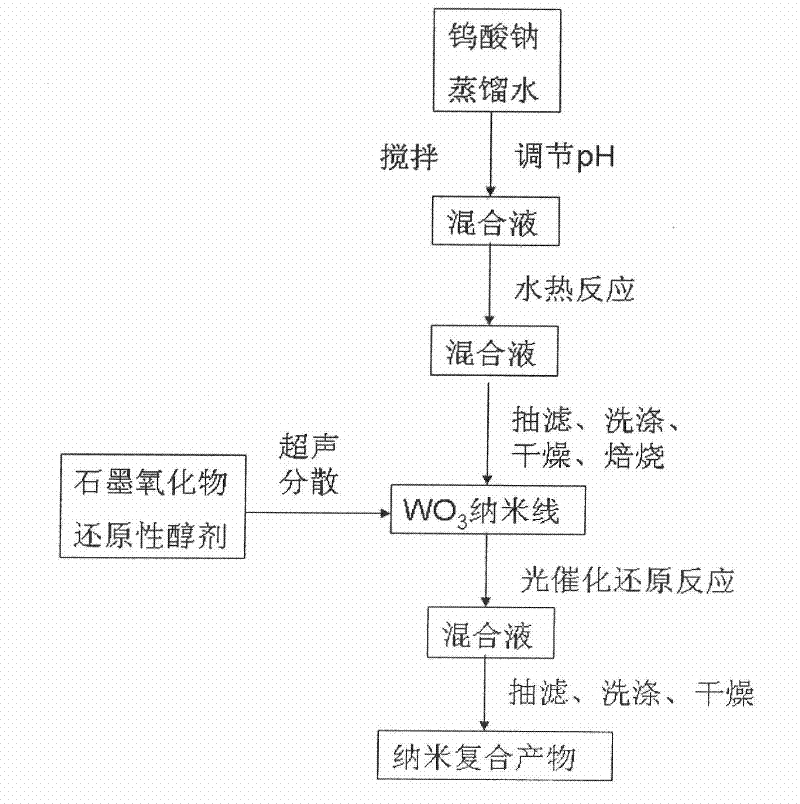

Image

Examples

Embodiment 1

[0035] (1) Preparation of graphite oxide. Add 2g of graphite powder to potassium persulfate (1g) and concentrated sulfuric acid solution (15mL) of phosphorus pentoxide (1g) at 80°C, pre-oxidize for 6 hours, then cool to room temperature, filter with suction, and wash until neutral. Add pre-oxidized graphite powder (2g) to 50mL of concentrated sulfuric acid solution at 0°C, then slowly add 6g of potassium permanganate, then react at 35°C for 2 hours, and finally slowly add 100mL of deionized water and 20mL of 30% hydrogen peroxide terminated the reaction, suction filtered, washed, and dialyzed to obtain graphite oxide, whose XRD pattern is shown in figure 2 ;

[0036] (2) WO 3 Preparation of nanowires. Add 3.32g of sodium tungstate to 60mL of distilled water, stir at room temperature for 10 minutes, then slowly add 6mol / L hydrochloric acid dropwise to adjust the pH of the solution to 1.5, then transfer to a 100mL hydrothermal reactor, and react at 180°C for 24 hours , suct...

Embodiment 2

[0040] (1) with the step (1) in the implementation example 1;

[0041] (2) with the step (2) in the implementation example 1;

[0042] (3) Preparation of graphite oxide dispersion. Ultrasonic disperse 100mg of graphite oxide in 70mL of absolute ethanol for 1.5 hours;

[0043] (4) Combine the WO obtained in step (2) and step (3) 3 The nanowires were mixed with the graphite oxide dispersion, then transferred to a photocatalytic reactor, subjected to photocatalytic reduction under simulated sunlight for 1.5 hours, filtered, washed, and dried in vacuum at 80°C for 12 hours to obtain graphene-loaded WO 3 nanowire nanocomposites.

Embodiment 3

[0045] (1) with the step (1) in the implementation example 1;

[0046] (2) with the step (2) in the implementation example 1;

[0047] (3) Preparation of graphite oxide dispersion. Ultrasonic disperse 200mg of graphite oxide in 70mL of absolute ethanol for 1.5 hours;

[0048] (4) Combine the WO obtained in step (2) and step (3) 3 The nanowires were mixed with the graphite oxide dispersion, then transferred to a photocatalytic reactor, subjected to photocatalytic reduction under simulated sunlight for 1.5 hours, filtered, washed, and dried in vacuum at 80°C for 12 hours to obtain graphene-loaded WO 3 nanowire nanocomposites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com