Preparation method of high-performance carbonized reinforced concrete

A technology for enhancing concrete and high performance, applied in the field of materials, can solve the problems of limited application scope of steel slag products, low mechanical strength of concrete, single means, etc., and achieve the effects of excellent working performance, improved molding method, and huge environmental benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The high-performance carbonation reinforced concrete of the present invention is obtained according to the following process:

[0036]

[0037]

[0038] According to drying time: 28 hours

[0039] Carbonization time: 12 hours;

[0040] Carbonization pressure: 0.3MPa;

[0041] Sand volume fraction: 40%.

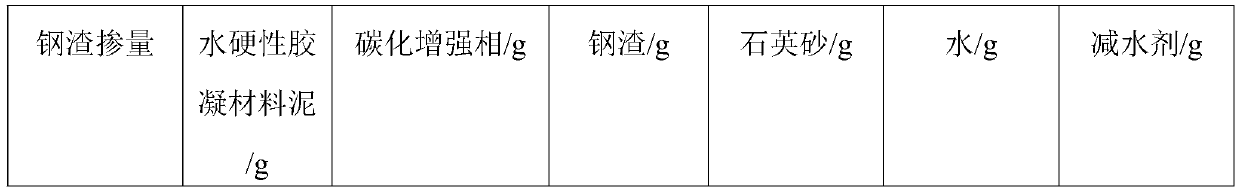

[0042] Raw materials are prepared, and the proportions of four different dosages are: hydraulic cementitious material 157.2, 78.6, 33.3, 0g, steel slag 898.5, 1010.8, 1054.8, 1137.6g, carbonized reinforcing phase 67.4, 33.7, 22.2, 0g, quartz sand Both are 1060g. After dry mixing evenly, add 175.2, 175.2, 176.7, 177.5g of water and 44.9, 44.9, 45.3, 45.5g of water reducing agent to mix, stir evenly, pour into the mold for molding; then Sealed and cured for 24 hours, placed in a drying oven to dry for 28 hours after demoulding; maintained for 12 hours in a carbonization curing room at 20°C, with a relative humidity of 85%, a carbon dioxide concentration of 95%, a...

Embodiment 2

[0045] The high-performance carbonation reinforced concrete of the present invention is obtained according to the following process:

[0046]

[0047] According to the amount of steel slag: 90%;

[0048] Drying time: 27 hours;

[0049] Carbonization time: 12 hours;

[0050] Carbonization pressure: 0.3MPa.

[0051]Prepare raw materials, prepare mortar samples according to the content of each component in the above table, stir evenly, pour into the mold for molding; then seal and maintain for 24 hours, and place it in a drying oven to dry for 27 hours after demoulding;; at 20 ° C, relative humidity 80%, carbon dioxide concentration 99.8%, air pressure 0.4MPa (0.3MPa higher than the external atmospheric pressure) carbonization curing room curing for 12 hours, to obtain composite reinforced carbonized products. After testing, the performance parameters of steel slag products with different aggregate volume fractions are shown in the table below.

[0052] aggregate...

Embodiment 3

[0054] The high-performance carbonation reinforced concrete of the present invention is obtained according to the following process:

[0055]

[0056] According to the amount of steel slag: 80%;

[0057] Drying time: 11 hours;

[0058] Carbonization time: 12 hours;

[0059] Carbonization pressure: 0.1, 0.2, 0.3, 0.4MPa.

[0060] Prepare raw materials, prepare mortar samples according to the content of each component in the above table, stir evenly, pour into the mold for molding; then seal and maintain for 24 hours, and place it in a drying oven to dry for 11 hours after demoulding; at 20°C, relative humidity 60 %, with a carbon dioxide concentration of 99.8%, respectively curing in carbonization curing rooms with air pressures of 0.1, 0.2, 0.3, and 0.4 MPa for 12 hours to obtain composite reinforced carbonized products. After testing, the performance parameters of steel slag products under different carbonization pressures are shown in the table below.

[0061] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com