Technique for extrusion pressing copper stephanoporate sectional material with follow-up composite needle

A combination of needle and hole technology, applied in metal extrusion forming tools, metal extrusion, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The basic design idea of the present invention is embodied in the following aspects.

[0017] One, the present invention has adopted follow-up combined needle.

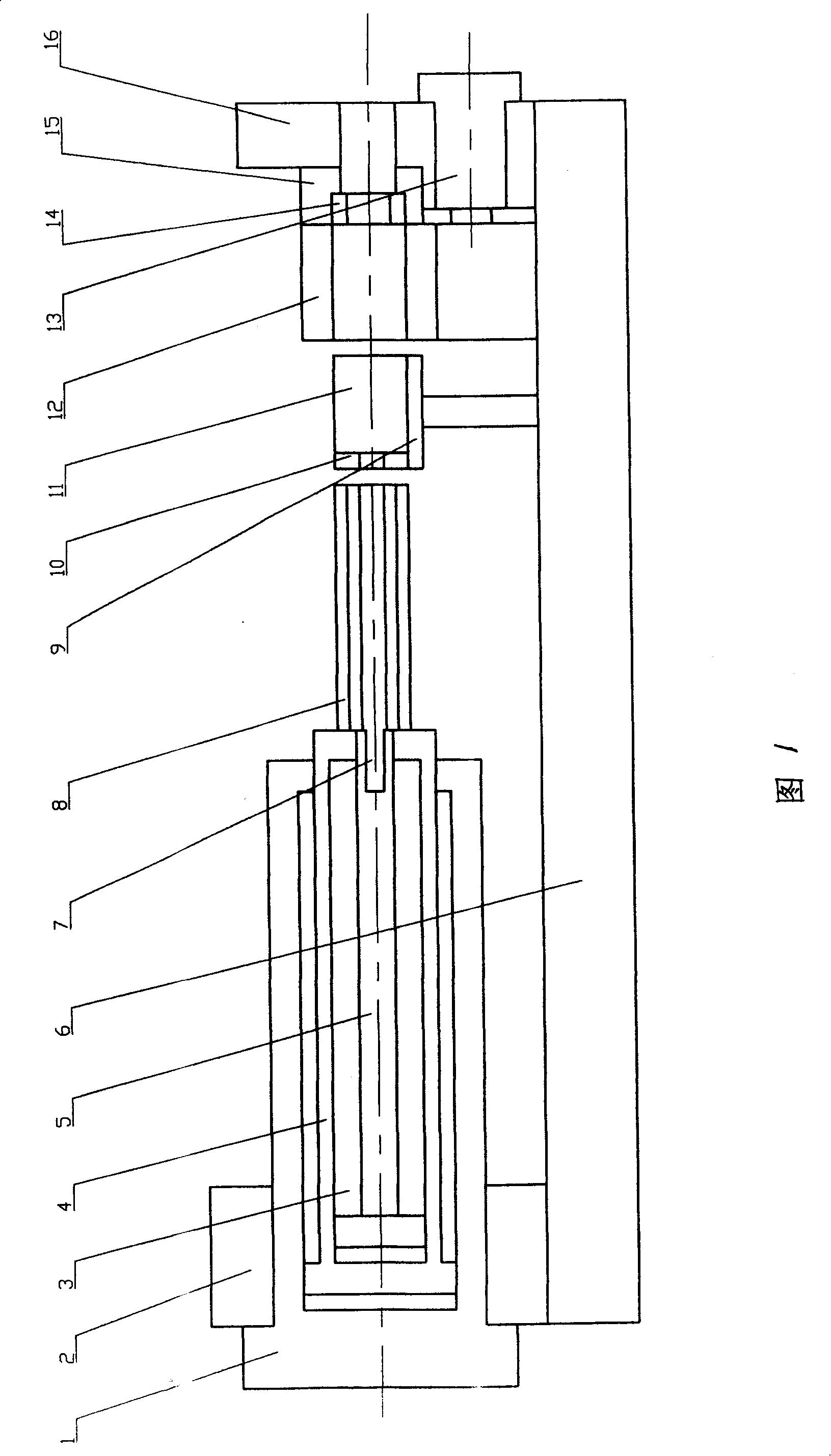

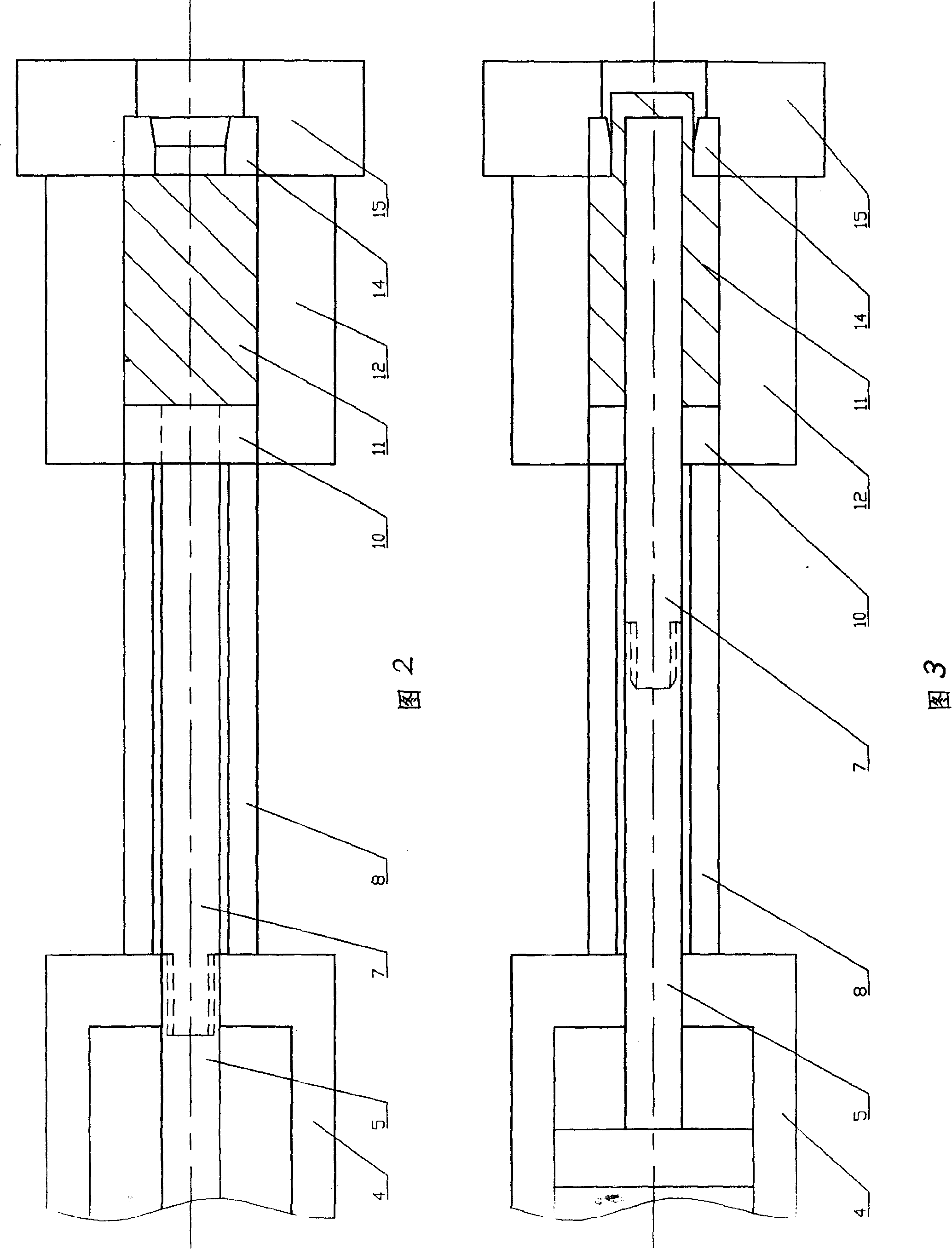

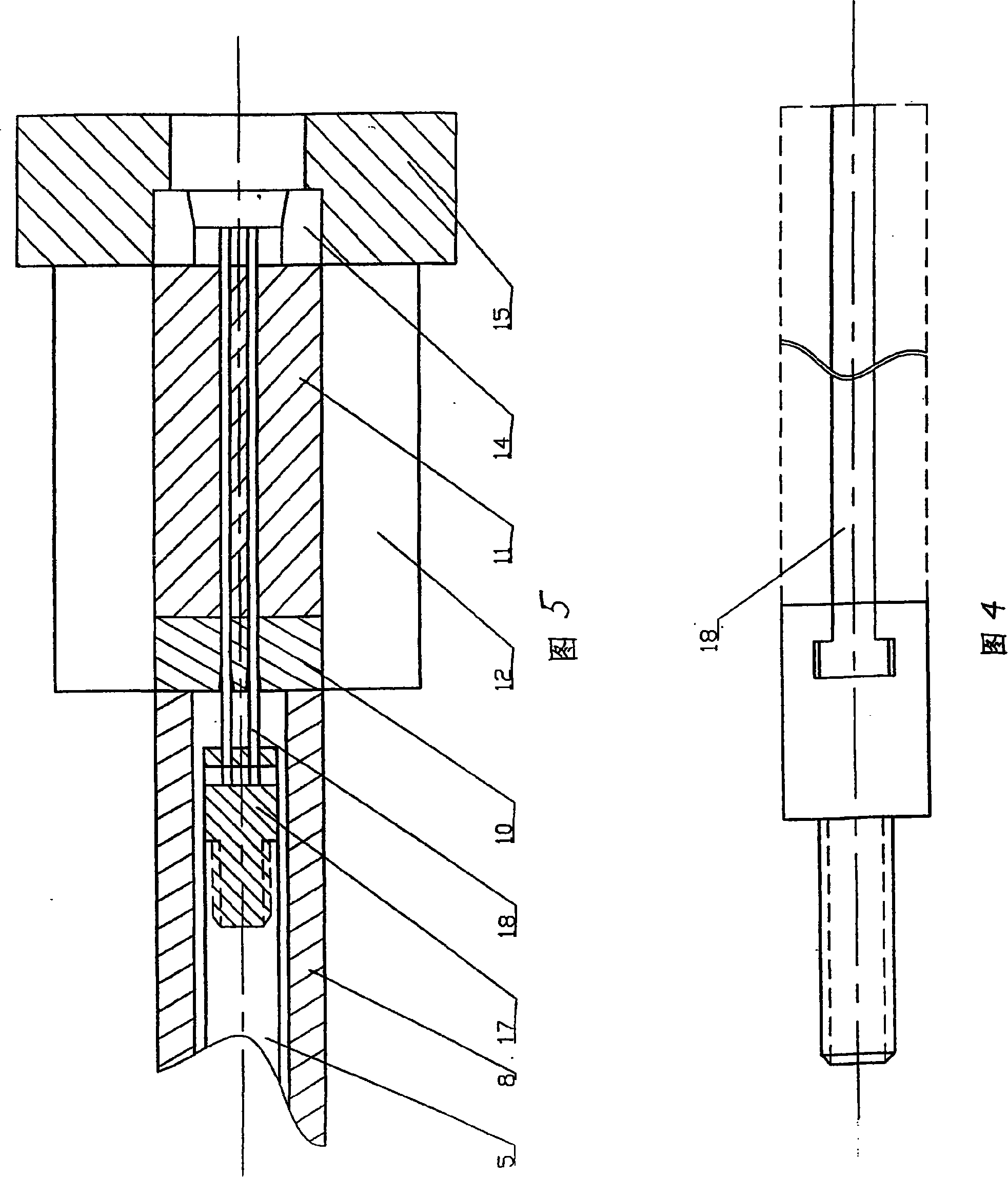

[0018] The perforating needle undertakes two tasks in the production process of the extruder, one is to complete the perforation on the solid ingot (see Figure 3), and the other is to participate in the pipe forming as an internal mold during the extrusion process. When piercing a solid ingot, the perforating needle must bear a lot of pressure. The follow-up extrusion is used as the inner mold, and the perforating needle bears a certain tensile force. Therefore, the perforating needle itself must have a certain strength. The conventional material is hot die steel. If the two functions of the perforating needle are viewed separately, with a thinner perforating needle, the perforating function cannot be realized, but it is completely possible to bear a certain pulling force as the function of the inner mold. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com