High-pressure seamless 10CrNi3MoV steel cylinder and manufacturing process thereof

A manufacturing process and seamless steel technology, applied in the field of 10CrNi3MoV high-pressure seamless steel cylinders and its manufacturing process, can solve the problems of low-temperature toughness of materials, difficulty in process determination, easy cracking, etc., achieve low cooling speed, low price, and prevent brittleness cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

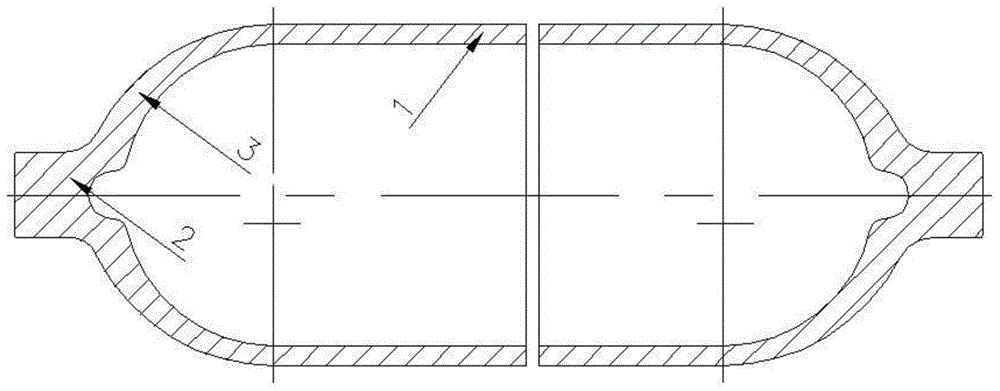

[0037] Cut the 10CrNi3MoV seamless steel pipe into a blank with a length of 3180mm according to the billet specification, and check the surface quality of the steel pipe.

[0038] One end of the blank is heated to 1150°C with the furnace, and the heating length is 350mm.

[0039] Immediately spin the heated blank to close, the spinning spindle speed is 260r / s, the mold rotation center is 40mm higher than the tube blank rotation center, the mold rotation centerline and the tube blank rotation centerline are 90°, and the mold rotates along the mold The center line is rotated 90° once to finish closing, and the time is 130s. The starting temperature of closing is 1100°C. During the spinning process, natural gas nozzles are used to supplement the heat, and after spinning, air-cooling is formed.

[0040] Then the other end of the steel cylinder is closed by hot spinning in the same way. After air cooling, trim and drill the neck of the bottle.

[0041] The above-mentioned steel ...

Embodiment 2

[0044] Cut the 10CrNi3MoV seamless steel pipe into a blank with a length of 3180mm according to the billet specification, and check the surface quality of the steel pipe.

[0045] One end of the blank is heated to 1200°C with the furnace, and the heating length is 400mm.

[0046] Immediately spin the heated blank to close, the spinning spindle speed is 260r / s, the mold rotation center is 40mm higher than the tube blank rotation center, the mold rotation centerline and the tube blank rotation centerline are 90°, and the mold rotates along the mold The center line is rotated 90° once to finish closing, and the time is 150s. The starting temperature of closing is 1150°C. During the spinning process, natural gas nozzles are used to supplement the heat, and after spinning, air-cooling is formed.

[0047] Then the other end of the steel cylinder is closed by hot spinning in the same way. After air cooling, trim and drill the neck of the bottle.

[0048] The above-mentioned steel ...

Embodiment 3

[0051] Cut the 10CrNi3MoV seamless steel pipe into a blank with a length of 3180mm according to the billet specification, and check the surface quality of the steel pipe.

[0052] One end of the blank is heated to 1250°C with the furnace, and the heating length is 400mm.

[0053] Immediately spin the heated blank to close, the spinning spindle speed is 260r / s, the mold rotation center is 40mm higher than the tube blank rotation center, the mold rotation centerline and the tube blank rotation centerline are 90°, and the mold rotates along the mold The center line is rotated 90° once to finish closing, and the time is 150s. The starting temperature of closing is 1200°C. During the spinning process, natural gas nozzles are used to supplement the heat, and after spinning, air-cooling is formed.

[0054] Then the other end of the steel cylinder is closed by hot spinning in the same way. After air cooling, trim and drill the neck of the bottle.

[0055] Heat treatment of the abov...

PUM

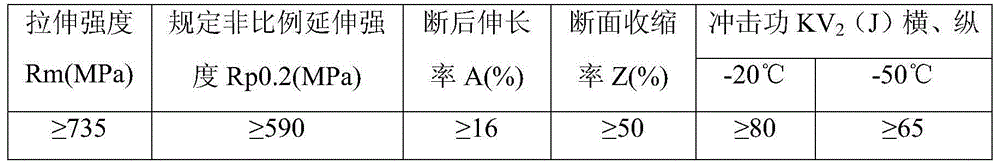

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| brittleness temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com