Waves-absorbing material for Ku waveband radar with film structure

A radar absorbing material and technology of absorbing materials, applied in the field of radar absorbing materials, can solve the problems of high surface density, heavy weight, and unsatisfactory electromagnetic wave absorbing effect of absorbing materials, and achieve high absorbing performance and light weight. , the effect of small overall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

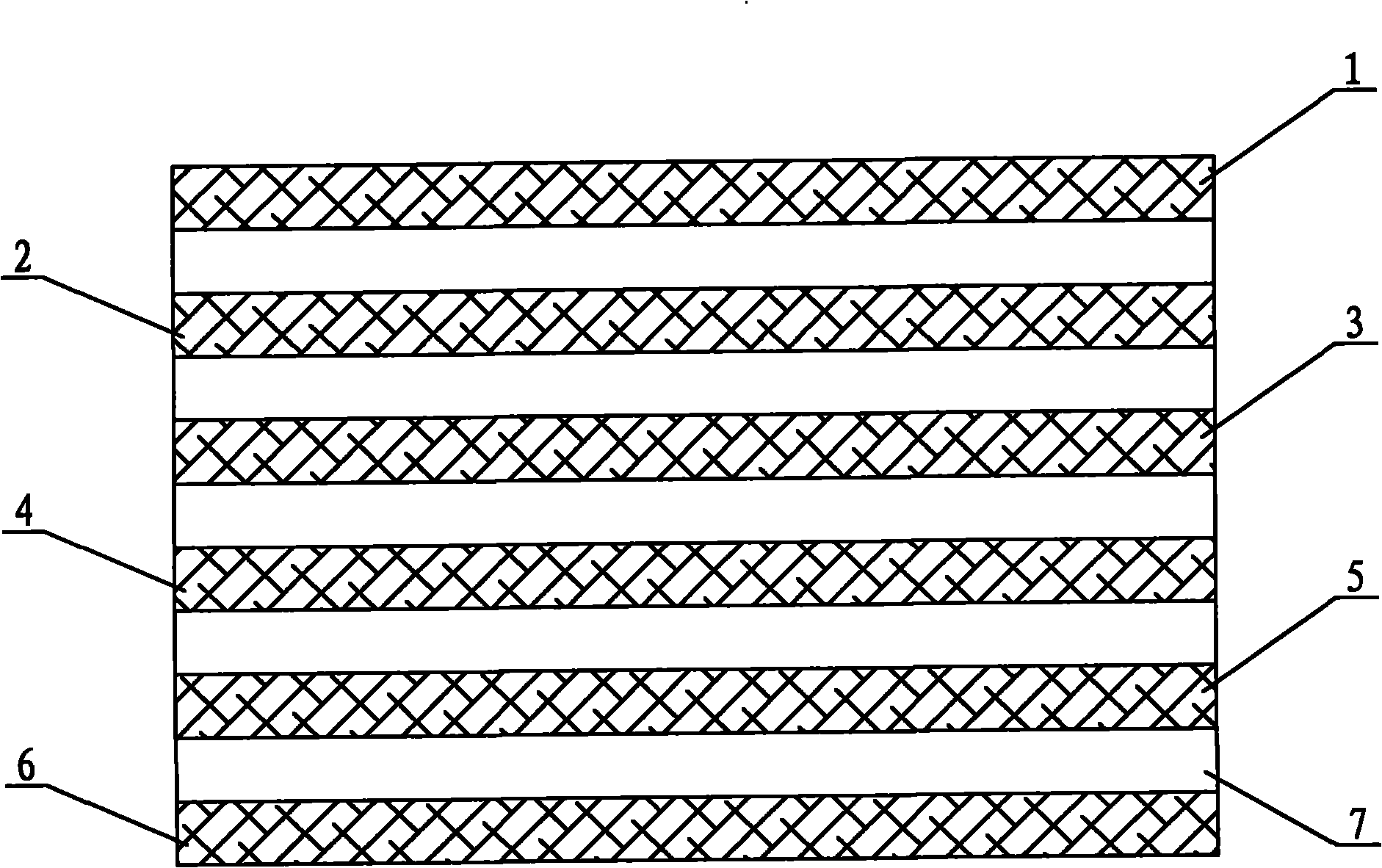

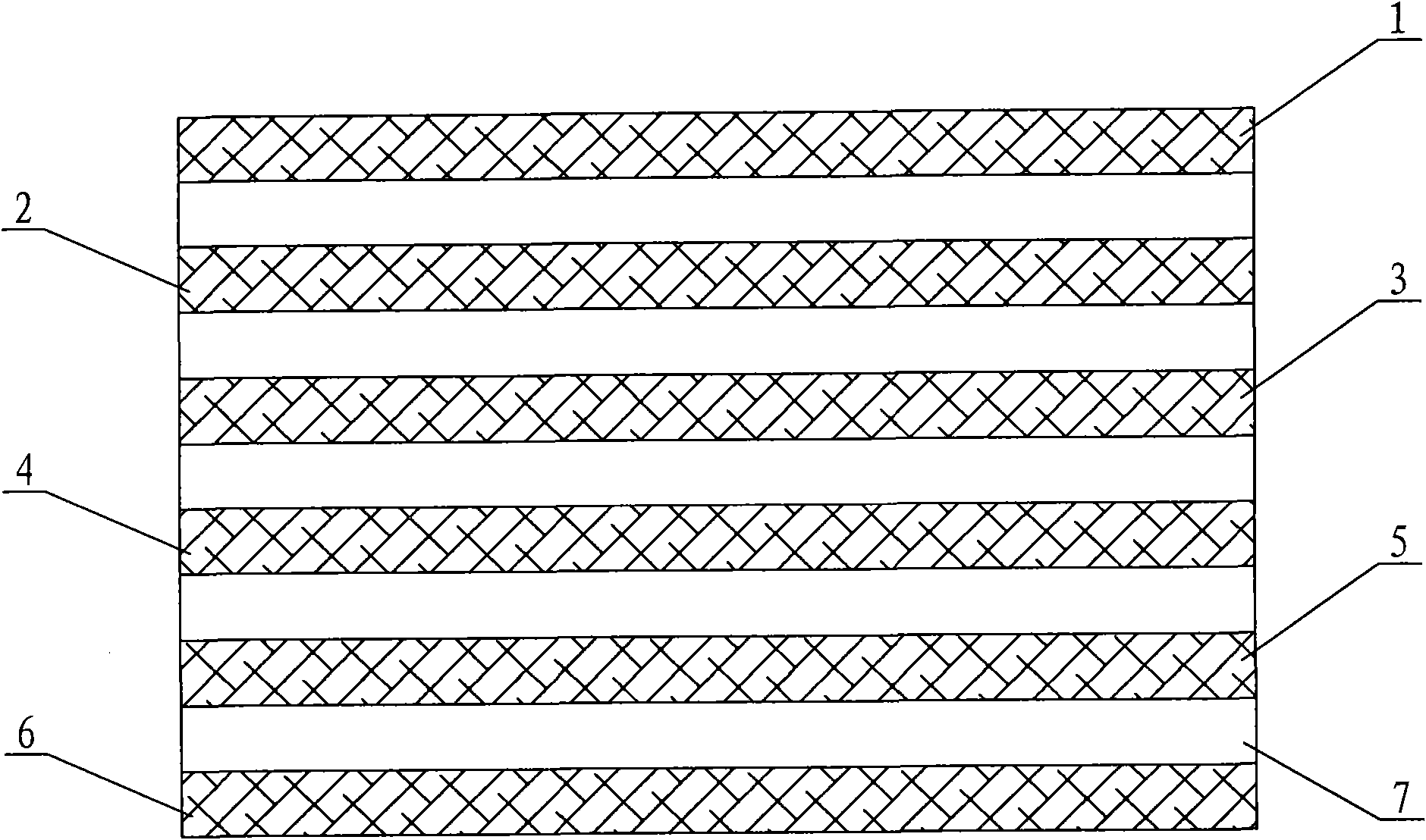

[0028] figure 1 The shown film structure Ku-band radar absorbing material mainly includes six layers of absorbing material layers 1, 2, 3, 4, 5, 6 and five layers of plastic film 7, and a plastic film is arranged between every two layers of absorbing material layers 7. The composition of the first wave-absorbing material layer 1 is: 1.50 parts of coupling agent, 50 parts of diluent, 150 parts of ferrite, 53.67 parts of 60% epoxy resin; the composition of the second wave-absorbing material layer 2 is : 1.50 parts of coupling agent, 50 parts of diluent, 150 parts of carbonyl iron absorbent, 39.83 parts of 60% epoxy resin, 12.93 parts of curing agent; the composition of the third layer of absorbing material layer 3 is: 1.50 parts of coupling agent, 50 parts of diluent, 150 parts of carbonyl iron absorbent, 109.02 parts of 60% epoxy resin, 33.10 parts of curing agent; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com