Microbial bubble liquid, and preparation method and application thereof

A microorganism and bubble technology, applied in separation methods, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of many auxiliary equipment for regeneration, poor treatment effect, low cost, etc., to achieve low investment cost and enhanced treatment effect. , good absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

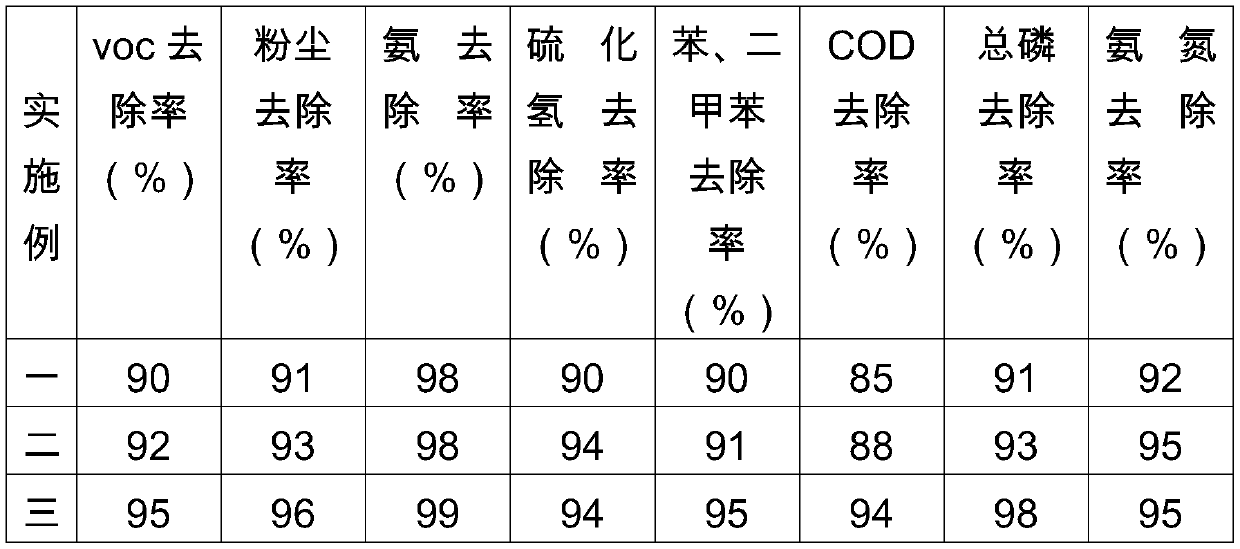

Examples

Embodiment 1

[0041] Add 487g of deionized water, 15g of sodium fatty alcohol vinyl ether sulfonate, 20g of sodium lauryl sulfate, and 5g of cocamide DEA into the stirring tank, start the stirrer, and stir at a speed of 400r / min until all the raw materials are completely dissolved. Then add 20g of glycerin, 10g of propylene glycol, 15g of polyvinyl alcohol, 5g of sucrose, 2g of protein powder, 110g of green tea extract, 200g of ginger extract, and 110g of black tea extract into the mixing tank, stir slowly for 20 minutes, and then insert the sulfide bacteria Seed 0.5g, then raise the temperature to 70 degrees Celsius, after cultivating for 3 hours, carry out cooling treatment, lower the temperature to about 25 degrees Celsius, insert 0.2g of nitrifying bacteria, add 0.3g of yeast strain after cultivating for 2 hours, and heat up to 37 After 3 hours of closed culture at 100°C, 1000 g of microbial air bubble liquid was obtained.

Embodiment 2

[0043] Add 495g of deionized water, 30g of sodium fatty alcohol polyoxyethylene ether sulfonate, 10g of sodium lauryl sulfate, and 10g of cocamide DEA into the mixing tank, start the stirrer, and stir at a speed of 400r / min until all the raw materials are dissolved , then add sorbitol 10g, glycerin 10g, hydroxyethyl cellulose 10g, polyvinyl alcohol 10g, sucrose 10g, protein powder 3g, lemon extract 200g, eucalyptus oil 200g, stir slowly for 20 minutes and insert actinomycetes 1g of seed and 1g of methane bacteria were added to the stirring tank, and then sealed and heated, the temperature was raised to about 37 degrees Celsius, and after cultivating for 5-8 hours, 1000g of microbial bubble liquid was obtained by standing still.

[0044] Real-time example three:

[0045] Add 402g of deionized water, 20g of sodium fatty alcohol polyoxyethylene ether sulfonate, 20g of sodium lauryl sulfate, and 5g of cocamide DEA into the stirring tank, start the stirrer, and stir at a speed of 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com