Radiated crosslinking PVC (Polyvinyl Chloride) rigid foaming material

A foaming material and PVC resin technology, applied in the field of PVC rigid foaming material and its preparation, can solve the problems of complex production process, harsh production process requirements and high equipment requirements of cross-linked PVC foam, and achieve light weight and uniform distribution , the effect of uniform cell distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

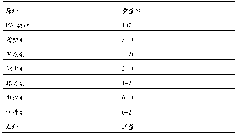

[0043] Present embodiment carries out batching as follows formula:

[0044]

[0045] (1) After measuring the raw materials in the above formula, preliminarily mix the raw materials on a high-speed mixer at room temperature, and then add them to the double-roller kneader for 5-15 minutes at 150-170°C to make the mixture material;

[0046] (2) Place the mixed material in a flat vulcanizer to form a tablet, and then irradiate it with an electron beam. The irradiation dose is 20-1000kGy; the irradiation speed is controlled at 10-20m / min;

[0047] (3) Put the irradiated PVC sheet into the oil bath, set the temperature of the oil bath at 180-200°C, and the treatment time is 5-20 minutes, so that it can be foamed at the corresponding process temperature; after the sheet is foamed , can be sent to the packaging process to be cut into products of specified size, and its performance is subject to random inspection or full inspection of all items required by the standard.

[0048] I...

Embodiment 2

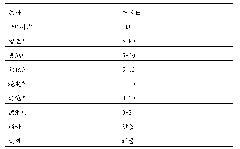

[0050] Present embodiment carries out batching as follows formula:

[0051]

[0052] (1) After measuring the raw materials in the above formula, preliminarily mix the raw materials on the high mixer at room temperature, and then add them to the double-roller kneader for 5-15 minutes at 120-170°C to make the mixture material;

[0053] (2) Put the above-mentioned mixed materials in a flat vulcanizer and press them into tablets, and then irradiate them with electron beams. The irradiation dose is 20-100kGy; the irradiation speed is controlled at 10-20m / min;

[0054] (3) Put the irradiated PVC sheet into the oil bath, set the temperature of the oil bath at 170-200°C, and the treatment time is 5-20min, so that it can be foamed at the corresponding process temperature; after the sheet is foamed , can be sent to the packaging process to be cut into products of specified size, and its performance is subject to random inspection or full inspection of all items required by the stand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com