Microporous wave-absorbing material with low surface density and high tensile strength and preparation method

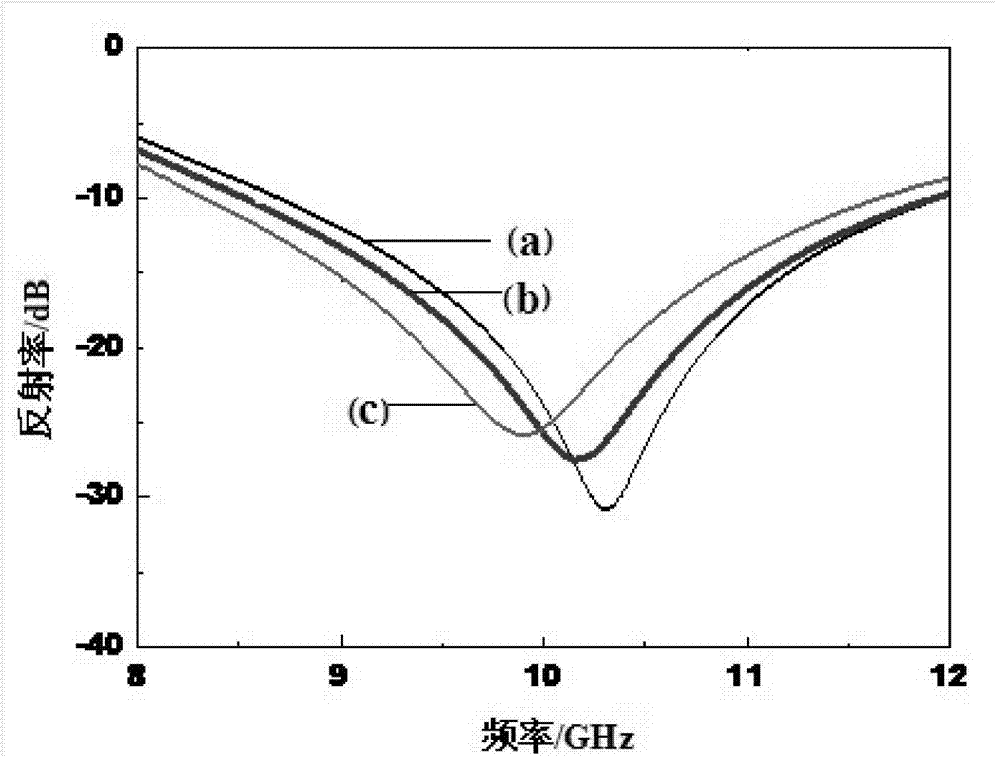

A technology of high tensile strength and wave-absorbing materials, applied in the field of wave-absorbing materials, can solve the problems of low mechanical properties, high surface density of wave-absorbing materials, poor temperature resistance, etc., and achieve increased mechanical properties and uniform cell distribution , the effect of excellent absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the microporous wave-absorbing material with low surface density and high tensile strength comprises the following steps:

[0027] (1) Physically stir rubber, zinc oxide, stearic acid, anti-aging agent, flow aid, sulfur, accelerator, foaming agent, plasticizer and absorbent, and then add them to the internal mixer and mix them uniformly. get the mixture;

[0028] The mass ratio of described rubber, zinc oxide, stearic acid, antioxidant, flow aid, sulfur, promotor, blowing agent and plasticizer is 100:5:2:2:1.5:2:1:(5 -18): (15-25), the blowing agent is azodicarbonamide, modified azodicarbonamide or N,N'-dimethylpentamethylenetetramine, and the absorbent is Micron-sized conductive carbon black, its quality is 30-40% of the total mass of rubber, zinc oxide, stearic acid, antioxidant, flow aid, sulfur, accelerator, blowing agent and plasticizer, preferably 5-18% % (according to the well-known in the field, the default blowing agent has no residu...

Embodiment 1

[0039] 100g nitrile rubber 220, 5g zinc oxide, 2g stearic acid, 2gN,N-nickel dibutyldithiocarbamate, 1.5g granular fatty acid, 2g sulfur, 1gN-cyclohexyl-2-benzothiazolium Sulfonamide, 5g of azodicarbonamide, 15g of dibutyl phthalate and 40.5g of micron-sized conductive carbon black are added to the internal mixer and mixed evenly within 85°C to obtain a mixture; the mixture obtained by banburying is moved to Open the mill to get a uniform and stable raw material, then cut 62.0g of raw material into a suitable size and put it into 200×200 2In the mold of mm, the height of the mold cavity is 1.2mm, and the microporous wave-absorbing material is obtained by vulcanizing and foaming in a flat vulcanizing machine at 150°C for 25 minutes. The mechanical properties of the material are shown in Table 1.

Embodiment 2

[0041] 100g nitrile rubber 220, 5g zinc oxide, 2g stearic acid, 2g2,2,4-trimethyl-1,2-dihydroquinoline polymer, 1.5g granular fatty acid derivative ZC-56, 2g sulfur , 1g2-mercaptobenzothiazole, 10g modified azodicarbonamide, 20g dioctyl phthalate and 50.225g micron-sized conductive carbon black are added in the internal mixer and mixed evenly to obtain the mixture; The mixture obtained by refining is moved to an open mill to obtain a uniform and stable raw material, and then 65.0g of raw material is cut into a suitable size and put into a 200×200 2 In the mold of mm, the height of the mold cavity is 1.5mm, and the microporous wave-absorbing material is obtained by vulcanizing and foaming in a flat vulcanizing machine at 155°C for 30 minutes. The mechanical properties of the material are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com