Fire-retardant type wide-frequency-band high-power compound wave-absorbing material and preparing method thereof

A composite absorbing material and a wide-band technology, which is applied in the intersection of materials science and microwave technology, and can solve problems such as bending, fire accidents, and difficulty in dissipating heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

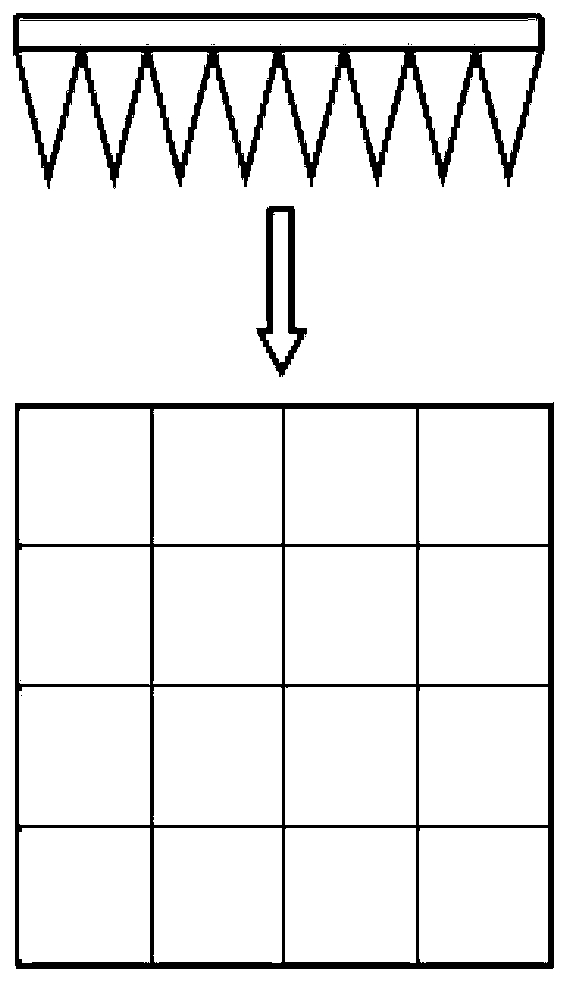

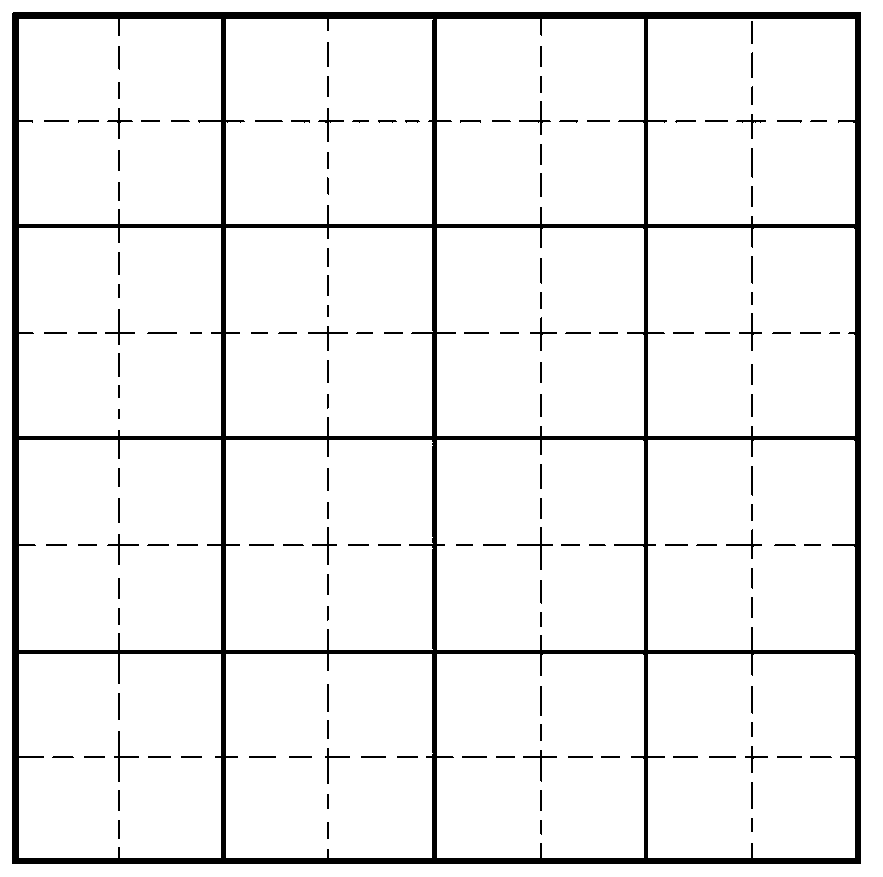

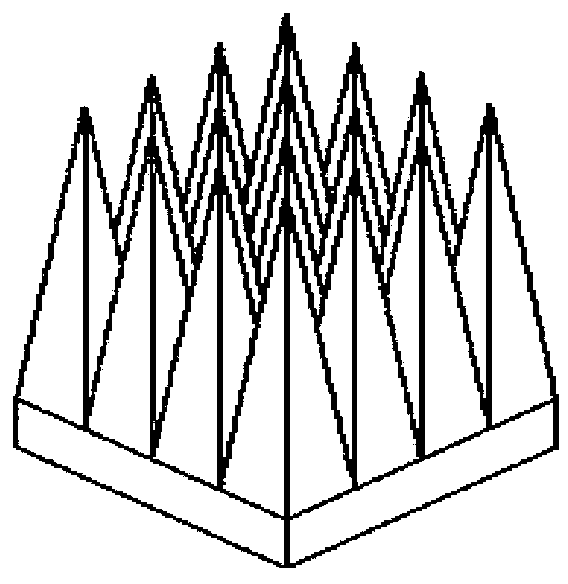

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1 manufactures the shell of absorbing material

[0050] The first step is to mix the components in the following table according to the weight ratio, and ball mill evenly to obtain the first flame retardant and wave absorbing agent;

[0051] components

Range of weight ratio

The weight ratio of this embodiment

2~5

4

α-SiC

1~3

2

Deionized water

60~63

62

PVA solution

10~15

12.5

Aluminum hydroxide

10~15

15

Kaolin

2~5

5

1~3

2

Ammonium polyphosphate App-3

1~2

1

0.1~0.2

0.2

Dispersant

0.1~0.2

0.2

0.1~0.2

0.1

[0052] The ball milling speed is at least 200 rpm, and the ball milling time is at least 4 hours; the mass concentration of the PVA solution is 4-20% (preferably 5%); the wetting agent is PE100; the dispersant is S...

Embodiment 2

[0056] Example 2 Prepare the core and base of the absorbing material, and prepare the absorbing material

[0057] The first step is to mix the components in the following table according to the weight ratio, and ball mill evenly to obtain the second flame retardant and wave absorbing agent;

[0058] components

Range of weight ratio

The weight ratio of this embodiment

5~8

6

α-SiC

3~5

3

Deionized water

63~66

65

PVA solution

10~15

12.5

Aluminum hydroxide

3~5

5

Kaolin

2~5

5

2~5

2

Ammonium polyphosphate App-3

1~3

1

0.1~0.2

0.2

Dispersant

0.1~0.2

0.2

0.1~0.2

0.1

[0059] The ball milling speed is at least 200 rpm, and the ball milling time is at least 4 hours; the mass concentration of the PVA solution is 4-20% (preferably 5%); the wetti...

Embodiment 3

[0063] Embodiment 3 Reflection loss performance detection

[0064] For the microwave-absorbing material prepared in Example 2, its reflection loss performance to 0.02-40GHz microwaves was detected, and the results are shown in the table below, indicating that the microwave-absorbing material obtained in Example 2 has excellent reflection loss performance in the 0.2-40GHz microwave band .

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com