Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Good microwave absorption characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ni-based alloy magnetic microwave absorbing material and preparation method thereof

ActiveCN104451265AGood microwave absorption characteristicsGood absorption bandIce waterOxidation resistant

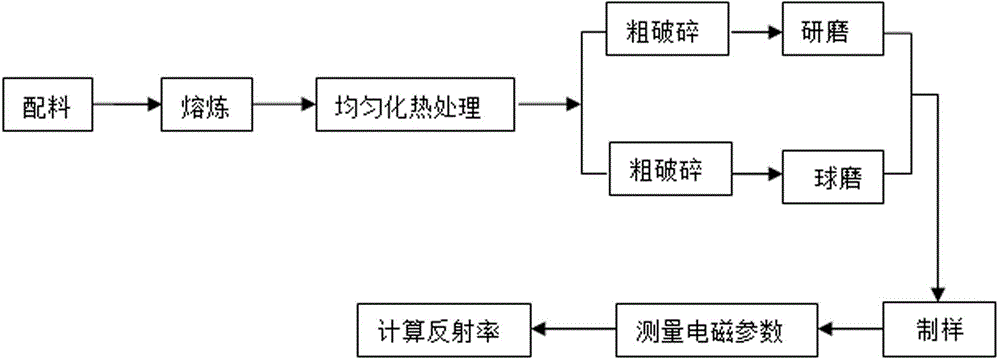

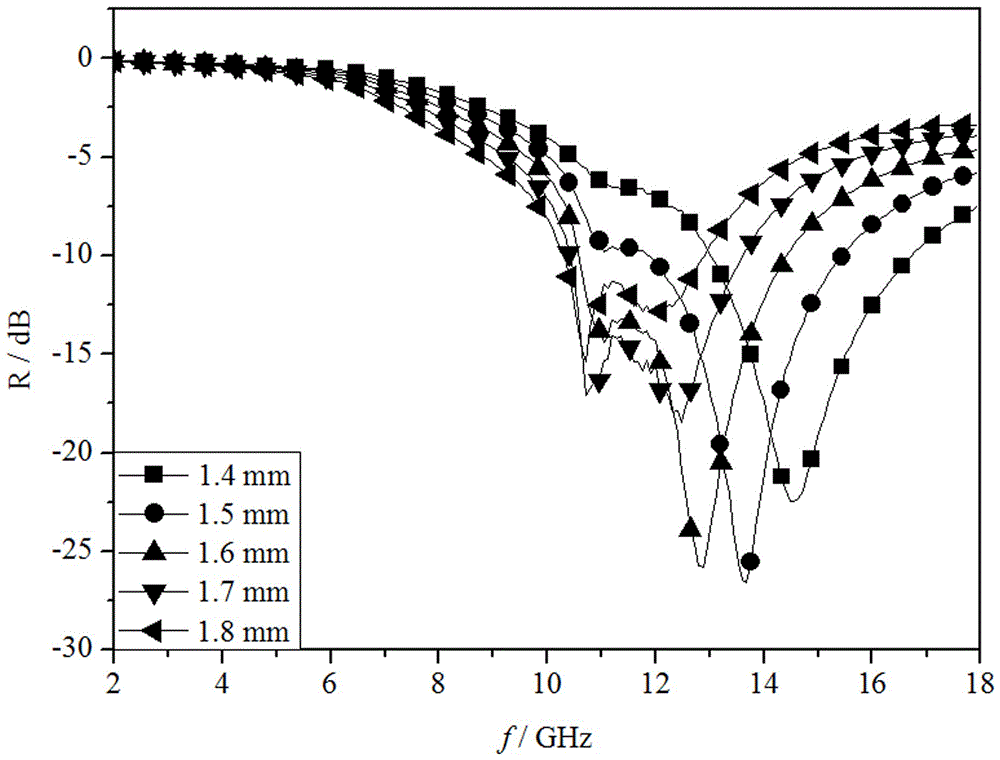

The invention discloses a Ni-based alloy magnetic microwave absorbing material and a preparation method thereof. The stoichiometric proportions of a molecular formula of the magnetic microwave absorbing material are as follows: 16.67% of Pr, 83.33%-75% of Ni and 0-8.33% of Fe. The Ni-based alloy magnetic microwave absorbing material is prepared by the following main steps: smelting Pr, Fe and Ni metals, of which the purities are greater than or equal to 99.50% as raw materials under argon or vacuum protection; carrying out heat treatment on a cast ingot at 600-1100 DEG C under vacuum or argon protection; quenching with ice water; and grinding into powder and carrying out ball milling to form powder after mechanically crushing. The Ni-based alloy disclosed by the invention has the advantages of relatively good microwave absorbing effect, wide absorbing frequency band, simple preparation process, high antioxidant resistance and the like in a 2-18GHz of microwave band; and the Ni-based alloy magnetic microwave absorbing material disclosed by the invention is suitable for preparation of microwave absorbing products of requiring wide absorbing frequency band, good wave absorbing property and high corrosion resistance in the magnetic wave absorbing material.

Owner:GUILIN UNIV OF ELECTRONIC TECH

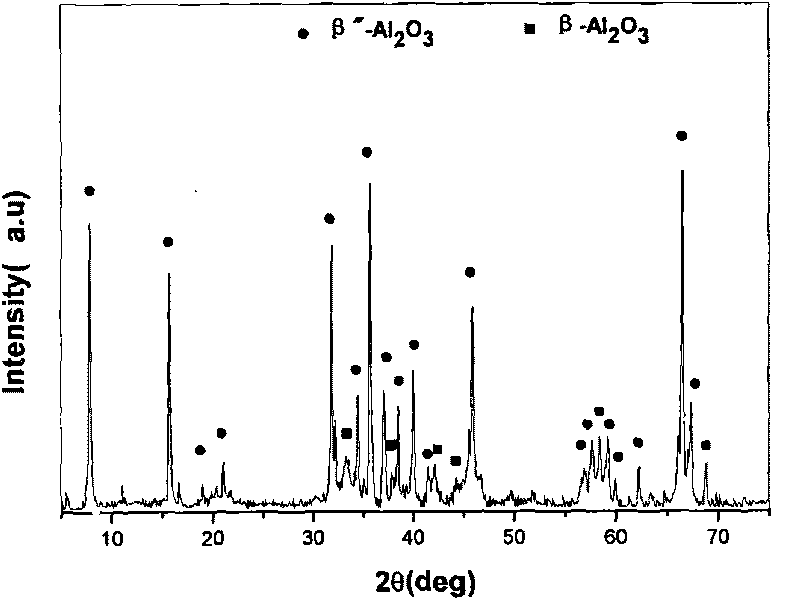

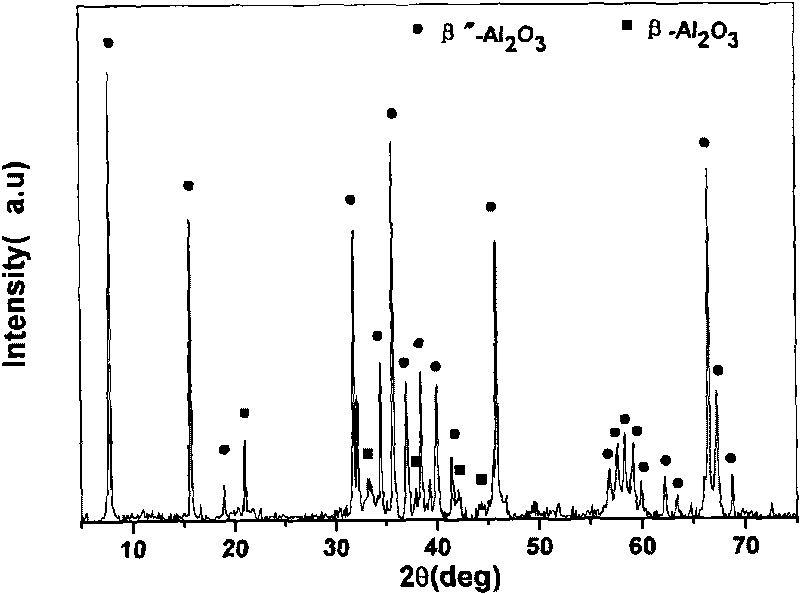

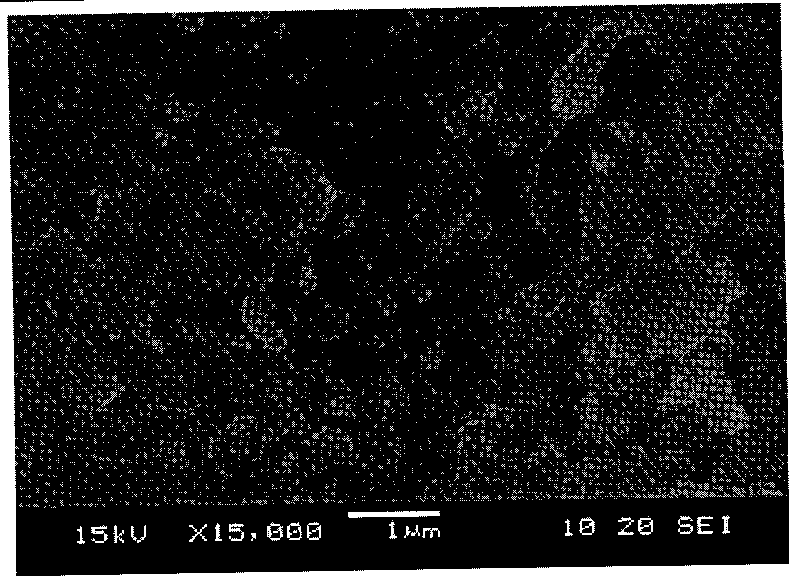

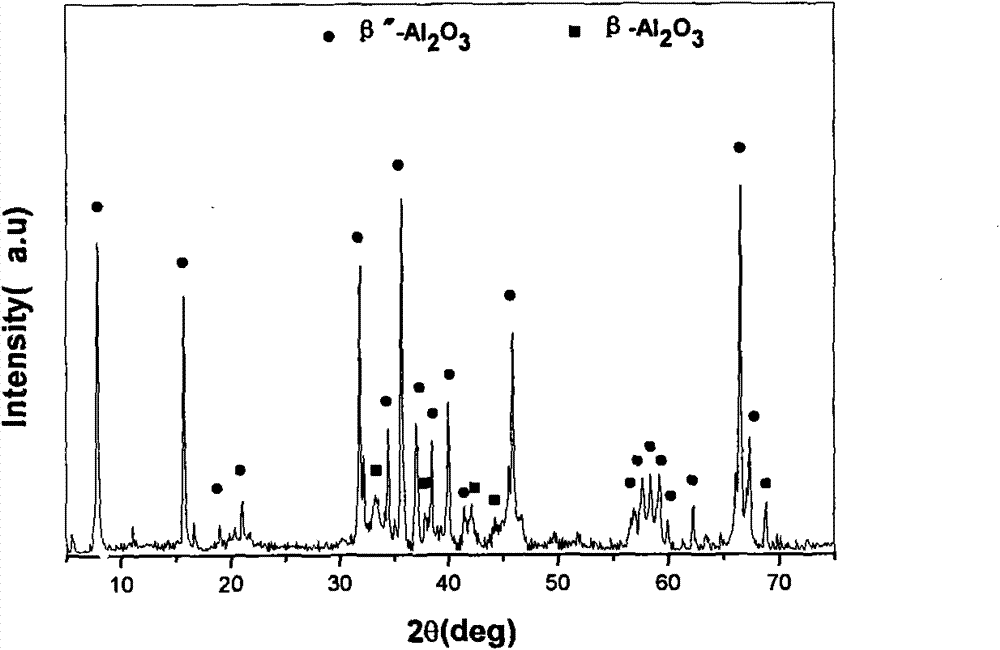

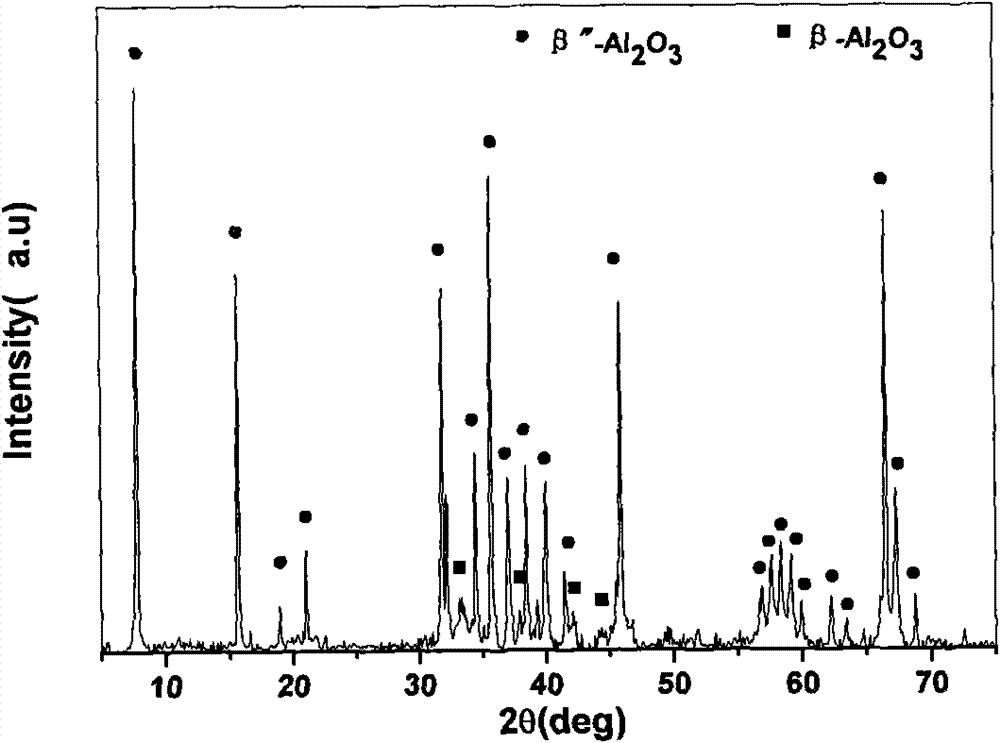

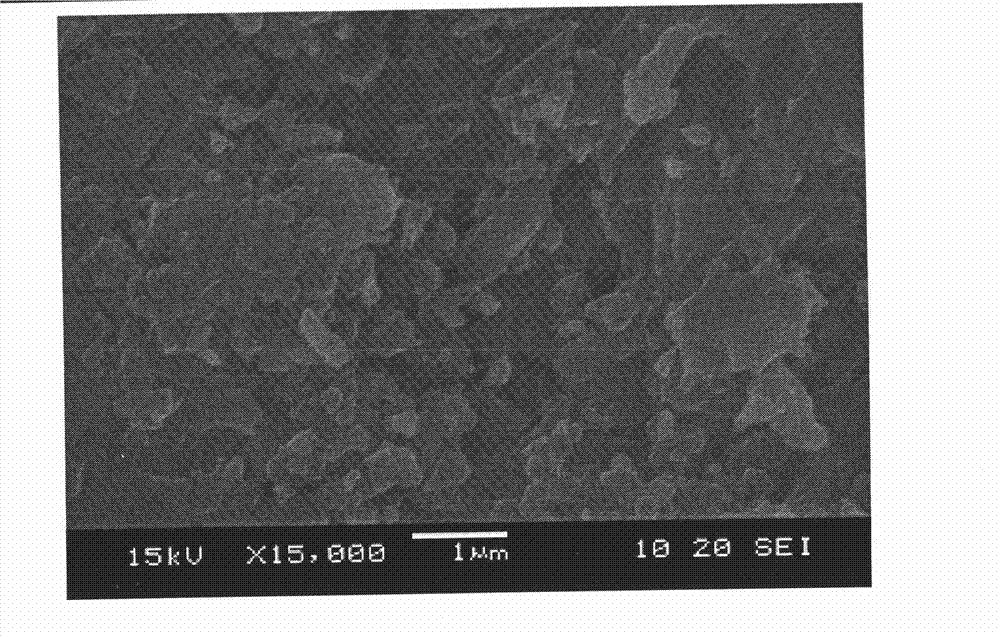

Preparation method of Na-beta''-Al2O3 solid electrolyte

InactiveCN101734911AAvoid churnReduce consumptionCell seperators/membranes/diaphragms/spacersLithiumMicrowave oven

The invention relates to a preparation method of a Na-beta''-Al2O3 solid electrolyte, comprising the following steps of: adding a stabilizer in a compound containing sodium, aluminium and magnesium or lithium as a raw material; preparing precursor powder; placing the prepared precursor powder into a microwave oven after being subjected to prilling and molding; and fast sintering to obtain the Na-beta''-Al2O3 electrolyte. The method not only has short reaction time and can furthest reduce the loss of Na2O and ensure the conductivity of the material, but also has low energy consumption and hightemperature rate and can obtain a sample with higher compactness; and in addition, the Na-beta''-Al2O3 solid electrolyte prepared by the method shows excellent property and is suitable for being usedas the solid electrolyte of a sodium-sulphur battery and a sodium-nickel chloride battery.

Owner:NANJING UNIV OF TECH

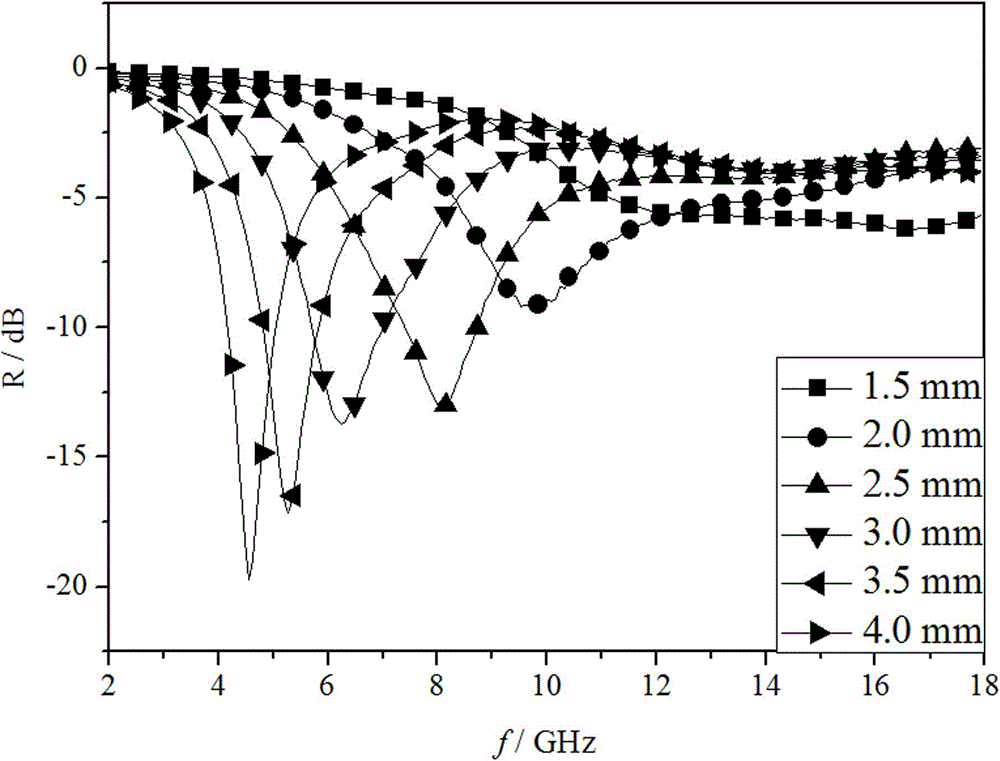

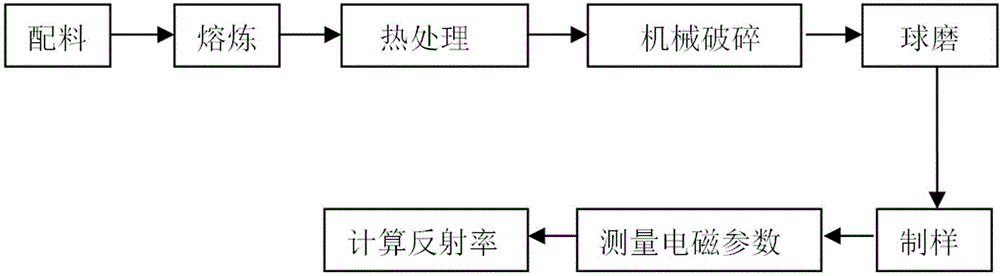

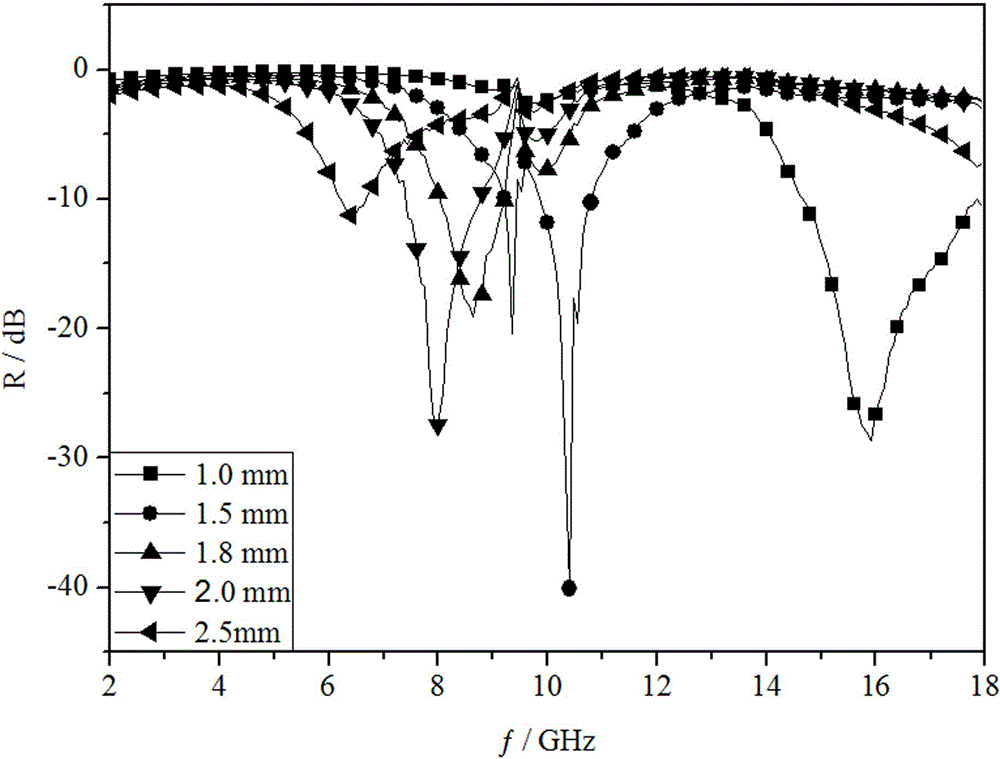

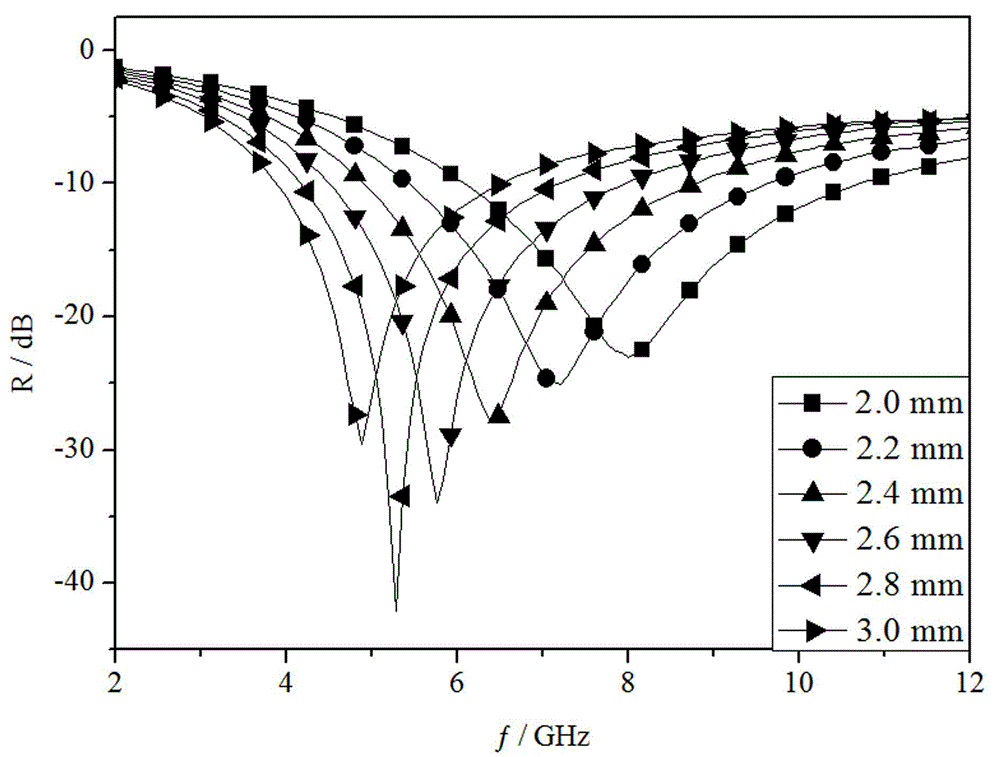

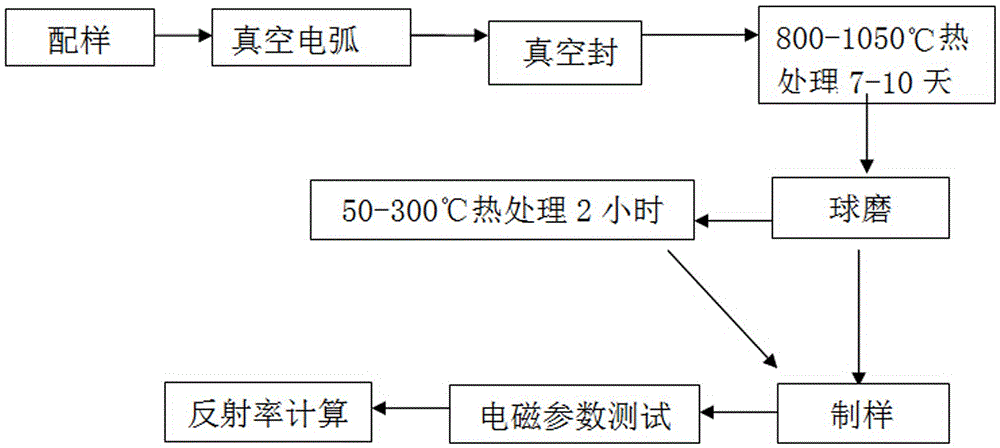

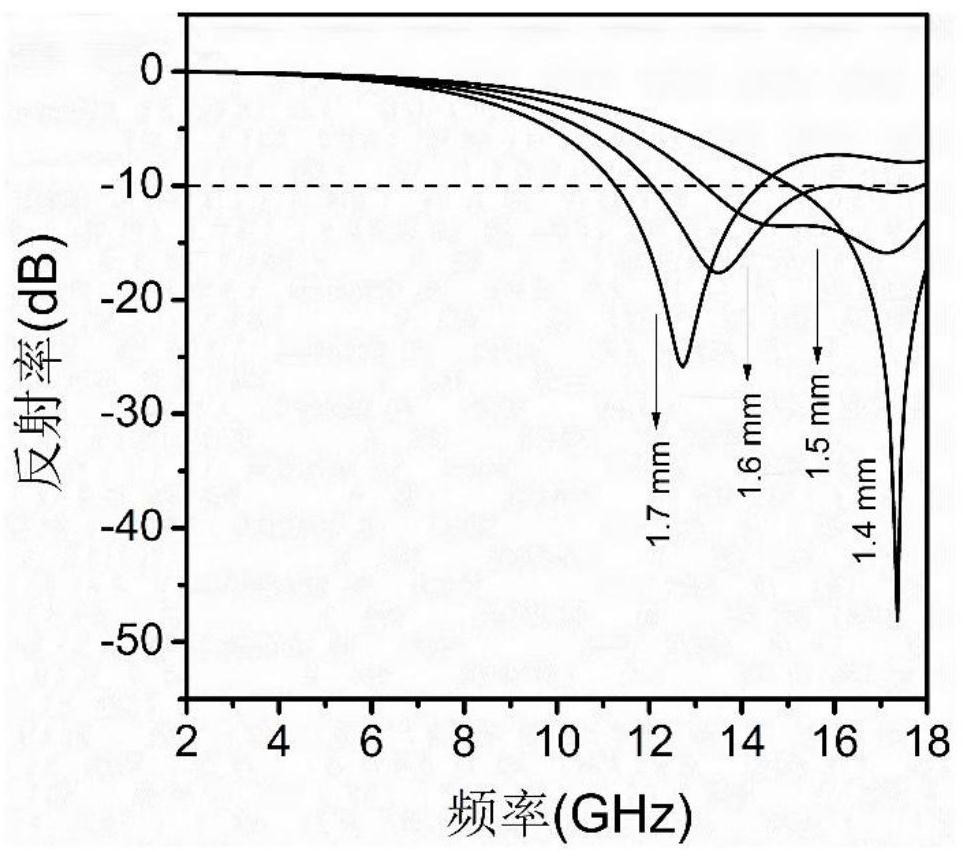

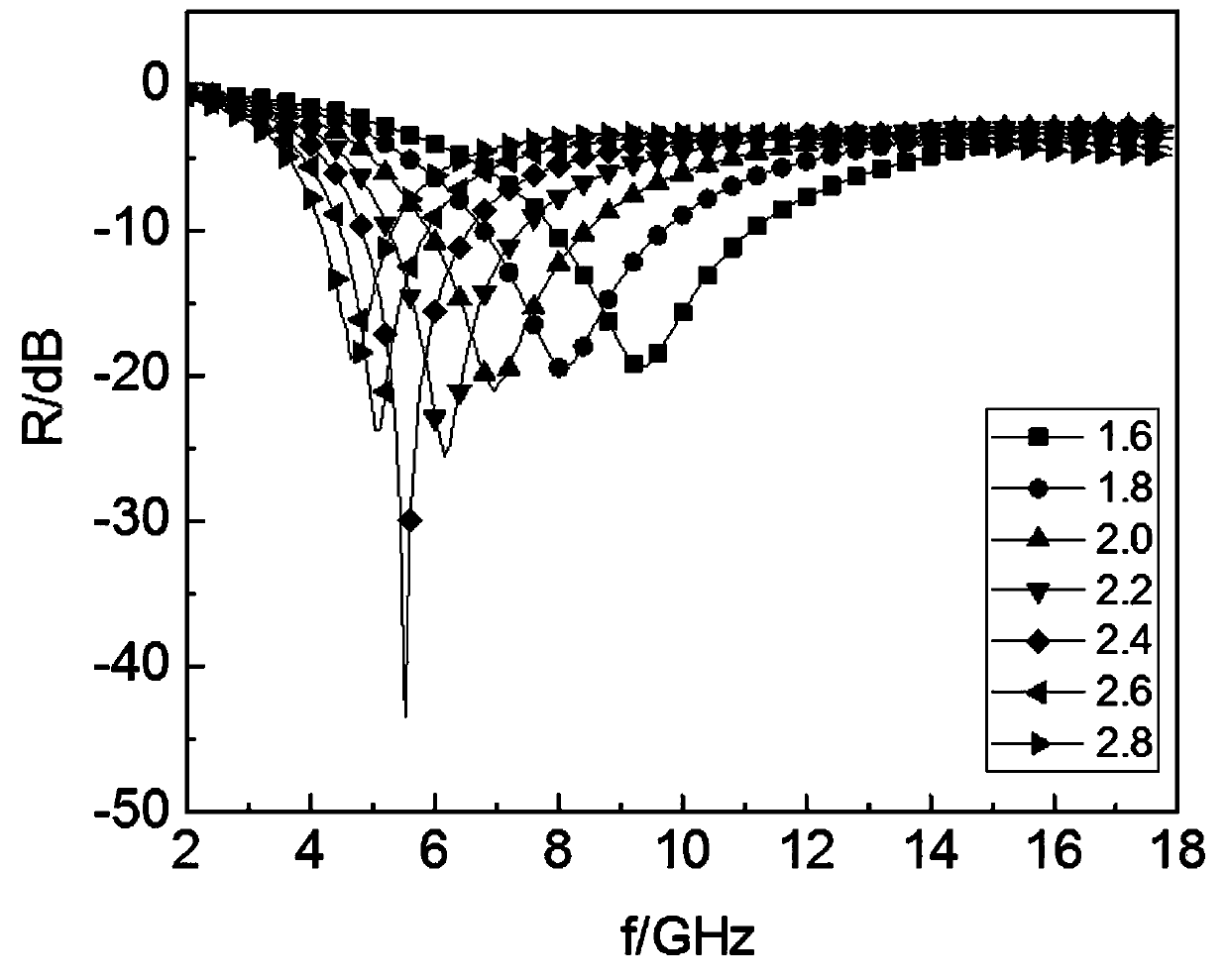

LaCeNi magnetic wave absorbing material and preparation method thereof

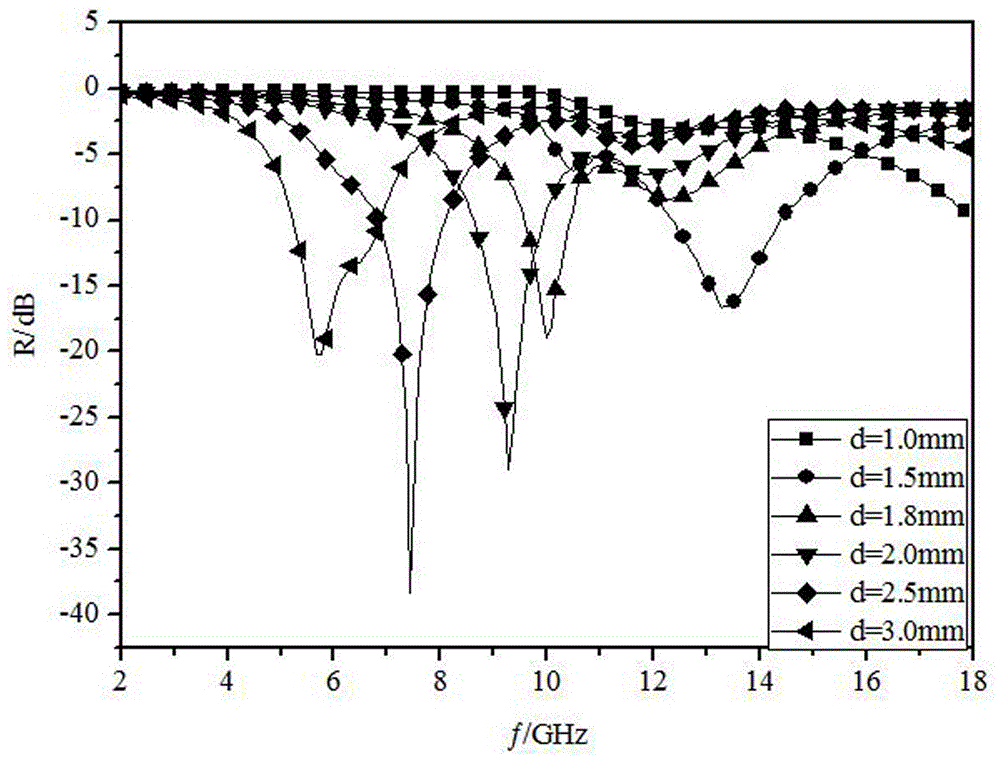

ActiveCN104451264AGood microwave absorption characteristicsGood absorption bandMagnetic materialsIngotHeat treated

The invention discloses a LaCeNi magnetic microwave absorbing material and a preparation method thereof. The stoichiometric proportions of a molecular formula of the magnetic wave absorbing material are as follows: 10.0%-16.7% of La, 0-6.0% Ce and 83.3% Ni. The LaCeNi magnetic microwave absorbing material is prepared by the following main steps: smelting La, Ce and Ni metals, of which the purities are greater than or equal to 99.90% as raw materials under argon protection; carrying out heat treatment on a cast ingot in vacuum at 800-1050 DEG C; quenching with ice water; and carrying out ball-milling to form powder after mechanically crushing. The LaCeNi magnetic microwave absorbing material has relatively excellent microwave absorbing property in a 2-18GHz of microwave band; when the thickness of a compound is 1.5mm, the minimal absorption peak can reach about 40.1dB; the LaCeNi alloy disclosed by the invention has the advantages of good wave absorbing property, wide absorbing frequency band, simple preparation process, good corrosion resistance and the like in the 2-18GHz of microwave band; and the LaCeNi magnetic microwave absorbing material disclosed by the invention is suitable for preparation of microwave absorbing products of requiring wide absorbing frequency band, good wave absorbing property and good corrosion resistance in the magnetic wave absorbing material.

Owner:GUILIN UNIV OF ELECTRONIC TECH +1

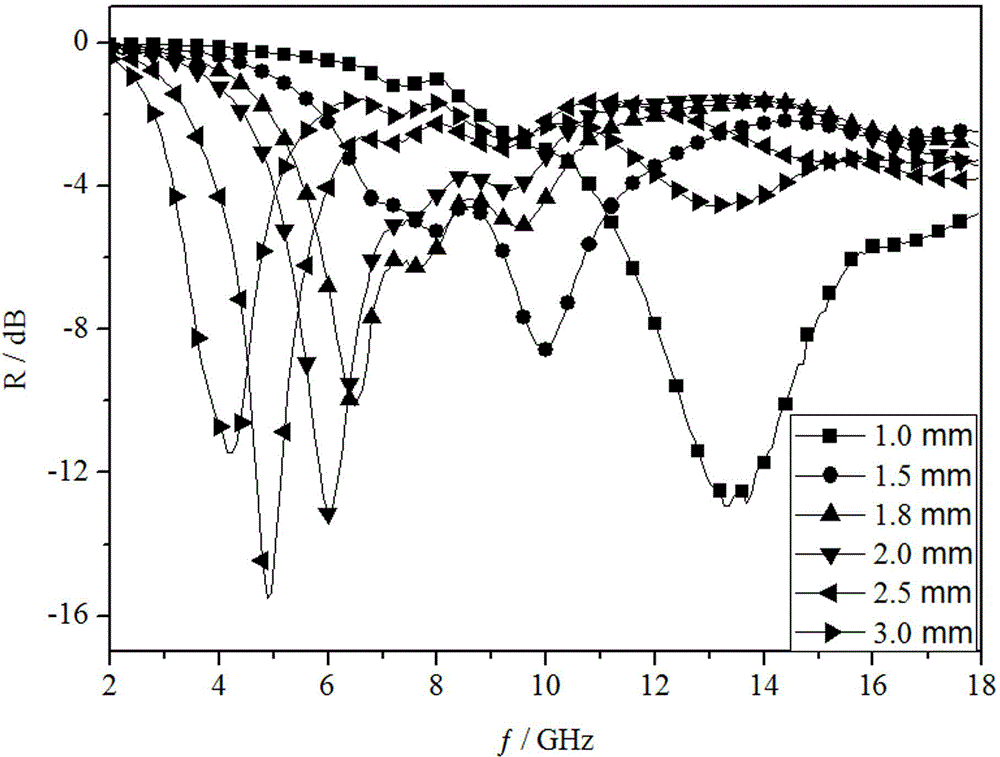

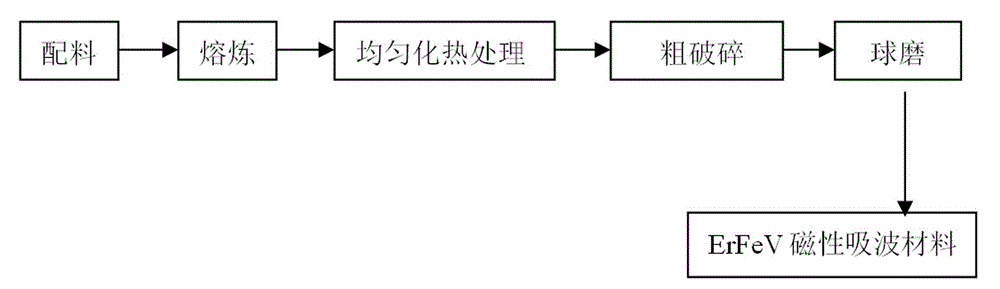

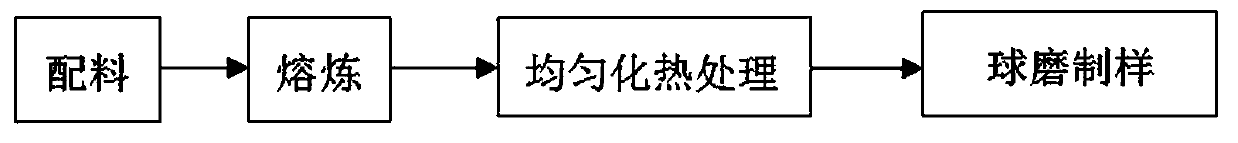

ErFeV magnetic wave-absorbing material and preparation method thereof

InactiveCN104388818AGood microwave absorption characteristicsGood absorption bandInorganic material magnetismIce waterIngot

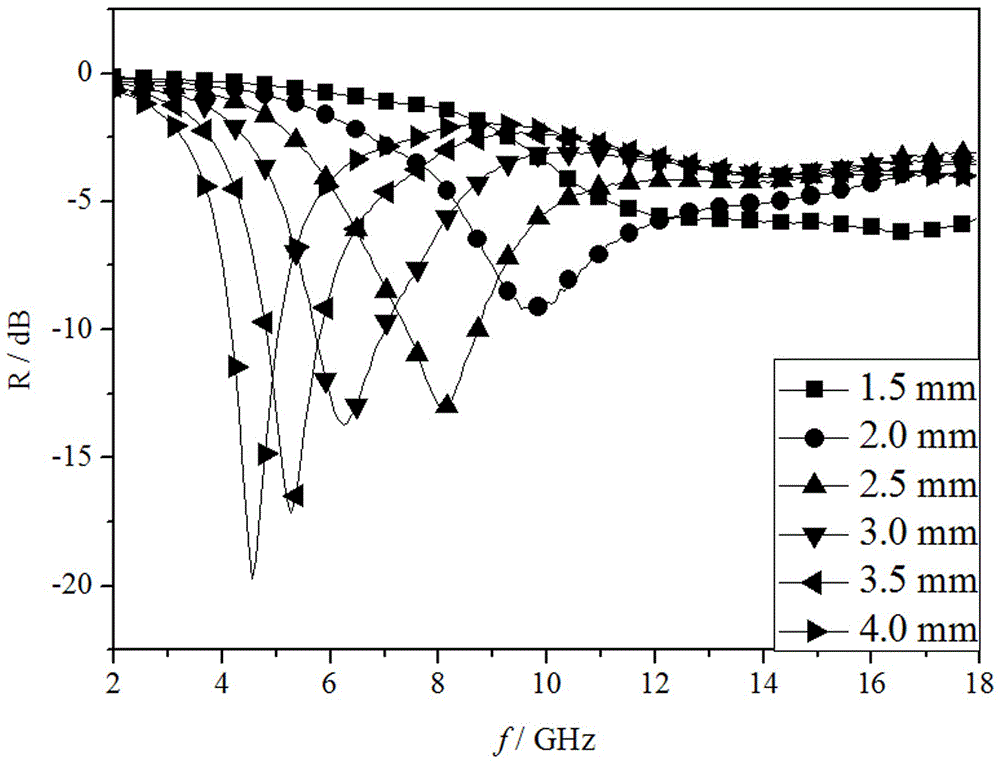

The invention discloses an ErFeV magnetic wave-absorbing material. The alloy comprises the following atoms in percentage: 10.5 percent of Er, 83.5-89.5 percent of Fe and 0-6 percent of V. The ErFeV magnetic wave-absorbing material is prepared by the method comprising the following main steps: taking metals Er, Fe and V with the purity of more than or equal to 99.90 percent as raw materials, smelting under argon shield, performing homogenizing thermal treatment on a cast ingot at the temperature of 600-800 DEG C in vacuum, quenching by using ice water, mechanically crushing, and ball-milling into powder. The ErFeV alloy disclosed by the invention has good wave-absorbing performance and wide absorption band in the microwave band of 2-18GHz and has the advantages of simple preparation process, abundant raw materials, low price and the like. According to the magnetic wave-absorbing material, the ErFeV magnetic wave-absorbing material disclosed by the invention is suitable for preparing microwave absorption products with wide absorption band, good wave-absorbing performance and low cost.

Owner:GUILIN UNIV OF ELECTRONIC TECH

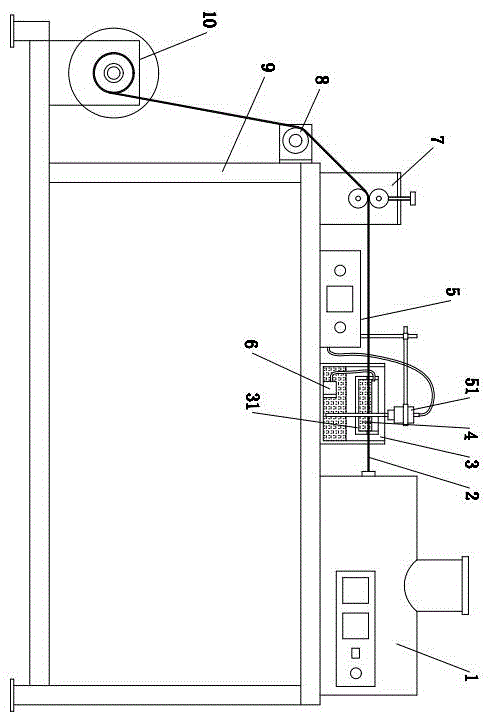

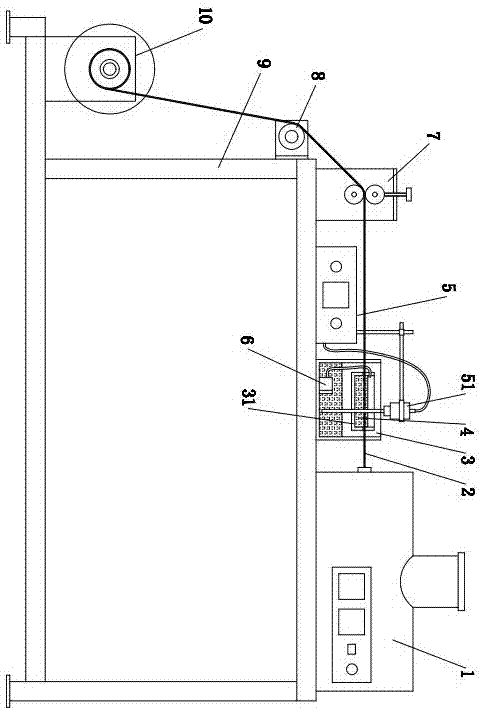

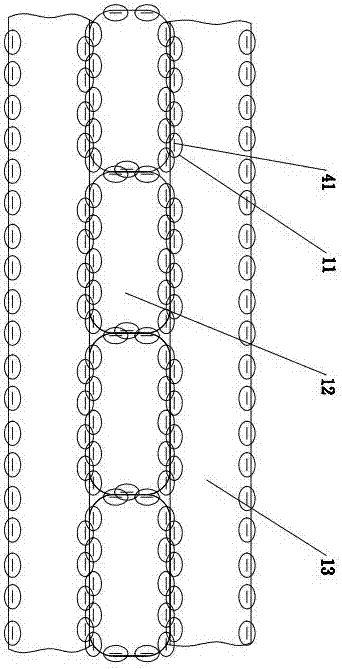

Method for improving strength of plastic quick-formed parts and equipment for producing special wires

ActiveCN105584048AHigh strengthImprove plastic strengthAdditive manufacturing apparatusThermoplasticWire rod

The invention relates to a method for improving strength of plastic quick-formed parts and equipment for producing special wires. The method is characterized by comprising the steps of: preparation of plastic wires bonded with graphene microchips on the surfaces, production of the quick-formed parts, microwave treatment and insulation and cooling. The equipment comprises a frame, a plastic extruder, a cooling tank, a ultrasonic disperser, a traction wheel set and a winder. The method has the following advantages: the produced plastic quick-formed parts are high in strength, excellent in layered strength and invariable in sizes and shapes of traditional workpieces; and the method is convenient to operate, low in cost, excellent in effect and suitable for various thermoplastic quick-formed parts.

Owner:泗县微腾知识产权运营有限公司

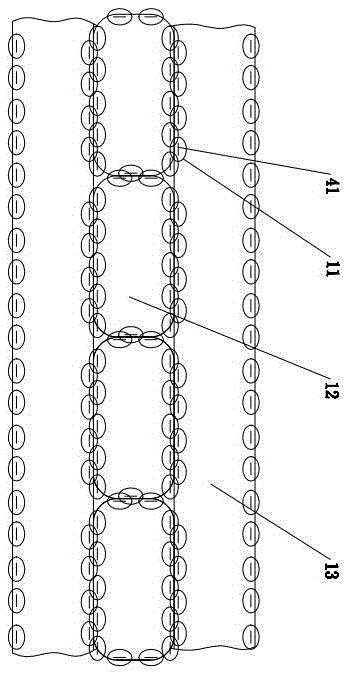

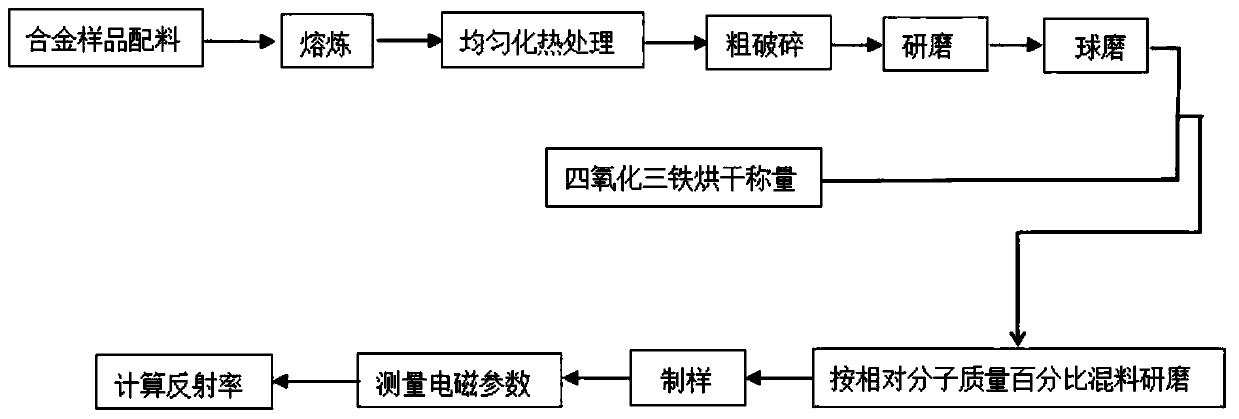

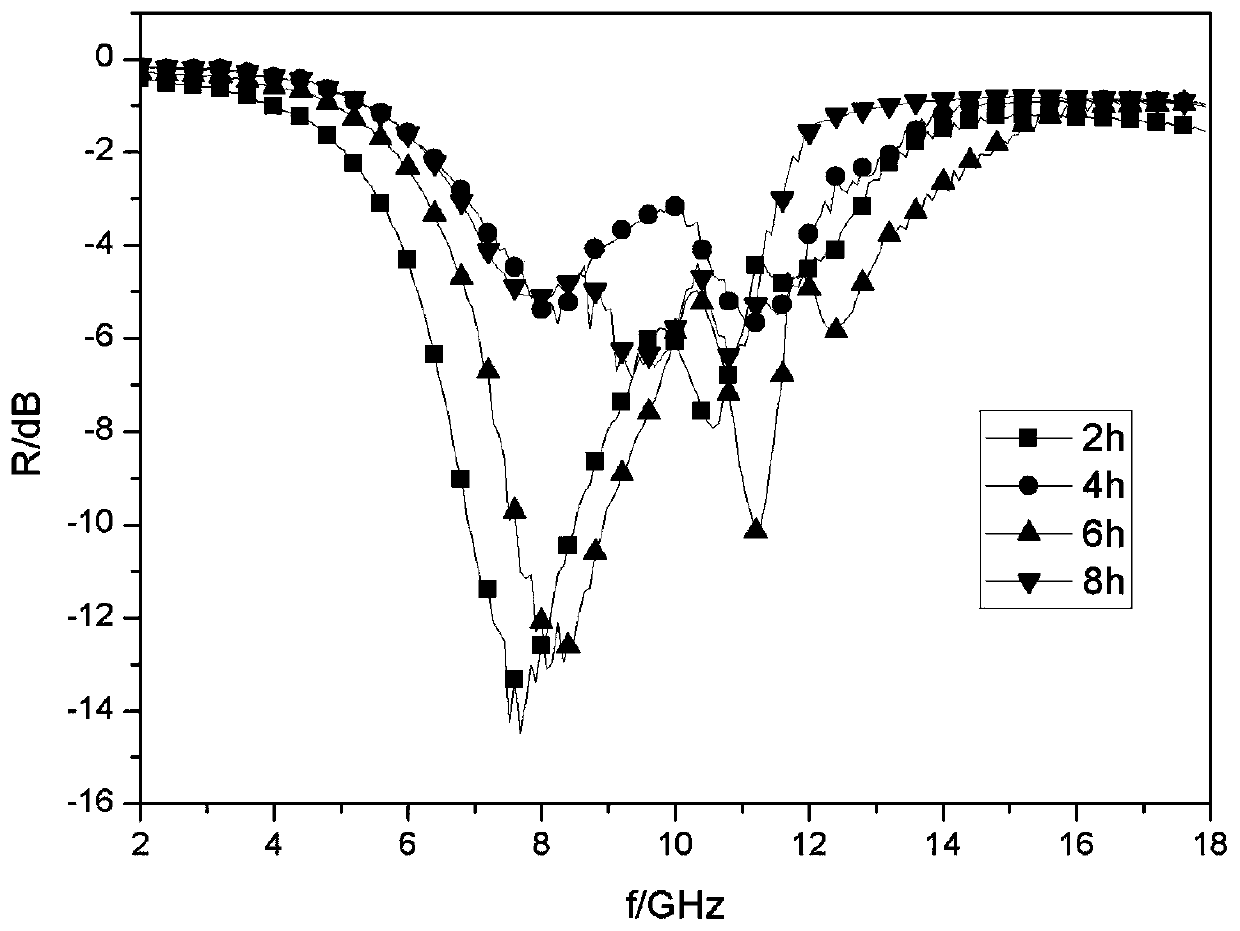

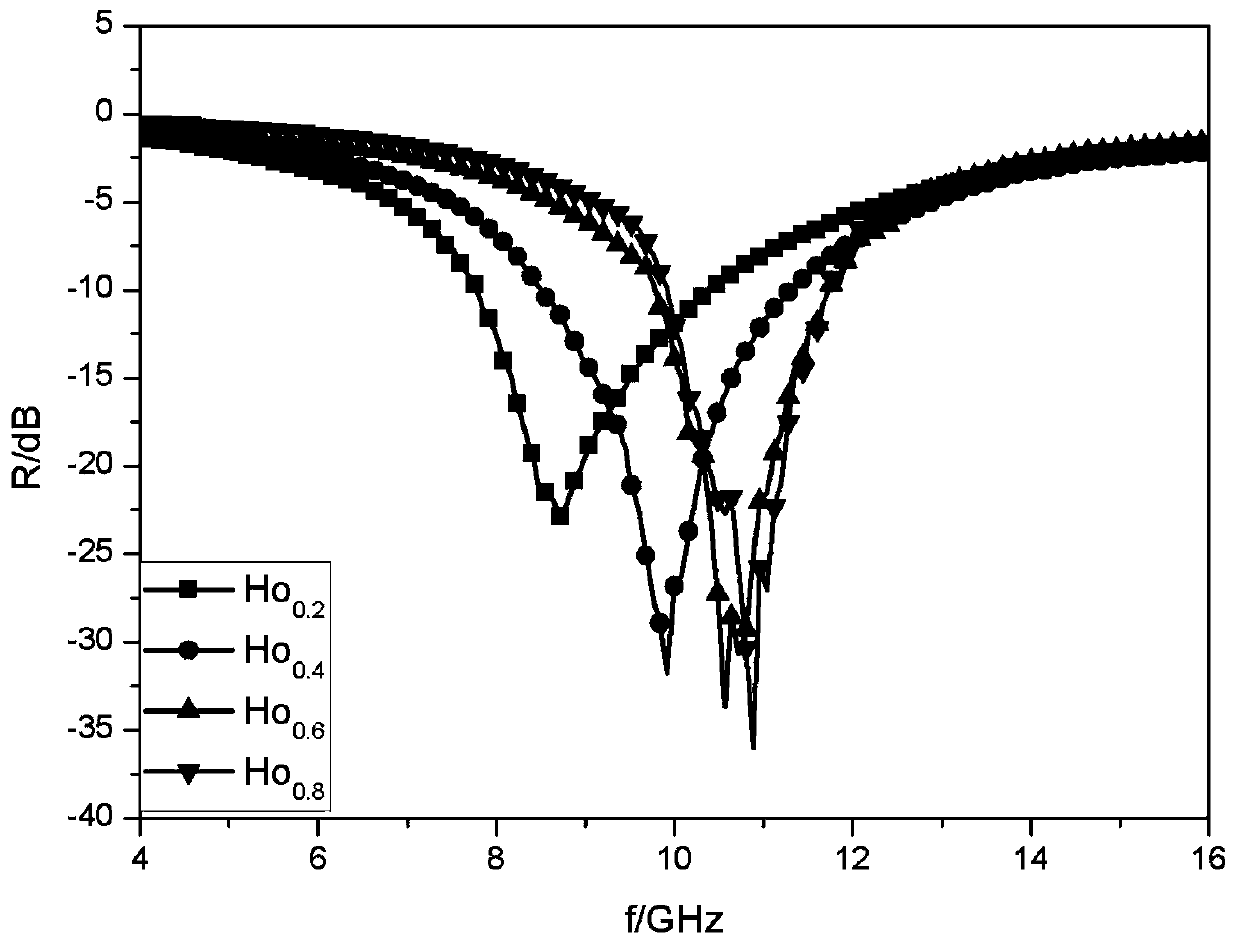

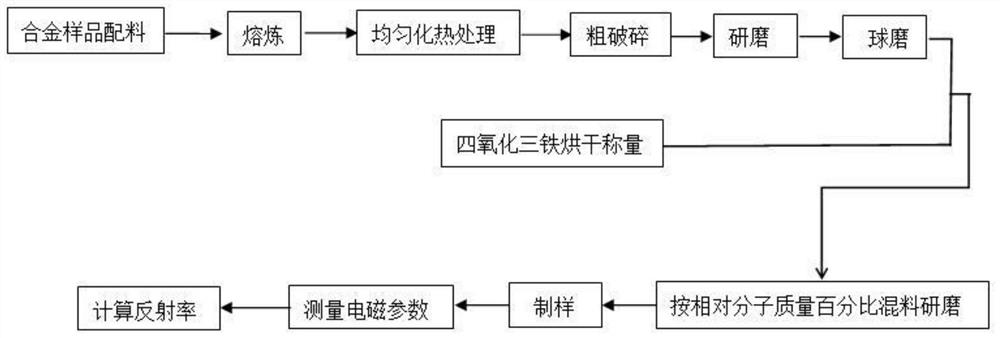

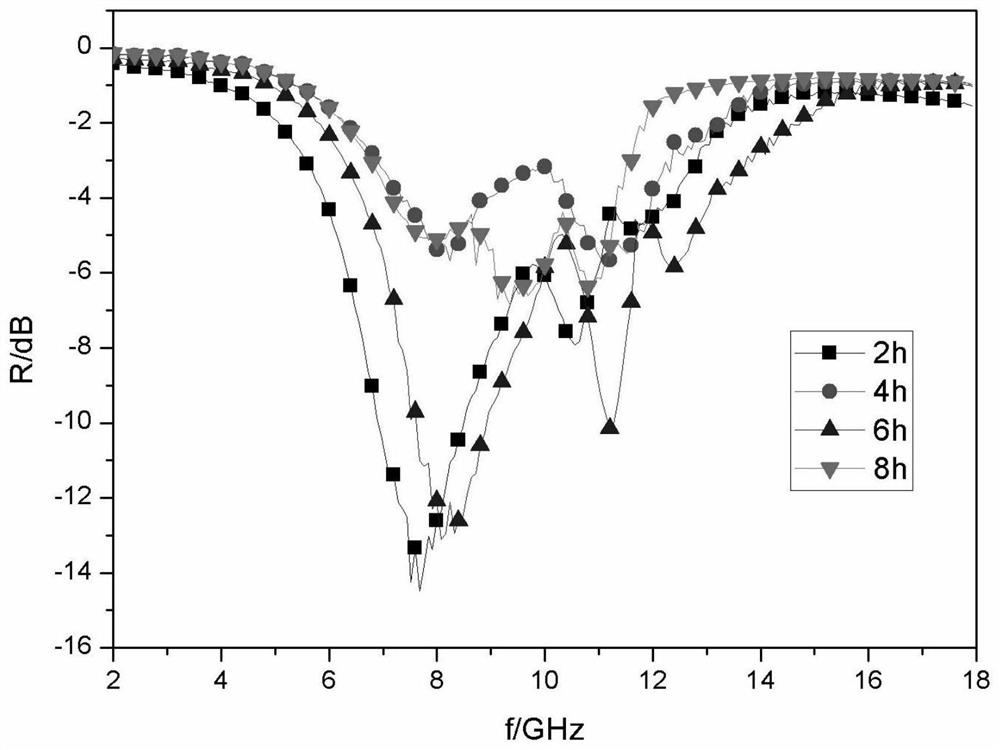

HoFeB/Fe3O4 wave-absorbing composite material and preparation method thereof

ActiveCN110171834AGood broadband effectGood microwave absorption characteristicsInorganic material magnetismFerroso-ferric oxidesIce waterMicrowave

The invention provides a HoFeB / Fe3O4 wave-absorbing composite material and a preparation method thereof. The HoFeB / Fe3O4 wave-absorbing composite material is suitable for the field of microwave absorbing materials. The preparation method includes the following steps that Ho, Fe and B with the purity equal to or more than 99.95% serve as raw materials respectively and are repeatedly molten into ingots with uniform compositions in an argon atmosphere, vacuumizing is conducted, and the ingots are sealed in quartz glass for homogeneous annealing at 800 DEG C, then quenched with an ice-water mixture, mechanically crushed into powder and ball-milled into powder by using high energy; the powder obtained after high-energy ball milling and ferroferric oxide are placed in an agate mortar for grinding and mixing according to the relative molecular mass ratio, and the HoFeB / Fe3O4 composite material is obtained. The wave-absorbing composite material has a very good microwave absorbing effect in themicrowave frequency band of 2-18 GHz and a wide wave-absorbing bandwidth, has the advantages of a simple preparation process, high oxidation resistance and the like, and can be suitable for preparation of microwave absorption products which require wide wave-absorbing bandwidth, good wave-absorbing performance and high oxidation resistance.

Owner:GUILIN UNIV OF ELECTRONIC TECH

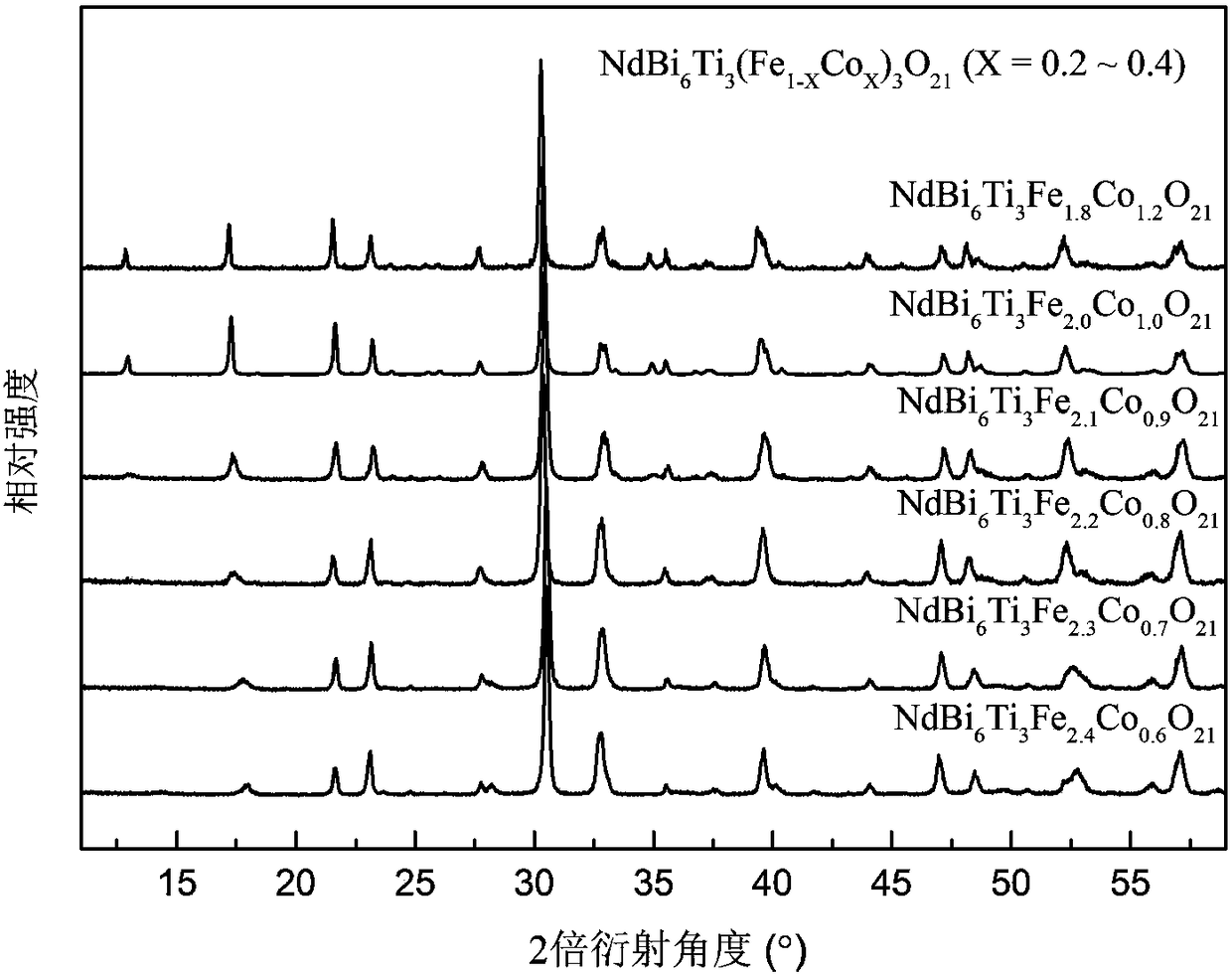

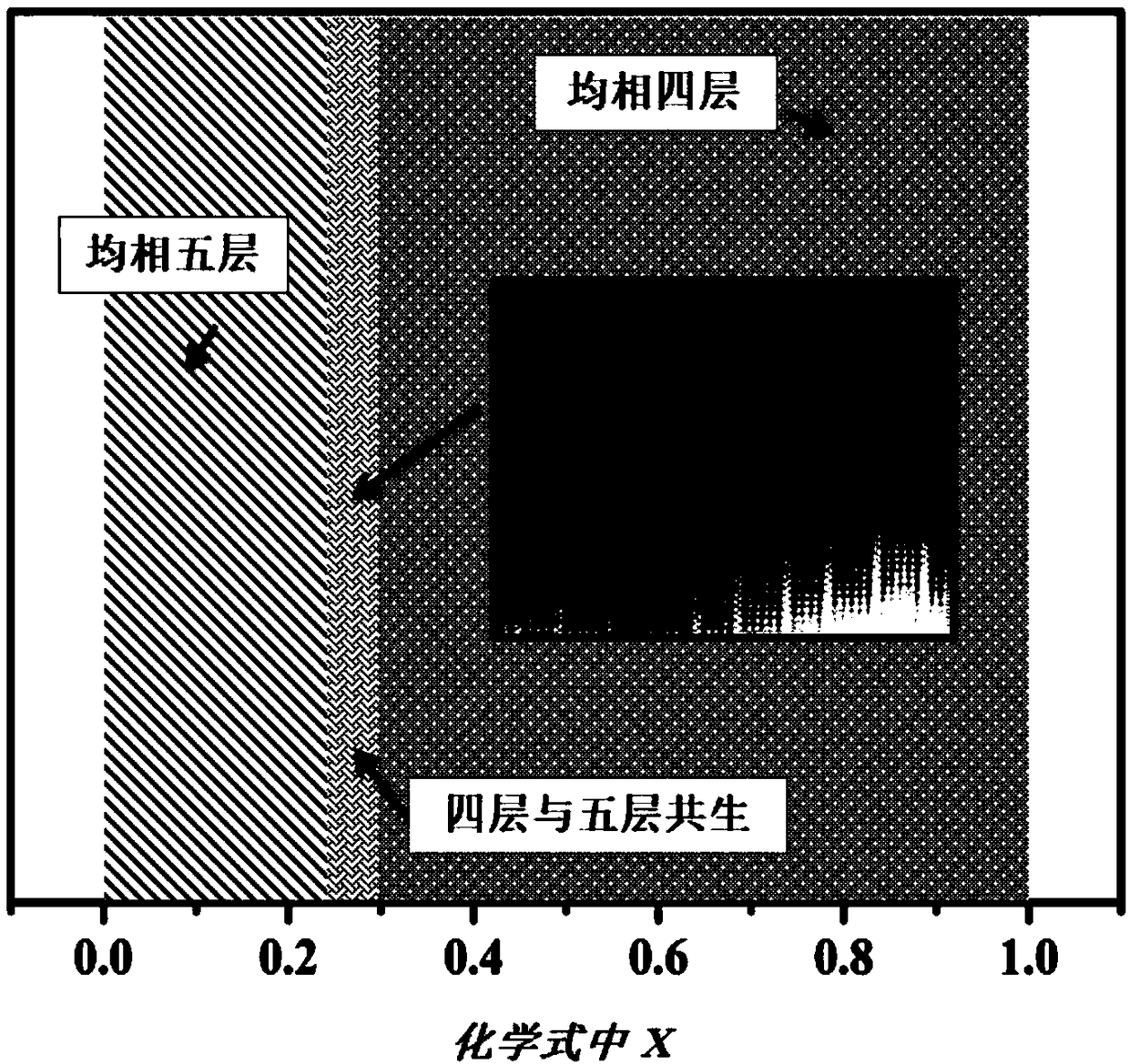

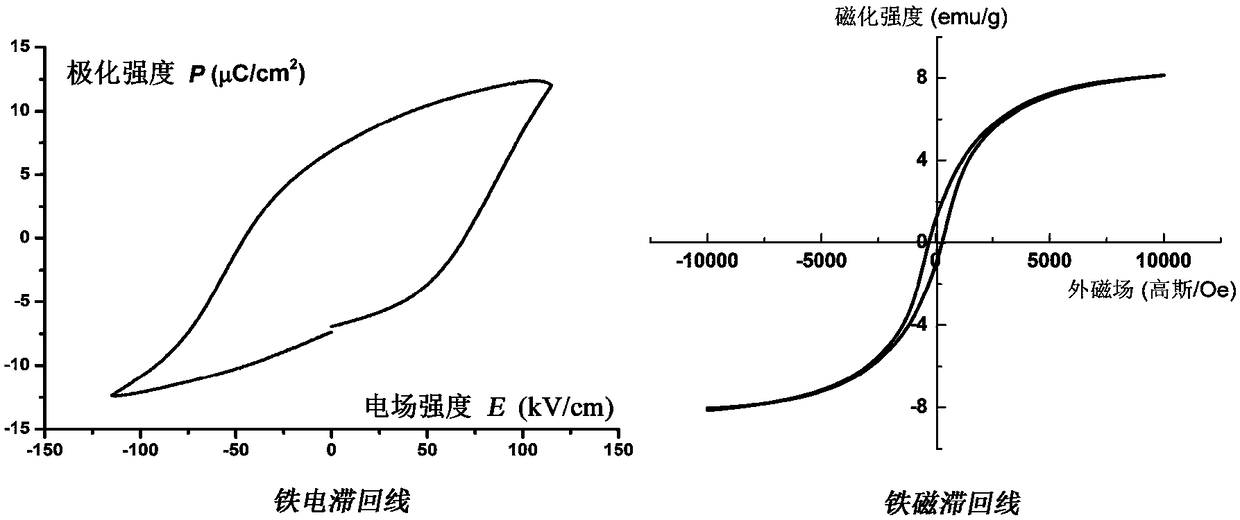

Single-phase multiferroic microwave absorbing material and preparation method thereof

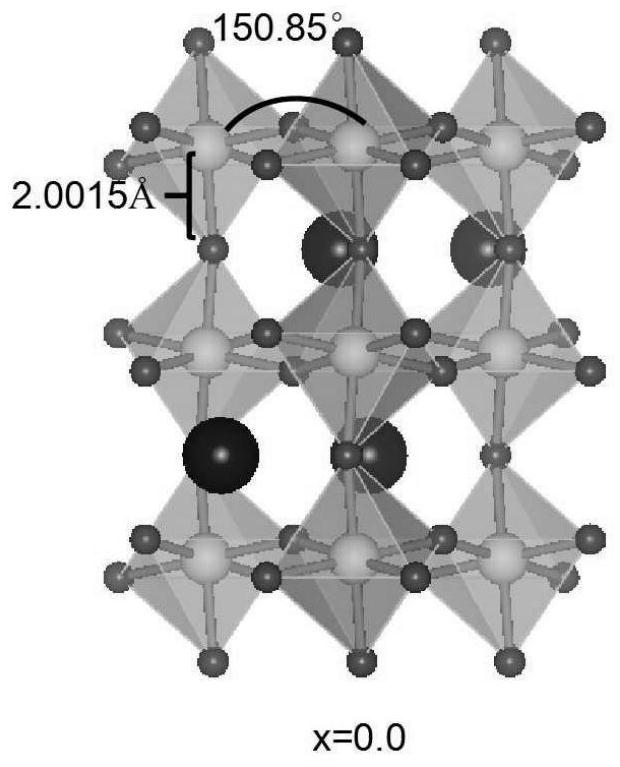

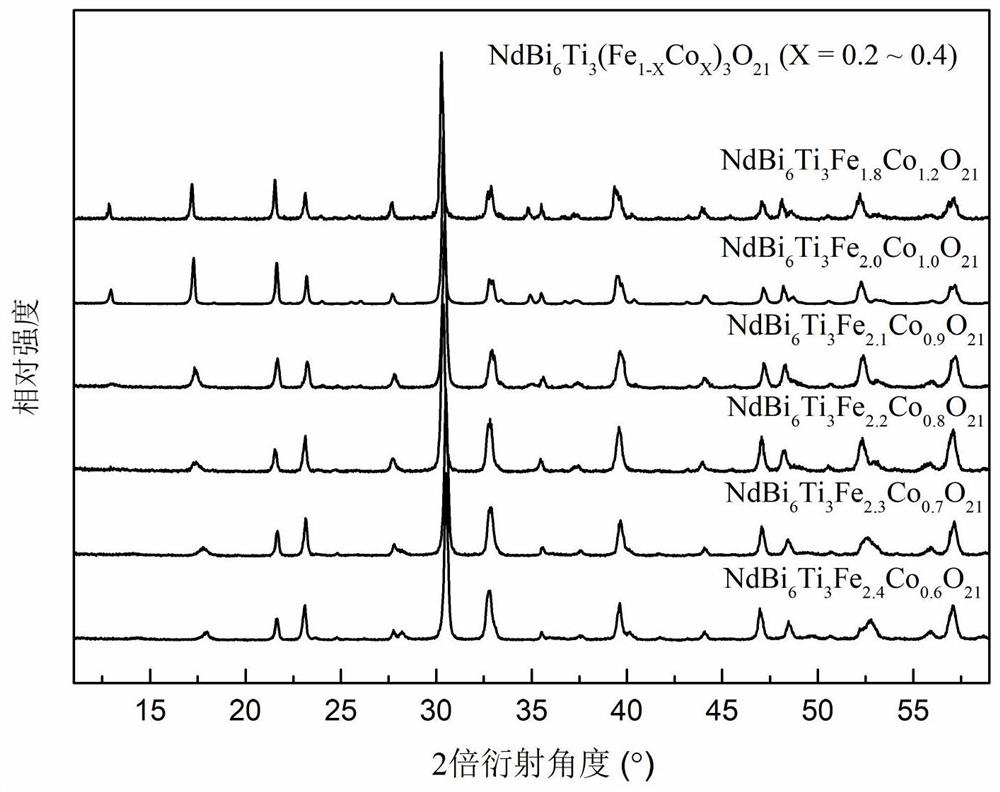

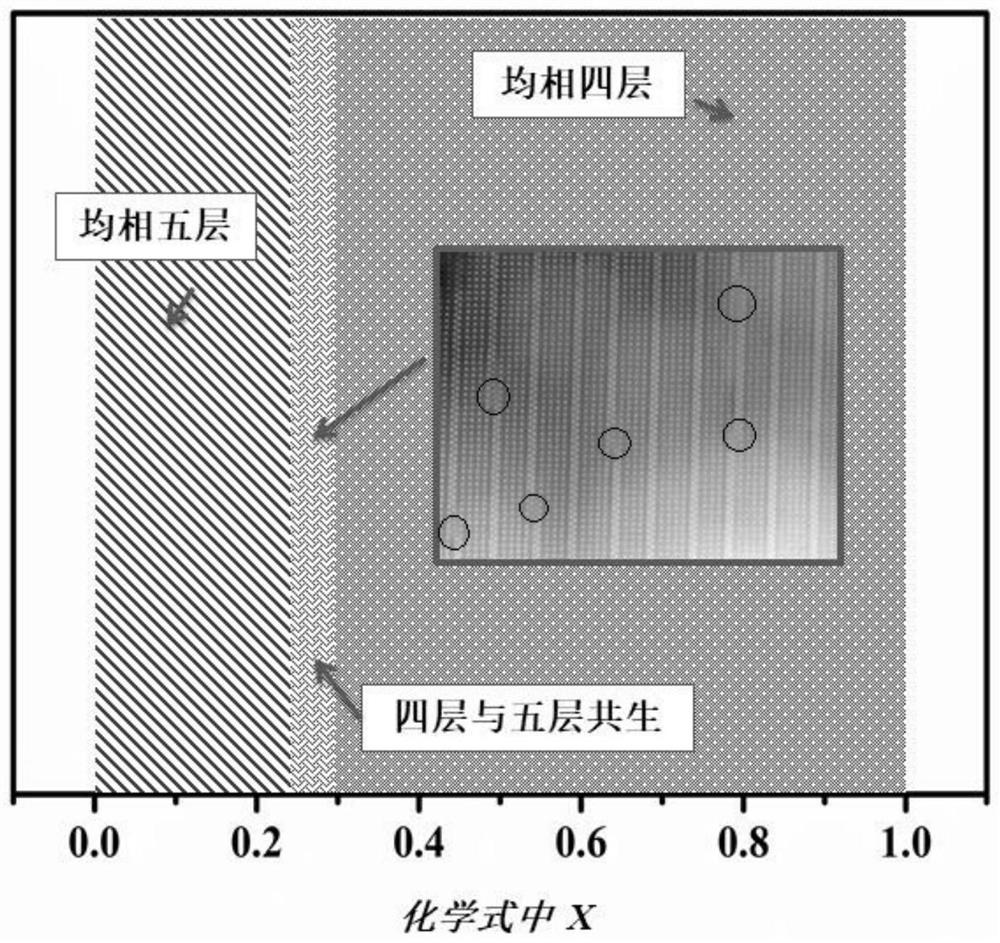

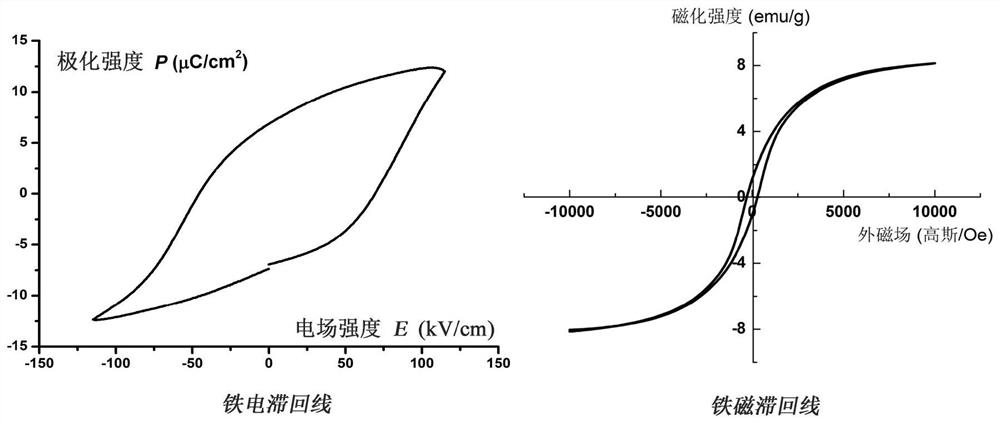

ActiveCN108558387AGood microwave absorption characteristicsHigh absorption strengthMagnetic/electric field screeningOctahedronHigh absorption

The invention discloses a single-phase multiferroic microwave absorbing material NdBi6Ti3 (Fe1-xCox) 3O21(x=0.25-0.3) and a preparation method thereof. Because of the symbiotic structure of layered perovskite and the chemical modification of neodymium, the microwave absorbing material exhibits excellent multiferrous properties due to the interaction between ferrite octahedron and cobalt-oxygen octahedron. Based on these physical characteristics, the material exhibits good microwave absorbing property in the microwave range of 2-18GHz, has high absorption intensity and wide absorption band, andis far superior to the microwave absorption performance of the partial carbon / ferrite composite material; and the preparation method has the advantages of simple operation, short experiment period, favorable for large-scale production and wide application prospect.

Owner:XINYANG NORMAL UNIVERSITY

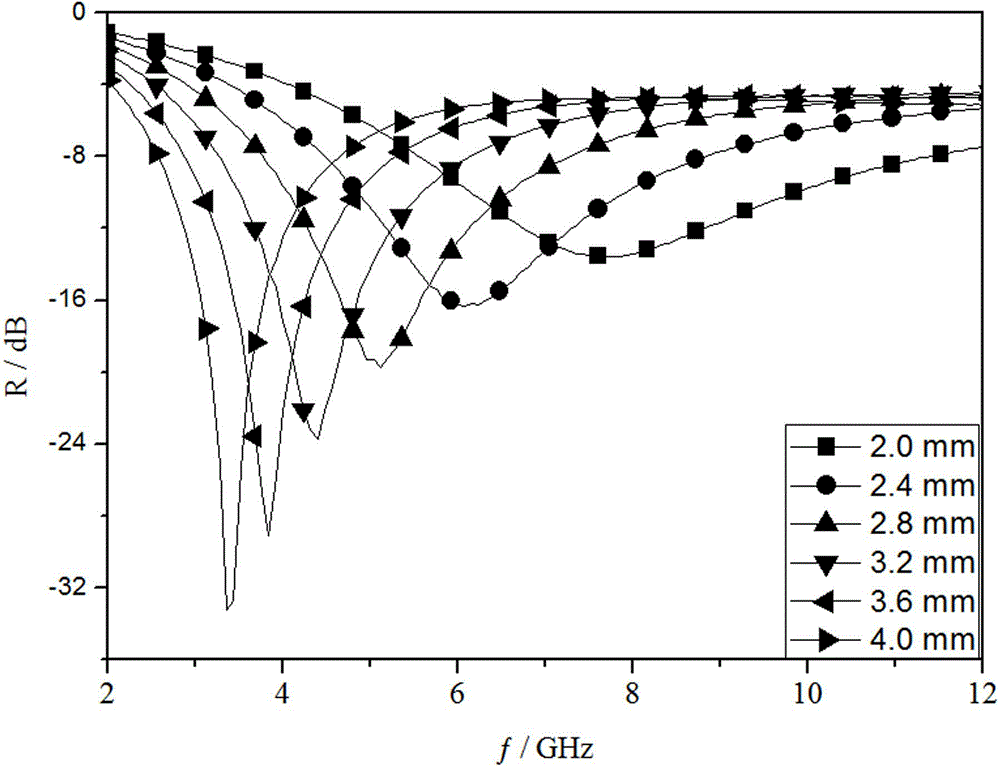

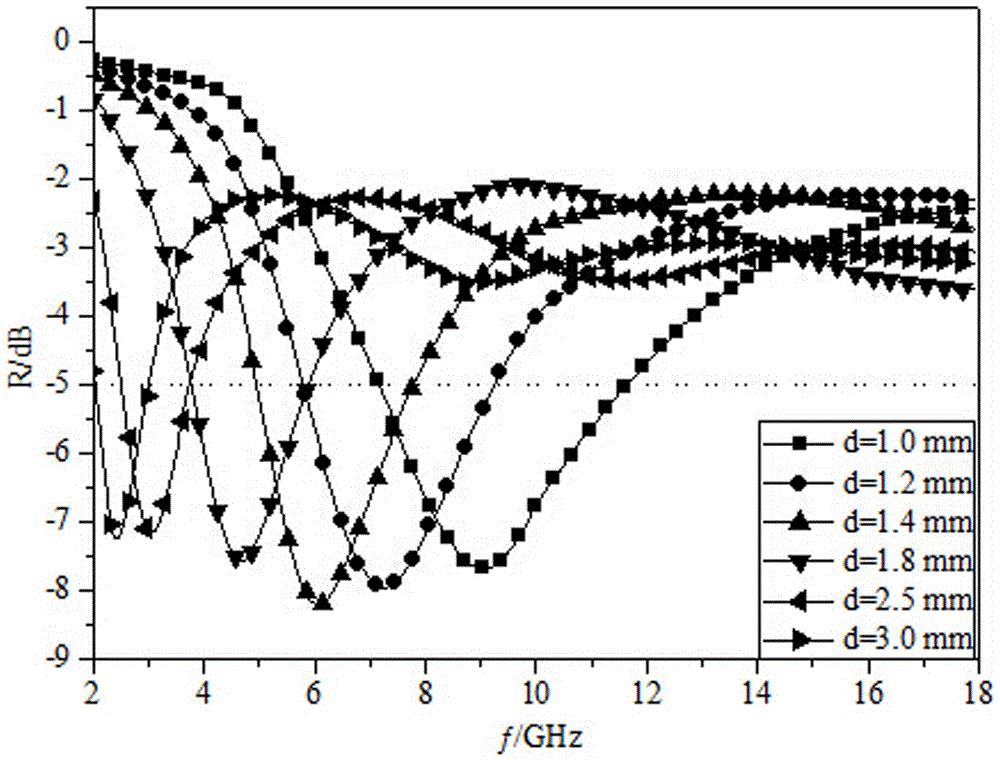

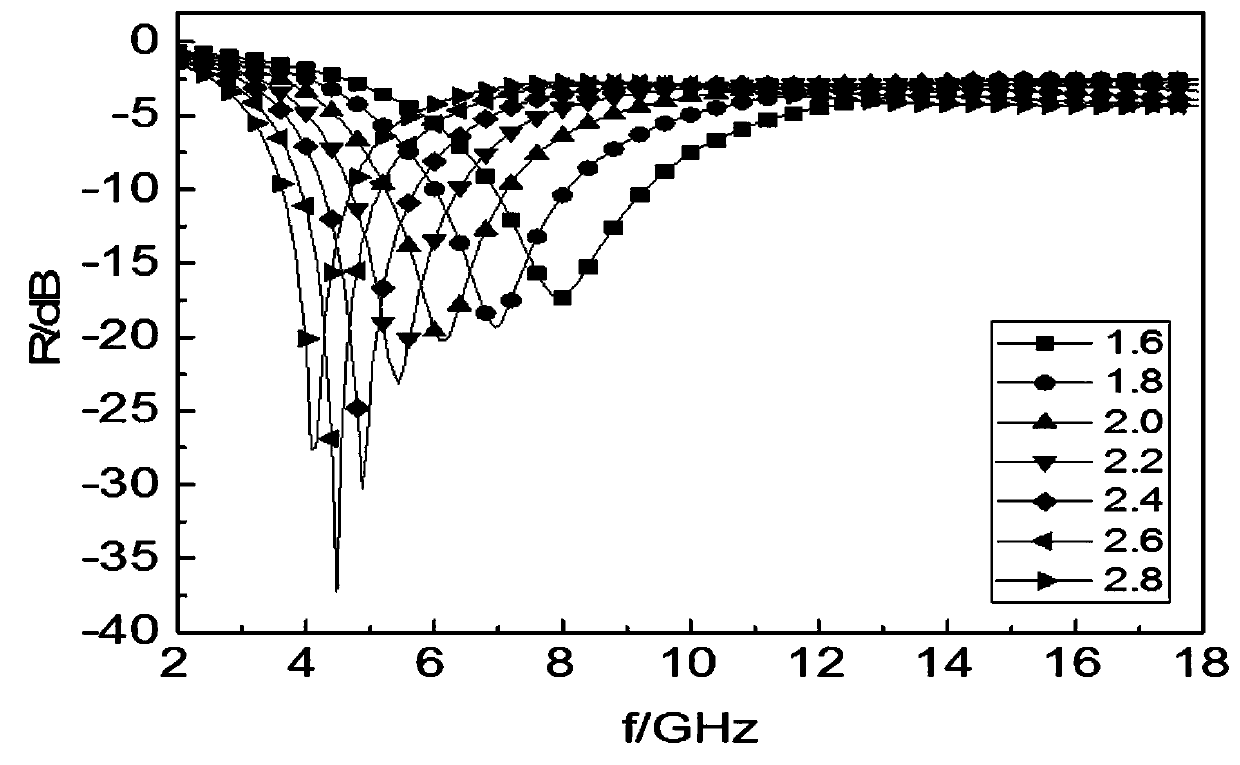

Rare earth Fe-based electromagnetic shielding material and preparation method thereof

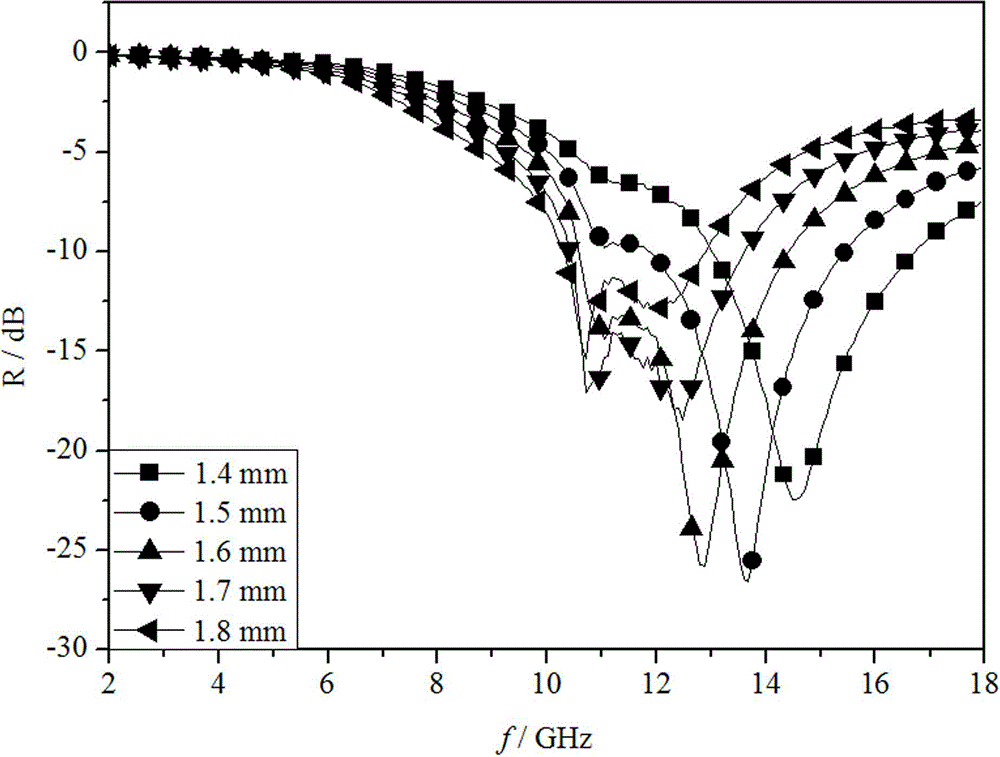

InactiveCN105603296AGood microwave absorption characteristicsAbsorption BandwidthMaterial analysis using microwave meansMagnetic materialsIce waterRare earth

The invention discloses a rare earth Fe-based electromagnetic shielding material and a preparation method thereof. The alloy comprises 10.5% of Nd, 81.6-89.5% of Fe and 0.0-7.9% of C in terms of atomic percent, and is prepared according to the following process: taking Nd, Fe and C with the purities of larger than or equal to 99.90% as raw materials, smelting in the protection of argon, performing uniform heat treatment to the alloy in vacuum at 800-1050 DEG C, quenching by using ice water / liquid nitrogen, performing ball milling after mechanically crushing, and performing tempering heat treatment at 50-300 DEG C to prepare a sample. The NdFeC electromagnetic shielding material has relatively excellent microwave absorbing property within a microwave band of 2-18GHz; when an alloy micropowder / paraffin compound has the thickness 1.8mm, the minimum absorption peak thereof can reach about -16.8dB; the electromagnetic shielding material has high microwave absorbing efficiency within the microwave band of 2-18GHz, a wide microwave absorbing band, high temperature stability and low economic cost, and has certain oxidation resistance and corrosion resistance; the electromagnetic shielding material is simple in preparation process, low in economic cost, and suitable for industrial production.

Owner:GUILIN UNIV OF ELECTRONIC TECH

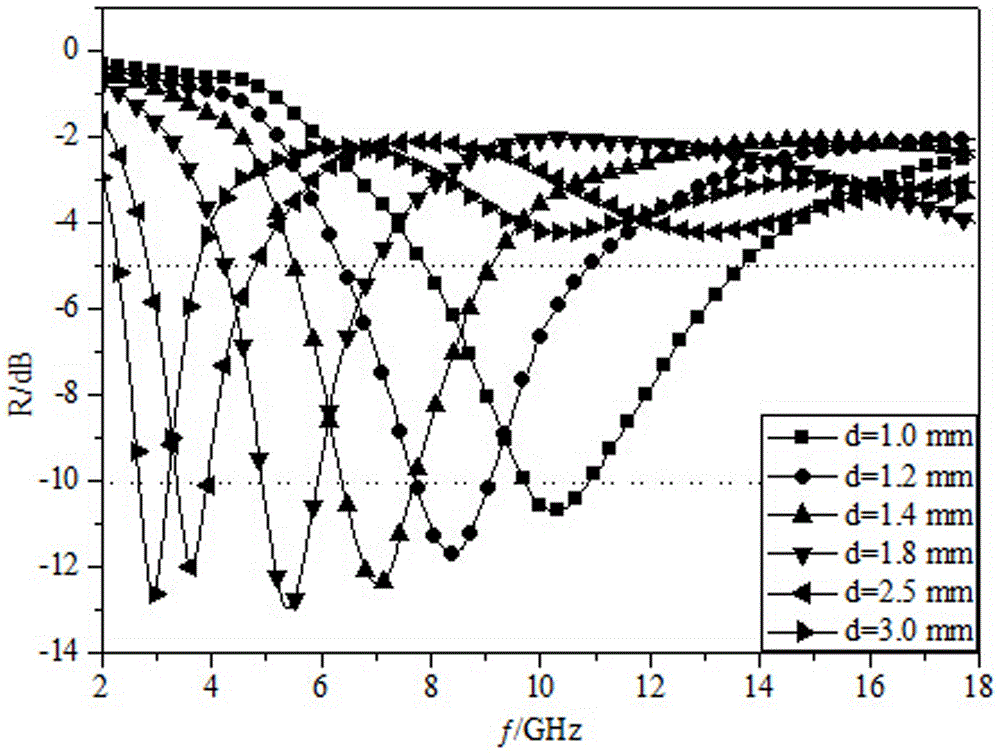

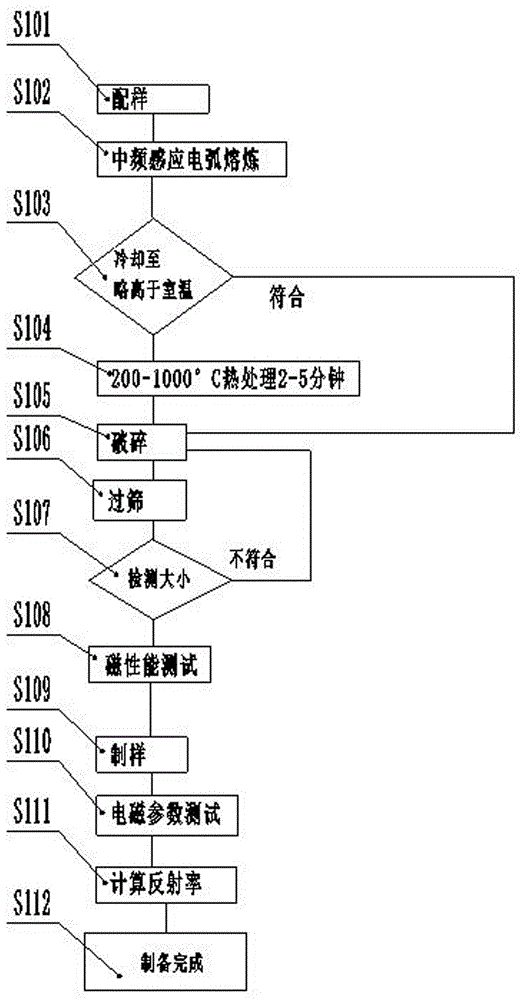

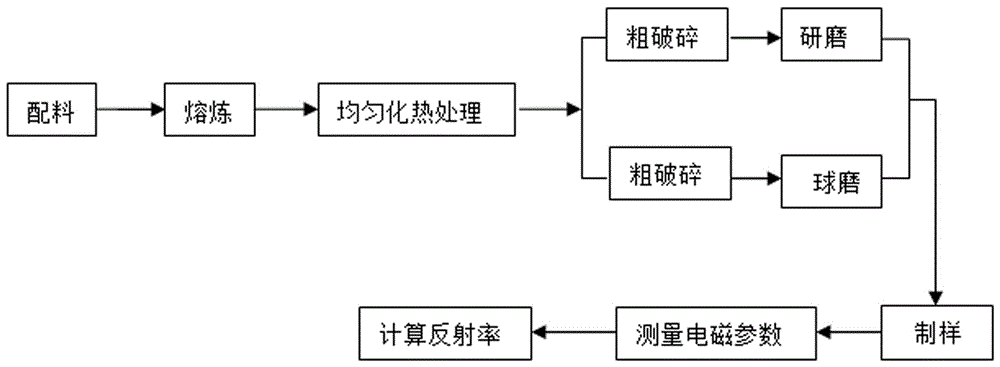

Neodymium-iron-boron permanent magnet wave-absorbing material and preparing method thereof

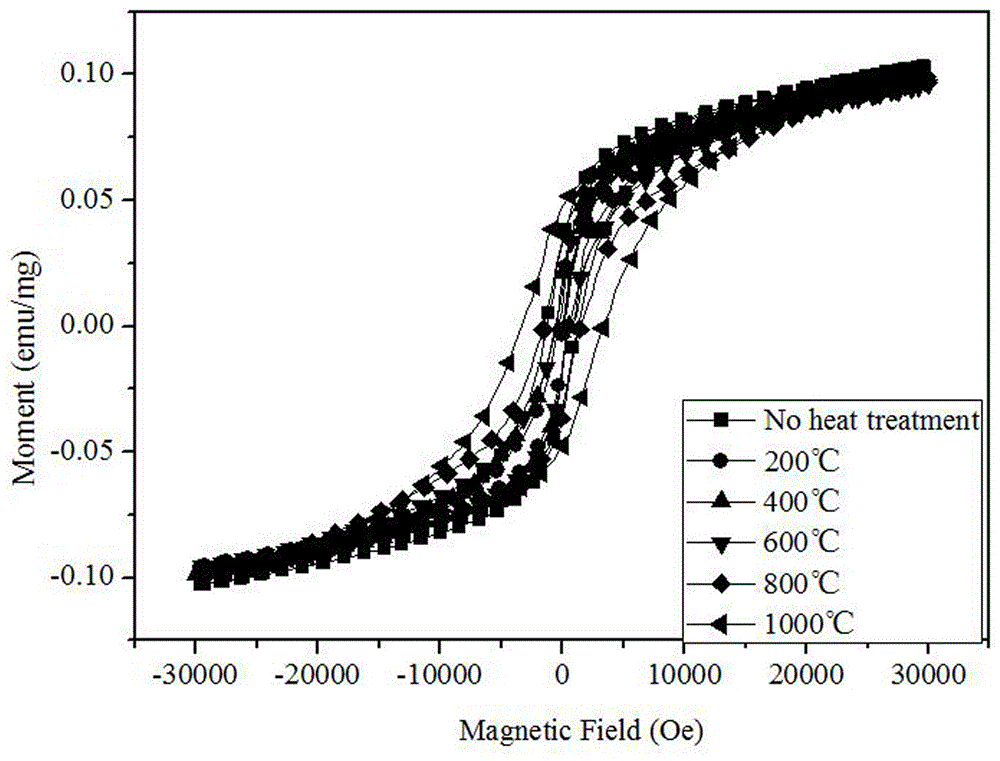

InactiveCN106024245AGood microwave absorption characteristicsSimple preparation processInorganic material magnetismMagnetizationRoom temperature

The invention discloses a neodymium-iron-boron permanent magnet wave-absorbing material and a preparing method thereof. The preparing method includes the steps that ingredients are put into a medium-frequency induction furnace to be melted; rapid-hardening pouring is carried out on a melted solution to obtain rapidly-hardened melt-spun sheets; the rapidly-hardened melt-spun sheets are taken out after being cooled; the rapidly-hardened melt-spun sheets are thermally treated within the temperature ranging from room temperature to 1000 DEG C and crushed, crushed powder is screened, magnetic property parameters such as saturation magnetization intensity, residual magnetism and coercive force are detected, and electromagnetic parameters and the reflectivity R of the powder are tested; a wave absorbing material is obtained, and the wave absorbing material has good microwave absorption characteristic within the microwave band of 2-18 GHz and has multiple absorption peaks. Permanent magnet performance and wave absorbing performance of the neodymium-iron-boron material are considered, and a new direction is developed for neodymium-iron-boron development. The method is simple in preparation process, facilitates industrialization and is convenient to put into production, and the industrial production technology is mature.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Surface scratch self-repairing plastic flooring

InactiveCN110776731AEnhance self-healing abilityIncrease the degree of cross-linkingSynthetic resin layered productsLaminationEpoxyPolymer science

The invention relates to the technical field of plastic flooring, particularly to surface scratch self-repairing plastic flooring, wherein the preparation method comprises four steps of graphene composite powder preparation, raw material blending, extrusion molding and composite molding. Compared with the existing common polyvinyl chloride plastic flooring, the plastic flooring prepared by the invention has the following advantages that thermoplastic polyurethane and an epoxy resin are mainly used as matrixes and are subjected to high-temperature kneading to replace a polyvinyl chloride resinso as to make the plastic flooring have the flame retardance and a certain self-repairing capacity of the thermoplastic polyurethane, the thermoplastic polyurethane is modified with castor oil and trimethylolpropane, the prepared graphene loaded nanometer silver-lanthanum nitrate composite powder as a filler is added into the plastic flooring, and the surface scratch self-repairing capacity of theplastic flooring is greatly improved from three aspects by utilizing a large amount of extremely-high activity epoxy groups, hydroxyl groups, ether bonds, amine bonds, ester bonds and other polar groups carried by the epoxy resin.

Owner:界首市鑫豪塑胶有限公司

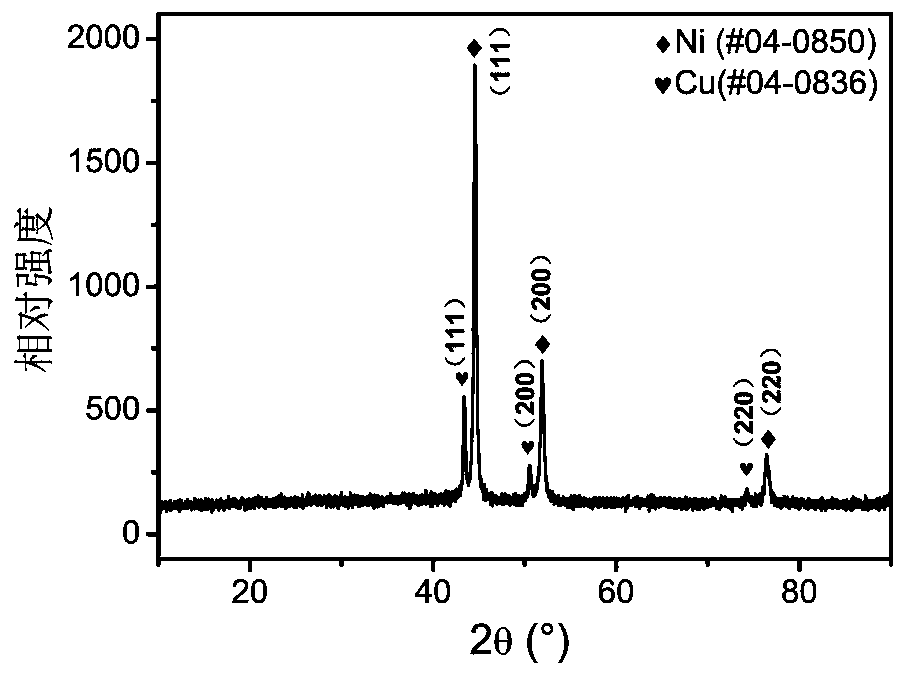

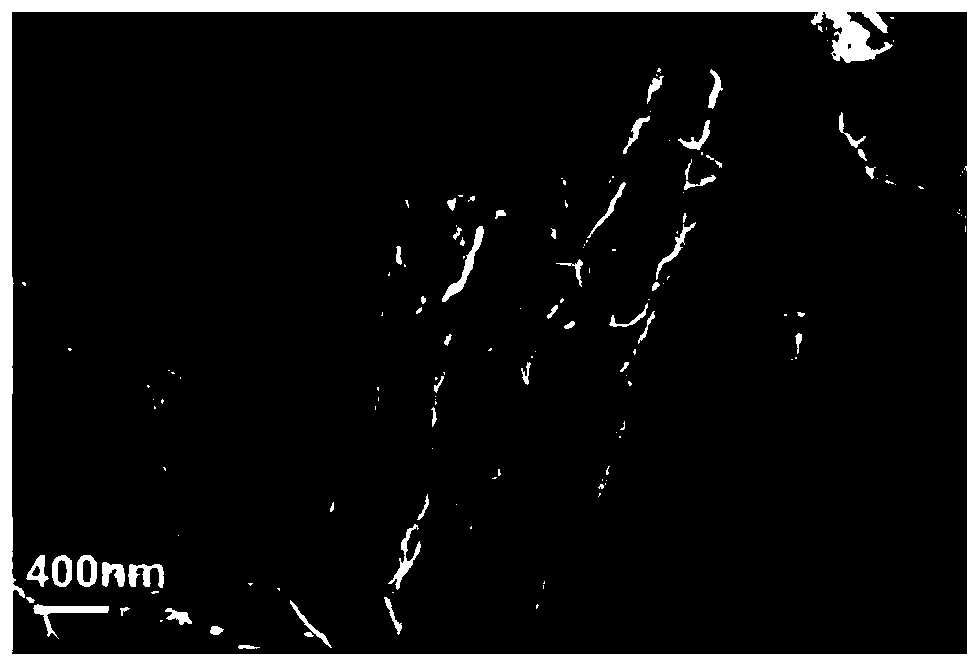

Magnetic hollow micro-nano material, preparation method and application thereof

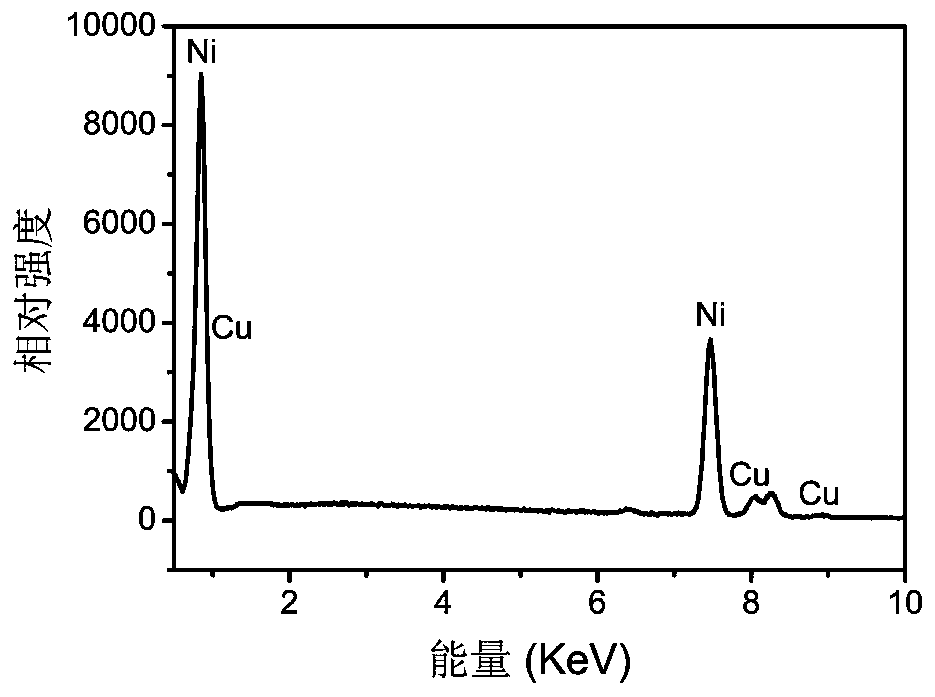

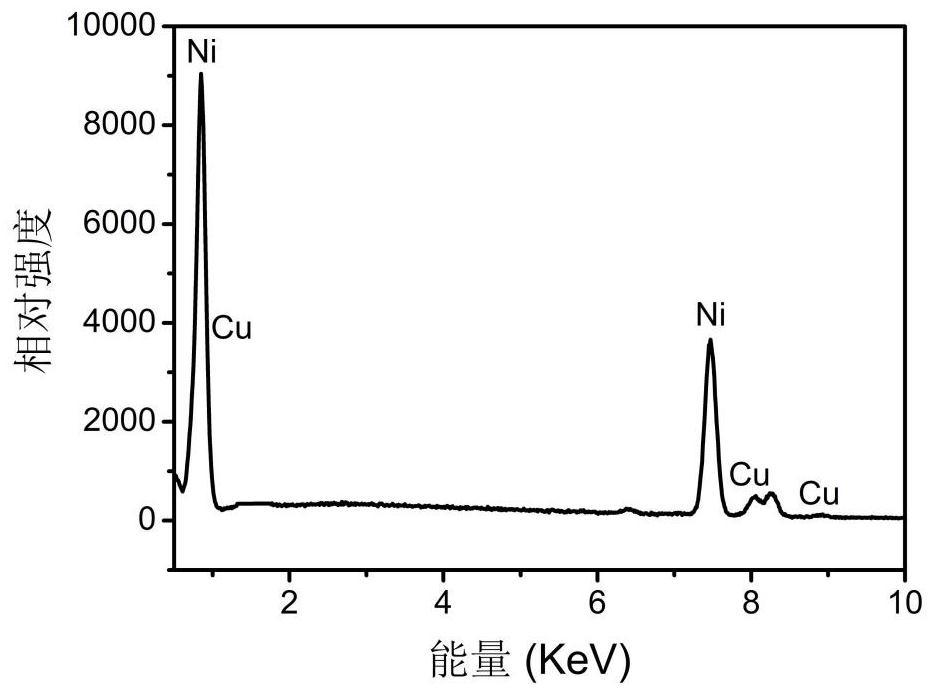

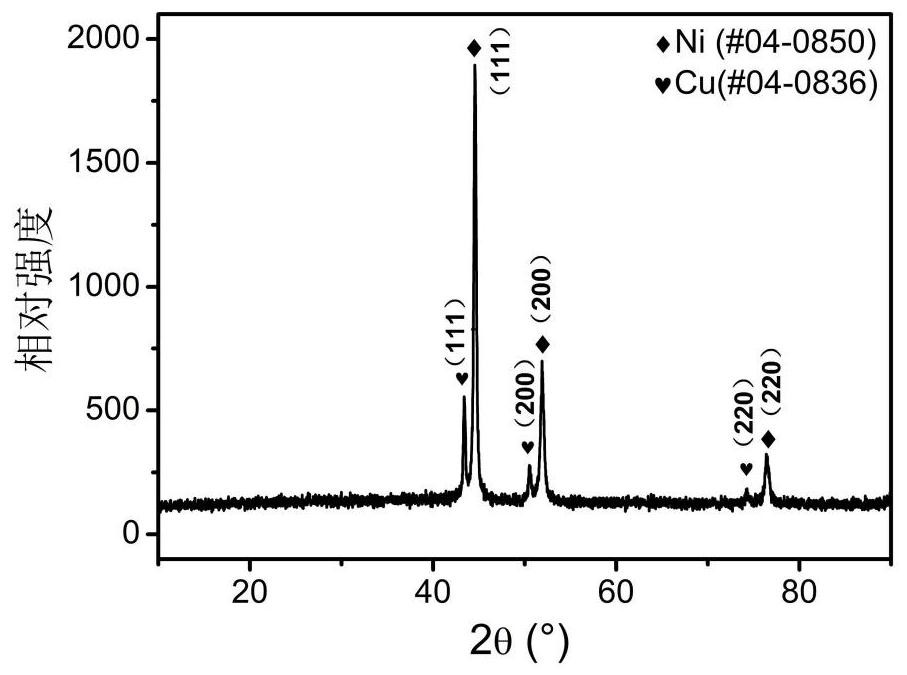

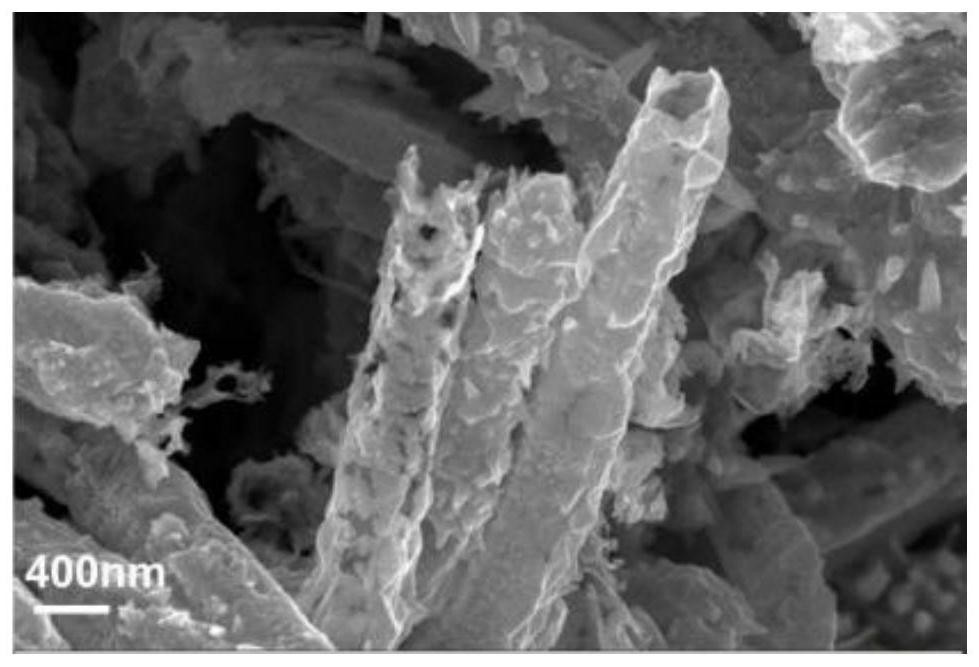

ActiveCN111014649ASimple production equipmentSimple and fast operationOther chemical processesTransportation and packagingMicro nanoSurface-enhanced Raman spectroscopy

The invention discloses a magnetic hollow micro-nano material, a preparation method and application thereof, and belongs to the technical field of nano materials. According to the magnetic hollow micro-nano material and the preparation method and application thereof, the magnetic hollow micro nano material prepared by a one-step liquid-phase reduction-oxidation method has novel structure and formation mechanism, the contents of Cu and Ni and the composition, feature, and structure of the magnetic hollow micro-nano material can be regulated by changing the reaction temperature, time, stirring speed, gas flow size, and reactant concentration, wherein the diameter of a micro-nano tube is 0.1 to 2 [mu]m, the length is 2 to 12 [mu]m, and the wall thickness is 10 to 140 nm; the diameter of a micro-nano sphere is 0.2 to 5 [mu]m, and the wall thickness is 10 to 180 nm. Because the magnetic hollow micro-nano material is good in dispersibility, good in homogeneity and has good microwave absorption characteristics, the magnetic hollow micro-nano material is widely used in the fields such as microwave absorbing and shield, electrocatalysis, lithium ion batteries and surface enhanced Raman spectroscopy. In addition, the disclosed preparation method is easy to operate, the environment-friendly effect is realized, industrial application potential is good, and the magnetic hollow micro-nano material and the preparation method are suitable for market promotion and application.

Owner:ZHEJIANG NORMAL UNIVERSITY

Biomass charcoal-based catalyst coupled microwave effect catalytic reforming hydrogen production method

PendingCN113753855AImprove absorbing performanceImprove economyHydrogenMetal/metal-oxides/metal-hydroxide catalystsCatalytic reformingPtru catalyst

The invention belongs to the field of biomass energy utilization, and particularly relates to a biomass charcoal-based catalyst coupled microwave effect catalytic reforming hydrogen production method which mainly comprises the steps of (1) conducting pretreatment, specifically, drying and crushing biomass to obtain a biomass raw material for later use; (2) conducting pyrolysis, specifically, putting a certain mass of biomass raw materials into a pyrolysis reactor, and completely reacting at the temperature of 450-550 DEG C in an inert atmosphere to obtain biomass pyrolytic carbon; (3) carrying out metal loading, specifically, carrying out acid pickling treatment, magnetic stirring, washing, filtering and drying on the biomass pyrolytic carbon, and then carrying out metal loading to obtain a carbon-based catalyst; and (4) carrying out catalytic reforming, specifically, carrying out catalytic reforming on the bio-oil model compound by utilizing a microwave reactor coupled carbon-based catalyst to obtain a hydrogen product. According to the invention, the bio-oil is subjected to catalytic reforming in a microwave coupling carbon-based catalyst manner, so that the reaction process is accelerated, the deactivation rate of the catalyst is reduced, and the hydrogen yield is remarkably improved.

Owner:ZHENGZHOU UNIV +1

Method for Improving the Strength of Plastic Rapid Forming Parts and Equipment for Producing Special Wires

ActiveCN105584048BHigh strengthImprove plastic strengthAdditive manufacturing apparatus3D object support structuresThermoplasticEngineering

The invention relates to a method for improving the strength of plastic rapid prototyping parts and equipment for producing special wire rods. The method is characterized in that the method includes the steps of: preparing plastic wire rods with graphene microchips on the surface, making rapid prototyping parts, microwave treatment, heat preservation and cool down. Its equipment includes frame, plastic extruder, cooling tank, ultrasonic disperser, traction wheel set and winder. Its advantages are: the manufactured plastic rapid prototyping parts have high strength and good strength along the layer direction, and can keep the original size and shape of the workpiece unchanged. This method is easy to operate, low in cost and good in effect. moldings.

Owner:泗县微腾知识产权运营有限公司

A kind of multiferroic absorbing material and preparation method thereof

Owner:HUNAN INSTITUTE OF ENGINEERING

Ni-based alloy magnetic microwave absorbing material and preparation method thereof

ActiveCN104451265BGood microwave absorption characteristicsGood absorption bandIce waterMechanical crushing

The Ni-based alloy magnetic microwave absorbing material and the preparation method thereof of the present invention have the stoichiometric ratio of the molecular formula as follows: Pr 16.67, Ni 83.33-75, Fe 0-8.33. It is prepared by the following main steps: Pr, Fe, Ni metals with purity ≥ 99.50% are used as raw materials, melted under the protection of argon or vacuum, and the ingot is heated at 600-1100°C under the protection of vacuum or argon. Carry out heat treatment, then quench with ice water, then carry out mechanical crushing, milling and ball milling. The Ni-based alloy of the invention has good microwave absorption effect in the 2-18 GHz microwave band, wide absorption frequency range, simple preparation process, strong oxidation resistance and the like. Among the magnetic wave-absorbing materials, the Ni-based alloy magnetic microwave-absorbing material of the present invention is suitable for preparing microwave-absorbing products that require wide absorption frequency band, good wave-absorbing performance and strong oxidation resistance.

Owner:GUILIN UNIV OF ELECTRONIC TECH

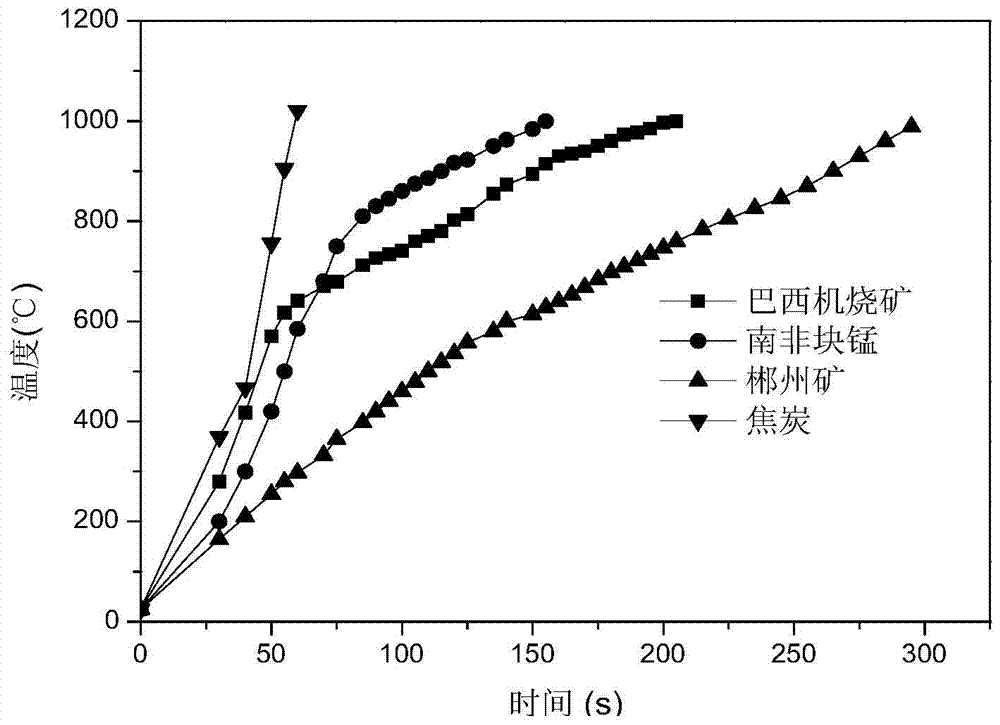

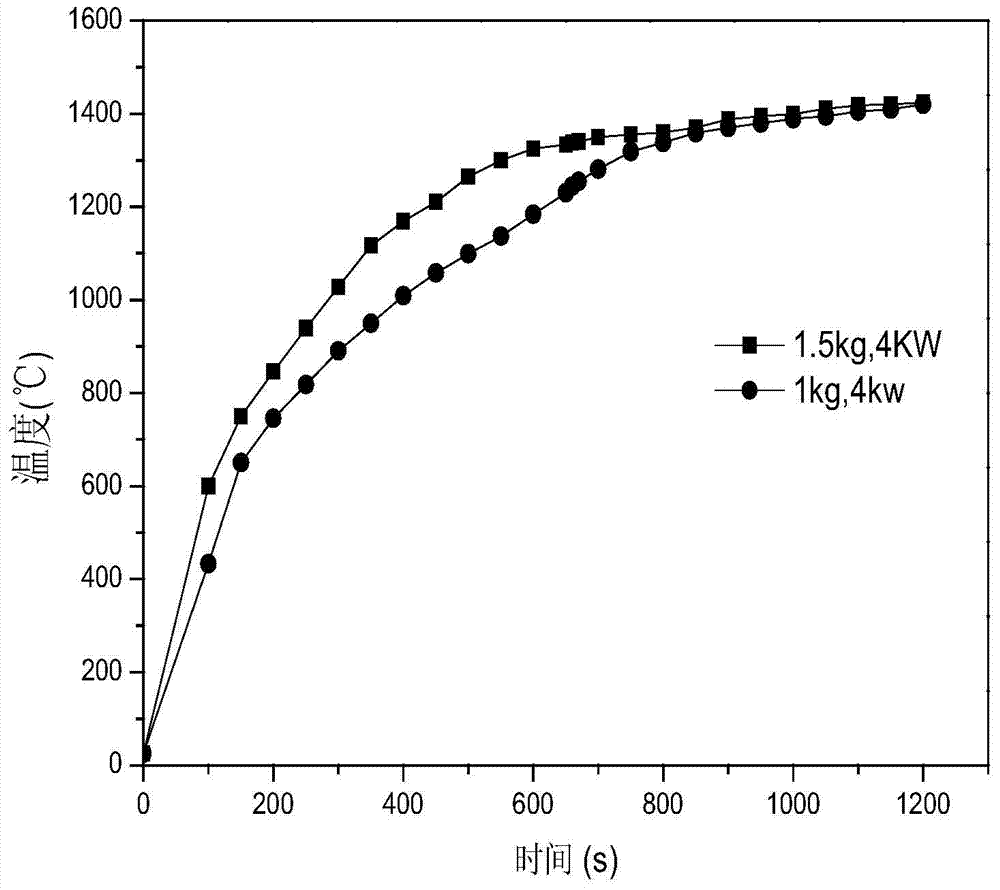

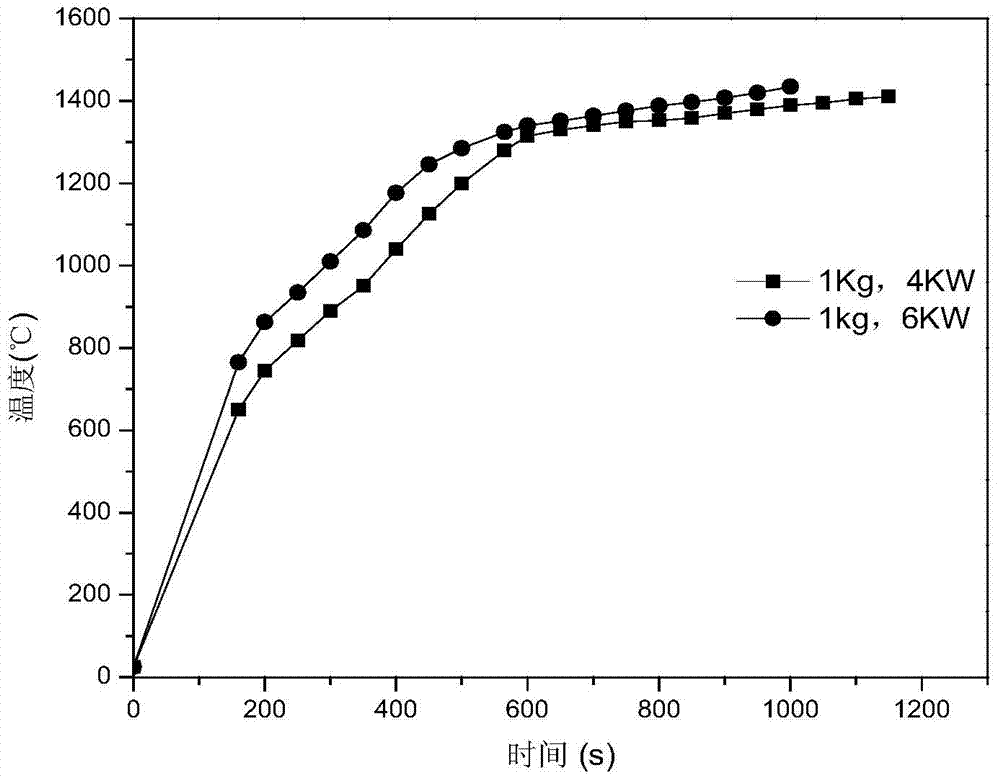

A method for smelting manganese-ferroalloy by heating manganese ore with microwave

The present invention relates to a method for smelting a manganese-iron alloy by using microwave heating of manganese ore. According to the method, a microwave generator produces microwaves with a frequency of 2.45 GHZ, the microwaves are introduced into a reactor by using a metal waveguide, the microwave and raw materials for manganese-iron alloy smelting interact in the reactor, the raw materials for manganese-iron alloy smelting absorb microwave energy in the microwave field and the temperature is rapidly increased, an oxidation reduction reaction of manganese oxide and carbon is generated between the raw materials at a temperature of 700-1500 DEG C and is the heat absorption reaction, the microwave is continuously used to heat the reaction raw materials so as to provide heat for the reaction, the microwave field provides the promoting effect for the manganese oxide reduction reaction, and under the microwave effect, the manganese oxide is rapidly reduced so as to generate the manganese-iron alloy. Compared with the method in the prior art, the method of the present invention has the following advantages that the microwave heating is used to smelt the manganese-iron alloy, and advantages of rapid heating, short raw material heating time, energy consumption reducing and the like are provided.

Owner:UNIV OF SCI & TECH BEIJING

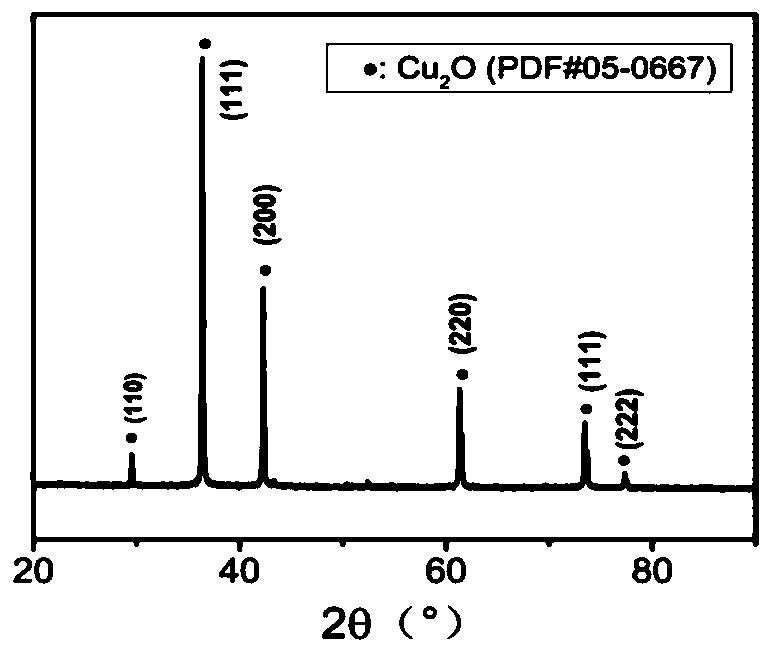

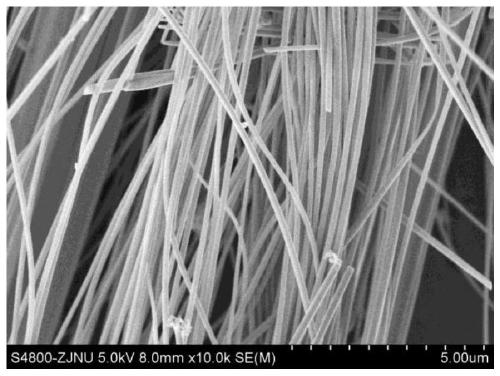

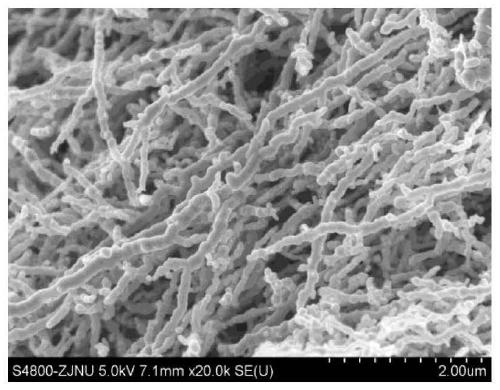

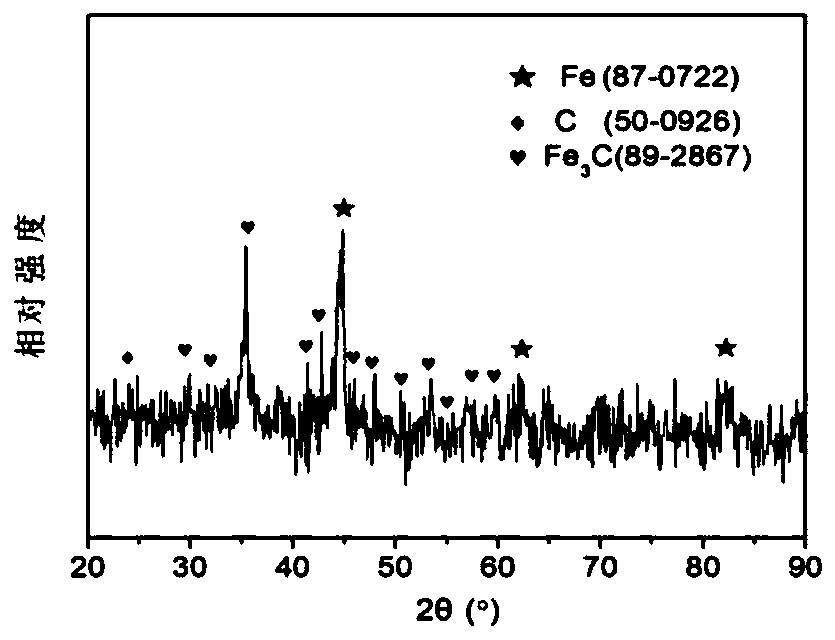

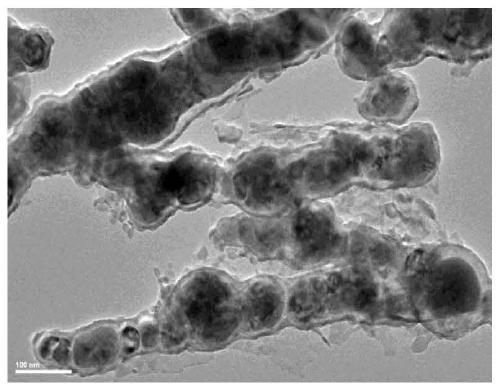

A core-shell heterostructure magnetic fiber and its preparation and application method

ActiveCN109128138BImprove light weightExcellent BroadbandMaterial nanotechnologyTransportation and packagingFiberSurface-enhanced Raman spectroscopy

The invention discloses a magnetic fiber with a core-shell heterogeneous structure and a preparation and application method thereof. The composition of the fiber is Fe, Cu, and C; the atomic percentages of Fe, Cu, and C elements are 12.2-29.6%, 9.2-55.2%, and 32.5-70.5% respectively; its structure is composed of Cu / Fe core and C shell Nanofibers with hollow or porous Cu / Fe / C core-shell structure, the fiber length is 50μm, the diameter is 70-380nm; its saturation magnetization is 80.4-152.89emu·g –1 . The fiber was fabricated by in-situ carbothermal reduction-chemical vapor deposition method, that is, the ceramic arks were loaded with organic polymer-coated Cu 2 O core-shell heterogeneous nanofibers and iron pentacarbonyl are placed in a tube furnace and roasted under the protection of an inert gas. The invention has the advantages of simple equipment, short cycle time, good repeatability, and large-scale production, and has broad application prospects in the fields of electrocatalysis, microwave absorption, lithium ion batteries, surface-enhanced Raman spectroscopy, and the like.

Owner:ZHEJIANG NORMAL UNIVERSITY

Preparation method of Na-beta''-Al2O3 solid electrolyte

InactiveCN101734911BAvoid churnReduce consumptionCell seperators/membranes/diaphragms/spacersLithiumMicrowave oven

The invention relates to a preparation method of a Na-beta''-Al2O3 solid electrolyte, comprising the following steps of: adding a stabilizer in a compound containing sodium, aluminium and magnesium or lithium as a raw material; preparing precursor powder; placing the prepared precursor powder into a microwave oven after being subjected to prilling and molding; and fast sintering to obtain the Na-beta''-Al2O3 electrolyte. The method not only has short reaction time and can furthest reduce the loss of Na2O and ensure the conductivity of the material, but also has low energy consumption and hightemperature rate and can obtain a sample with higher compactness; and in addition, the Na-beta''-Al2O3 solid electrolyte prepared by the method shows excellent property and is suitable for being usedas the solid electrolyte of a sodium-sulphur battery and a sodium-nickel chloride battery.

Owner:NANJING TECH UNIV

a hofeb/fe 3 o 4 Composite wave-absorbing material and its preparation method

ActiveCN110171834BGood microwave absorption characteristicsAbsorption BandwidthInorganic material magnetismFerroso-ferric oxidesIce waterArgon atmosphere

The invention provides a HoFeB / Fe 3 o 4 The composite wave-absorbing material and its preparation method are applicable to the field of wave-absorbing materials, and the preparation method comprises, respectively using Ho, Fe and B with a purity ≥ 99.95% as raw materials, repeatedly melting them into an ingot with uniform composition in an argon atmosphere, Vacuumize and seal in quartz glass for homogenization annealing at 800°C, then quench with ice-water mixture, and then perform mechanical crushing and high-energy ball milling. The powder after high-energy ball milling was mixed with ferroferric oxide in an agate mortar according to the relative molecular mass percentage to obtain HoFeB / Fe 3 o 4 composite material. The composite wave-absorbing material of the invention has good microwave absorption effect in the microwave frequency range of 2-18 GHz, wide absorption frequency point, simple preparation process, strong oxidation resistance and the like. It can be applied to the preparation of microwave absorbing products that require wide absorbing frequency band, good absorbing performance and strong oxidation resistance.

Owner:GUILIN UNIV OF ELECTRONIC TECH

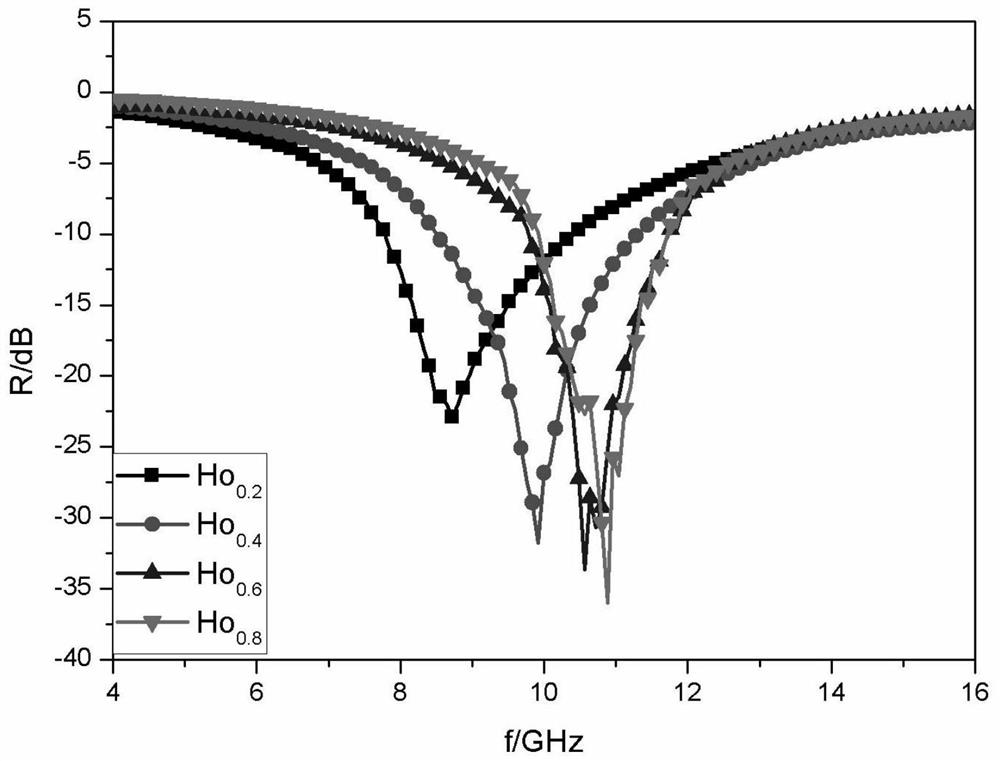

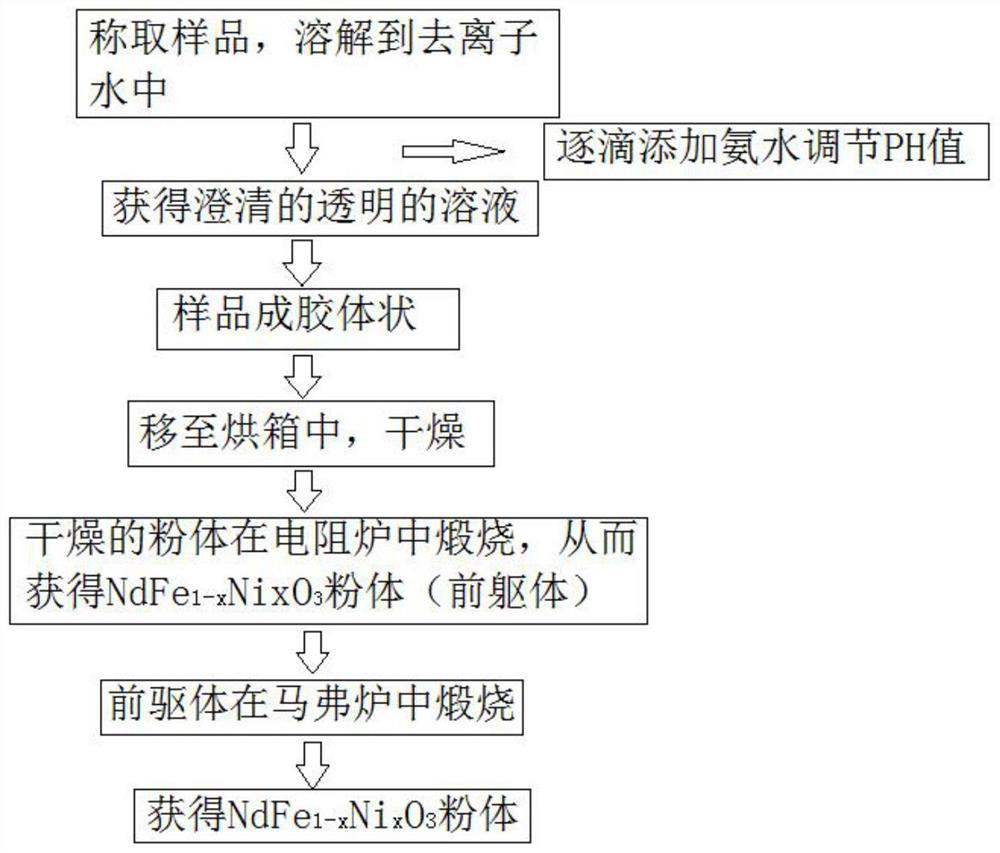

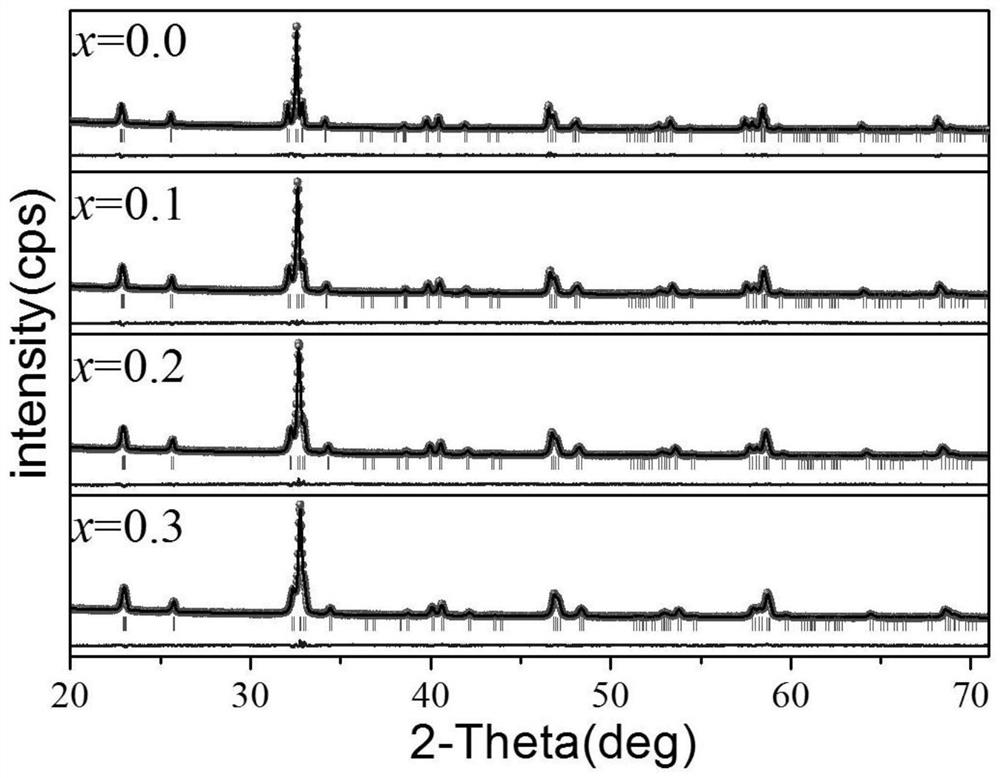

Ferrite wave-absorbing material with perovskite structure and preparation method of ferrite wave-absorbing material

InactiveCN113173783AFascinating VersatilityExcellent perovskite structurePerovskite (structure)Materials science

The invention provides a ferrite wave-absorbing material with a perovskite structure and a preparation method of the ferrite wave-absorbing material. The molecular formula of the ferrite wave-absorbing material with the perovskite structure is NdFe<1-x>Ni<x>O<3> (wherein x is equal to 0, 0.1, 0.2 or 0.3). The preparation method comprises the following steps: with neodymium nitrate hexahydrate, iron nitrate nonahydrate and nickel nitrate hexahydrate as raw materials, dissolving the raw materials in deionized water according to a stoichiometric ratio, adding a proper amount of citric acid monohydrate, dropwise adding ammonia water to adjust a pH value to achieve an alkaline environment, and then conducting heating and stirring in a water bath kettle to obtain uniform wet gel; and drying the prepared wet gel in an air dry oven, conducting pre-sintering to obtain a precursor, adding PVA into obtained precursor powder, conducting granulating, performing uniformly grinding, and and carrying out mould pressing to prepare a cylindrical block. The ferrite wave-absorbing material with the perovskite structure has a very good microwave absorbing effect in a microwave band of 2-18 GHz, is wide in absorbing frequency band, and has the advantages that the preparation process is simple, the preparation process is easy to regulate and control and the like.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Single-phase multiferroic microwave absorbing material and preparation method thereof

ActiveCN108558387BGood microwave absorption characteristicsHigh absorption strengthMagnetic/electric field screeningPerovskite (structure)Microwave range

The invention discloses a single-phase multiferroic microwave absorbing material NdBi6Ti3 (Fe1-xCox) 3O21(x=0.25-0.3) and a preparation method thereof. Because of the symbiotic structure of layered perovskite and the chemical modification of neodymium, the microwave absorbing material exhibits excellent multiferrous properties due to the interaction between ferrite octahedron and cobalt-oxygen octahedron. Based on these physical characteristics, the material exhibits good microwave absorbing property in the microwave range of 2-18GHz, has high absorption intensity and wide absorption band, andis far superior to the microwave absorption performance of the partial carbon / ferrite composite material; and the preparation method has the advantages of simple operation, short experiment period, favorable for large-scale production and wide application prospect.

Owner:XINYANG NORMAL UNIVERSITY

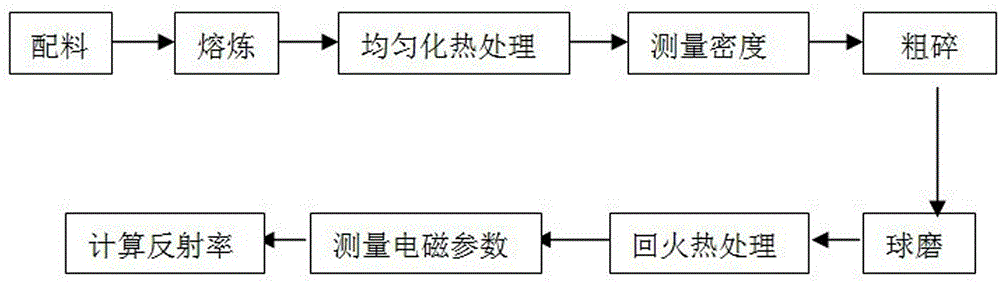

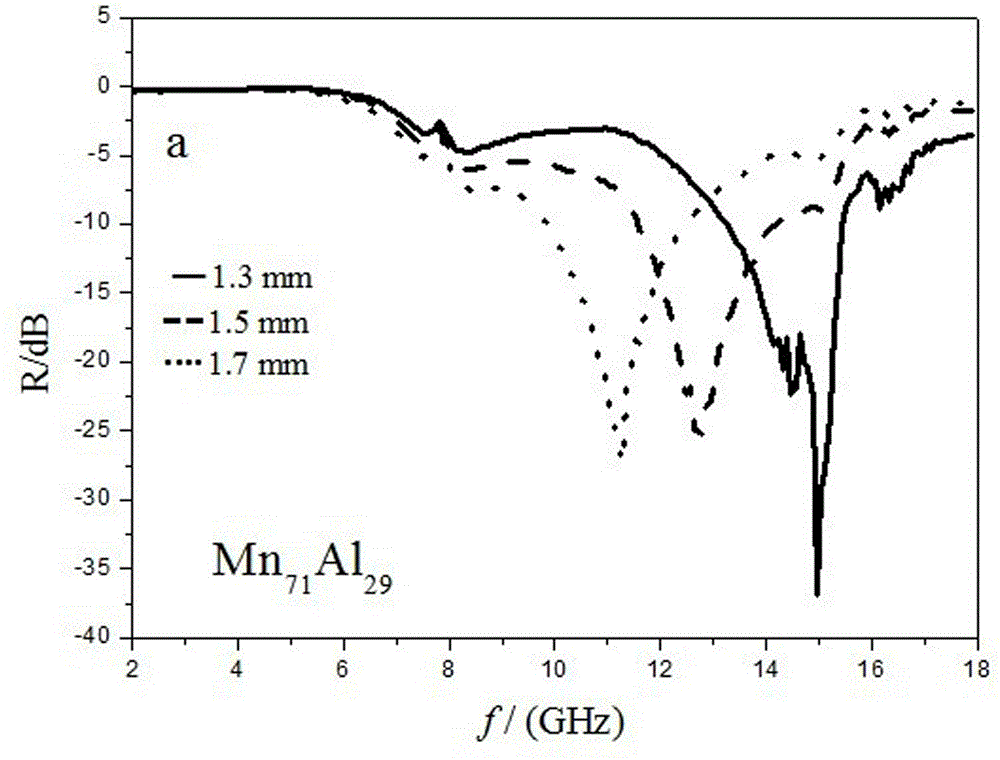

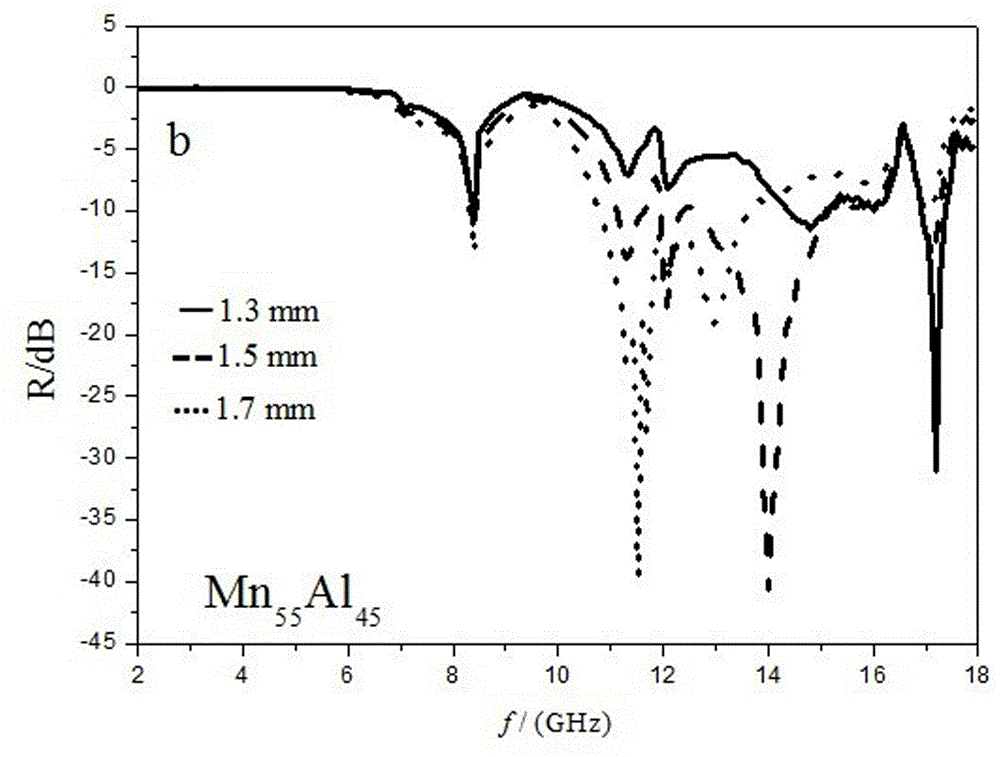

Mnal alloy magnetic wave-absorbing material and preparation method thereof

A MnAl alloy magnetic absorbing material provided by the invention comprises atoms in the following percentage: 37-72% of Mn and 28-63% of Al. The absorbing material is prepared by a method comprising the following steps: melting raw materials of metal Mn and Al with purity no less than 99.50% under protection of argon; carrying out uniformization treatment on cast ingots at 900-1100 DEG C in vacuum or under protection of argon; milling the cast ingots; and carrying out tempering heat treatment at 200-600 DEG C. The MnAl alloy magnetic absorbing material has characteristics of small density, good microwave absorption characteristics in microwave band of 2-18 GHz, wide frequency band of absorption, good oxidation resistance, corrosion resistance and temperature stability, does not contain strategic metal elements like Co, Ni and rare earths, simple preparation technology, abundant raw materials and low price. Among the magnetic absorbing materials, the MnAl alloy magnetic absorbing material provided by the invention is more suitable for preparation of microwave absorption products with wide frequency band of absorption, high absorbing efficiency, small material density, good oxidation resistance, corrosion resistance and temperature stability, and low cost.

Owner:GUILIN UNIV OF ELECTRONIC TECH

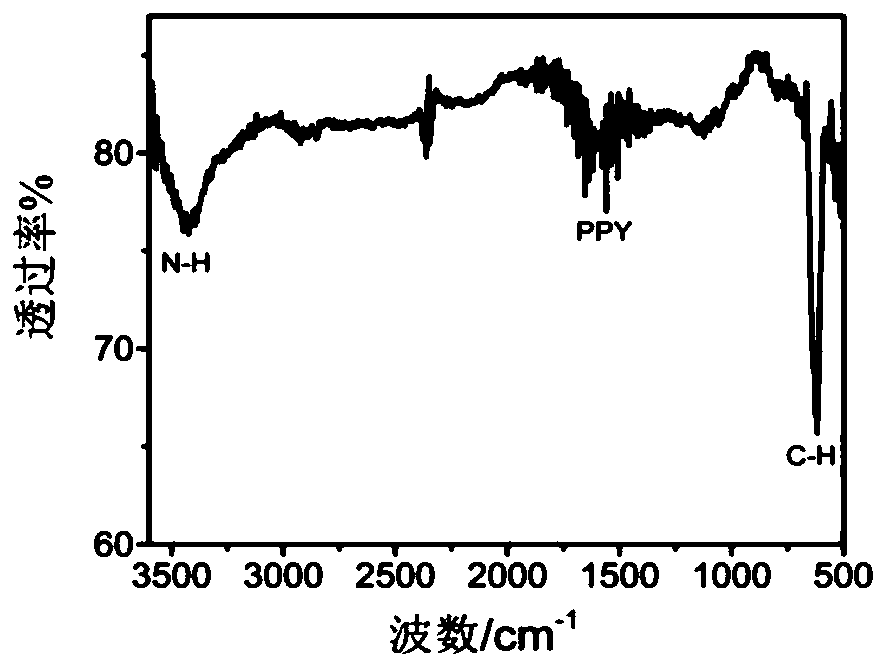

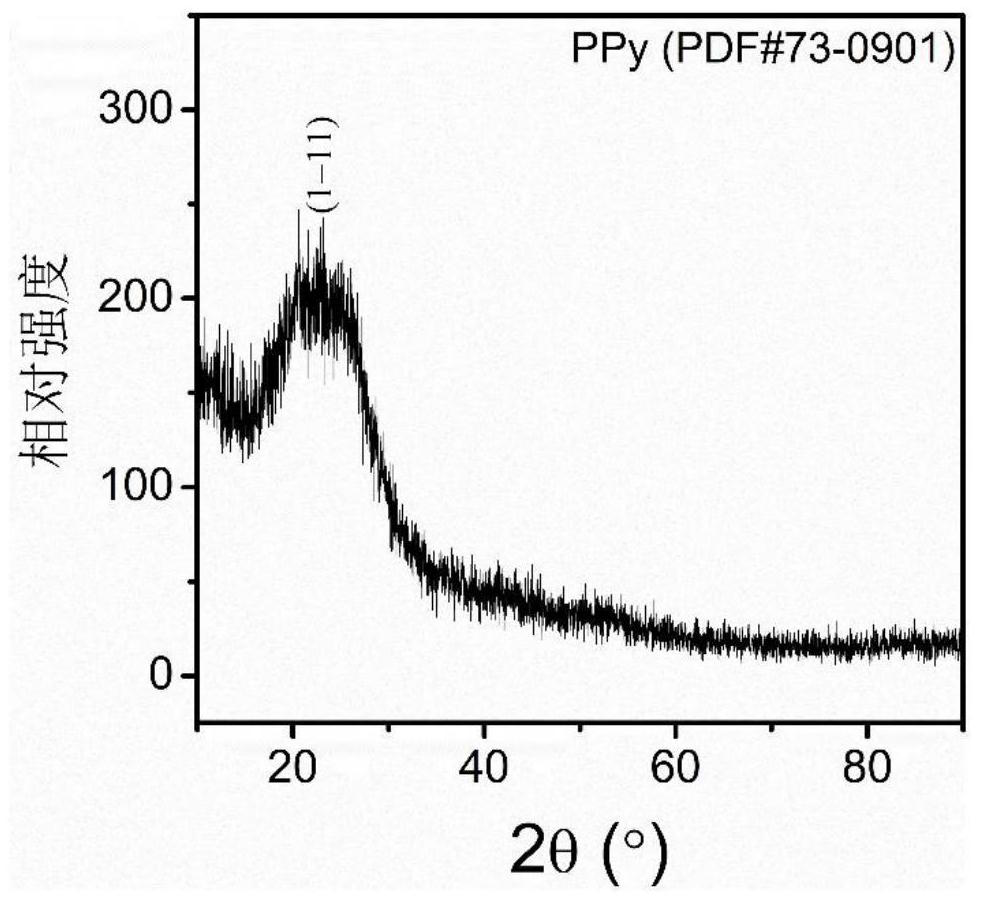

Chiral planar spiral PPy/Fe3O4 composite broadband microwave absorbent as well as preparation method and application thereof

ActiveCN113088075AUnique shapeNoveltyOther chemical processesChemical industryPolymer sciencePolypyrrole

The invention belongs to the field of microwave absorption, and discloses a chiral planar spiral PPy / Fe3O4 composite broadband microwave absorbent as well as a preparation method and application thereof. The planar spiral polypyrrole with unique morphology is prepared by taking a surfactant as a soft template and adopting a chemical oxidative polymerization reaction method, and the diameter of the planar spiral polypyrrole is 20-40 microns. By taking the material as a precursor, the compound of chiral polypyrrole and Fe3O4 is prepared from the precursor, ferric salt and other raw materials through a dissolution heat method; not only is the morphology novel and unique, but also the content and size of Fe3O4 growing on the surface of polypyrrole can be regulated and controlled by changing the concentration of iron ions in the system and the volume of the added deionized water; and the material has excellent microwave absorption characteristics. The controllable preparation process disclosed by the invention is simple, the product morphology is novel, the characteristics that the reaction conditions are harsh, the morphology of the reaction product is difficult to regulate and control, the experimental repeatability is poor and the like in the previous preparation process are overcome, and the industrial application potential is good.

Owner:ZHEJIANG NORMAL UNIVERSITY +1

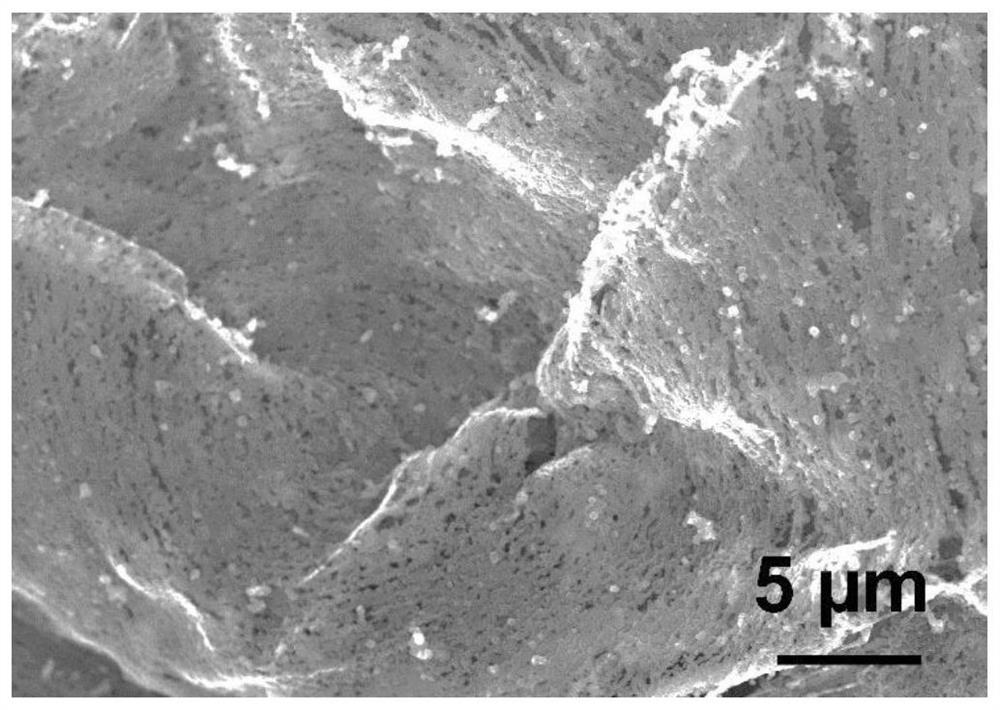

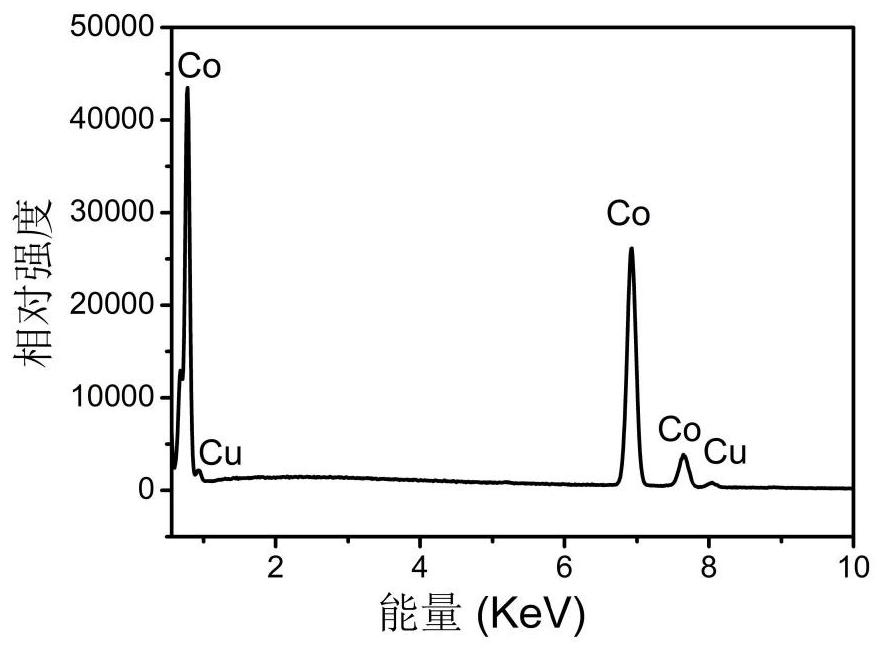

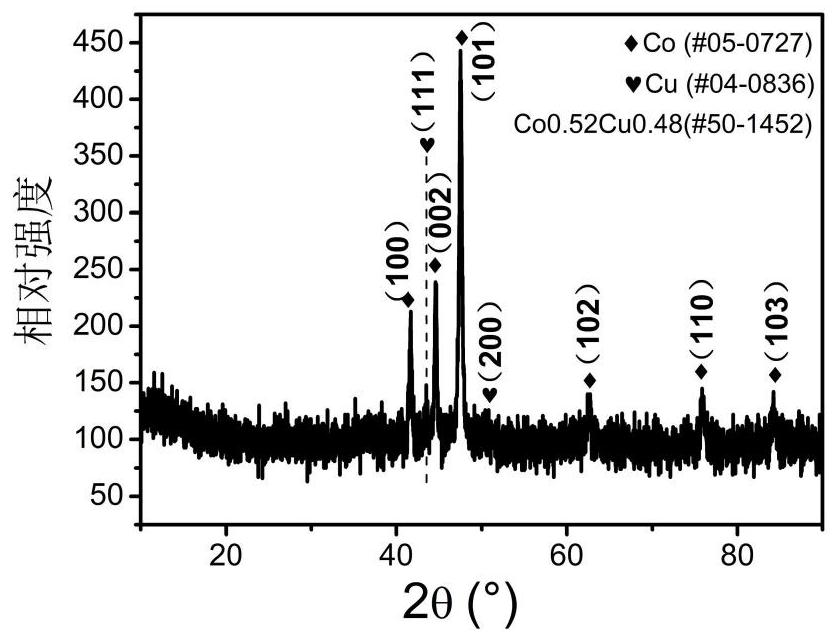

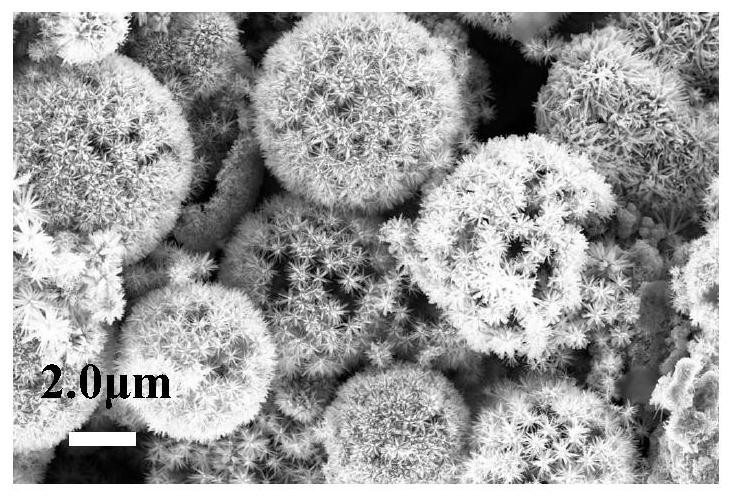

Magnetic hollow microsphere and preparation method and application thereof

ActiveCN112296350AReduced precision requirementsThe method steps are simpleMaterial nanotechnologyNanomagnetismSurface-enhanced Raman spectroscopyMicrosphere

The invention discloses a magnetic hollow microsphere and a preparation method and application thereof, and belongs to the technical field of nano materials. The magnetic hollow microsphere prepared by a one-step hydrothermal method is novel in structure and formation mechanism, and the content of Cu and Co in the product and the composition, morphology and structure of the magnetic hollow microsphere can be regulated and controlled by changing the reaction temperature, time, surfactant ratio, mass ratio of copper salt to cobalt salt and reactant concentration; and the diameter of the preparedmagnetic hollow microsphere is 2.2 microns-10.2 microns, and the magnetic hollow microsphere is widely applied to the fields of microwave absorption and shielding, electro-catalysis, lithium ion batteries, surface enhanced Raman spectroscopy and the like due to good dispersity and uniformity and good microwave absorption characteristics. The preparation method is simple to operate, green and environment-friendly, has good industrial application potential, and is suitable for market popularization and application.

Owner:ZHEJIANG NORMAL UNIVERSITY

A kind of lanico magnetic wave-absorbing material and preparation method thereof

ActiveCN108149076BGood microwave absorption characteristicsGood absorption bandHeat stabilityOxidation resistant

Owner:GUILIN UNIV OF ELECTRONIC TECH

A magnetic hollow micro-nano material and its preparation method and application

ActiveCN111014649BSimple production equipmentSimple and fast operationOther chemical processesTransportation and packagingMicro nanoSurface-enhanced Raman spectroscopy

The invention discloses a magnetic hollow micro-nano material, a preparation method and application thereof, and belongs to the technical field of nano-materials. The invention discloses that the magnetic hollow micro-nano material prepared by a one-step liquid-phase reduction-oxidation method not only has a novel structure and formation mechanism, but also can regulate the concentration of Cu and Ni by changing the reaction temperature, time, stirring speed, gas flow, and reactant concentration. Content and composition, morphology and structure of magnetic hollow micro-nano materials, in which the diameter of micro-nanotubes is 0.1-2 μm, the length is 2-12 μm, and the wall thickness is 10-140 nm; the diameter of micro-nanospheres is 0.2-5 μm, and the wall thickness is 10~180nm. Because of the good dispersion and uniformity of the magnetic hollow micro-nano material and good microwave absorption characteristics, it is widely used in the fields of microwave absorption and shielding, electrocatalysis, lithium-ion batteries, and surface-enhanced Raman spectroscopy. In addition, the preparation method disclosed in the present invention is simple to operate, environmentally friendly, has good potential for industrial application, and is suitable for market promotion and application.

Owner:ZHEJIANG NORMAL UNIVERSITY

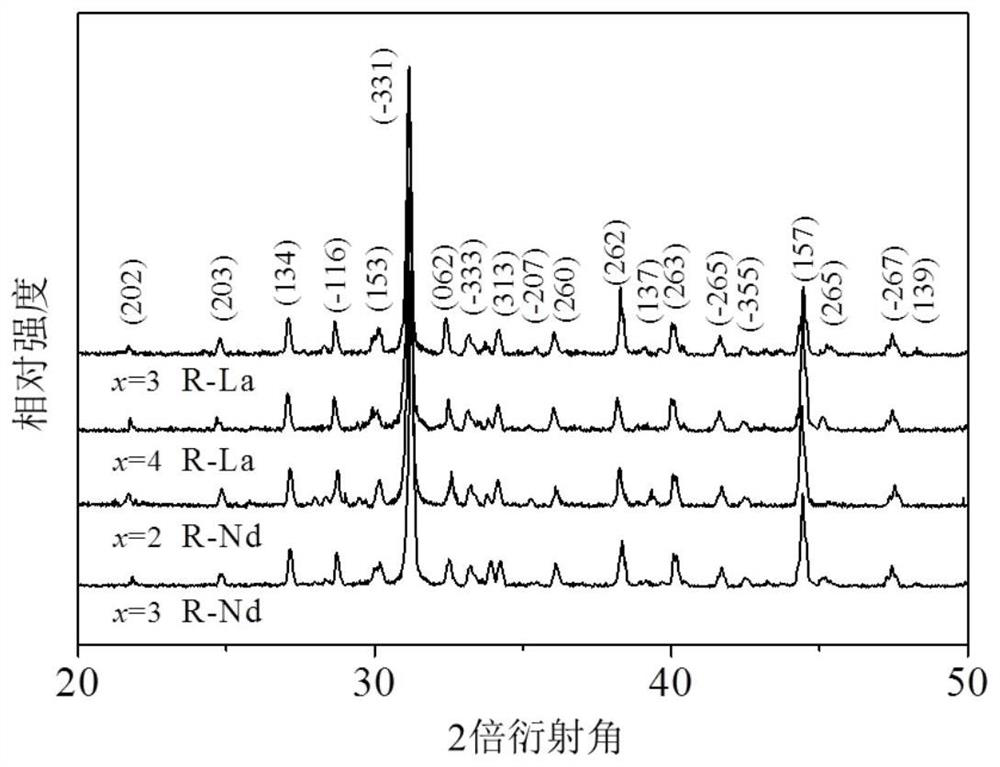

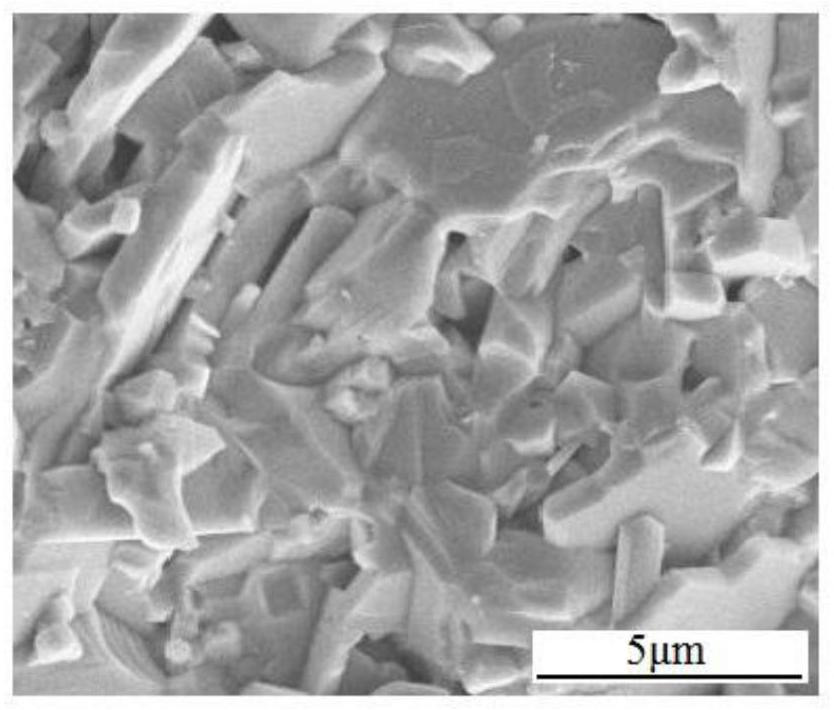

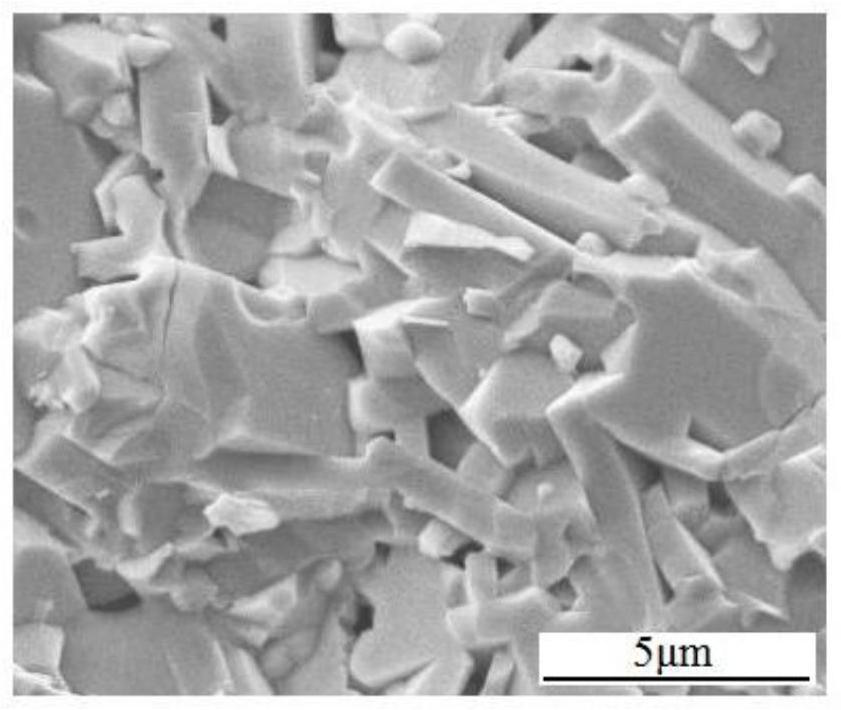

A kind of sheet-like ceramic wave-absorbing material and its preparation method

ActiveCN110922181BEnhanced magnetic exchangeEnhanced magnetic lossOther chemical processesRare-earth elementCrystal structure

A kind of sheet ceramic wave-absorbing material and preparation method thereof, the chemical formula of this wave-absorbing material is Ba 12‑x R x Fe 28 Ti 15 o 84 ,in x is 2≤ x ≤4; R in the chemical formula is a rare earth element La or Nd; the absorbing material is a type of layered oxide with a monoclinic crystal structure, and the space group is C 2 / m ; The monoclinic crystal structure is randomly arranged flaky or plate-like grains, with a diameter of 2 to 7 µ m, thickness 1~2 µ m; the present invention also includes the preparation method of the wave-absorbing material, including the following steps: (1) preparation of sol; (2) preparation of primary powder; (3) preparation of wave-absorbing material; The sheet / plate microstructure features and is modified by magnetic element doping, showing excellent electromagnetic loss characteristics and good microwave impedance matching characteristics; the material shows good microwave absorption characteristics in the microwave range of 2~18GHz, the best The frequency bandwidth with return loss values below ‑17dB and return loss below ‑10dB is greater than 4.0GHz.

Owner:HUNAN INSTITUTE OF ENGINEERING

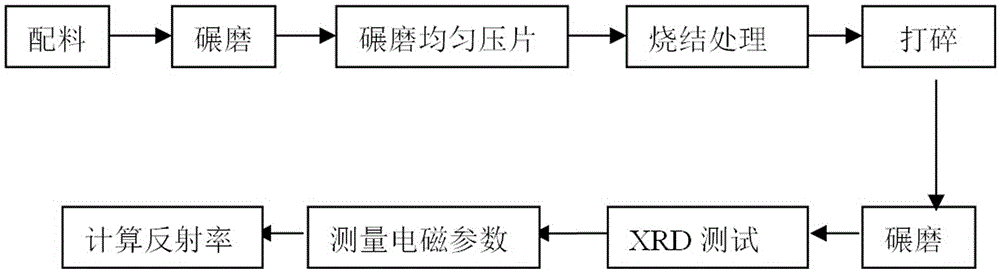

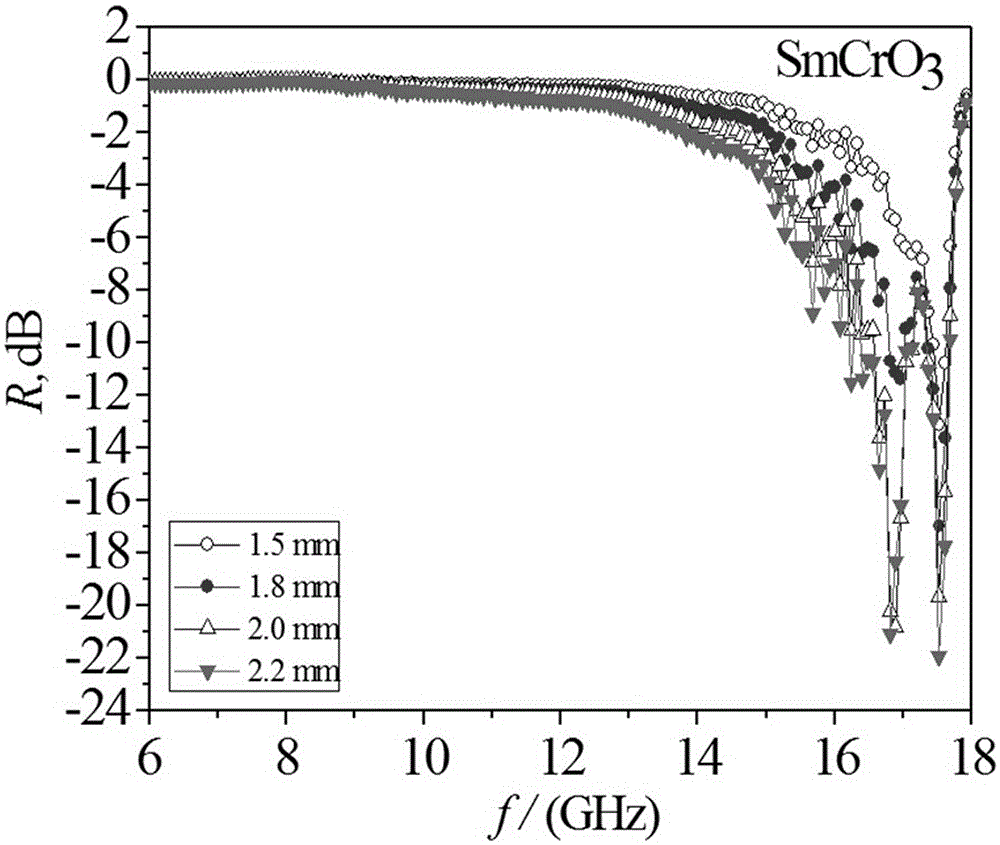

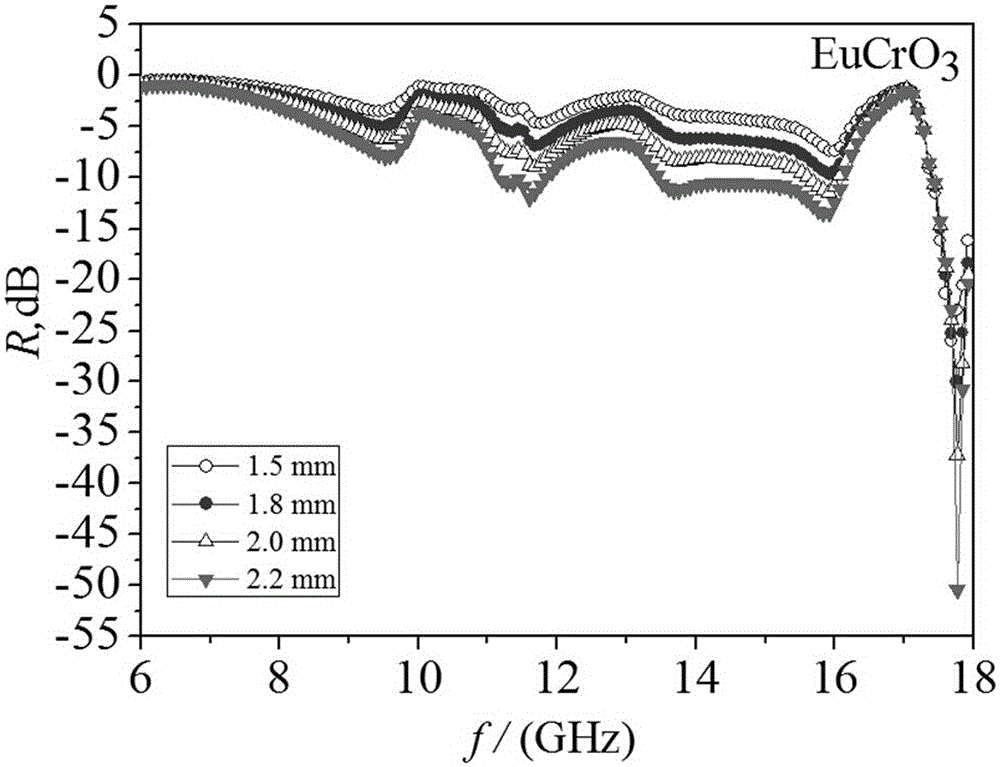

Rare earth recro 3 Magnetic wave absorbing material and preparation method thereof

ActiveCN104402417BAbsorption BandwidthAccelerated corrosionOther chemical processesHeat stabilityPhysical chemistry

The rare earth ReCrO3 magnetic wave-absorbing material and its preparation method of the present invention are prepared by mixing Re2O3 and Cr2O3 powders with a molecular ratio of 1:1 with a purity of ≥99.50%, and grinding them in an agate bowl mill for half an hour to mix Evenly, after mixing evenly, the powder is pressed into flakes, and the flakes are sintered at 1500°C for 24 hours under the protection of vacuum or argon, and then cooled with the furnace. The invention has the advantages of simple preparation process, good microwave absorption characteristics in the 2-18 GHz microwave band, wide absorption frequency band, good oxidation resistance and good temperature stability, and does not contain strategic metal elements such as Co and Ni, and has the characteristics of low price and the like. . It is more suitable for preparing microwave absorbing products with high microwave absorption efficiency, low material density, good non-oxidation and corrosion resistance, and good thermal stability.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Preparation method and application of microwave absorbing diatom mud coating

ActiveCN107502004BGood dispersionWide range of sizesCovering/liningsRadiation-absorbing paintsFiberMicro nano

The invention relates to a preparation method for a microwave absorption diatom ooze coating material and an application. The method comprises the following steps: mixing diatom ooze dry powder, a microwave absorbent and a dispersant according to a mass ratio of 1:1.5:(18-25), performing soaking for 10-20min, and performing electric stirring for 30-60min to obtain the microwave absorption diatom ooze coating material; and the microwave absorbent is a carbon magnetic heterostructural micro nano fiber. According to the microwave absorption diatom ooze coating material prepared from the method, when the microwave absorption diatom ooze coating material is applied, a concrete construction method comprises the following steps: scraping bottom-layer putty on cleaned wall surfaces, grinding wall surfaces until the wall surfaces are smooth, dispersing the microwave absorption diatom ooze coating material to building wall surfaces uniformly by 2-3 times, making diatom ooze patterns or performing coloring or making a press polishing layer at the treated building wall surfaces, and performing maintenance for 1-2 days to obtain the finished product. The microwave absorption diatom ooze coating material is an ideal green and environmentally-friendly building and decorative material, has excellent microwave absorbing characteristics, beautifies and decorates environments, and can avoid electromagnetic pollution and information leakage; and the microwave absorption diatom ooze coating material can be used at wall surfaces of buildings such as electromagnetic shielding darkrooms, residential power distribution rooms, military meeting rooms and secret rooms, television towers, broadcasting rooms, radars, and satellite communication launching pads.

Owner:ZHEJIANG NORMAL UNIVERSITY

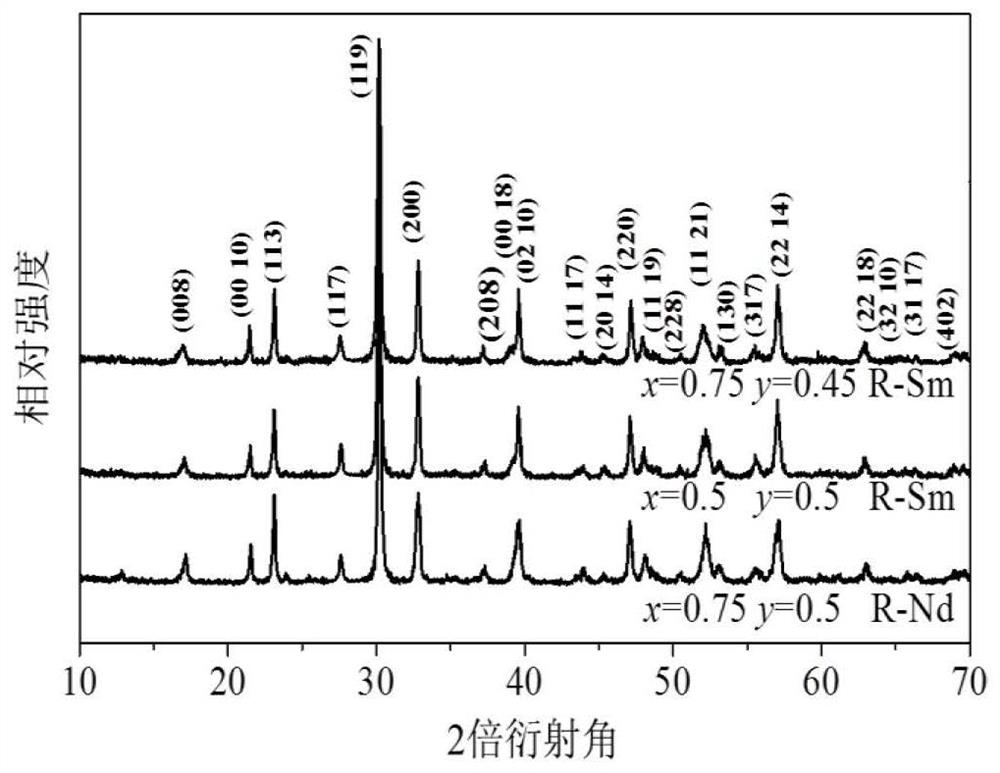

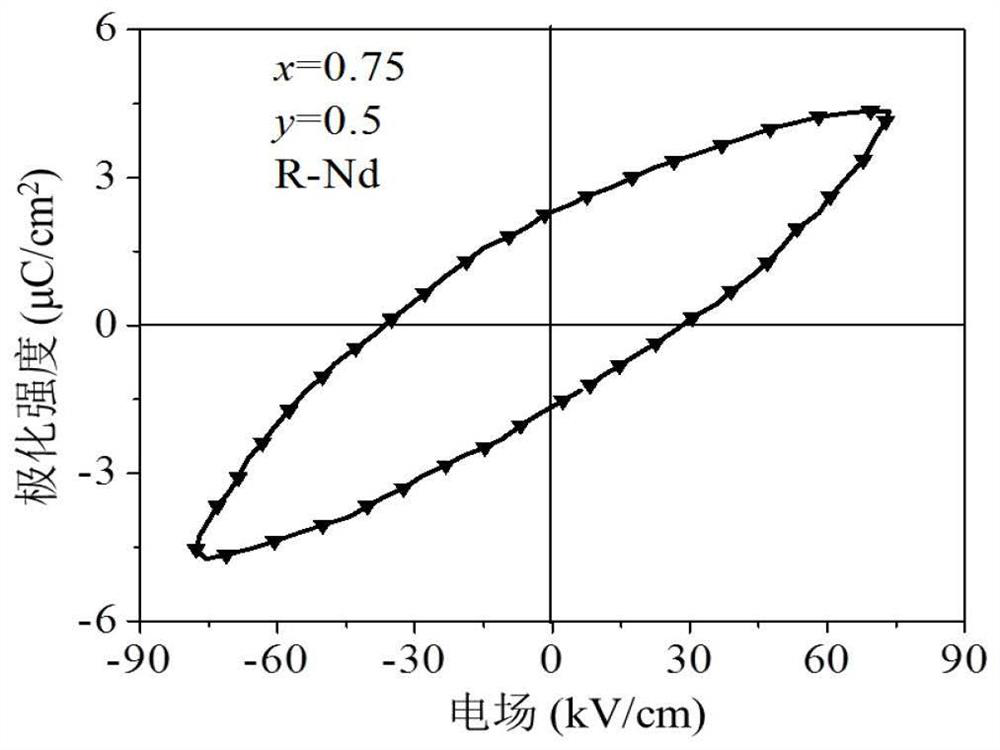

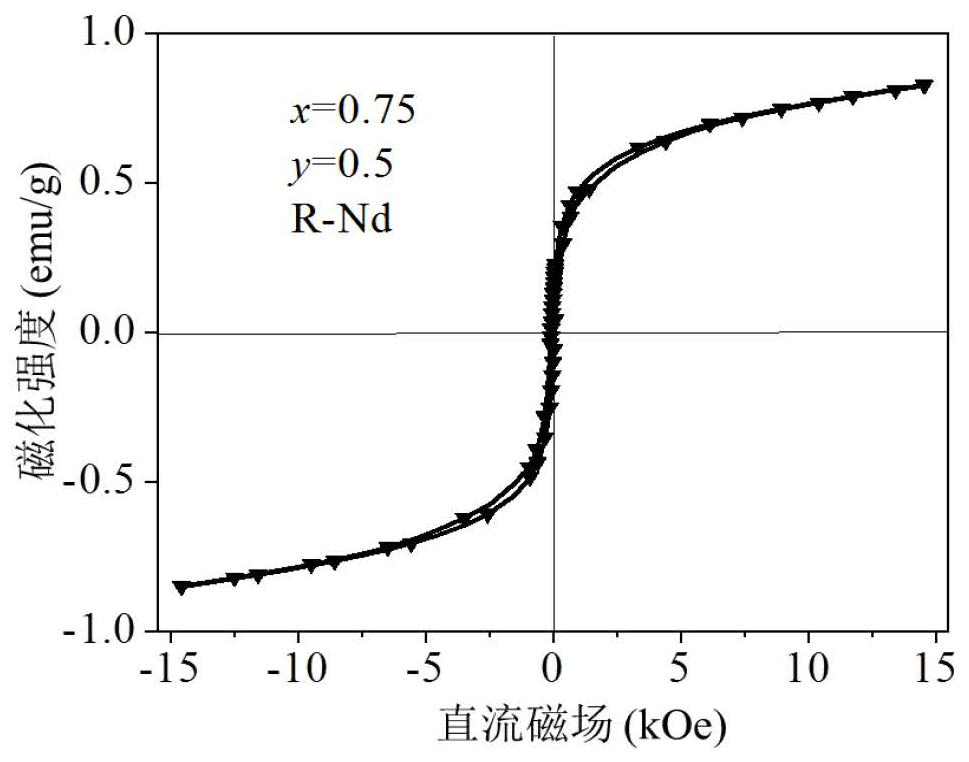

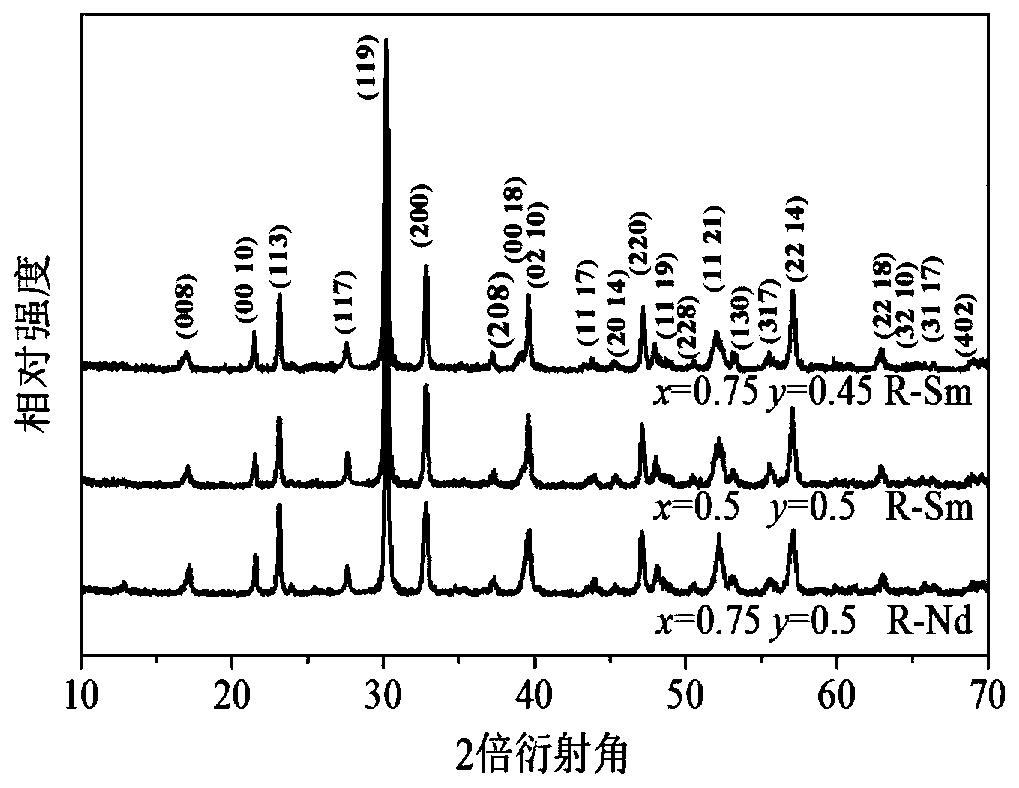

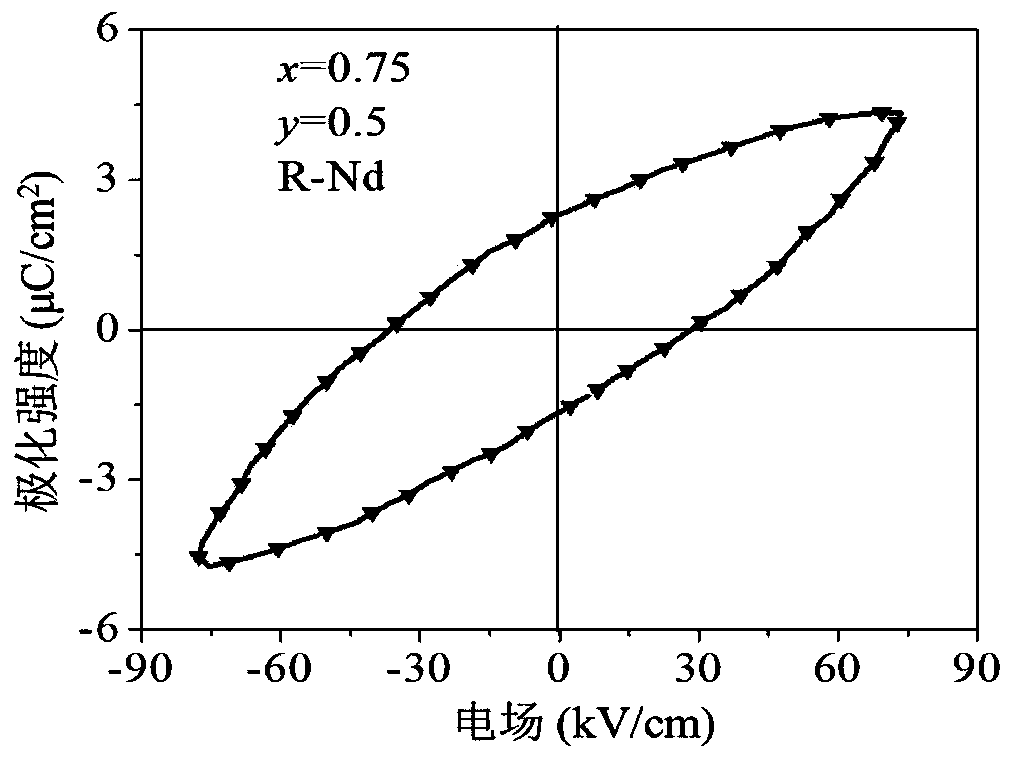

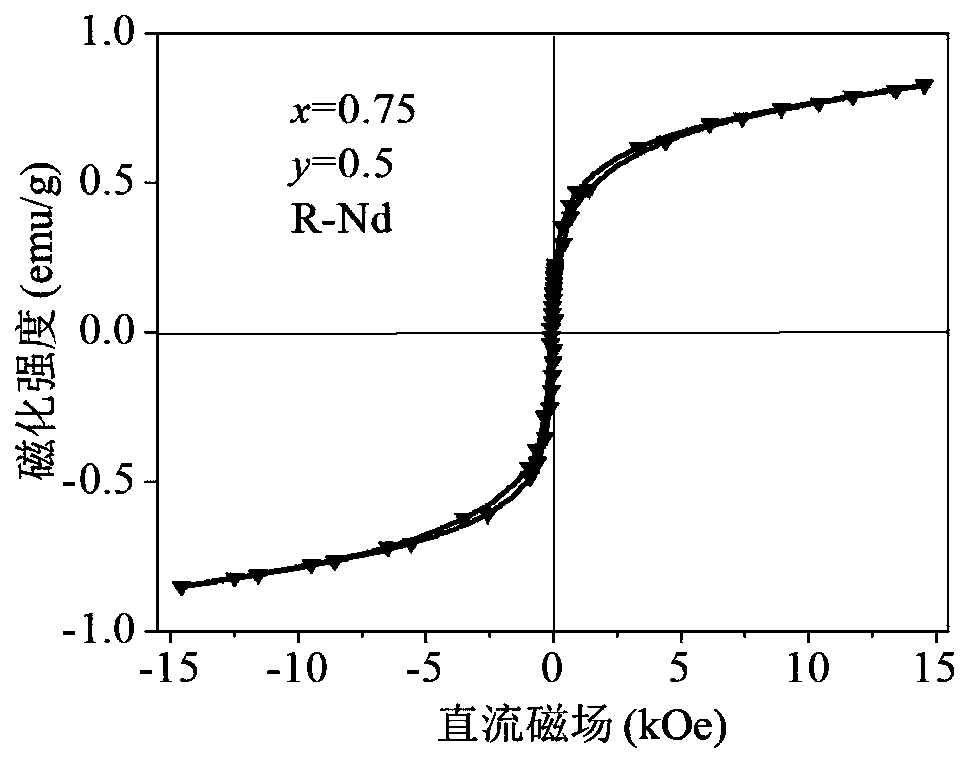

Multiferroic wave absorbing material and preparation method thereof

The invention discloses a multiferroic wave absorbing material and a preparation method thereof. The material belongs to a kind of Aurivillius phase bismuth layered perovskite oxides, and has a chemical formula of Bi<5-x>R<x>Fe<1-y>N<y>Ti<3>O<15>, 0.5<=x<=0.75, 0.3<=y<=0.5, and R is one of rare earth elements (Nd and Sm). The invention also provides a preparation method of the multiferroic wave absorbing material. The material has an excellent magnetic performance, a good reflection loss characteristic in a microwave frequency band of 8-18 GHz, a high absorption strength, and a wide absorptionfrequency band. The preparation method has the advantages of simple operation, easily controlled technological conditions, and wide application prospect.

Owner:HUNAN INSTITUTE OF ENGINEERING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com