Preparation method of Na-beta''-Al2O3 solid electrolyte

A solid electrolyte and mixed solution technology, applied in circuits, electrical components, battery pack components, etc., can solve problems such as reducing ionic conductivity, and achieve the effects of inhibiting grain growth, high heating rate, and shortening sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

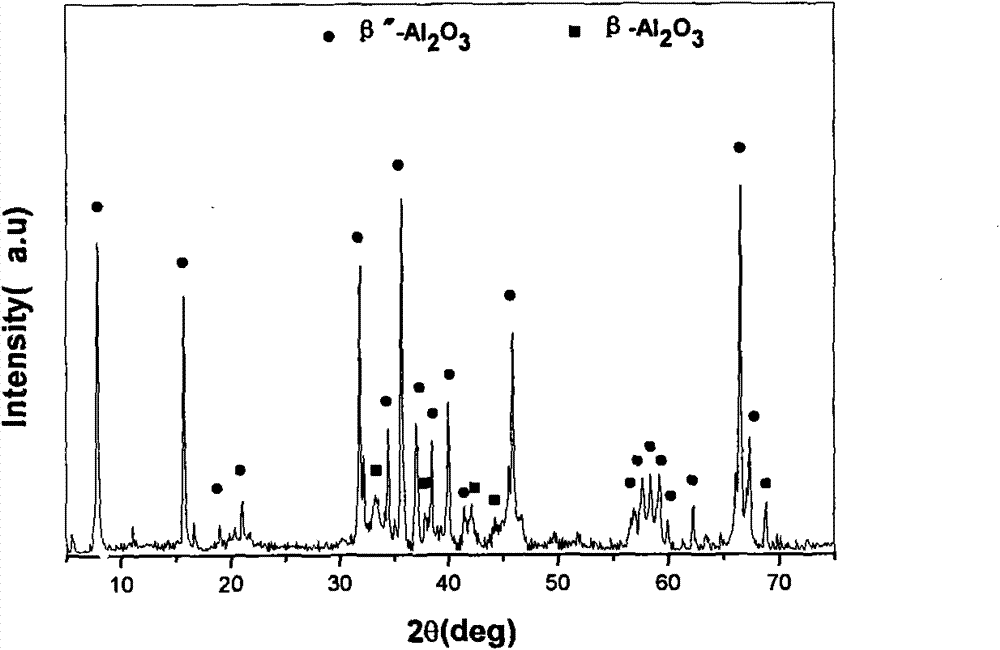

Embodiment 1

[0021] Al(NO 3 ) 3 9H 2 O(A.R.), NaNO 3 (A.R.) and Mg(NO 3 ) 2 (A.R.) is the raw material, the polymer compound is citric acid (A.R.), and polyethylene glycol is used as the dispersant. Weigh 25.8g of aluminum nitrate, 0.95g of sodium nitrate, and 0.66g of magnesium nitrate, add 45ml of distilled water, heat and stir at a constant temperature of 60°C to form a uniform solution. Then add 16.9g citric acid therein, and the polyethylene glycol of 2.45g, continue to heat and stir, form wet gel gradually through 8 hours. The obtained wet gel was dried in an oven at 200° C. to obtain a dry gel. Then the gel was calcined at 1250°C for 2 hours, the heating rate was 3°C / min, and kept at 600°C for 2 hours, so as to facilitate the full decomposition of organic matter and obtain ultrafine powder. The powder was ball-milled for 8 hours with absolute ethanol as the medium, dried, and sieved. The obtained powder is isostatically pressed at 300MPa into a disc with a diameter of 20mm. ...

Embodiment 2

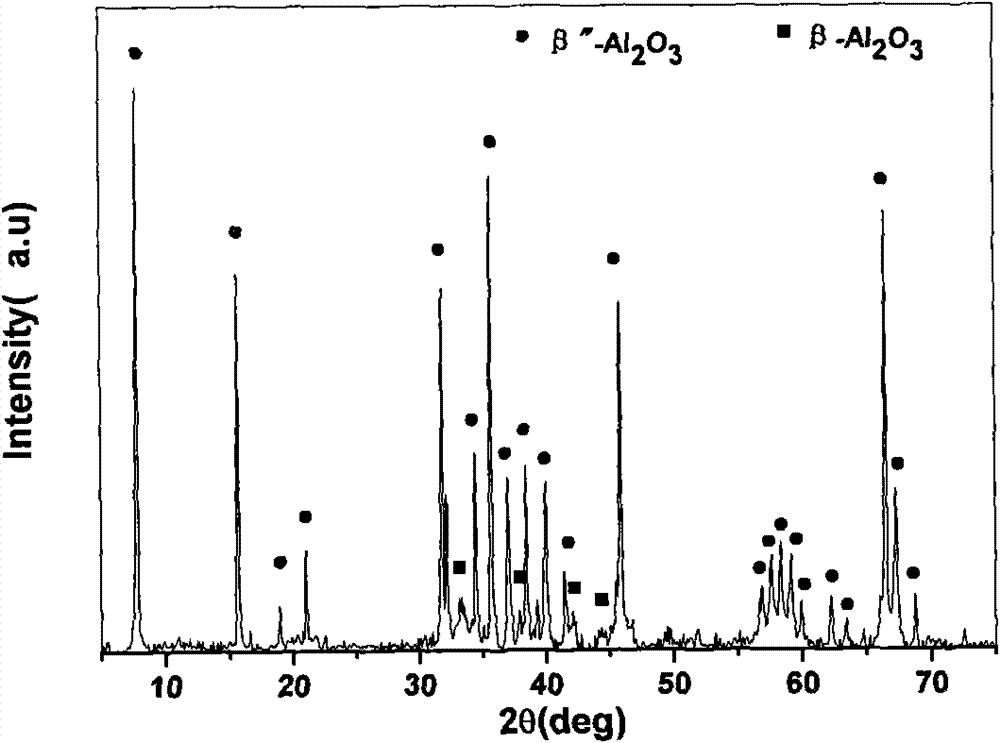

[0023] Al(NO 3 ) 3 9H 2 O(A.R.), NaNO 3 (A.R.) and Mg(NO 3 ) 2 (A.R.) is the raw material, the polymer compound is citric acid (A.R.), and polyvinyl alcohol is used as the dispersant. Weigh 38.74g of aluminum nitrate, 1.42g of sodium nitrate, and 0.99g of magnesium nitrate, add 50ml of distilled water, heat and stir at a constant temperature of 80°C to form a uniform solution. Then add 25.36g citric acid therein, and the polyvinyl alcohol of 2.79g, continue to heat and stir, form wet gel gradually through 6 hours. The obtained wet gel was dried in an oven at 250° C. to obtain a dry gel. Then the gel was calcined at 850°C for 3 hours, the heating rate was 2°C / min, and kept at 500°C for 2 hours, so as to facilitate the full decomposition of organic matter and obtain ultrafine powder. The powder was ball-milled for 5 hours with absolute ethanol as the medium, dried, and sieved. The obtained powder is isostatically pressed at 300MPa into a disc with a diameter of 20mm. In ...

Embodiment 3

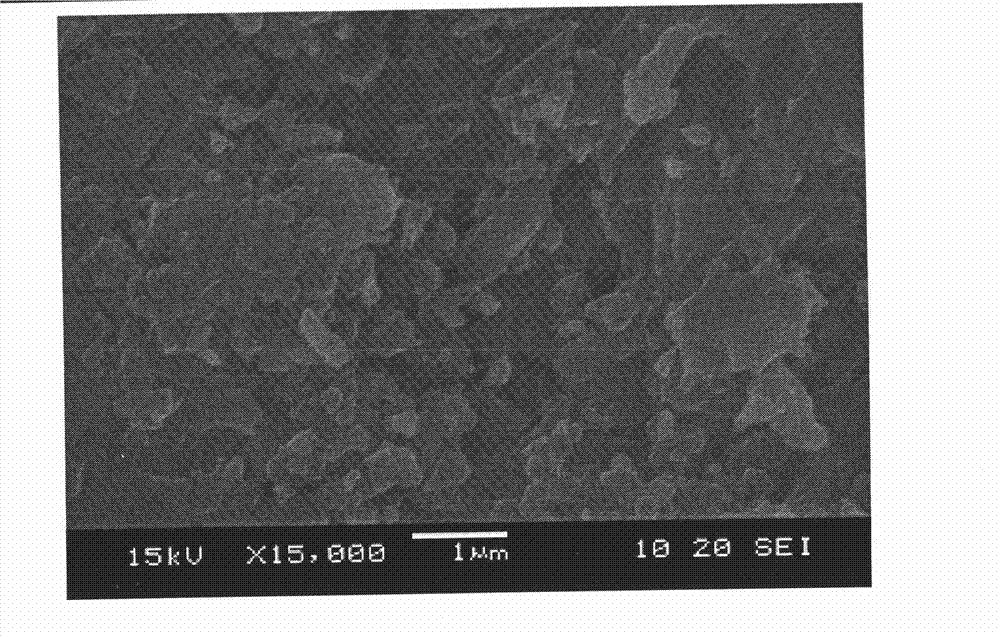

[0025] Weigh Al 2 o 3 8.94g, Na 2 CO 3 1.78g, Li 2 CO 3 0.056g, put it into an agate jar, use absolute alcohol as the medium, mix and ball mill for 15 hours, pass through a 200-mesh sieve, dry in an oven at 80°C, and isostatically press the obtained powder into a disc with a diameter of 20mm at 300MPa Put it into a microwave sintering furnace, raise the temperature at a rate of 10°C / min, and keep it at 1425°C for 60 minutes, then raise the temperature at a rate of 12°C / min to 1550°C and keep it for 30 minutes, then quench and cool it, keep it at 1475°C for 30 minutes, and keep it at 1450°C Insulated for 15 minutes to obtain β″-Al 2 o 3 ceramic electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com