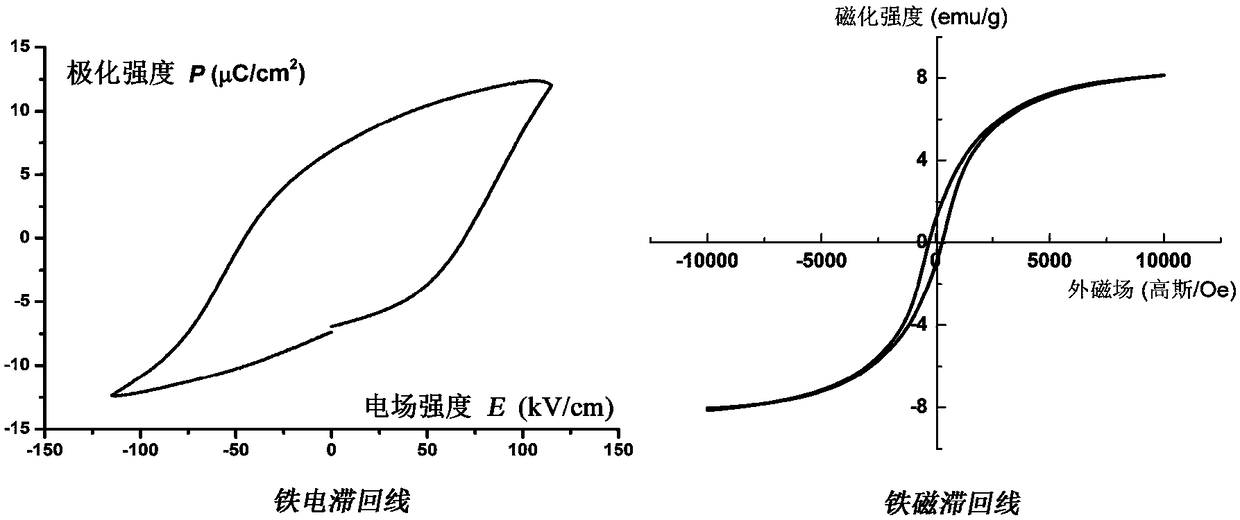

Single-phase multiferroic microwave absorbing material and preparation method thereof

A microwave absorbing material, single-phase technology, applied in the direction of electrical components, magnetic field/electric field shielding, etc., to achieve the effect of wide absorption frequency band, high absorption intensity and short experimental period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

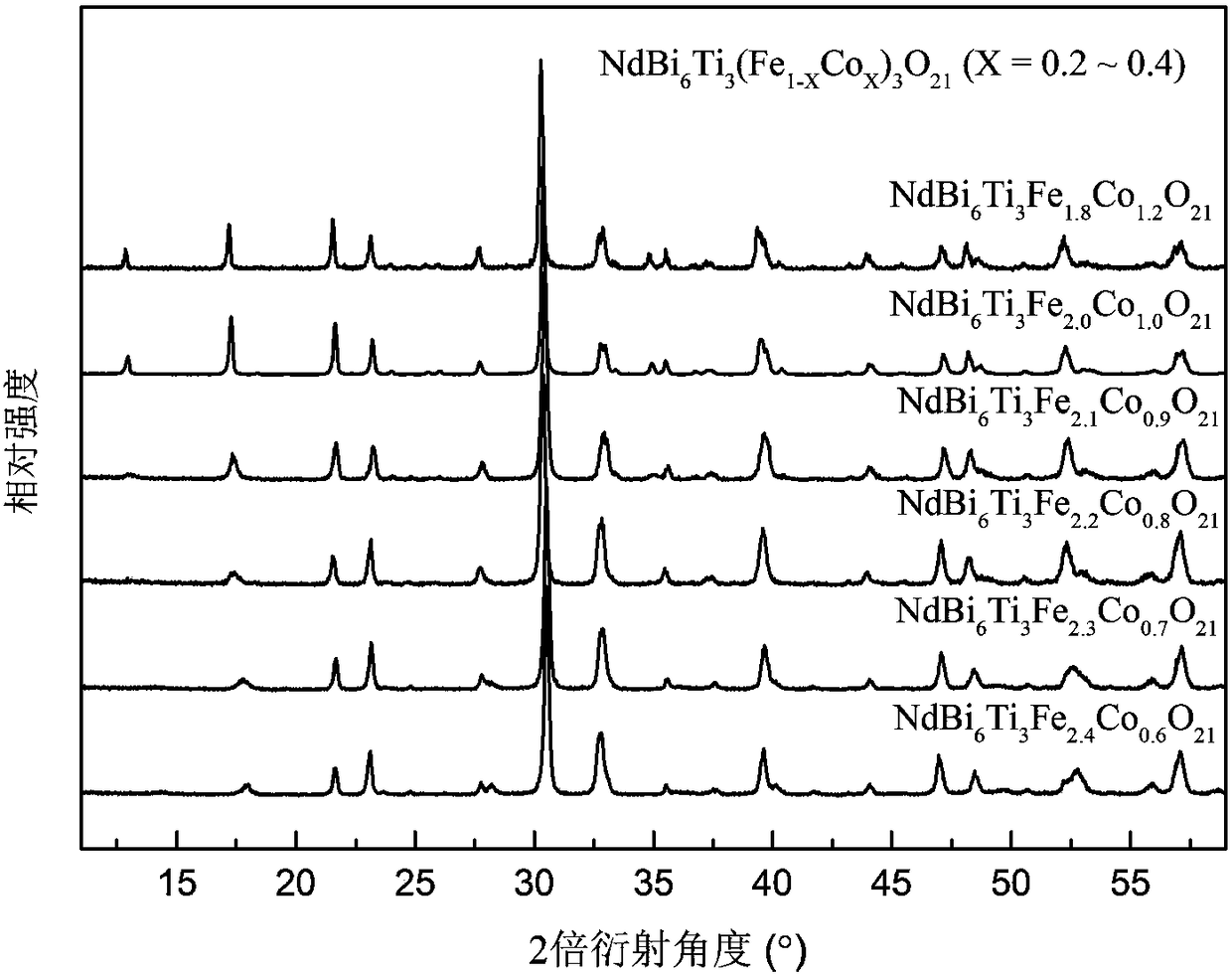

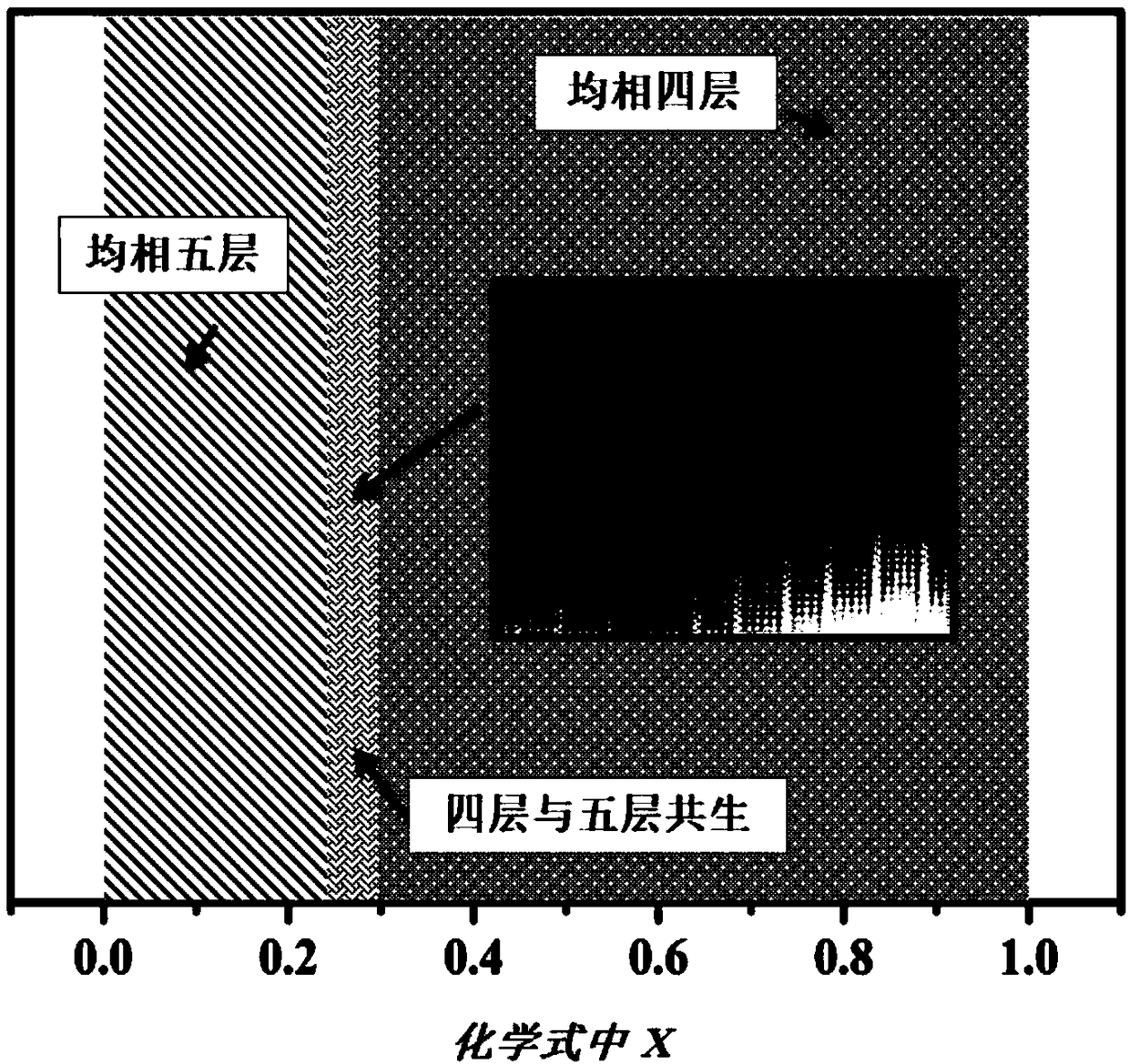

[0032] The embodiment of the present application provides a preparation method of a single-phase multiferroic microwave absorbing material shown in formula (I), the preparation method comprising the following steps:

[0033] (1) Mix n-butyl titanate, bismuth-containing compound, neodymium-containing compound, iron-containing compound, cobalt-containing compound and complexing agent in dilute nitric acid solution according to the stoichiometric ratio to obtain a mixed solution; wherein n-butyl titanate , the molar ratio of titanium, bismuth, neodymium, iron and cobalt in the bismuth-containing compound, neodymium-containing compound, iron-containing compound and cobalt-containing compound is 3:6:1:(3-3x):3x, and x is 0.25-0.3; And the bismuth-containing compound is bismuth nitrate pentahydrate, the neodymium-containing compound is neodymium nitrate hexahydrate, the iron-containing compound is iron nitrate nonahydrate, the cobalt-containing compound is cobalt nitrate hexahydrate,...

specific Embodiment 1

[0041] Follow the steps below to prepare NdBi 6 Ti 3 (Fe 1-x co x ) 3 o 21 (x=0.25) Single-phase multiferroic microwave absorbing materials.

[0042] Step 1: Weigh (0.05 / 7) mol sample raw material according to Nd:Bi:Ti:Fe:Co stoichiometric ratio 1:6:3:2.25:0.75, namely take 7.442g n-butyl titanate (purity is 98 %), 2.163g neodymium nitrate hexahydrate (purity is 99%), 20.998g bismuth nitrate pentahydrate (purity is 99%), 6.592g ferric nitrate nonahydrate (purity is 98.5%), 1.575g cobalt nitrate hexahydrate (purity 98.5%) dissolved in nitric acid solution (take 20mL from the nitric acid solution with a concentration of 65-68%, add it to a beaker of about 500mL distilled water, then add 100ml distilled water), add ethylenediaminetetraacetic acid (EDTA) with a purity of 98% ) 18.616g and purity are 98% citric acid 19.123g as complexing agent, obtain mixed solution after stirring.

[0043] Step 2: adjust the pH value of the mixed solution to neutral with ammonia water, stir...

specific Embodiment 2

[0049] Follow the steps below to prepare NdBi 6 Ti 3 (Fe 1-x co x ) 3 o 21 (x=0.3) Single-phase multiferroic microwave absorbing materials.

[0050] Step 1: Weigh (0.05 / 7) mol sample raw materials according to Nd:Bi:Ti:Fe:Co stoichiometric ratio 1:6:3:2.1:0.9, that is, weigh 7.442g n-butyl titanate (purity is 98 %), 2.163g neodymium nitrate hexahydrate (purity is 99%), 20.998g bismuth nitrate pentahydrate (purity is 99%), 6.153g ferric nitrate nonahydrate (purity is 98.5%), 1.899g cobalt nitrate hexahydrate (purity 98.5%) dissolved in nitric acid solution (take 20mL from the nitric acid solution with a concentration of 65-68%, add it to a beaker of about 500mL distilled water, then add 100ml distilled water), add ethylenediaminetetraacetic acid (EDTA) with a purity of 98% ) 18.616g and purity are 98% citric acid 19.123g as complexing agent, obtain mixed solution after stirring.

[0051] Step 2: adjust the pH value of the mixed solution to neutral with ammonia water, sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| optical bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com