Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

116results about How to "Improve ferromagnetic properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing bismuth ferrite based multifunctioanl oxide ceramic material

InactiveCN101050120ARoom temperature ferromagneticInhibition of price changeRare-earth elementOxide ceramic

This invention relates to a method for preparing BiFeO3-based multifunctional oxide ceramic. The method comprises: (1) pre-pressing BLTFO8 powder into a disc, loading oxide protective powder (Al2O3, CeO2, ZrO2 or FeO) into a graphite mold, and pressing; (2) transferring the BLTFO8 disc onto the oxide protective powder layer in the mold; (3) continuing adding oxide protective powder into the mold to embed the BLTFO8 disc, and pressing; (4) transferring the mold into an SPS sintering furnace, heating to 600 deg.C within 3 min, then heating to the sintering temperature at a rate of 50 deg.C / min, keeping the temperature, and sintering. Since BiFeO3 has G-type antiferromagnetic structure, doping with rare earth element such as La or Tb, or metal element such as Ba or K can alter its antiferromagnetic structure, and the obtained BiFeO3-based multifunctional oxide ceramic has ferromagnetism at room temperature. The method can inhibit the valency change of the elements and reduce loss, and the BiFeO3-based multifunctional oxide ceramic has good ferroelectric and ferromagnetic properties at room temperature.

Owner:TSINGHUA UNIV

Preparation method of magnetic layered molybdenum disulfide nanosheets

ActiveCN103787417AStrong ferromagnetismSimple processMaterial nanotechnologyMolybdenum sulfidesSolventUltrasonic dispersion

The invention provides a preparation method of magnetic layered molybdenum disulfide nanosheets. The preparation method comprises the following steps that Step1, molybdenum disulfide is added into stripping solvents, and a molybdenum disulfide dispersion liquid with an initial concentration in a ranged of 0.5-2 mg / ml is prepared, the molybdenum disulfide dispersion liquid is conducted ultrasonic dispersion 0.5-8 h at a temperature of 25-35 DEG C, a surface tension rang of the molybdenum disulfide dispersion liquid is 40-65 mJ / m2 tested at a temperature of 25 DEG C; Step2, the molybdenum disulfide dispersion liquid after being ultrasonic dispersed is centrifuged, upper suspensions of the molybdenum disulfide dispersion liquid after being centrifuged is filtered, filter cakes acquired from the upper suspensions are heated to dry in a vacuum drying chamber at a temperature of 60-100 DEG C. By the adoption of a chemical solvent method and an ultrasonic oscillation condition, stripping among atomic layers are conducted, so that the striping and preparation of the two-dimensional layered molybdenum disulfide nanosheets with a strong ferromagnetic performance can be achieved. The preparation is simple in technology, easy to operate, low in cost and high in productivity.

Owner:SHENZHEN INST OF ADVANCED TECH

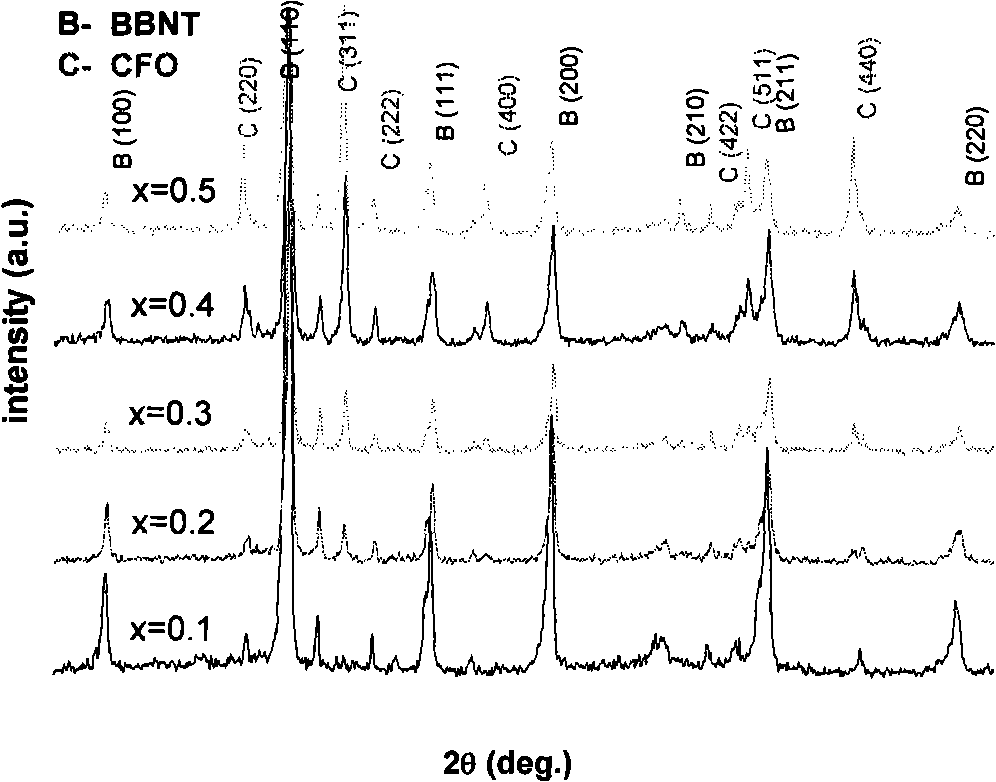

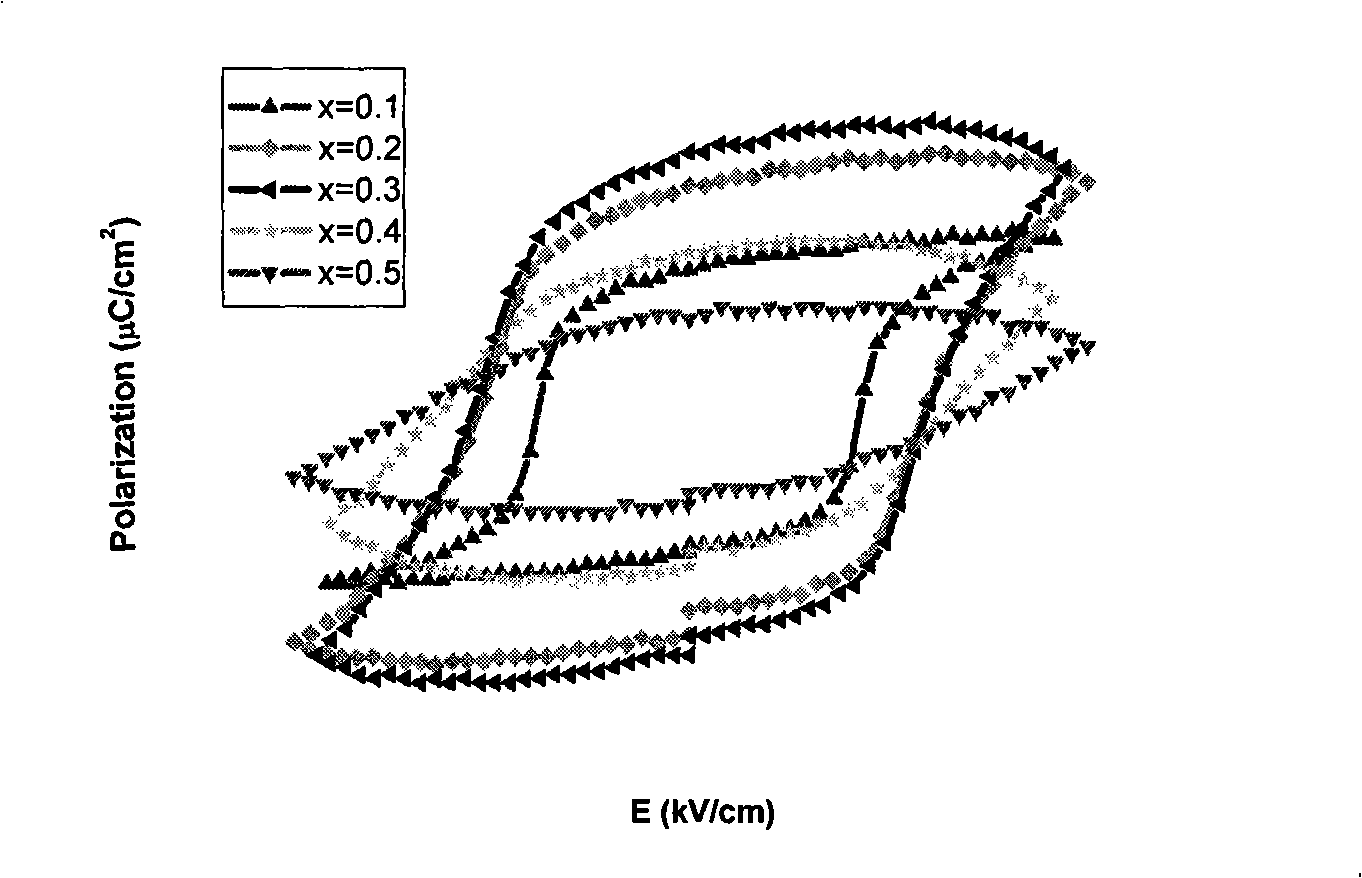

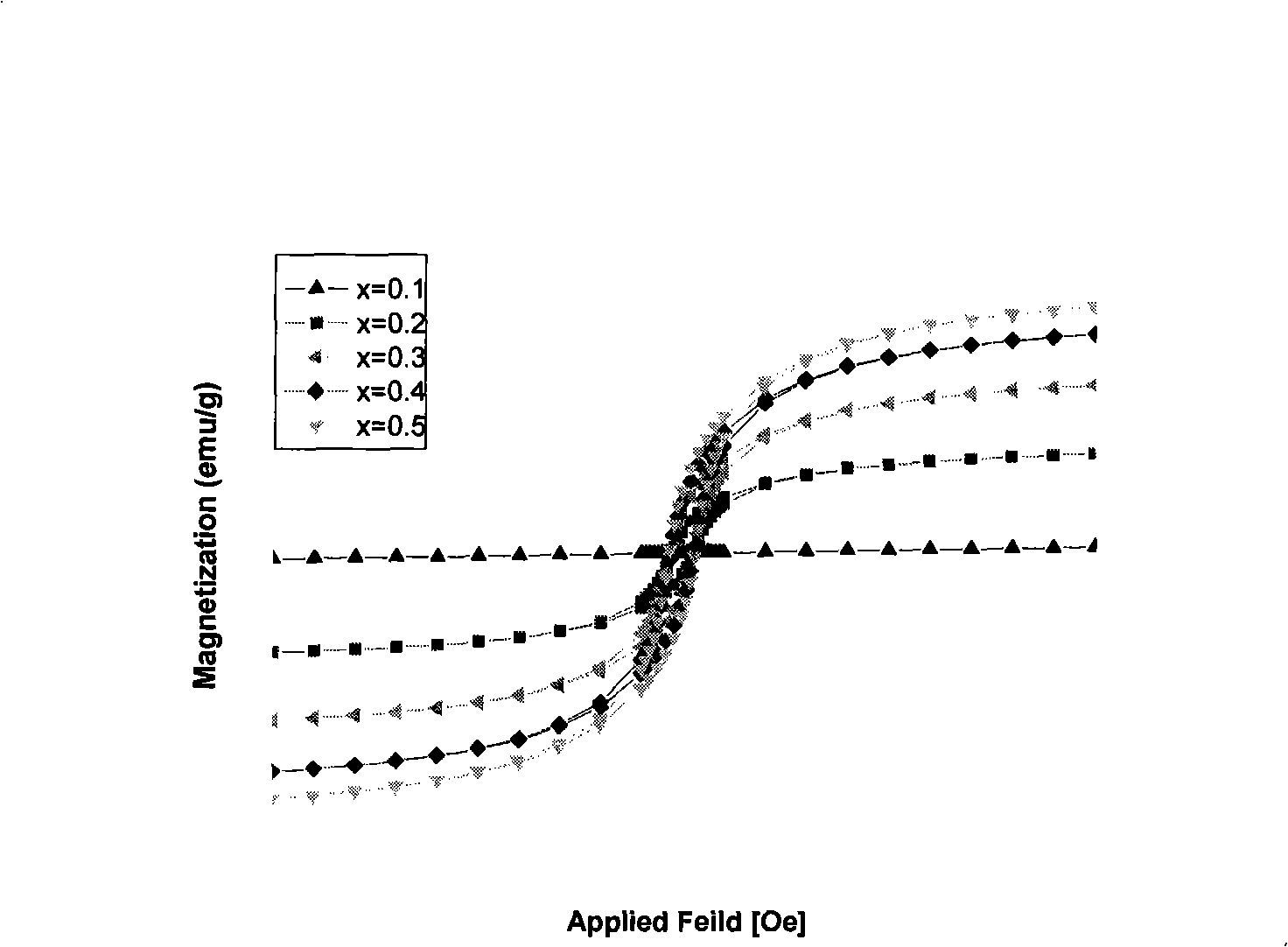

(1-x)(ba,bi,na)tio3-xcofe2o4 composite multi-iron ceramic and preparation method thereof

InactiveCN101265084AImprove ferroelectric propertiesExcellent piezoelectric propertiesCompression moldingAdhesive

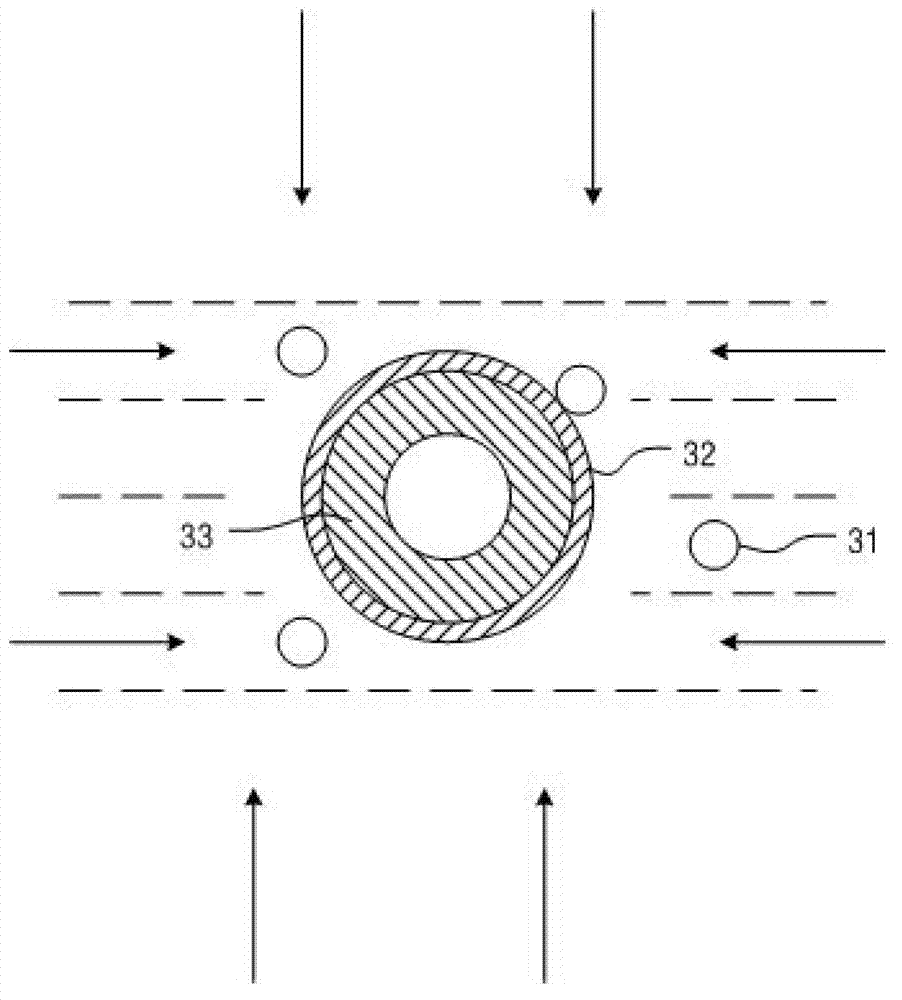

The invention relates to a composite multiferroic ceramic (1-x)(Ba, Bi, Na)TiO3-xCoFe2O4, wherein x is more than or equal to 0.1 but less than or equal to 0.5. A production method of the composite multiferroic ceramic is also disclosed. The method comprises the following steps: 1) weighing Bi2O3, Na2CO3, BaTiO3, Co2O3 and Fe2O3 at the given ratio mentioned above, grinding and mixing thoroughly; 2) mixing the fine powder obtained in the step 1) with a binder and mixing thoroughly; 3) compression-molding the powder obtained in the step 2) under 10-20 MPa to obtain sheet with a thickness of 2.0 plus or minus 10% mm; and 4) in a sealed container, placing the sheet obtained in the step 3) over the fine powder obtained in the step 1), covering the sheet with the fine powder, placing the sealed container loading the sheet and powder in a heating furnace, and sintering, to obtain the composite multiferroic ceramic (1-x)(Ba, Bi, Na)TiO3-xCoFe2O4, wherein the sintering temperature is 1000-1250 DEG C and the sintering time lasts 2-3 hours. The product is free of lead and environment-friendly. The production equipment and process are simplified.

Owner:NANJING UNIV

Ferrotitanium bismuth cobaltate ceramic material with five-laminated structure and multiferroic performance and preparation method thereof

The invention discloses a ferrotitanium bismuth cobaltate ceramic material with five-laminated structure and multiferroic performance and a preparation method thereof, belong to the technical field of oxide ceramic materials. The chemical formula of the ferrotitanium bismuth cobaltate ceramic material is Bi6FeCoTi3O18. The preparation method comprises the following steps of: selecting analytically pure Bi2O3, analytically pure Fe2O3, analytically pure Co2O3 and spectroscopically pure TiO2 serving as raw materials, wherein the molar ratio of Bi2O3 to Fe2O3 to Co2O3 to TiO2 is (6-6.6):1:1:6; and performing ball milling, drying, pre-synthesis, secondary ball milling, drying, molding, plastic removal and sintering by adopting the conventional solid-phase sintering process to obtain Bi6FeCoTi3O18. Conventional raw materials and the current solid-phase process are adopted, and the preparation steps are performed at the low-pressure condition, so that the obtained product has high ferroelectricity and high ferromagnetism. The ferrotitanium bismuth cobaltate ceramic material has the advantages of simple process, high stability, low sintering temperature, material nontoxicity and high environmental coordination.

Owner:YANGZHOU UNIV

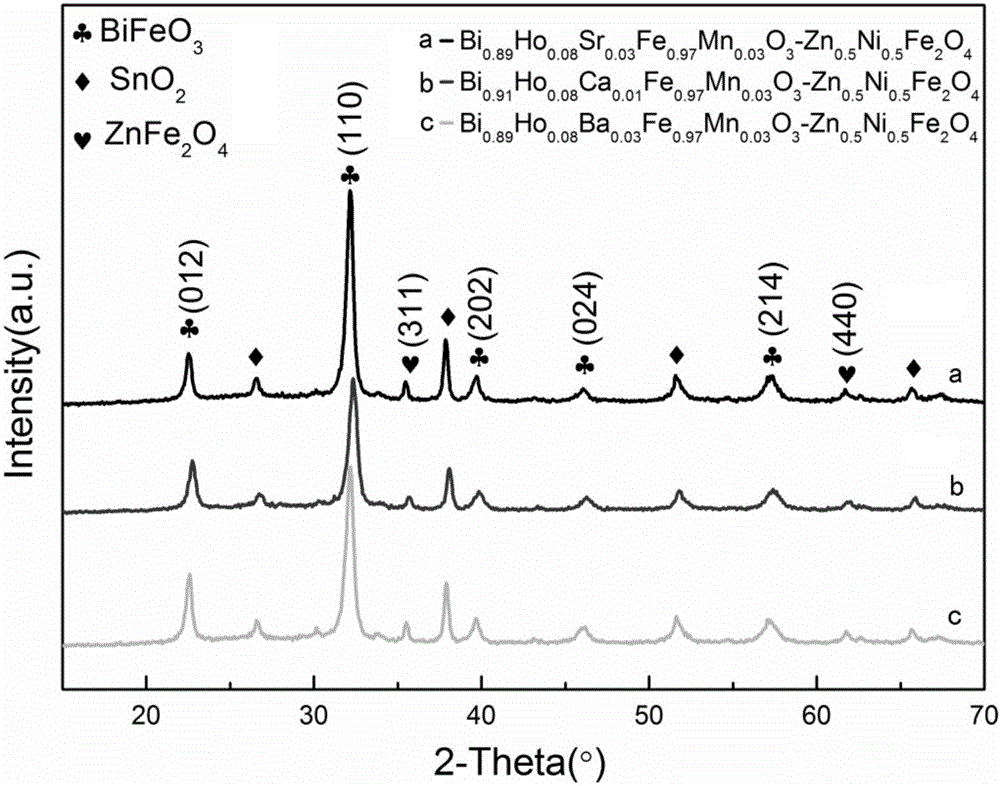

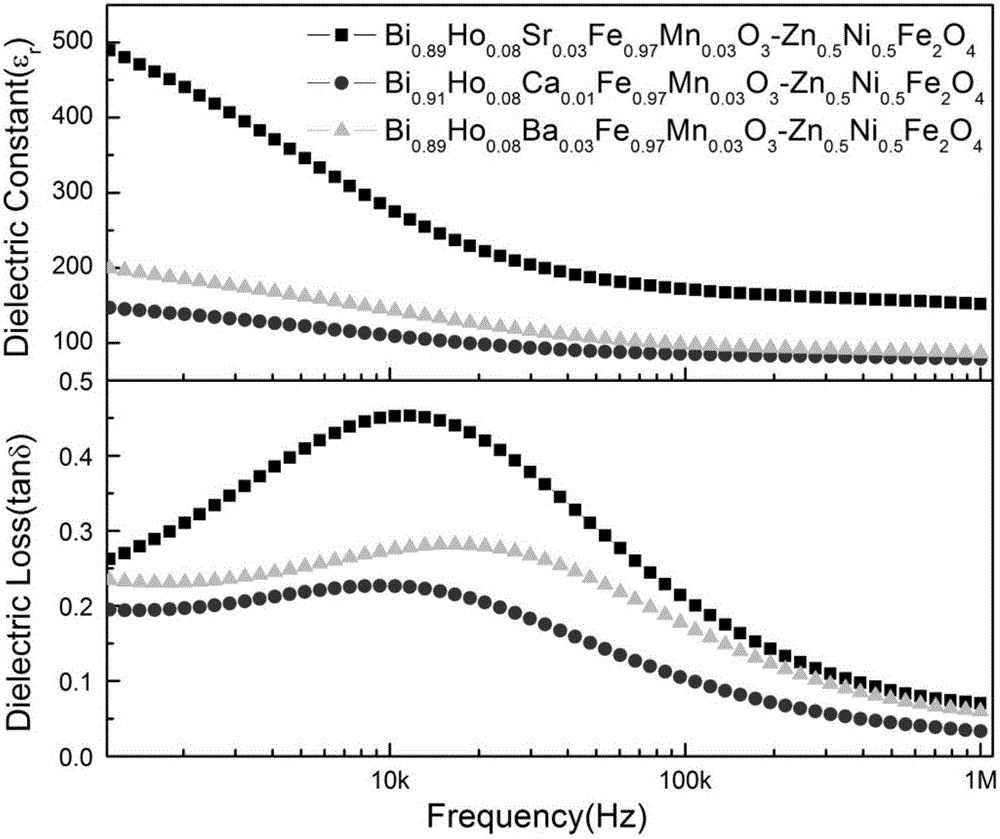

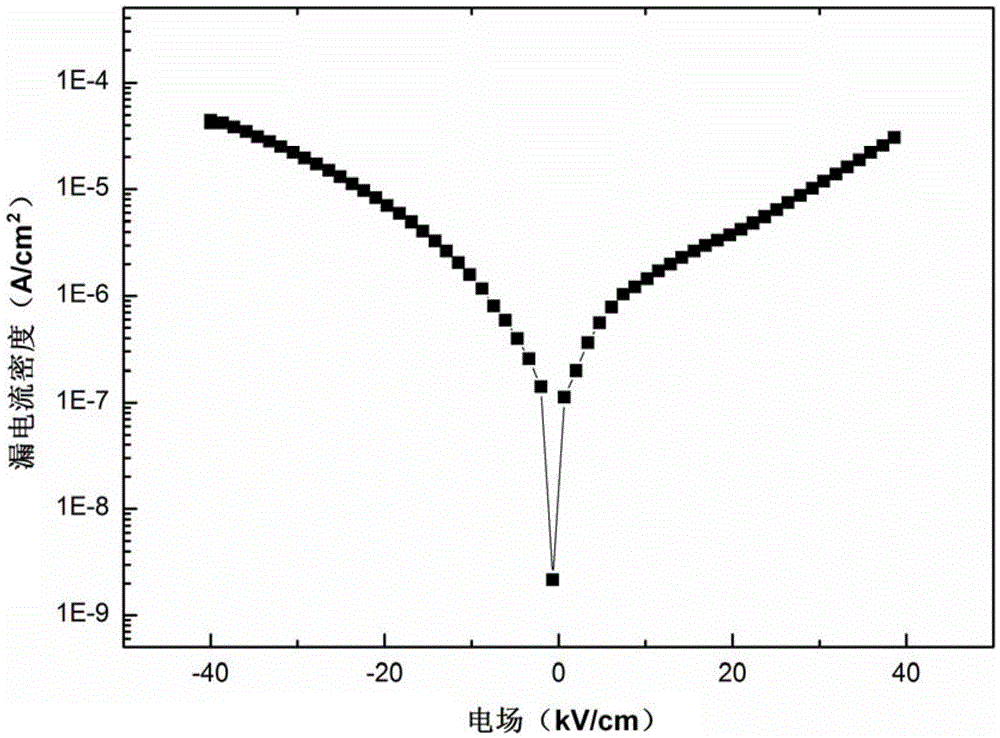

Bi0.92-xHo0.08AExFe0.97Mn0.03O3-Zn1-yNiyFe2O4 ferromagnetic composite film and preparation method thereof

InactiveCN105837196AReduce contentHigh polarizationCeramic layered productsMagnetic layerMagnetic composite

The invention provides a Bi0.92-xHo0.08AExFe0.97Mn0.03O3-Zn1-yNiyFe2O4 ferromagnetic composite film and a preparation method thereof. The ferromagnetic composite film comprises a Bi0.92-xHo0.08AExFe0.97Mn0.03O3 crystalline film and a Zn1-yNiyFe2O4 crystalline film, which are compounded together. The preparation method is as below: first respectively preparing a Zn1-yNiyFe2O4 precursor solution and a Bi0.92-xHo0.08AExFe0.97Mn0.03O3 precursor solution, wherein AE is Sr, Ca, Ba or Pb, x equals to 0.01-0.04, and y equals to 0.1-0.9; preparing a plurality of Zn1-yNiyFe2O4 films on a substrate by spin coating; and then preparing plurality of Bi0.92-xHo0.08AExFe0.97Mn0.03O3 films on the Zn1-yNiyFe2O4 films by spin coating, so as to obtain the ferromagnetic composite film. The method regulates the crystal structure of BiFeO3 by doping, and uses ferromagnetic Zn1-yNiyFe2O4 as the magnetic layer, so as to substantially increase the ferroelectric and ferromagnetic properties of the film, and effectively reduce the leakage current density of the film.

Owner:SHAANXI UNIV OF SCI & TECH

Multiferroic Bi0.96-xSr0.04RExFe0.94Mn0.04Cr0.02O3-NiFe2O4 composite film and preparation method thereof

The invention discloses a multiferroic Bi0.96-xSr0.04RExFe0.94Mn0.04Cr0.02O3-NiFe2O4 composite film and a preparation method thereof. The composite film comprises a Bi0.96-xSr0.04RExFe0.94Mn0.04Cr0.02O3 crystalline state film and a NiFe2O4 crystalline state film which are compounded together. The preparation method comprises the following steps: respectively preparing a Bi0.96-xSr0.04RExFe0.94Mn0.04Cr0.02O3 precursor solution and a NiFe2O4 precursor solution; and spinning on a substrate to prepare a multilayer NiFe2O4 film, and spinning on the NiFe2O4 film to prepare a multilayer Bi0.96-xSr0.04RExFe0.94Mn0.04Cr0.02O3 film, thereby obtaining the target product. The equipment requirement is simple, the prepared film is high in uniformity, the doping amount is easy to control, and the ferroelectric properties and ferromagnetic properties of the film are greatly improved. Meanwhile, the leakage current density of the film is effectively reduced.

Owner:SHAANXI UNIV OF SCI & TECH

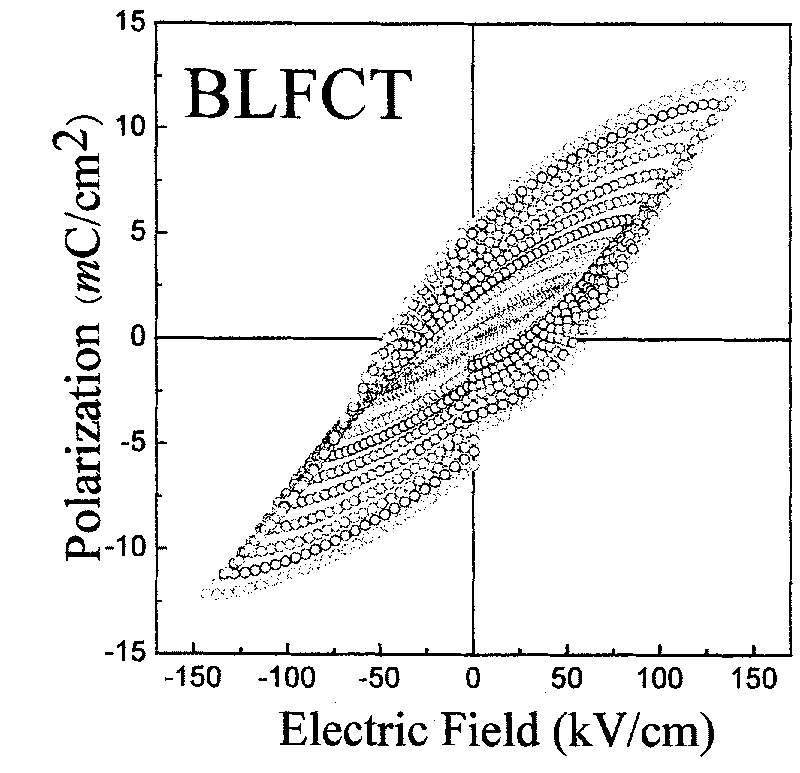

Layered structure ferrotitanium lanthanum bismuth cobaltate ceramic with multiferroic and preparation method thereof

InactiveCN101704669AImproved ferroelectric and magnetic propertiesThe process is simple and reasonableLayered structureLanthanum

The invention relates to a layered structure ferrotitanium lanthanum bismuth cobaltate ceramic with multiferroic and a preparation method thereof, relating to the technical field of oxide ceramic material preparation. The method comprises the following steps: firstly preparing Bi3.25L0.75Ti3O15 powder, then implanting BiCoO3 and BiFeO3 in Bi3.25L0.75Ti3O15 to form Bi4.25L0.75Fe0.5Co0.5Ti3O15 ceramic. In the obtained BLFCT sample, the octahedral arrangement of Fe-O and Co-O is relatively orderly so that the local coupling between Fe-O-Co and La-O-Co / Fe can be obtained and the ferroelectric property and magnetic property of the sample can be improved. The ceramic of the invention has simple and reasonable technology and good compatibility with the current technology, and the sample preparation temperature is much lower than the preparation temperature of the current technology so as to greatly reduce the energy consumption, thus the ceramic is applicable to industrial production.

Owner:YANGZHOU UNIV

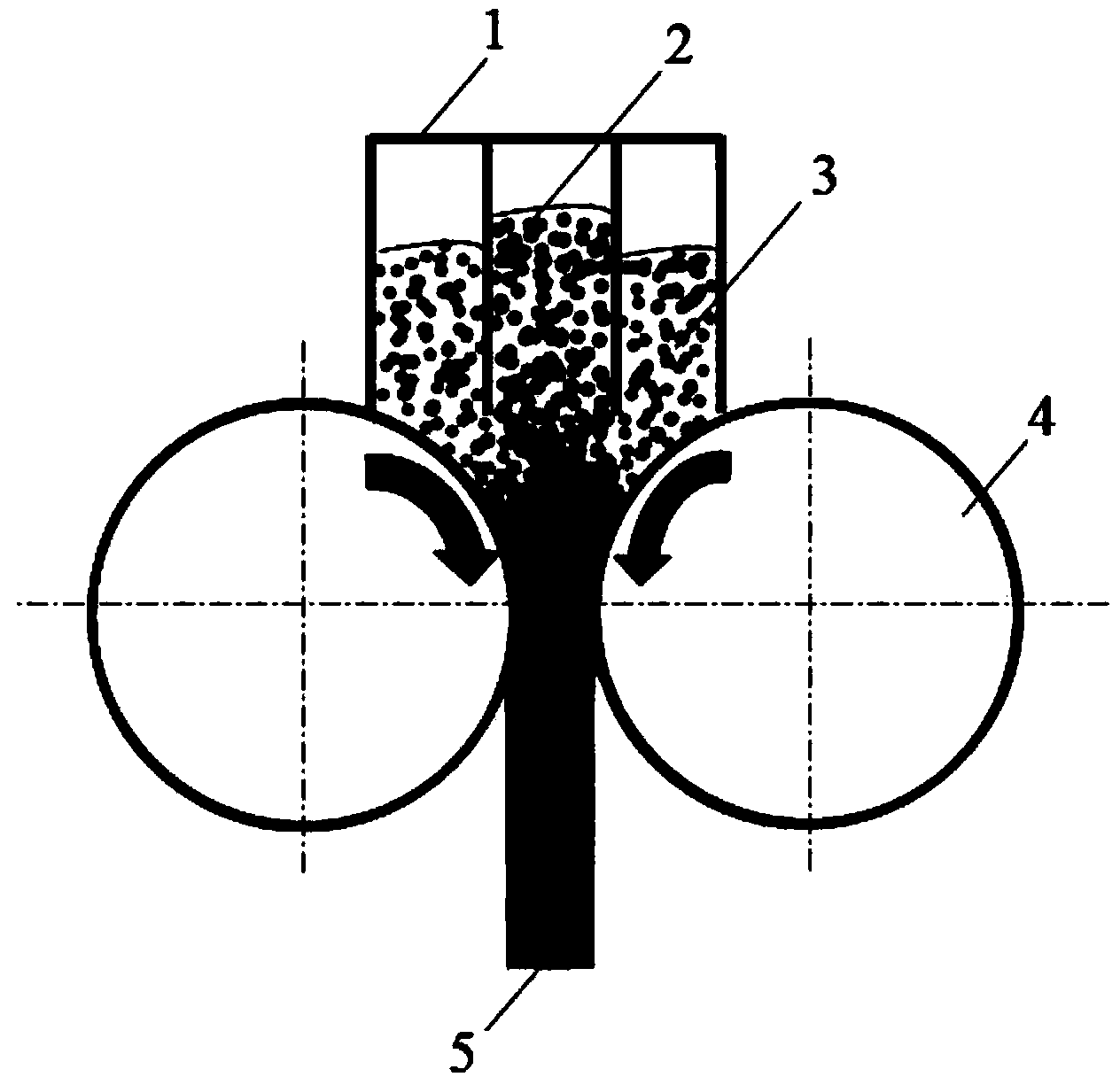

Method of preparing strong-cubic texture composite base band for coating superconductor by metal powder rolling

ActiveCN103817330AImprove ferromagnetic propertiesGuaranteed strong cubic texture contentFerromagnetismMetal powder

A method of preparing a strong-cubic structure composite base band for a coating superconductor by metal powder rolling belongs to the technical field of high-temperature coating superconducting base bands. Adopted materials are high-purity nickel powder, tungsten powder and chrome powder with the purities over 99.9 percent; an initial raw plate blank is obtained by a powder rolling method, and is subjected to long-term high sintering, hot rolling and surface polishing to obtain a nickel tungsten-nickel chromium composite initial billet with compact interlayer bonding; then multi-pass cold rolling, rolling intermediate restorative heat treatment and final high-temperature recrystallization annealing are performed to obtain the nickel tungsten-nickel chromium alloy composite base band which is provided with a strong cubic structure at the outer layer and a magnetism-free high-strength core layer. According to the method, the high-performance nickel tungsten-nickel chromium alloy composite base band is obtained by a special method of preparing a composite billet; the alloy base band prepared by the method has the characteristics of convenient preparing process, strong cubic structure content, no ferromagnetism, high strength and the like, and is easy for large-scale industrial production.

Owner:深创超导(深圳)科技有限公司

Bi0.90Er0.10Fe0.96Co0.02Mn0.02O3/Mn(1-x)CoxFe2O4 composite film and preparation method thereof

The invention provides a Bi0.90Er0.10Fe0.96Co0.02Mn0.02O3 / Mn(1-x)CoxFe2O4 composite film and a preparation method thereof. The composite film comprises a Bi0.90Er0.10Fe0.96Co0.02Mn0.02O3 crystalline-state film and a Mn(1-x)CoxFe2O4 crystalline-state film which are compounded together. The preparation method comprises the following steps: respectively preparing a Bi0.90Er0.10Fe0.96Co0.02Mn0.02O3 precursor solution and a Mn(1-x)CoxFe2O4 precursor solution; then spinning on a substrate to prepare a multi-layer Mn(1-x)CoxFe2O4 film; and spinning on the Mn(1-x)CoxFe2O4 film to prepare a multi-layer Bi0.90Er0.10Fe0.96Co0.02Mn0.02O3 film which is the target product. In the invention, the equipment requirements are simple, the prepared film has relatively good uniformity, the doping amount is easy to control, the ferroelectric property and ferromagnetic property of the film are remarkably improved, and the leak current density of the film is effectively reduced at the same time.

Owner:SHAANXI UNIV OF SCI & TECH

Multiferroic Bi(0.98-x)Sr0.02RExFe0.97Mn0.03O3-CuFe2O4 composite film and preparation method thereof

The invention discloses a multiferroic Bi(0.98-x)Sr0.02RExFe0.97Mn0.03O3-CuFe2O4 composite film and a preparation method thereof. The composite film comprises Bi(0.98-x)Sr0.02RExFe0.97Mn0.03O3 crystal films and CuFe2O4 crystal films which are composited together. The preparation method comprises the following steps: firstly, preparing a Bi(0.98-x)Sr0.02RExFe0.97Mn0.03O3 precursor solution and a CuFe2O4 precursor solution respectively; secondly, preparing multiple layers of CuFe2O4 films on a substrate by spin coating, and preparing multiple layers of Bi(0.98-x)Sr0.02RExFe0.97Mn0.03O3 films on the CuFe2O4 films by spin coating to obtain a target product. The equipment requirement is simple, the uniformity of the prepared film is high, the doping amount is easy to control, the ferroelectric and ferromagnetic properties of the film are improved, and the leakage current density of the film is effectively reduced.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of magnetic carbon-covering nano material

InactiveCN105965009AIncrease productionHigh saturation magnetizationMaterial nanotechnologyTransportation and packagingDispersityHysteresis

The invention discloses a preparation method of a magnetic carbon-covering nano material, and belongs to the field of preparation of nanocarbon@metal composites. The preparation method of the magnetic carbon-covering nano material is characterized in that the magnetic carbon-covering nano material is obtained through carrying out high-temperature pyrolysis on a metal-organic framework compound in the atmosphere of inert protection. According to the preparation method, the metal-organic framework compound is utilized as a precursor, and the carbon-covering nano material with a uniform size is prepared through a one-step high-temperature pyrolysis process; and according to a product obtained through the method, the phase is single, the impurities are extremely few, the collection is particularly easy, the yield is high, the large-scale synthesis is facilitated, the product has quite good ferromagnetism, the dispersity is quite good, the response time is short, and the magnetic carbon-covering nano material has quite typical ferromagnetism hysteresis loop and relatively high saturation magnetization intensity, and is a kind of quite potential biomagnetic nano material.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Dysprosium-doped BiFeO3 multi-ferroic ceramic block and preparation method thereof

The invention relates to a dysprosium-doped BiFeO3 multi-ferroic ceramic block and a preparation method thereof and belongs to the field of functional ceramic. The preparation method comprises the following steps: weighting Bi(NO3)3.5H2O, Dy2O3 and Fe(NO3)3.9H2O at a ratio of (1-x):x:1; respectively dissolving in glacial acetic acid, diluted nitric acid and water, heating and stirring; mixing thethree solutions, and then adding citric acid, heating and stirring; after adjusting PH, continuously heating and stirring, thereby obtaining gel; foaming the gel, thereby obtaining aerogel; crushing the aerogel, thereby obtaining powder; pre-processing the powder; making the pre-processed powder into block and sintering; and removing a surface oxide layer, thereby obtaining the B(i1-x)DyxFeO3 multi-ferroic ceramic block, wherein x is equal to 0.03-0.20. The Bi(1-x)DyxFeO3 multi-ferroic ceramic block is single-phase ceramic; the ferroelectricity is enhanced; and when x is equal to 0.05 and 0.07, the ceramic block has ferromagnetism at room temperature.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Bi0.9Er0.1Fe1-xCoxO3 film with high ferromagnetism and ferroelectricity, and making method thereof

The invention provides a Bi0.9Er0.1Fe1-xCoxO3 film with high ferromagnetism and ferroelectricity, and a making method thereof. The method comprises the following steps: preparing a Bi0.9Er0.1Fe1-xCoxO3 precursor solution from bismuth nitrate, iron nitrate, cobalt nitrate and erbium nitrate, spin-coating a substrate with the Bi0.9Er0.1Fe1-xCoxO3 (x is 0.01-0.03) precursor solution, uniformly sizing, drying, and annealing to obtain the Bi0.9Er0.1Fe1-xCoxO3 film with high ferromagnetism and ferroelectricity. The method has the advantages of simple device requirements, easy reaching of experiment conditions, easy control of the doping amount, and great improvement of the ferromagnetism of a BiFeO3 film, and the Bi0.9Er0.1Fe1-xCoxO3 film made in the invention has the advantages of good uniformity, high magnetic intensity and high remanent polarization.

Owner:SHAANXI UNIV OF SCI & TECH

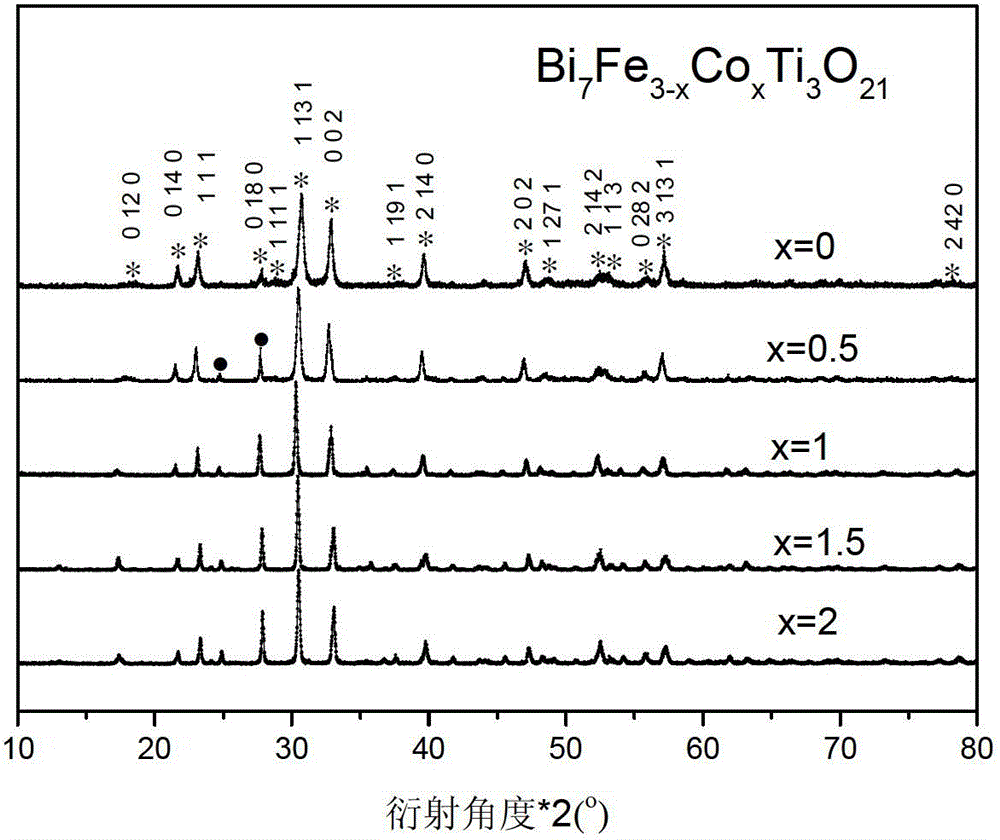

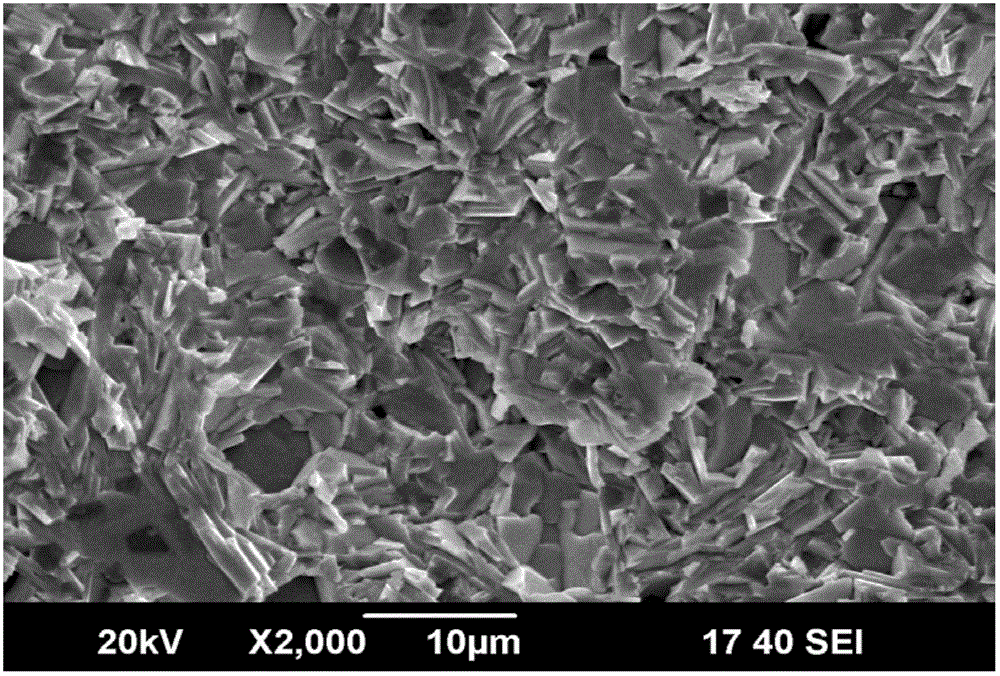

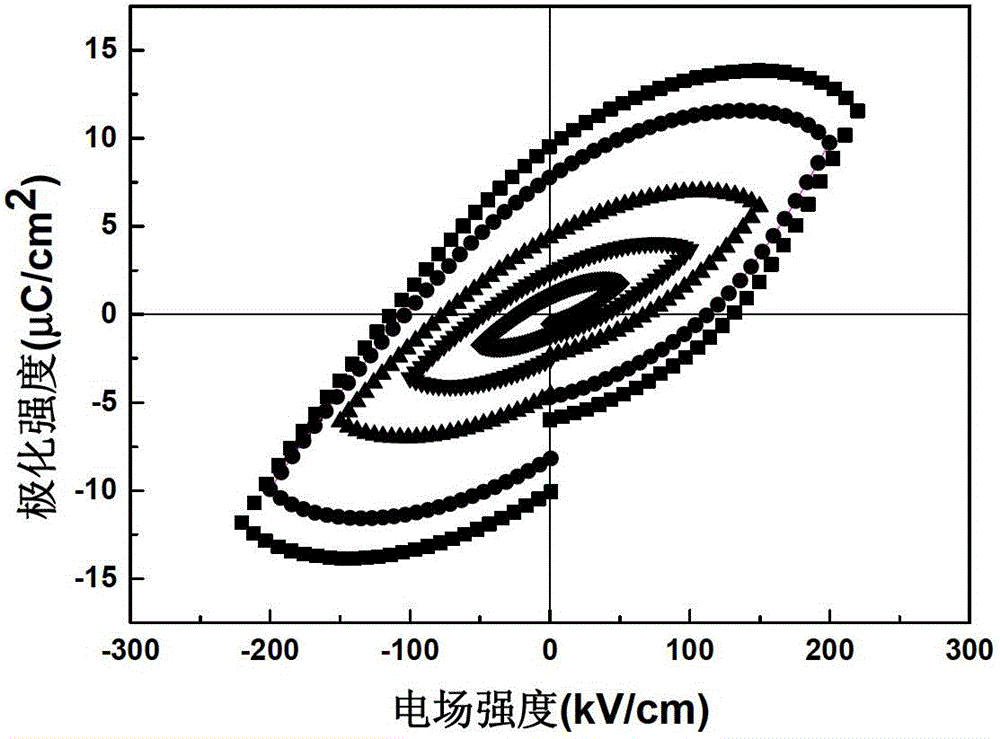

Ferrotitanium bismuth cobaltate ceramic material having layered structure and preparation method thereof

InactiveCN102942361AImprove ferroelectric propertiesImprove ferromagnetic propertiesOctahedronTitanium oxide

The present invention provides a ferrotitanium bismuth cobaltate ceramic material having a layered structure. A part of iron ions are replaced by cobalt ions to obtain Bi7Fe3-xCoxTi3O21 layered Aurivillius type multi-iron oxide ceramic, and the structure thereof includes two bismuth oxide layers ((Bi2O2)2+) and titanium oxide (Ti-O) octahedrons, iron oxide (Fe-O) octahedrons and cobalt oxide (Co-O) octahedrons sandwiched between the bismuth oxide layers, wherein because iron atoms and cobalt atoms are similar in structure, after part of the cobalt ions replace part of iron ions, the Fe-O octahedrons and Co-O octahedrons are ranked relatively in order, the Fe-O-Co coupling can be formed locally, and ferroelectric and ferromagnetic of the ceramic material are enhanced. The present invention also provides a preparation method of the ferrotitanium bismuth cobaltate ceramic material having the layered structure. The preparation temperature of the ceramic material is much lower than the preparation temperature of the prior art, the energy consumption is reduced, and the industrialization production is facilitated.

Owner:UNIV OF SCI & TECH OF CHINA

Free-cutting ferritic stainless steel

InactiveCN101153375AImprove cutting performanceImprove ferromagnetic propertiesChemical compositionElectromagnetic valve

The invention discloses an easy-cutting ferritic stainless steel relating to the easy-cutting ferritic stainless steel material used for making electromagnetic valve, etc., wherein, the chemical composition weight percent of the steel is as follows: less than or equal to 0.03 percent of C, 1.0 percent to 1.5 percent of Si, 0.6 percent to 1.0 percent of Mn, 0.15 percent to 0.30 percent of S, less than or equal to 0.04 percent of P, 16.5 percent to 18.0 percent of Cr, 0.75 percent to 1.25 percent of Mo, 0.20 percent to 0.50 percent of Ti and the rest, Fe and other inevitable impurities. Through reasonable improvement in composition proportion, the invention ensures that the ferritic stainless steel has excellent machinability, ferromagnetism and weldability and can meet the requirements of performances such as corrosion resistance, coercive force, magnetic induction and salt spray corrosion, thereby according with the requirements of electromagnetic valve manufacturers.

Owner:BAOSHAN IRON & STEEL CO LTD

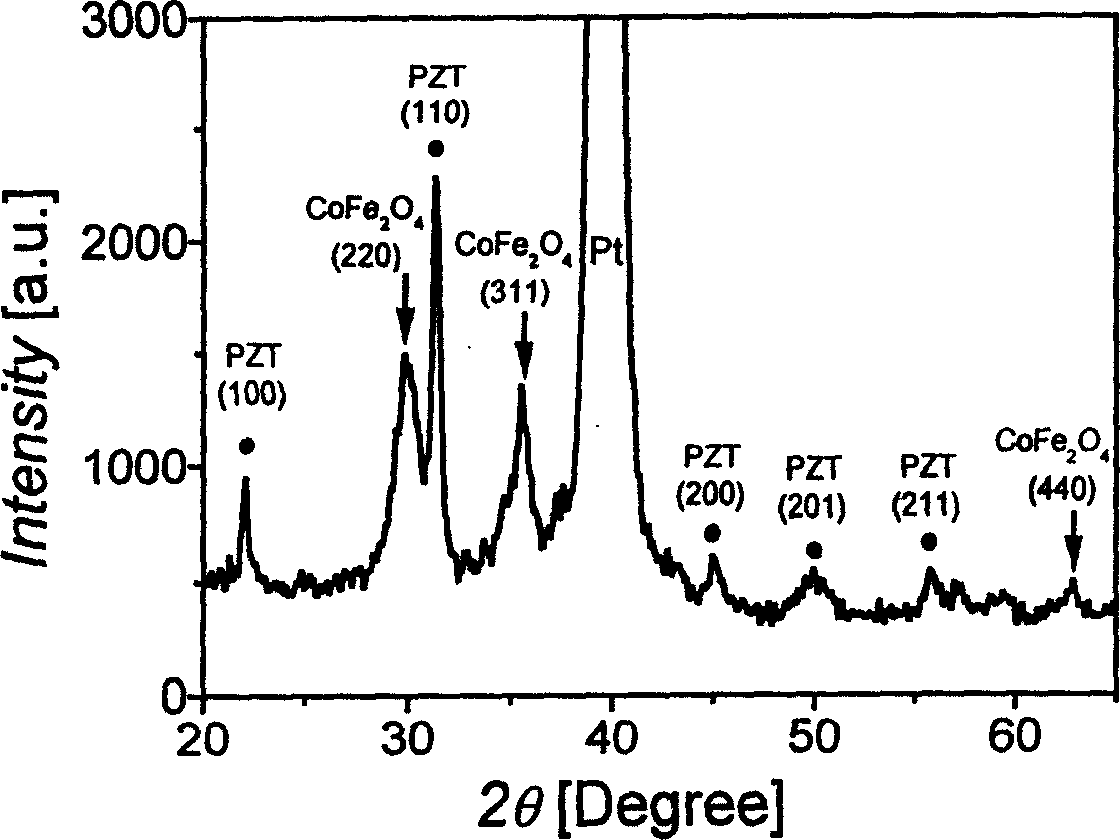

Magnetoelectric composite film and its preparation method

InactiveCN1597612APromote crystallizationImprove ferroelectric propertiesInorganic material magnetismElectricityLead zirconate titanate

A composite magneto-electric film with magneto-electric effect and better ferromagnetic and ferroelectric properties is composed of the ferroelectric substrate of lead iron zirconate titanate, and the magnetic cobalt ferrite particles uniformly distributed in said substrate. Its preparing process is also disclosed.

Owner:NANJING UNIV

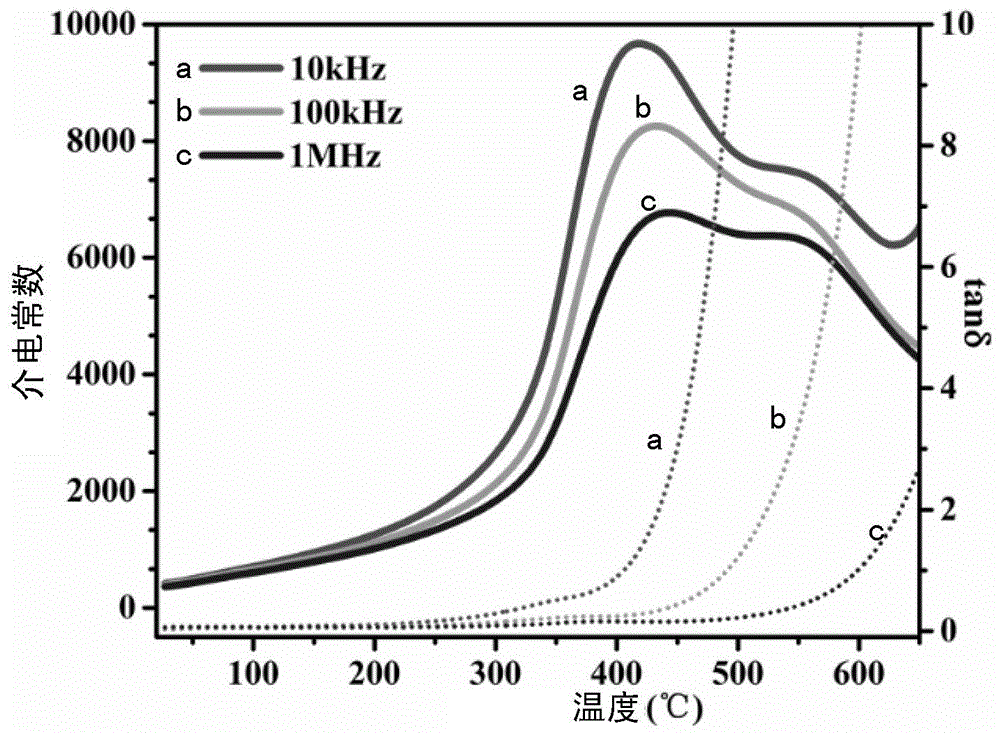

Multiferroic ceramics with room-temperature highly ferromagnetic-ferroelectric and highly-magnetic dielectric effects and preparation method of multiferroic ceramics

The invention discloses multiferroic ceramics with room-temperature highly ferromagnetic-ferroelectric and highly-magnetic dielectric effects and a preparation method of the multiferroic ceramics, relates to multiferroic ceramics and a preparation method thereof, and aims to solve the problem in the prior art that the existing BiFeO3-based solid soluble multiferroic ceramics have poor ferroelectricity and ferromagnetism at room temperature and lower magnetic dielectric effect as well. The multiferroic ceramics have the chemical formula of (1-x)Ba0.70Ca0.30TiO(3-x)BiFeO3. The method comprises the following steps: (1) weighing raw materials; (2) mixing the raw materials, performing ball-milling, drying and compacting to obtain to-be-prefired pellets; (3) prefiring the to-be-prefired pellets to obtain presintered pellets; and (4) grinding the presintered pellets, performing ball-milling, adding a polyvinyl alcohol solution as binder, grinding, sieving, compacting to obtain to-be-sintered sheets, removing the binder, burying the sheets in a powdery material of the same composition, sintering to obtain ceramics, and polishing the ceramic blocks to obtain the final products of multiferroic ceramics with room-temperature highly ferromagnetic-ferroelectric and highly-magnetic dielectric effects. The multiferroic ceramics can be applied in the field of multiferroic materials.

Owner:HARBIN INST OF TECH

Bi0.92Ho0.08Fe0.97Mn0.03O3-Zn1-xNixFe2O4 multiferroic composite film and preparation method thereof

The invention discloses a Bi0.92Ho0.08Fe0.97Mn0.03O3-Zn1-xNixFe2O4 multiferroic composite film and a preparation method thereof. The composite film comprises a Bi0.92Ho0.08Fe0.97Mn0.03O3 crystalline film and a Zn1-xNixFe2O4 crystalline film, which are compounded together. The method comprises the following steps: firstly, respectively preparing a Bi0.92Ho0.08Fe0.97Mn0.03O3 polymeric precursor solution and a Zn1-xNixFe2O4 precursor solution during preparation; spinning on a substrate, and preparing a multi-layer Zn1-xNixFe2O4 film; and spinning on the Zn1-xNixFe2O4 film and preparing a multi-layer Bi0.92Ho0.08Fe0.97Mn0.03O3-Zn1-xNixFe2O4 film, so as to obtain a target product. The method disclosed by the invention is simple in demands on equipment; the prepared film is good in uniformity; the doping amount is easy to control; the ferroelectric properties and the ferromagnetic properties of the film are improved; and meanwhile, the leakage current density of the film is effectively reduced.

Owner:SHAANXI UNIV OF SCI & TECH

Bi(1-x)RExFe0.96Co0.02Mn0.02O3 ferroelectric film and preparation method thereof

The invention provides a Bi(1-x)RExFe0.96Co0.02Mn0.02O3 ferroelectric film and a preparation method thereof. The preparation method comprises the following steps: preparing a Bi(1-x)RExFe0.96Co0.02Mn0.02O3 precursor solution from bismuth nitrate, ferric nitrate, cobalt nitrate, manganese acetate and nitric acid RE which serve as raw materials, wherein x is 0.06-0.12, and RE is La, Eu or Er; and coating the precursor solution on a substrate in a spinning manner, uniformly coating, baking and annealing to obtain the Bi(1-x)RExFe0.96Co0.02Mn0.02O3 ferroelectric film. By adopting the method, requirement for equipment is simple, the experiment condition can be easily achieved, the doping amount can be easily controlled, and the ferroelectric performance of the film can be greatly improved, so that the prepared Bi(1-x)RExFe0.96Co0.02Mn0.02O3 ferroelectric film has good uniformly, less current leakage and high remanent polarization.

Owner:SHAANXI UNIV OF SCI & TECH

SrTiO3-based high-frequency layered magnetoelectric composite material and preparation method thereof

The invention discloses a SrTiO3-based high-frequency layered magnetoelectric composite material and a preparation method thereof. The preparation method comprises the following steps: granulating SrTiO3 powder and Ni0.8Zn0.2Fe2O4 powder, pressing and molding the powder in a mold according to a 2-2 composite base superposition arrangement mode, discharging a PVA adhesive, sintering at the temperature of 1250 to 1300 DEG C, thereby obtaining the SrTiO3-based high-frequency layered magnetoelectric composite material. Because the SrTiO3 powder and Ni0.8Zn0.2Fe2O4 powder is molded according to the 2-2 composite base superposition arrangement mode, a ferroelectric phase and a ferrimagnetic phase are cofired together in a layered compounding mode, and the mutual reaction between the two phases can be effectively inhibited so as to remain the respective characteristics. Therefore, the composite material has excellent dielectricity and ferromagnetic property.

Owner:SHAANXI UNIV OF SCI & TECH

Multiferroic Bi0.83Pr0.15Sr0.02Fe0.97-xMn0.03CuxO3-CuFe2O4 composite film and preparation method thereof

ActiveCN105906221APrevent volatilizationInhibition transitionCoatingsLeakage current densityComposite film

The invention discloses a multiferroic Bi0.83Pr0.15Sr0.02Fe0.97-xMn0.03CuxO3-CuFe2O4 composite film and a preparation method thereof. The composite film comprises a Bi0.83Pr0.15Sr0.02Fe0.97-xMn0.03CuxO3 (x=0.01-0.05) crystalline film in the upper layer and a CuFe2O4 crystalline film in the lower layer. The preparation method comprises respectively preparing a Bi0.83Pr0.15Sr0.02Fe0.97-xMn0.03CuxO3 precursor solution and a CuFe2O4 precursor solution, carrying out spin-coating on a substrate with multiple CuFe2O4 films and carrying out spin-coating on the CuFe2O4 film with multiple Bi0.83Pr0.15Sr0.02Fe0.97-xMn0.03CuxO3 films to obtain the multiferroic Bi0.83Pr0.15Sr0.02Fe0.97-xMn0.03CuxO3-CuFe2O4 composite film. The preparation method has simple equipment requirements, can prepare the film with good uniformity, easily controls a doping amount, improves ferroelectric and ferromagnetic properties of the film and effectively reduces film leakage current density.

Owner:SHAANXI UNIV OF SCI & TECH

Six-layer ferrotitanium yttrium bismuth cobaltate ceramic material with multiferroic performance and preparation method thereof

The invention relates to a six-layer ferrotitanium yttrium bismuth cobaltate ceramic material with multiferroic performance and a preparation method thereof. The Aurivillius-type oxide ceramic with a chemical formula Bi6YFe2CoTi3O21 has good ferroelectricity and ferromagnetism over room temperature. A Bi6YFe2CoTi3O21 sample is prepared by an improved Pechini method, and the Fe-O and Co-O octahedrons are orderly arranged relatively so as to locally obtain coupling between Fe-O-Co and Y-O-Co / Fe to improve the ferroelectric and magnetic performance of the sample. The technology is simple, reasonable and efficient, the sample preparation temperature is far lower than the preparation temperature of the prior art, and the technology is environment-friendly and very convenient for industrial production.

Owner:UNIV OF SCI & TECH OF CHINA

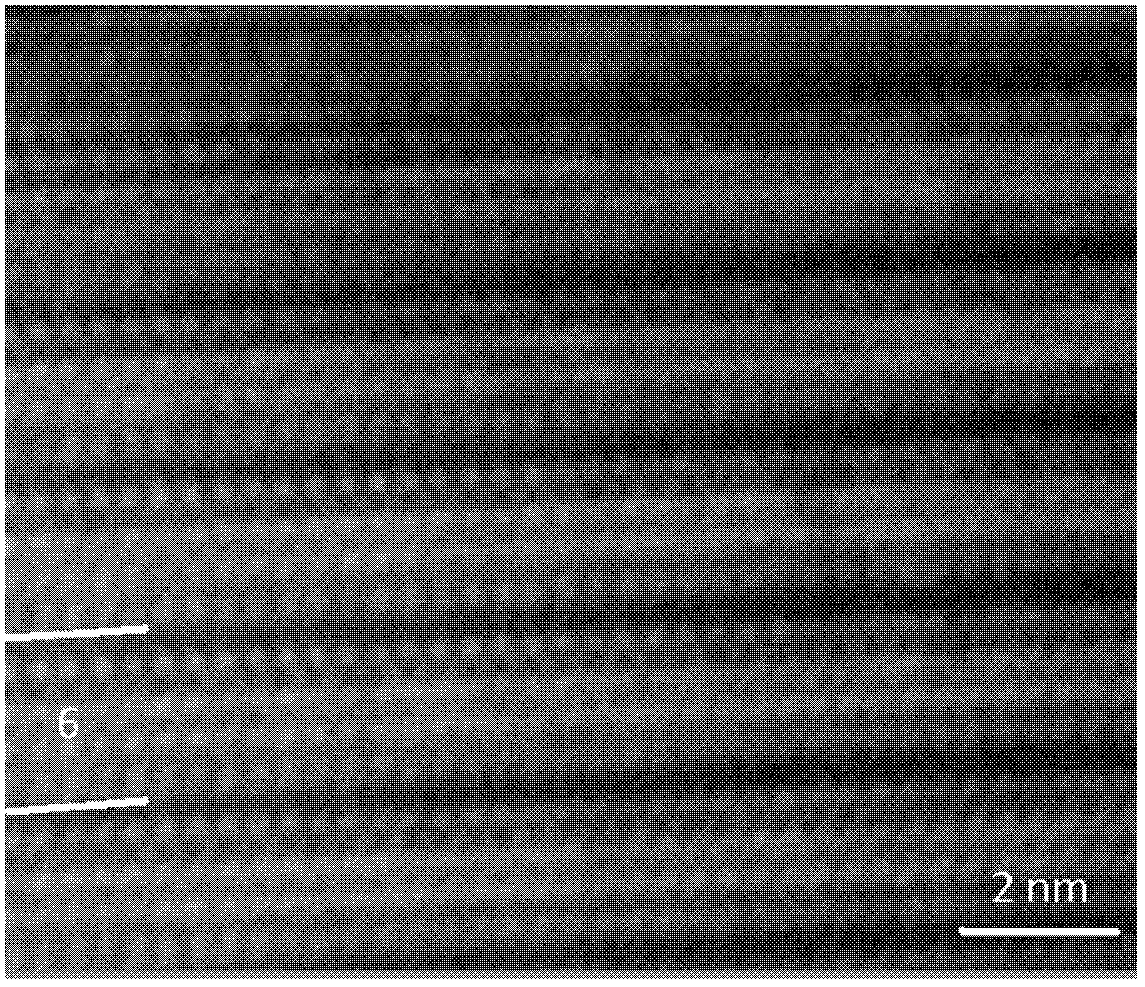

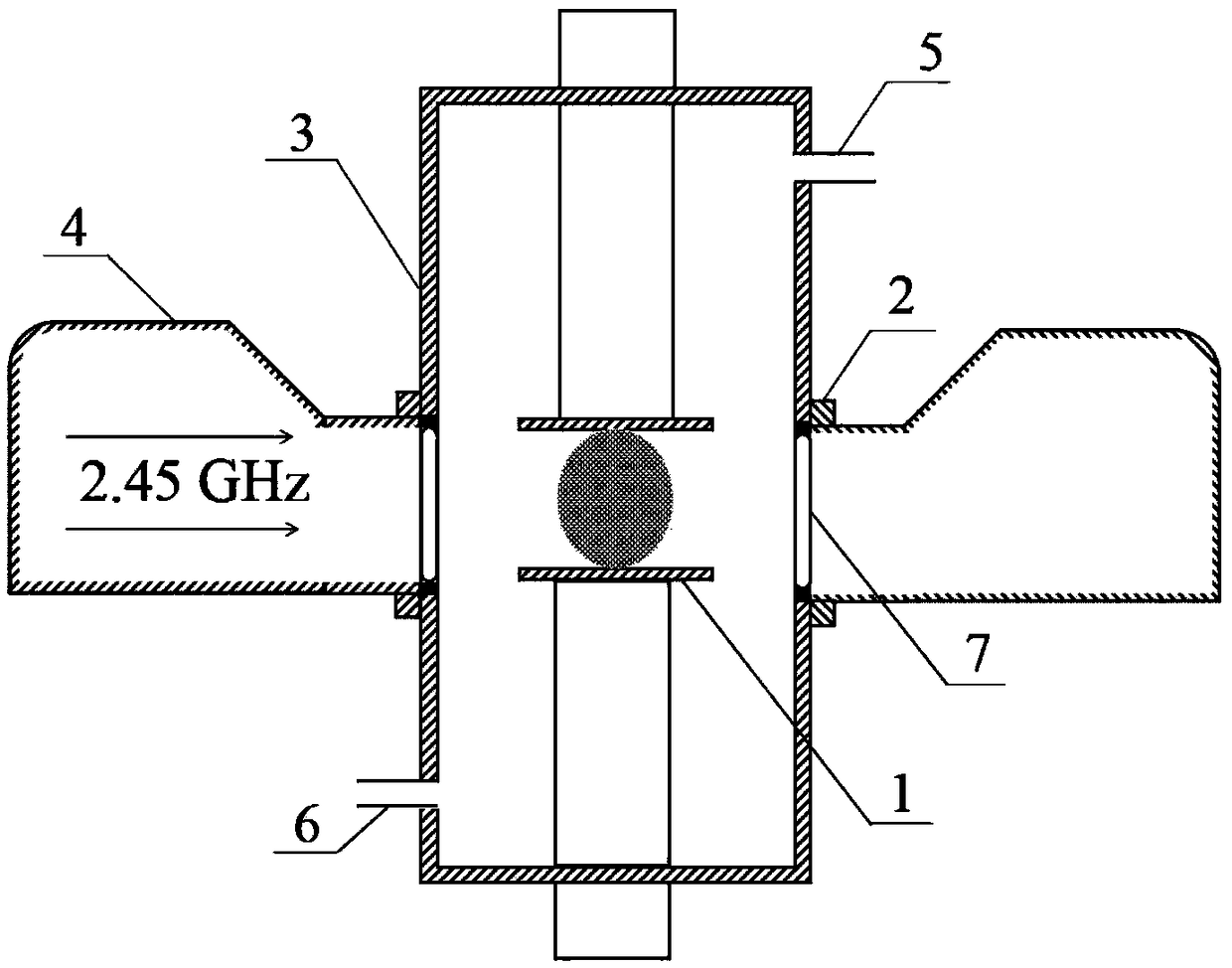

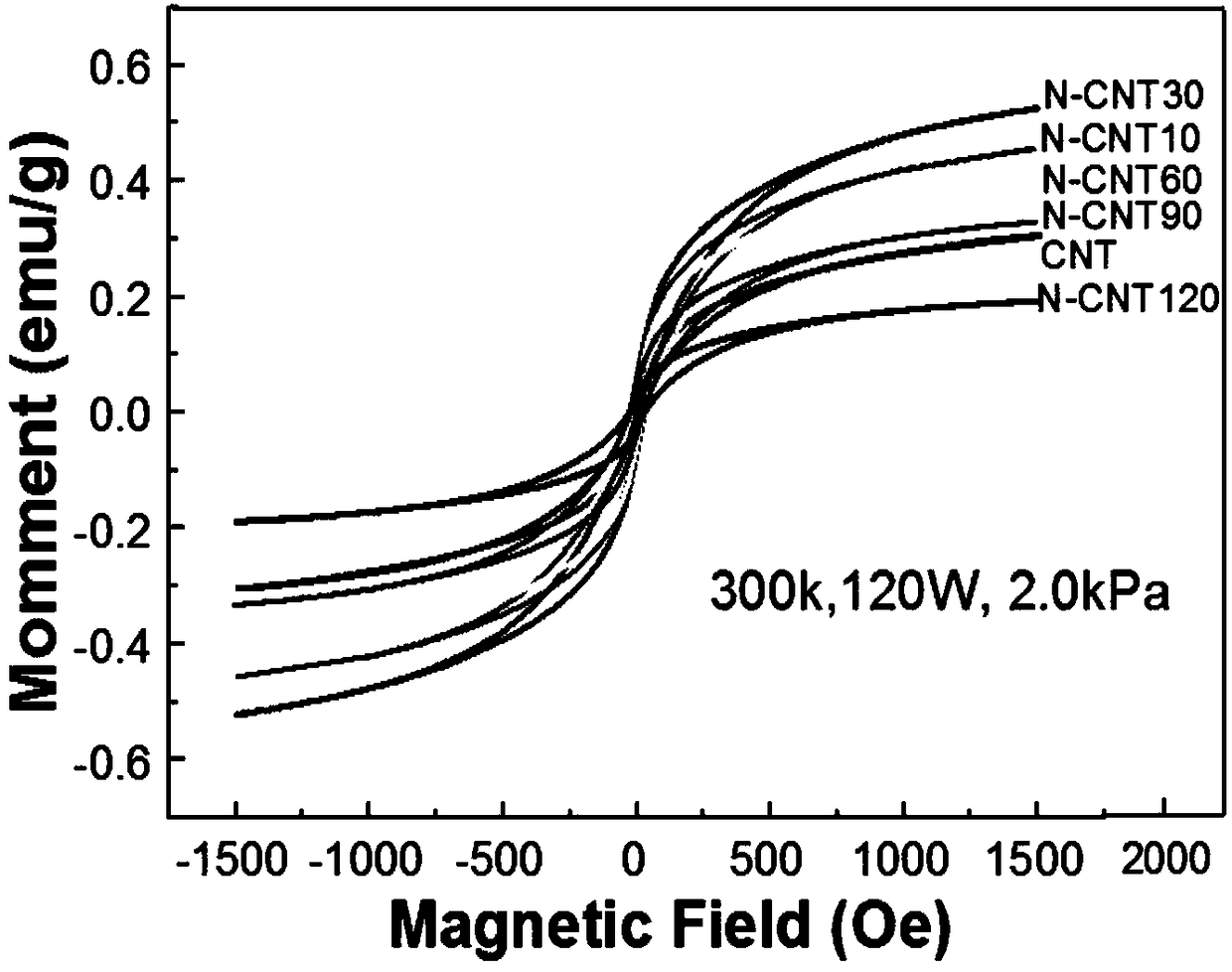

Method and device for preparing nitrogen-doped carbon nanotubes by using microwave vapor deposition

InactiveCN108190862AIncrease the chance of ionizationLow deposition pressureCarbon nanotubesNitrogen doped carbon nanotubeChemistry

The invention discloses a method and device for preparing nitrogen-doped carbon nanotubes by using microwave vapor deposition. The method comprises the following steps that carbon nanotube powder is placed in a closed cavity, and the cavity is vacuumized; nitrogen gas is introduced to the cavity, the flow rate and air pressure of the nitrogen gas are adjusted, and meanwhile microwave irradiation is conducted to make the gas in the cavity absorb microwave energy and be excited to generate plasma; nitrogen atoms after plasma treatment can be doped into the surfaces and internal structures of carbon nanotubes to form the nitrogen-doped carbon nanotubes, and by controlling the microwave power and nitrogen doping time, the nitrogen carbon nanotubes with different nitrogen contents are obtained.A nitrogen gas source is subjected to plasma treatment by adopting a microwave plasma technology. Since the microwave power and the energy density are high and radical groups have high activity, thegas can be easily dissociated; the nitrogen carbon nanotubes prepared by means of the method are high in quality and purity and facilitates the test and characterization of ferromagnetic properties, optical properties and other properties, and prepared samples show good ferromagnetism.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

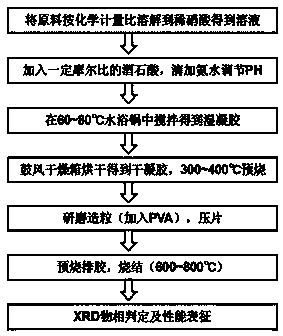

Preparation method of Bi1-xNdxFeO3 rare earth ferrite magnetic wave-absorbing material

InactiveCN111205078AImprove uniformityHigh purityMagnetic/electric field screeningPolyvinyl alcoholGranulation

The invention discloses a preparation method of a Bi1-xNdxFeO3 rare earth ferrite magnetic wave-absorbing material, wherein the method comprises the steps: (1) dissolving raw materials bismuth nitrate, ferric nitrate and neodymium nitrate respectively as ion sources of Bi, Fe and Nd into dilute nitric acid; (2) adding tartaric acid, and adjusting the pH value to 5-7; (3) stirring at the temperature of 60-80 DEG C until the solution is uniform and is in a transparent gel wet gel state; (4) drying the obtained wet gel at the temperature of 100-120 DEG C to obtain dry gel; (5) presintering the dry gel at the temperature of 300-400 DEG C to remove organic matters to obtain precursor powder; (6) granulating the precursor powder by using polyvinyl alcohol glue, grinding, and pressing and formingthe powder; and (7) carrying out heat preservation and glue discharging on the pressed and formed sample in an annealing furnace at the temperature of 400 DEG C, and annealing at the temperature of 600-800 DEG C. The magnetic wave-absorbing material prepared by the method disclosed by the invention has a relatively wide microwave absorption frequency band and relatively wide microwave absorptionefficiency in a 2-18 GHz microwave frequency band.

Owner:GUILIN UNIV OF ELECTRONIC TECH

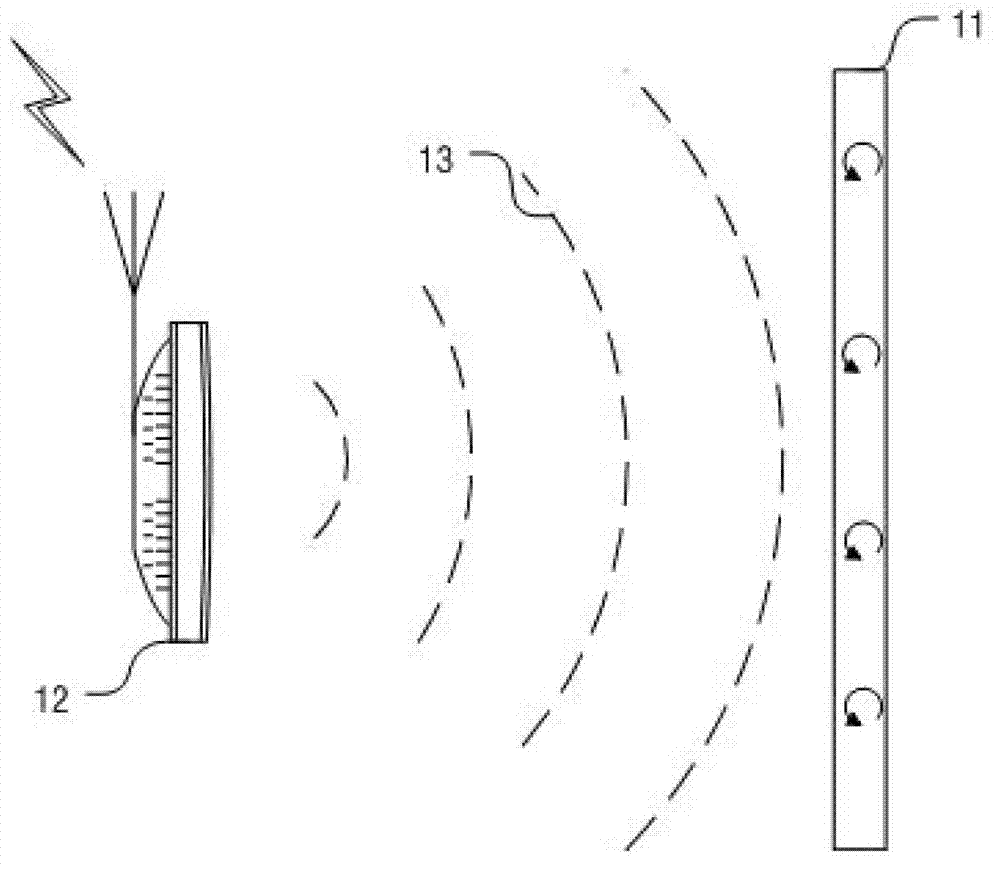

Ocean precipitation process for improving radiation protection performance of metal and iron-based mixture

ActiveCN103194696AGood radiation protectionImprove radiation protection performanceOther chemical processesMetal fibersVolumetric Mass Density

The invention discloses an ocean precipitation process for improving radiation protection performance of metal and an iron-based mixture. An iron base is used as a matrix to bear the deep sea static pressure, so that the physical property is changed. A non-crystal protective film has stable property to protect the iron base from corrosion and is used for adsorbing polynuclear metal. At a predetermined temperature, the protective film softens, so that the modified iron base and the polynuclear metal are stored. The iron base and the polynuclear are mixed to obtain a metal fiber. According to parts by weight, the iron-based mixture comprises iron, germanium, tin, lead and nickel in proportion of 1: 1.8-2.1: 0.8-1.3: 1.2-1.5; and the density of the mixture is not less than 8.1g / cm3. The iron-based mixture provided by the invention contains a plurality of metals and has favorable electric conductivity and ferromagnetic property, so that the protection to the electromagnetic radiation is improved.

Owner:NANCHANG JOYNCLEON CLOTHING

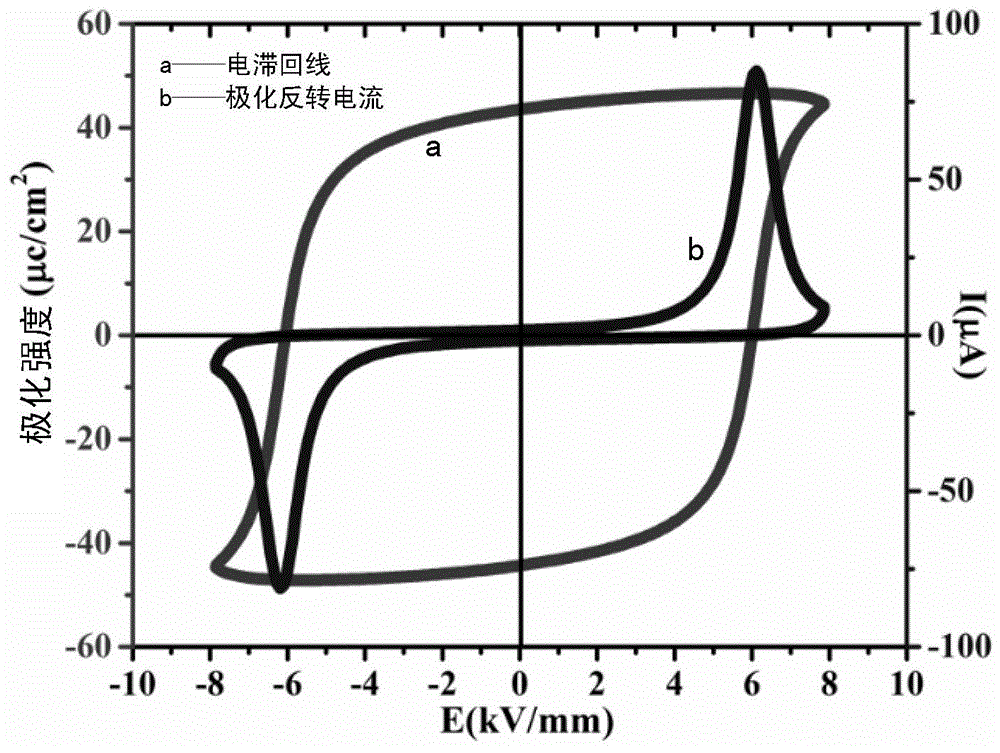

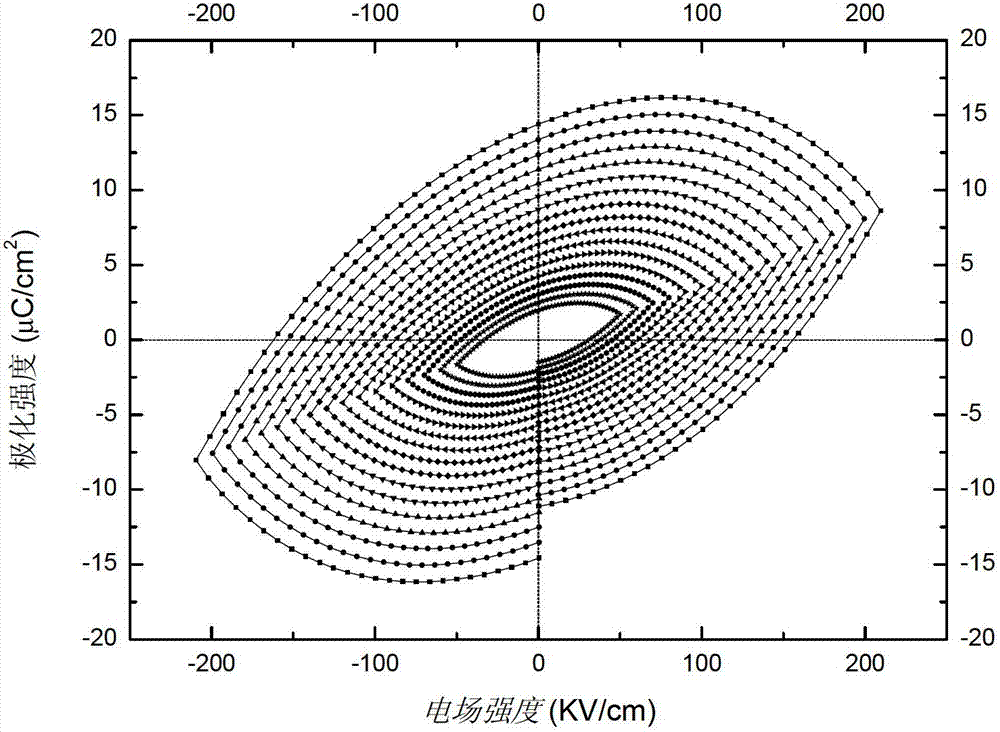

Novel room-temperature multi-ferroic ceramic with high polarization intensity and preparation method of novel room-temperature multi-ferroic ceramic

ActiveCN106242546AImprove ferromagnetic propertiesImprove ferroelectric propertiesChemical compositionRoom temperature

The invention relates to novel room-temperature multi-ferroic ceramic with high polarization intensity and a preparation method of the novel room-temperature multi-ferroic ceramic. The chemical composition of a room-temperature multi-ferroic ceramic material is 0.75 ((1-x)BiFeO<3>-xBiGaO<3>)-0.25Ba<0.85>Ca<0.15>Ti<0.90>Zr<0.10>O3 +yMnCO<3>, wherein x is greater than 0 and is smaller than or equal to 0.05, and y is smaller than or equal to 0.5wt%. By adjusting and controlling components, the novel room-temperature multi-ferroic ceramic material simultaneously having excellent ferromagnetism and excellent ferroelectricity is obtained, and has high remanent polarization intensity (22-44 [mu]C / cm<2>) and high ferromagnetism properties (0.09-0.27emu / g).

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Titanium-iron-gadolinium cobaltate-bismuth ceramic material in layer structure and preparation method of titanium-iron-gadolinium cobaltate-bismuth ceramic material

InactiveCN102863211AImprove ferroelectric propertiesImprove ferromagnetic propertiesOxide ceramicsOctahedron

The invention provides a titanium-iron-gadolinium cobaltate-bismuth ceramic material in a layer structure. Gadolinium ions substitute for part of bismuth ions, and cobalt ions substitute for part of iron ions so that Bi7-xGdxFe1.5Co1.5Ti3O21 layered Aurivillius type multiferroic oxide ceramics are obtained. The titanium-iron-gadolinium cobaltate-bismuth ceramic material has the advantages that on one hand, an iron atomic structure and a cobalt atomic structure are approximate, and after part of the cobalt ions substitutes for part of iron ions in position, Fe-O octahedrons and Co-O octahedrons are arrayed in order, and Fe-O-Co coupling can be generated partially, so that ferroelectricity and ferromagnetism of the ceramic material can be improved; and on the other hand, since the gadolinium ions partially having magnetism substitute for part of bismuth ions, leakage current is effectively reduced while ferroelectricity of the ceramic material is enhanced, and partially existing coupling of Gd-O-Co / Fe enables the ferromagnetism of the ceramic material to be improved.

Owner:UNIV OF SCI & TECH OF CHINA

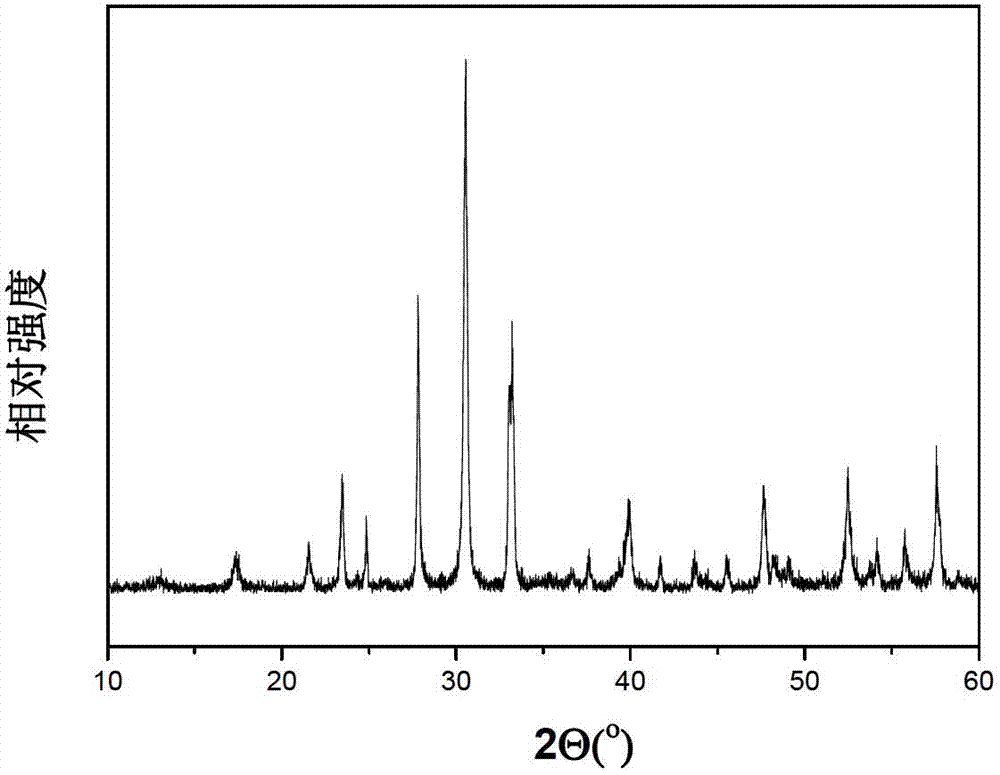

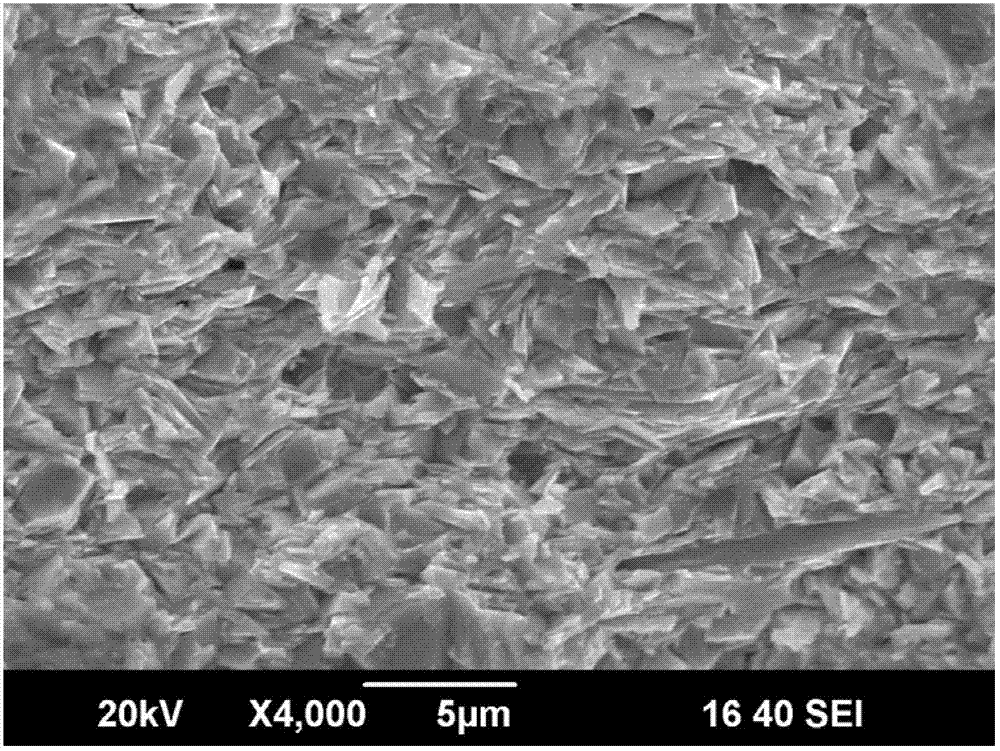

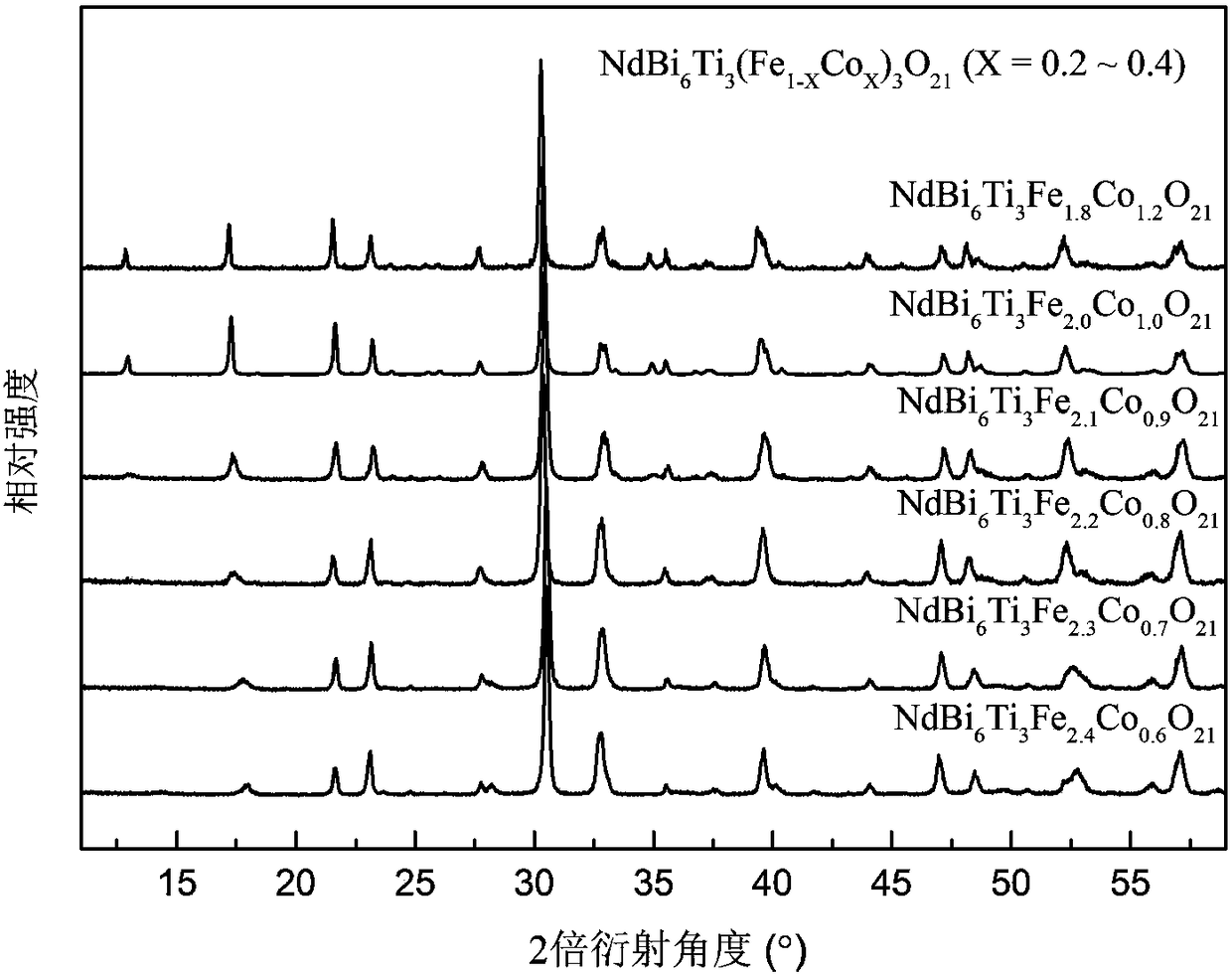

Single-phase multiferroic microwave absorbing material and preparation method thereof

ActiveCN108558387AGood microwave absorption characteristicsHigh absorption strengthMagnetic/electric field screeningOctahedronHigh absorption

The invention discloses a single-phase multiferroic microwave absorbing material NdBi6Ti3 (Fe1-xCox) 3O21(x=0.25-0.3) and a preparation method thereof. Because of the symbiotic structure of layered perovskite and the chemical modification of neodymium, the microwave absorbing material exhibits excellent multiferrous properties due to the interaction between ferrite octahedron and cobalt-oxygen octahedron. Based on these physical characteristics, the material exhibits good microwave absorbing property in the microwave range of 2-18GHz, has high absorption intensity and wide absorption band, andis far superior to the microwave absorption performance of the partial carbon / ferrite composite material; and the preparation method has the advantages of simple operation, short experiment period, favorable for large-scale production and wide application prospect.

Owner:XINYANG NORMAL UNIVERSITY

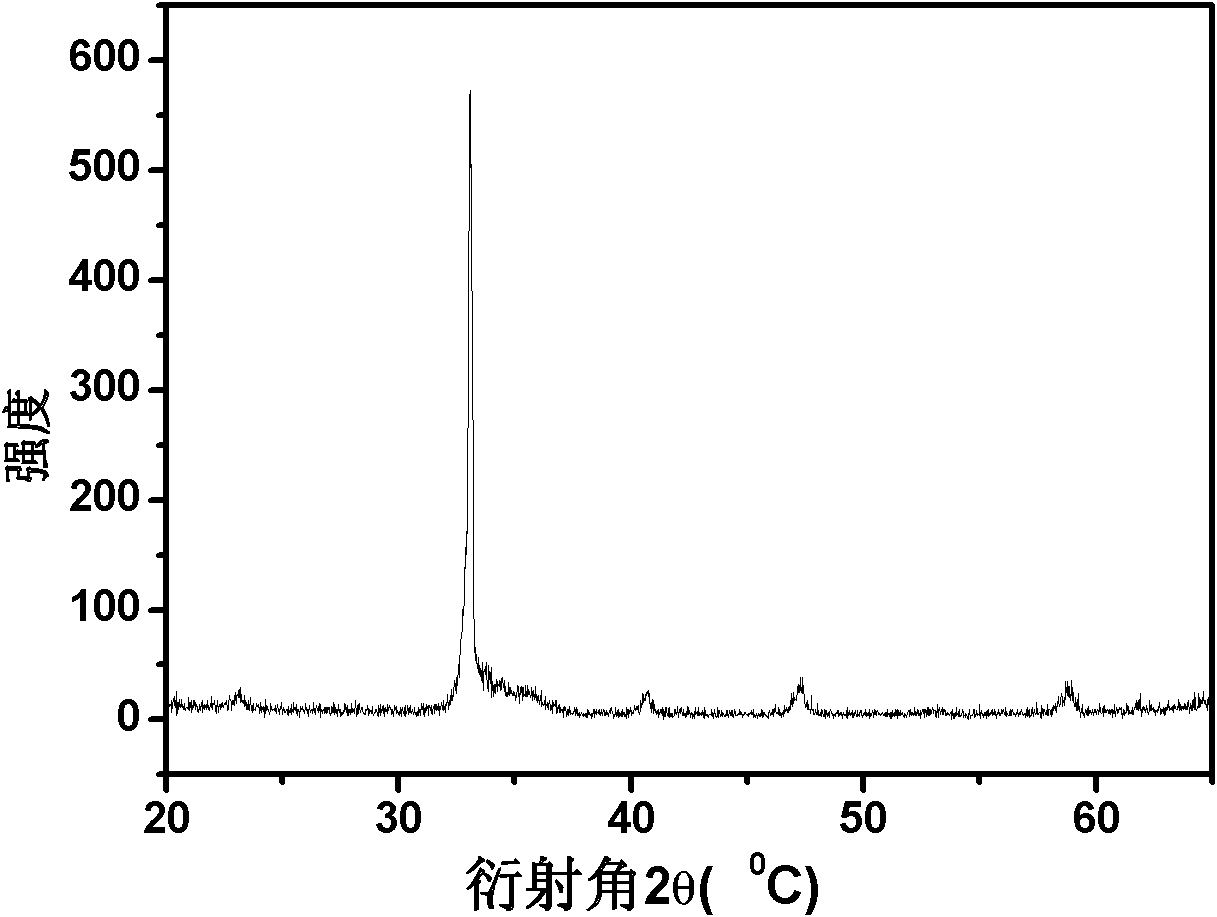

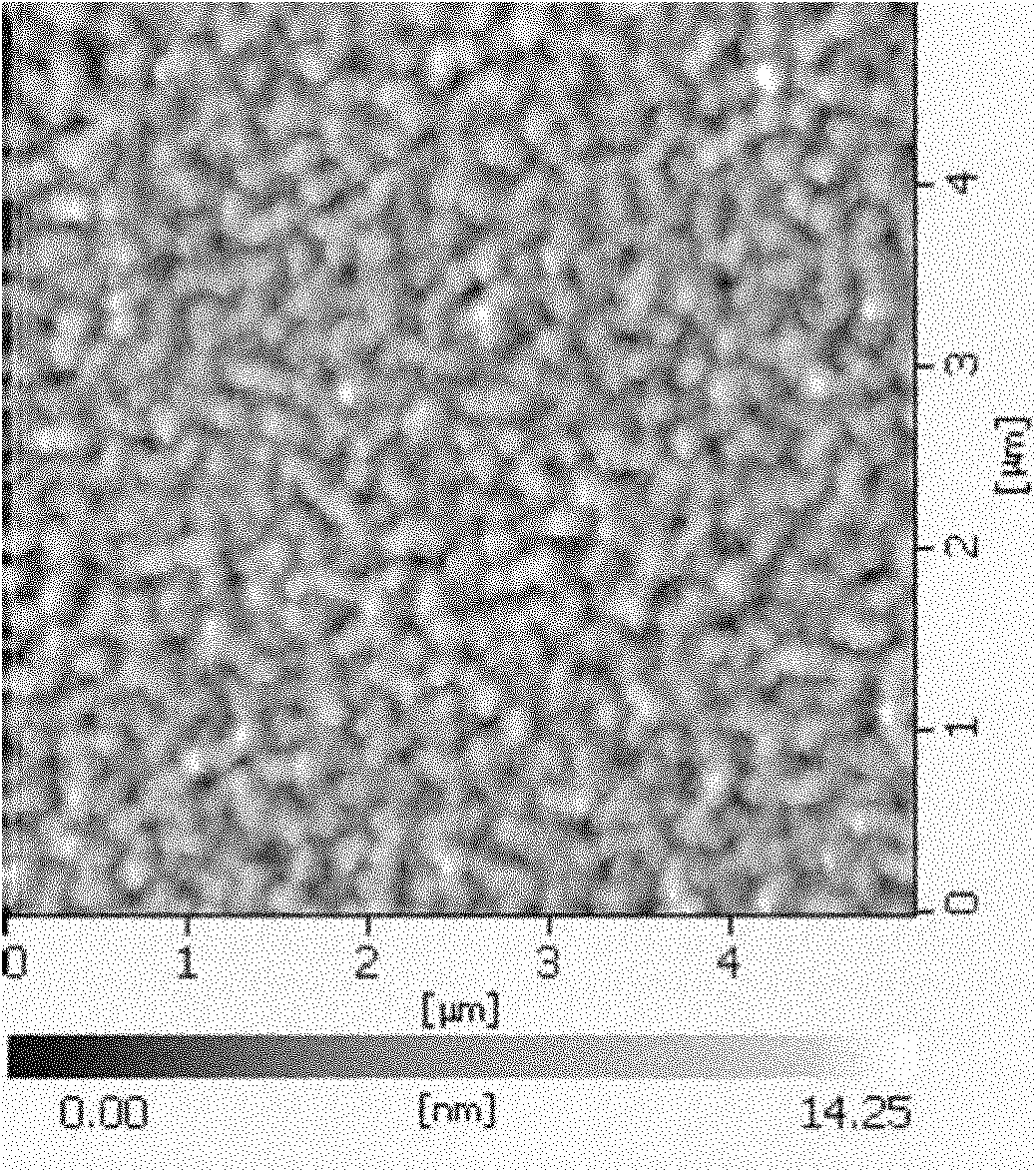

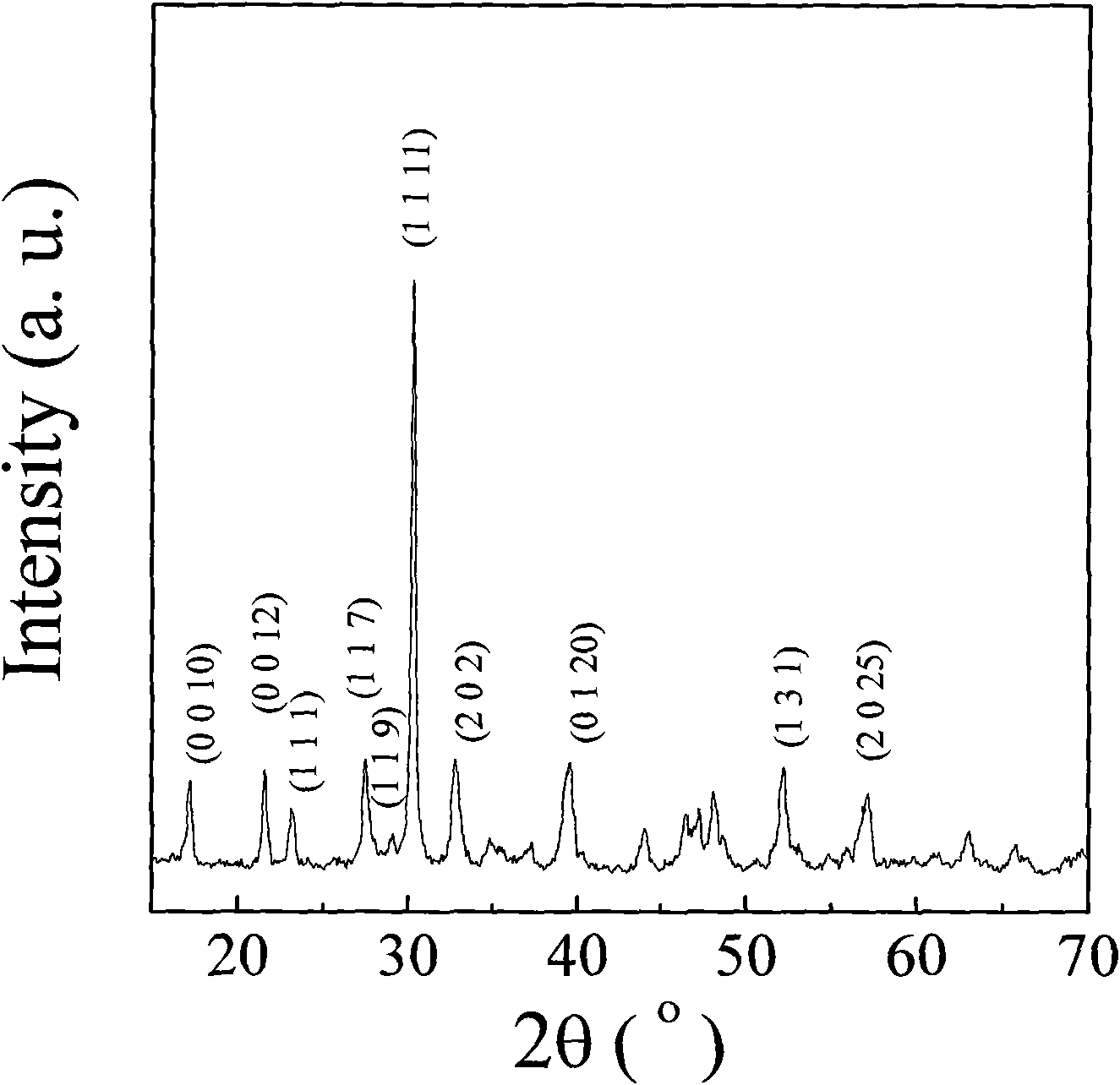

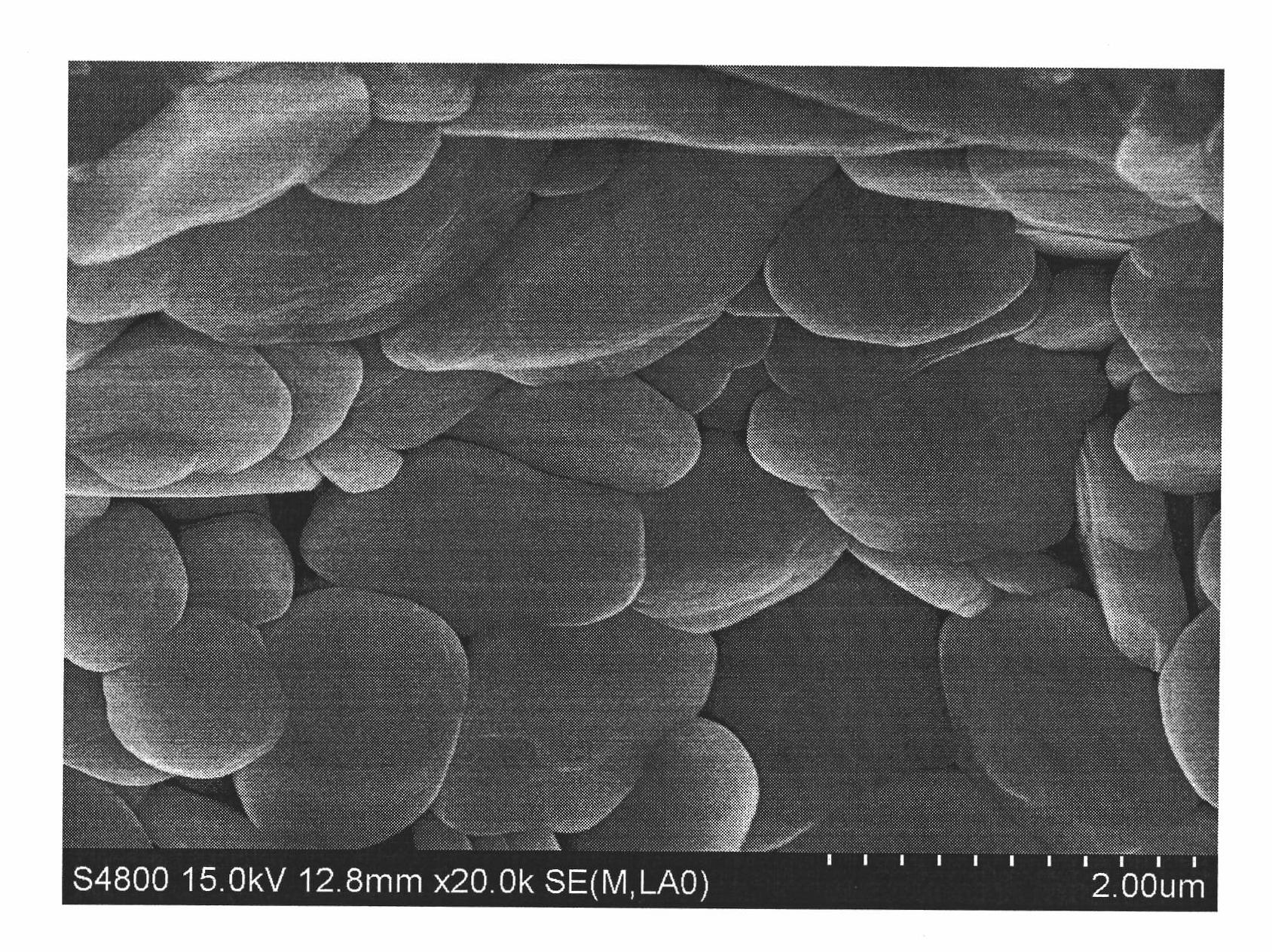

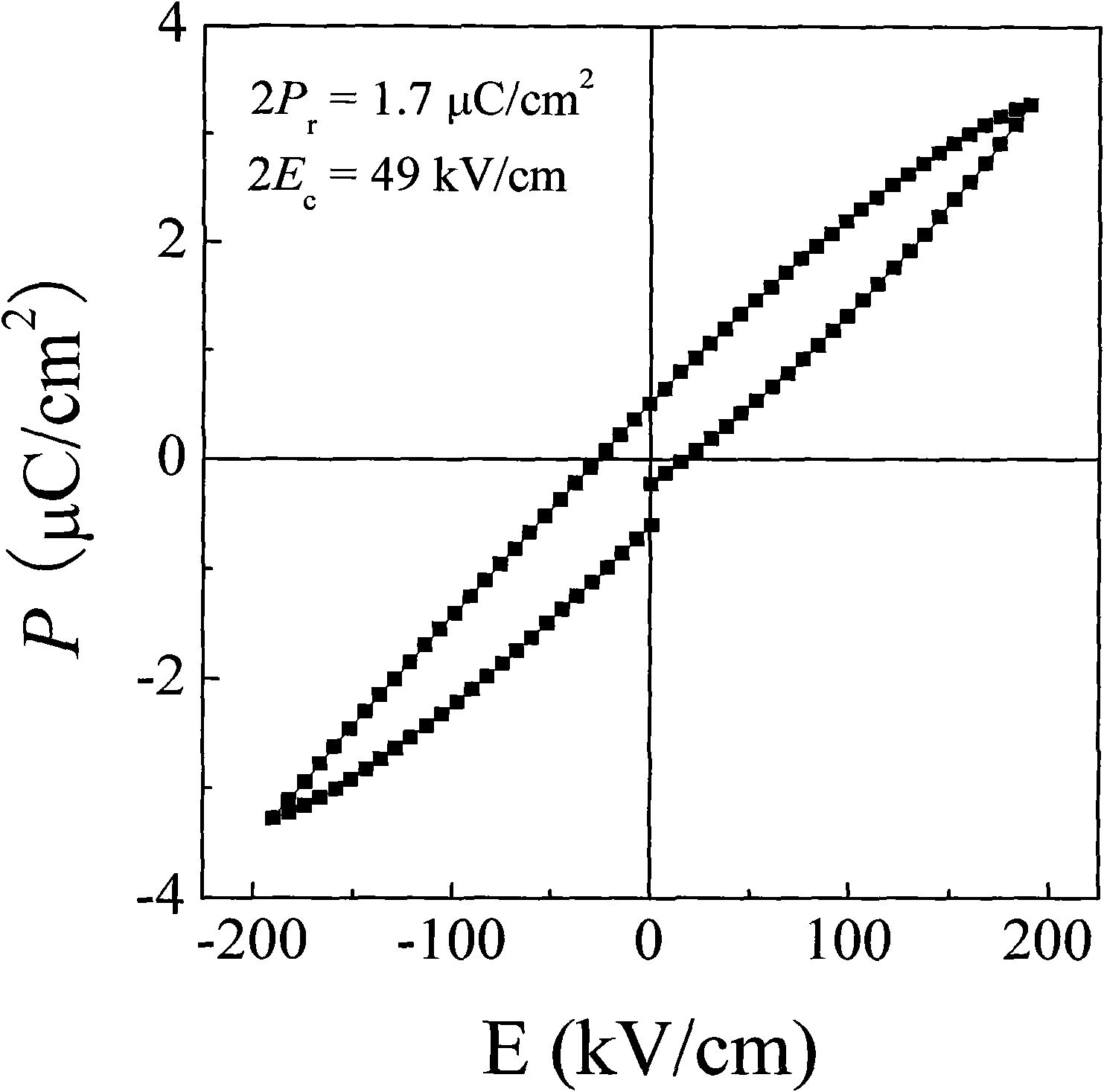

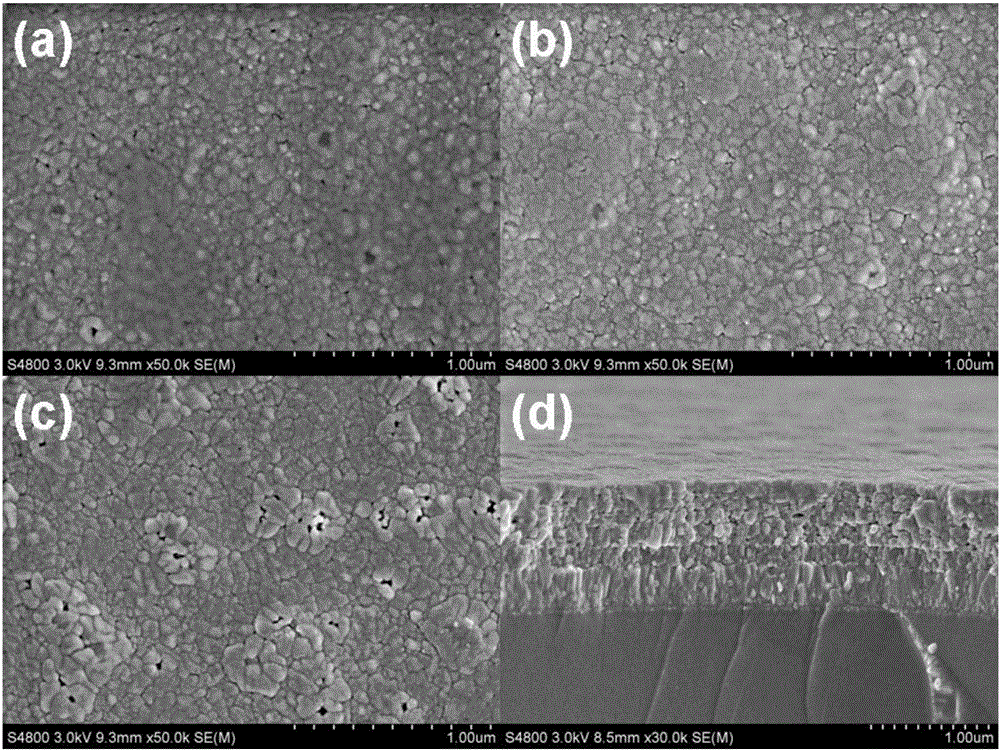

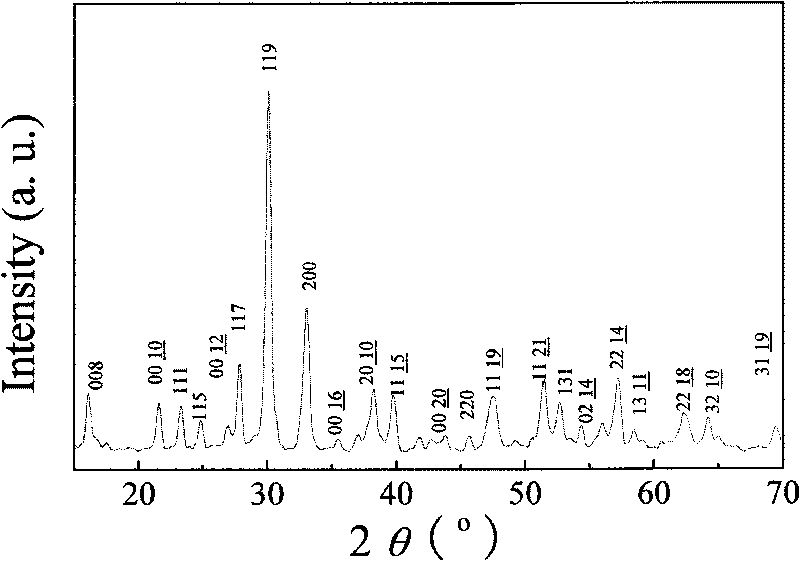

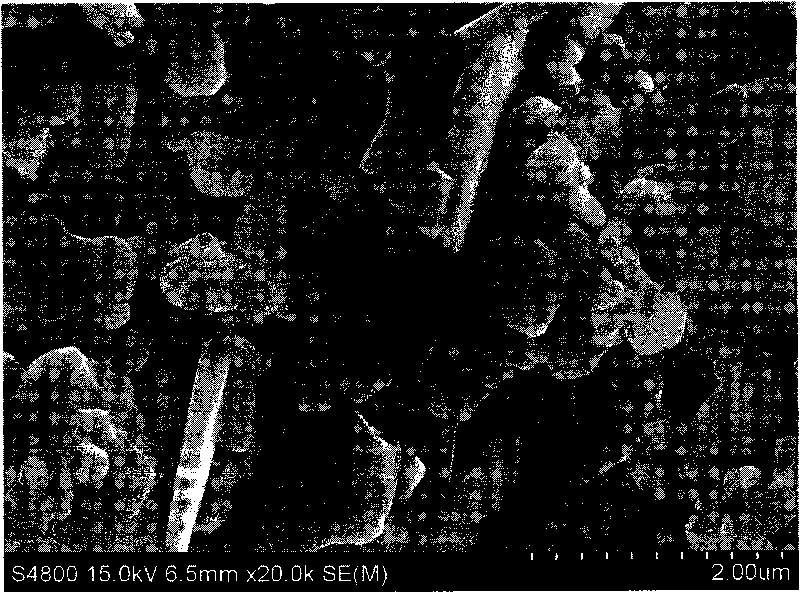

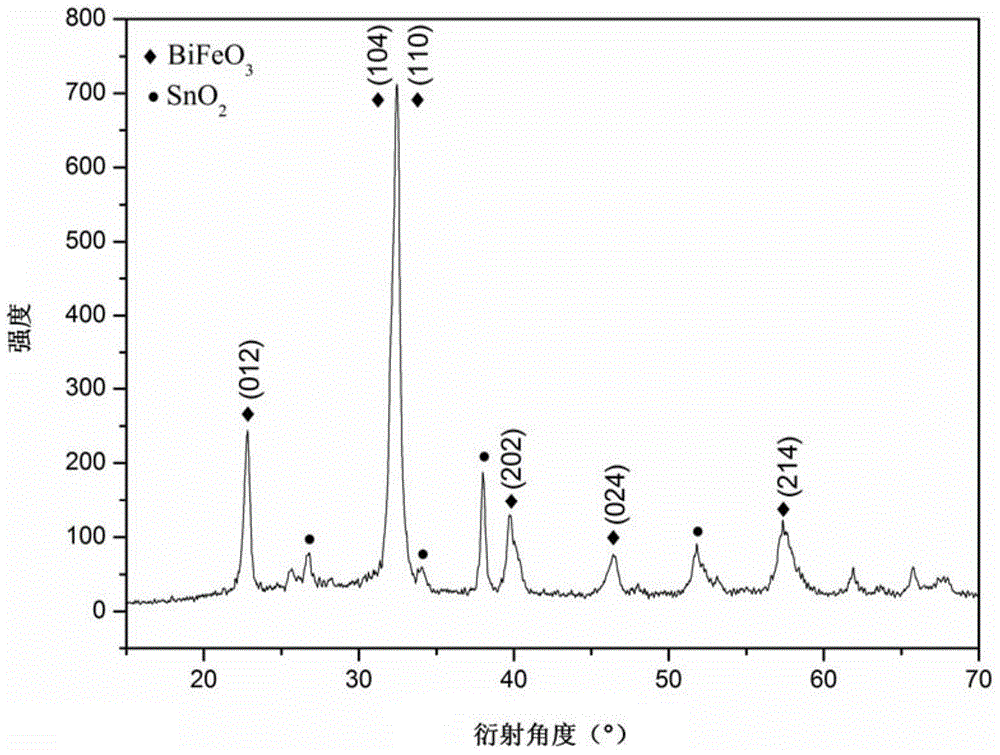

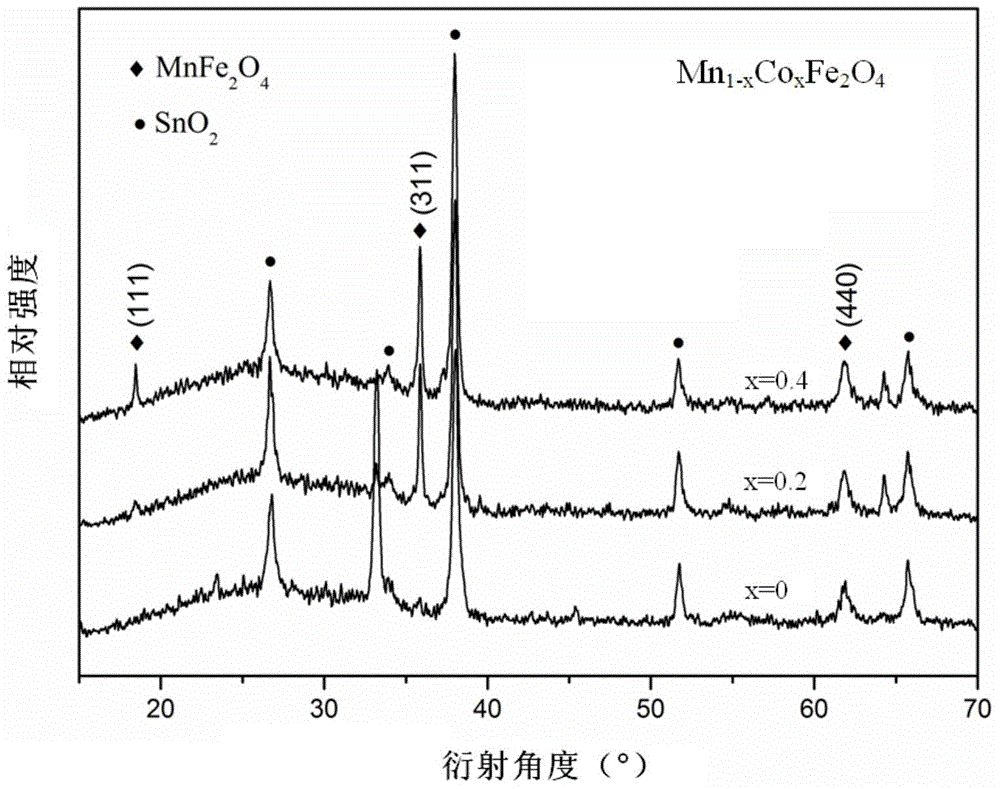

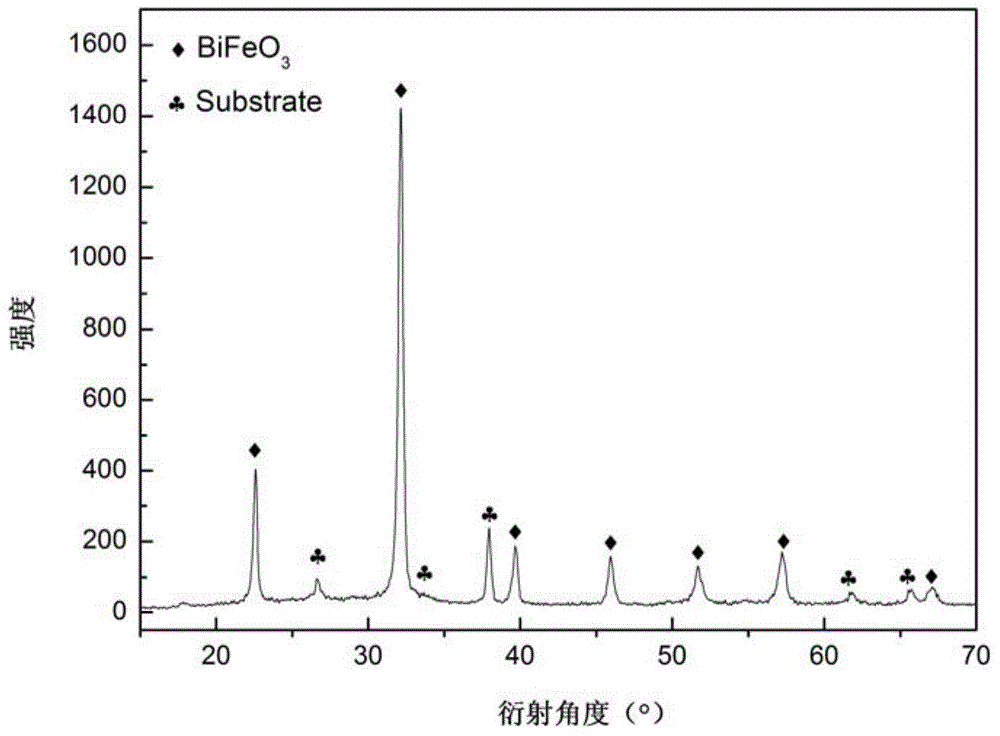

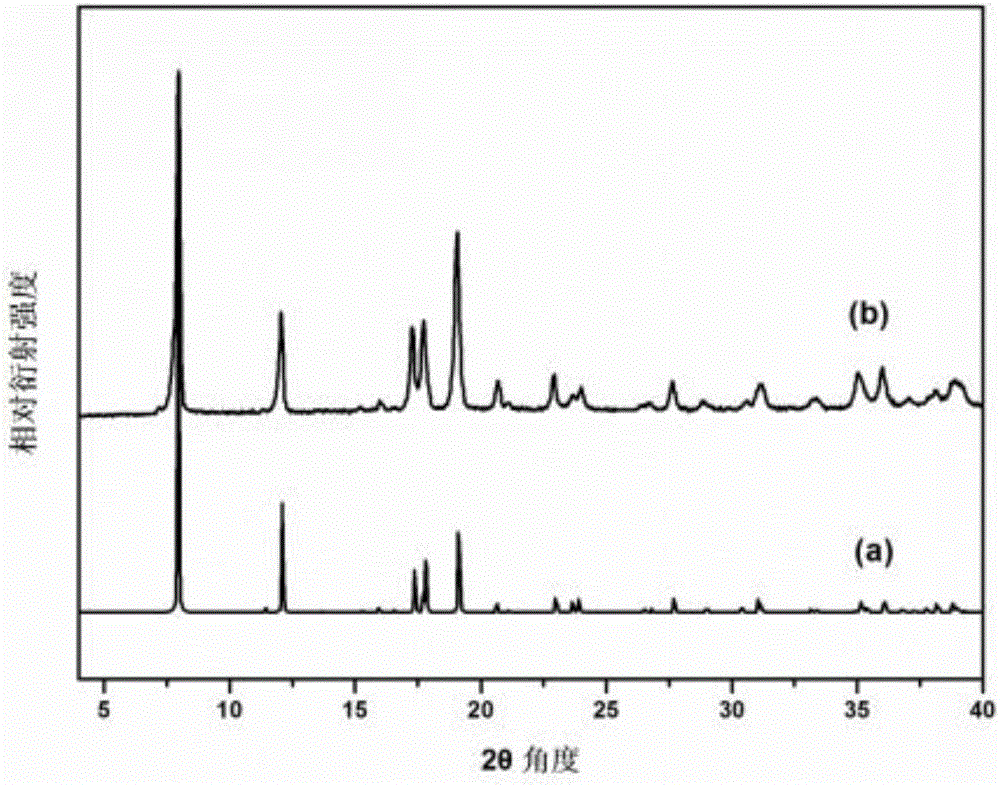

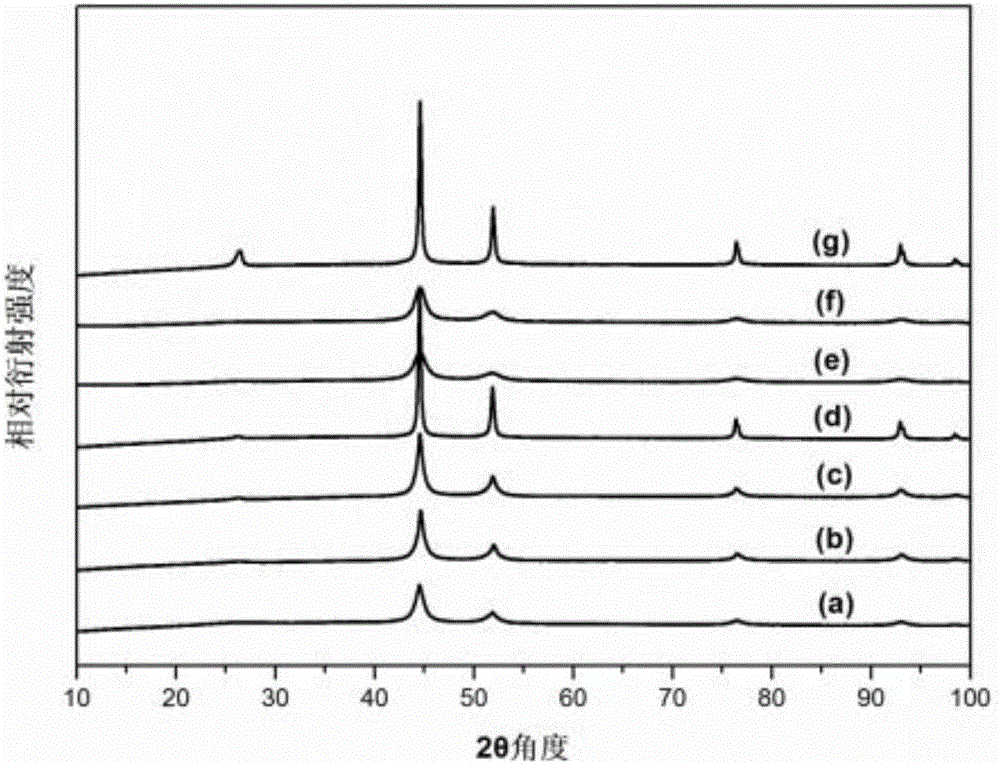

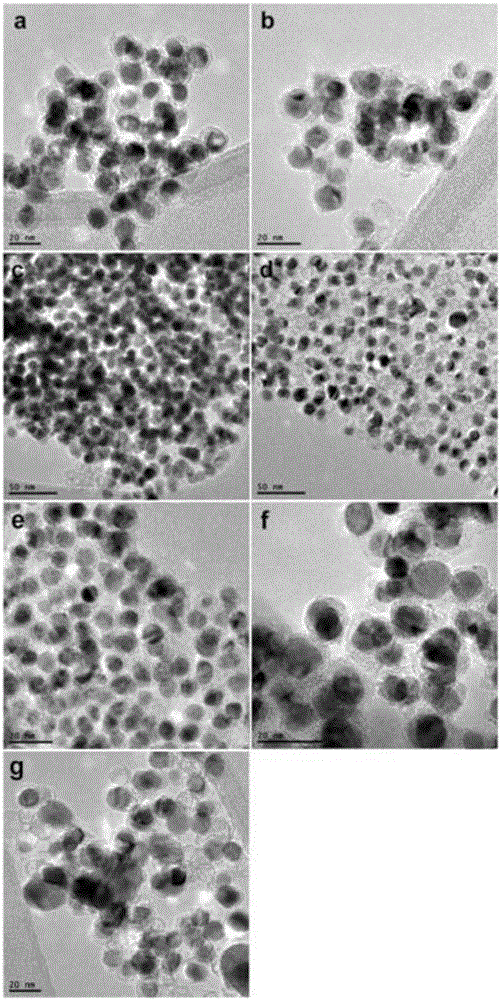

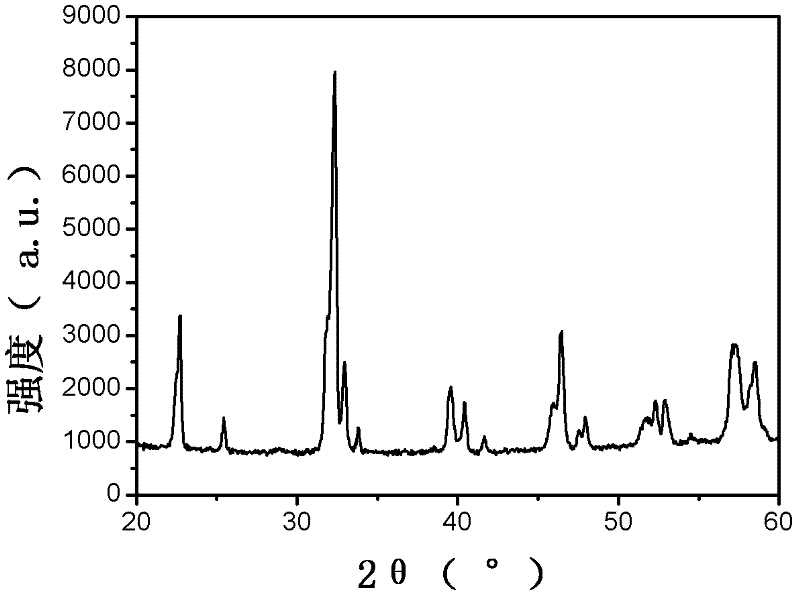

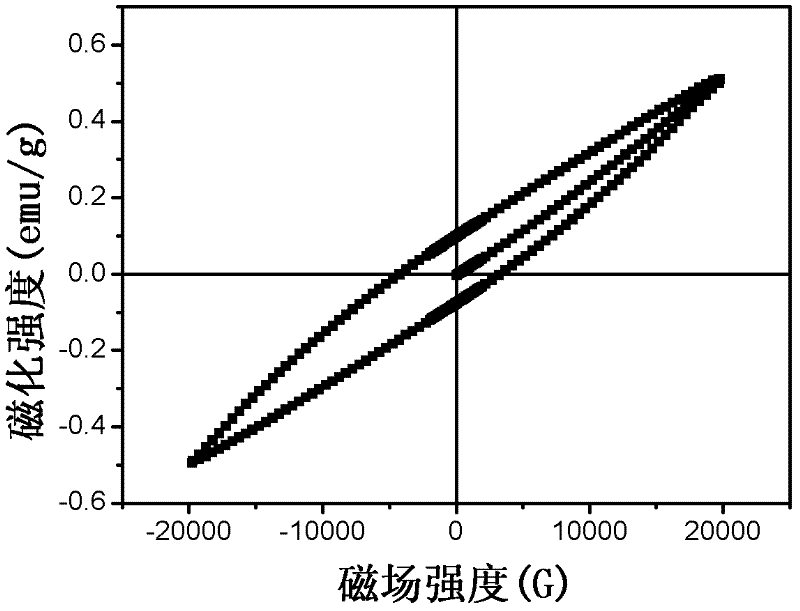

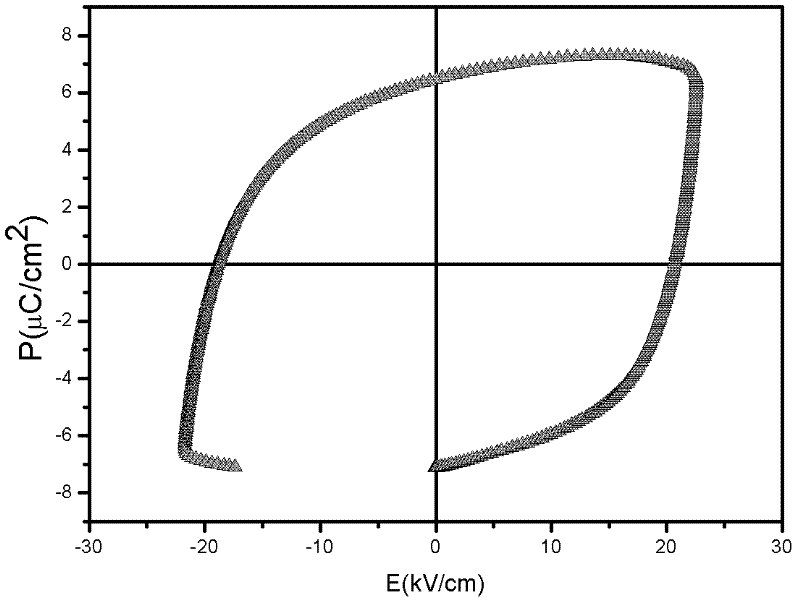

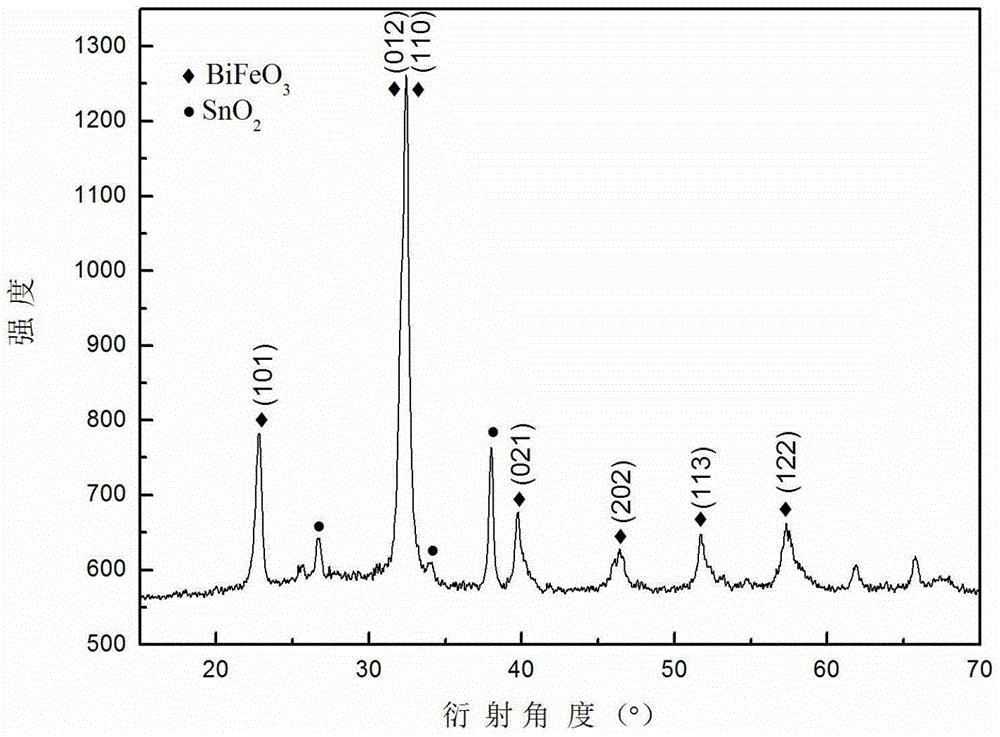

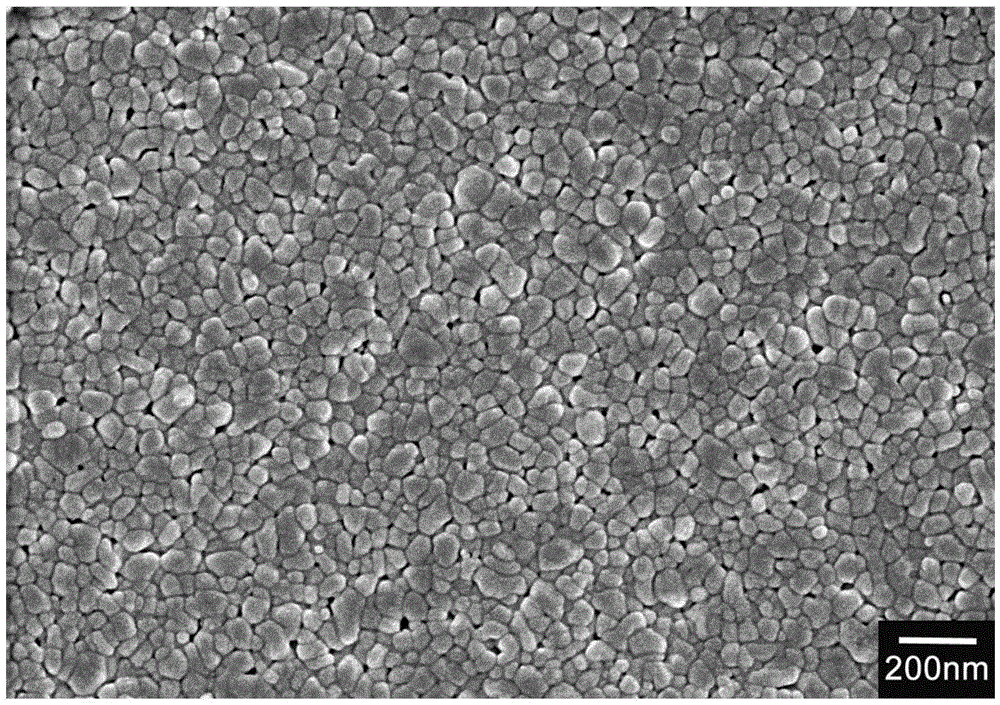

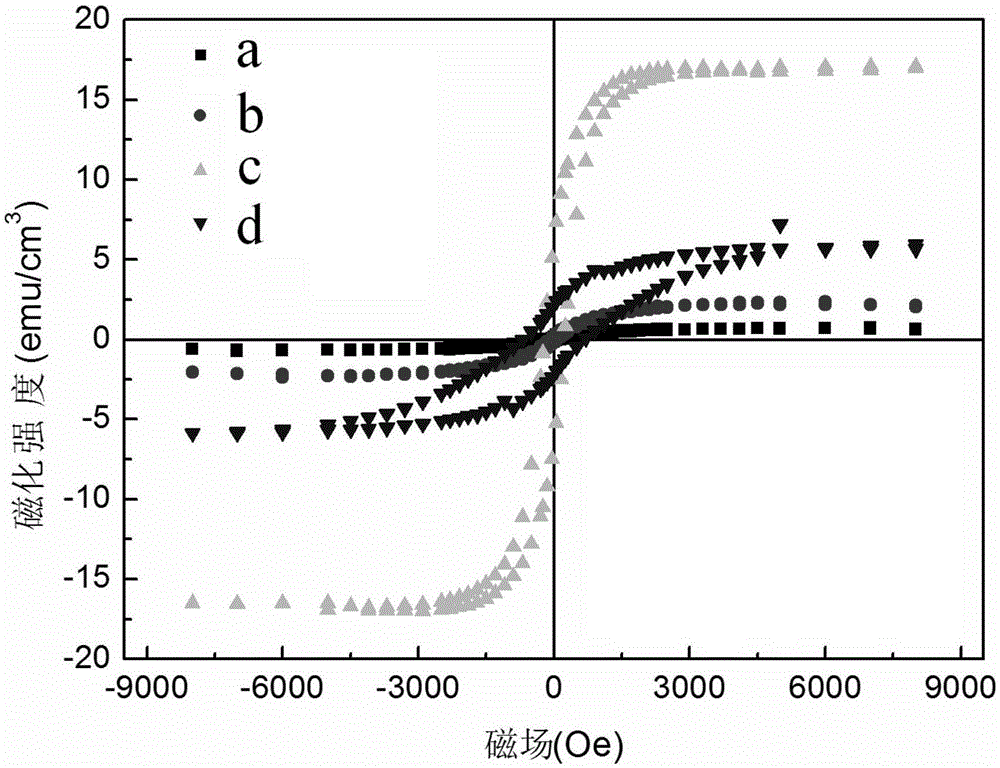

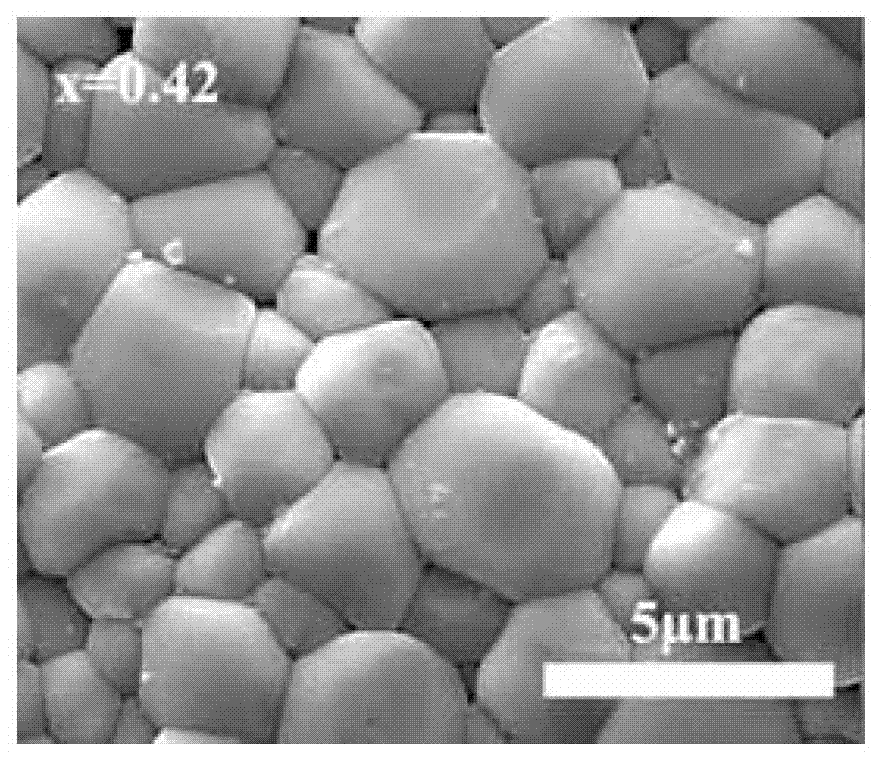

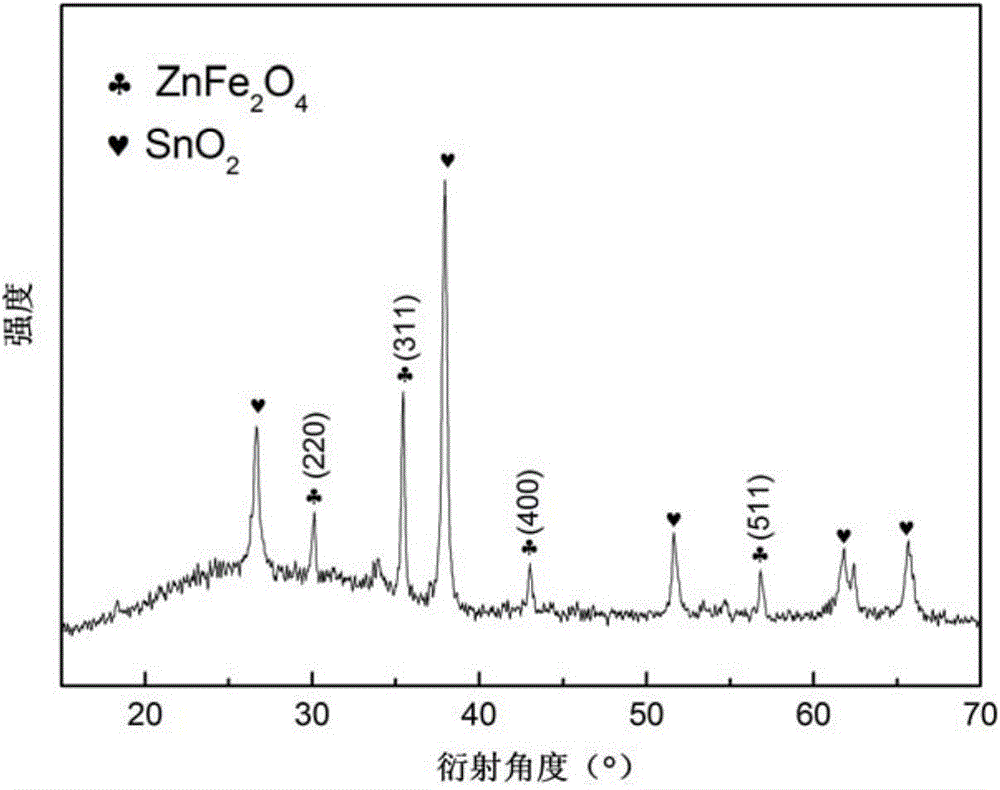

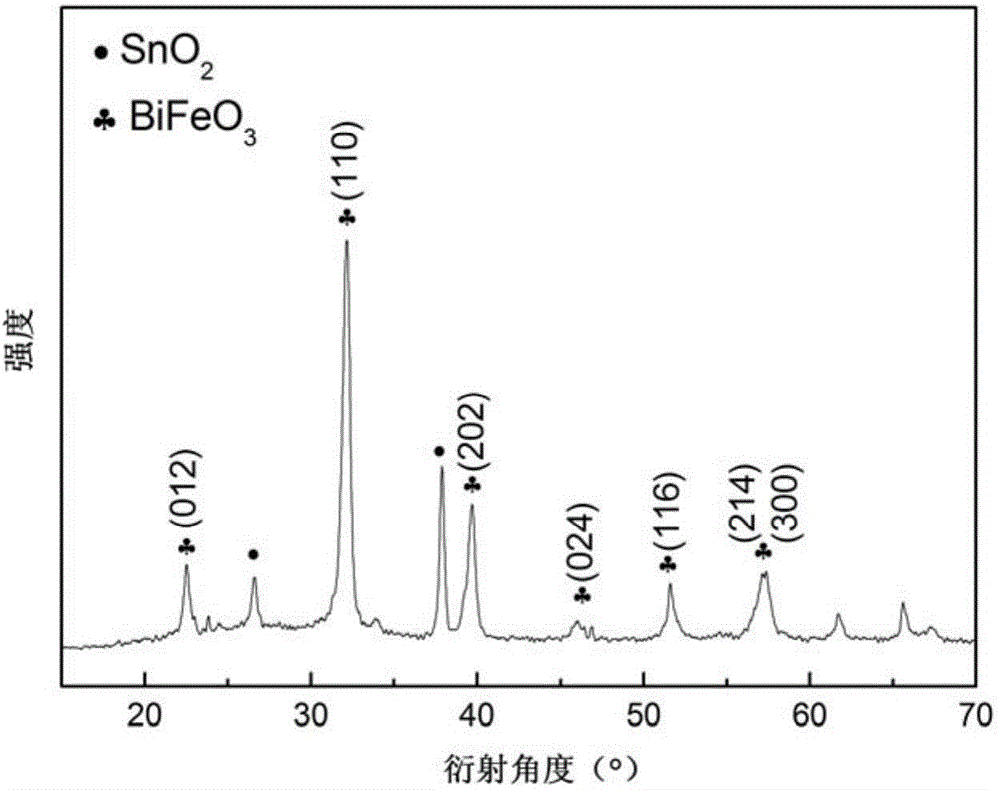

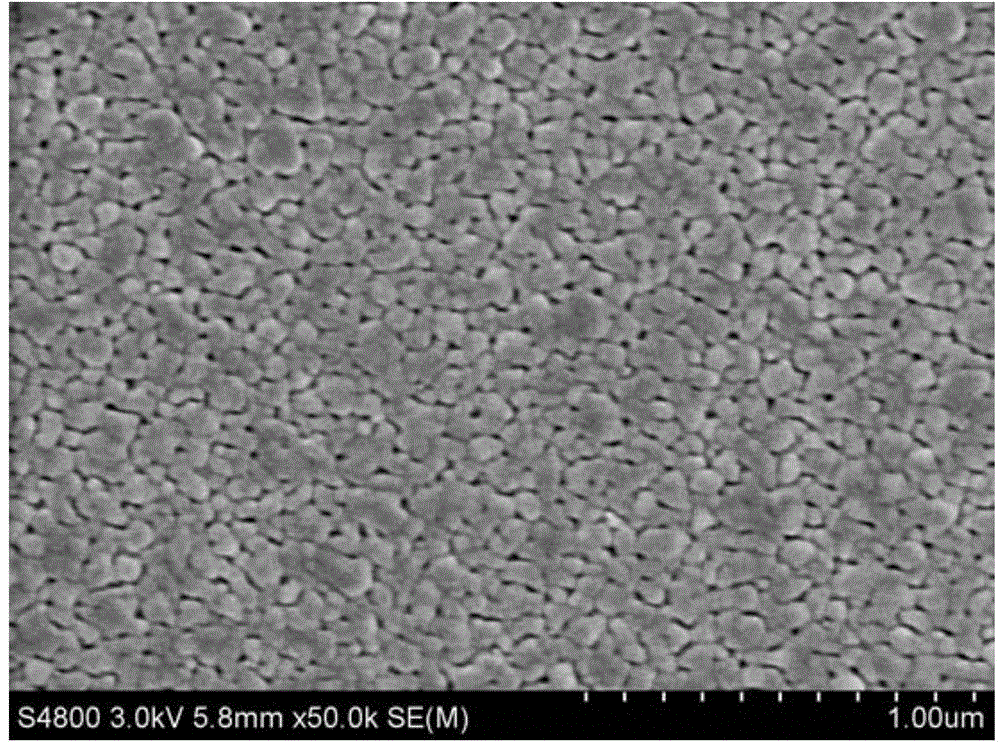

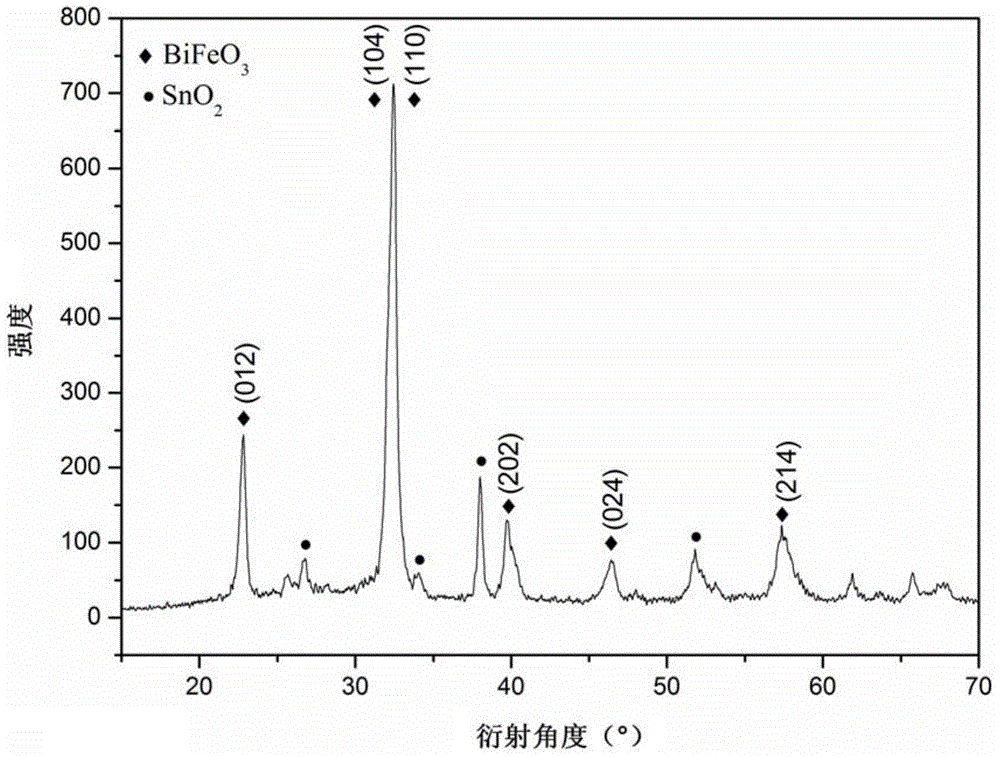

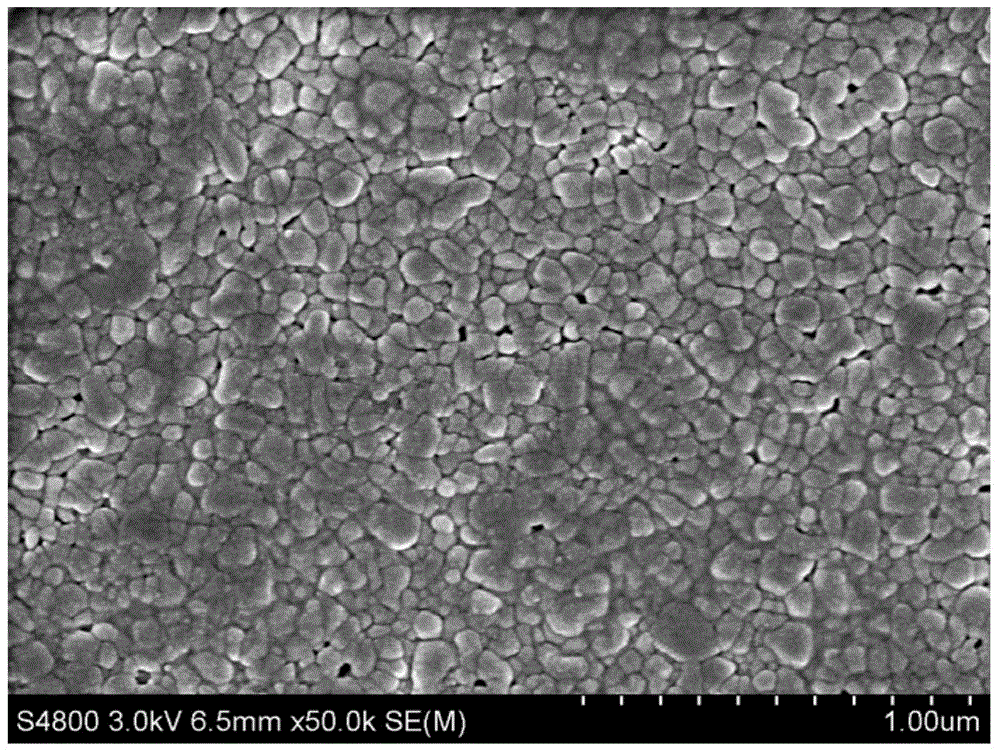

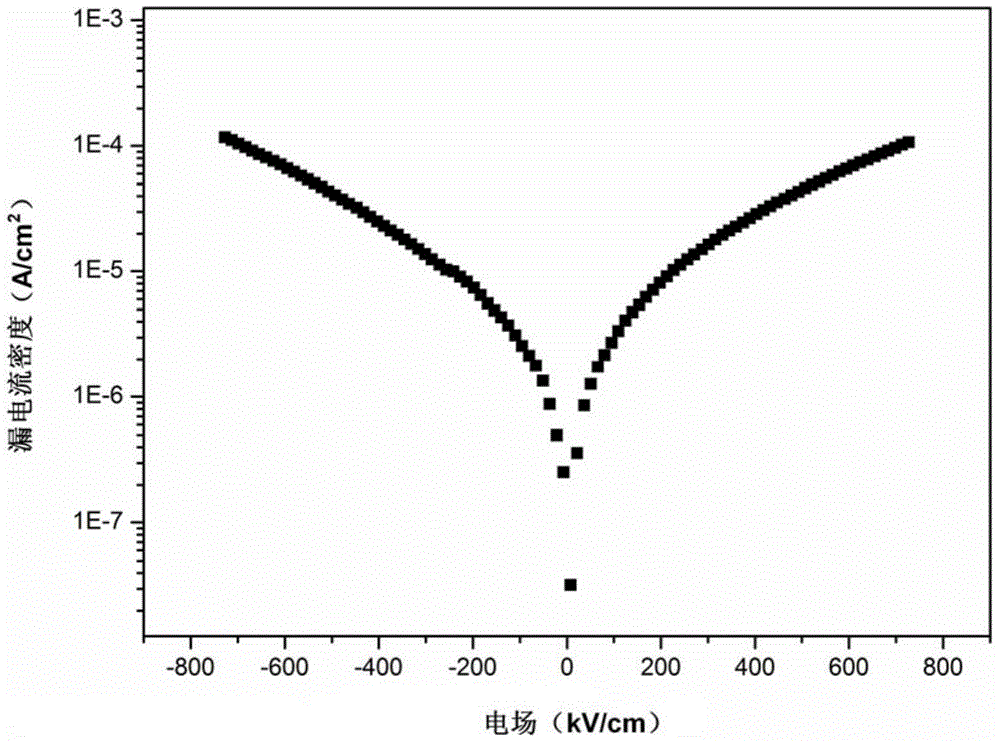

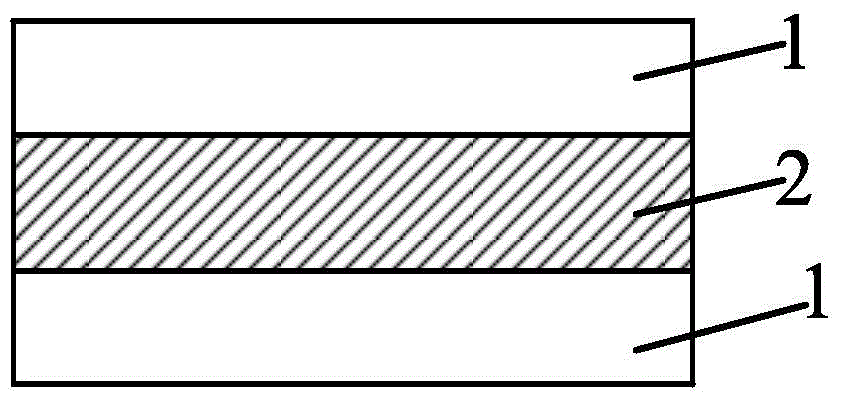

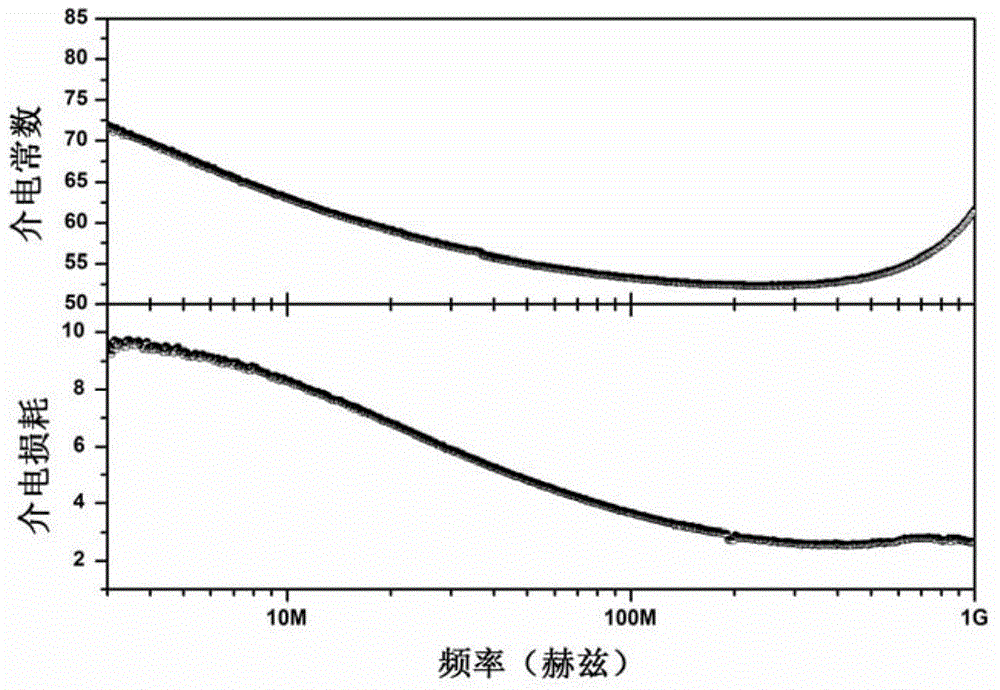

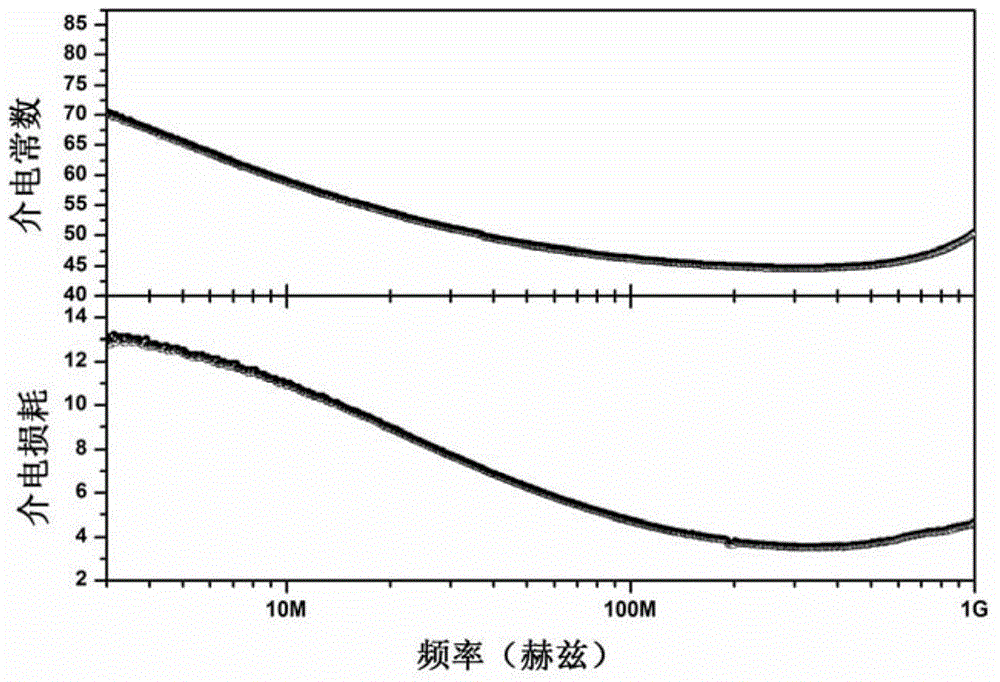

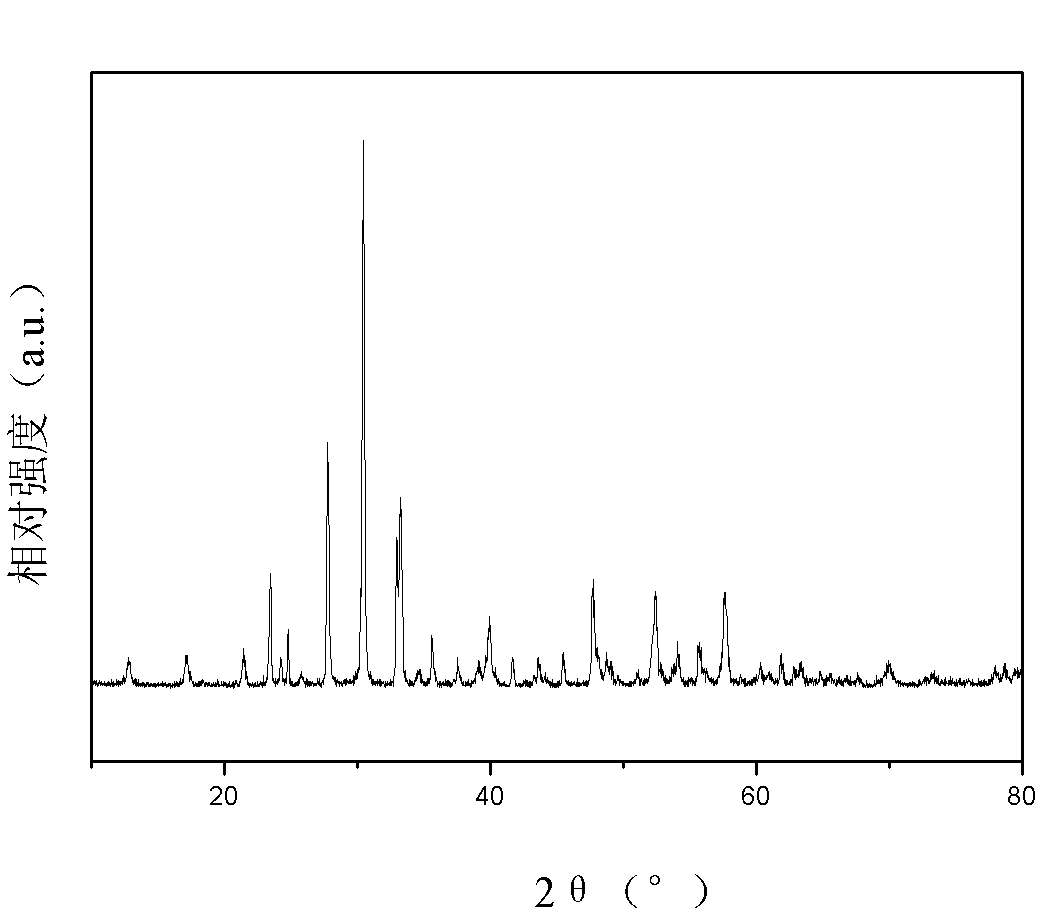

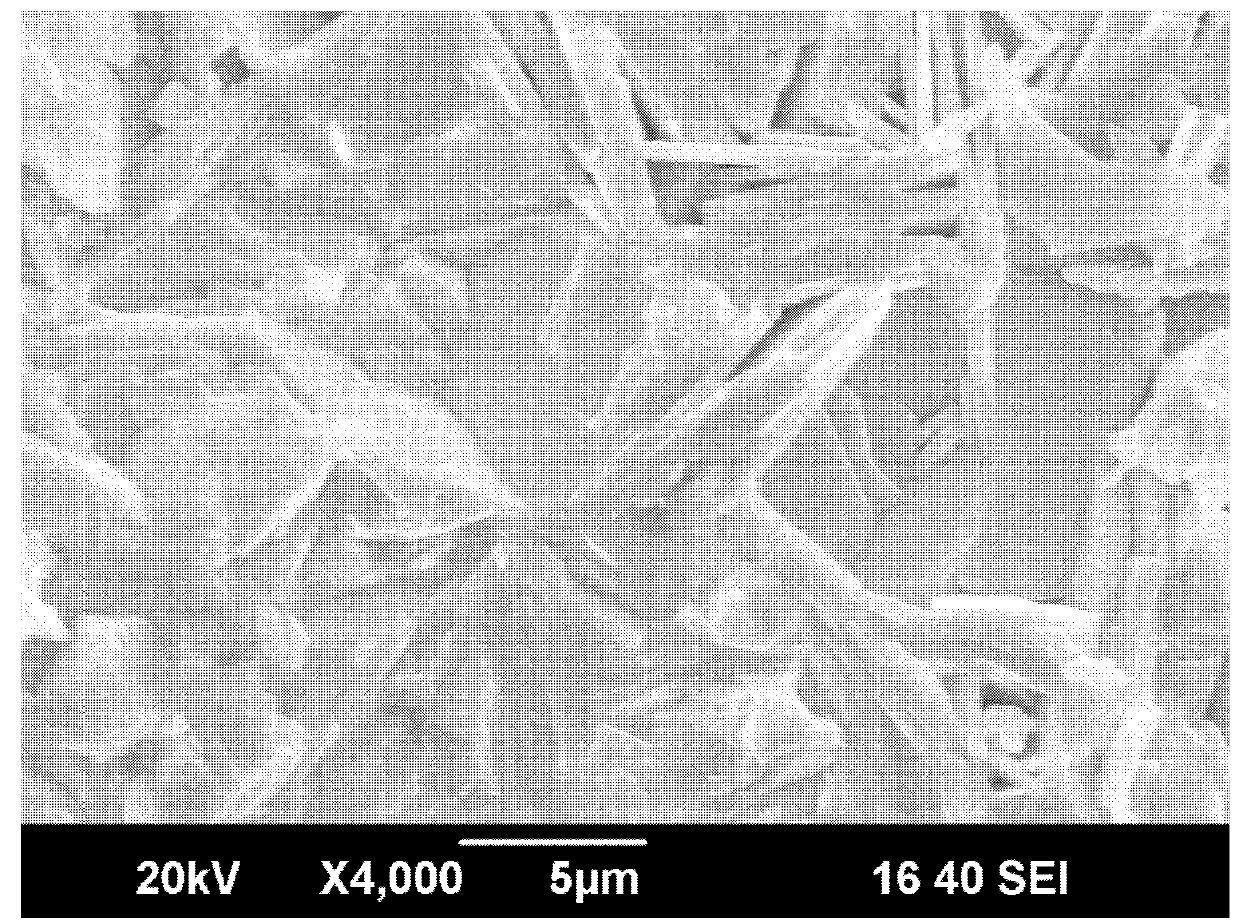

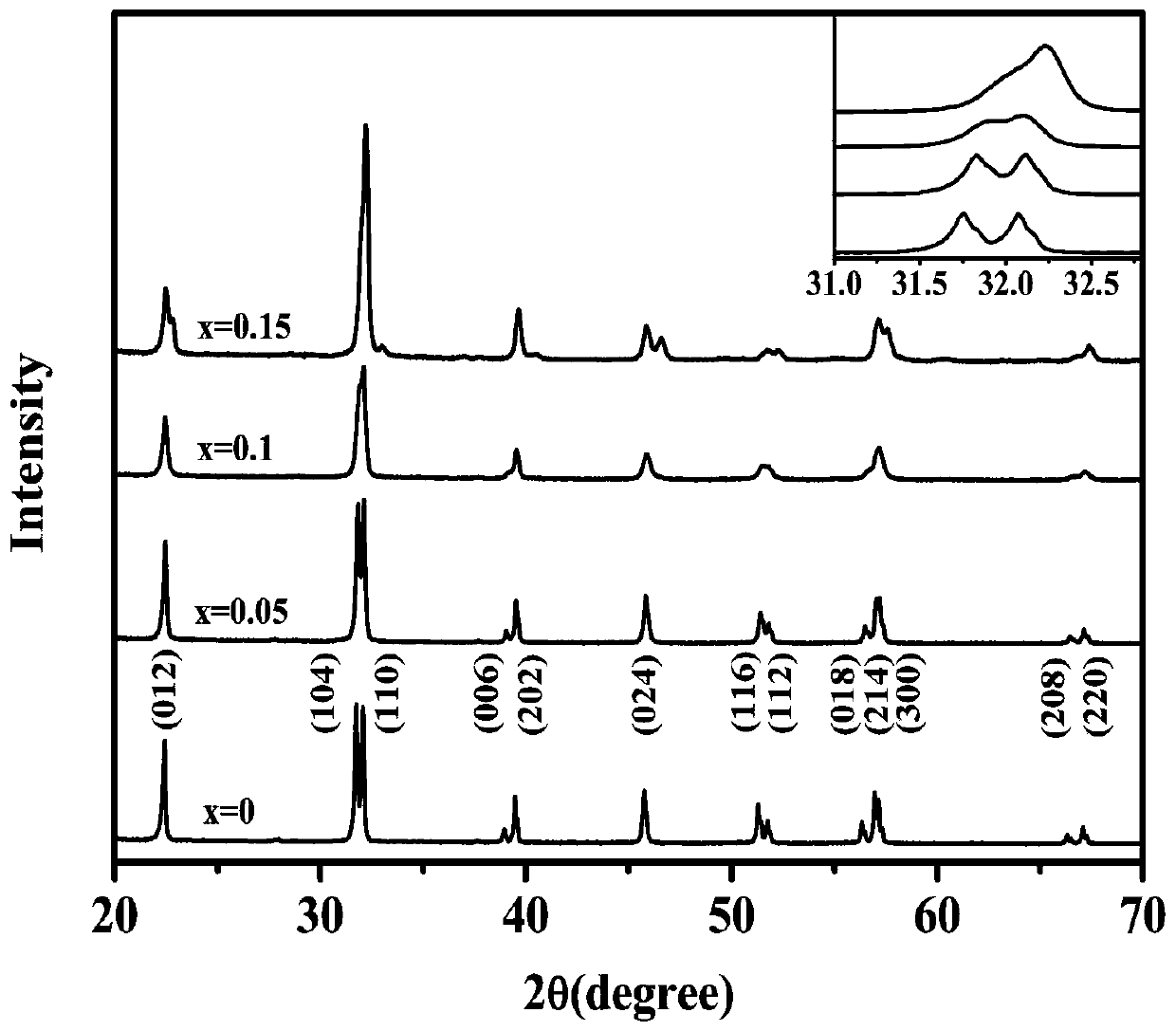

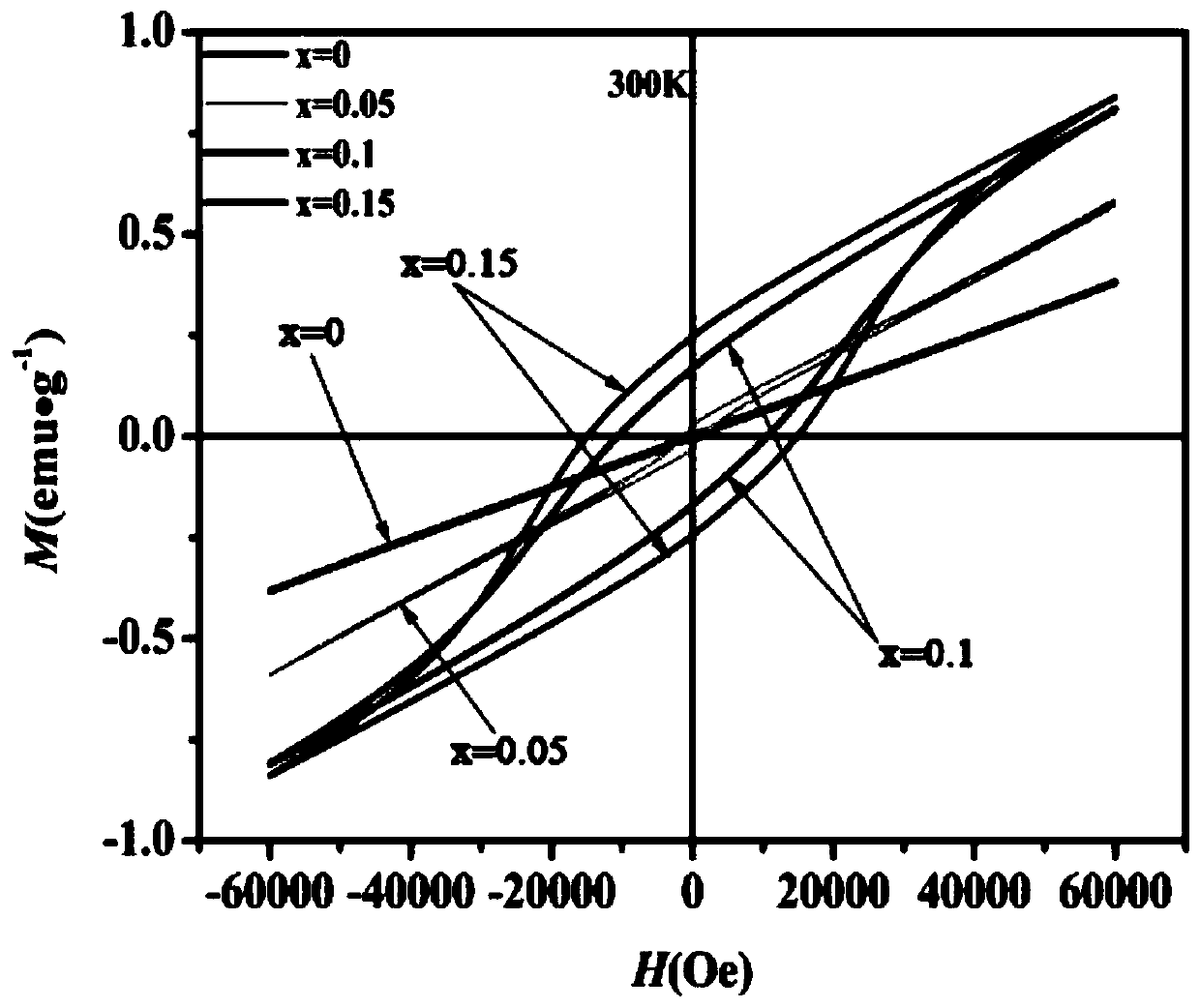

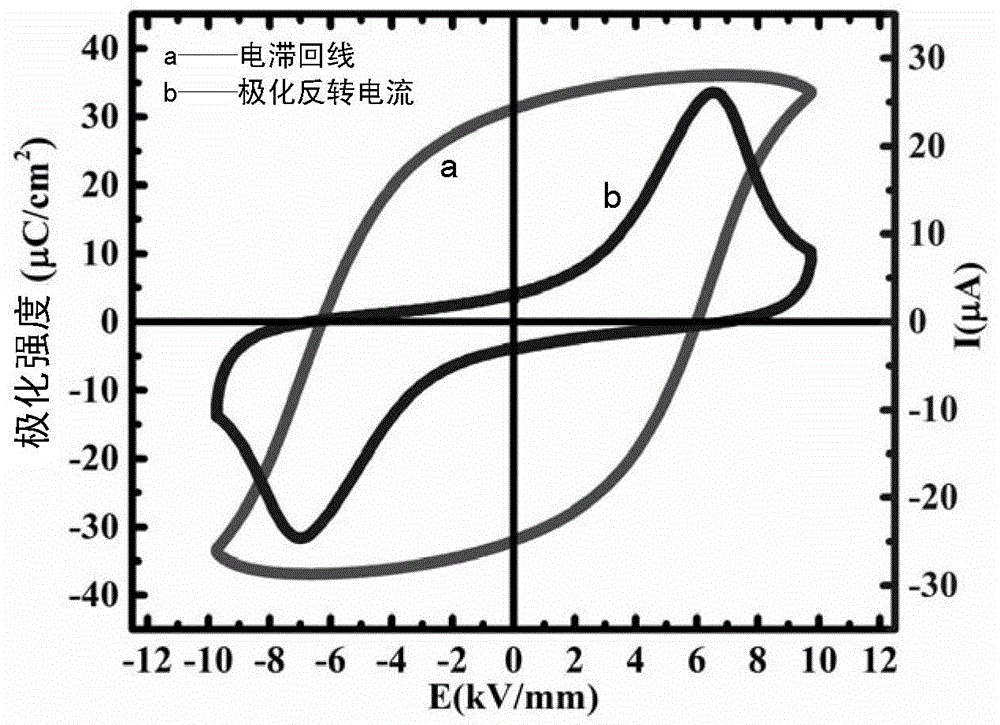

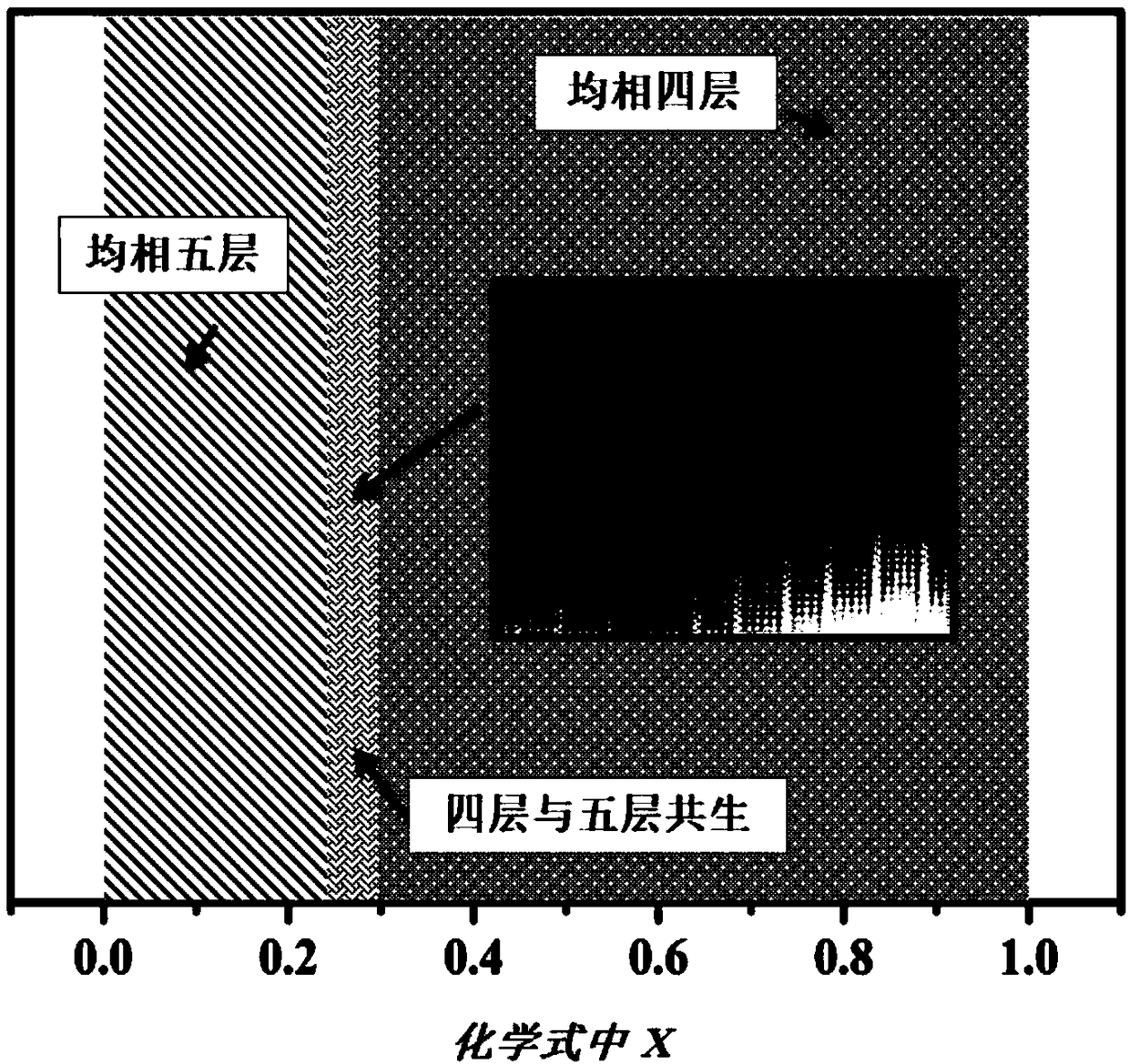

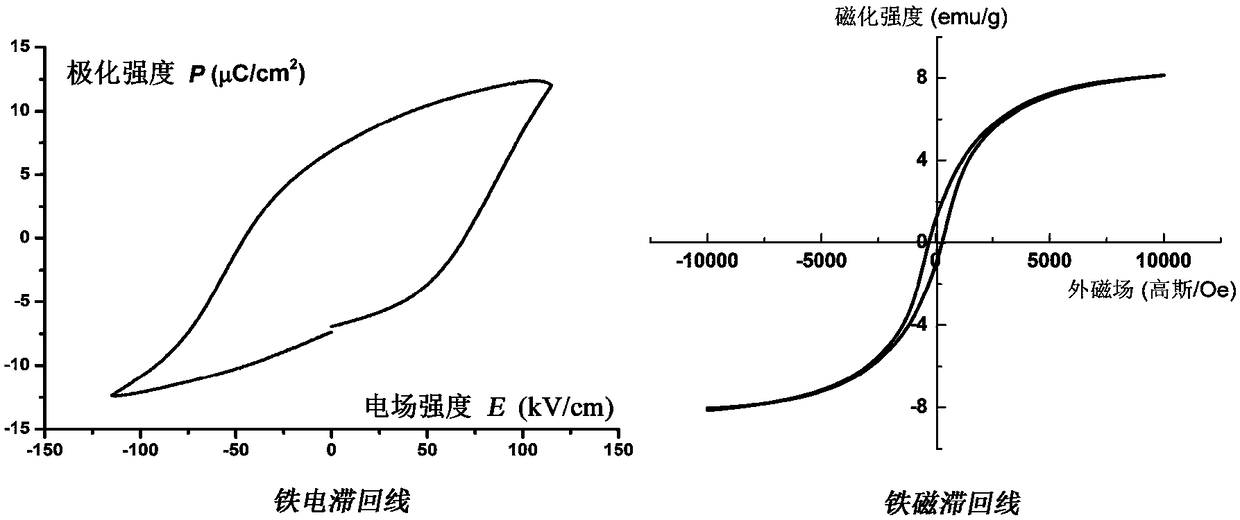

Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof

The invention provides a Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and a preparation method thereof. The method comprises the following steps: preparing a Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 precursor solution from bismuth nitrate, praseodymium nitrate, hydrogen nitrate AE, ferric nitrate and manganous nitrate, wherein AE is Sr, Ca or Ba, and x=0.02-0.05; spinning the precursor solution on a substrate; and then spinning, drying and annealing, so as to obtain the Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film. The Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film is simple in demands on equipment; the experiment condition is easy to achieve; the doping amount is easy to control; the ferroelectric property of the film can be greatly improved; and the prepared Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film is good in uniformity, low in leakage current, and low in coercive field, and has relatively high remanent polarization.

Owner:SHAANXI UNIV OF SCI & TECH

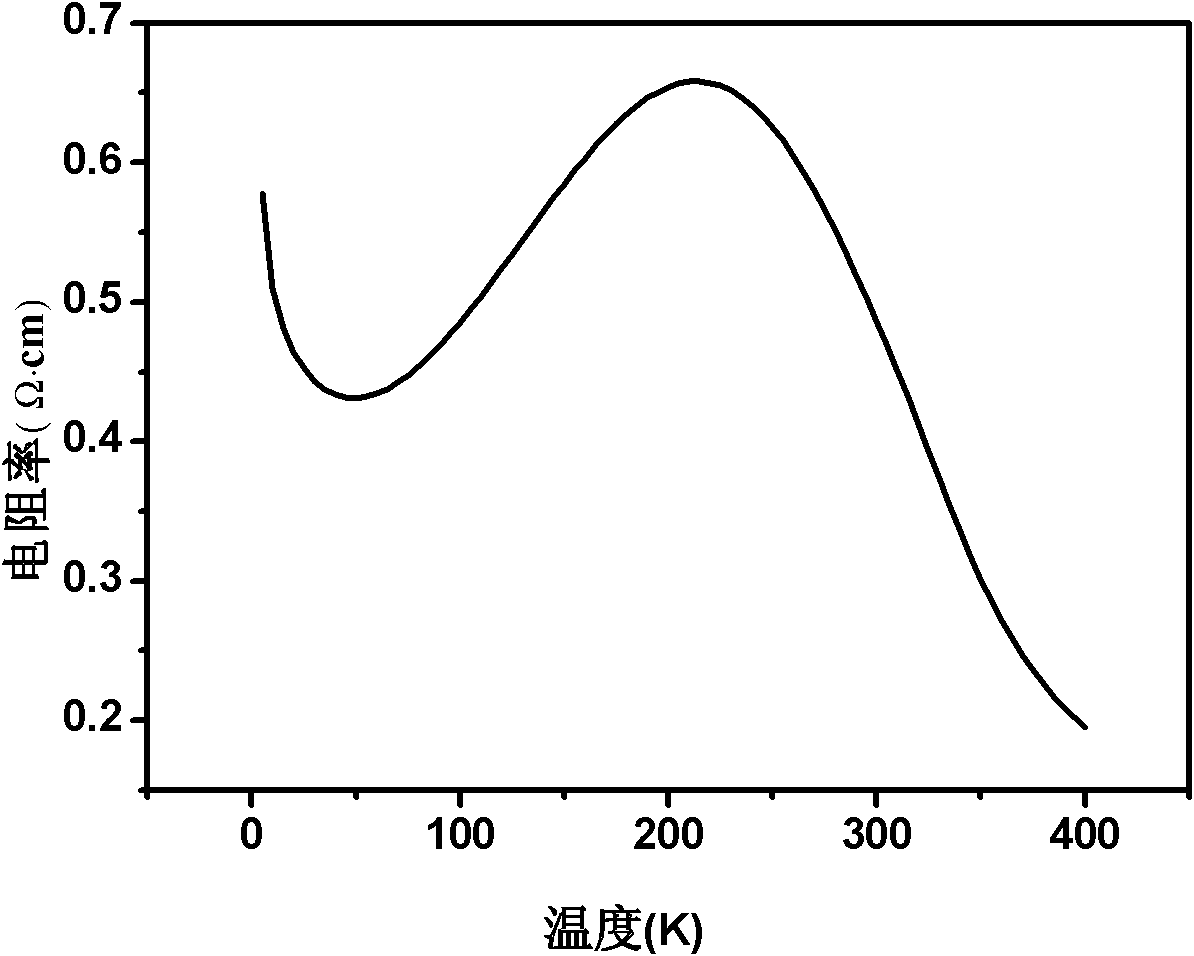

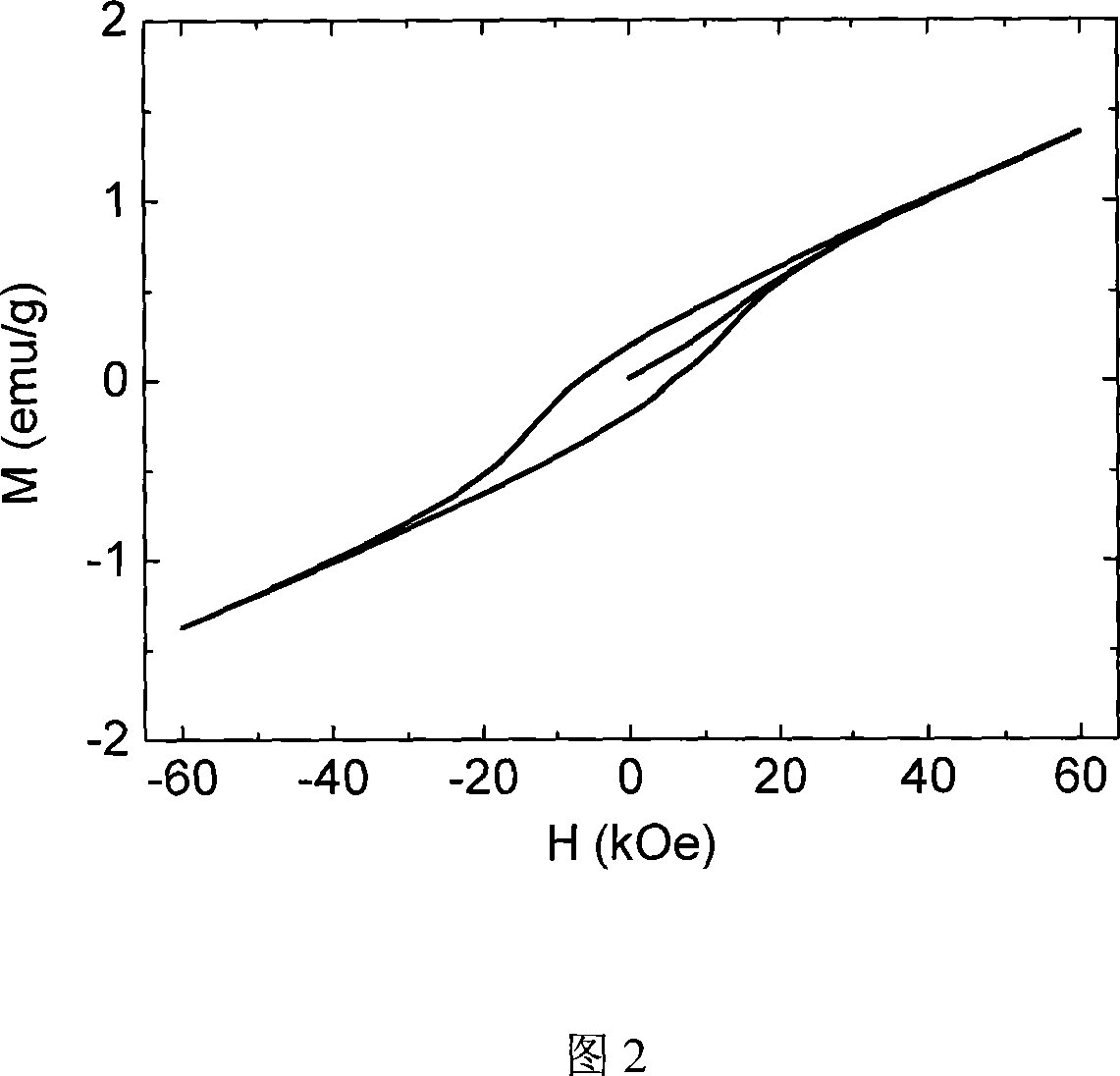

Method for preparing lanthanum-strontium-manganese-oxygen film

ActiveCN101985749ASave raw materialsReduce environmental pollutionLiquid applicationInorganic material magnetismIonSolvent

The invention discloses a method for preparing a lanthanum-strontium-manganese-oxygen film material on a silicon substrate by adopting an acetate chemical solution method. The method comprises the step of preparing precursor solution, namely preparing uniform, stable and transparent precursor solution at certain temperature by adding solutes of lanthanum acetate, strontium acetate and manganese acetate into a mixed solvent consisting of acetic acid and deionized water; preparing a gel film by performing spin coating on the prepared precursor solution on a silicon substrate, and performing heat treatment in stages in a short annealing furnace. The preparation method has the advantages that: the raw materials are cheap and nontoxic; pollution is prevented basically; the preparation process is simple; special equipment is not required; large-scale production is convenient; and the like. Meanwhile, the prepared film has large area, high uniformity, low roughness, no microcrack, stable performance, good electrical property and ferromagnetic performance and potential application prospect in intelligent thermal control devices of ferromagnetic film devices, spin electronic devices and spacecrafts.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

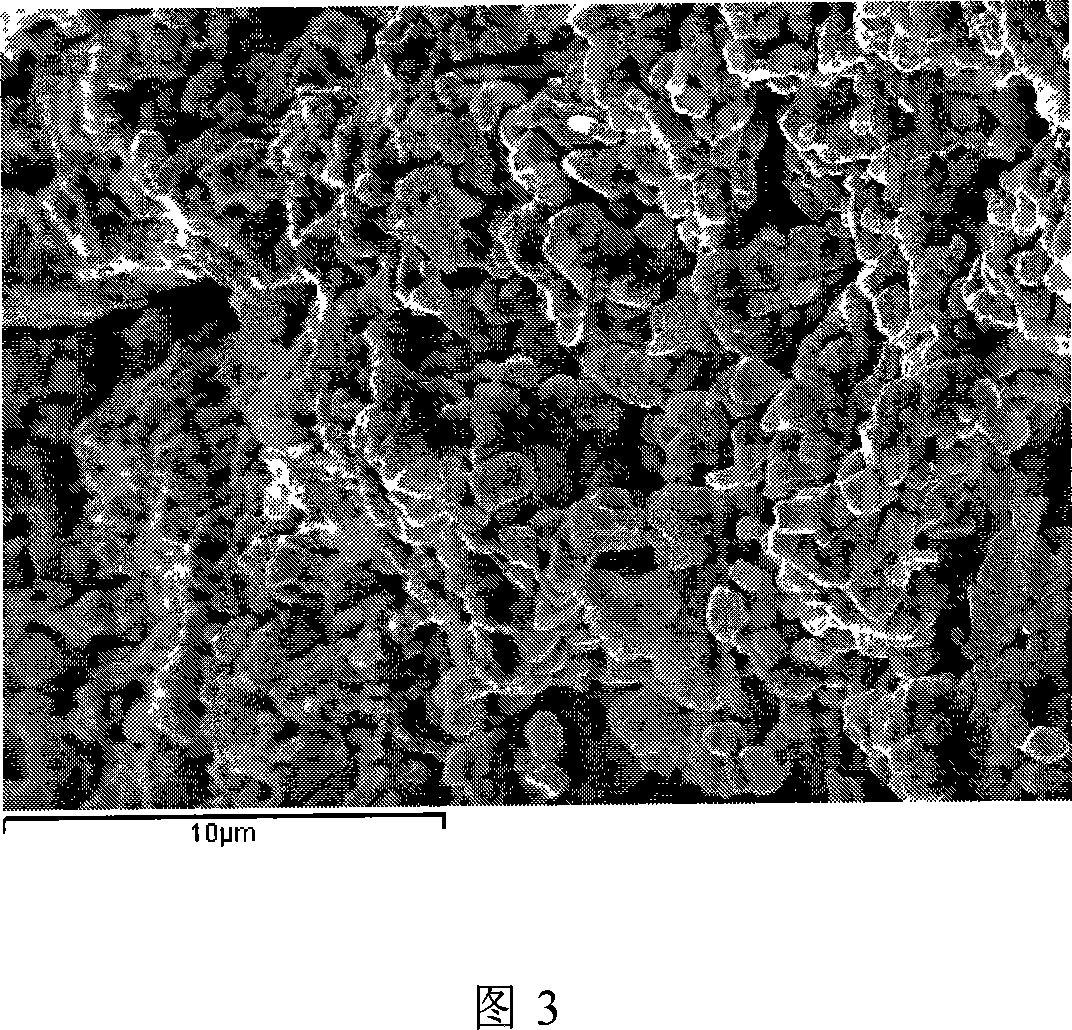

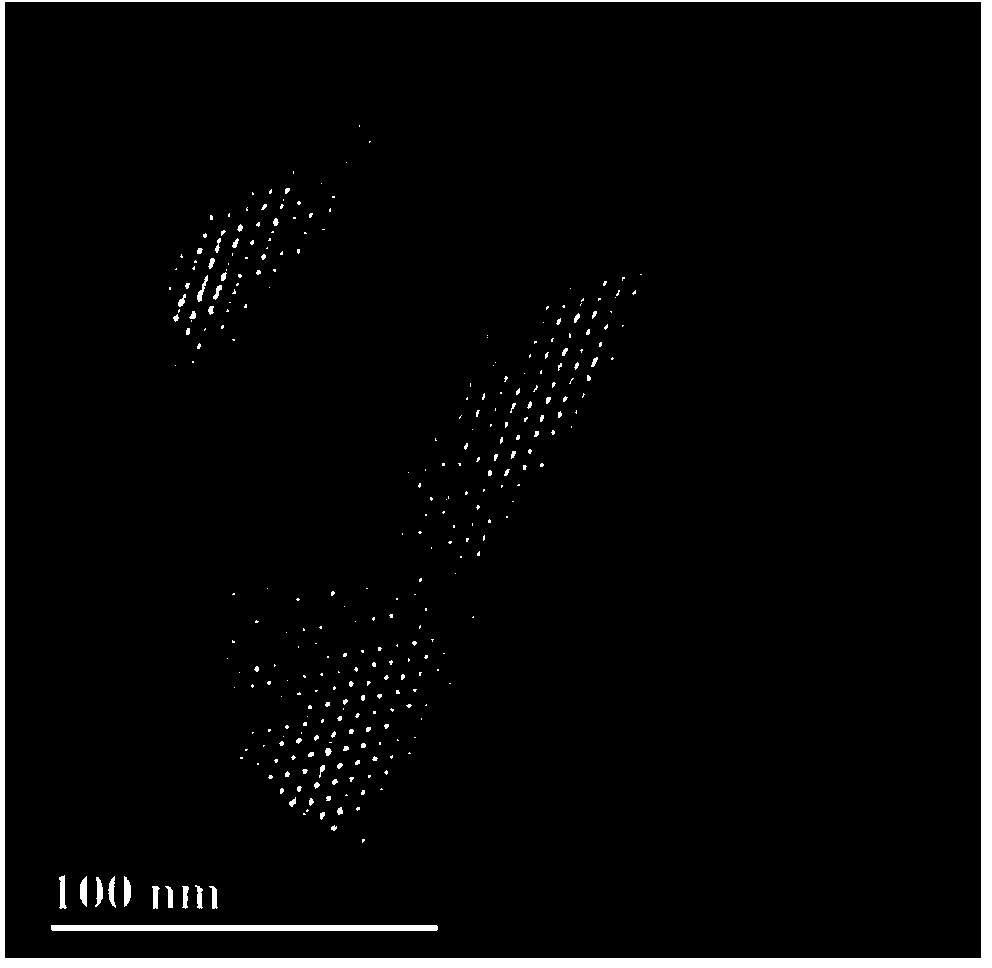

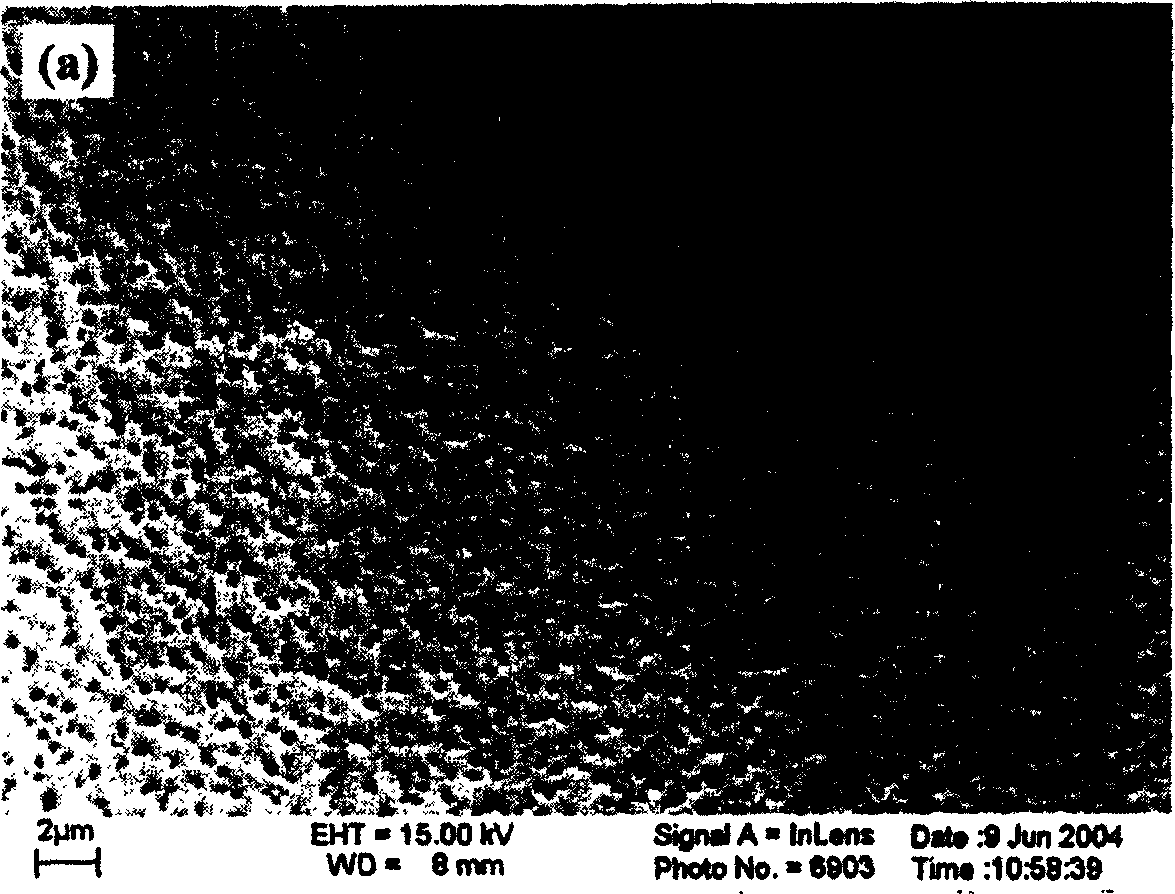

![Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d33c2ba5-ceec-44cc-a709-6bfddffa1e71/HDA0000631192430000011.PNG)

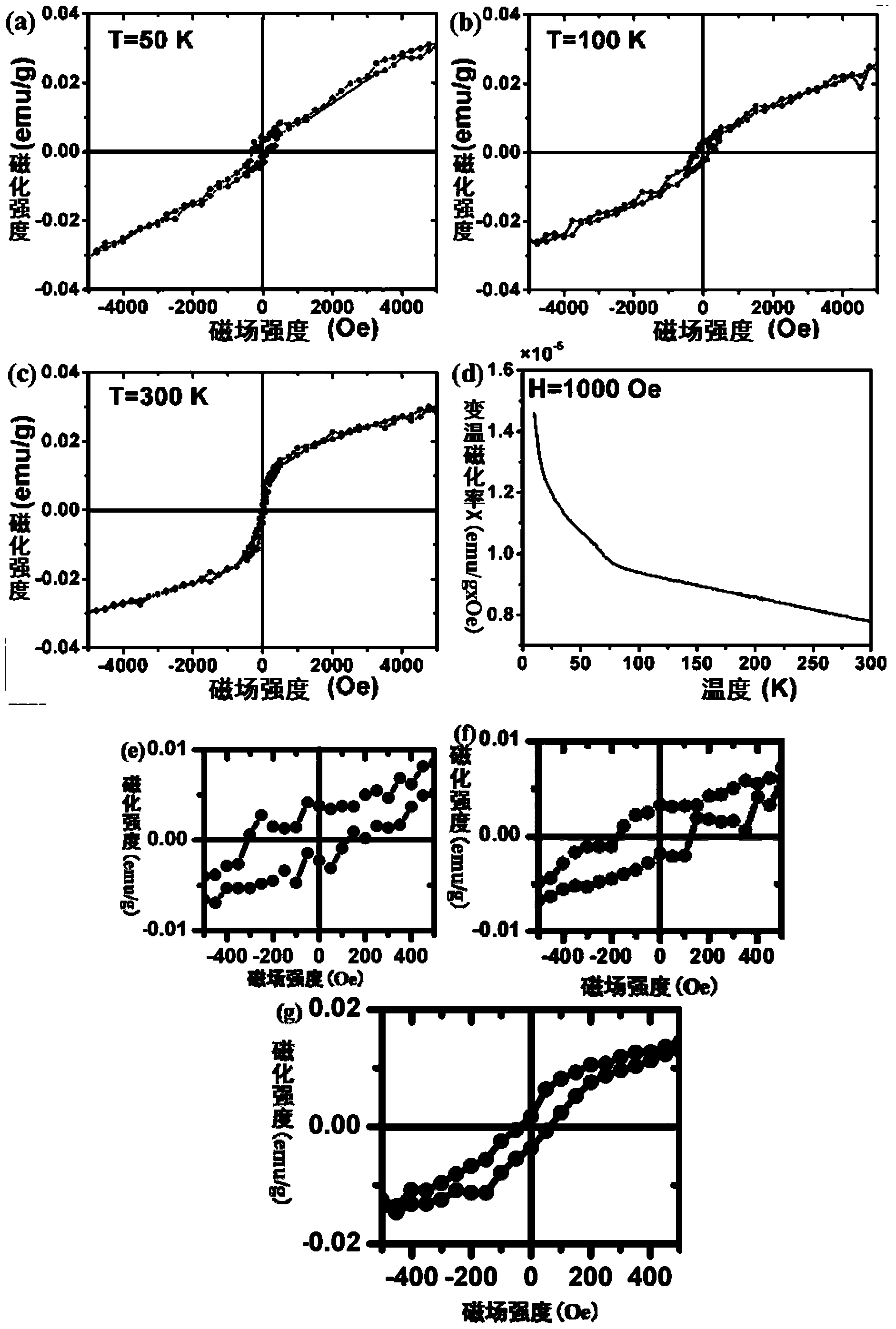

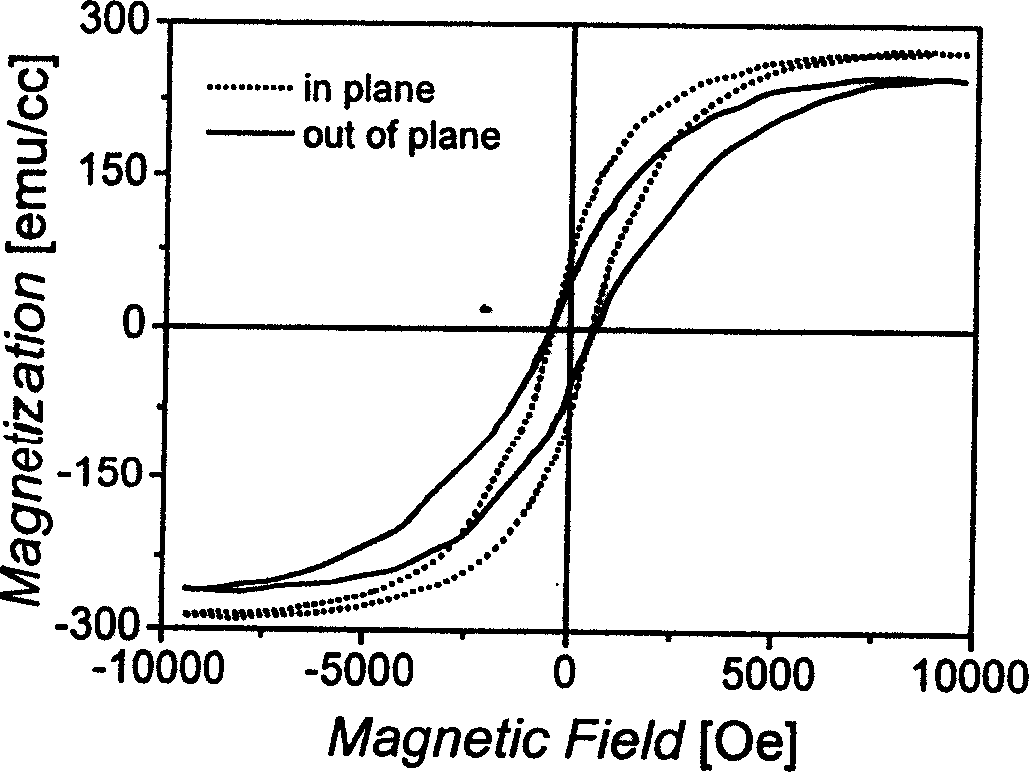

![Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d33c2ba5-ceec-44cc-a709-6bfddffa1e71/HDA0000631192430000012.PNG)

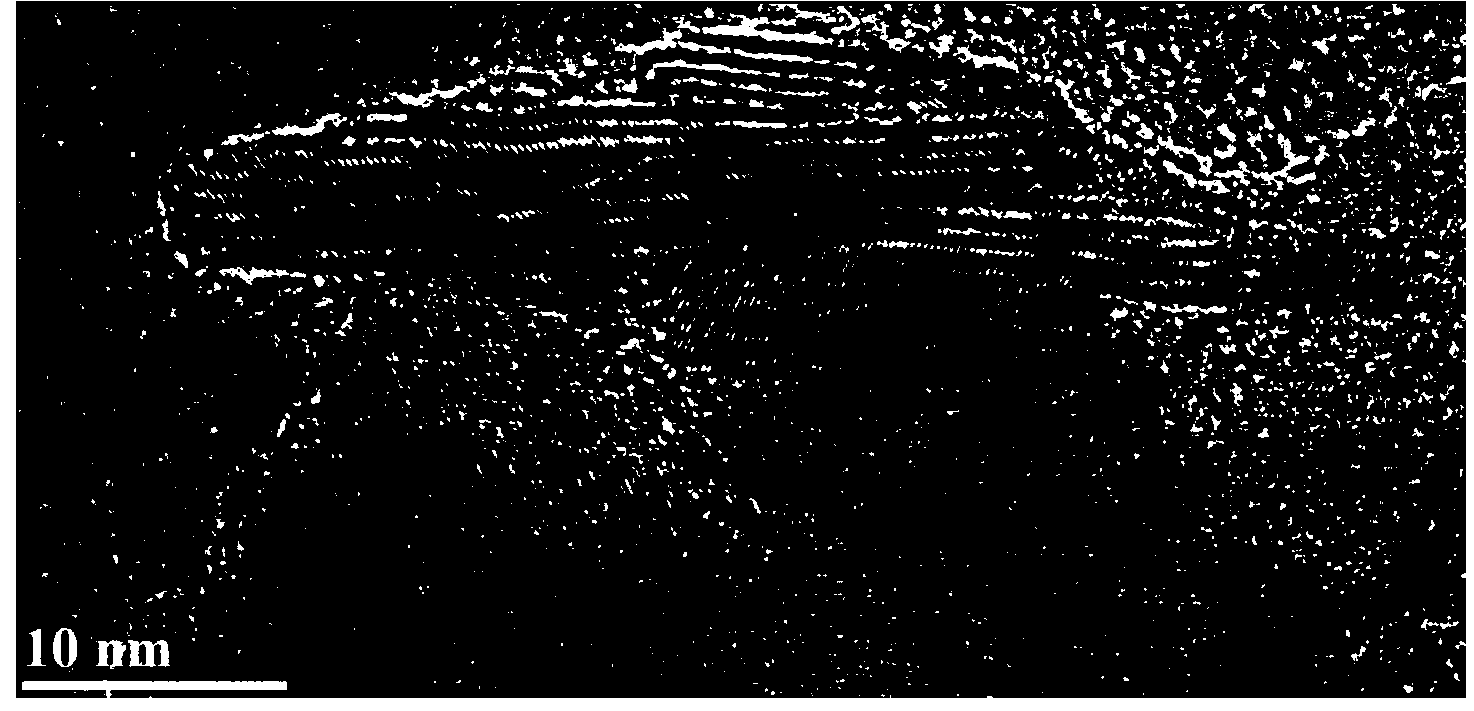

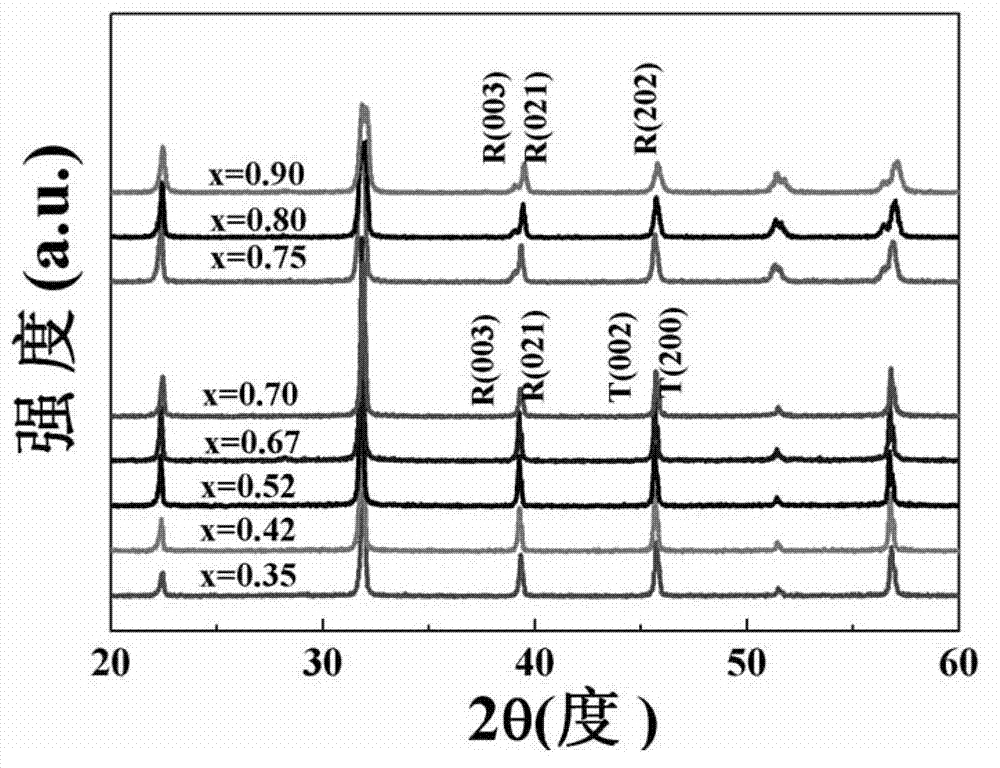

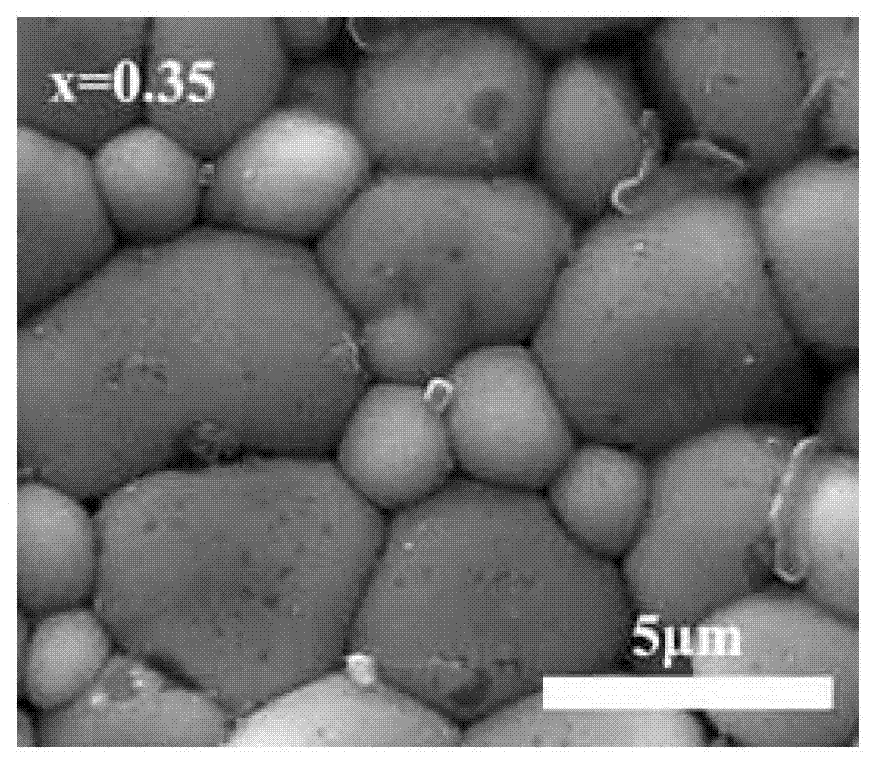

![Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d33c2ba5-ceec-44cc-a709-6bfddffa1e71/HDA0000631192430000021.PNG)