Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Improve magnetoelectric properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

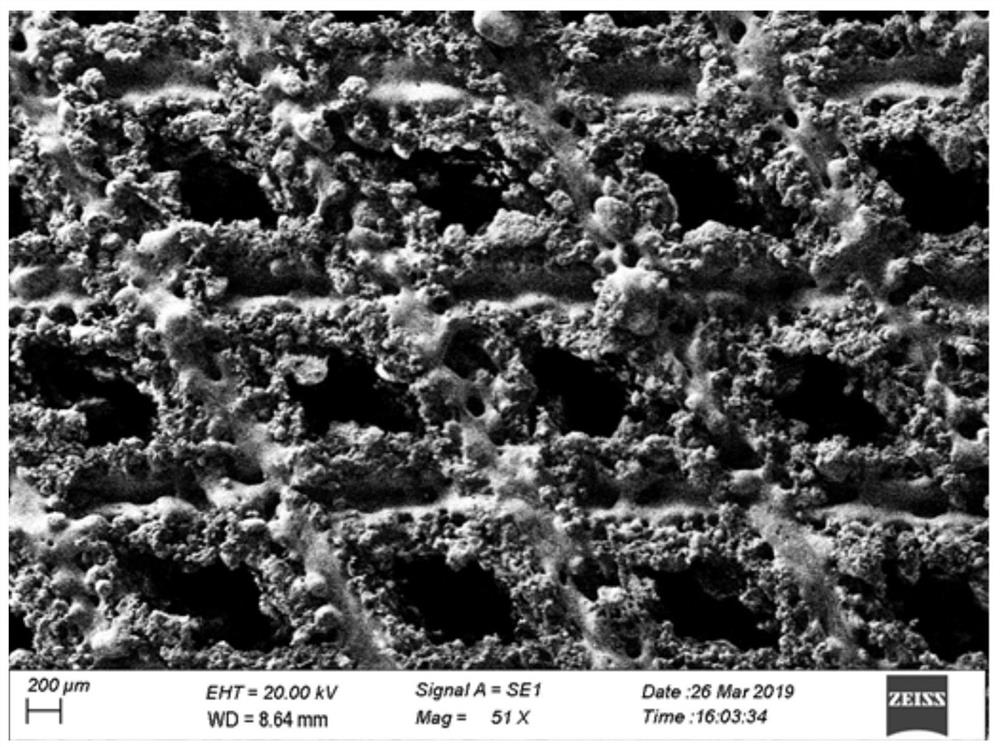

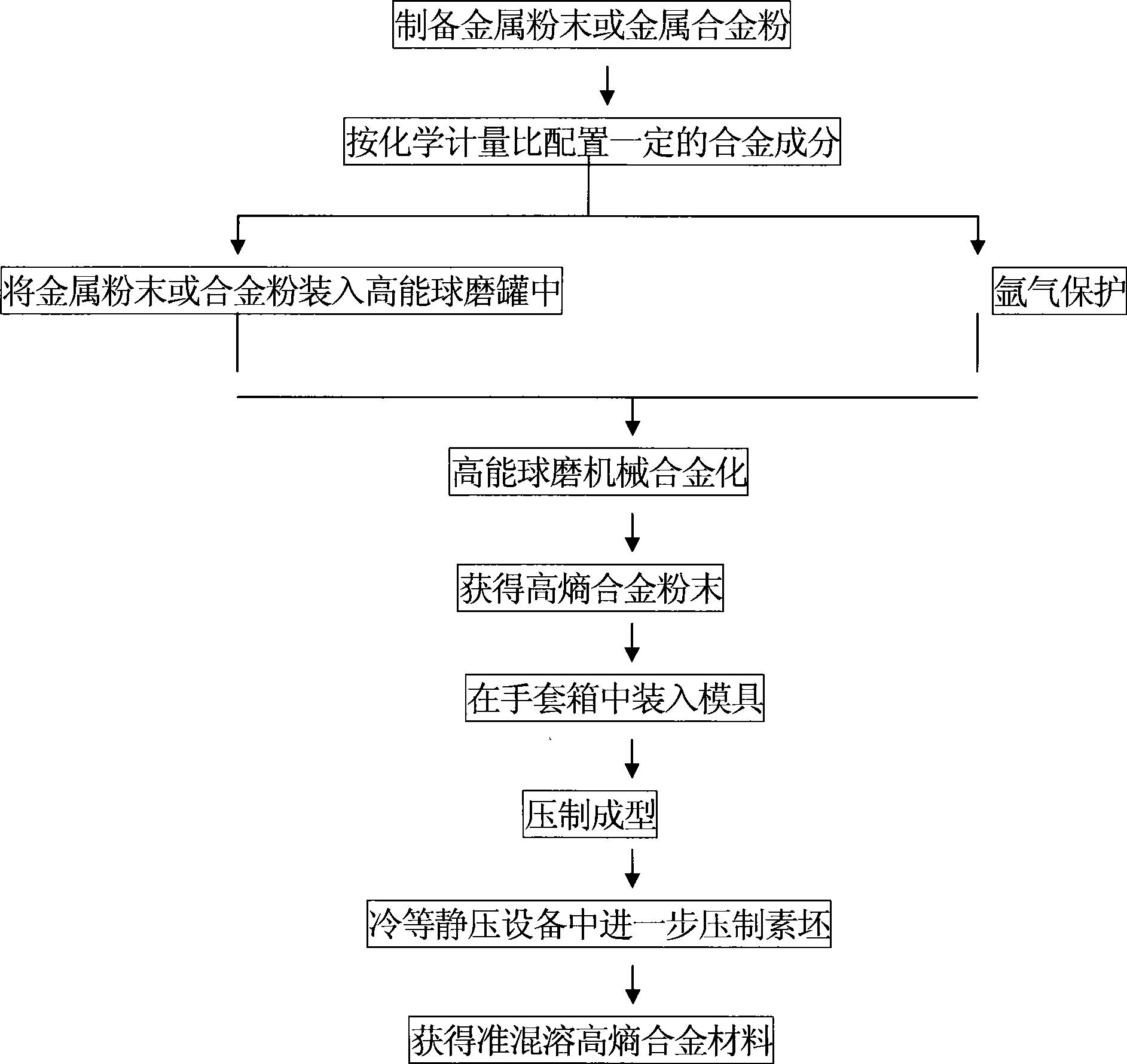

Method for preparing high-entropy alloy containing immiscible element

The invention discloses a preparation method for a novel high-entropy alloy structure material. A plurality kinds of alloy element powder which can not form a miscible system are used as raw materials, thereby solving the solid solution problem of the alloy elements without solid solution region during the high-entropy alloy preparation, that is, mixing the powders in a planetary high-energy ball milling machine and obtaining ultra-fine powder of an immiscible system simultaneously through strong mechanical alloying function. When the alloy powder is pressed into a pressing blank, the heating treatment process condition is controlled to allow the alloy elements to diffuse through a short path and form a uniform multi-principal element mixing body containing no intermetal compound in a blank body, and a single-phase solid solution is obtained. The novel alloy prepared by the method is widely used in engine parts made of a high-temperature and creep resistance material, skins and tails of large thrust weight ratio high-speed aircrafts, corrosion resistant and wear resistant parts, wear-resistant materials such as pipes, gears and bearings and other structural material fields.

Owner:KUNMING UNIV OF SCI & TECH

Stack ferro-electricity /magnetic multiferrou magnetoelectric compound film with conductive oxide as buffer layer and preparation thereof

InactiveCN101376600ASimple preparation processImprove magnetoelectric propertiesLayered productsElectricityComposite film

The invention discloses laminated ferroelectric / magnetic multiferroic and magnetoelectric composite film and preparation method thereof. The film comprises a substrate, a ferroelectric oxide layer and a magnetic oxide layer, and also a buffer layer positioned between the substrate layer and the ferroelectric oxide layer or the magnetic oxide layer. The layer can be LaNiO3, YBa2Cu3O7-x or SrRuO3, among which LaNiO3 is preferred. The preparation method comprises the following steps: firstly, buffer layer sol is prepared; secondly, the buffer layer sol is uniformly coated on the substrate to obtain the buffer layer; thirdly, sol of the ferroelectric oxide layer and the magnetic oxide layer is respectively prepared; fourthly, the sol obtained in step 3 is coated on the buffer layer, and then the end product is obtained. After the composite film is introduced into the buffer layer, the stress restraint of the substrate to the composite film is effectively reduced, the magnetoelectric coupling performance of the composite film with laminated structure is obviously enhanced, the cost is reduced, the preparation technique is simple, the requirement on the equipment is low, and the compatibility with the prior technique is good.

Owner:TSINGHUA UNIV

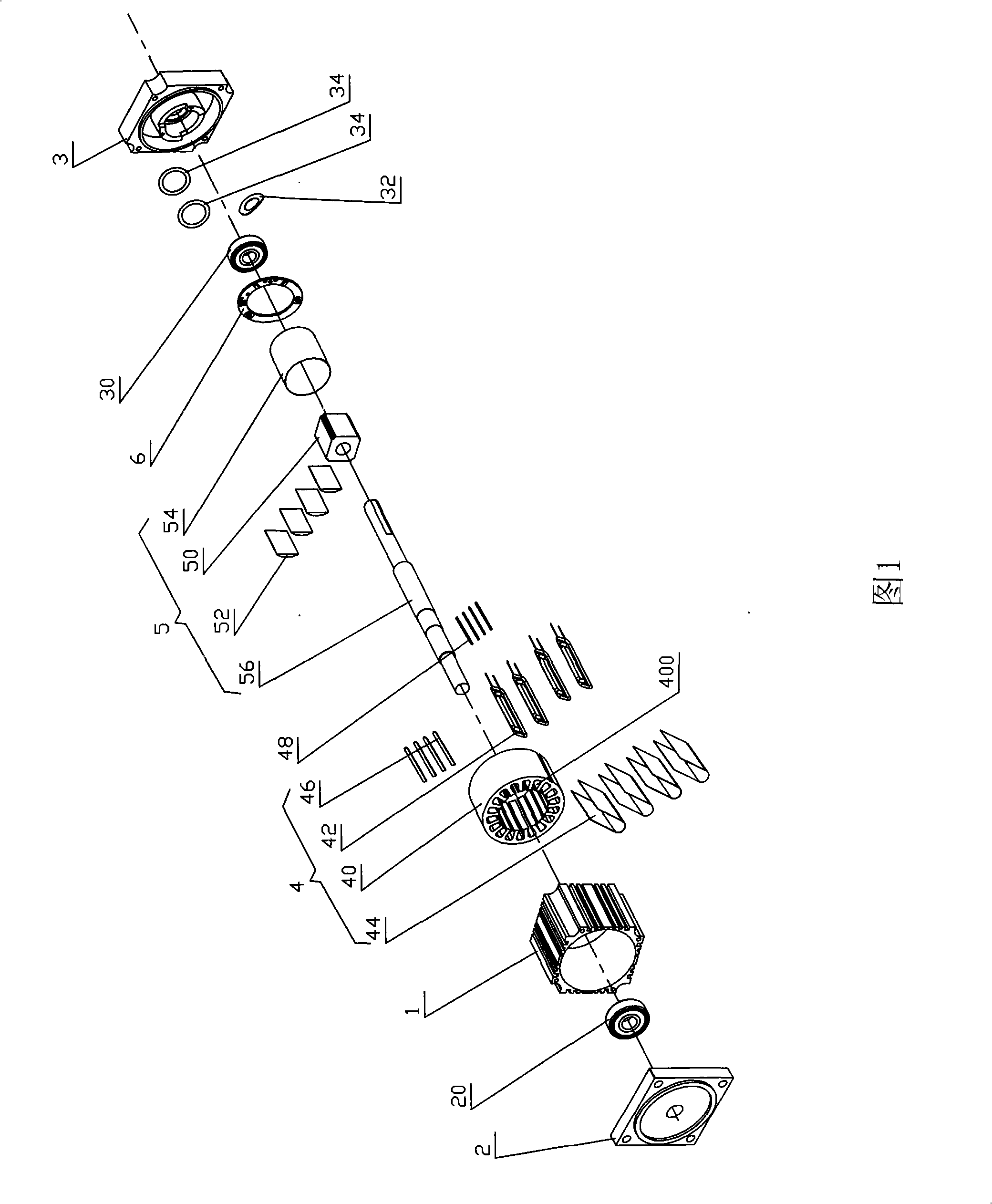

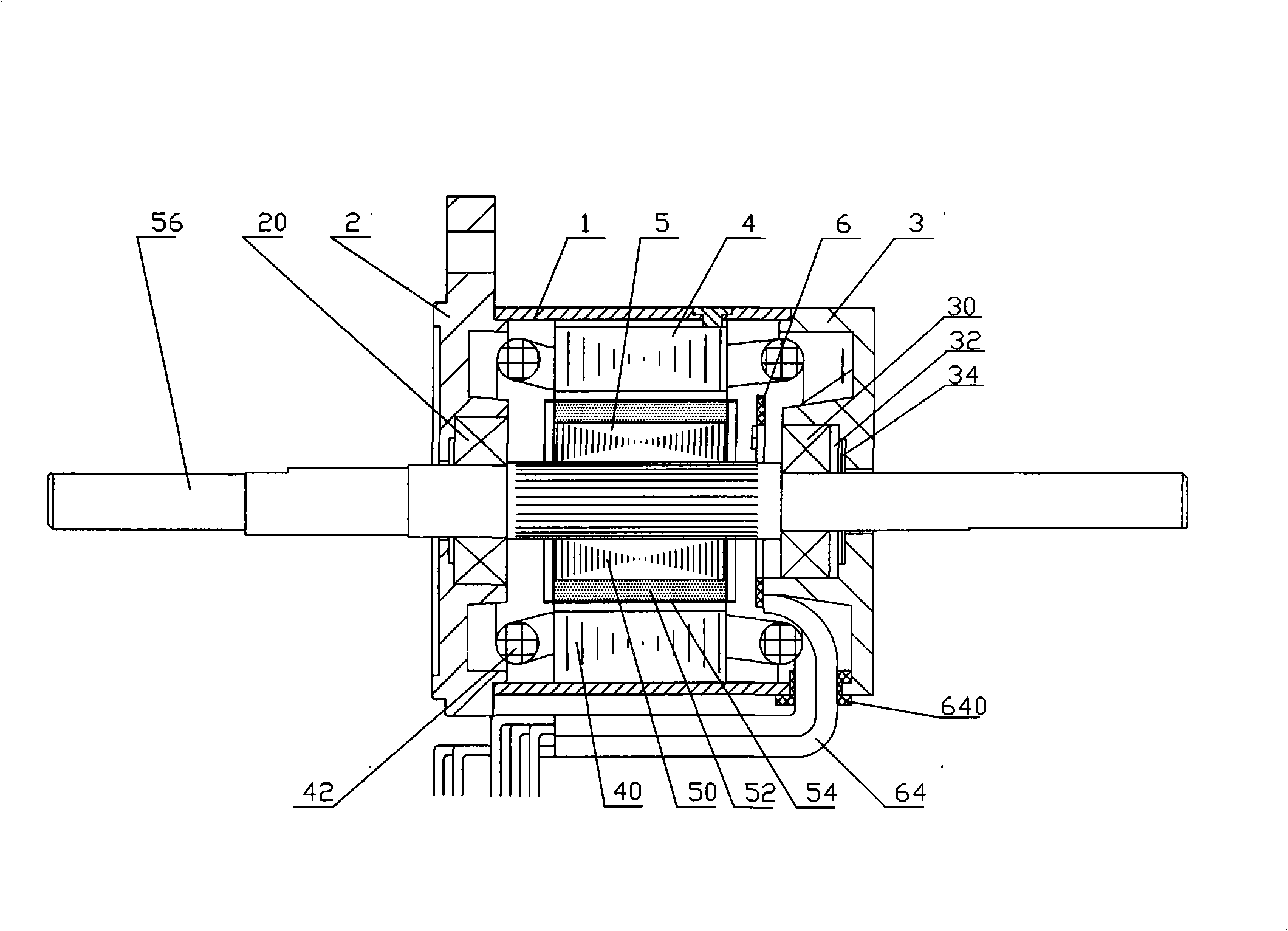

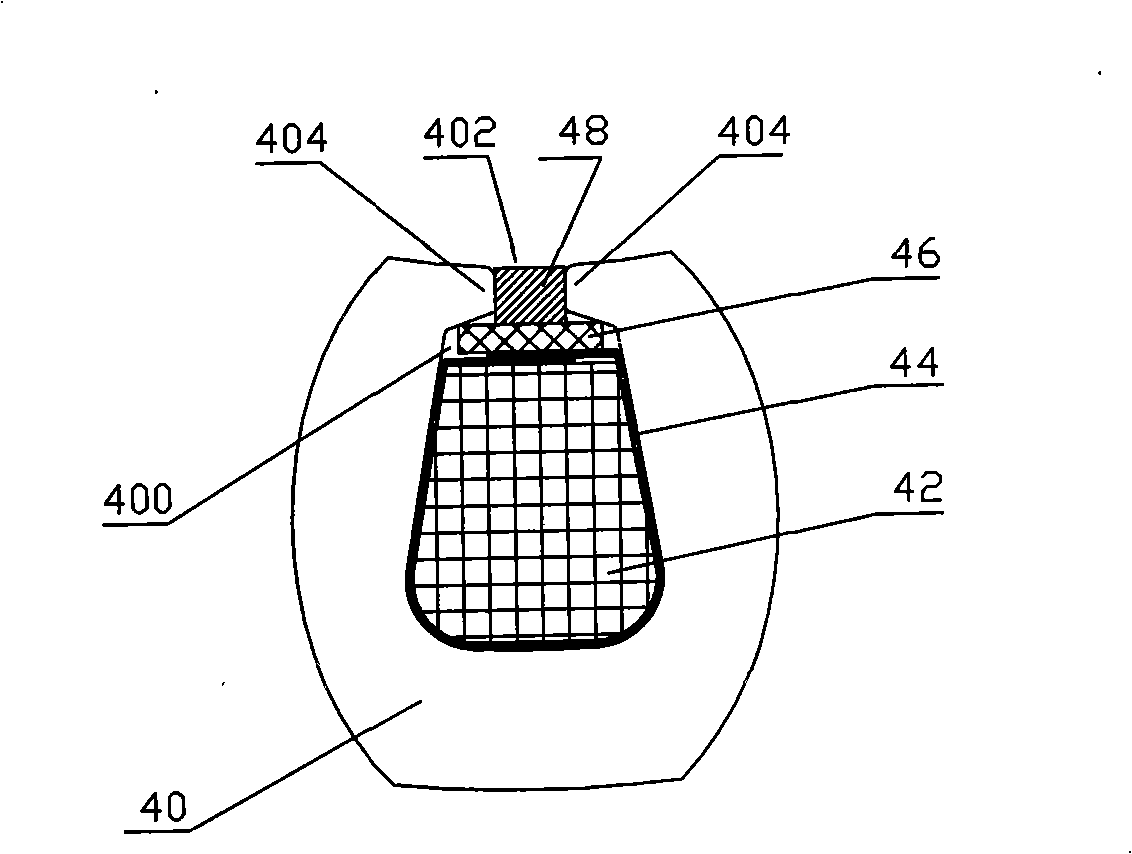

Permanent-magnet brushless DC motor

InactiveCN101355283AStrong central magnetismConcentrated magnetic effectMagnetic circuit rotating partsWork performanceHall element

The invention relates to a permanent-magnetic brushless direct current motor which comprises a shell, a front end cover, a rear end cover, a stator, a rotor, and a position sensor, wherein the stator comprises a stator iron core and a winding, the inner side of the stator iron core is provided with a plurality of tooth grooves, the winding passes through the tooth grooves; the rotor comprises a rotating shaft, a rotor iron core and at least one pair of magnetic steels, the rotor iron core is sleeved on the rotating shaft, the magnetic steels are arranged at the periphery of the rotor iron core; and the position sensor comprises a circuit board and a Hall element connected with the circuit board, wherein magnetic conduction inlaid strips used for magnetic conduction are arranged in the tooth grooves of the stator iron core, the cross sections of the magnetic steels of the rotor have an arc shape the thickness at the middle part of which is more than those at both sides, and the Hall element of the position sensor is close to end parts of the magnetic steels of the rotor and takes the magnetic leakage of the magnetic steels of the rotor as a running signal of the Hall element. The permanent-magnetic brushless direct current motor can effectively save production cost and improve the working performance of the motor.

Owner:范安成

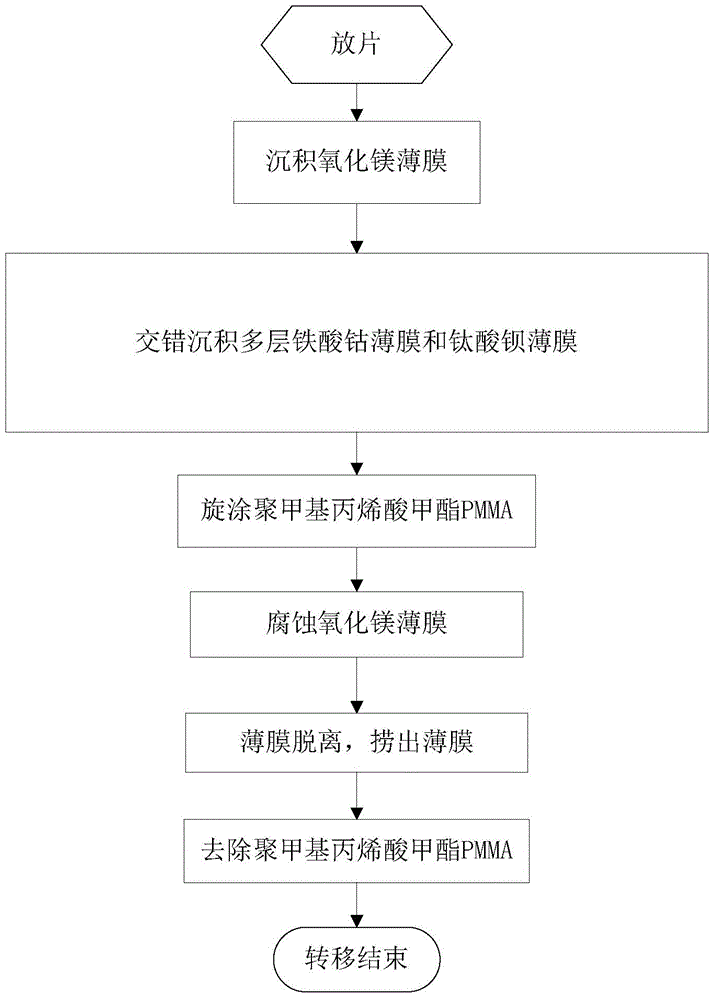

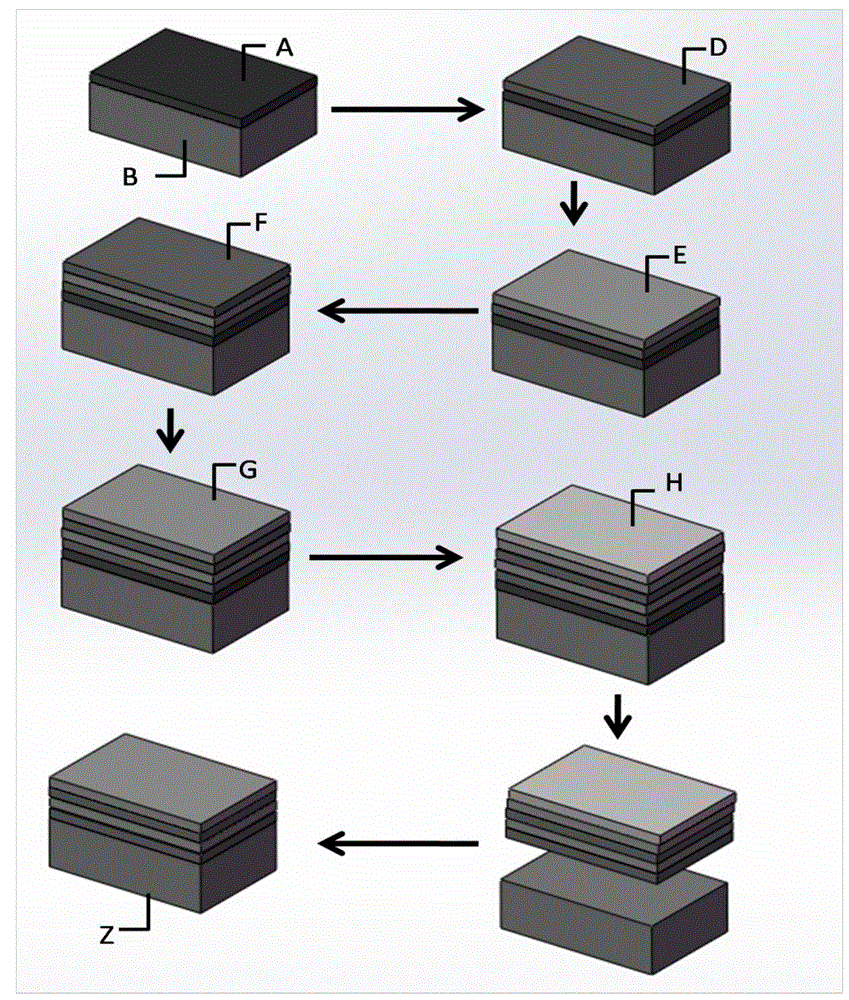

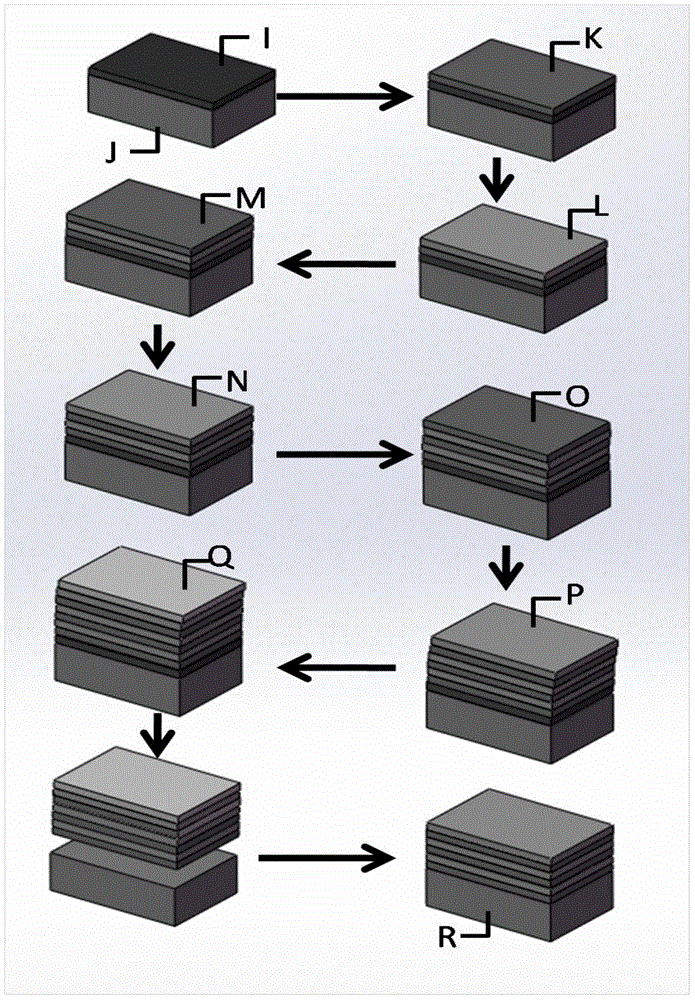

Method for preparing and transferring multilayer barium titanate and multilayer cobalt ferrite magnetoelectric composite film

The invention discloses a method for preparing and transferring a multilayer barium titanate and multilayer cobalt ferrite magnetoelectric composite film. The problems that the substrate clamping effect and electric leakage cannot be simultaneously reduced by the composite material of the conventional structures 1-3 are mainly solved. The method comprises the following implementation steps: depositing a magnesium oxide film on a sapphire substrate, and alternatively depositing a multilayer cobalt ferrite film and a multilayer barium titanate film on the substrate; spinning polymethyl methacrylate on the surface of the final barium titanate film, and removing a single crystal magnesium oxide film by using an ammonium sulfate solution, so that the magnetoelectric composite film attached to polymethyl methacrylate is separated from the sapphire substrate; and transferring the magnetoelectric composite film separated from the sapphire substrate onto a subsequent needed substrate, thereby obtaining a self-supported magnetoelectric film compounded by the multilayer cobalt ferrite film and the multilayer barium titanate film. The multilayer barium titanate and multilayer cobalt ferrite composite film disclosed by the invention is large in surface coupling property, the magnetic and electrical properties are enhanced, the substrate clamping and electric leakage problems are reduced, and the method can be used for preparing a magnetoelectric sensor.

Owner:XIDIAN UNIV

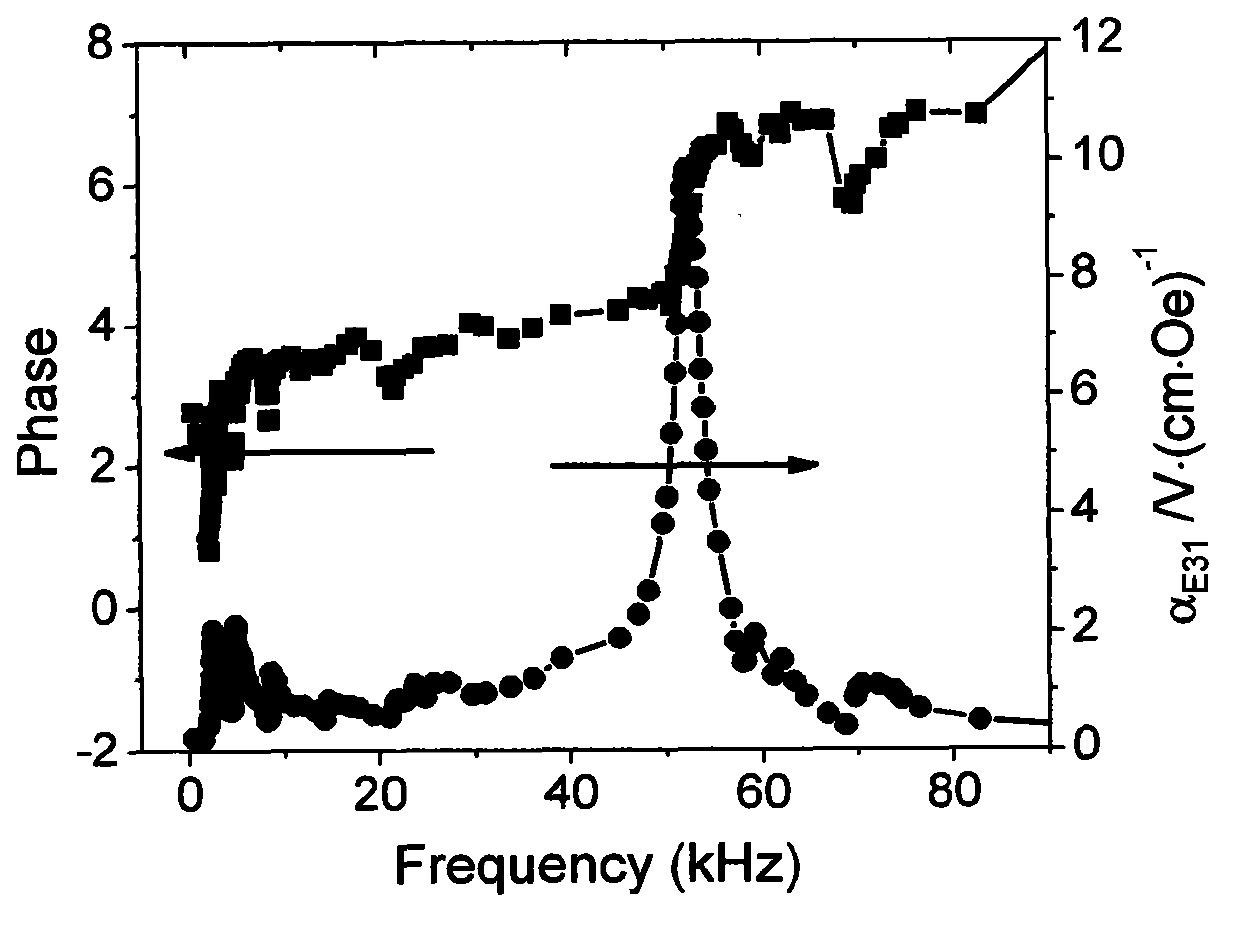

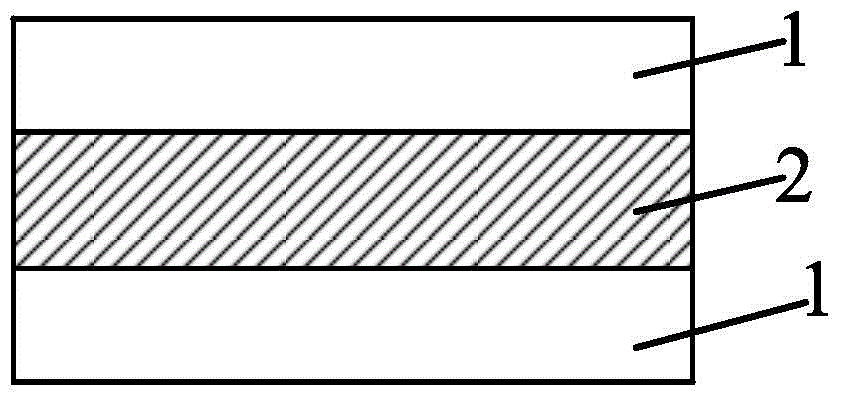

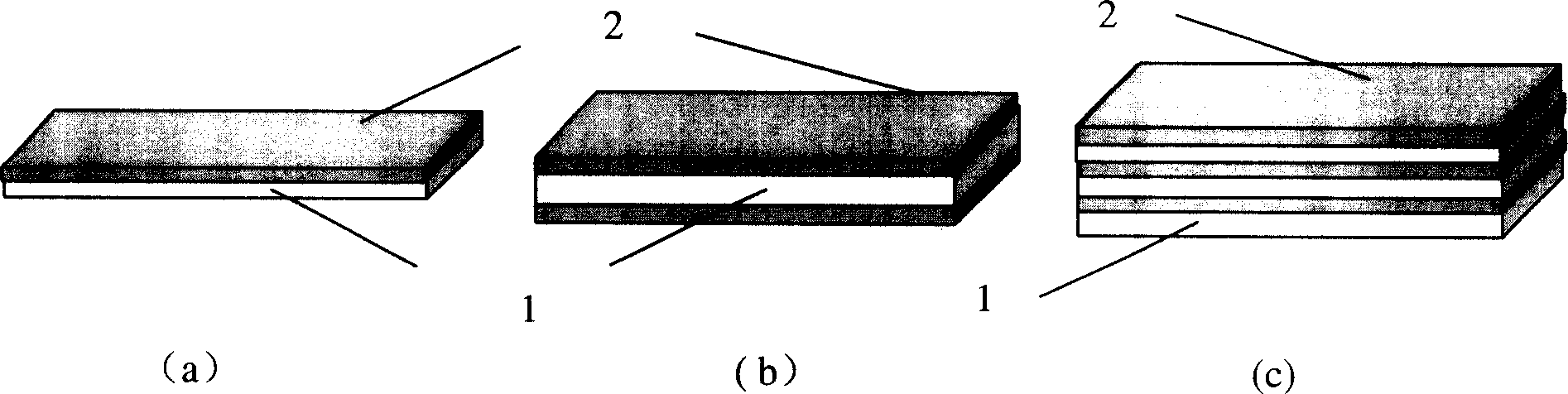

Nickel/piezoelectric ceramic laminar composite material with magnetoelectric effect and preparation process thereof

InactiveCN1755962ALow priceSimple preparation processPiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyComposite structureSilver electrode

The invention relates to a nickel / piezoelectric ceramic layered composite material with magneto-electric effect and its relative preparing method. Wherein, said composite material is compounded by the nickel plate and piezoelectric ceramic plates by the method of adhering while the thickness rate between nickel layer and piezoelectric ceramic layer is 0.1-5. The preparing method comprises that plating gold or silver electrode on the upper and lower surfaces of piezoelectric ceramic plate whose thickness is 0.2-1mm and the electrode will be polarized along the direction of thickness of piezoelectric ceramic plate; utilizing the organic conductive binder to bind the nickel plate and the piezoelectric ceramic plate whose thickness ranges from 0.1-1 mm to be solidified in room temperature to attain said composite material. The inventive composite material, compared to present electromagnetic material, has high electromagnetic performance, simple preparing process, lower cost, stable property and higher designable ability, which can change the electromagnetic property of material via changing the size and the layer pattern of composite structure.

Owner:NAT UNIV OF DEFENSE TECH

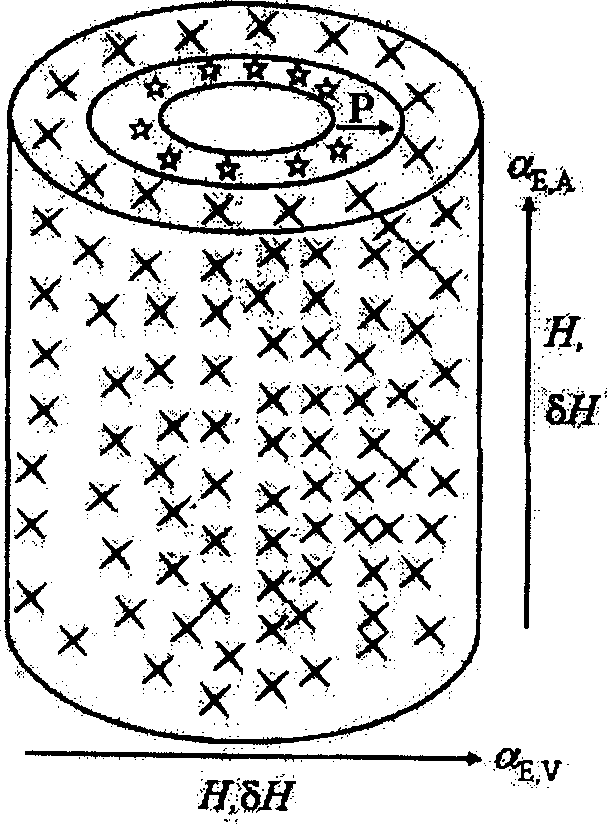

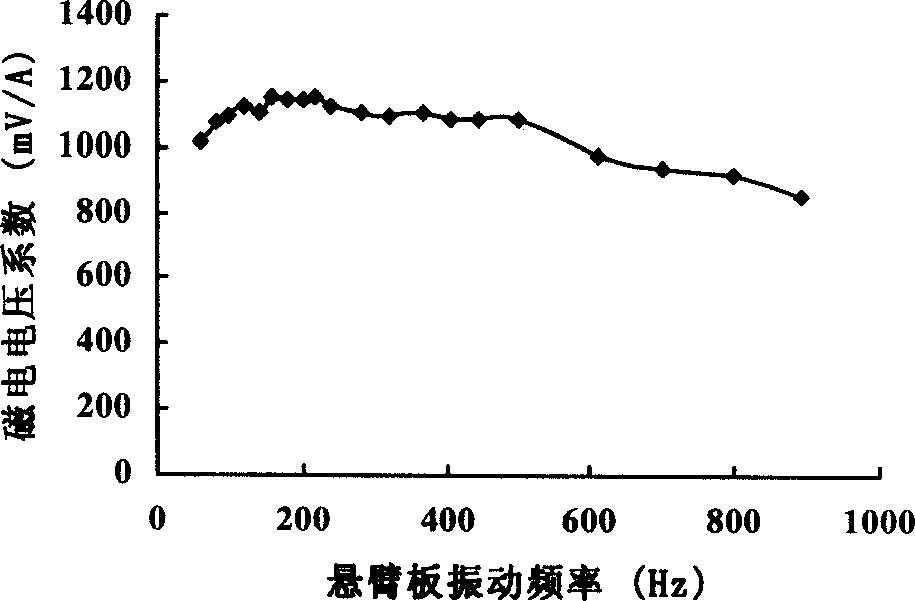

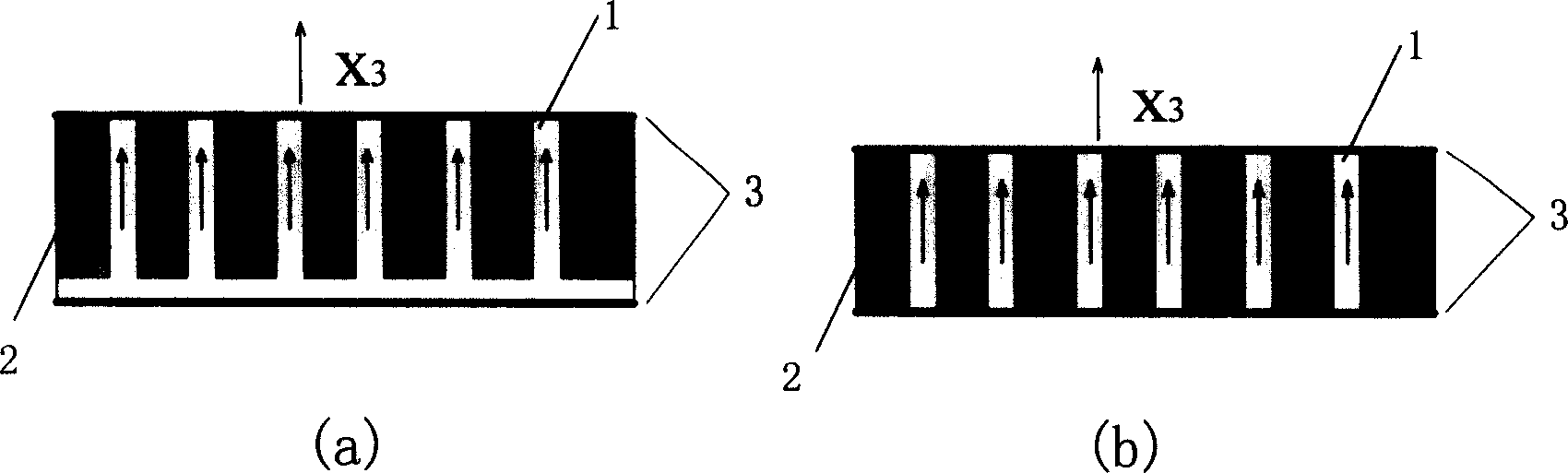

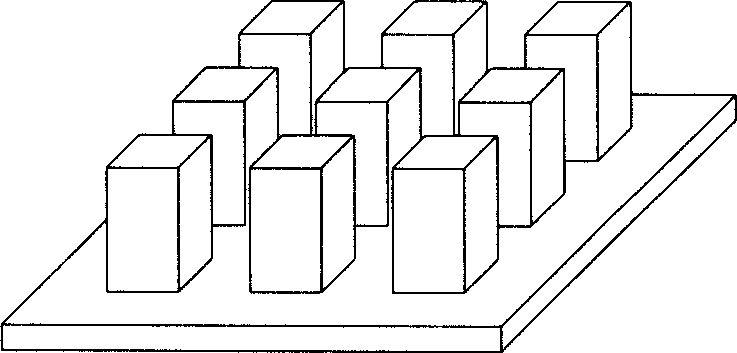

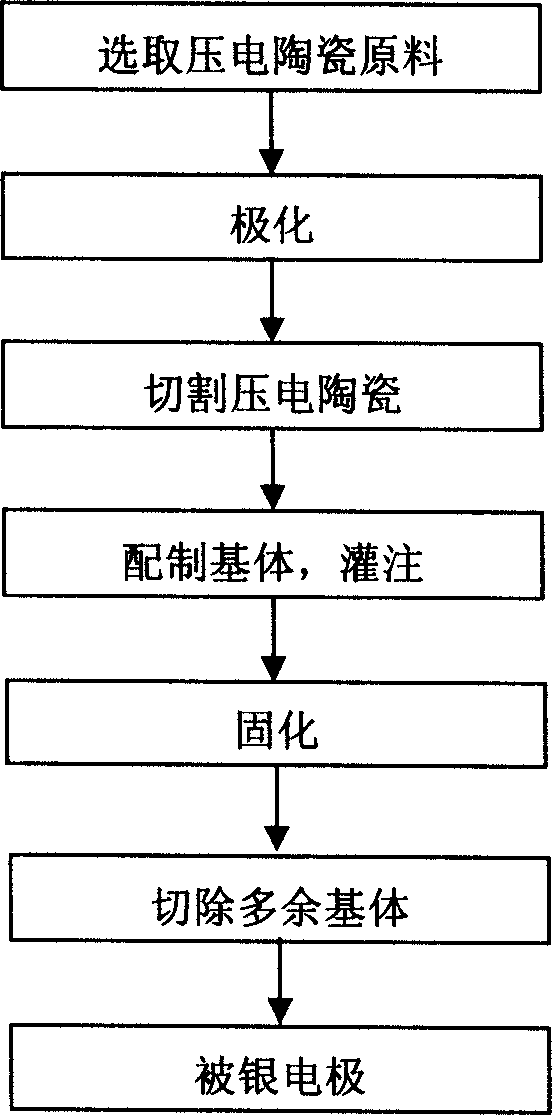

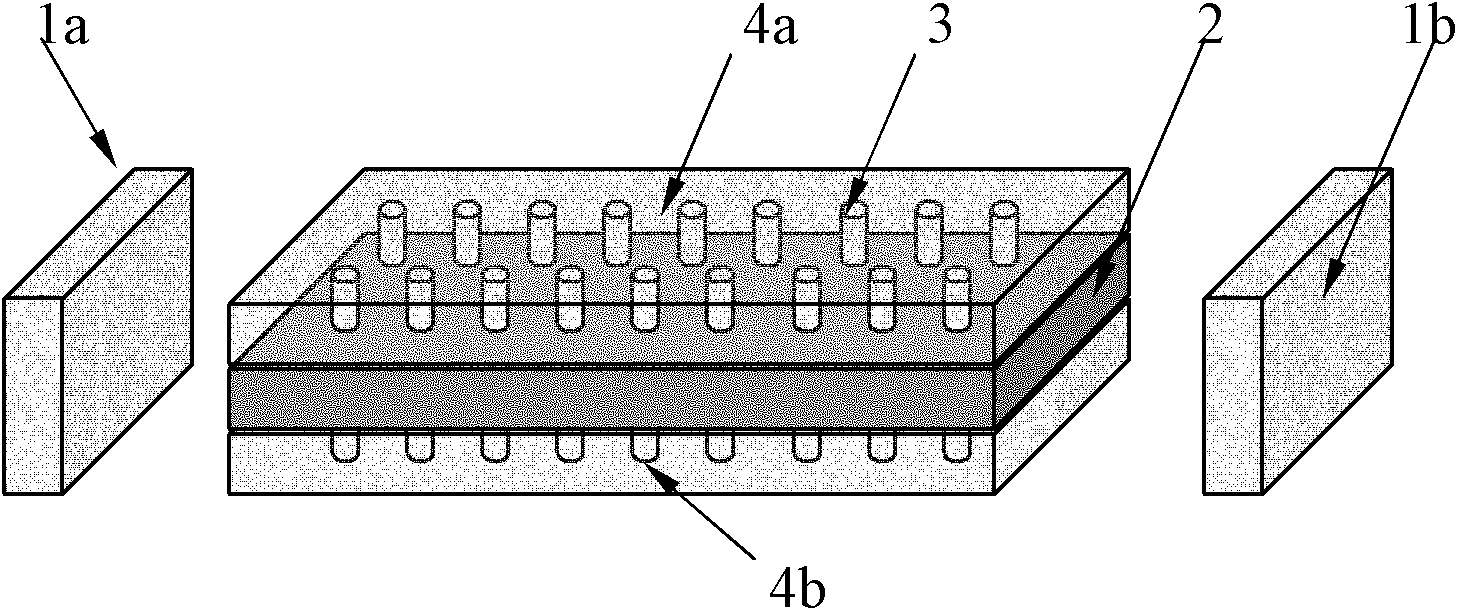

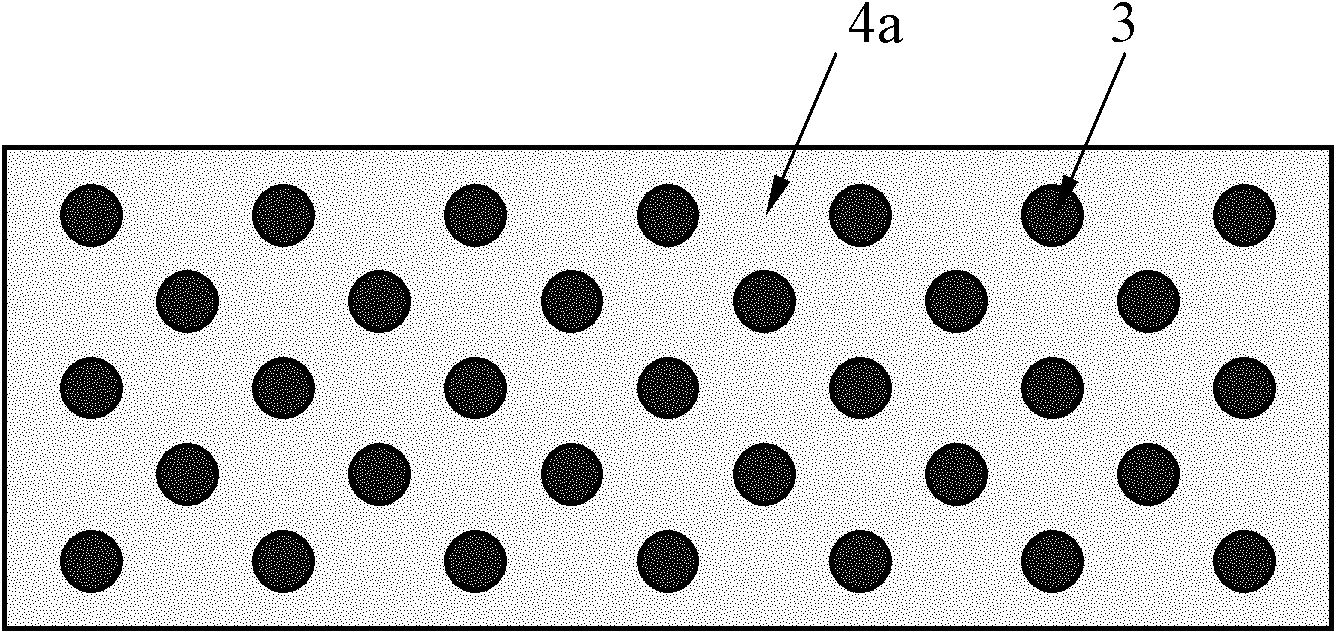

1-3 structure huge magnetoelectric material and preparing process thereof

InactiveCN1719635AImprove magnetoelectric propertiesEasy to makeDevice material selectionGalvano-magnetic material selectionElectricityConversion coefficients

This invention relates to a 1-3 structured huge magnet electric material and its preparation method. The material is composed of piezoelectric ceramics, magnetostriction materials and a high-molecular binding agent, among which, one of the dimension of the piezoelectric ceramics is greater than the other two shaped in a long column and distributed in a 3-D matrix composed of the magnetostriction materials powder and the high-molecular binding agent. This 1-3 structured material has high and stable magnetoelectric conversion coefficient, which can be regulated by altering contents of the piezoelectric ceramics.

Owner:TSINGHUA UNIV

Free-machining ferritic stainless steel for ferromagnetic component

InactiveCN101492792AImprove thermal stabilityImprove magnetoelectric propertiesChemical compositionSS - Stainless steel

The invention provides an easy-cutting ferritic stainless steel used for a ferromagnetic part. The ferritic stainless steel comprises the following chemical composition: less than or equal to 0.03wt% of C, 0.6-1.2wt% of Si, less than or equal to 0.30wt% of Mn, 13.0-20.0wt% of Cr, less than or equal to 0.5wt% of Ni, 0.12-0.3wt% of S, 0.3-0.6wt% of V, 0.01-0.40wt% of Cu, less than or equal to 0.03wt% of P, and the balance Fe and impurities. The ferritic stainless steel of the invention is prepared by adjusting the contents of Si, Cr and S, adding V of proper amount and adopting reasonable manufacturing technique; the ferritic stainless steel has good corrosion resisting property and cutting property, with a magnetic property index coercive force Hc being less than or equal to 94.8A / m.

Owner:BAOSHAN IRON & STEEL CO LTD

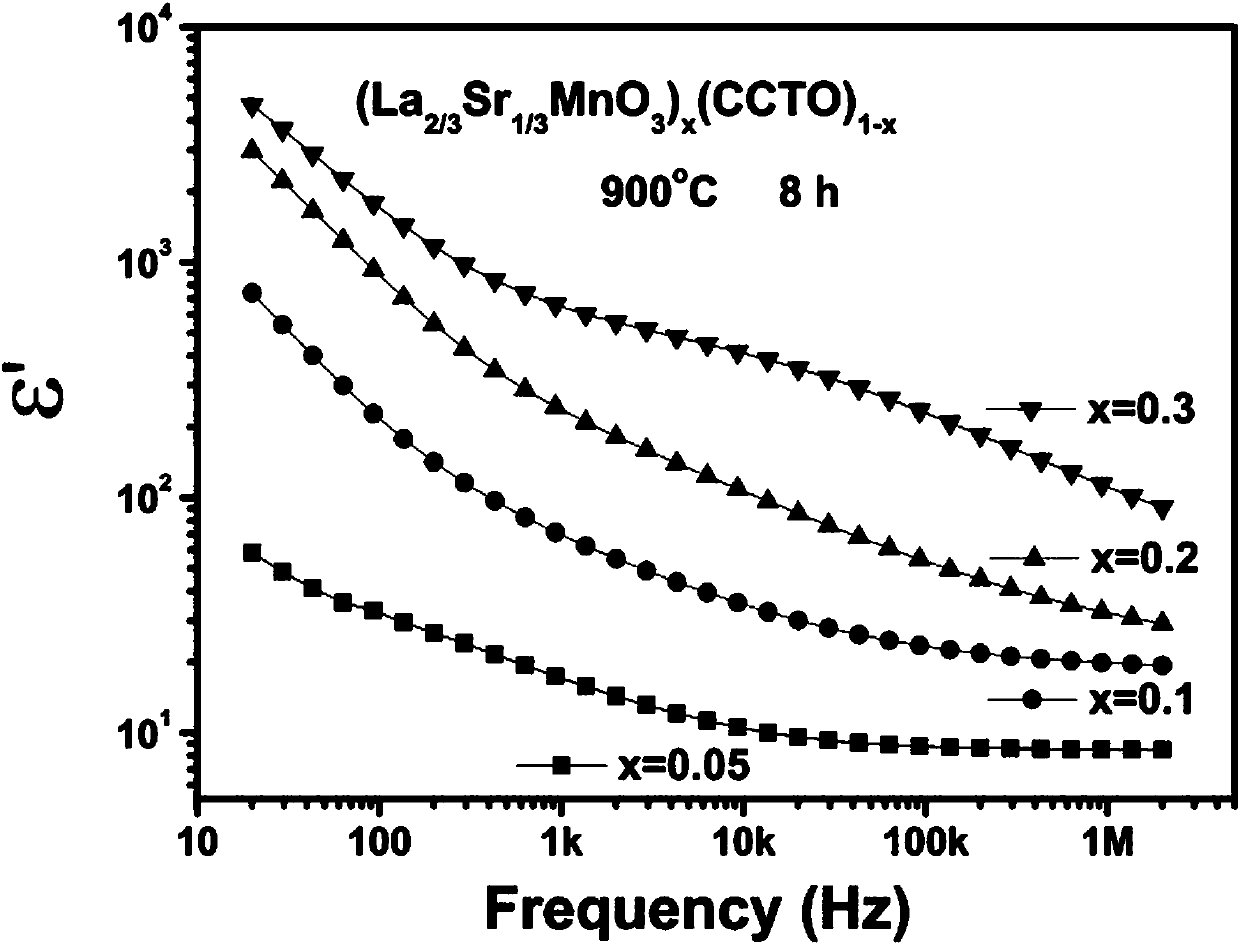

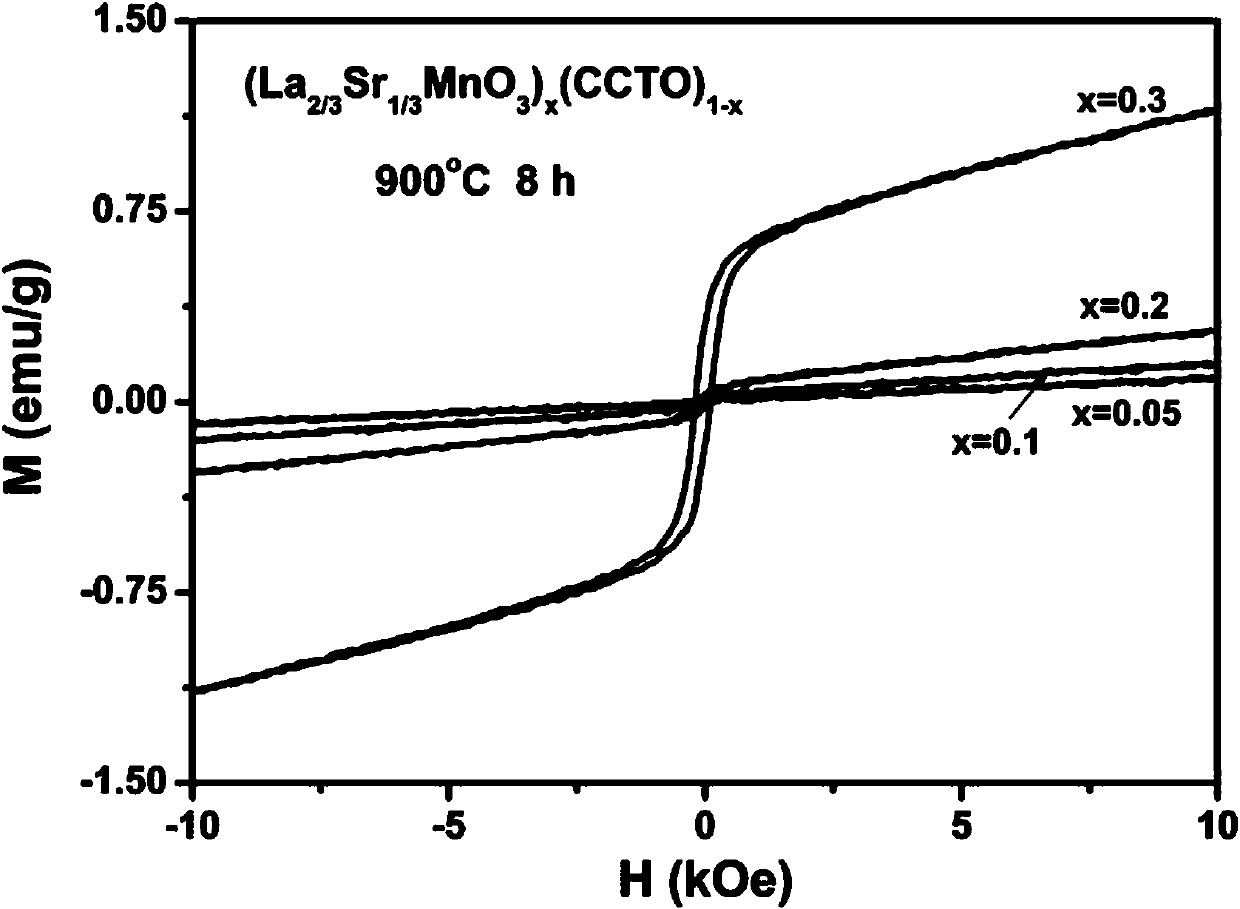

Method for preparing lanthanum strontium manganite/copper calcium titanate composite magnetoelectric ceramic material by virtue of sol-gel method

InactiveCN107759216AImprove uniformityImprove featuresInductances/transformers/magnets manufactureLanthanum strontium manganiteAdhesive

The invention belongs to the technical field of ceramic synthesis and provides a method for preparing a strontium lanthanum manganate / copper calcium titanate composite magnetoelectric ceramic materialby virtue of a sol-gel method. The method comprises the steps of respectively preparing lanthanum strontium manganite (LSMO) precursor powder, copper calcium titanate and CCTO precursor powder by virtue of the sol-gel method, mixing the LSMO precursor powder with the CCTO precursor powder, adding an adhesive, uniformly mixing, pressing to form a ceramic blank, and sintering a ceramic blank, so asto obtain a strontium lanthanum manganate / copper calcium titanate (LSMO-CCTO) composite magnetoelectric ceramic sample. The method has the beneficial effects that the raw materials are low in cost; components in the reaction process are controllable, and an impure phase is avoided; the gelling time is short; a preparation process is simple, and the dielectric property and magnetism of the ceramicsample have very strong regularity; a ceramic wafer is high in density and grain uniformity; and the process is simple and easy for industrial production, the prepared ceramic sample is high in density and grain uniformity and excellent in magnetoelectric performance.

Owner:TAIYUAN UNIV OF TECH

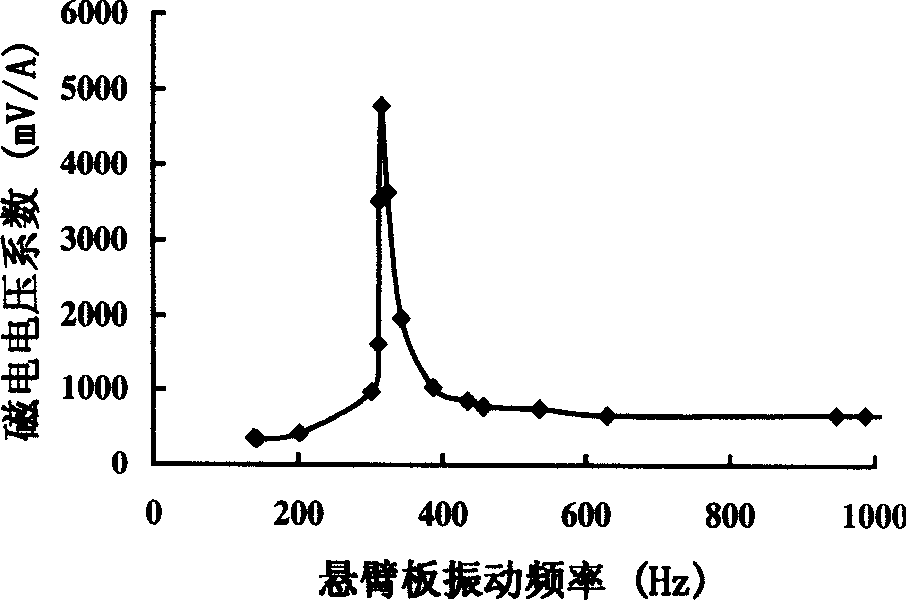

Magnetoelectric sensor

InactiveCN102062612AChanging the Magnetoelectric Voltage CoefficientHigh sensitivityConverting sensor output electrically/magneticallyComposite materialDetection performance

The invention discloses a magnetoelectric sensor, which comprises a magnetoelectric sensor body compounded by a magnetostrictive material layer, a piezoelectric material layer and powder with high magnetic conductivity. In the magnetoelectric sensor, a composite layer of the powder with high magnetic conductivity and a magnetostrictive material is adopted, the magnetoelectric properties in various sections tend to be consistent and the integral performance is optimized; the obtained magnetoelectric efficiency of the magnetoelectric sensor is improved by 20 percent compared with that of a magnetoelectric sensor not provided with the composite layer; and the detection performance of the magnetoelectric sensor is greatly improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

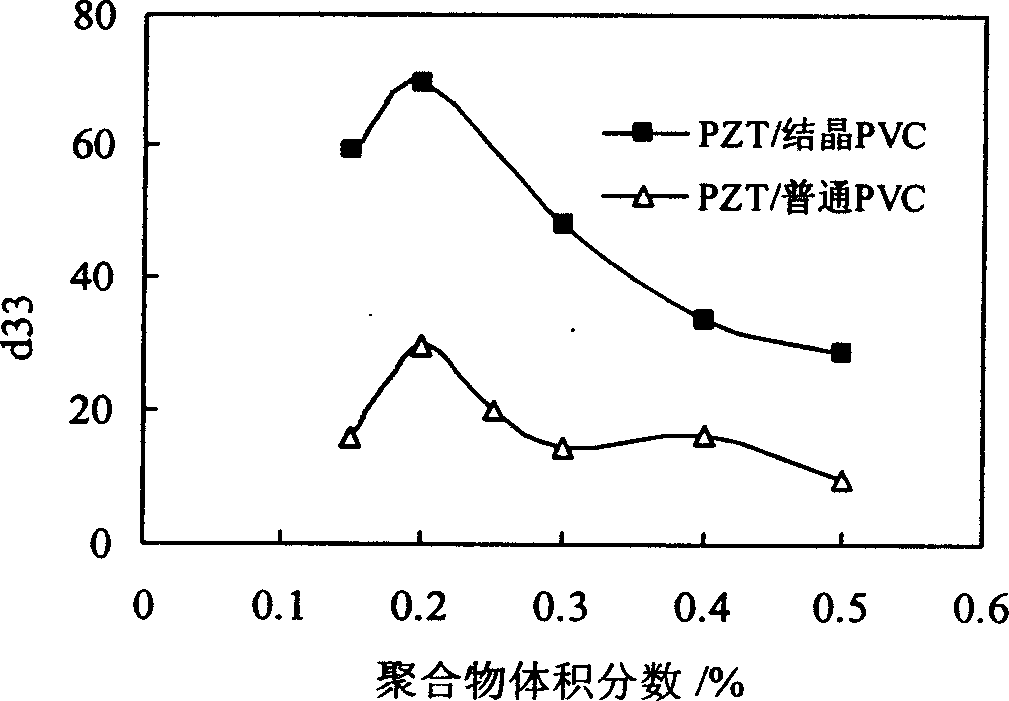

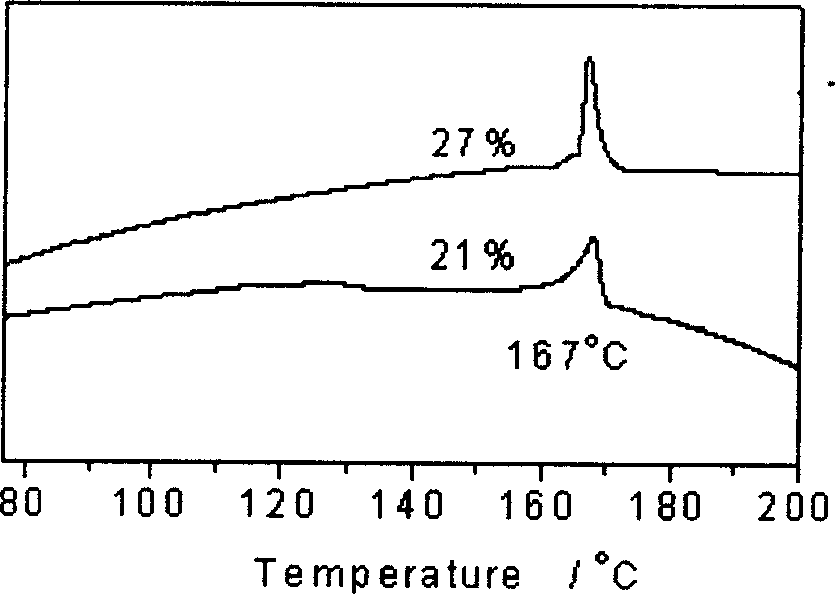

Crystalline modified method for transfering phase polymer in magnetic-force-electro-coupling effect

InactiveCN1657554AImprove piezoelectric performanceImprove magnetoelectric propertiesDevice material selectionPolymer scienceSolvent

A crystalline modifying method for the polymer used for piezoelectric ceramic-polymer composition and ferromagnetic material-polymer composition to improve their piezoelectric or ferromagnetic performance includes such steps as preparing nucleator solution of non-crystal polymer, spraying it onto non-crystal polymer powder, heat treating, airflow grinding, proportionally mixing it with piezoelectric ceramic powder and ferromagnetic powder, cold die pressing, hot die pressing and annealing.

Owner:WUHAN UNIV OF TECH

Bi(1-x)RExFe0.96Co0.02Mn0.02O3 ferroelectric film and preparation method thereof

The invention provides a Bi(1-x)RExFe0.96Co0.02Mn0.02O3 ferroelectric film and a preparation method thereof. The preparation method comprises the following steps: preparing a Bi(1-x)RExFe0.96Co0.02Mn0.02O3 precursor solution from bismuth nitrate, ferric nitrate, cobalt nitrate, manganese acetate and nitric acid RE which serve as raw materials, wherein x is 0.06-0.12, and RE is La, Eu or Er; and coating the precursor solution on a substrate in a spinning manner, uniformly coating, baking and annealing to obtain the Bi(1-x)RExFe0.96Co0.02Mn0.02O3 ferroelectric film. By adopting the method, requirement for equipment is simple, the experiment condition can be easily achieved, the doping amount can be easily controlled, and the ferroelectric performance of the film can be greatly improved, so that the prepared Bi(1-x)RExFe0.96Co0.02Mn0.02O3 ferroelectric film has good uniformly, less current leakage and high remanent polarization.

Owner:SHAANXI UNIV OF SCI & TECH

SrTiO3-based high-frequency layered magnetoelectric composite material and preparation method thereof

The invention discloses a SrTiO3-based high-frequency layered magnetoelectric composite material and a preparation method thereof. The preparation method comprises the following steps: granulating SrTiO3 powder and Ni0.8Zn0.2Fe2O4 powder, pressing and molding the powder in a mold according to a 2-2 composite base superposition arrangement mode, discharging a PVA adhesive, sintering at the temperature of 1250 to 1300 DEG C, thereby obtaining the SrTiO3-based high-frequency layered magnetoelectric composite material. Because the SrTiO3 powder and Ni0.8Zn0.2Fe2O4 powder is molded according to the 2-2 composite base superposition arrangement mode, a ferroelectric phase and a ferrimagnetic phase are cofired together in a layered compounding mode, and the mutual reaction between the two phases can be effectively inhibited so as to remain the respective characteristics. Therefore, the composite material has excellent dielectricity and ferromagnetic property.

Owner:SHAANXI UNIV OF SCI & TECH

Method for designing and preparing spherical shell layered magnetoelectric composite material structure

InactiveCN101330124AHigh modulus of elasticityImprove magnetoelectric propertiesPiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyCompression moldingChemical plating

The invention discloses a spherical shell laminar magneto-electric composite material structure and a manufacturing method, and relates to the design and manufacture method of an isotropic magneto-electric effect laminar magneto-electric composite material structure. The method comprises the following steps: hemispherical shell piezoelectric ceramic is achieved through compression molding and sintering, after the high-temperature polarizing is performed, metallizing is performed by adopting the chemical plating method, two metallized piezoelectric ceramic hemispherical shells are bonded into a complete piezoelectric ceramic hemispherical shell through the strong glue, and then the shell is laid in the prepared electroplating solution to be electroplated till a magnetic layer with the required thickness is electroplated, thereby the spherical shell laminar magneto-electric composite material is achieved. Compared with the prior simple laminar composite material, such as a flat plate, because the dimensions of the structure in the three-dimensional direction are identical, the magneto-electric performances of the structure in all directions are identical, and by adopting the isotropic magneto-electric performance, the spherical shell laminar magneto-electric composite material can be applied to the magnetic field detection in the unknown directions.

Owner:UNIV OF SCI & TECH BEIJING

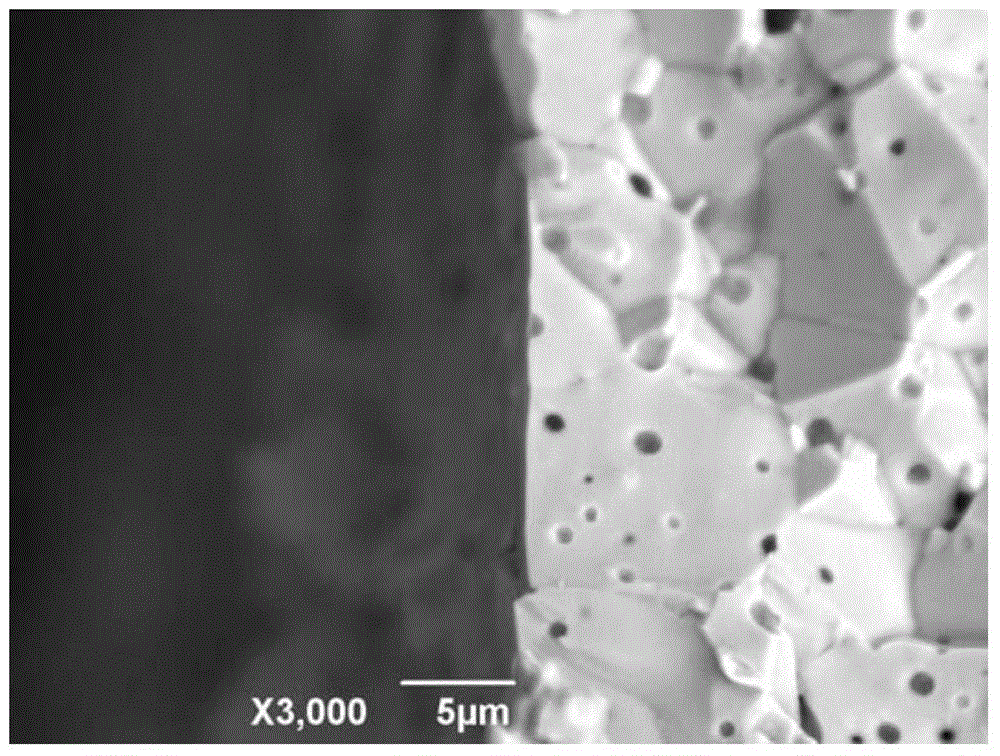

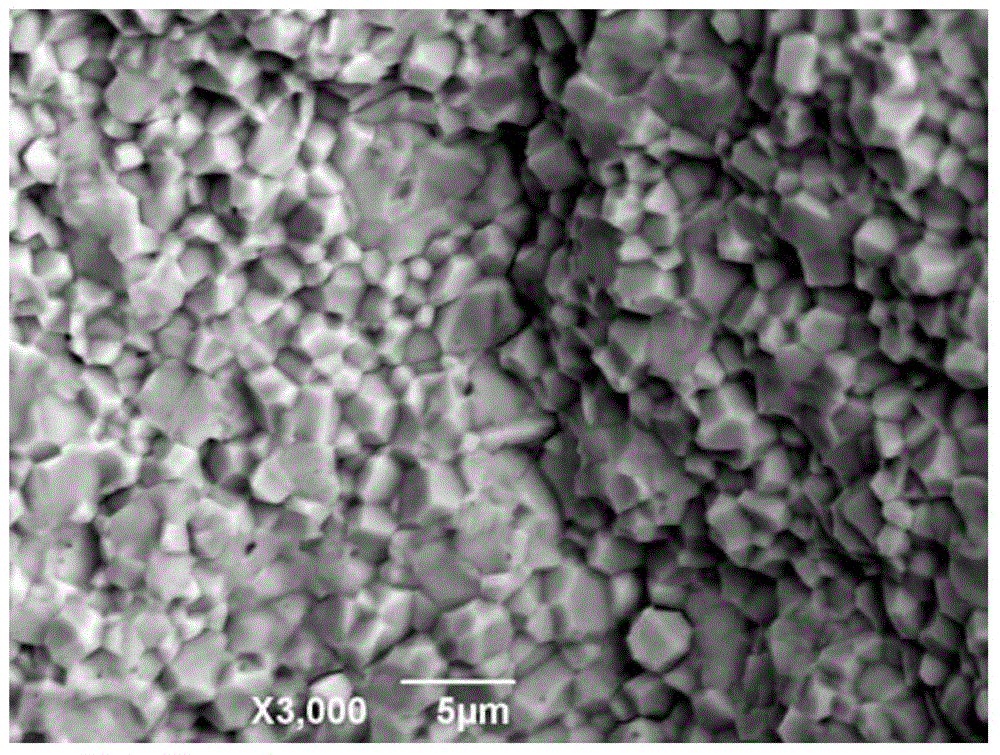

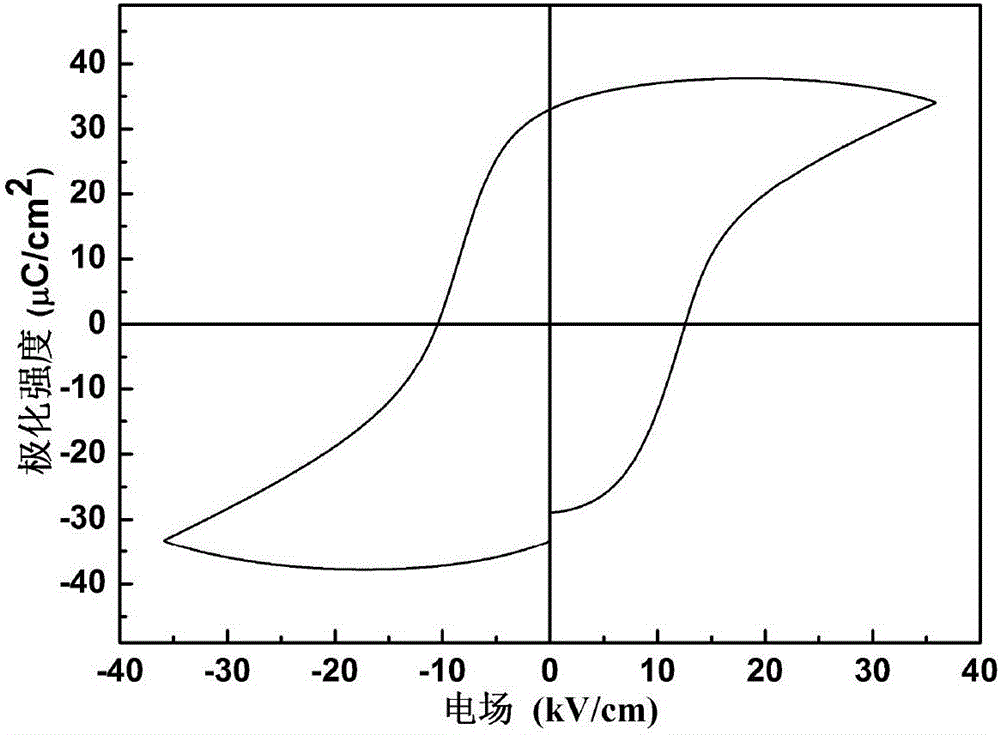

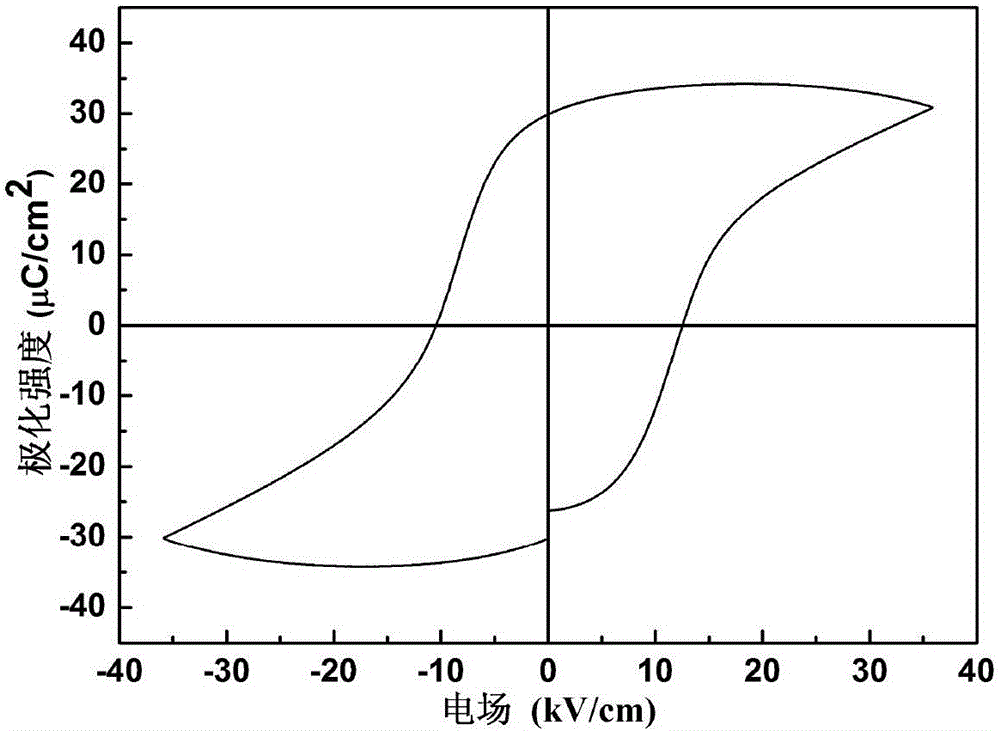

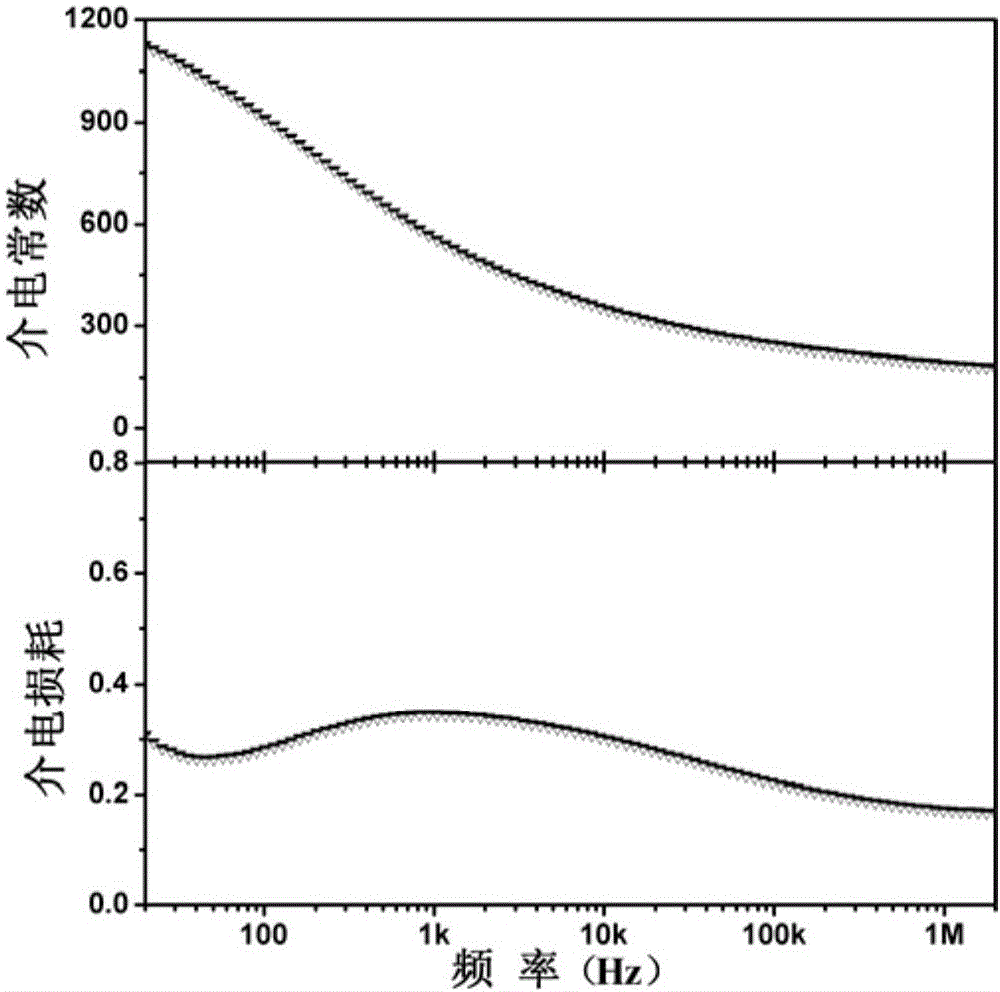

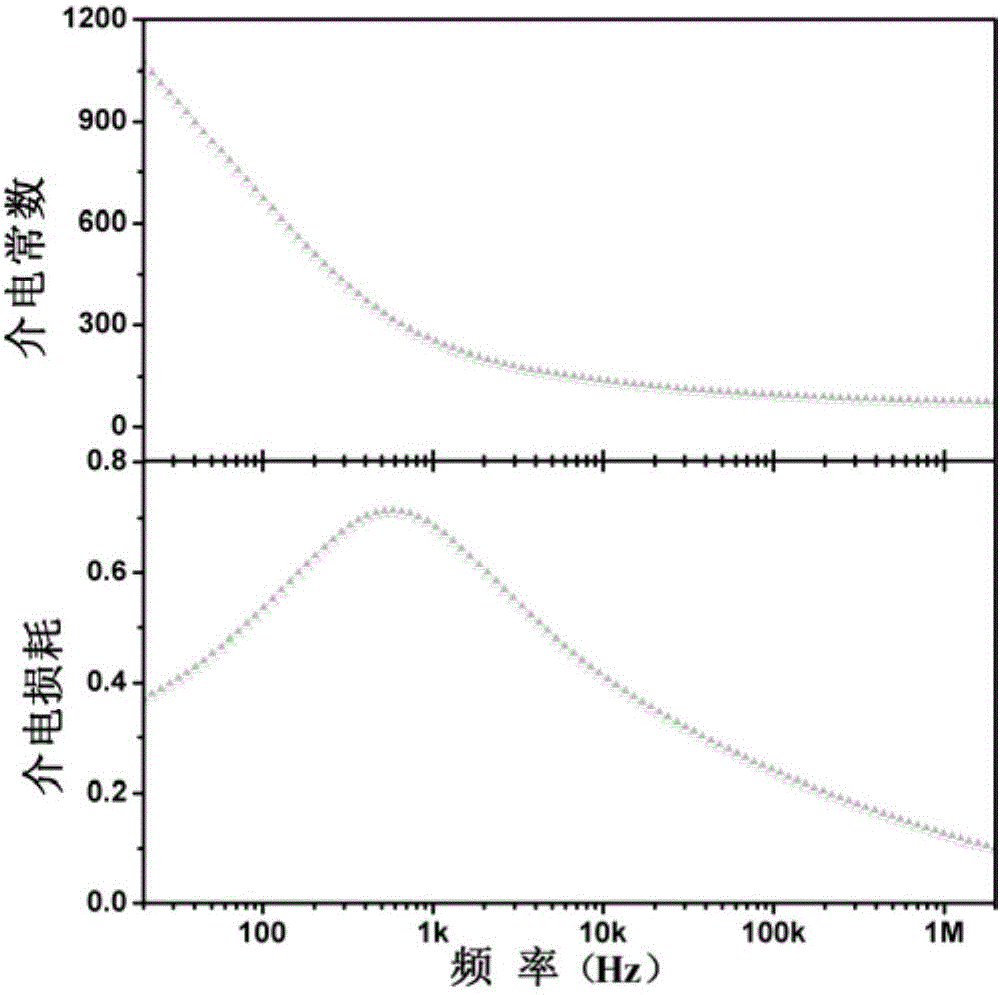

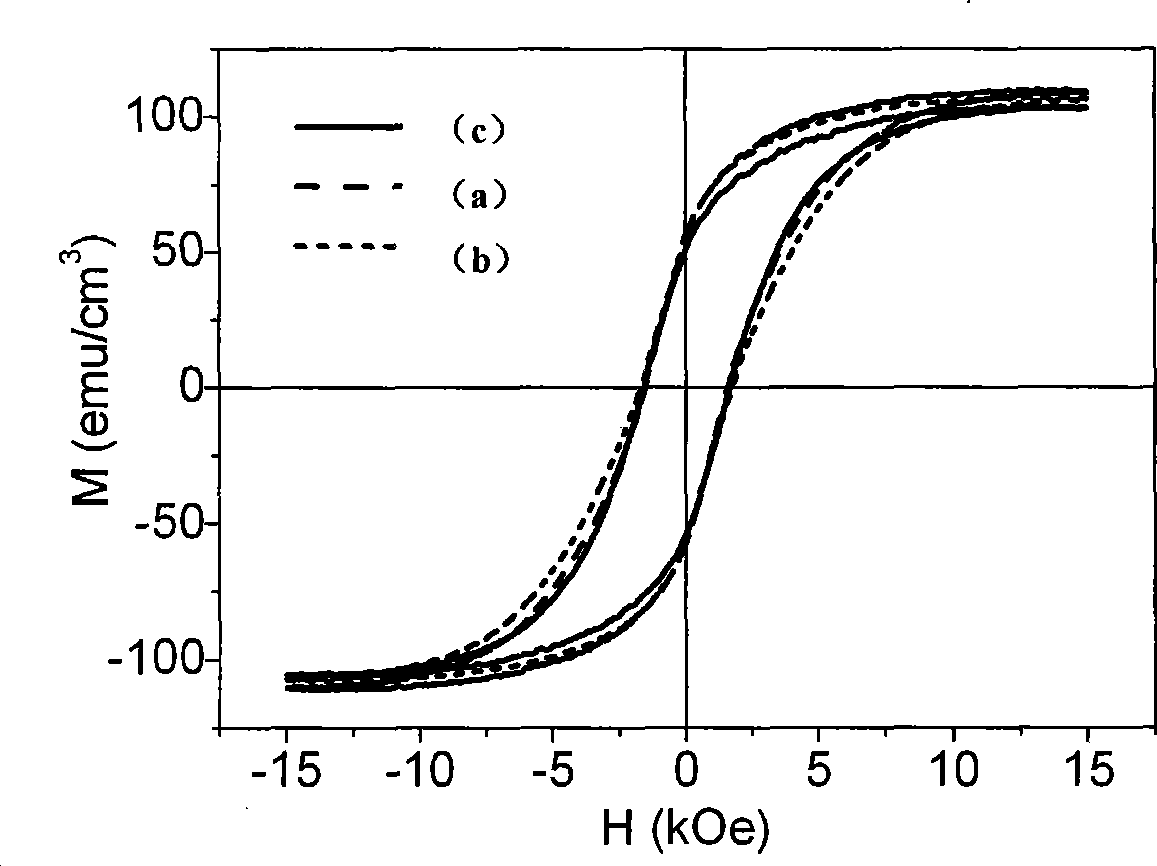

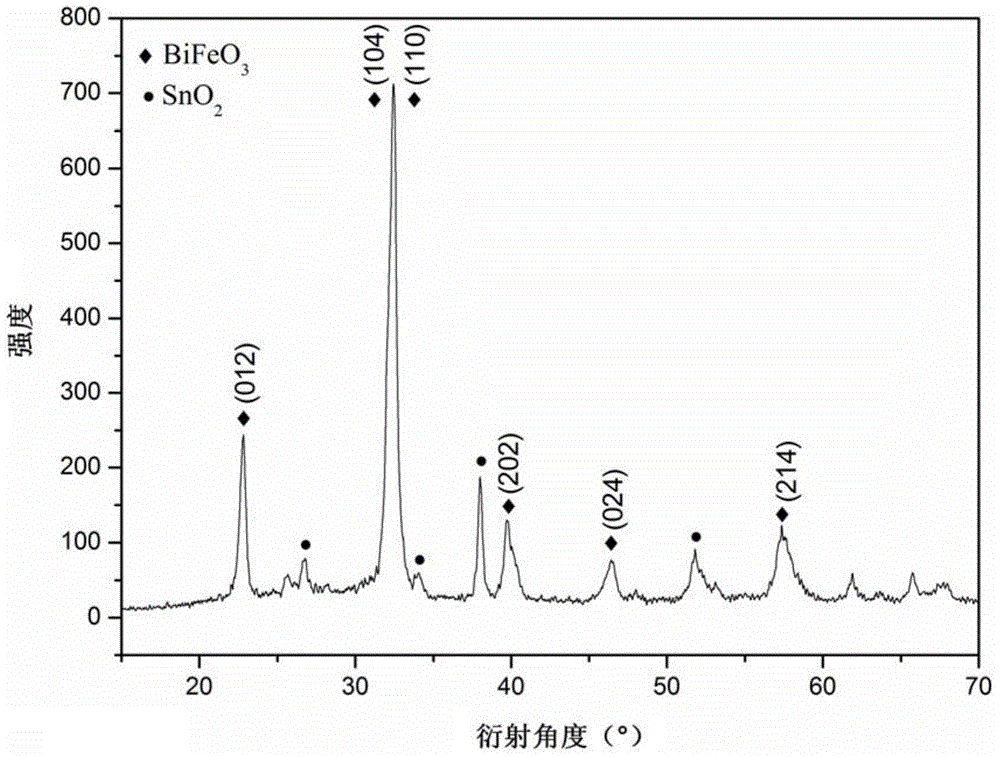

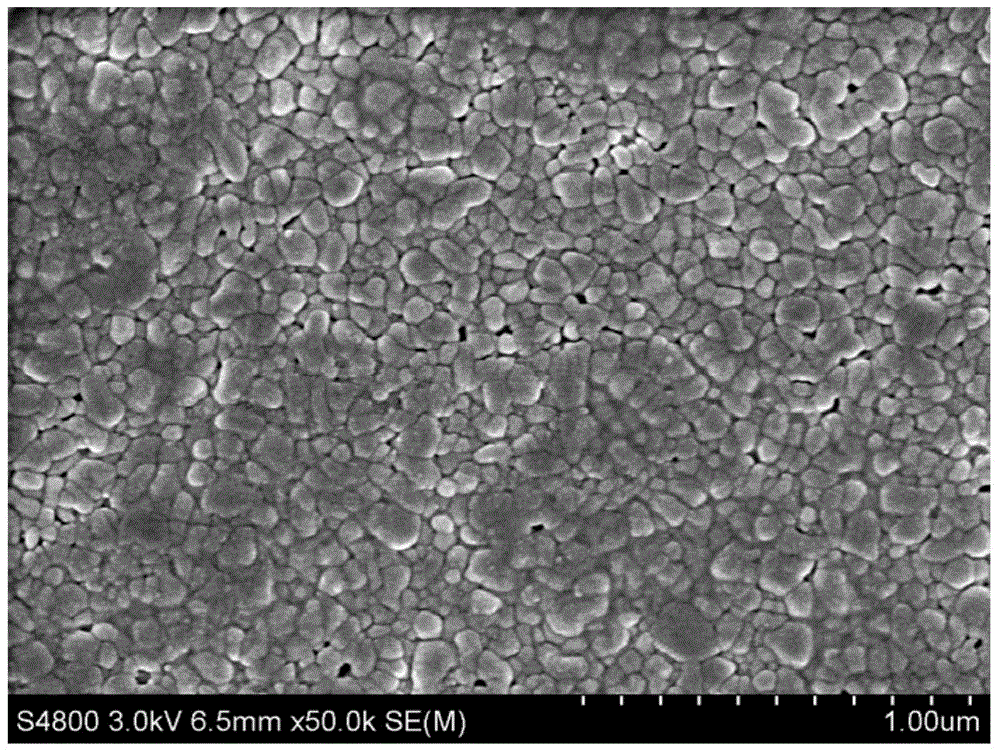

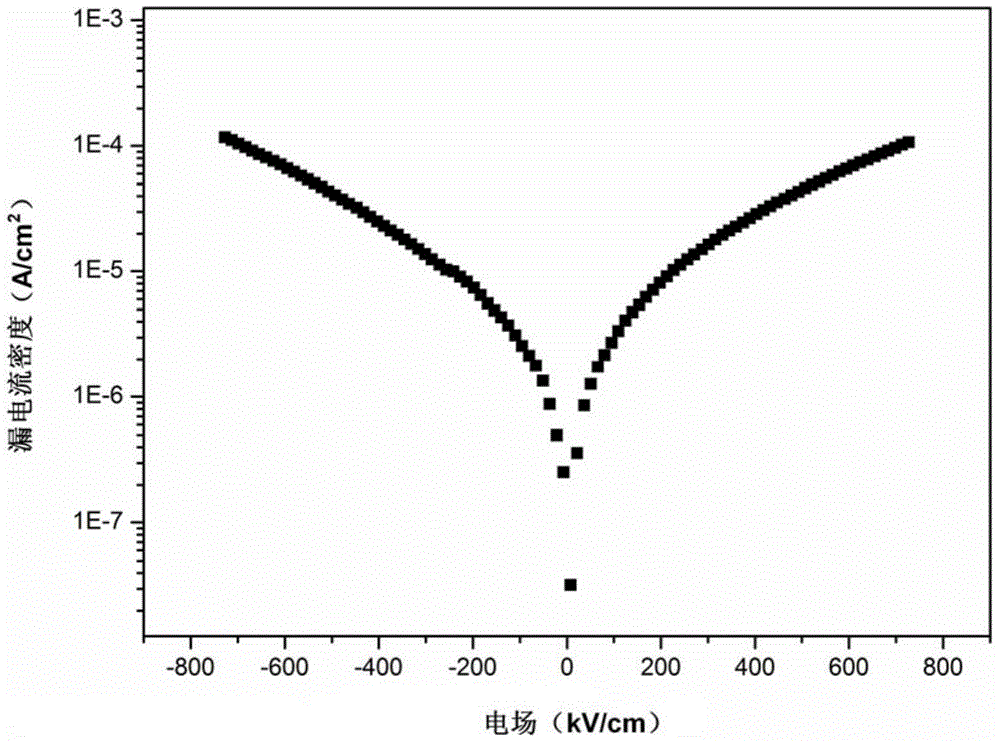

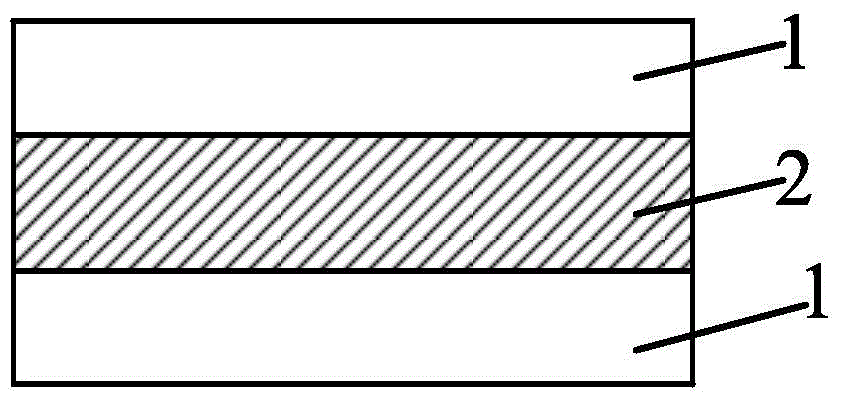

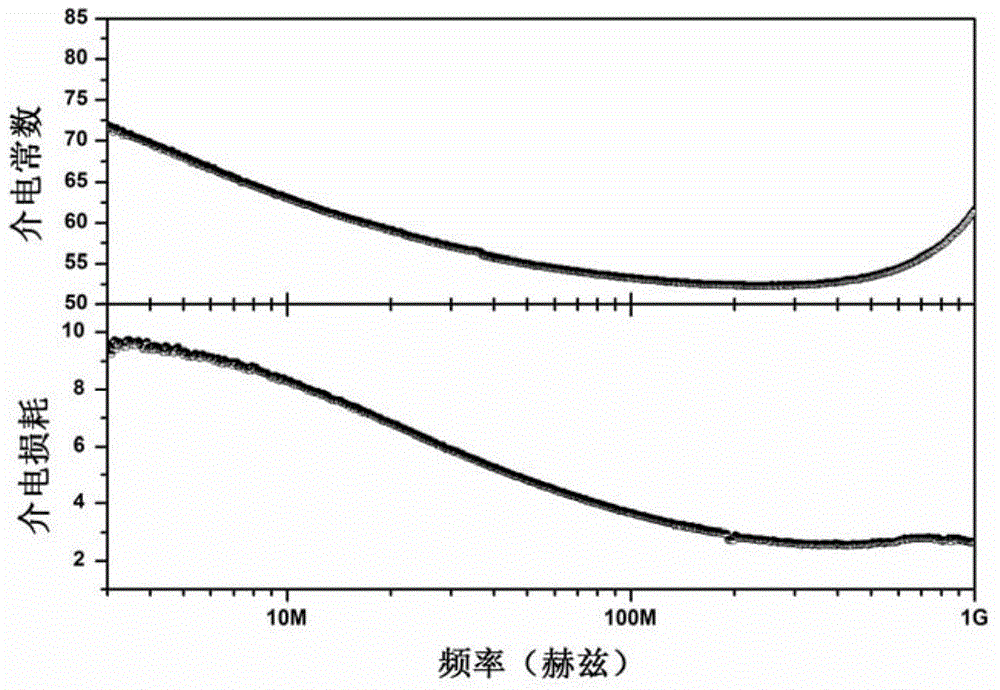

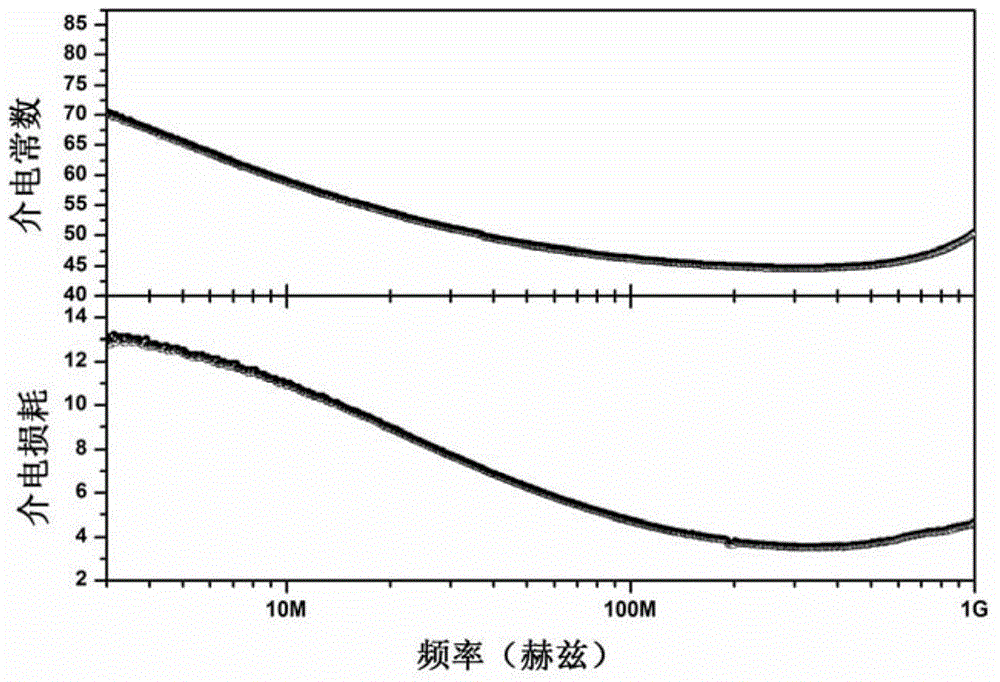

Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof

The invention provides a Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and a preparation method thereof. The method comprises the following steps: preparing a Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 precursor solution from bismuth nitrate, praseodymium nitrate, hydrogen nitrate AE, ferric nitrate and manganous nitrate, wherein AE is Sr, Ca or Ba, and x=0.02-0.05; spinning the precursor solution on a substrate; and then spinning, drying and annealing, so as to obtain the Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film. The Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film is simple in demands on equipment; the experiment condition is easy to achieve; the doping amount is easy to control; the ferroelectric property of the film can be greatly improved; and the prepared Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film is good in uniformity, low in leakage current, and low in coercive field, and has relatively high remanent polarization.

Owner:SHAANXI UNIV OF SCI & TECH

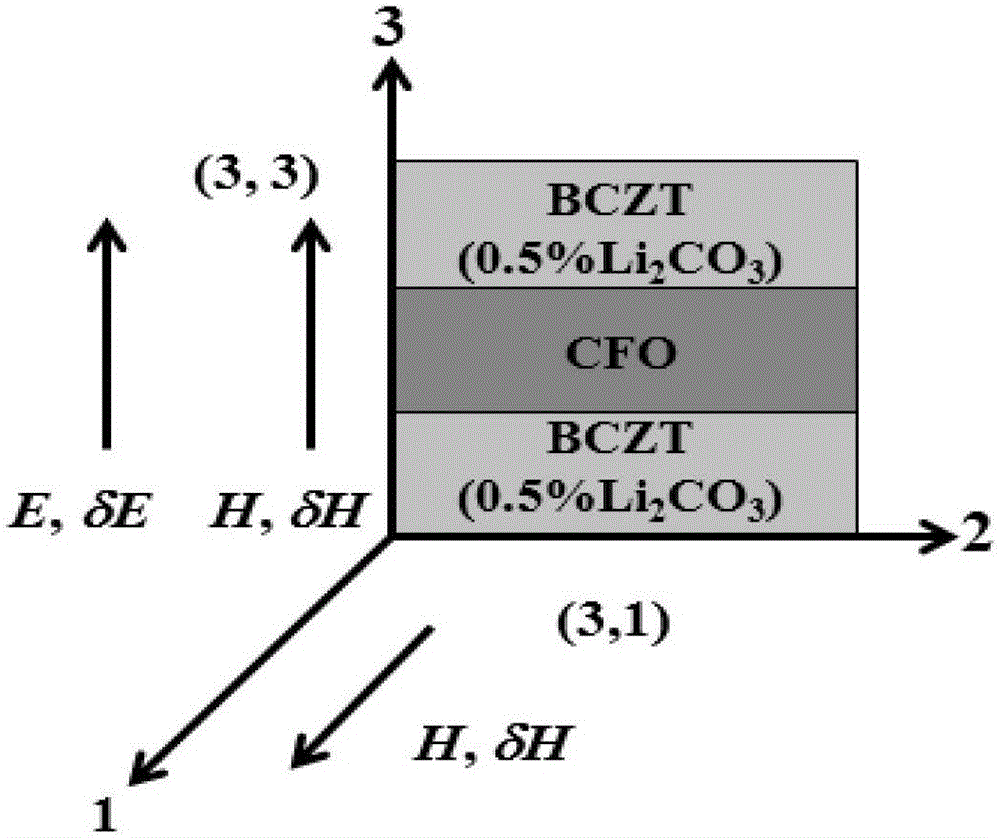

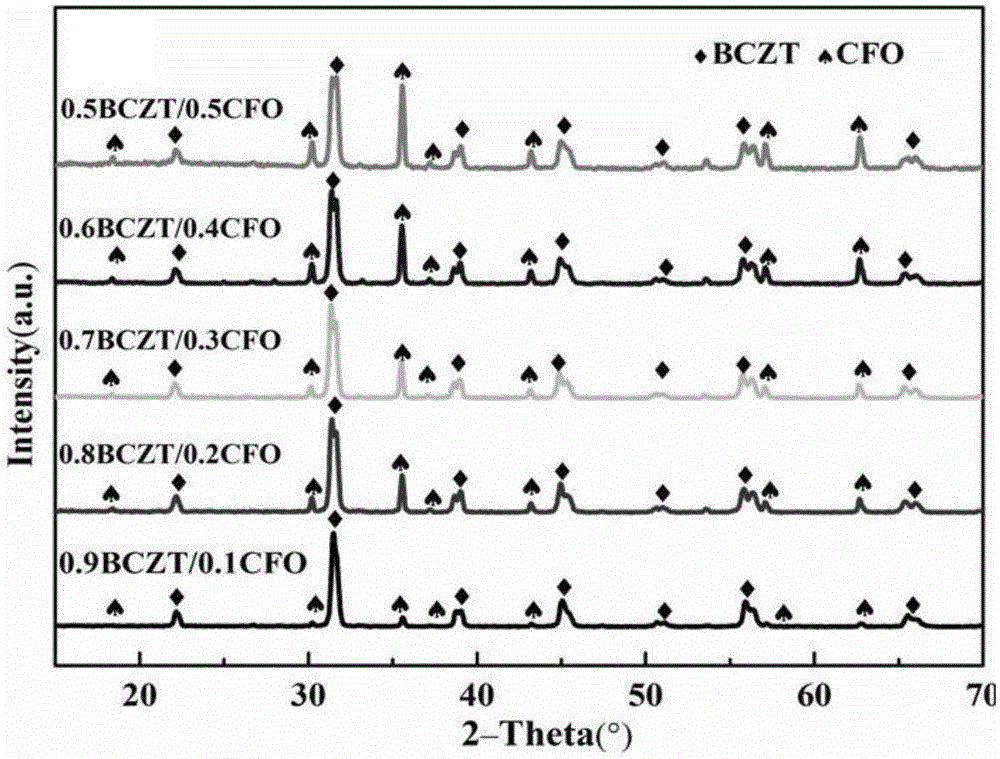

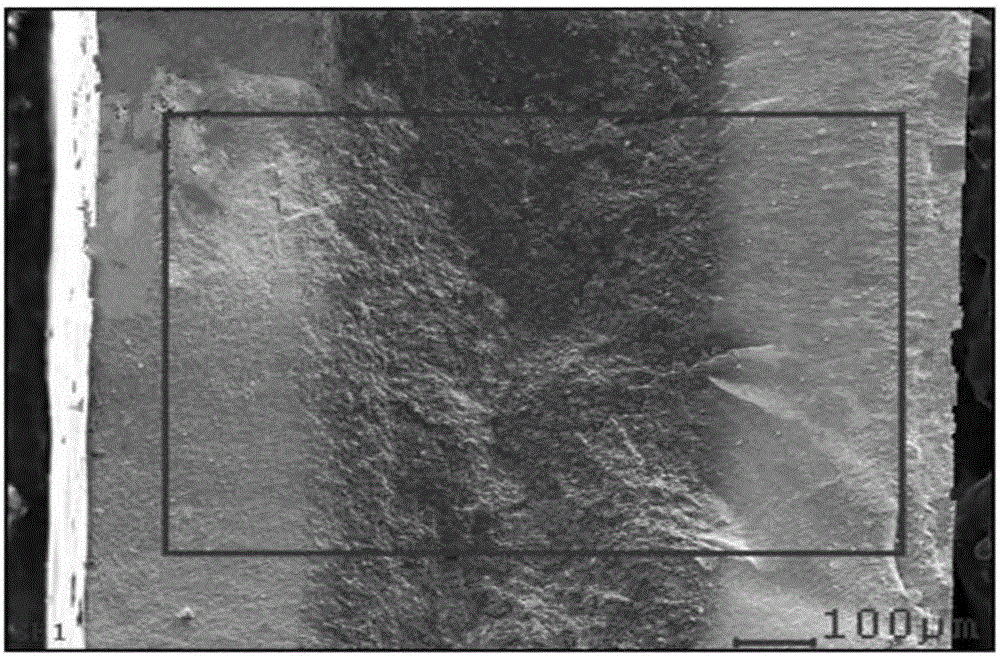

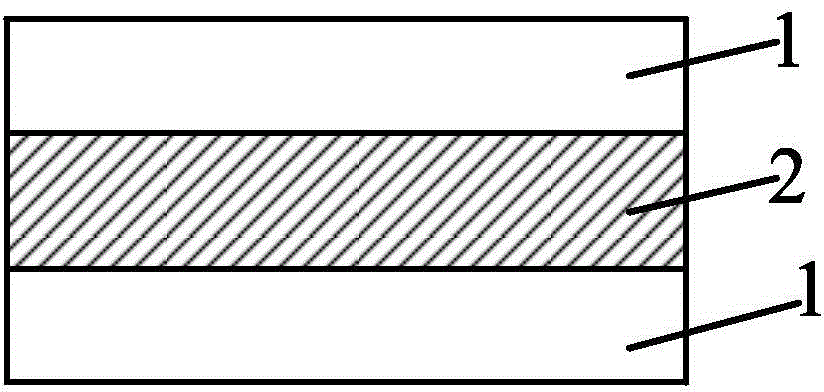

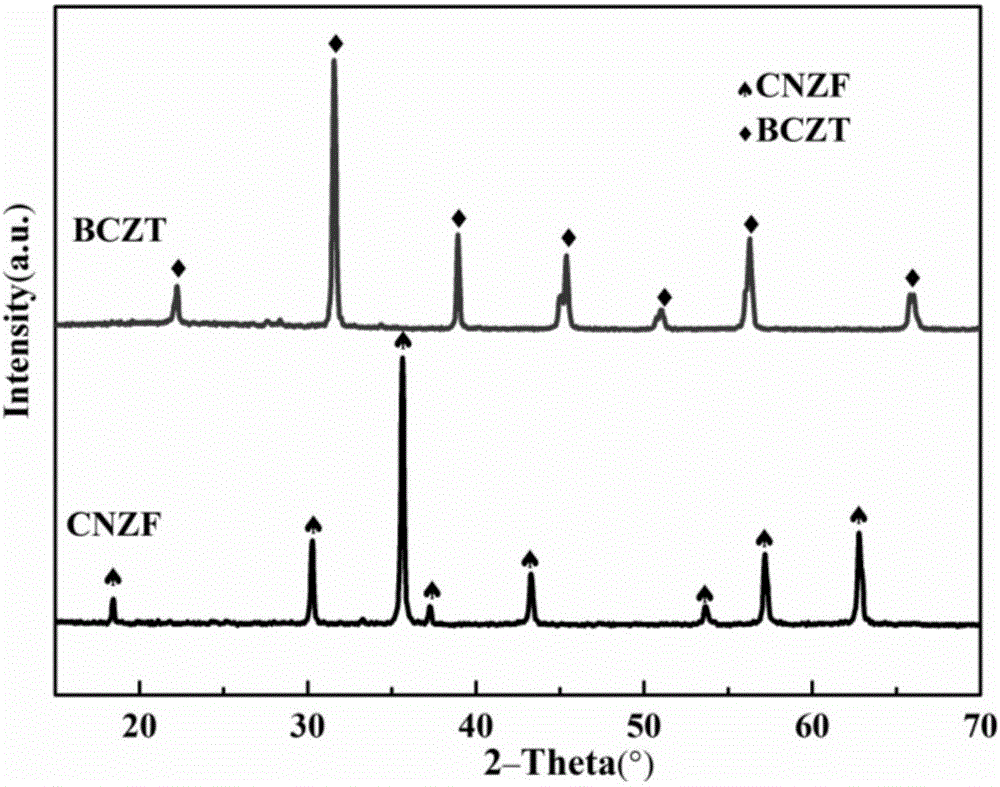

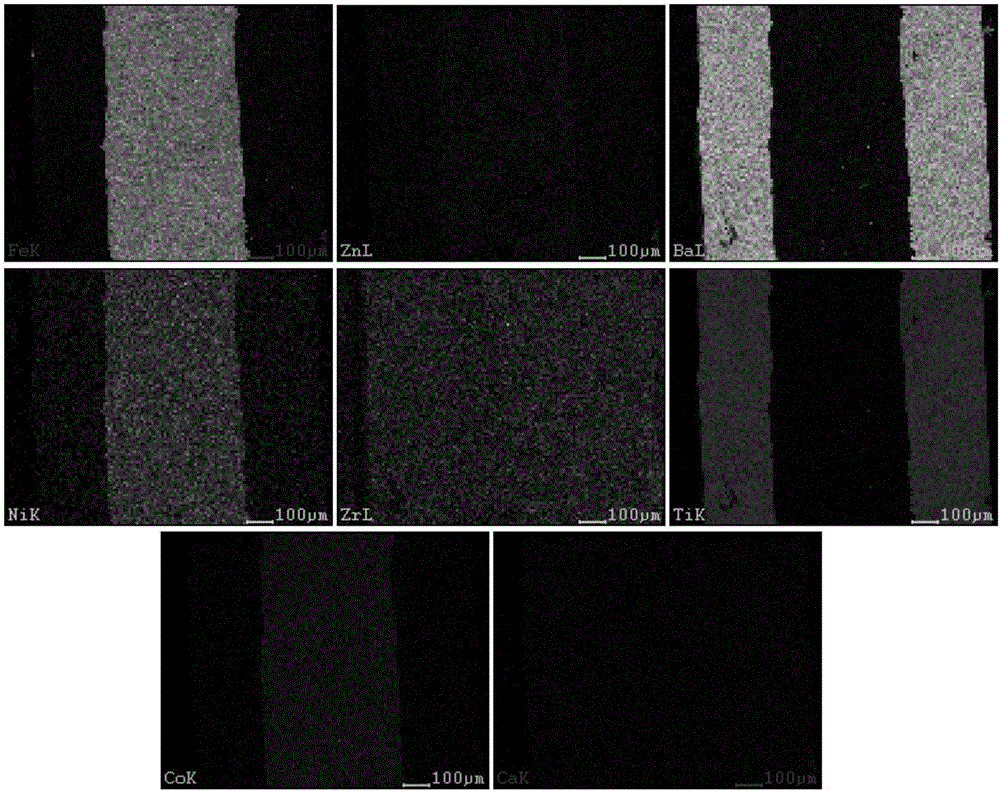

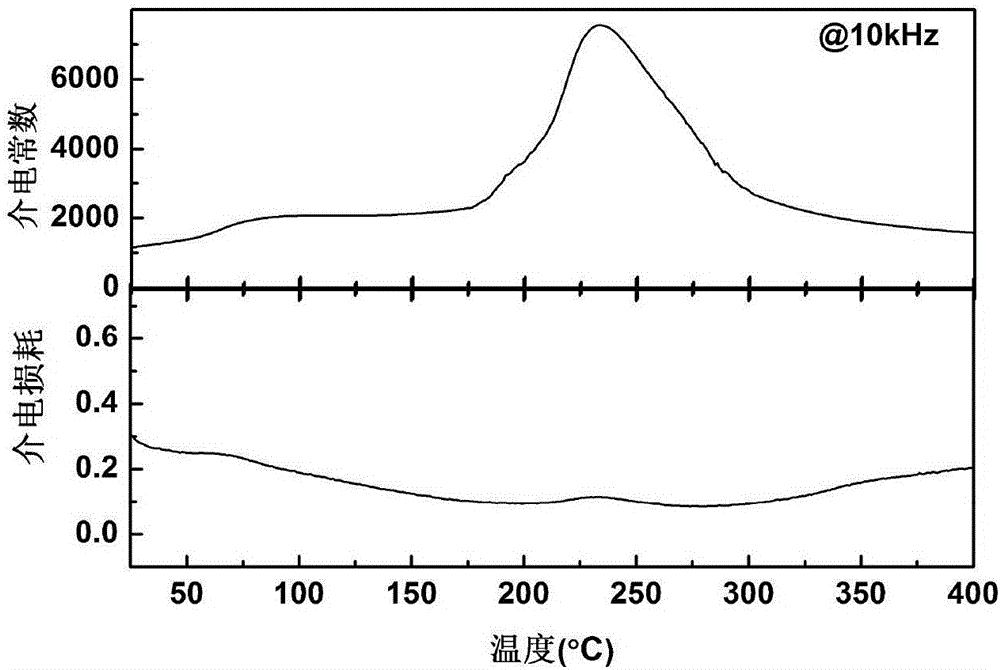

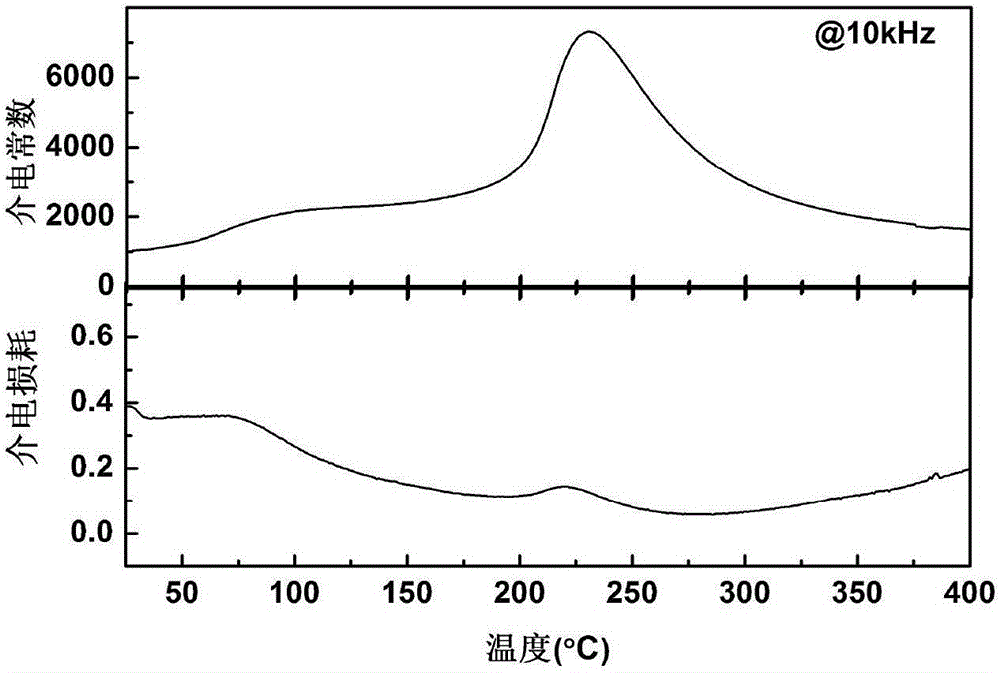

Ba0.9Ca0.1Ti0.9Zr0.1O3/CoFe2O4 layered magnetoelectric composite and preparation method thereof

The invention discloses a Ba0.9Ca0.1Ti0.9Zr0.1O3 / CoFe2O4 layered magnetoelectric composite and a preparation method thereof. The method comprises the following steps: preparing BaCO3, CaCO3, TiO2 and ZrO2 taken as raw materials respectively into precursor powder Ba0.9Ca0.1Ti0.9Zr0.1O3 and Co2O3, and preparing Fe2O3 as a raw material into precursor powder CoFe2O4; adding the two kinds of powder into a polyvinyl alcohol (PVA) aqueous solution, pelleting respectively, and pressing the two kinds of materials into a sandwich-shaped green body, wherein an upper layer and a lower layer are made from Ba0.9Ca0.1Ti0.9Zr0.1O3, and a middle layer is made from CoFe2O4; sintering the prepared green body at the temperature of 1,100 DEG C to obtain the layered magnetoelectric composite. The prepared Ba0.9Ca0.1Ti0.9Zr0.1O3 / CoFe2O4 layered magnetic composite has the advantages of simple preparation process, low cost, high dielectric performance, high ferroelectric performance, high magnetic performance and high magnetoelectric coupling performance.

Owner:SHAANXI UNIV OF SCI & TECH

Layered magnetoelectric composite material and preparation method thereof

The invention discloses a layered magnetoelectric composite material and a preparation method thereof. The preparation method comprises the following steps: granulating 0.65BaTiO3-0.35(Na0.5Bi0.5)TiO3 powder and BiY2Fe5O12 powder respectively, then carrying out compression moulding in a mould in a manner of 2-2 composite barrier layer superposition arrangement, then removing a PVA adhesive, and sintering at 1100-1150 DEG C to obtain the layered magnetoelectric composite material. According to the layered magnetoelectric composite material and the preparation method thereof disclosed by the invention, because the 0.65BaTiO3-0.35(Na0.5Bi0.5)TiO3 powder and the BiY2Fe5O12 powder are moulded in the manner of 2-2 composite barrier layer superposition arrangement to co-sinter a ferroelectric phase and a ferromagnetic phase in a layered composite manner, inter-reaction between the two phases can be effectively suppressed, thus keeping the respective characteristics, and enabling the layered magnetoelectric composite material to be good in both ferroelectricity and ferromagnetism.

Owner:SHAANXI UNIV OF SCI & TECH

Microwave dielectric ceramic material with high magnetic conductivity and preparation method thereof

The invention relates to a microwave dielectric ceramic material with high magnetic conductivity and a preparation method thereof. The ceramic material comprises a complex system (1-x)A(GazNb1-z)yTi1-yO3 / (x)B(MnO4) composed of a main body A(GazNb1-z)yTi1-yO3 and a complex B(MnO4)3 wrapping the main body, wherein x is more than or equal to 0.20 mol but less than or equal to 0.50 mpl, and y is morethan or equal to 0.50 mol but less than or equal to 1.00 mol; A in the main body is one or more of Ni, Zn, Pb or Co; and B in the complex is one or more of Y, Yb, Fe, Ce, La or Lu. The preparation method of the microwave dielectric ceramic material provided by the invention adopts a microwave assisted sintering method, and the microwave dielectric ceramic material prepared by the method has a bimorphic crystal structure and a good microwave absorption property, and is low in electromagnetic loss, low in dielectric constant, high in magnetic conductivity and high in sintering speed.

Owner:WUXI INST OF ARTS & TECH

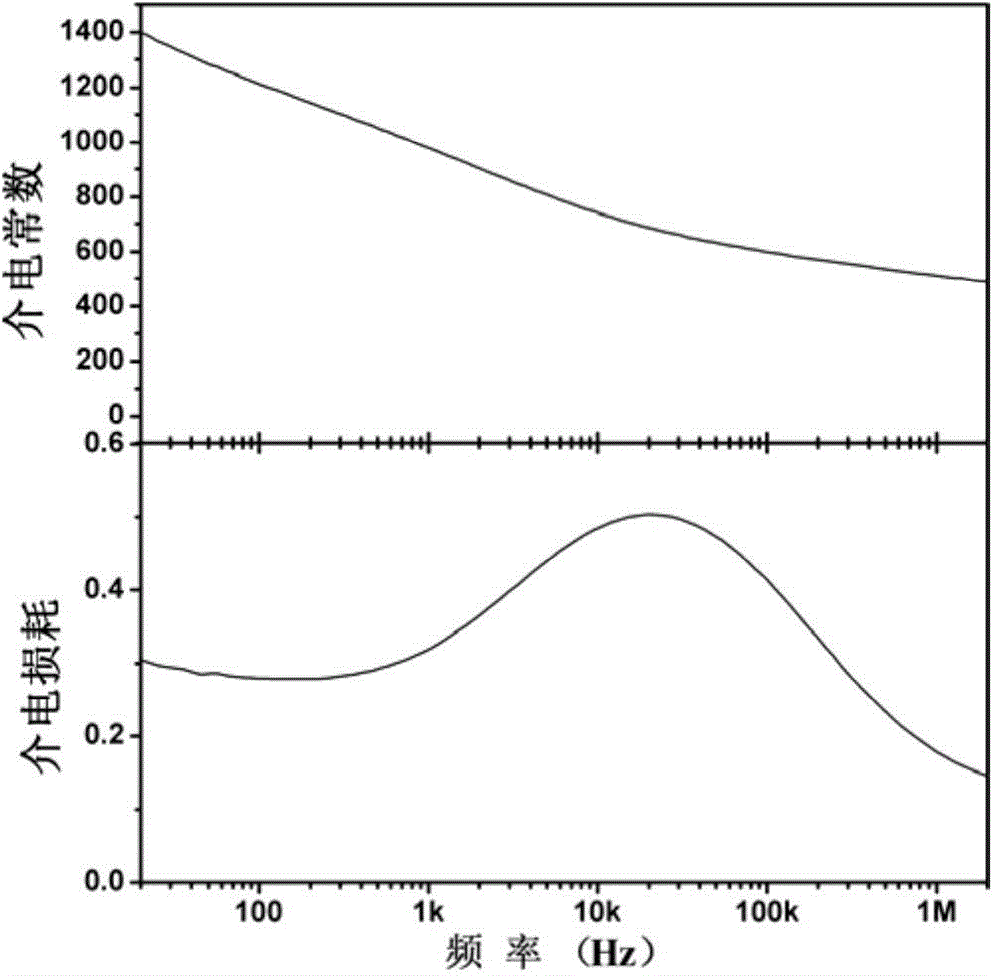

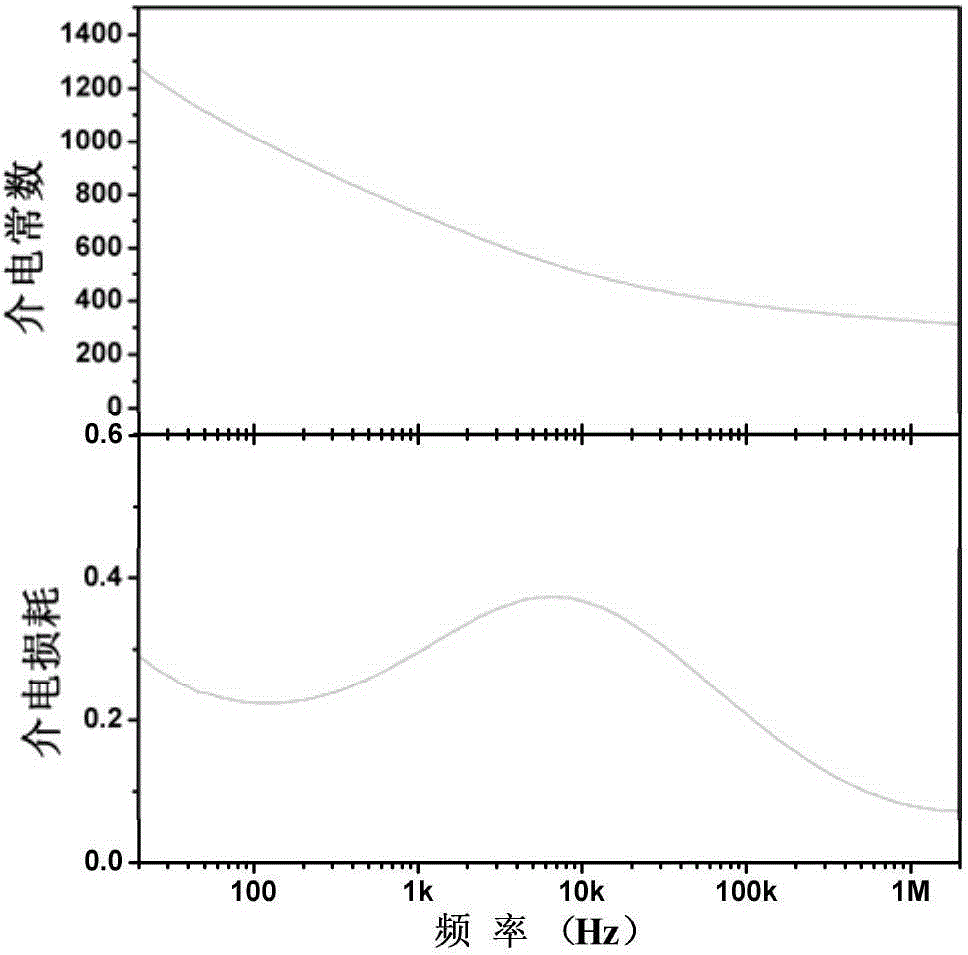

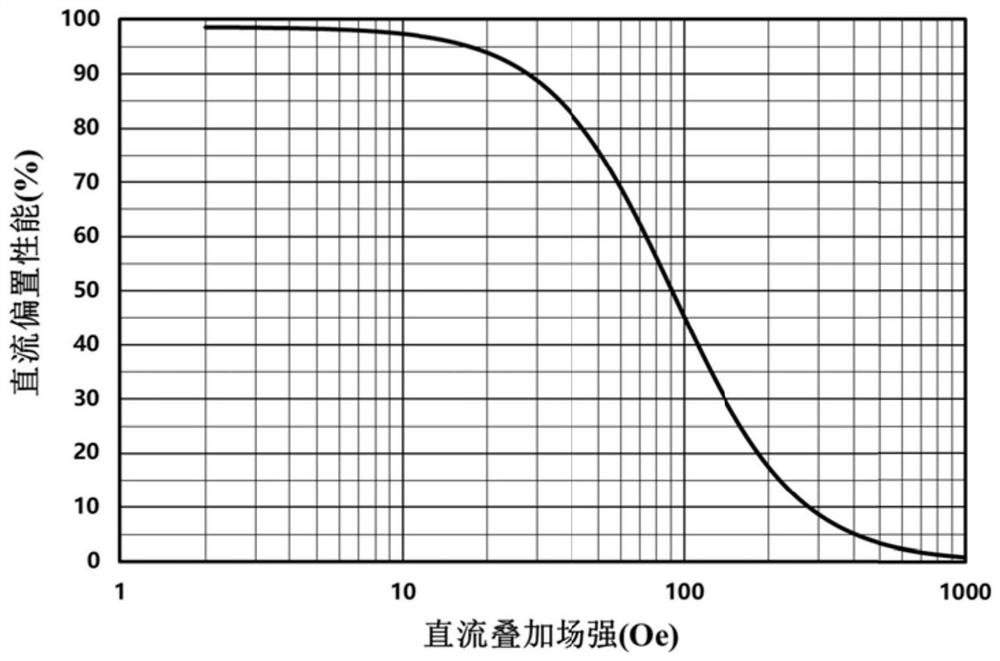

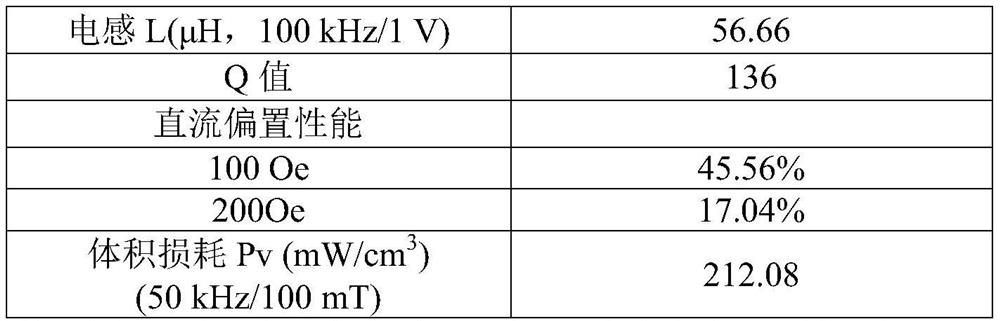

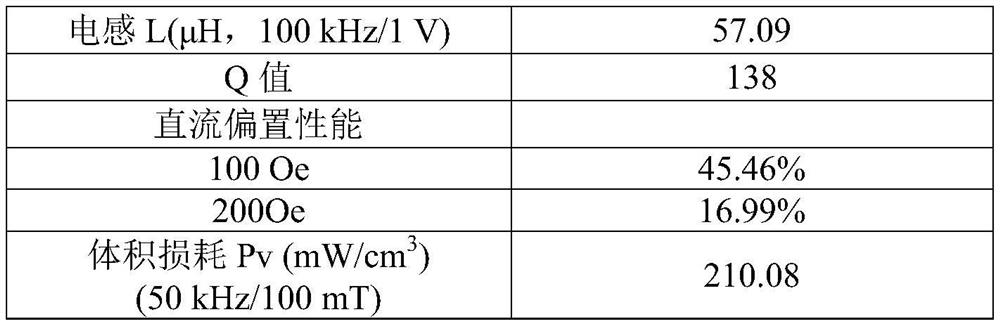

Iron-silicon-aluminum soft magnetic powder core with high direct-current bias performance and preparation method of iron-silicon-aluminum soft magnetic powder core

PendingCN111696744AUniform coating insulation effectDC bias characteristic optimizationInorganic material magnetismInductances/transformers/magnets manufactureEpoxyPhysical chemistry

The invention belongs to the technical field of soft magnetic materials, and relates to an iron-silicon-aluminum soft magnetic powder core with high direct-current bias performance and a preparation method of the magnetic powder core. The method comprises the following steps: selecting crushing-method iron-silicon-aluminum magnetic powder with the particle size of less than 200 meshes, andcarryingout insulation coating treatment on the iron-silicon-aluminum powder particles by using organic silicon modified epoxy resin to preparethe iron-silicon-aluminum soft magnetic powder core with the effective magnetic conductivity of 75.The soft magnetic powder core has excellent soft magnetic performance, especially the direct current bias performance of the soft magnetic powder core is greatly improved, the direct current bias performance of the powder core under the condition of 100Oe is higher than 40%, and the volume loss Pcv under the conditions of 50kHz and 100mT is lower than 250mW / cm <3 >.

Owner:SINOSTEEL NANJING NEW MATERIALS RES INST CO LTD

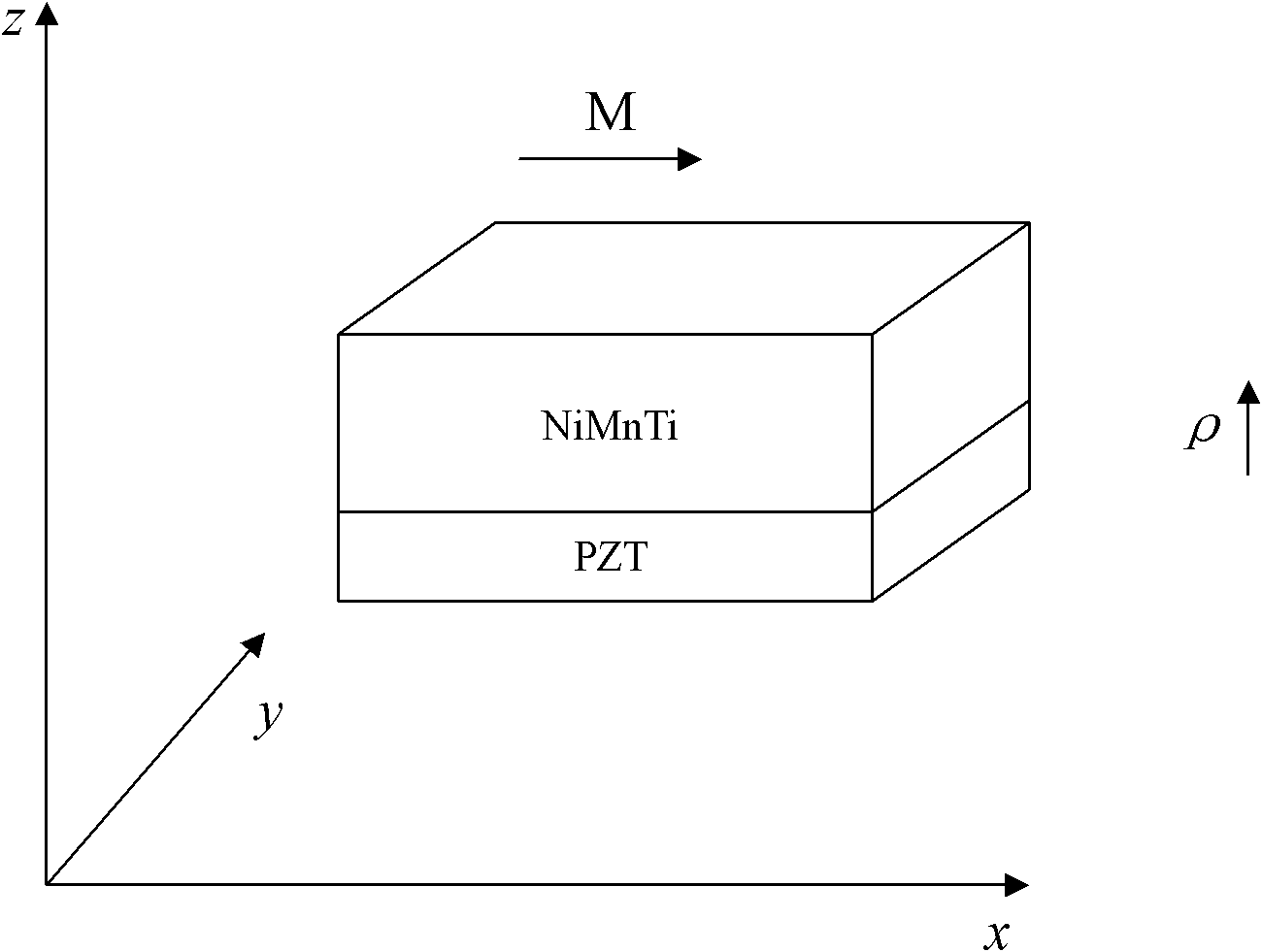

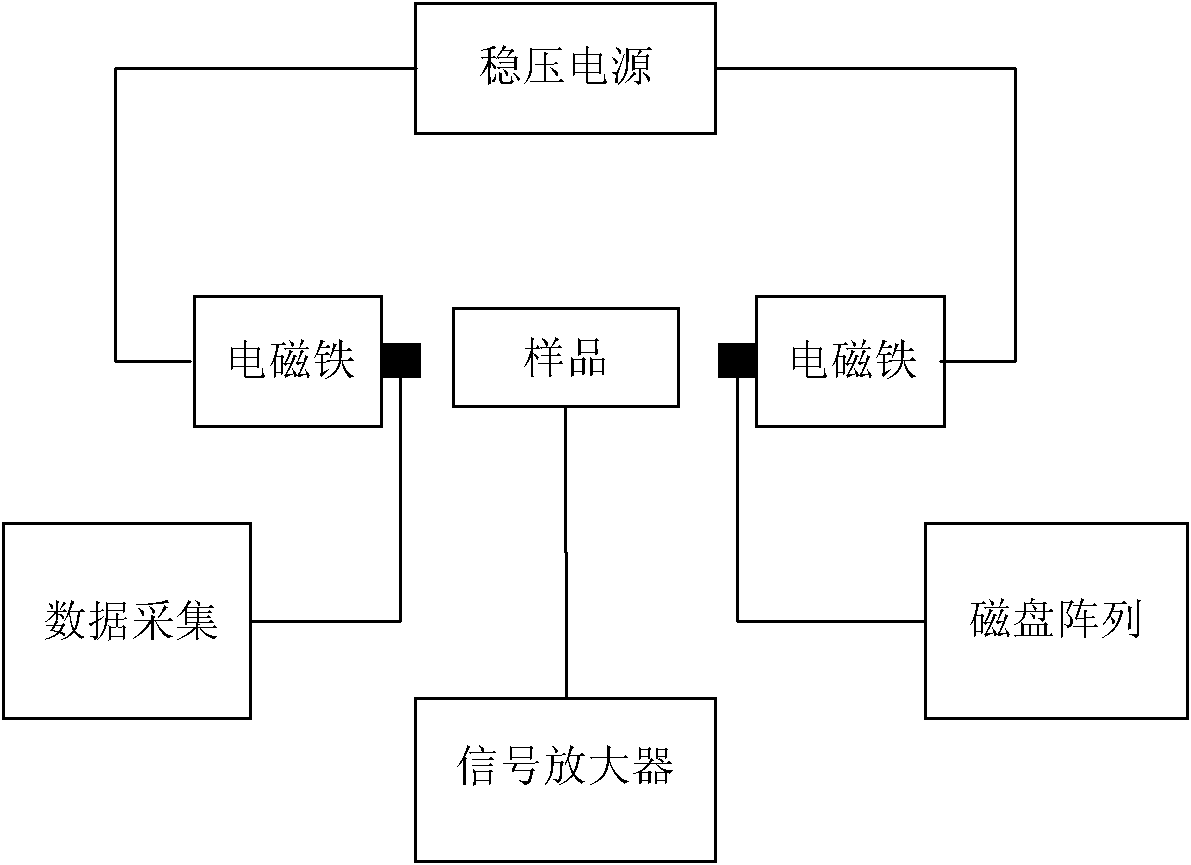

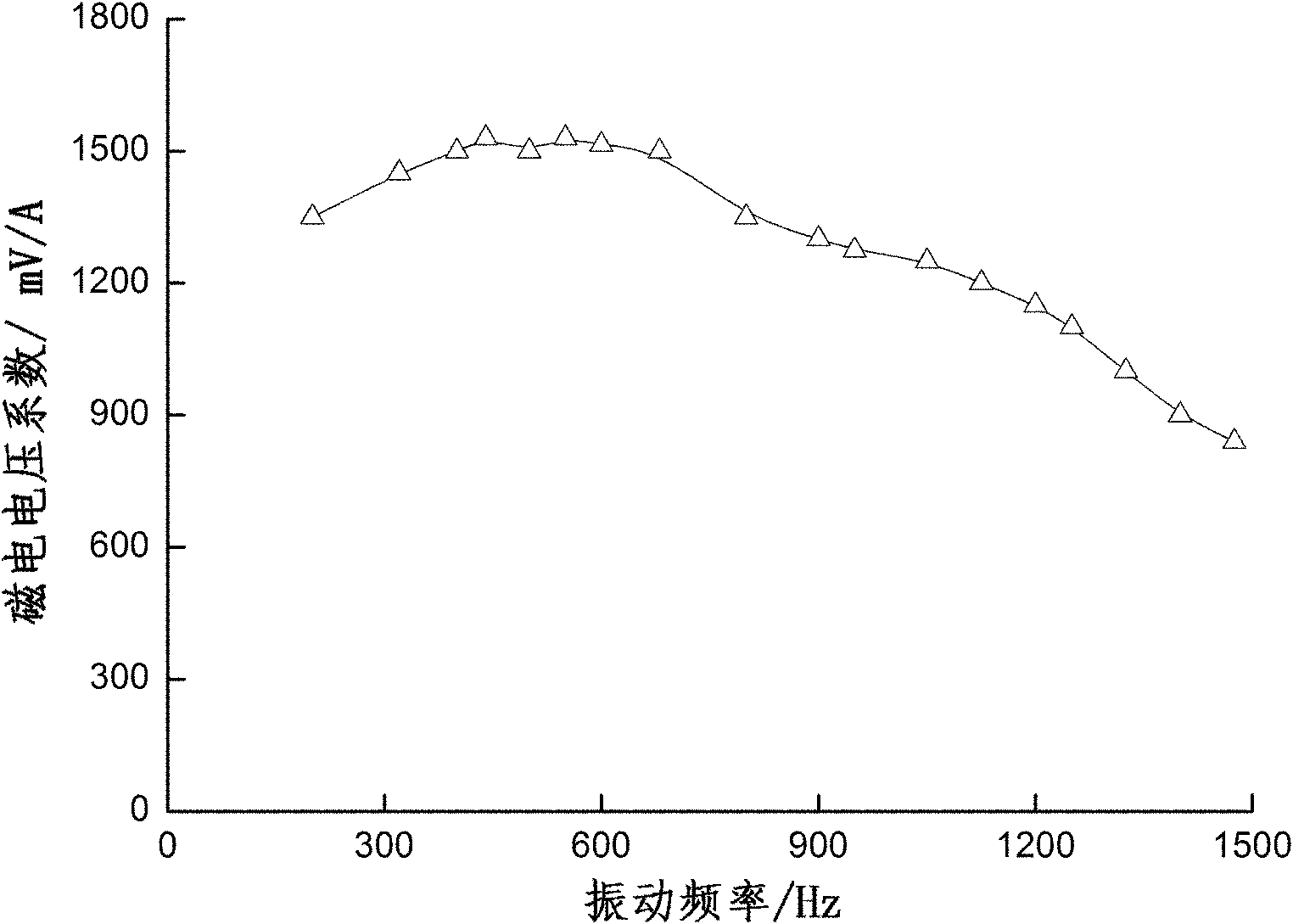

Method for increasing magnetoelectric property of gradient material

InactiveCN102130292AImprove magnetoelectric propertiesMagnetoelectric performance adjustablePiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive material selectionLead zirconate titanateGradient material

The invention relates to a method for increasing a magnetoelectric property of a gradient material, comprising the step of preparing Ni-based alloy and piezoelectric ceramics into a gradient material, wherein the Ni-based alloy is Ni / Mn / Ti, and the piezoelectric ceramics is PZT (Lead Zirconate Titanate) and belongs to ferroelectric ceramics. Compared with the traditional gradient material, the gradient material provided by the invention has the characteristics of high magnetoelectric property, simple preparation process, stabile property, strong designability, and by changing the method for designing and preparing the material, the magnetoelectric property of the material can be obviously improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method multi-field coupling preparation magnetoelectric composite

InactiveCN103066201BImprove magnetoelectric propertiesGalvano-magnetic device manufacture/treatmentElectricityTemperature control

The invention discloses a method of a plurality of fields coupling preparation magnetoelectric composite. The multi-field coupling preparation magnetoelectric composite relates to a method of the magnetoelectric composite, and in particular to the method of force, heat, magnetism multi-field coupling preparation shape magnetoelectric composite. Rare earth super magnetic causing flexible material powder with less than 250Mu Mu granularity and a binder and a coupling agent are placed in a sealing container according to a proportion according to the requirement and are mixed evenly, thus a mixed powder is obtained. A shaping mould with a temperature controlling device is heated up to reserving temperature and the shaping mould is placed in the mixed powder. 5MPa presetting pressure is exerted after the shaping mould is heat preserved for a period of time. A certain oriented magnetic field and a certain shaping pressure are exerted, thus bonding magnet base body is obtained after the oriented magnetic field and the shaping pressure are pressure preserved for a period of time. The bonding magnet basebody is placed in a warm-box and the bonding magnet base body is solidified for a certain time, thus a bonding magnet is obtained. A stratiform magnetoelectric composite is formed by the bonding magnet and piezoelectric ceramic piece of polarization with room temperature solidifying tackiness agent in a gluing mode. The stratiform magnetoelectric composite is placed in a magnetoelectricity testing system to be tested, thus magnetoelectricity performance is obtained. Compared with the prior art, according to the method of a plurality of fields coupling preparation magnetoelectric composite, due to the fact that the force, heat, magnetism multi-field coupling way preparation magnetoelectric composite is adopted, the bonding magnet of a preferred orientation can be prepared, thus the multi-field coupling preparation magnetoelectric composite is beneficial for improving the magnetoelectricity performance.

Owner:UNIV OF SCI & TECH BEIJING

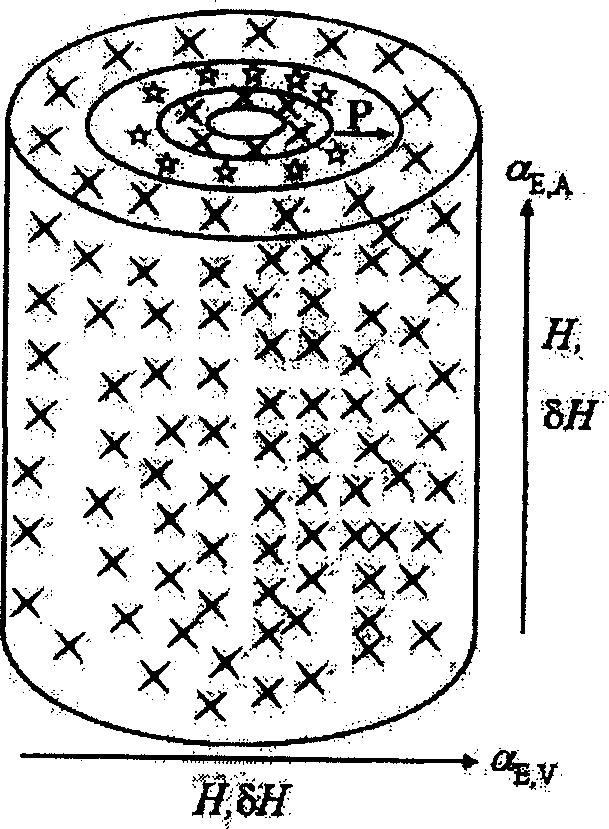

Circular cylinder-shaped composite material with giant magnetoelectric effect and method for making same

InactiveCN100502076CStrong magnetismHigh modulus of elasticityPiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblySilicone oilPiezoelectricity

The present invention relates to a cylinder shape magnetoelectricity compound material which has a large magnetoelectricity effect and belongs to the structure design and making of the magnetoelectricity compound material. The present invention is made by polarizing and plating the prior Ni electrode cylinder shape porcelain in high temperature. The present invention is the piezoelectricity porcelain which has piezoelectricity effect and is sintered and cut, and then plated with a conductive Ni electrode; then the porcelain of the Ni electrode is polarized in silicon oil and the polarized sample is plated in the prepared plating liquid till the present invention gets the necessary magnetic layer to form the magnetoelectricity compound material. Compared with the prior flat structure, the present invention has a self bound capability to make the magnetic layer couple perfectly with the piezoelectricity layer; and the present invention can enhance the magnetoelectricity effect.

Owner:UNIV OF SCI & TECH BEIJING

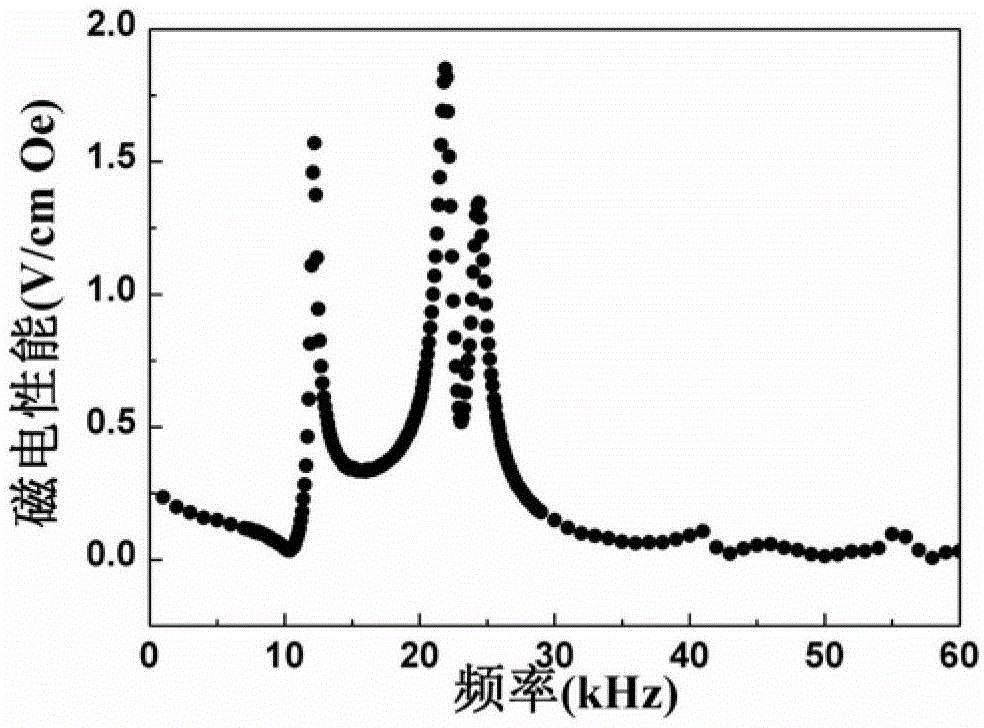

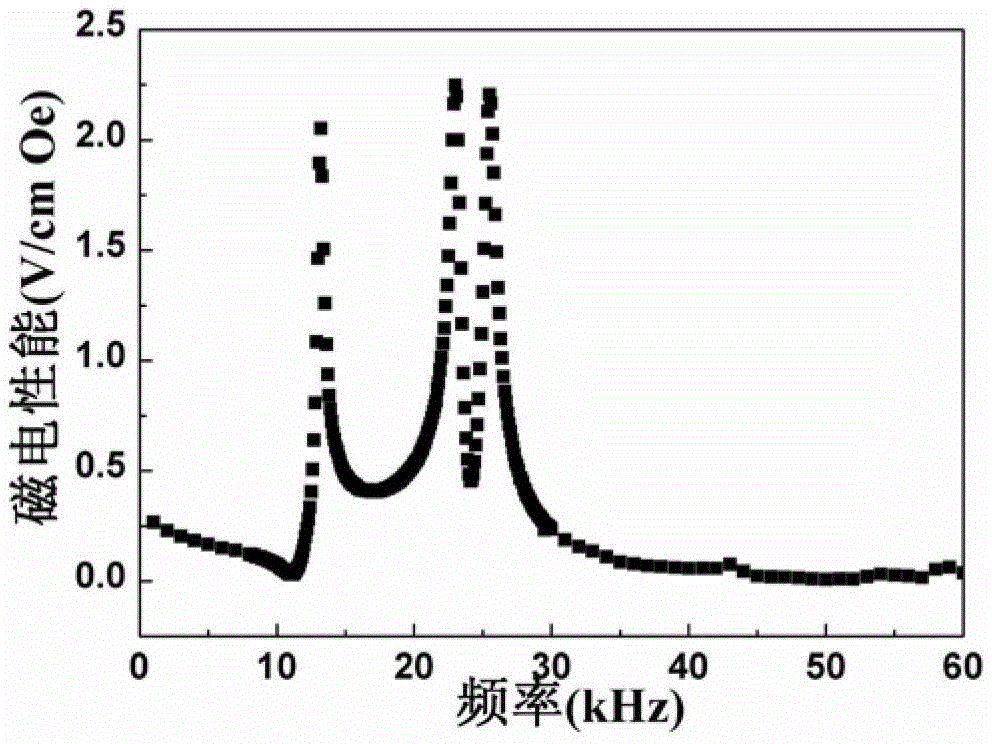

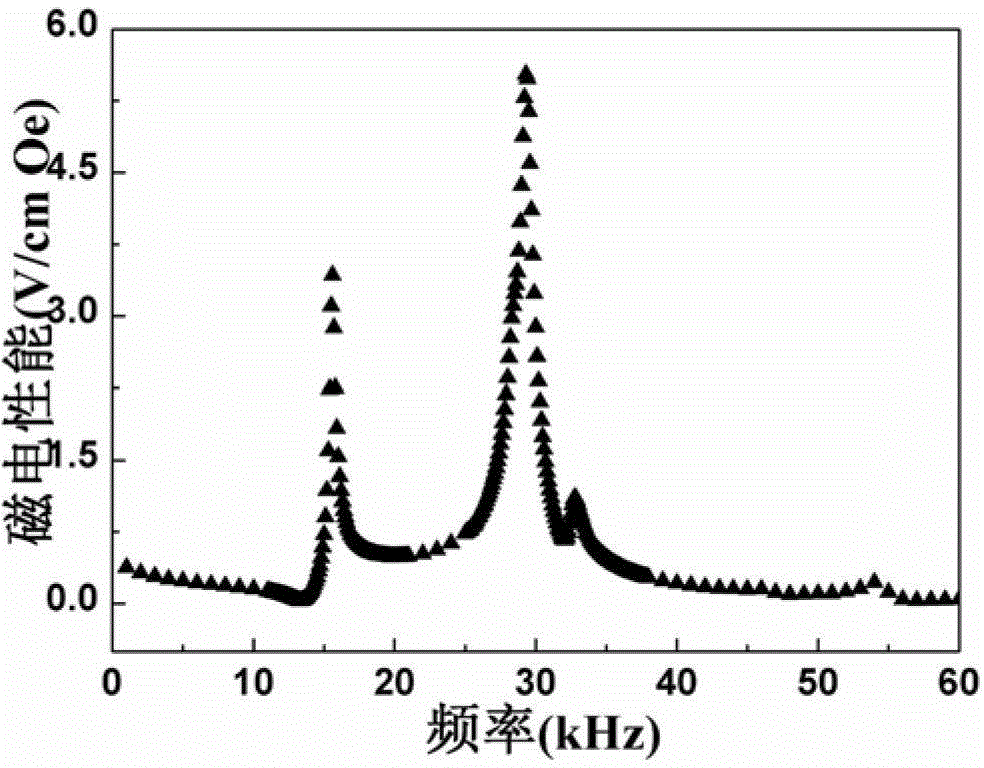

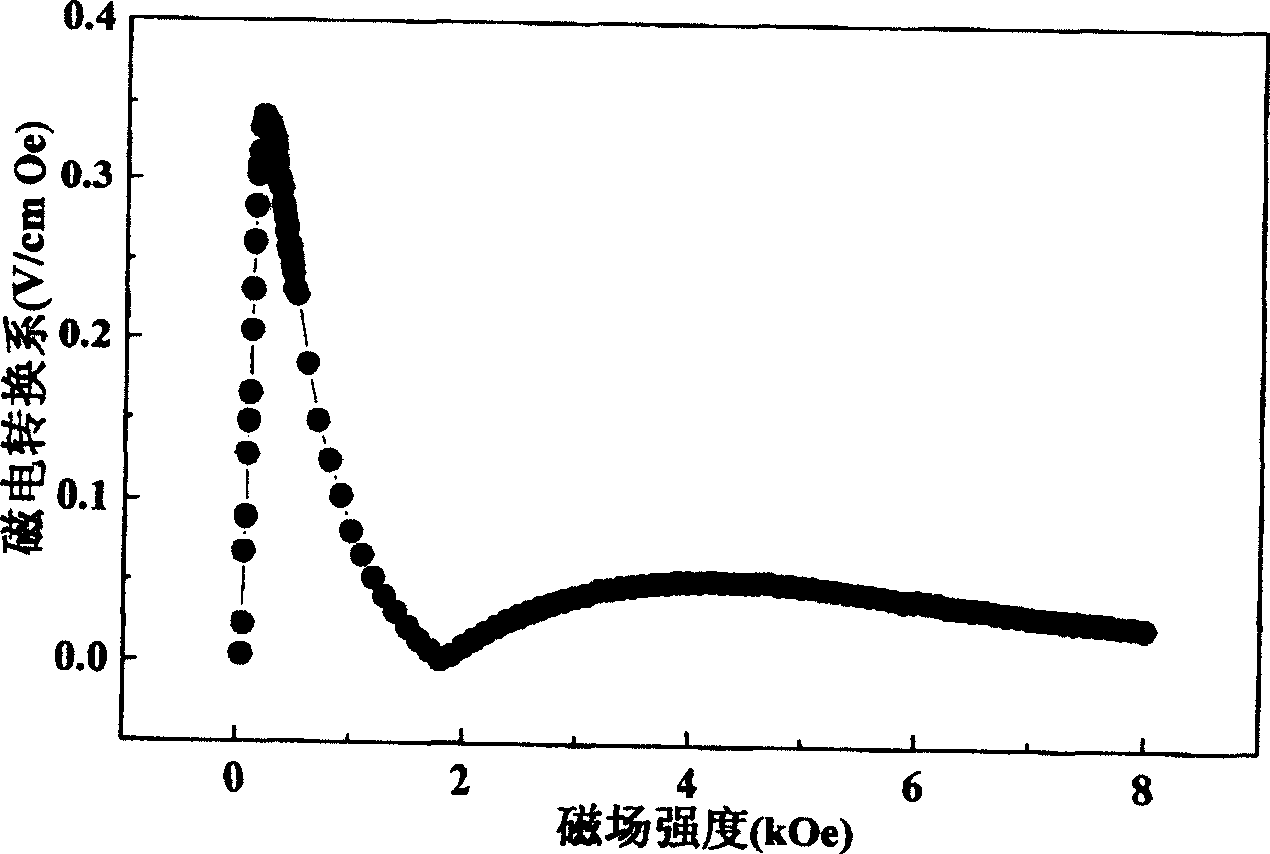

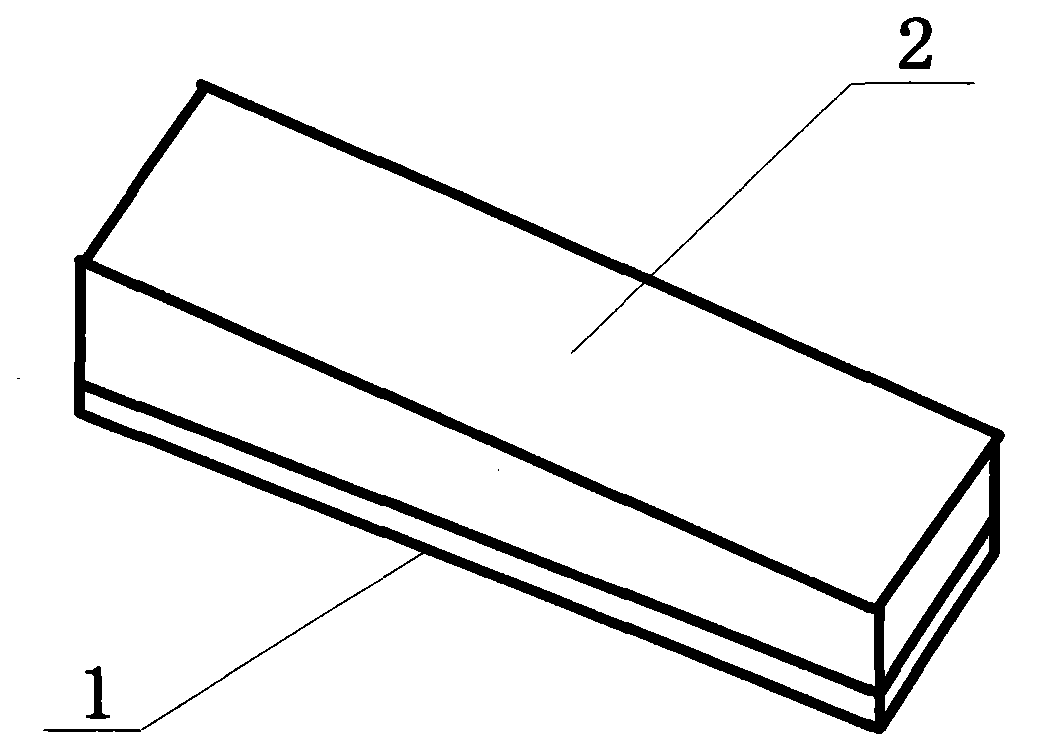

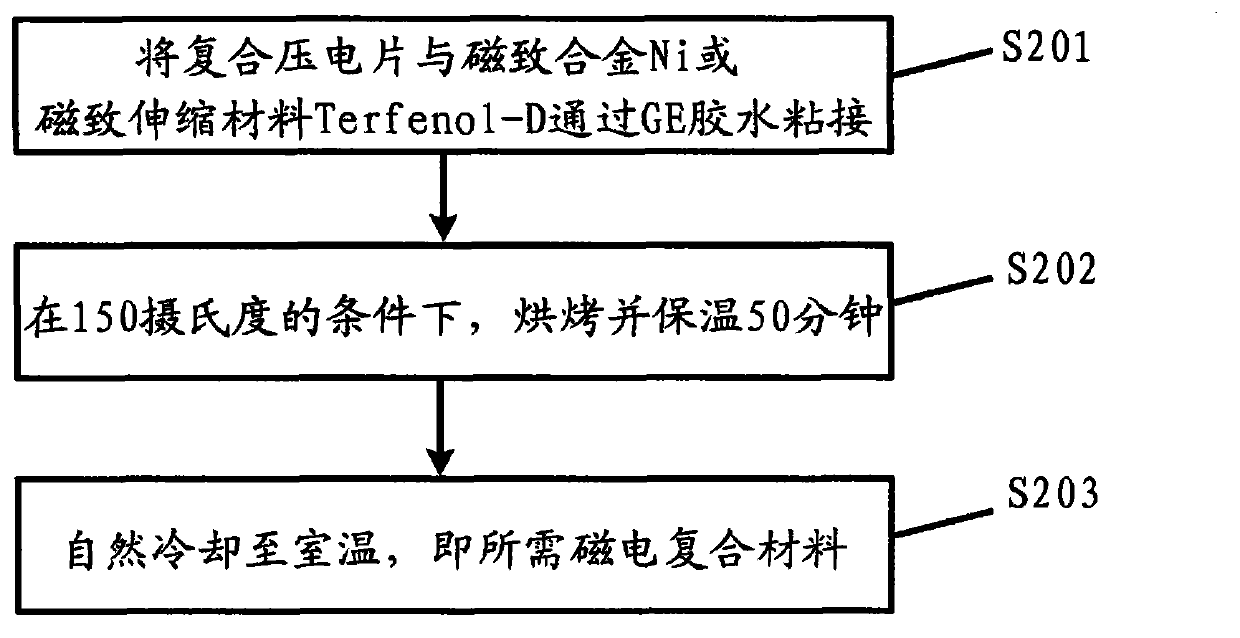

Two magnetoelectric composite materials and preparation method thereof

InactiveCN103280521AIncrease capacitanceHigh magnetoelectric conversion sensitivityPiezoelectric/electrostrictive device manufacture/assemblyDevice detailsCapacitanceFree cooling

The invention discloses two magnetoelectric composite materials and a preparation method thereof. The magnetoelectric composite material consists of a composite piezoelectric piece and a magnetostrictive alloy Ni or magnetostrictive material Terfenol-D, wherein the composite piezoelectric piece is fixedly adhered to the magnetostrictive alloy Ni or magnetostrictive material Terfenol-D through GE glue, and the composite piezoelectric piece is made by connecting a plurality of layers of composite piezoelectric pieces in parallel; and the composite piezoelectric piece has great capacitance, and the magnetoelectric composite material has high magnetoelectric conversion sensitivity. The preparation method comprises the following steps of: firstly, adhering the composite piezoelectric piece and the magnetostrictive alloy Ni or magnetostrictive material Terfenol-D through GE glue; secondly, baking and holding for 50 min at a temperature of 150 DEG C; and finally, naturally cooling to room temperature to obtain the required magnetoelectric composite material. The magnetoelectric composite materials have very high magnetoelectric sensitivity and inverse magnetoelectric effects at normal temperature, and the sample preparation is simple, so that the materials can be mass-produced; the compounding of the composite piezoelectric piece and the magnetostrictive alloy Ni requires a low bias ratio, so that the materials are favorable for application in practical devices; and the structure is simple, and the practicality is strong, so that the materials have stronger popularization and application values.

Owner:SHAANXI NORMAL UNIV

Ca(Zn1/3Nb2/3)O3-based high-frequency layered magnetoelectric composite material and preparation method thereof

The invention discloses a Ca(Zn1 / 3Nb2 / 3)O3-based high-frequency layered magnetoelectric composite material and a preparation method thereof. The preparation method comprises the following steps: granulating Ca(Zn1 / 3Nb2 / 3)O3 powder and Ni0.8Zn0.2Fe2O4 powder, and pressing and molding the powder in a mold according to a 2-2 composite layered superposition arrangement mode; and discharging a PVA adhesive, and sintering at the temperature of 1250-1300 DEG C, thereby obtaining the Ca(Zn1 / 3Nb2 / 3)O3-based high-frequency layered magnetoelectric composite material. Because the Ca(Zn1 / 3Nb2 / 3)O3 powder and Ni0.8Zn0.2Fe2O4 powder can be arranged according to the 2-2 composite layered superposition arrangement mode, and a ferroelectric phase and a ferromagnetic phase are co-fired together by virtue of a layered compounding mode, mutual reaction between the two phases can be effectively inhibited, and the respective characteristics are maintained. Therefore, the composite material has high dielectric properties and also has good ferromagnetic properties.

Owner:SHAANXI UNIV OF SCI & TECH

Cross-linked modification method of polymer phase in magnetic-force- electric coupling effect

The present invention is method of raising the piezoelectric performance and magnetoelectric performance of composite material with cross-linking polymer. The cross-linking polymer for the composite material may be polyvinylidene fluoride, polyethylene, epoxy resin, phenolic resin, unsaturated polyester resin, rubber or nylon. The present invention features that linear polymer is made to form crosslinked structure chemically or through irradiation. The chemical crosslinking process is to adding crosslinking agent or initiator into the composite material and the composite material is formed through mixing and hot pressing. The irradiating crosslinking process includes mixing the cross-linking polymer with the composition material, cold pressing to form at room temperature, and irradiating for crosslinking the polymer in the composite material.

Owner:WUHAN UNIV OF TECH

Ba0.9Ca0.1Ti0.9Zr0.1O3/Co0.8Ni0.1Zn0.1Fe2O4 layered magnetoelectric composite and preparation method thereof

InactiveCN106431398AInhibitory interactionGood ferroelectricityLaminationLamination apparatusAdhesiveMetallurgy

The invention discloses a Ba0.9Ca0.1Ti0.9Zr0.1O3 / Co0.8Ni0.1Zn0.1Fe2O4 layered magnetoelectric composite and a preparation method thereof. After Ba0.9Ca0.1Ti0.9Zr0.1O3 powder and Co0.8Ni0.1Zn0.1Fe2O4 powder are granulated, the Ba0.9Ca0.1Ti0.9Zr0.1O3 powder and the Co0.8Ni0.1Zn0.1Fe2O4 powder are pressed and formed in a mold in a 2-2 compounding layered superimposing arrangement manner, then, a PVA adhesive is discharged, the mixture is sintered at the temperature of 1,100-1,150 DEG C, and the layered magnetoelectric composite is obtained. The Ba0.9Ca0.1Ti0.9Zr0.1O3 powder and the Co0.8Ni0.1Zn0.1Fe2O4 powder are prepared in a 2-2 compounding manner, two phases are sintered in the absence of organic adhesives, the layered composite with the two phases better combined is finally obtained, the reaction between the two phases and mutual dispersion of elements are effectively controlled, and the composite not only has ferroelectric properties and ferromagnetic properties, but also has high magnetoelectric coupling coefficients.

Owner:SHAANXI UNIV OF SCI & TECH

KNN-based layered magnetoelectric composite and preparation method thereof

InactiveCN106278262AImprove performanceAvoid interactionInorganic material magnetismInductances/transformers/magnets manufactureAdhesiveCurie temperature

The invention discloses a KNN-based layered magnetoelectric composite and a preparation method thereof. The preparation method includes the steps that (K0.45Na0.55)0.98Li0.02(Nb0.77Ta0.18Sb0.05)O3 powder and Ni0.37Cu0.20Zn0.43Fe1.92O3.88 powder are subjected to granulation and then subjected to compression moulding in a mould in a 2-2 composite layer piling and overlying arrangement mode, then a PVA adhesive is discharged, sintering is carried out at 1060-1090 DEG C, and the layered magnetoelectric composite can be obtained. According to the KNN-based layered magnetoelectric composite and the preparation method thereof, a ferroelectric phase and a ferromagnetic phase are co-sintered in a layered composite mode by adopting the 2-2 composite layer piling and overlying arrangement mode for the two kinds of powder, interreaction between the two phases can be effectively inhibited, and accordingly the characteristics of the two phases can be kept, so that the KNN-based layered magnetoelectric composite has a high Curie temperature and good ferroelectricity and ferromagnetism.

Owner:SHAANXI UNIV OF SCI & TECH

Layered magnetoelectric composite material with high Curie temperature and high magnetoelectric coupling performance and preparation method of layered magnetoelectric composite material

A layered magnetoelectric composite material with high Curie temperature and high magnetoelectric coupling performance and its preparation method, comprising Li 0.058 (Na 0.535 K 0.48 ) 0.942 NbO 3 Powder, Co 0.6 Zn 0.4 Fe 1.7 mn 0.3 o 4 After the powder is granulated, it is pressed and formed in a mold according to the stacked arrangement of 2-2 composite barrier layers, and then the PVA binder is discharged, and sintered at 1020-1040°C to obtain a layered magnetoelectric composite material. In the present invention, since Li 0.058 (Na 0.535 K 0.48 ) 0.942 NbO 3 Powder, Co 0.6 Zn 0.4 Fe 1.7 mn 0.3 o 4 The powder is superimposed and arranged in a 2-2 composite barrier layer, and the ferroelectric phase and the ferromagnetic phase are co-fired together in a layered composite manner, so that it has a higher Curie temperature, better ferroelectric properties and magnetic properties. electric effect.

Owner:SHAANXI UNIV OF SCI & TECH

CoFe2O4/BaTiO3-(Na0.5Bi0.5)TiO3 material and preparation method thereof

The invention discloses a CoFe2O4 / BaTiO3-(Na0.5Bi0.5)TiO3 material and a preparation method thereof. The preparation method comprises the following steps: preparing 0.65BaTiO3-0.35(Na0.5Bi0.5)TiO3 powder with barium carbonate, titania, bismuth oxide and sodium carbonate as raw materials, carrying out granulation on CoFe2O4 powder and the 0.65BaTiO3-0.35(Na0.5Bi0.5)TiO3 powder, carrying out compression moulding in a die according to a 2-2 compounding layering staking arrangement mode, discharging rubber, and calcining. According to the CoFe2O4 / BaTiO3-(Na0.5Bi0.5)TiO3 material and the preparation method thereof disclosed by the invention, as a ferroelectric phase and a ferromagnetic phase are co-fired together in a layering compounding mode according to the 2-2 compounding layering staking arrangement mode, mutual reaction between the ferroelectric phase and the ferromagnetic phase can be effectively inhibited so as to keep respective characteristics, and the CoFe2O4 / BaTiO3-(Na0.5Bi0.5)TiO3 material is good in both ferroelectricity and ferromagnetism.

Owner:SHAANXI UNIV OF SCI & TECH

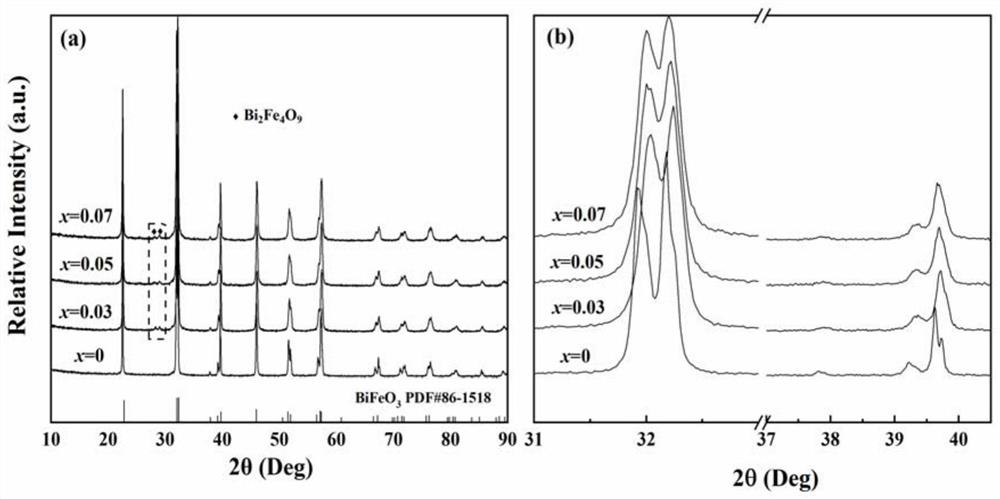

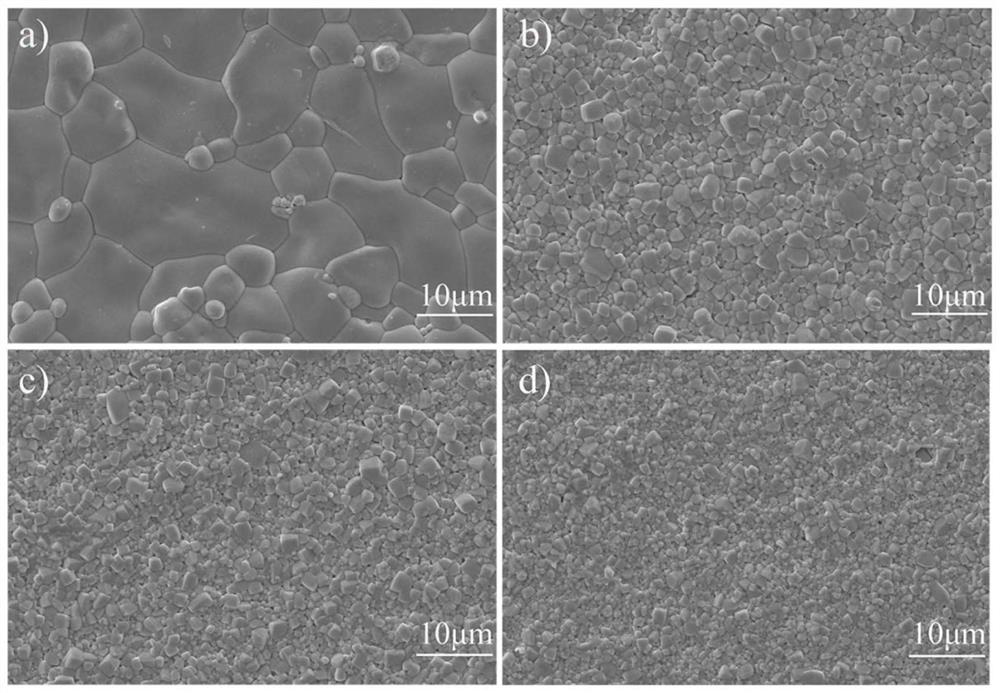

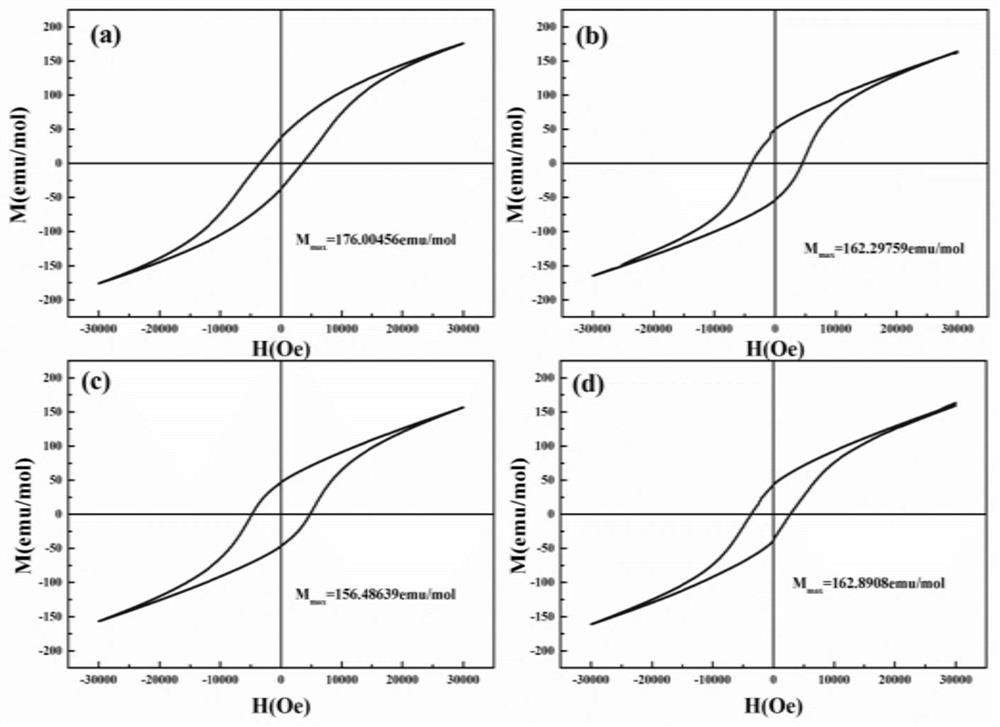

Bismuth ferrite-based ceramic with excellent magnetoelectric properties and preparation method thereof

ActiveCN112537952AImprove magnetoelectric propertiesImprove performanceSustainable buildingsGreen bodyBismuth ferrite

The invention discloses bismuth ferrite-based ceramic with excellent magnetoelectric properties and a preparation method of the bismuth ferrite-based ceramic. The bismuth ferrite-based ceramic is a bismuth ferrite-based ceramic material with co-doping at an A position and a B position, the Curie ferroelectric transition temperature TC of the bismuth ferrite-based ceramic material is higher than the Neel temperature TN, and the difference value between the TC and the TN ranges from 10 DEG C to 60 DEG C. The bismuth ferrite-based ceramic is prepared by adopting a standard solid-phase reaction sintering method, and the method comprises the following steps: proportioning raw materials according to a stoichiometric ratio, carrying out primary ball milling, conducting sieving, conducting presintering at 860-880 DEG C to obtain pre-synthesized powder, and carrying out secondary ball milling, sieving, granulating, tabletting and other processes to obtain a BiFeO3-based ceramic green body withexcellent magnetic properties; and finally, conducting sintering at a high temperature of 900-950 DEG C to obtain the BiFeO3-based ceramic material. The preparation method is stable and reliable, theprocess is simple and easy to operate, and large-scale production can be performed; and the bismuth ferrite-based ceramic with uniform components, compact structure and excellent performance can be prepared.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

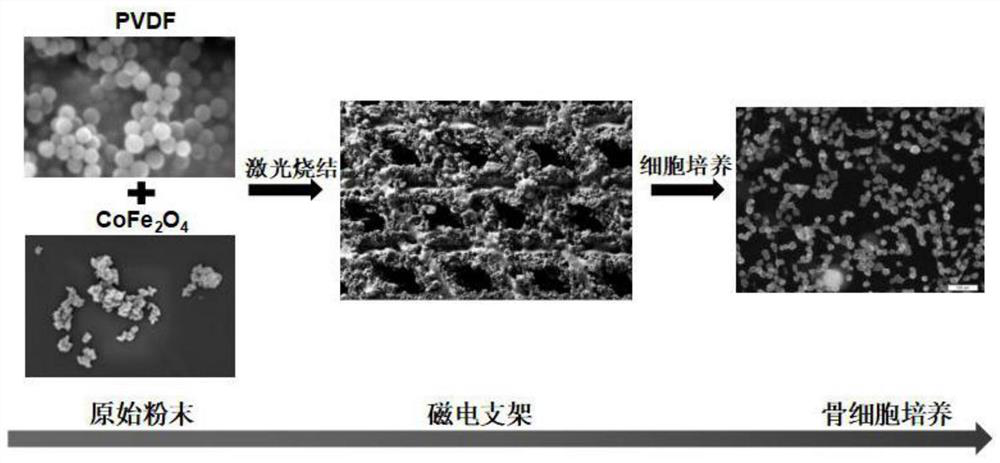

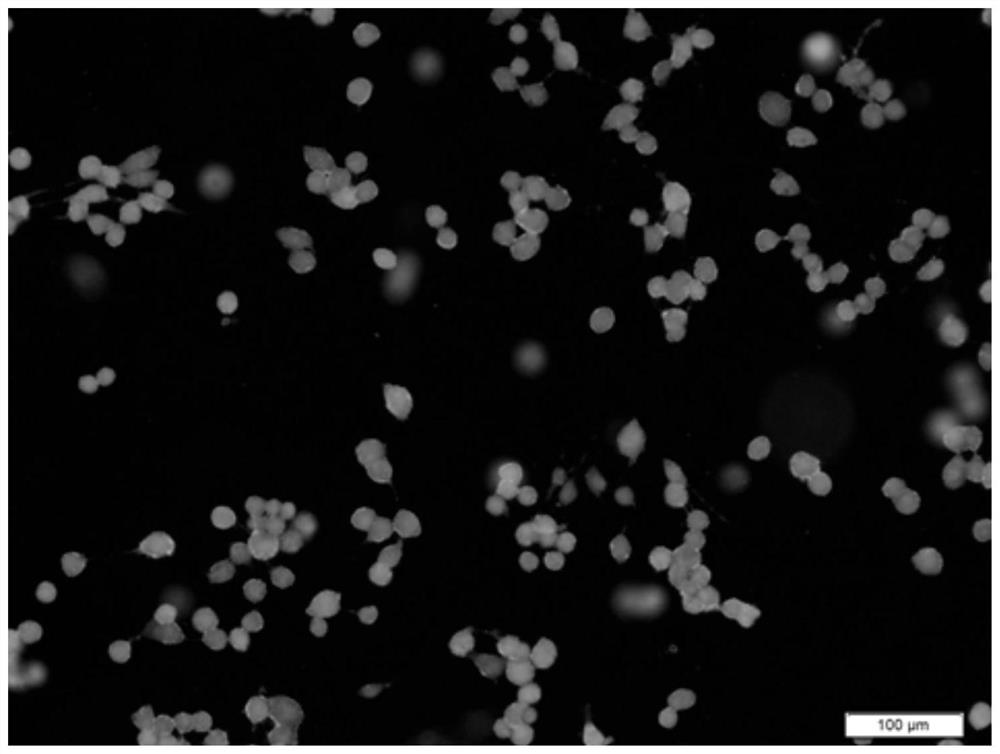

CoFe2O4/PVDF composite bone scaffold and preparation method thereof

ActiveCN112076345AImprove adhesionPromote proliferationTissue regenerationProsthesisSelective laser sinteringFluid phase

The invention relates to a CoFe2O4 / PVDF composite bone scaffold and a preparation method thereof. The CoFe2O4 / PVDF composite bone scaffold is prepared by the following steps: mixing and stirring ethanol suspension of CoFe2O4 and ethanol suspension of PVDF, performing solid-liquid phase separation on the obtained CoFe2O4 / PVDF mixed suspension, drying and ball-milling the obtained solid phase to obtain composite powder, and performing selective laser sintering on the composite powder. According to the CoFe2O4 / PVDF composite bone scaffold provided by the invention, remote non-contact electrical stimulation on bone cells can be realized by externally applying an alternating magnetic field, so that growth of osteoblasts and regeneration and reconstruction of defective tissues are promoted.

Owner:JIANGXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d33c2ba5-ceec-44cc-a709-6bfddffa1e71/HDA0000631192430000011.PNG)

![Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d33c2ba5-ceec-44cc-a709-6bfddffa1e71/HDA0000631192430000012.PNG)

![Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d33c2ba5-ceec-44cc-a709-6bfddffa1e71/HDA0000631192430000021.PNG)