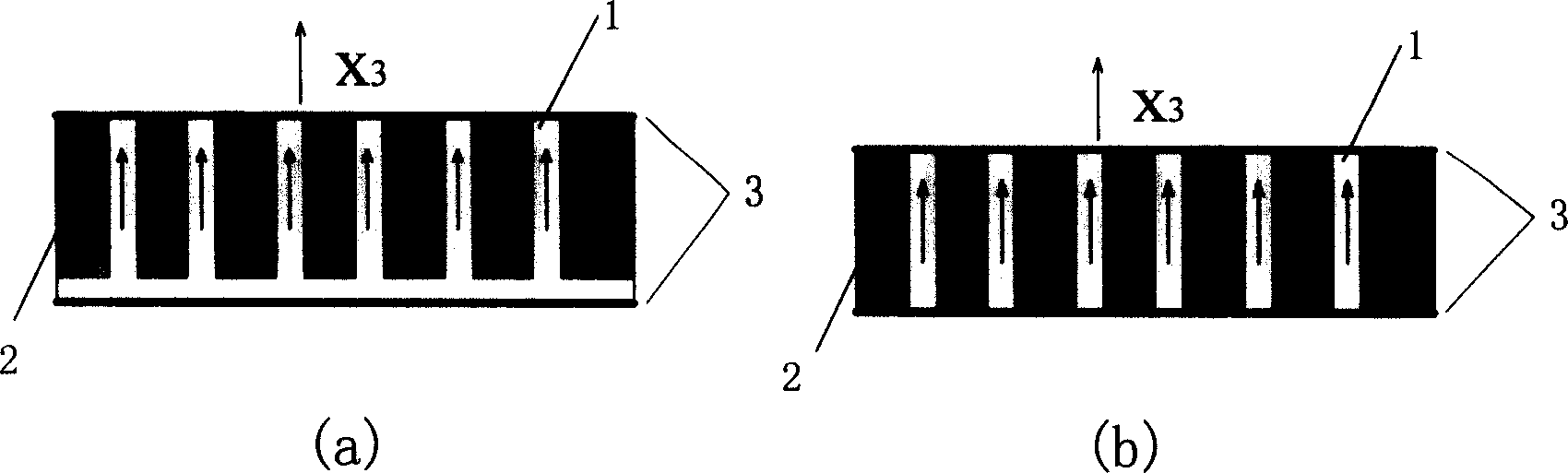

1-3 structure huge magnetoelectric material and preparing process thereof

A technology of electrical materials and magnetostrictive materials, applied in the direction of material selection, device material selection, adhesive type, etc., to achieve high magnetoelectric performance, low high-frequency loss, and avoid high-frequency loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

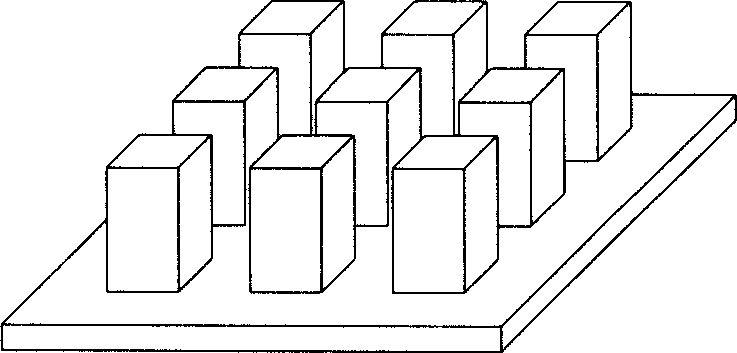

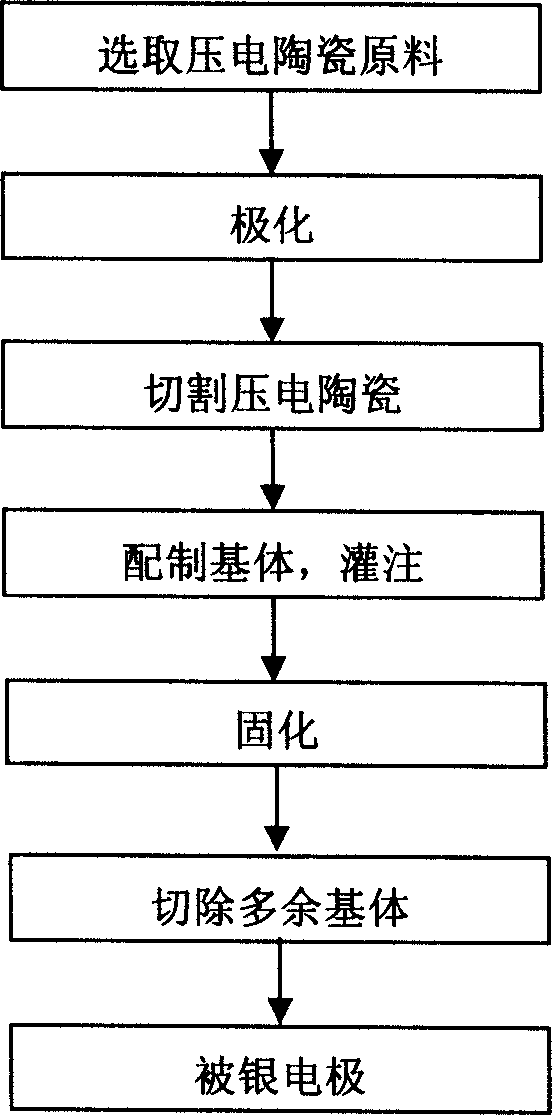

Embodiment 1

[0043] A PZT ceramic block with a length of 10 mm, a width of 10 mm, and a thickness of 3 mm was selected, and silver electrodes were applied on both sides, and polarized along the thickness direction with a field strength of 2 kV / mm to obtain a green body. The groove width is set to 2.83mm, the cutting depth is set to 2.46mm, and the green body is cut along the length and width directions respectively to obtain a ceramic array (3×3) with an aspect ratio of 4.9 and a volume percentage of 2.25% of PZT columns. , put the cut PZT array into the mold. The Terfenol-D powder and the epoxy resin were uniformly mixed at a volume percentage of 22%:78%, and then the mixture was slowly poured into a mold, and after vacuum defoaming, it was allowed to stand for one day to solidify. After the epoxy resin is cured, take it out, grind off the excess matrix on the top until the PZT array is exposed, and cover both sides with silver electrodes to obtain a 1-3 structure giant magnetoelectric ma...

Embodiment 2

[0045] A PZT ceramic block with a length of 10 mm, a width of 10 mm, and a thickness of 3 mm was selected, and silver electrodes were applied on both sides, and polarized along the thickness direction with a field strength of 2 kV / mm to obtain a green body. The groove width is set to 1.2mm, the cutting depth is set to 2.38mm, and the green body is cut along the length and width directions respectively to obtain a ceramic array (5×6) with an aspect ratio of 4.8 and a volume percentage of 7.5% PZT columns. , put the cut PZT array into the mold. The Terfenol-D powder and the epoxy resin were uniformly mixed at a volume percentage of 23%:77%, and then the mixture was slowly poured into a mold, and after vacuum defoaming, it was allowed to stand for one day to solidify. After the epoxy resin is cured, take it out, grind off the excess matrix on the top until the PZT array is exposed, and cover both sides with silver electrodes to obtain a 1-3 structure giant magnetoelectric materia...

Embodiment 3

[0047] A PZT ceramic block with a length of 10 mm, a width of 10 mm, and a thickness of 3 mm was selected, and silver electrodes were applied on both sides, and polarized along the thickness direction with a field strength of 2 kV / mm to obtain a green body. The groove width is set to 0.4mm, the cutting depth is set to 2.32mm, and the green body is cut along the length and width directions respectively to obtain a ceramic array (10×10) with an aspect ratio of 4.6 and a volume percentage of 25% PZT columns. , put the cut PZT array into the mold. The Terfenol-D powder and the epoxy resin were uniformly mixed at a volume ratio of 19%:81%, and then the mixture was slowly poured into a mold, and after vacuum defoaming, it was left to stand for one day to solidify. After the epoxy resin is cured, take it out, grind off the excess matrix on the top until the PZT array is exposed, and cover both sides with silver electrodes to obtain a 1-3 structure giant magnetoelectric material with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com