Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

113 results about "Magnetoelectric effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In its most general form, the magnetoelectric effect (ME) denotes any coupling between the magnetic and the electric properties of a material. The first example of such an effect was described by Wilhelm Röntgen in 1888, who found that a dielectric material moving through an electric field would become magnetized. A material where such a coupling is intrinsically present is called a magnetoelectric.

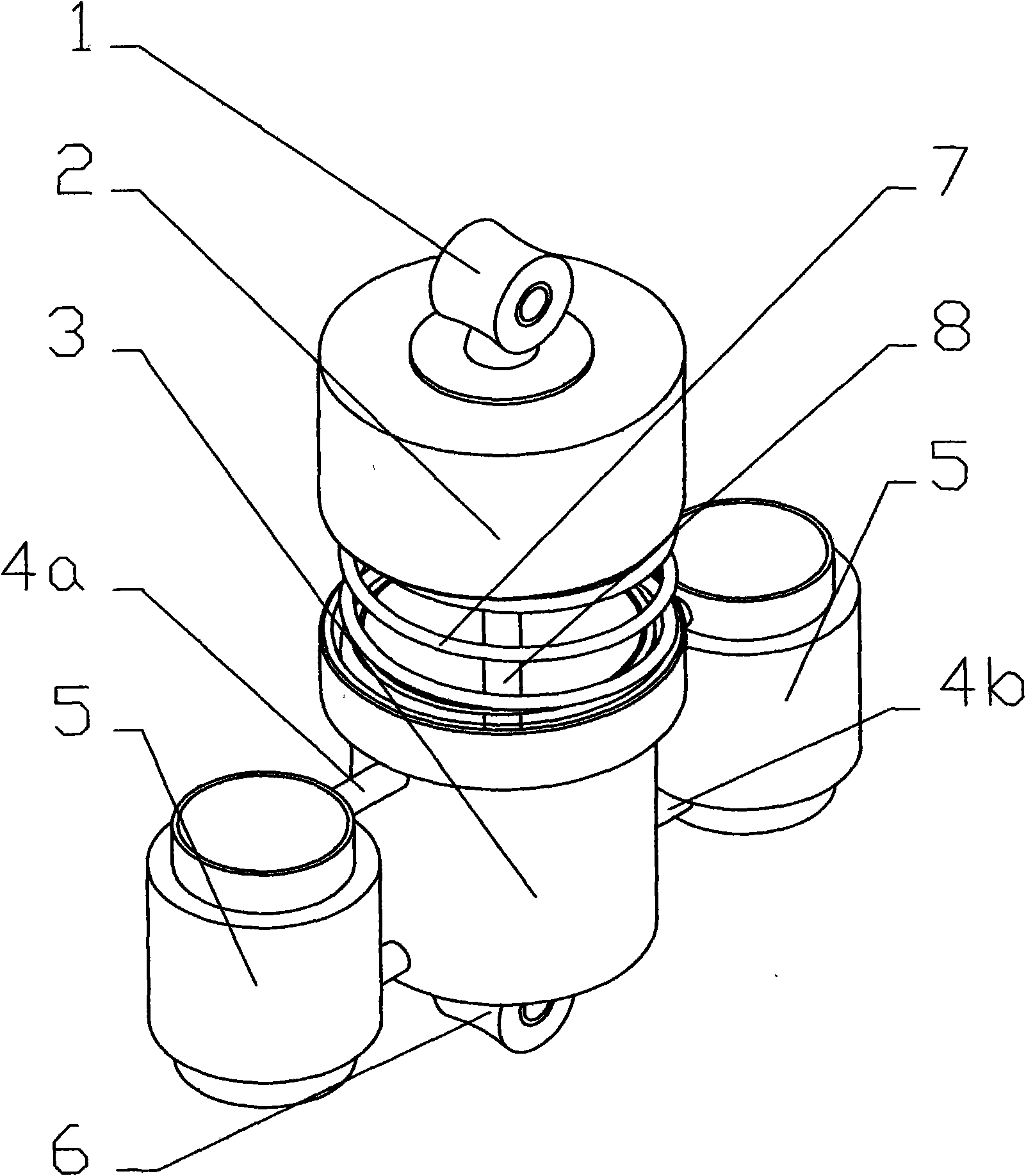

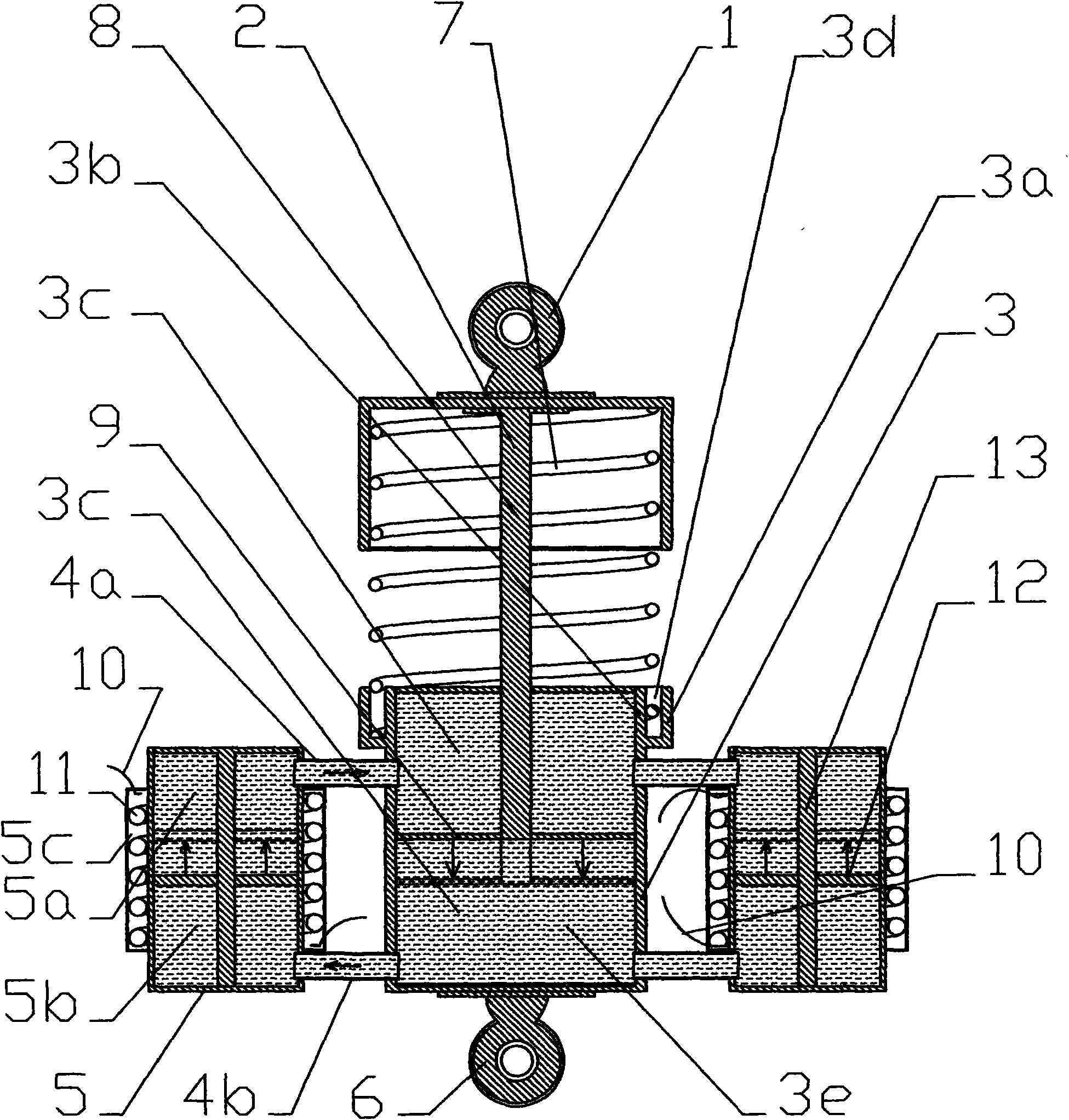

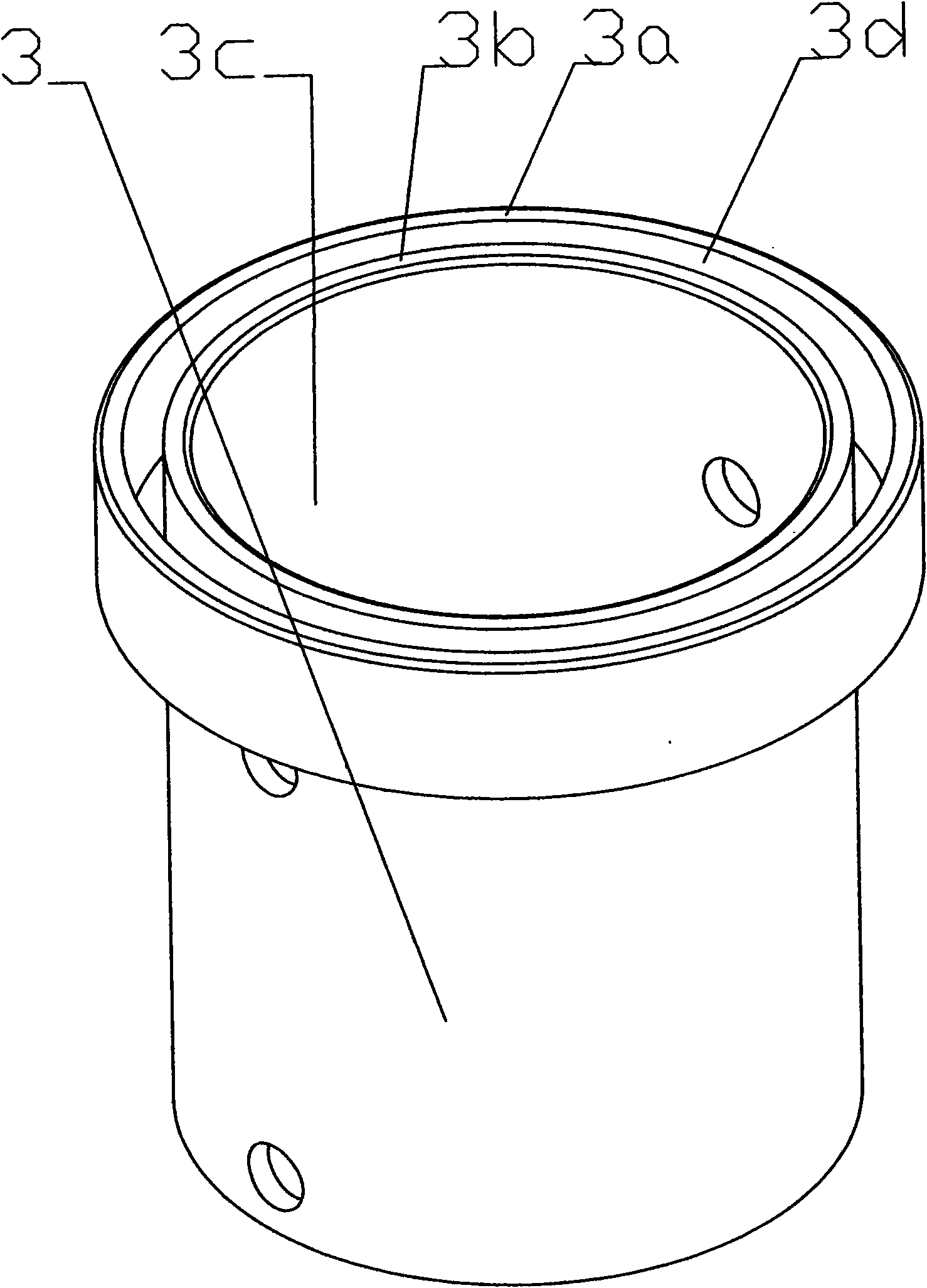

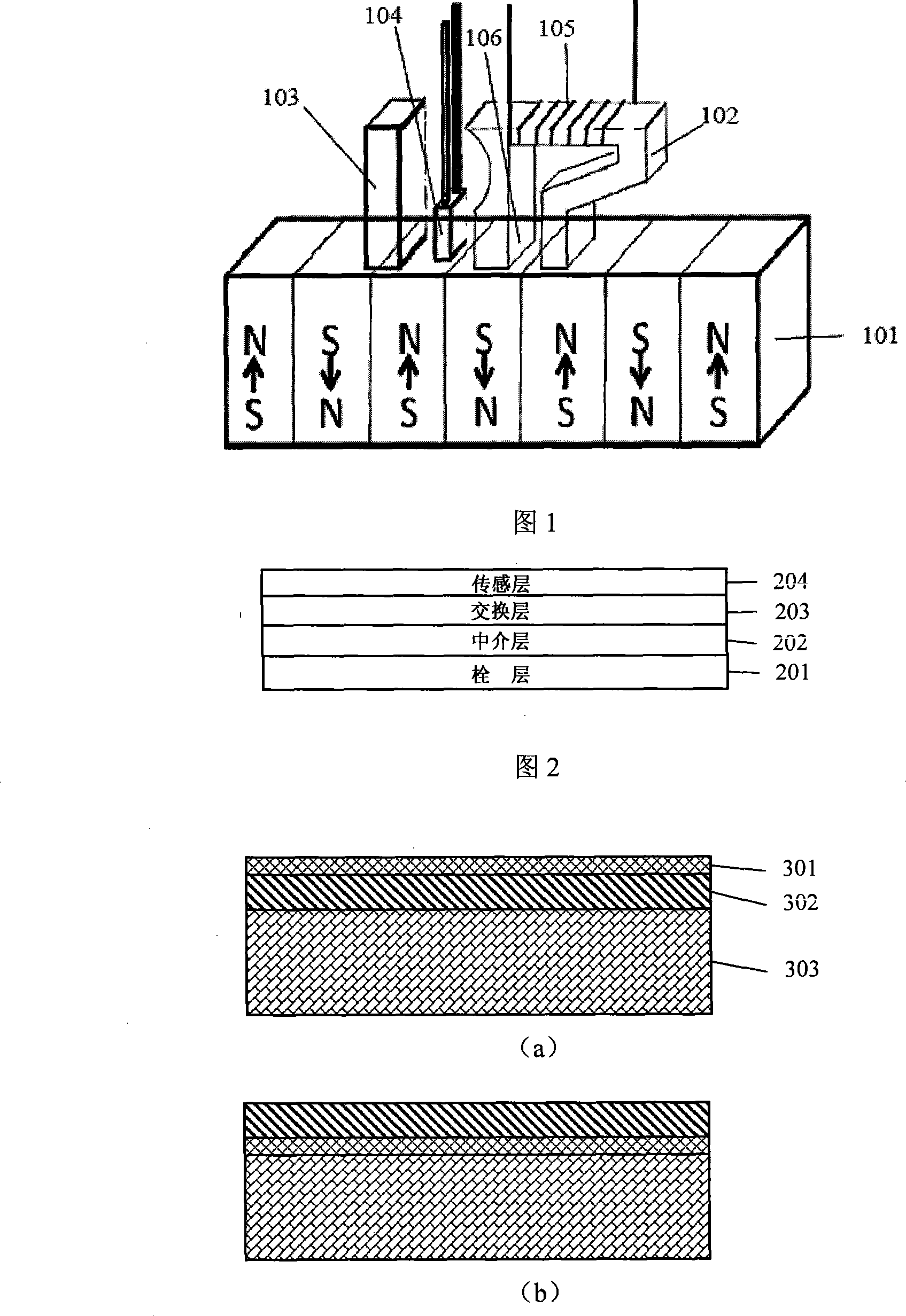

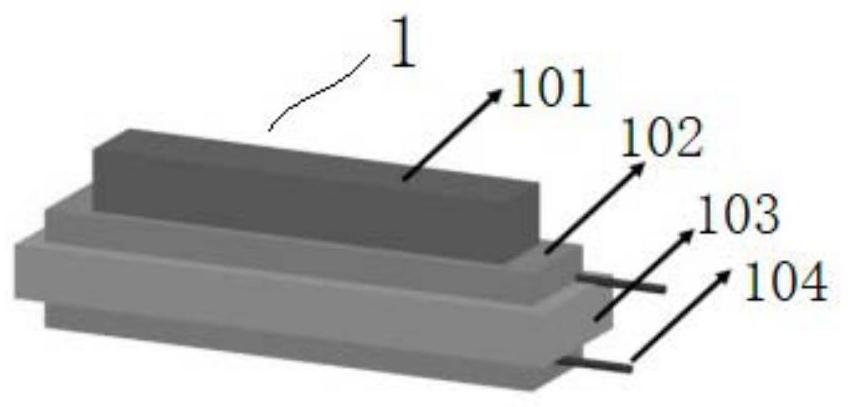

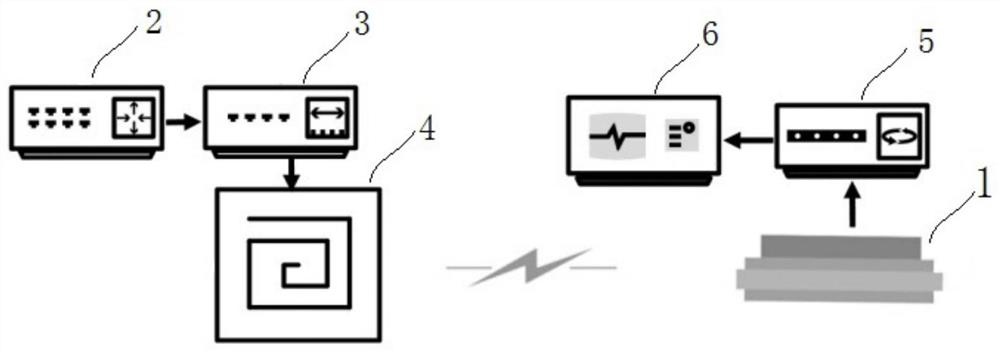

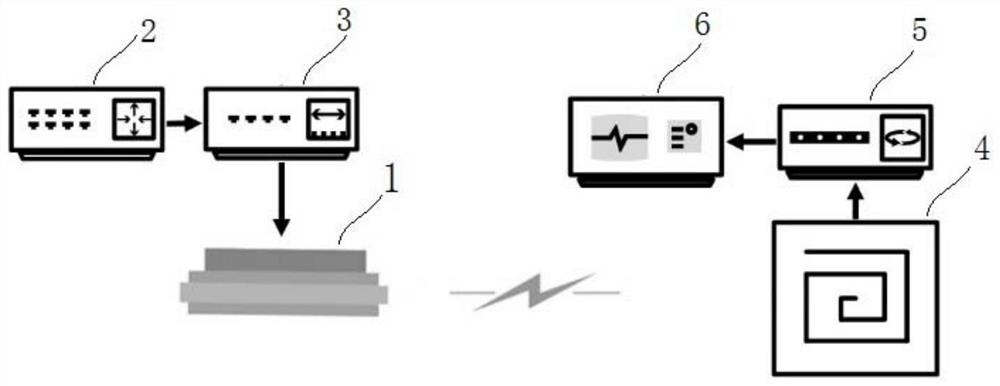

Stress monitoring device of elasto-magneto-electric (EME) effect type

ActiveUS20140298916A1Reduce distractionsExtended service lifeForce measurement by measuring magnetic property varationWork measurementNon destructiveEngineering

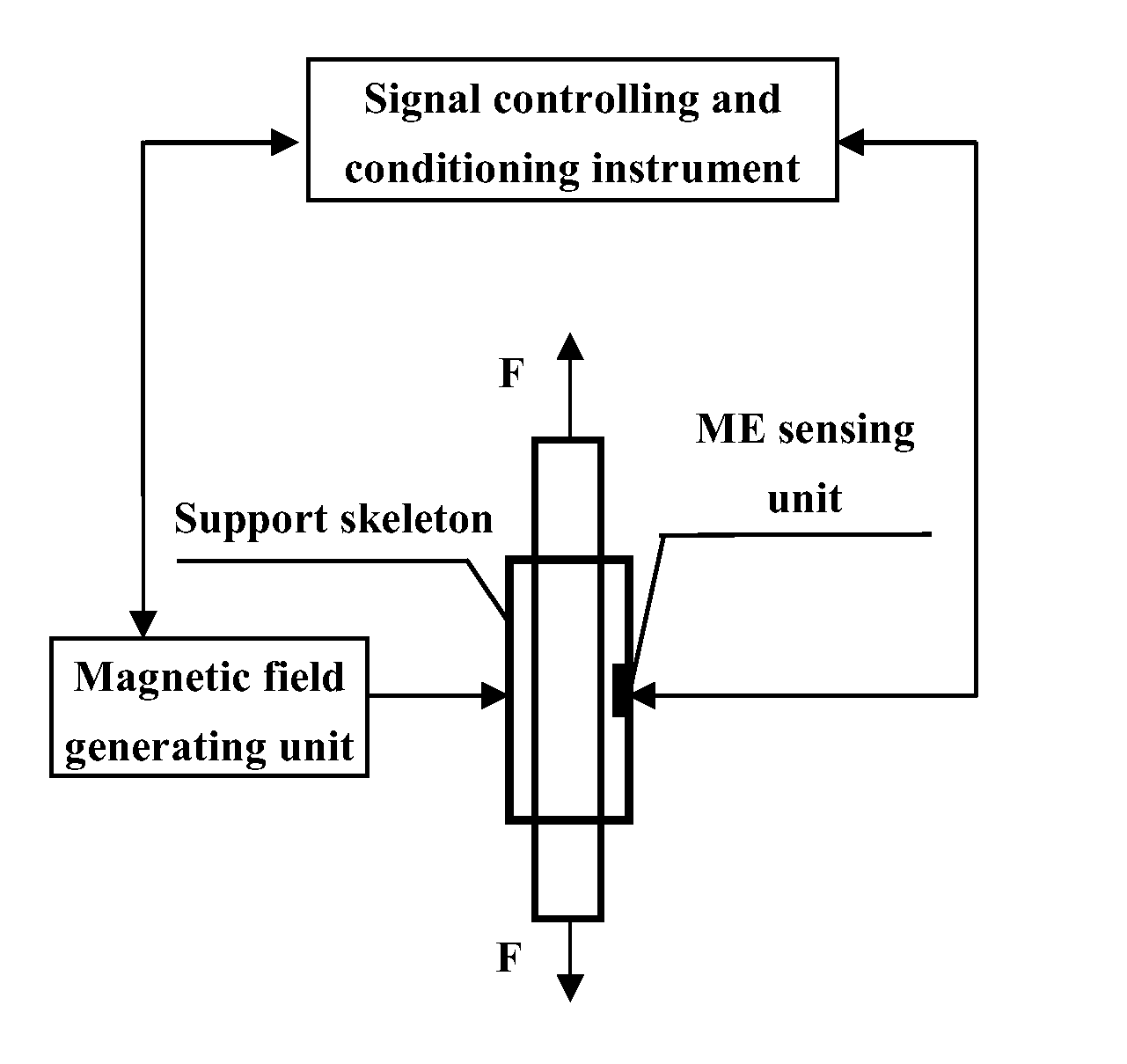

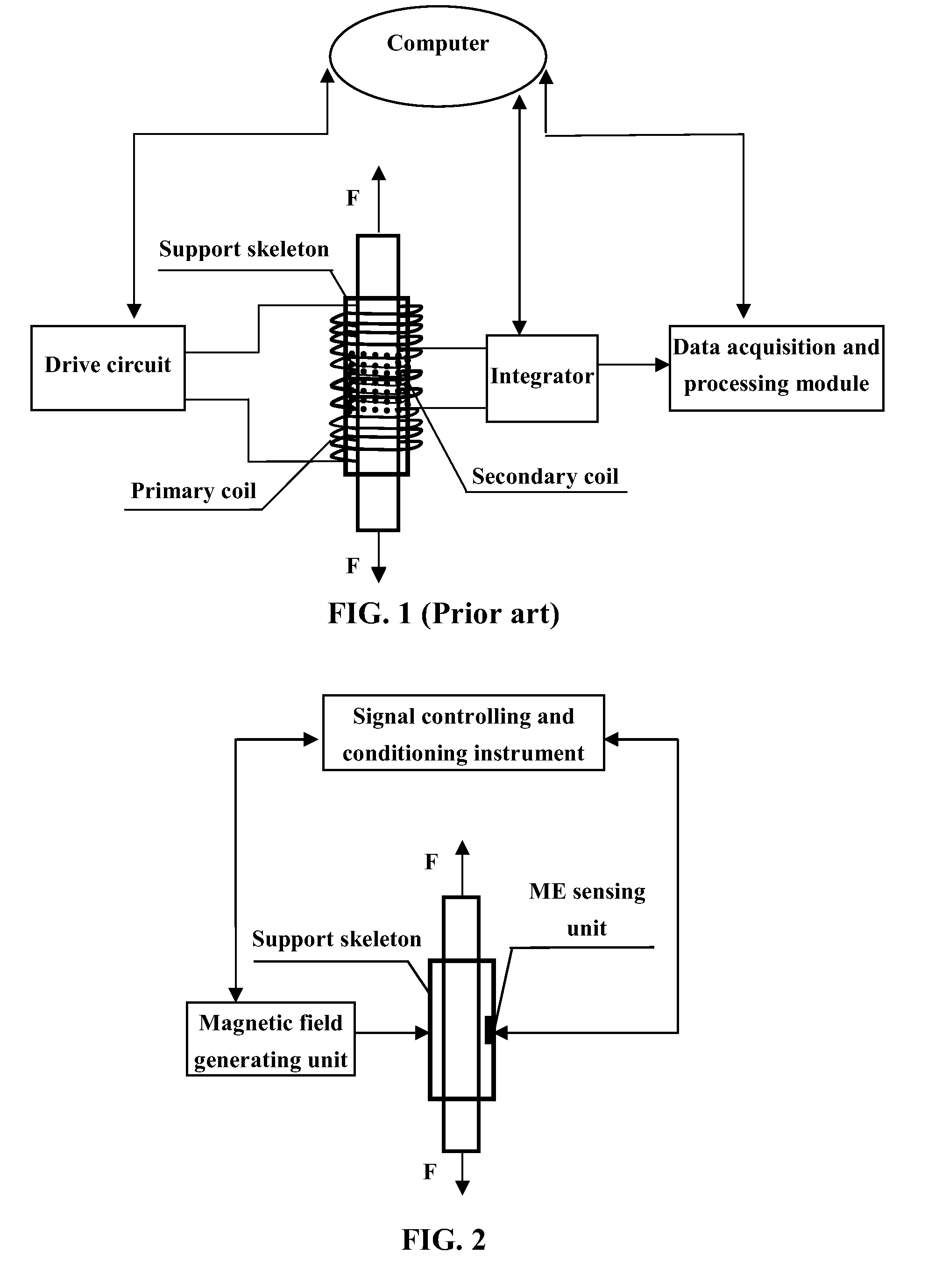

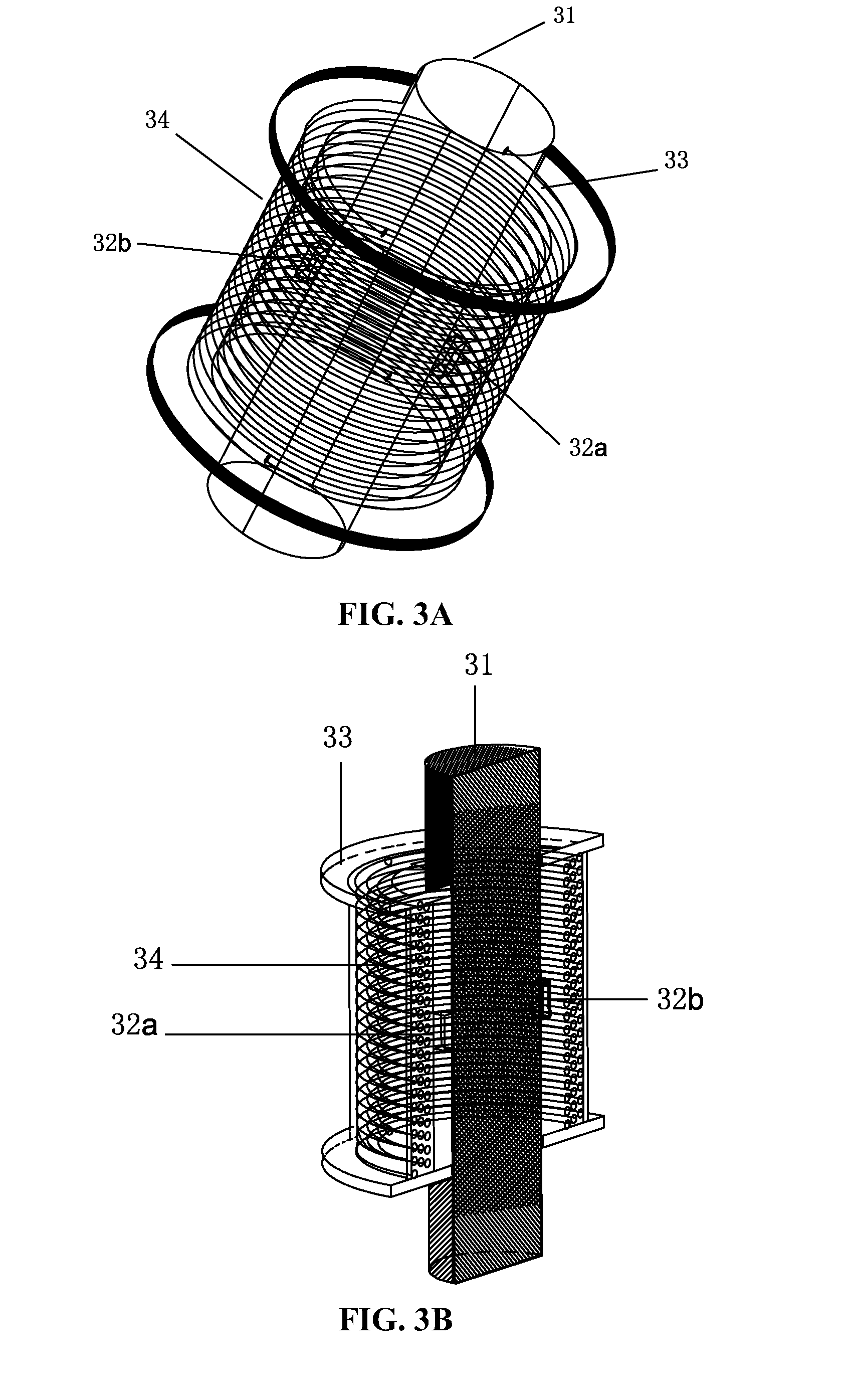

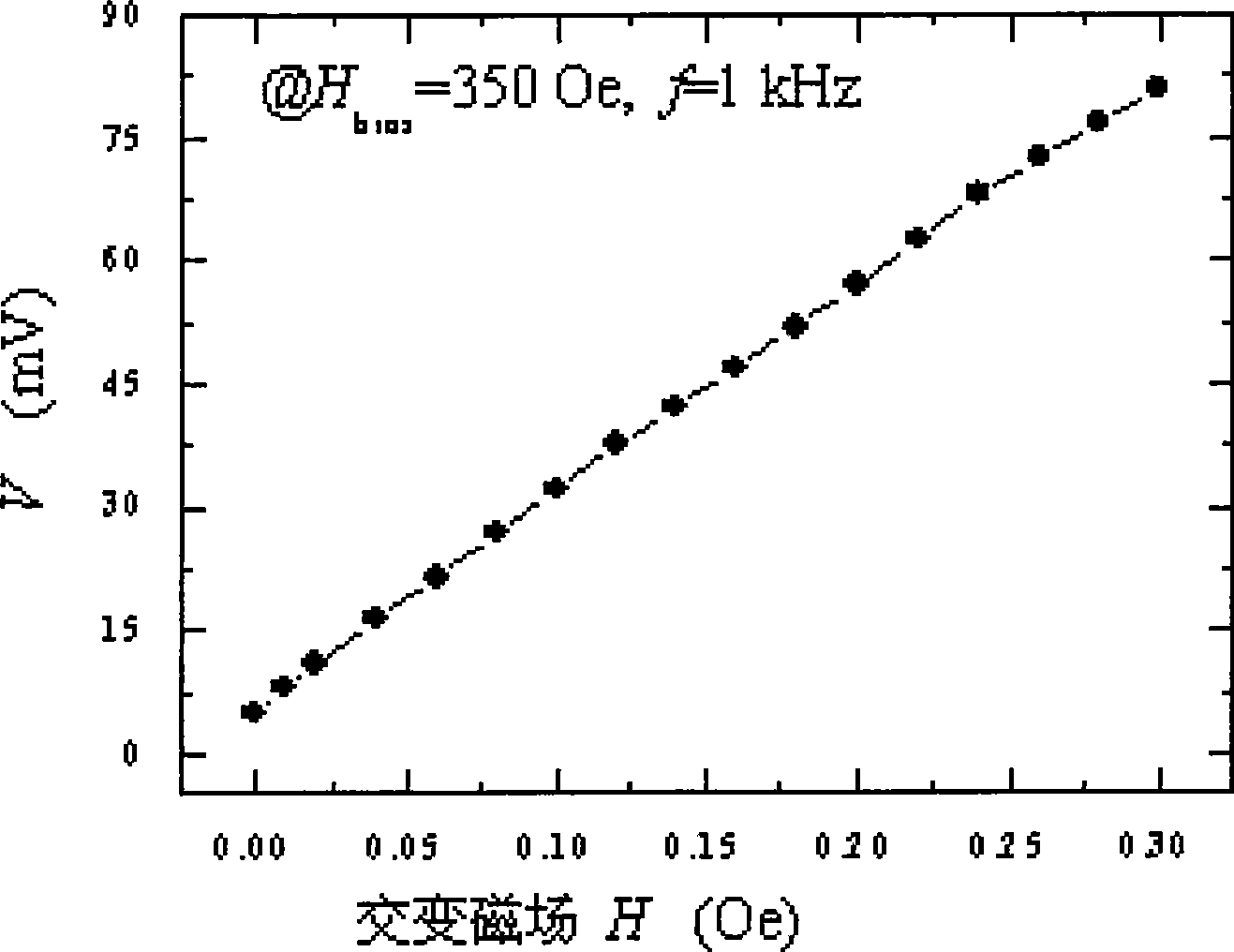

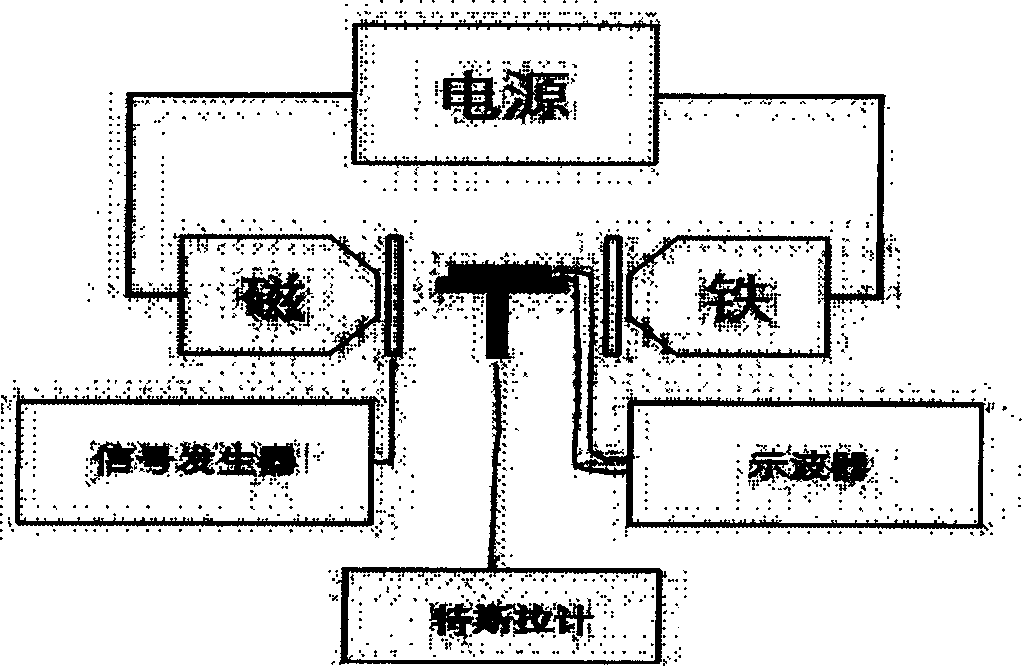

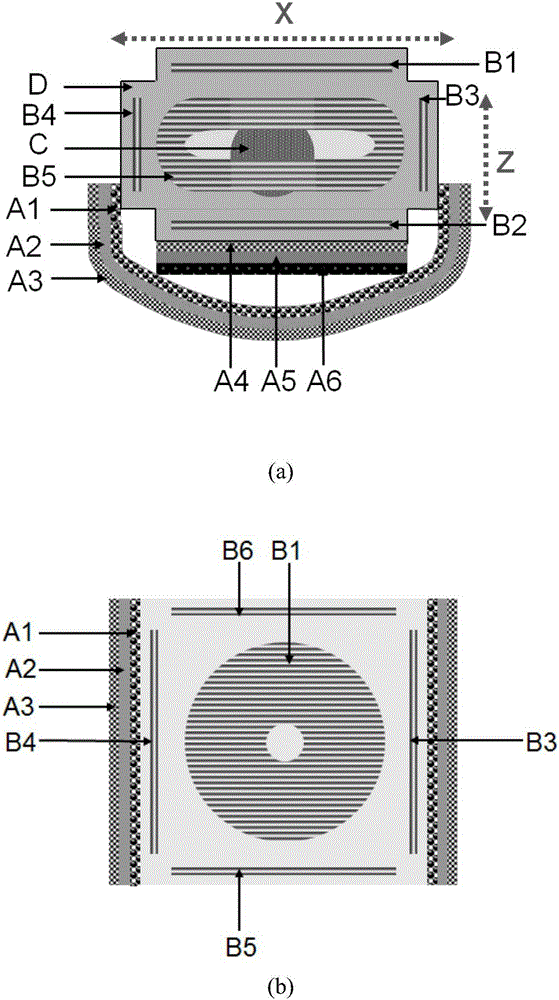

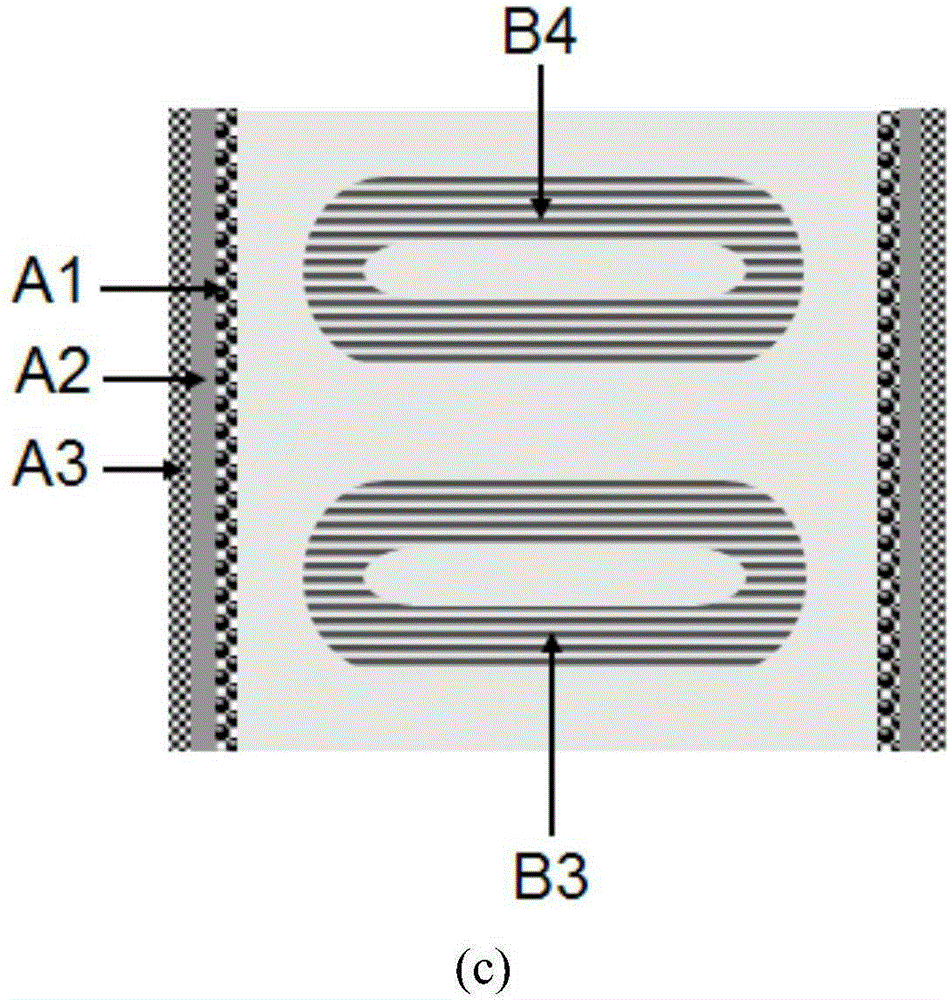

A stress monitoring device of elasto-magneto-electric (EME) effect type, for monitoring stress of a structural component of ferromagnetic materials, includes a magnetic field generating unit, a magneto-electric (ME) sensing unit, a support skeleton, and a signal controlling and conditioning instrument. Under the control of the signal controlling and conditioning instrument, the magnetic field generating unit generates a magnetic field for magnetizing the structural component. The ME sensing unit outputs an electrical signal VME characterizing the magnetic field without a need of external power supply. This electrical signal VME is analyzed and processed by the signal controlling and conditioning instrument to output a magnetic characteristic value Vst corresponding to the changes of the external forces that are exerted on the component. This stress monitoring device realizes on-line, real-time, and nondestructive monitoring, as well as off-line nondestructive monitoring.

Owner:ZHEJIANG UNIV

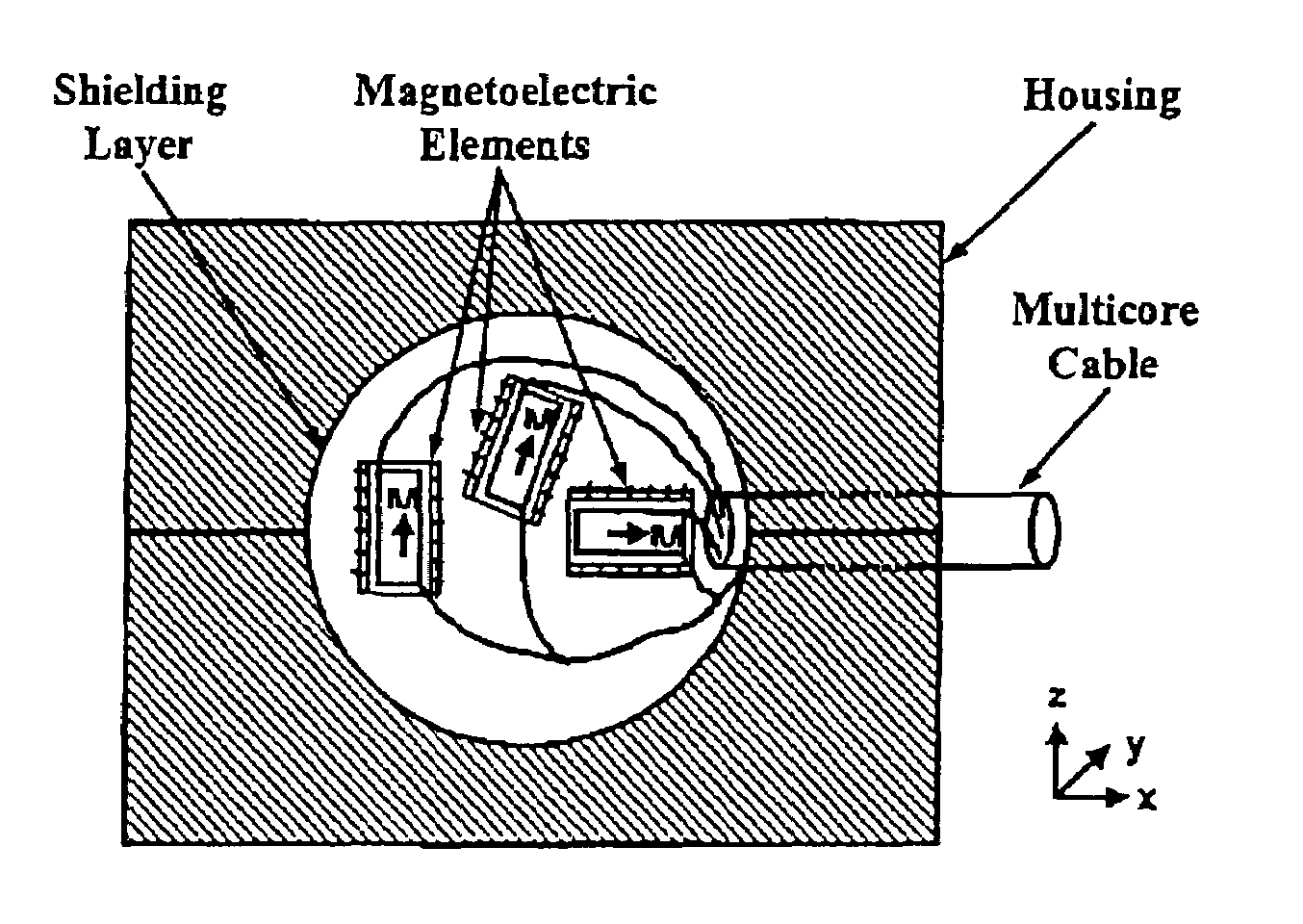

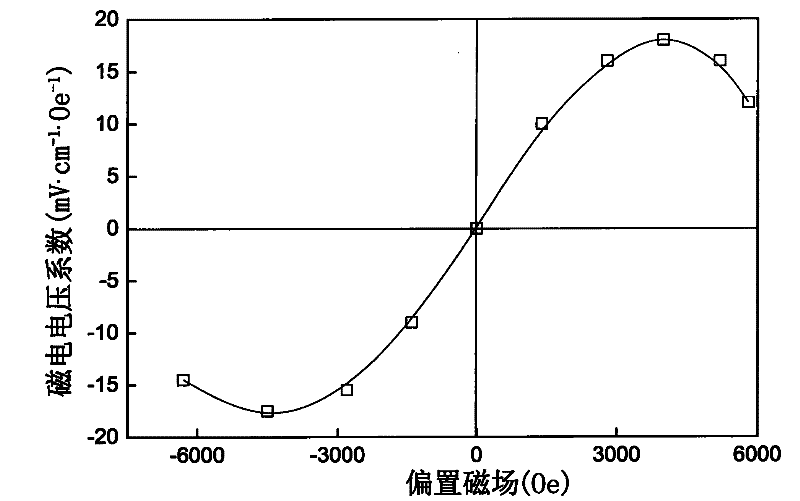

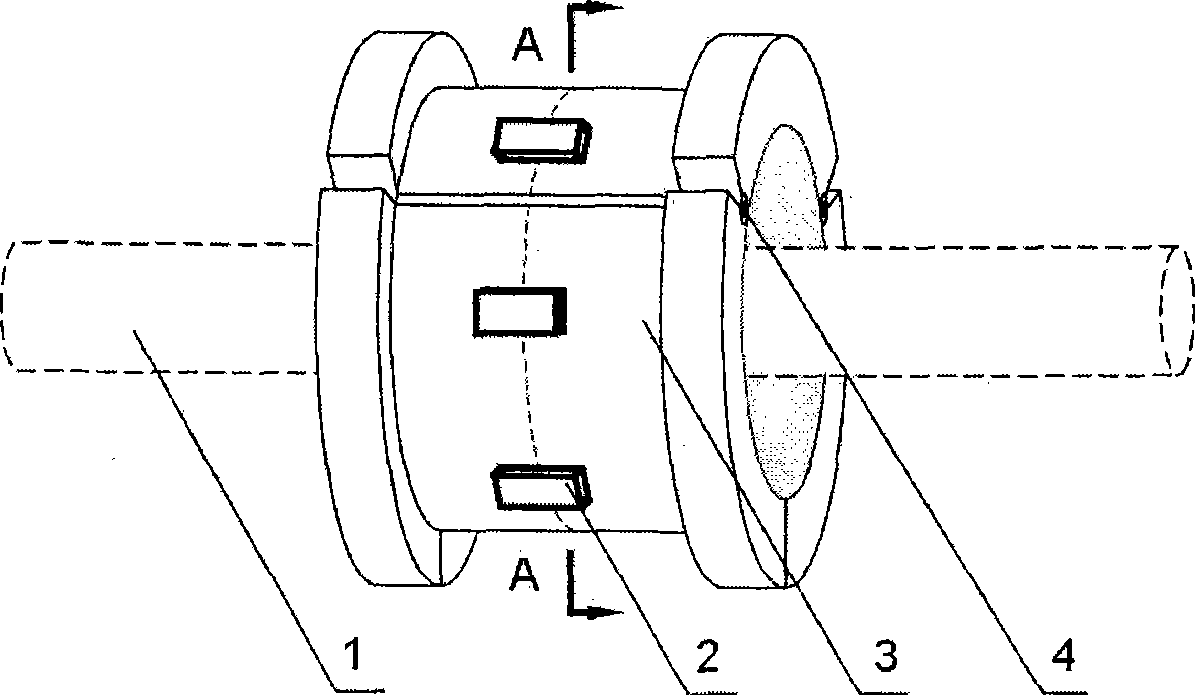

Non-contact type current/voltage converter

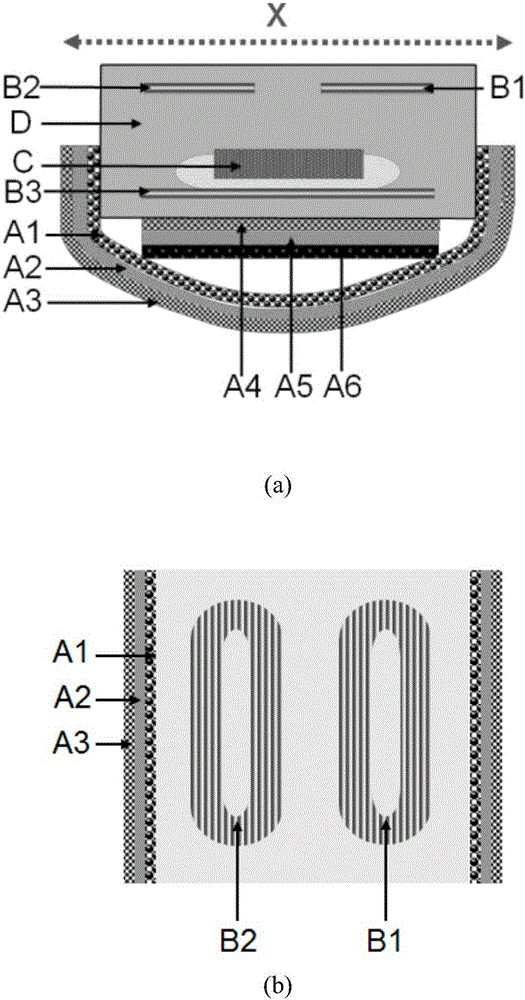

InactiveCN101369484ATransformersDevice material selectionTransimpedance amplifierElectromagnetic induction

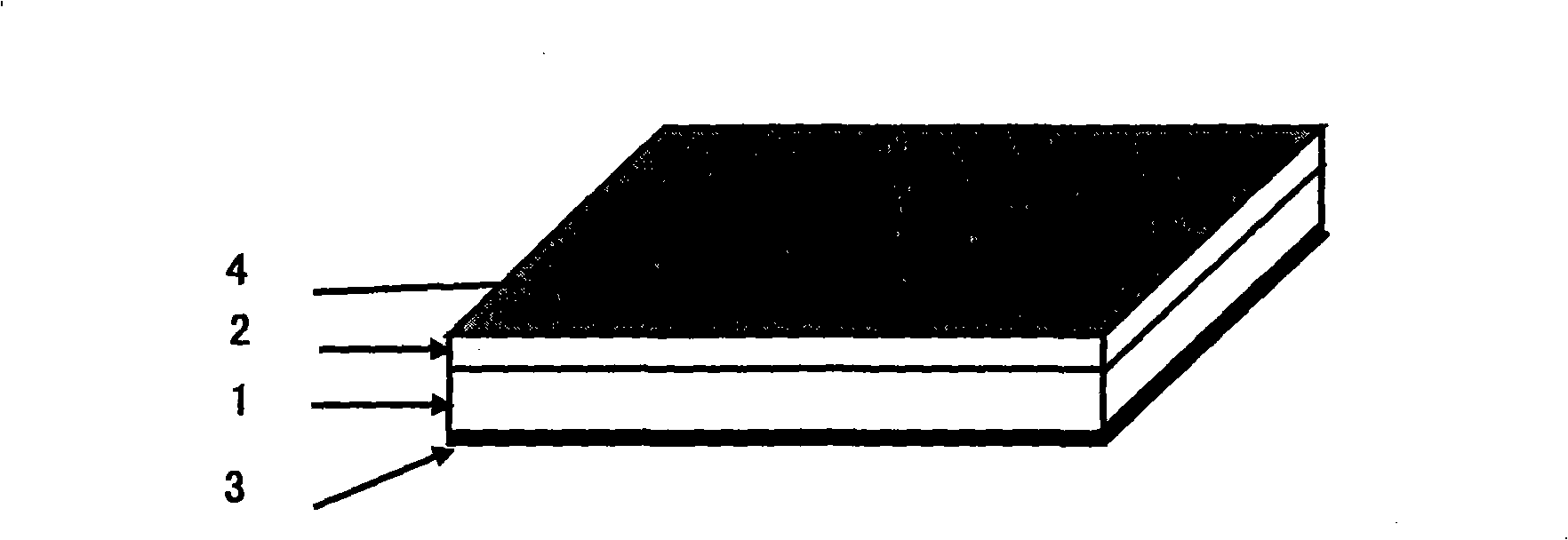

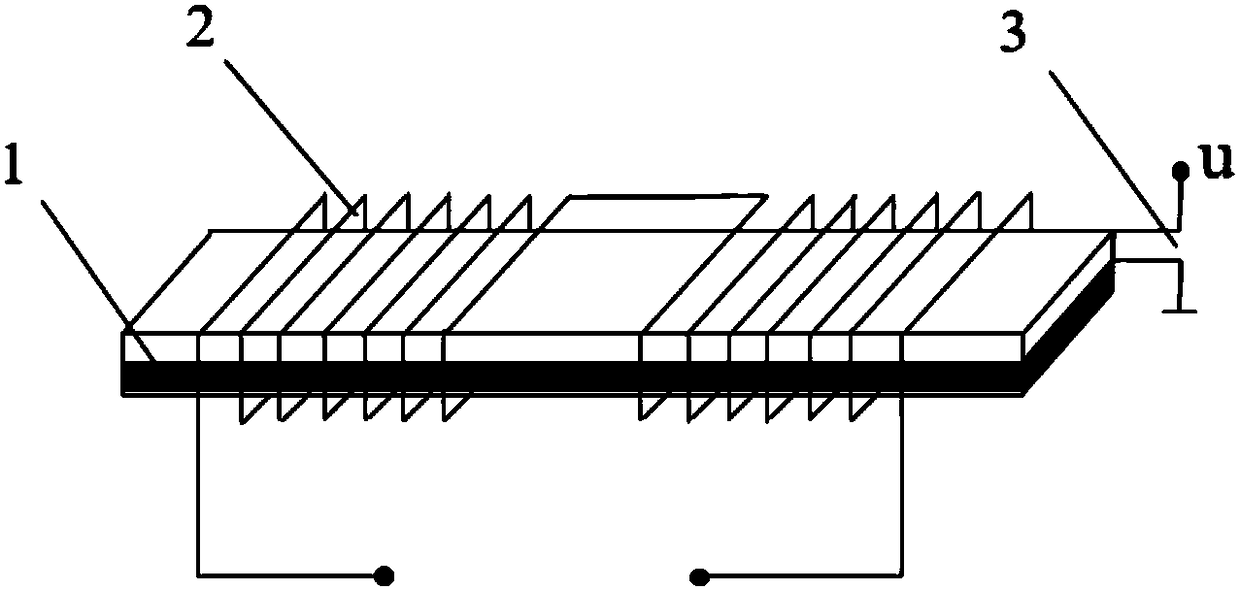

The invention relates to a non-contact type current / voltage converter comprising a composite magnetoelectric material (1), a bias magnet (3), a shielding casing (4), a grounding electrode (5), an voltage input / output electrode (6) and belonging to electric device field, in which, the composite magnetoelectric material is of layer-shaped sandwich structure composed of magnetostrictive material-piezoelectric material-magnetostrictive material; the bias magnet using one block of the magnet for providing the bias magnetic field on one end or two blocks of magnets distributed left and right symmetrically for providing the even bias magnetic field; the shielding casing enwraps the composite magnetoelectric material; the shielding casing is connected with the total ground wire. The device realizes bilateral conversion among voltage-magnetic field strength-current by magnetoelectric, reverse magnetoelectric effects and Faraday electromagnetic induction effect. Compared with the traditional current / voltage converter based on electric circuit, the device has advantages of passive, bidirectional reversibility, inactive mode, fast response speed, safety, isolation, simple design, low cost and good compatibility with other devices.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

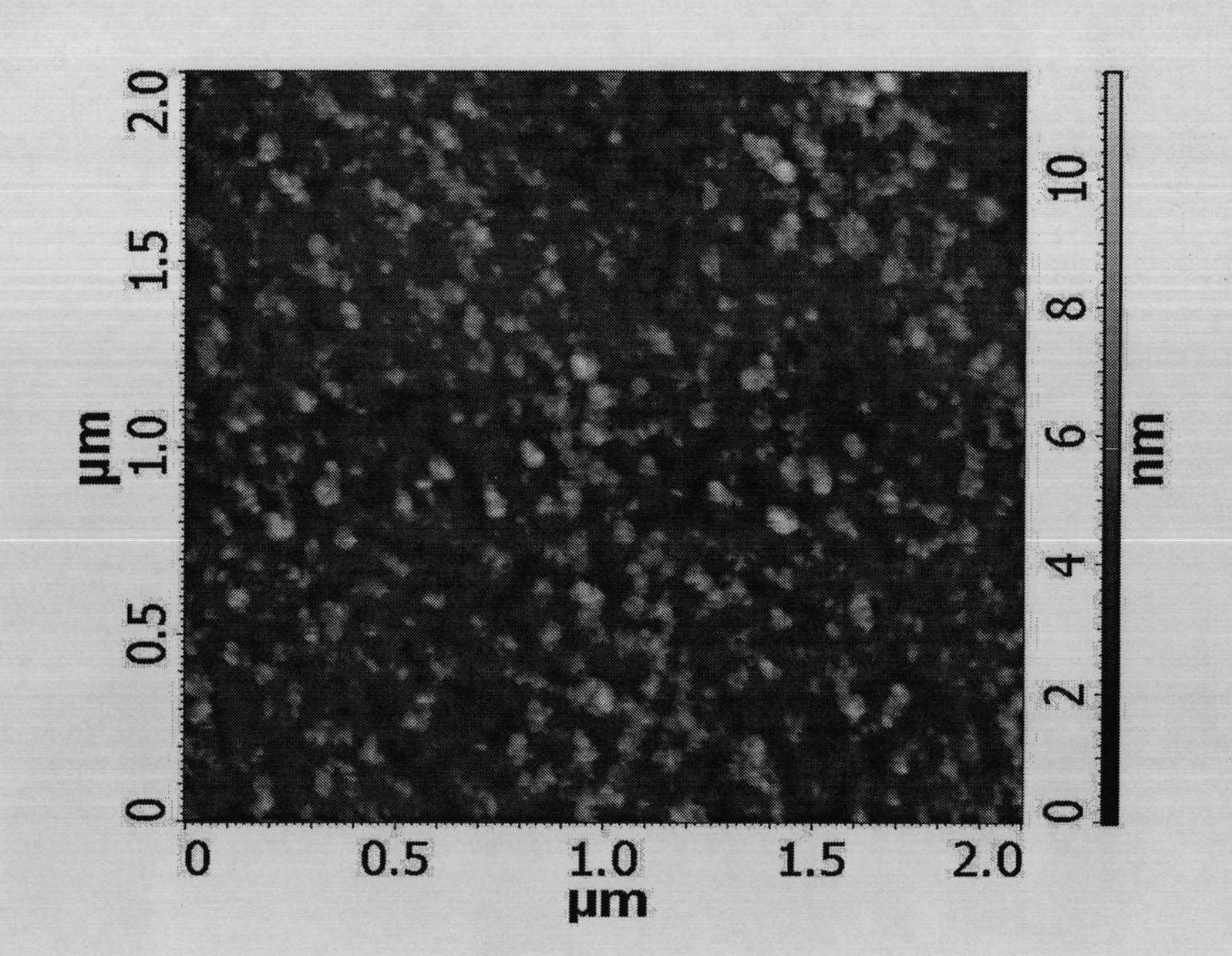

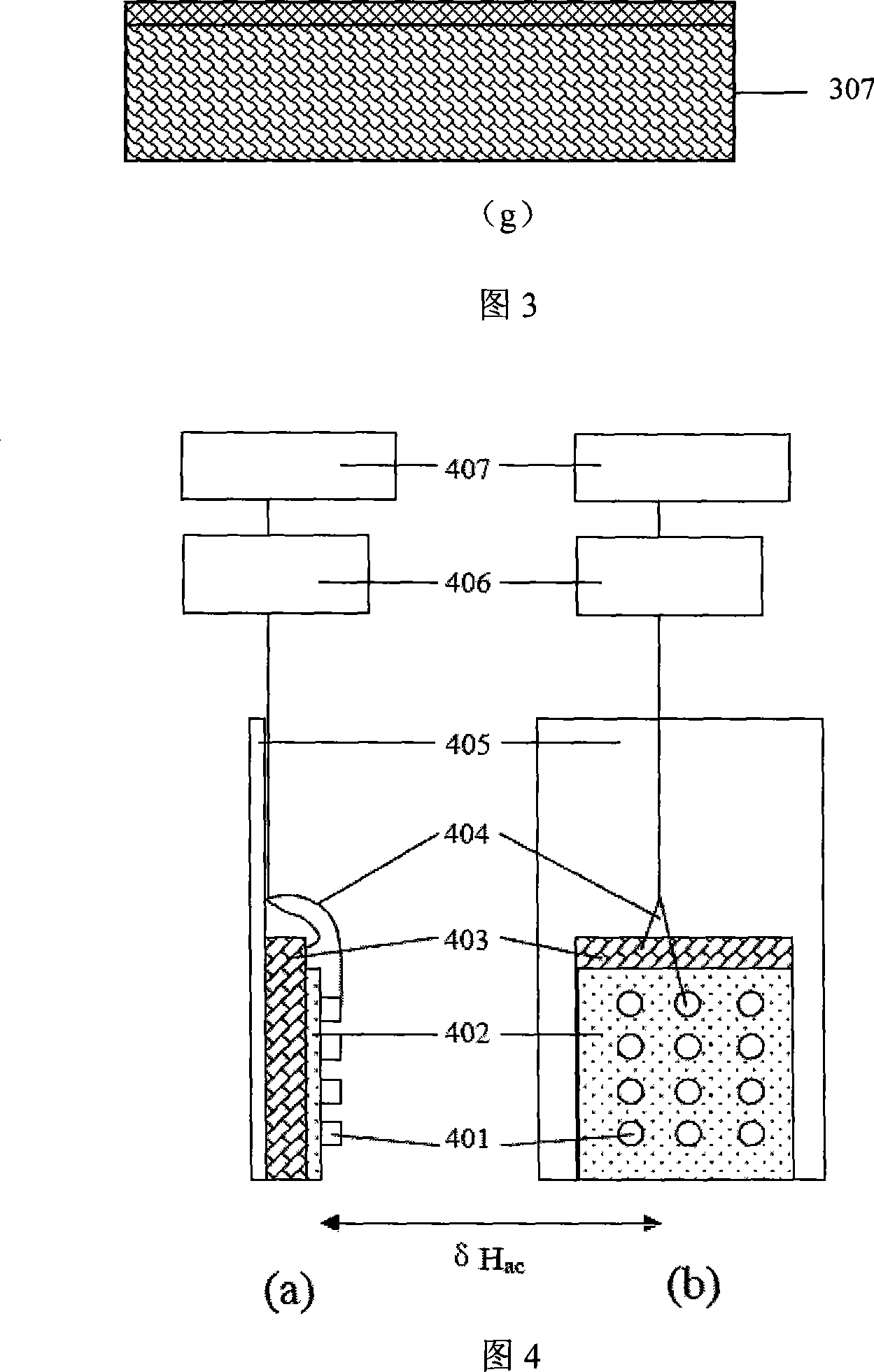

Compound film hetero-junction having magnetoelectric effect and preparing method thereof

InactiveCN101286545AAvoid disadvantagesEffective magnetoelectric couplingPiezoelectric/electrostrictive device manufacture/assemblyGalvano-magnetic material selectionHeterojunctionRare-earth element

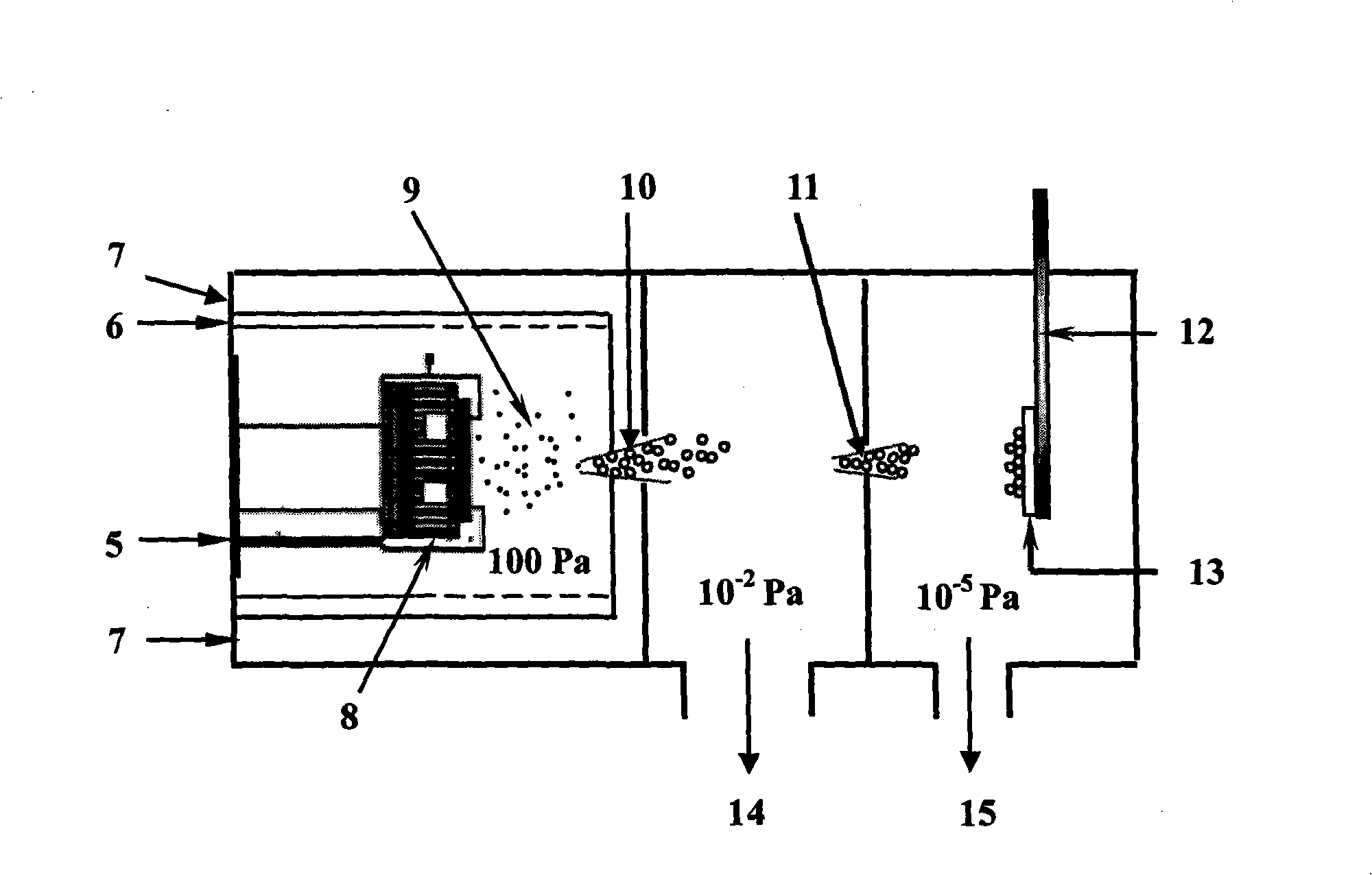

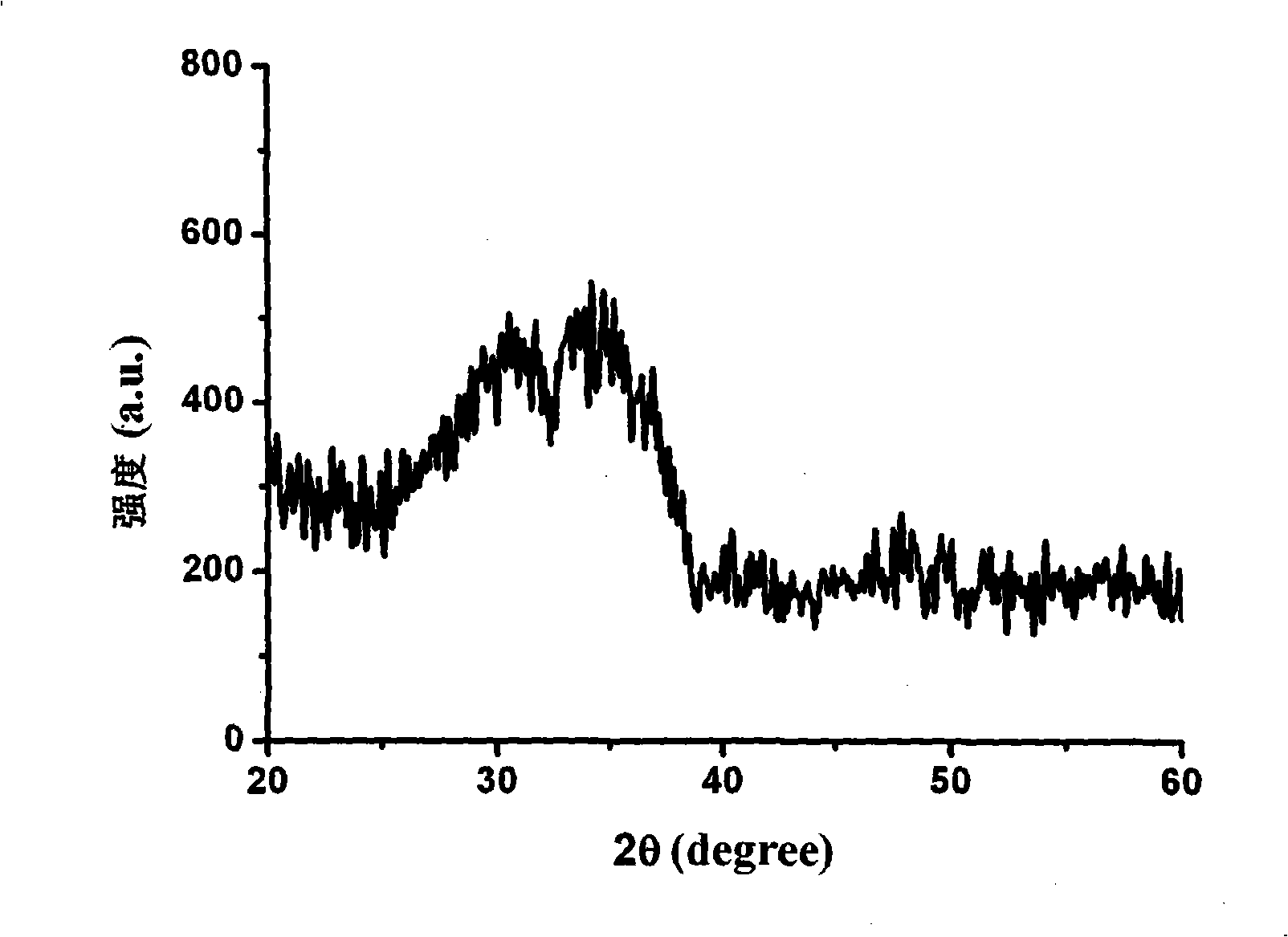

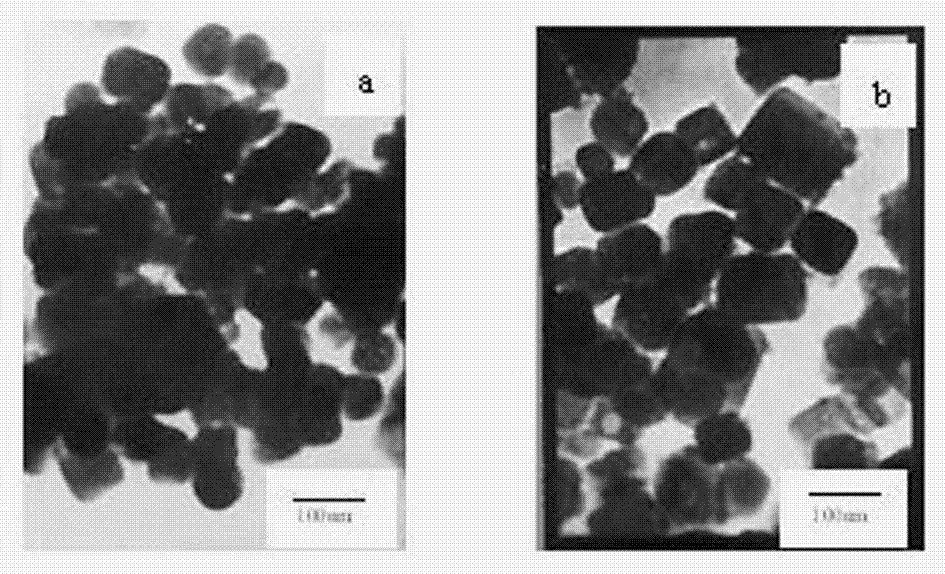

The invention relates to a composite film heterojunction with magnetoelectric effect, which is formed by the compound of material with piezoelectric effect and material with magnetostrictive effect and characterized in that: the material with the magnetostrictive effect is a rare earth ferroalloy RFe2 nano film, wherein, R is a rare earth element; the material with the piezoelectric effect is a soft PVDF polymer piezoelectric film; the compound mode of the two films is that: the rare earth ferroalloy RFe2 nano film is deposited on the PVDF piezoelectric film to form a RFe2 / PVDF double-layer nano composite film. The preparation method of the RFe2 / PVDF double-layer nano composite film comprises the steps that: RFe2 / PVDF nano-cluster beam current is continuously deposited on the surface of the PVDF piezoelectric film to form a RFe2 nano film layer. In the invention, the PVDF polymer film is a piezoelectric functional layer as well as the underlay of the RFe2 nano film layer. In the composite film heterojunction of the invention, interface stress transfer is more effective, thus having stronger magnetoelectric effect.

Owner:NANJING UNIV

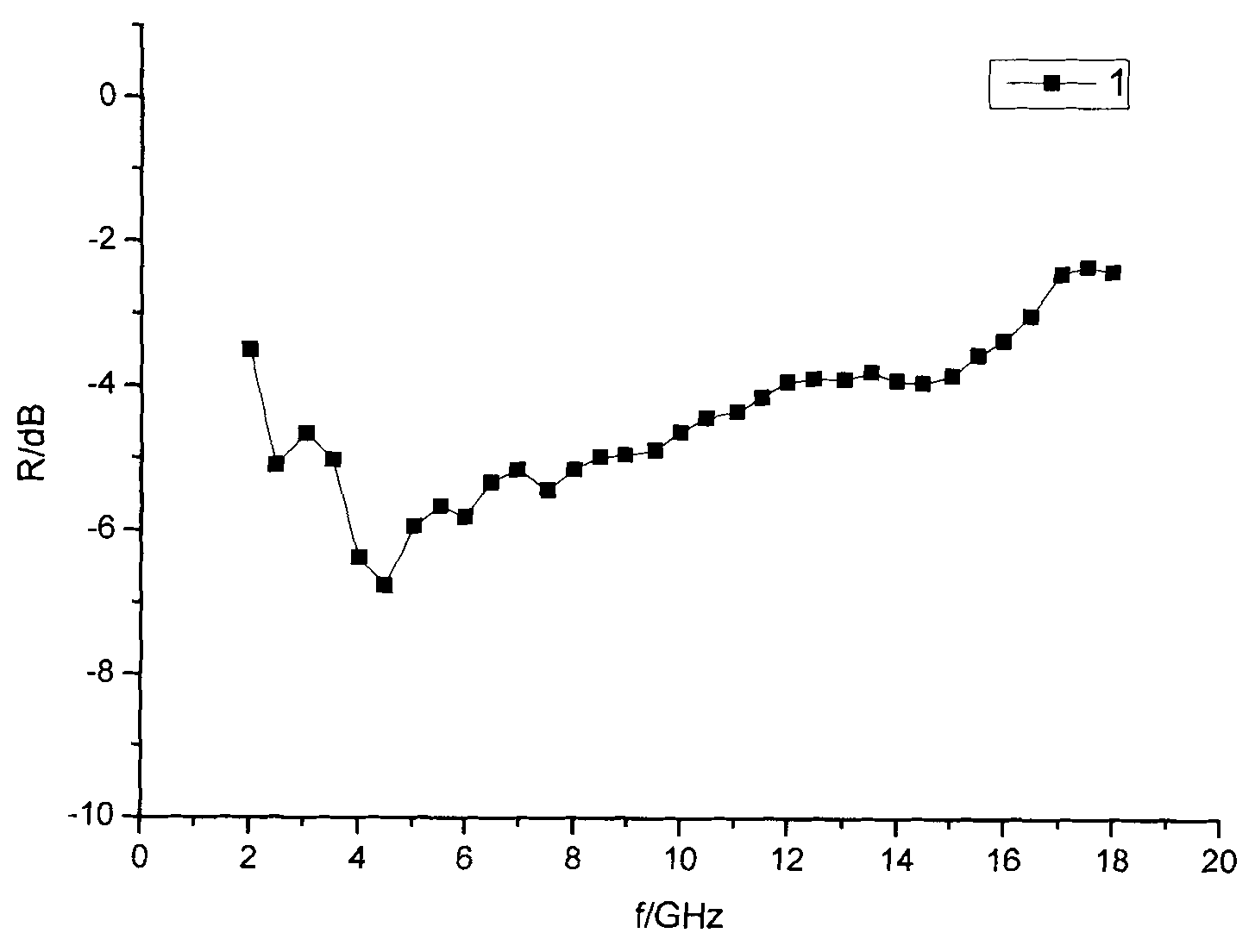

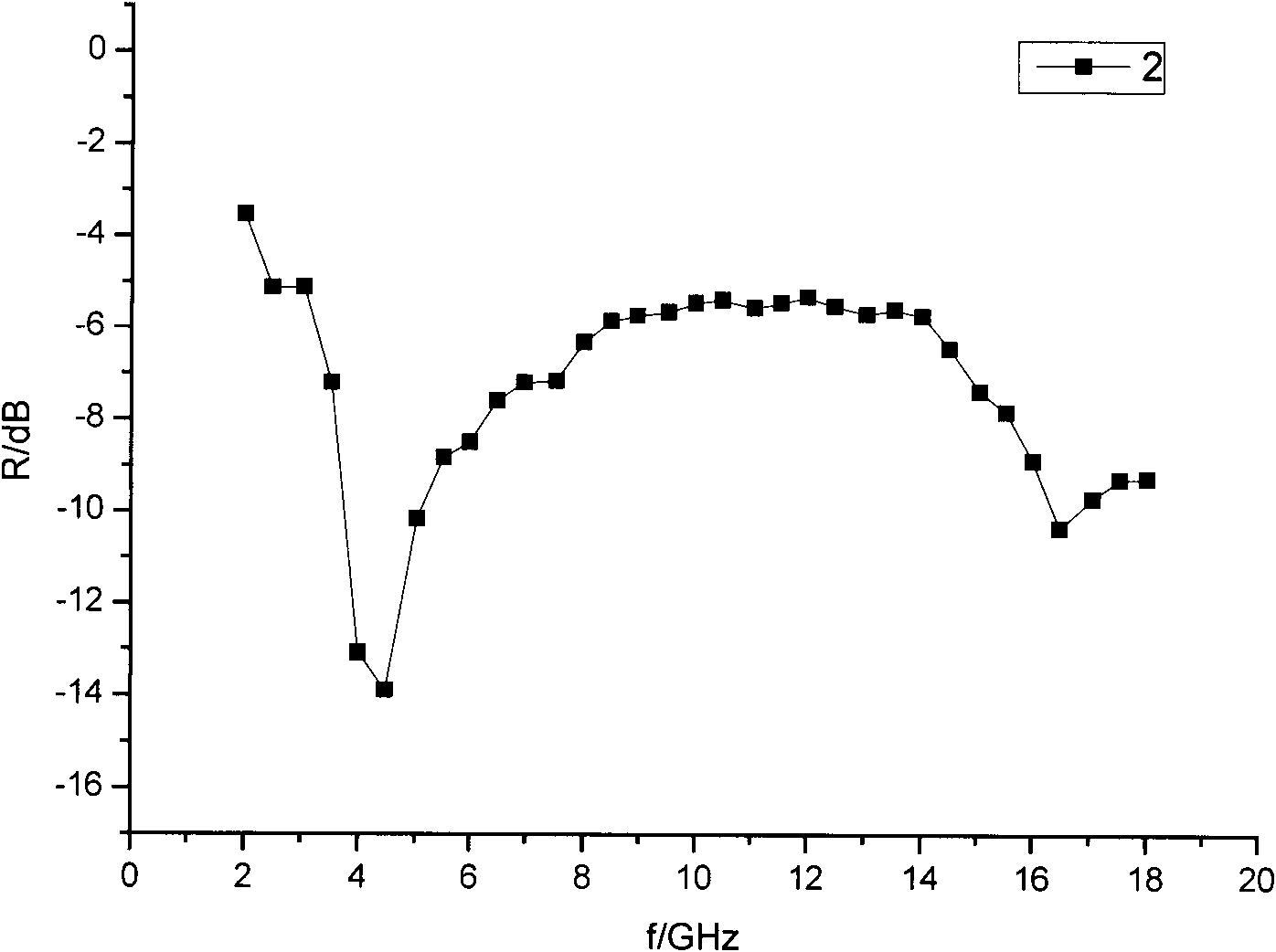

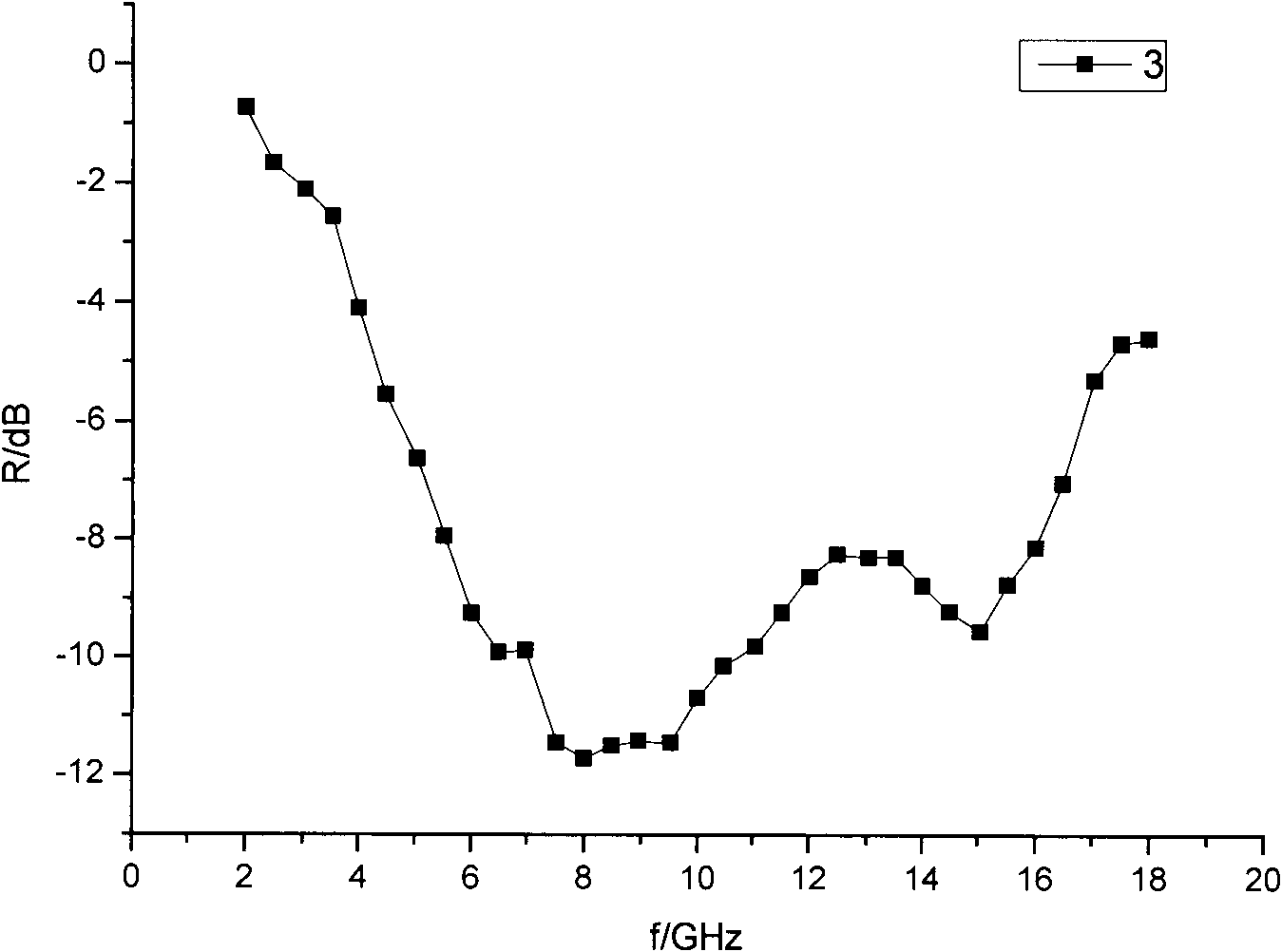

Method for preparing core-shell type barium titanate/polyaniline composite wave-absorbing material

InactiveCN102775604AImprove the disadvantage of poor compatibilityGood claddingFrequency waveBarium titanate

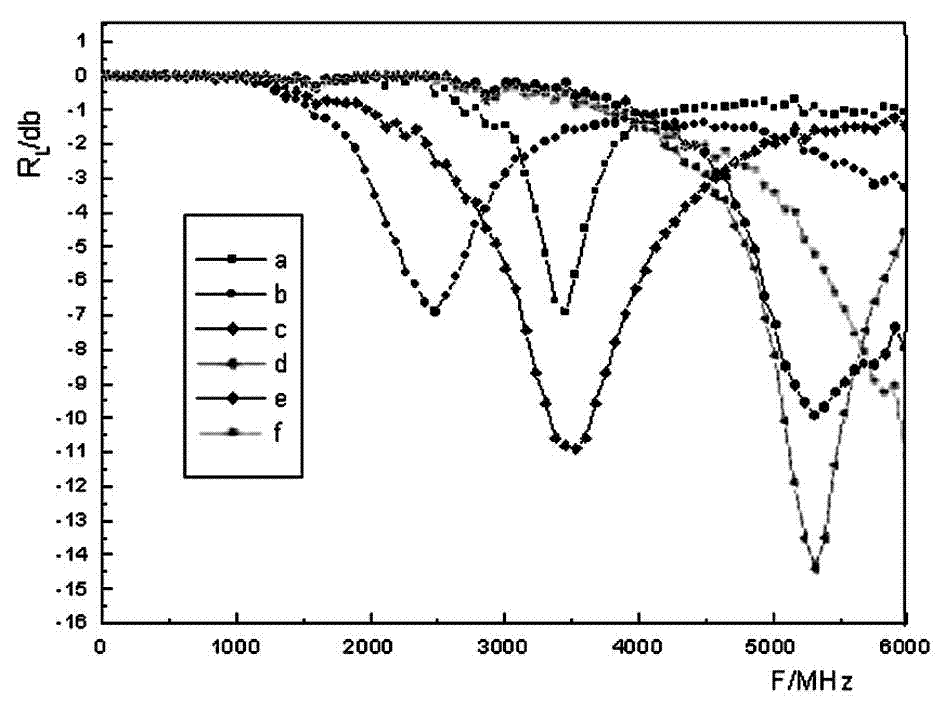

The invention discloses a method for preparing a core-shell type barium titanate / polyaniline composite wave-absorbing material. The method comprises the following steps of: adding an alcohol / water solution of a silane coupling agent into water dispersing agent of a nanometer barium titanate powder body; slowly dipping a hydrochloric acid solution of phenylamine; and finally dipping a hydrochloric acid solution of ammonium persulfate, and reacting to prepare the core-shell type barium titanate / polyaniline composite wave-absorbing material. Surface finishing on the nanometer barium titanate powder body is performed by using the silane coupling agent, so that polyaniline forms a good covering layer on the surface of barium titanate; and the prepared core-shell type barium titanate / polyaniline composite material has dielectric loss and magnetic loss; and because of specific magnetoelectric effect of the core-shell structure, the wide frequency wave-absorption performance of the material is obviously improved; the maximum reflectivity of the material is minus14.5dB in the range of 0-6GHz and is superior to minus 5dB and minus10dB; and the bandwidths are 1,200MHz and 750MHz respectively.

Owner:ZHONGBEI UNIV

Composite material with tremendous electromagnetic coupling effect and its application

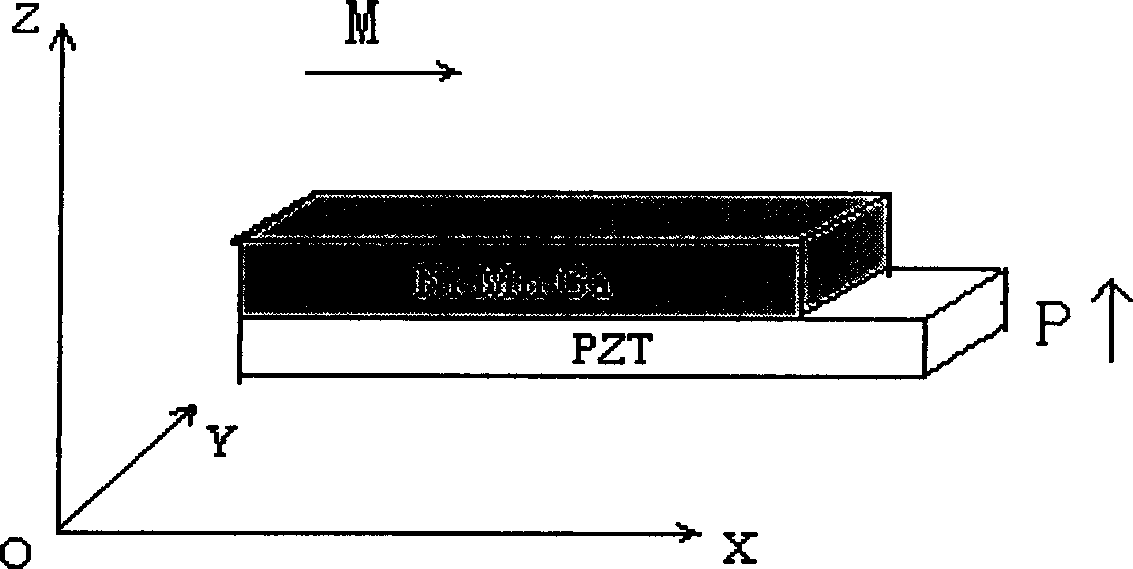

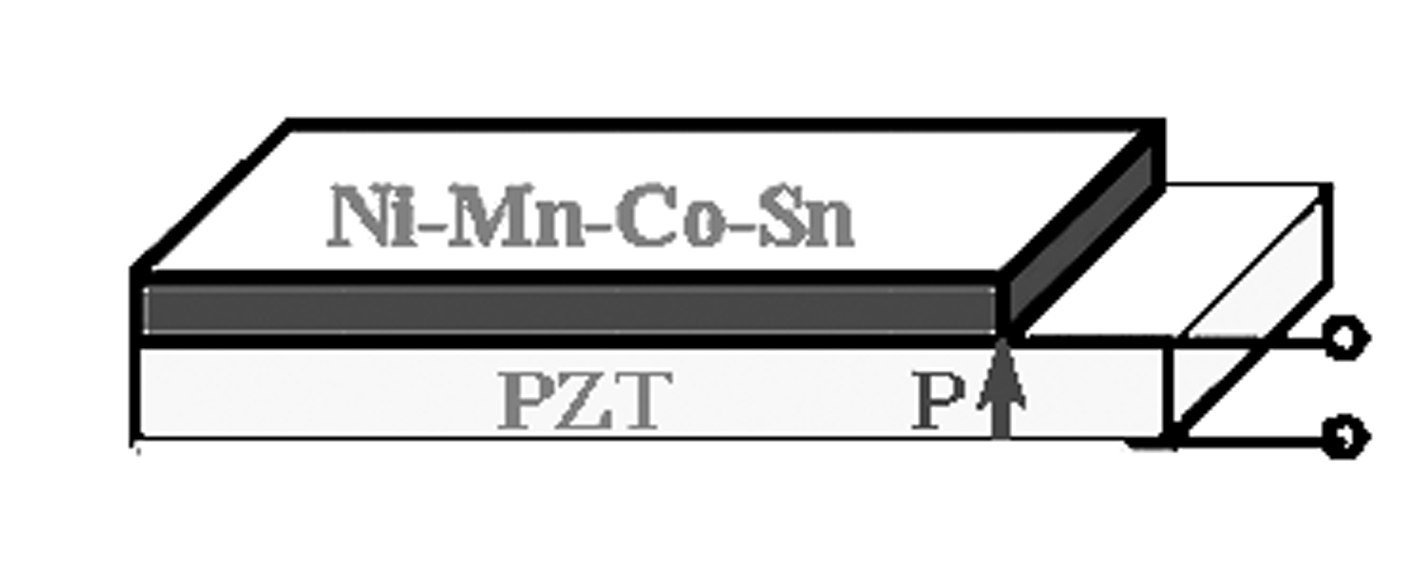

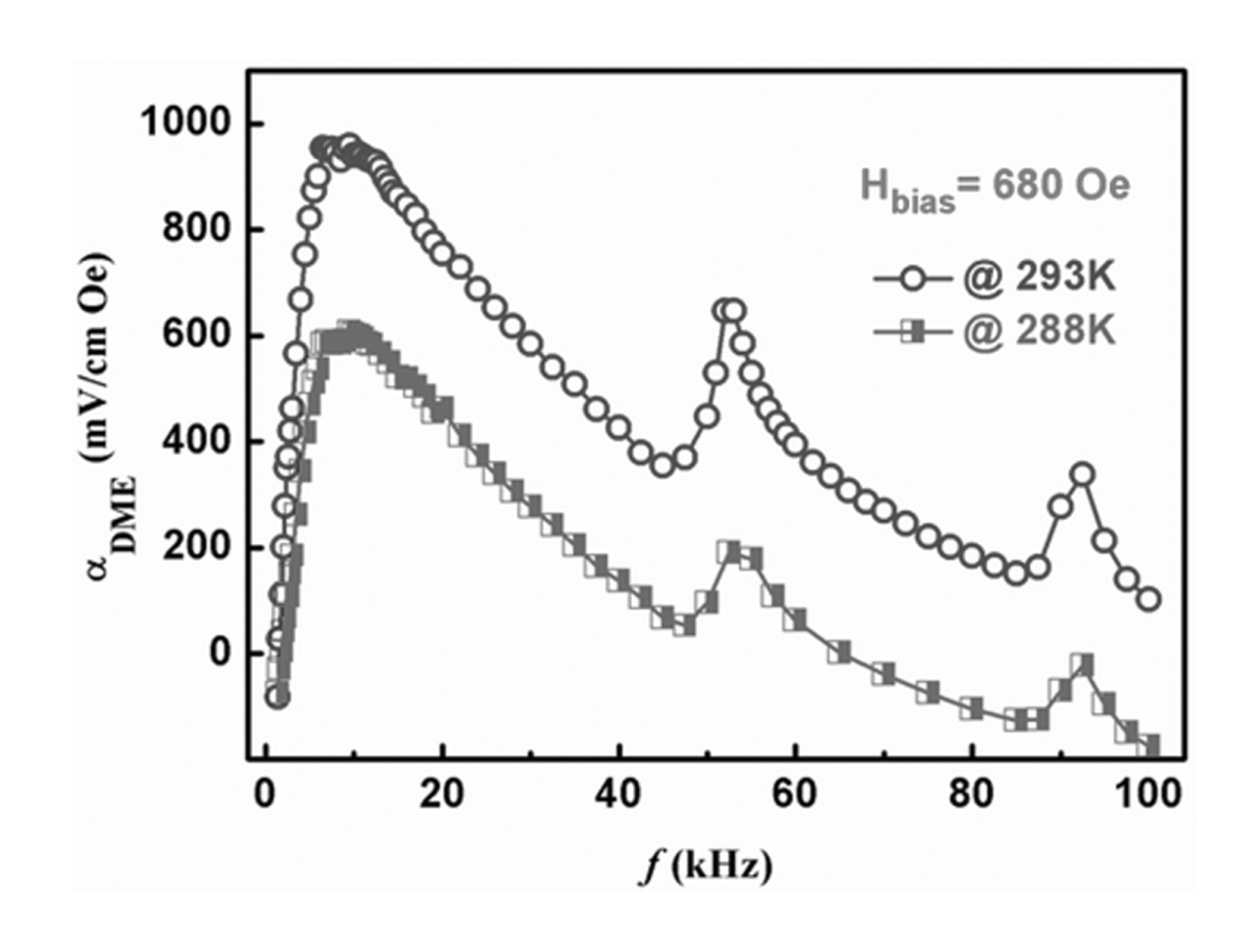

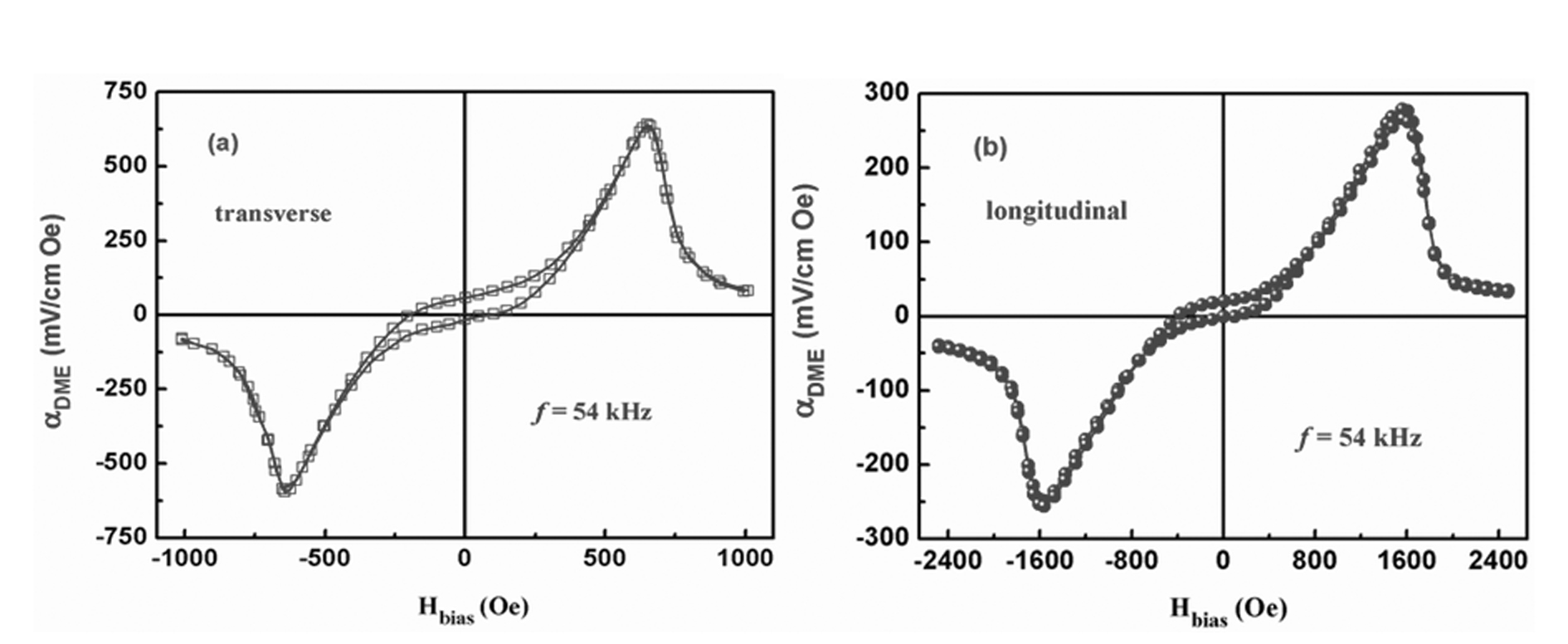

A new type of composite material with a huge magnetoelectric coupling effect. The Ni-based alloy and the piezoelectric material are made into a layered composite material. The Ni-based alloy can be a binary alloy of NiMn, NiFe, NiCo, and NiTi, or a ternary alloy of the above alloys , such as NiFeGa, NiTiHf, NiMnGa, NiFeO, NiCoO, NiTiPd, etc.; piezoelectric materials can be PZT, PMN-PT, LiNbO3, etc. with large piezoelectric coefficients. The invention adopts a novel composite material with magnetoelectric effect, and utilizes some temperature-related effects in Ni base alloy to obtain unexpected large magnetoelectric coupling effect. Thus, materials with temperature-dependent magnetoelectric coupling effects can be designed.

Owner:NANJING UNIV

Ni-Mn based ferromagnetic shape memory alloy/piezoelectric composite and application in magnetoelectric effect thereof

InactiveCN101982893AExcellent magnetostrictive propertiesImprove permeabilityGalvano-magnetic material selectionPiezoelectric/electrostrictive/magnetostrictive devicesMartensite transformationMetallic electrode

Owner:NANJING UNIV

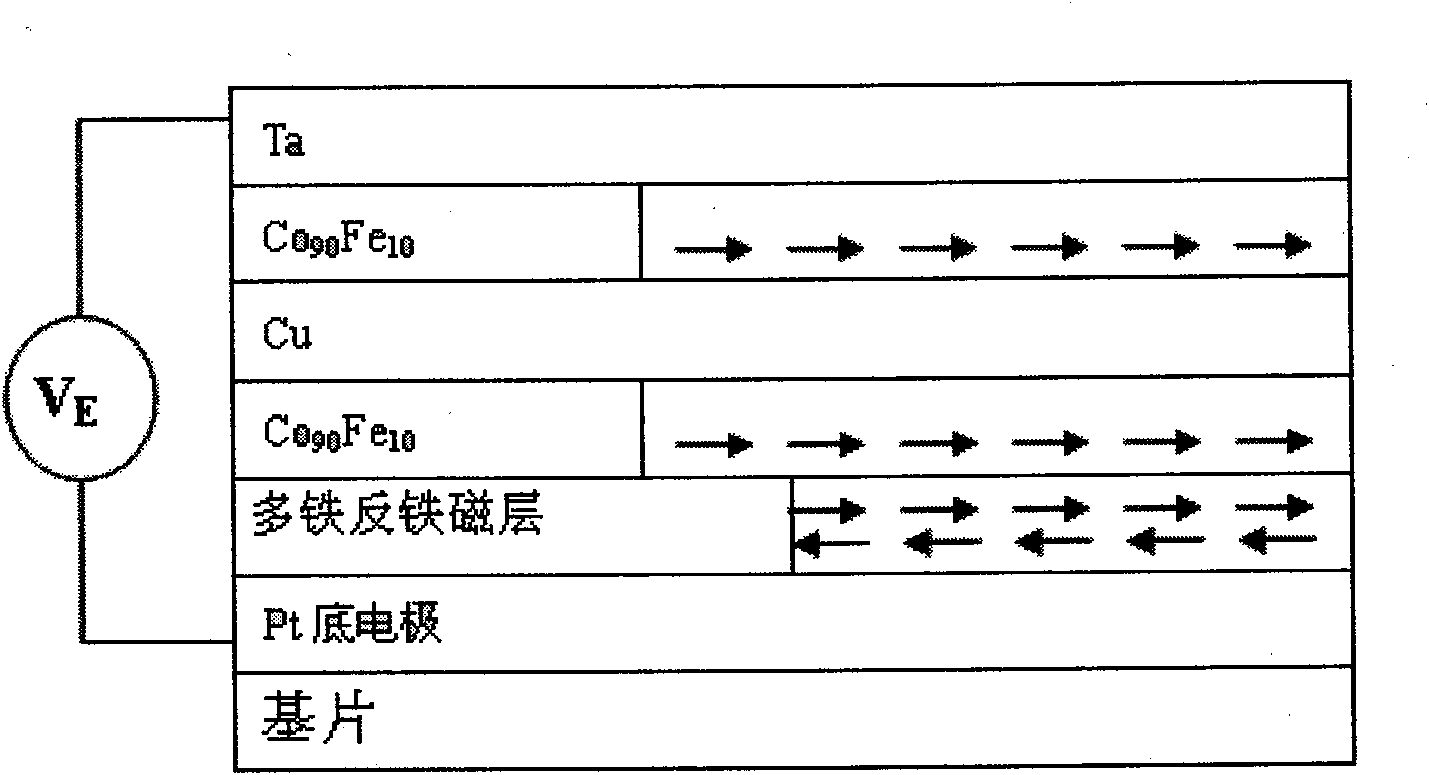

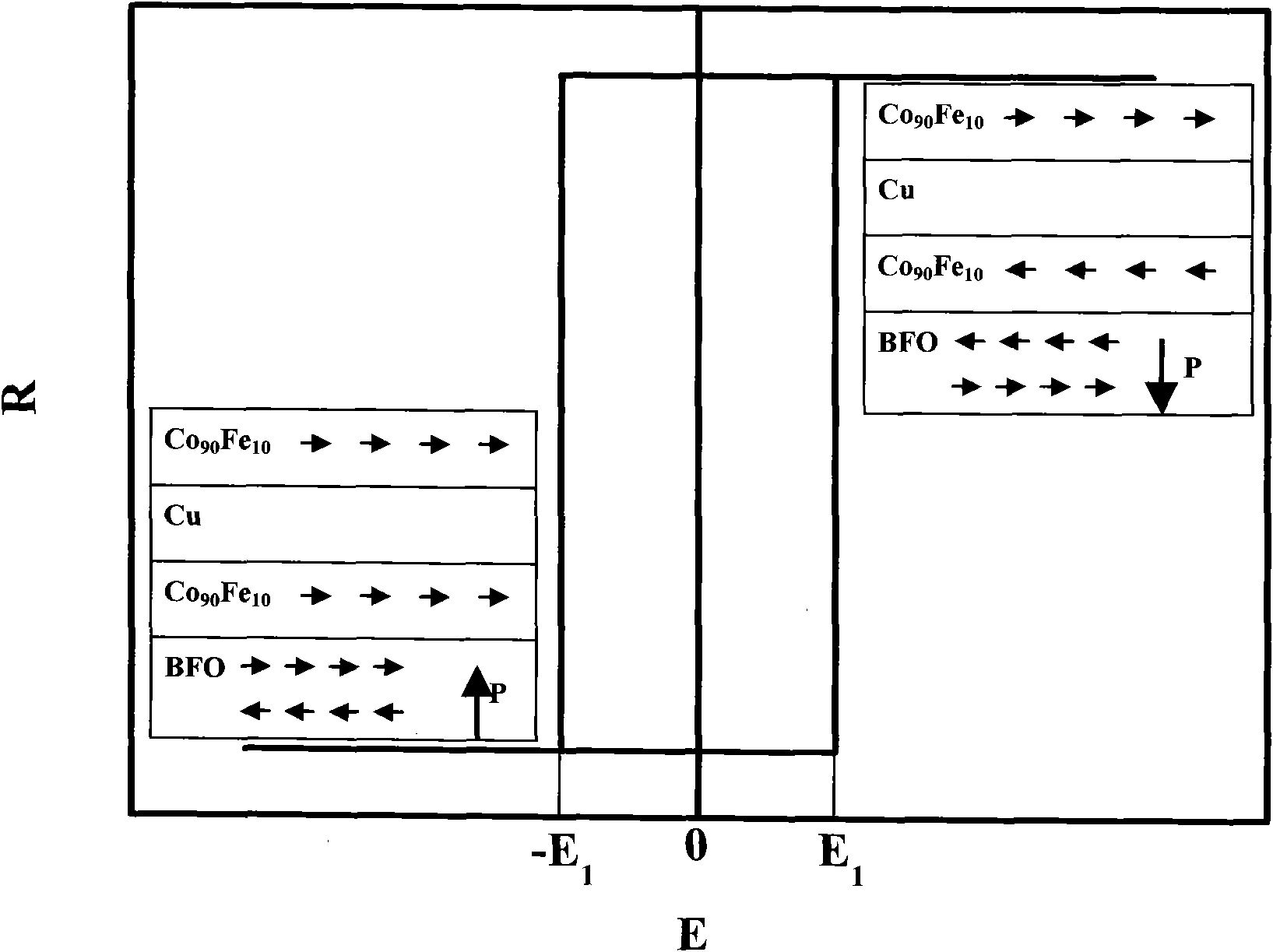

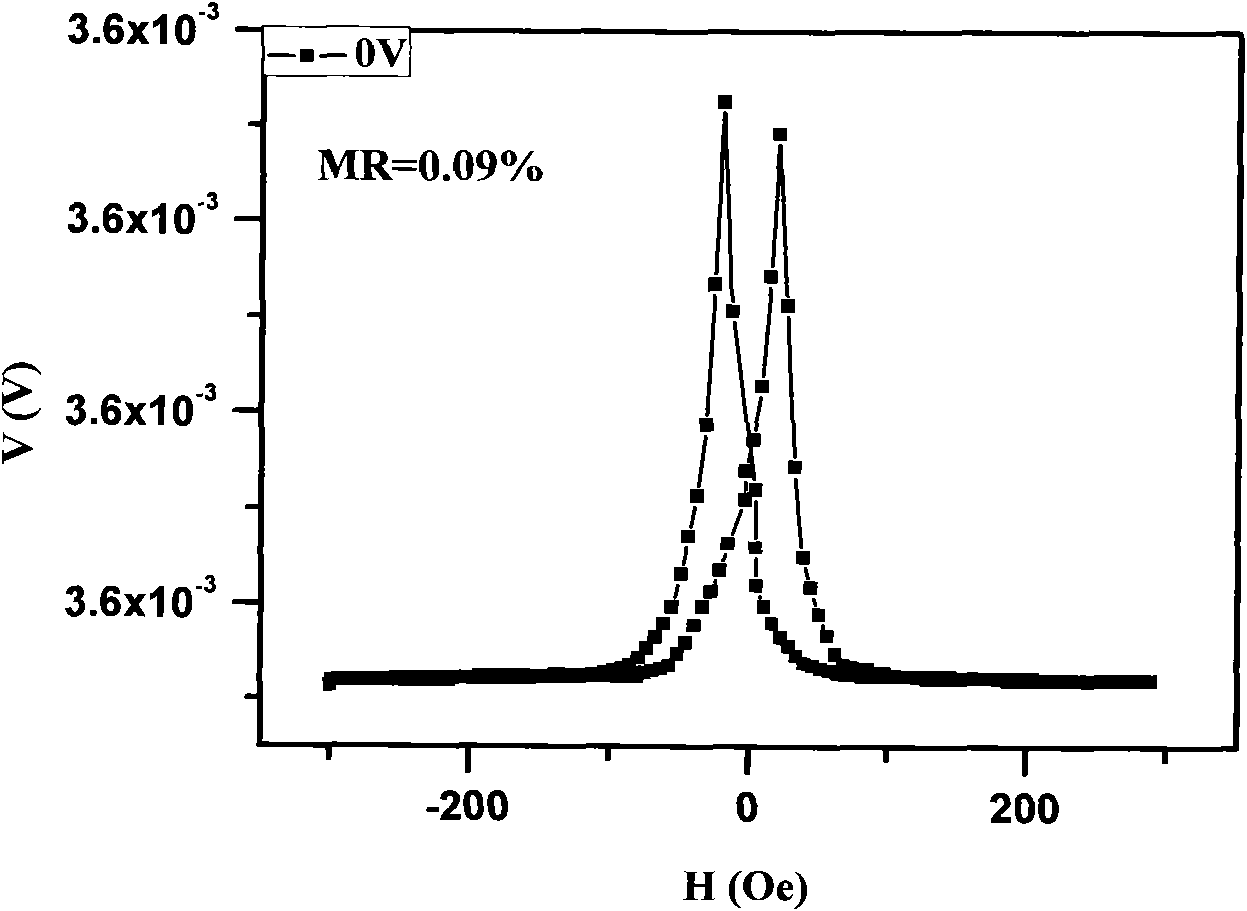

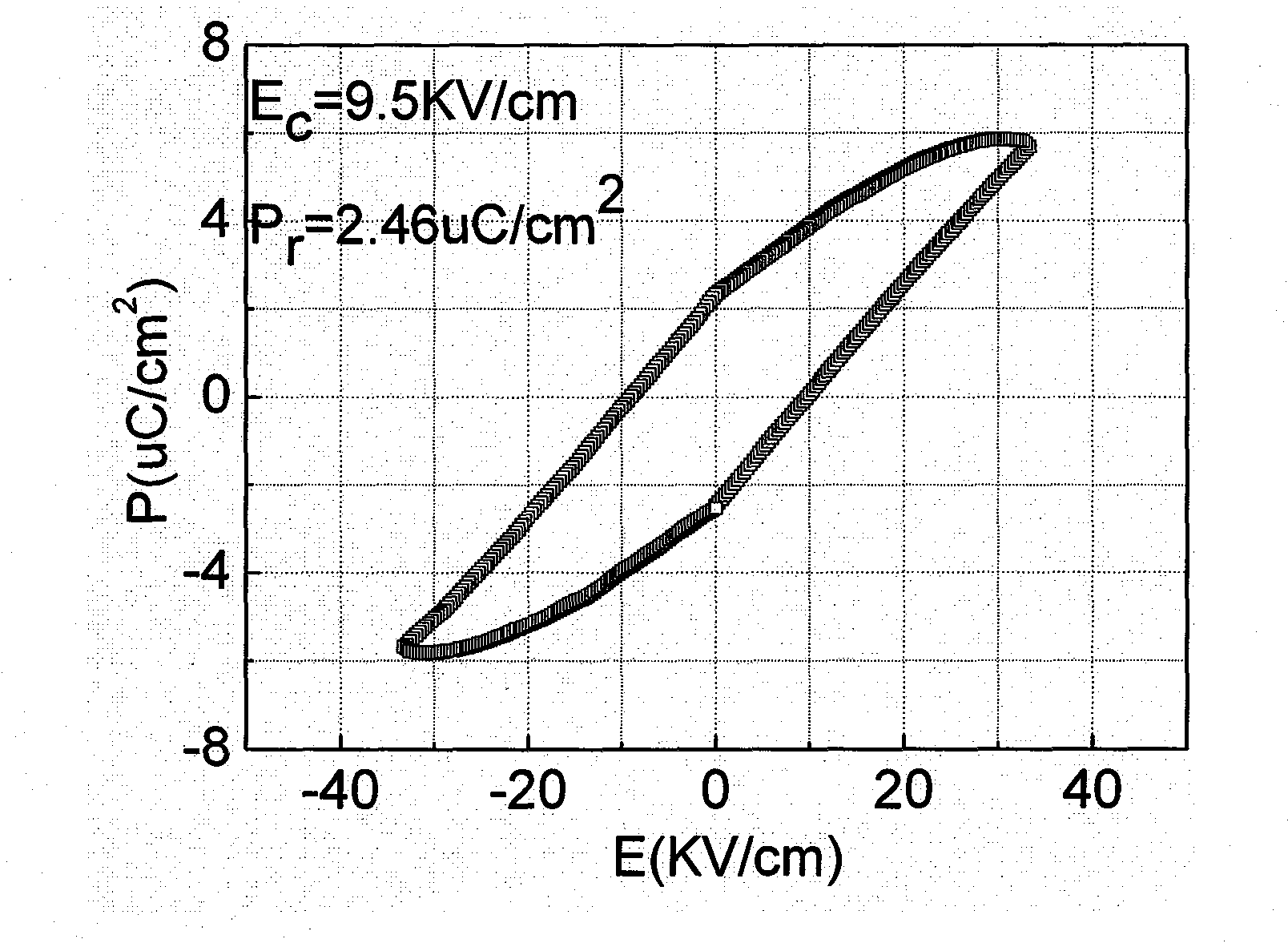

Spin valve structure with electric field-adjustable magnetoresistance and preparation process thereof

ActiveCN102129863AChange the direction of the magnetic domainChange resistanceManufacture of flux-sensitive headsCathode sputtering applicationElectrical resistance and conductanceNon magnetic

The invention discloses a spin valve structure with electric field-adjustable magnetoresistance. The spin valve structure is characterized in that: the spin valve structure with a multi-ferroic anti-ferromagnetic layer\a pinning layer\a non-magnetic layer / a free layer is prepared by replacing the anti-ferromagnetic layer in a conventional spin valve with a multi-ferroic material; and the magnetoresistance of the overall spin valve is adjusted and controlled by the anti-ferromagnetic layer. The invention also discloses a preparation process for the structure. The spin valve structure has the advantages that: the adjustment mode of the conventional spin valve is that the adjustment and the control of two states of the magnetoresistance are realized by changing a magnetic field direction of the free layer through an external magnetic field; and the spin valve utilizes a magnetoelectric effect of the multi-ferroic material and realizes the adjustment and the control of the two states of the magnetoresistance, namely an electric field readable and writable magnetic spin valve, by applying an external voltage to change an electric field direction so as to change the magnetic field direction thereof to influence the magnetic field direction of the pinning layer.

Owner:UNIV OF SCI & TECH BEIJING

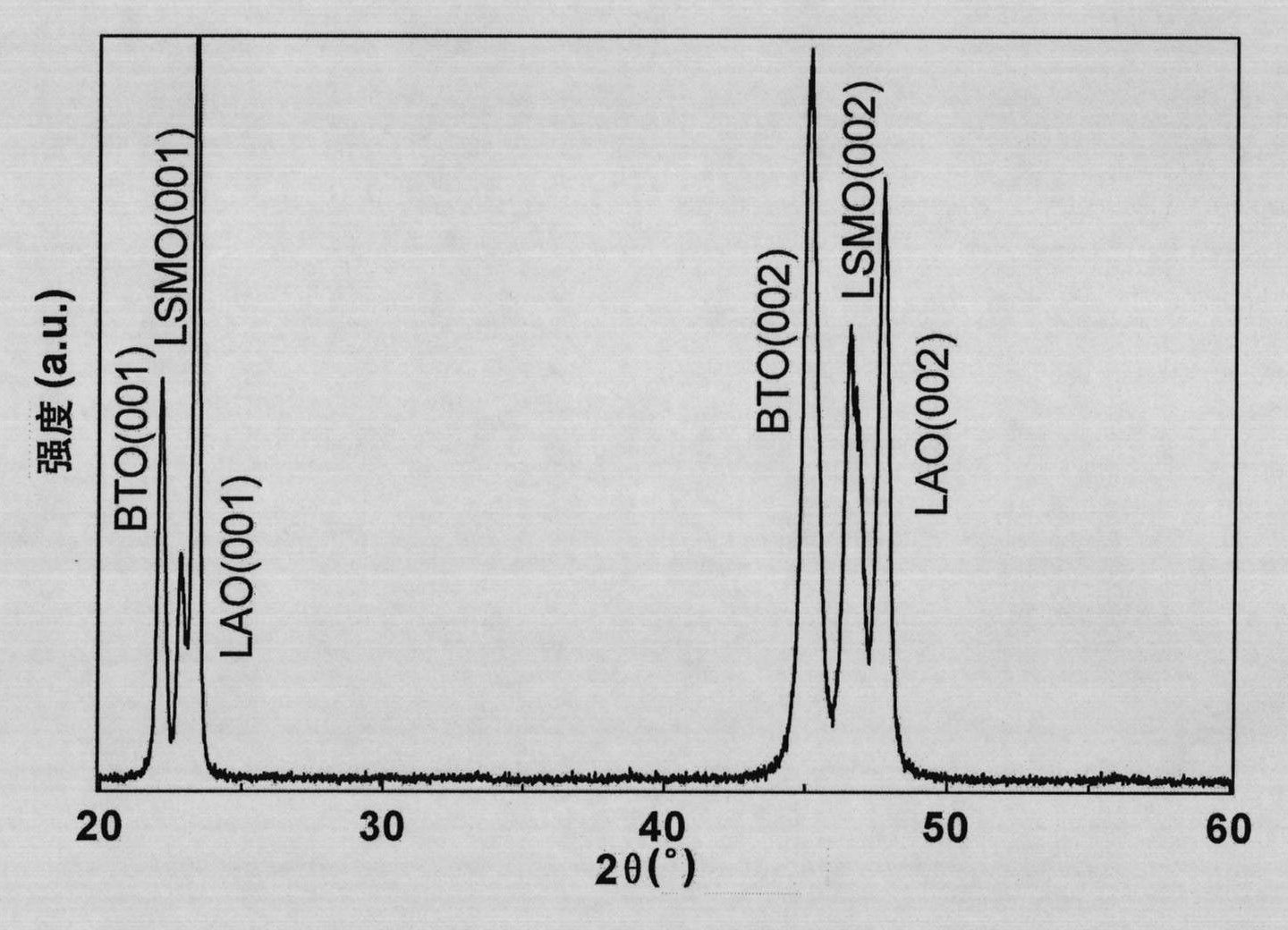

All-perovskite multiferroic magnetoelectric compound film and preparation method thereof

InactiveCN102071399AIdeal chemical ratioConsistent proportionVacuum evaporation coatingSputtering coatingSingle crystal substrateSingle crystal

The invention discloses an all-perovskite multiferroic magnetoelectric compound film and a preparation method thereof, belonging to the technical field of films. The La2 / 3Sr1 / 3MnO3 / BaTiO3 multiferroic magnetoelectric compound film with an all-perovskite structure is deposited on the surface of a LaAlO3 (001) single crystal substrate, and successively comprises a La2 / 3 Sr1 / 3MnO3 film and a BaTiO3 ferroelectric film from bottom to top; and the thickness of the La2 / 3Sr1 / 3MnO3 ferromagnetic film is 400-800nm, and the thickness of the BaTiO3 ferroelectric film is 400nm. The preparation method is as follows: deposing a La2 / 3Sr1 / 3MnO3 film and a BaTiO3 film on the LaAlO3 single crystal substrate by using pulse laser; and then annealing at the temperature of 850 DGE C. By using the preparation method, the ferromagnetic and ferroelectric properties of the La2 / 3Sr1 / 3MnO3 and BaTiO3 can be effectively improved, and the magnetoelectric effect of the compound film can also be improved.

Owner:BEIJING UNIV OF TECH

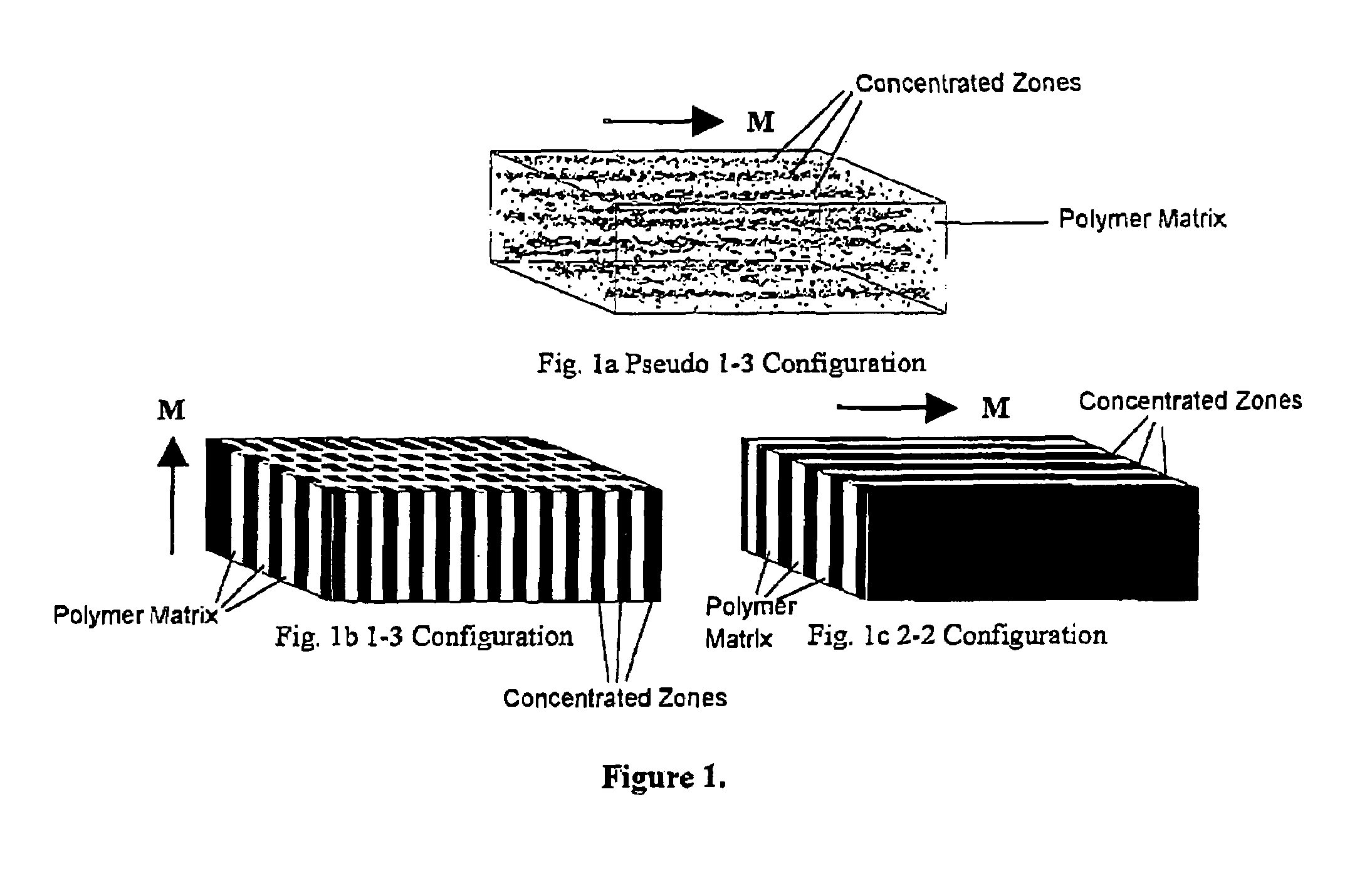

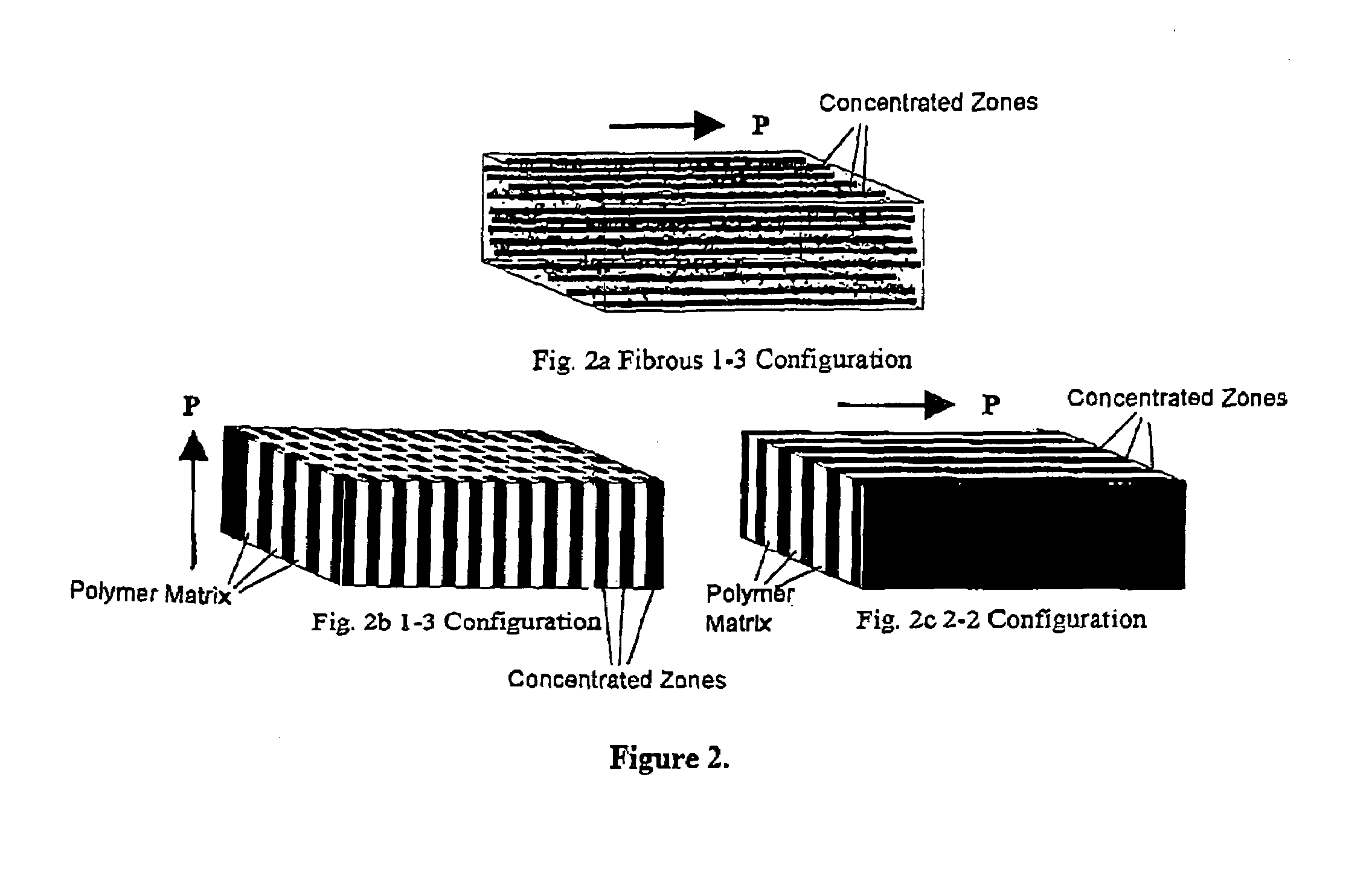

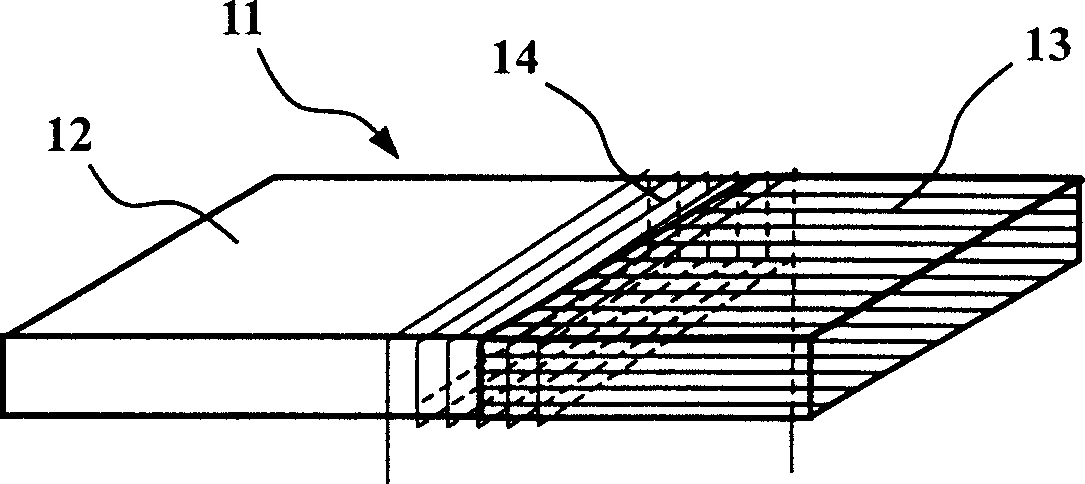

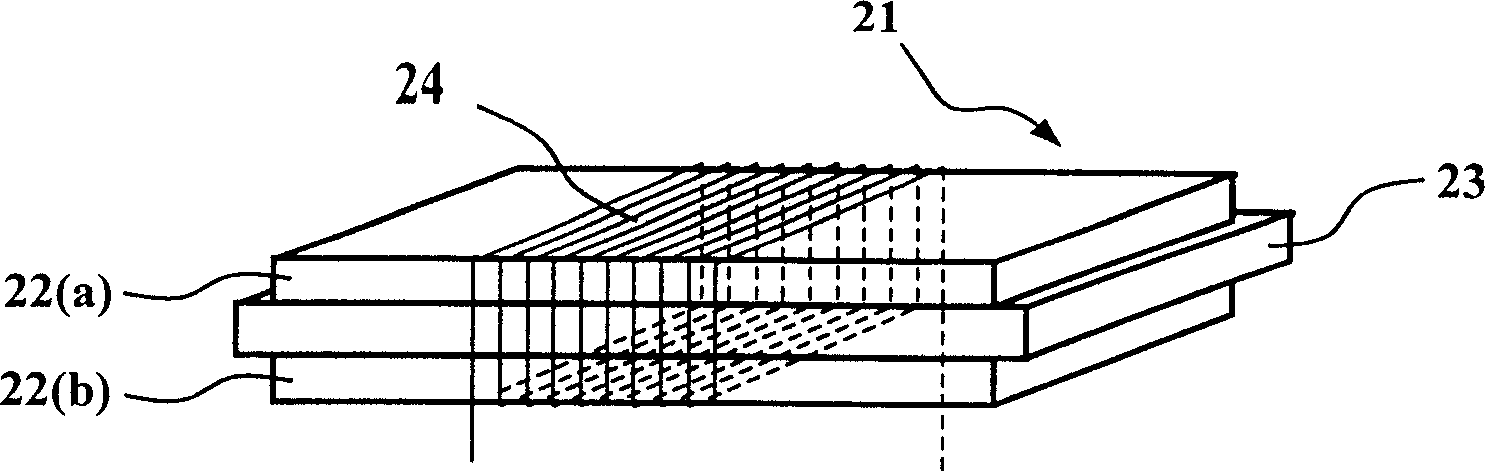

Magnetoelectric devices and methods of using same

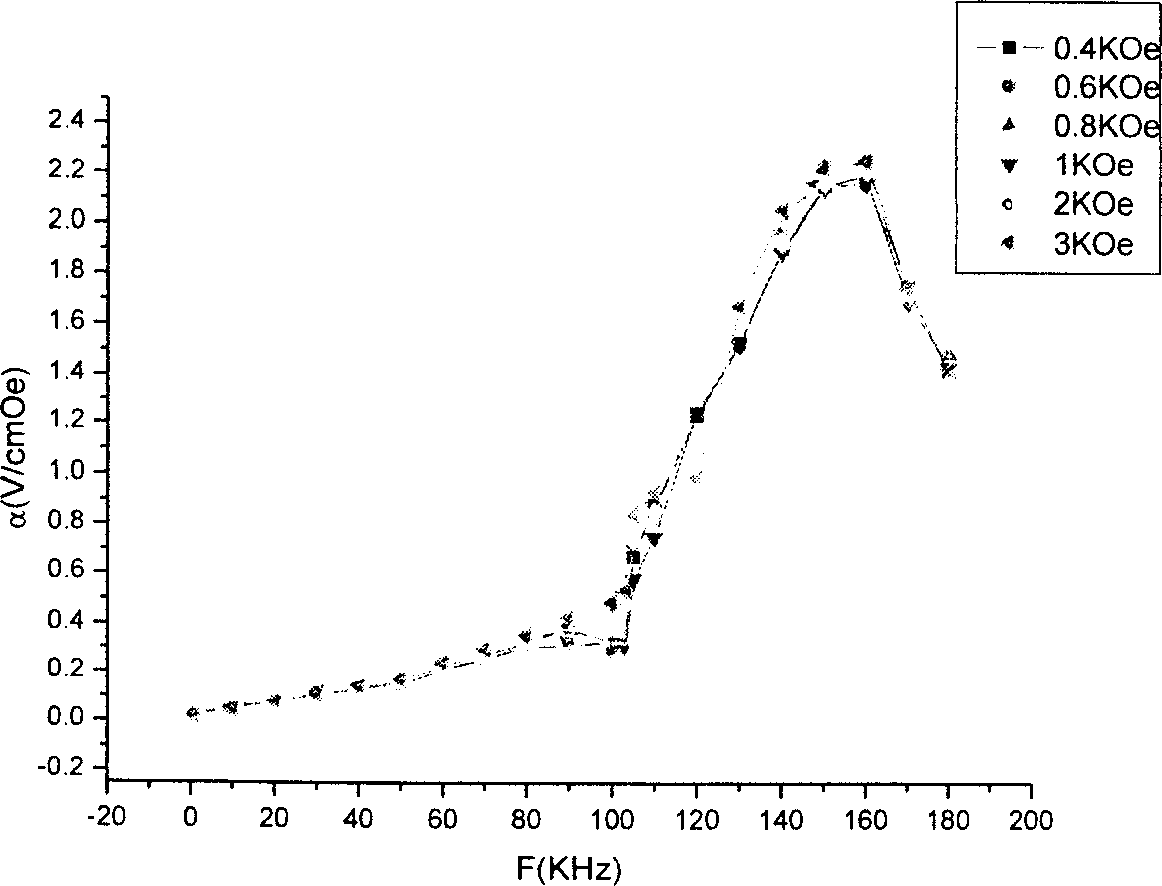

ActiveUS7199495B2Piezoelectric/electrostriction/magnetostriction machinesDevice material selectionElectricityEddy current

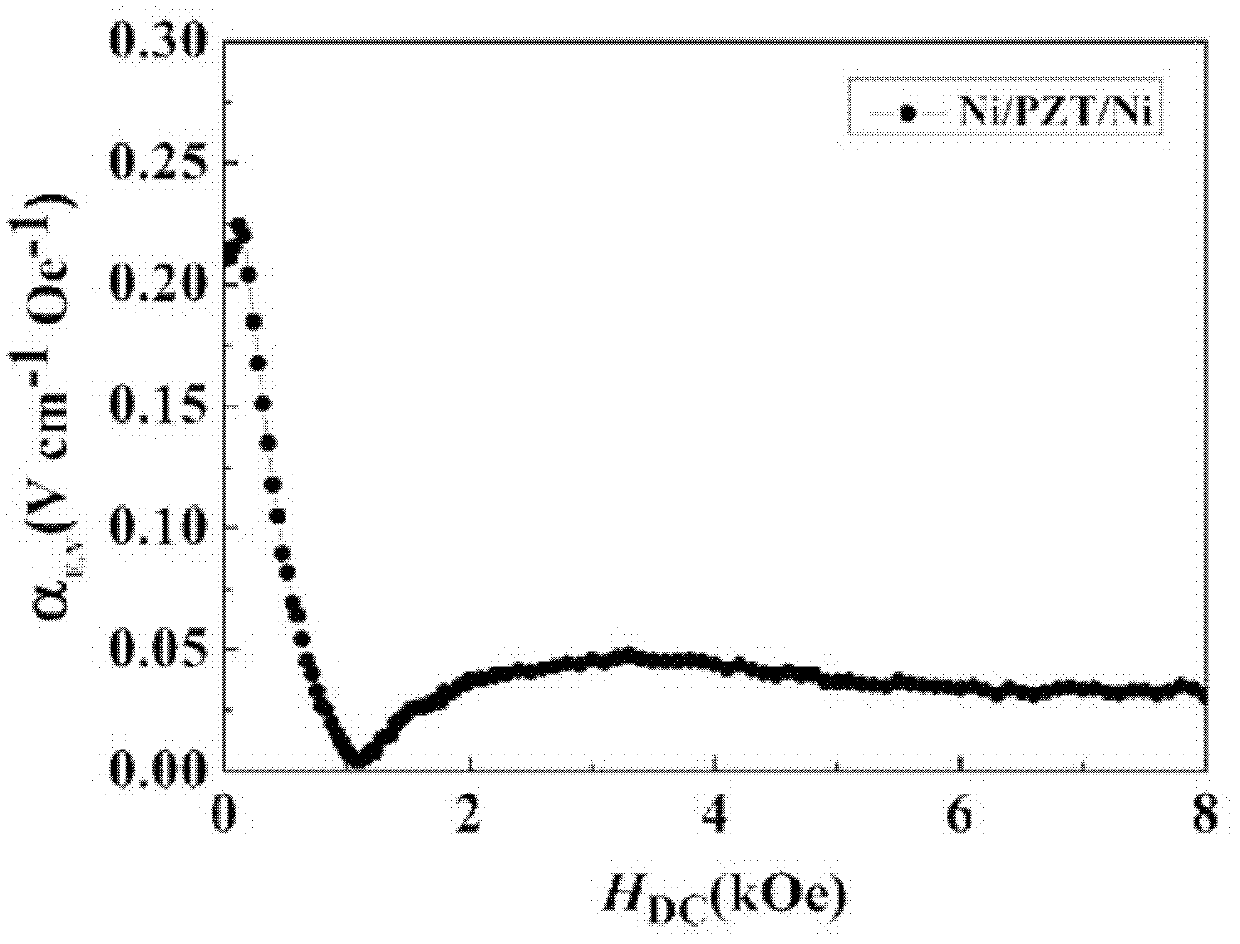

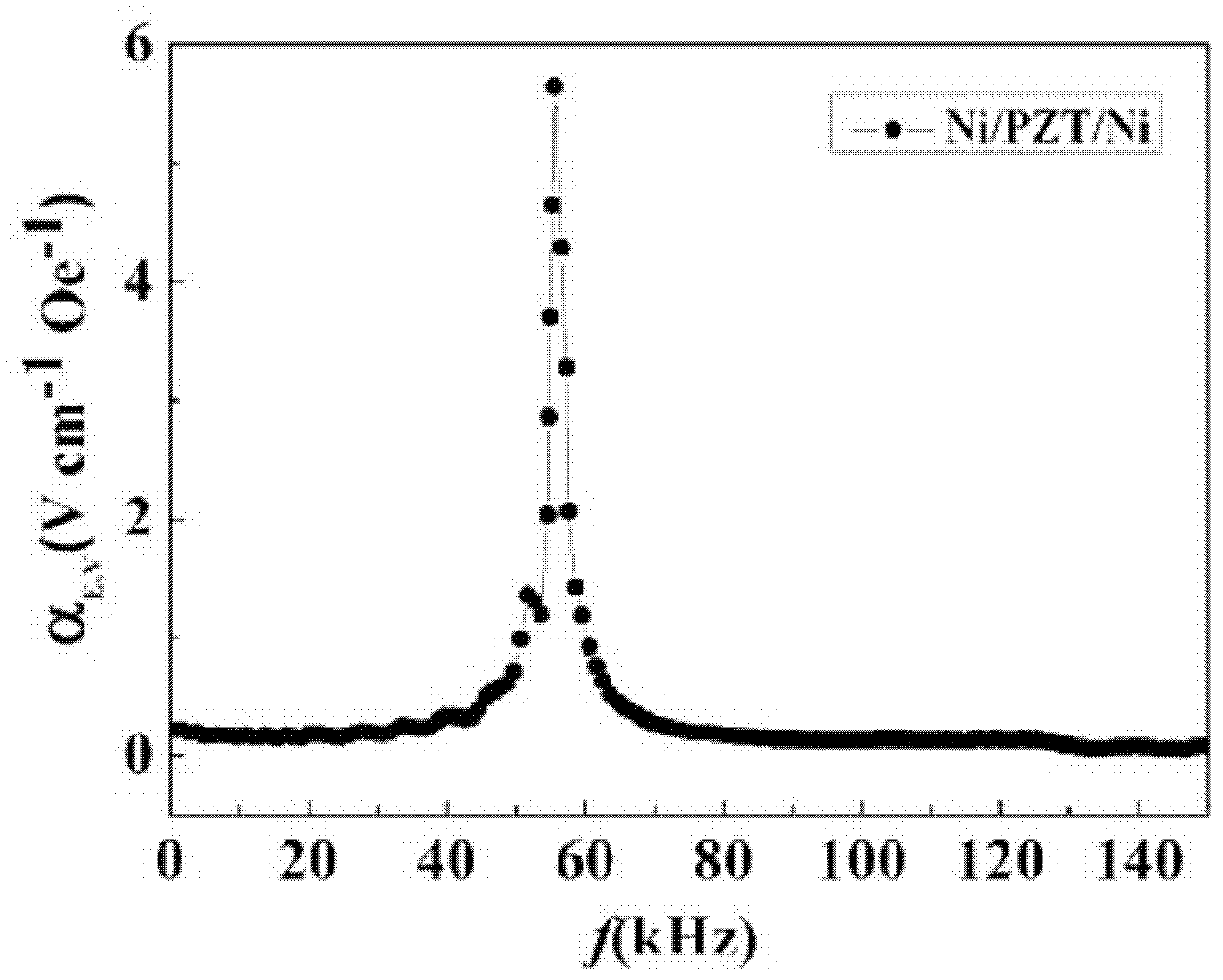

The operational frequency of existing magnetoelectric materials having metallic or ceramic magnetostrictive materials and ceramic piezoelectric materials may be limited to a few kilohertz due to the presence of eddy-current losses in the metallic magnetostrictive phase. Further, these materials may be difficult to machine and fabricate due to their brittleness. Additionally, it may be difficult to tailor and optimize the properties (i.e., magnetoelectric voltage coefficient αE, etc.) of the devices. This invention provides a magnetoelectric element including at least one set of alternative piezoelectric layer and magnetostrictive composite layer. The magnetostrictive composite layer includes at least one magnetostrictive material dispersed in first concentrated zones within a first polymer matrix, wherein all of said concentrated zones are orientated along a first direction. It is found that the conversion efficiency (i.e., αE) varies in accordance with applied magnetic control field Hcontrol.

Owner:THE HONG KONG POLYTECHNIC UNIV

Fluid power-generation shock damper of electric bicycle

ActiveCN101892968AReduce wasteIncrease mileageReciprocating piston enginesMechanical power devicesHydraulic cylinderEngineering

The invention relates to a fluid power-generation shock damper of an electric bicycle. The telescopic action of a spring is used for pressing fluid in order to promote magnetoelectric effect for realizing power generation in a shocking process. The fluid power-generation shock damper comprises a damping device and a fluid power-generating device, wherein the damping device comprises a damping cylinder, a main hydraulic cylinder, a main piston rod, a main piston and a damping spring, wherein the top of the damping cylinder is provided with an upper lifting ring, the lower part of the main hydraulic cylinder is provided with a transmitting pipe, the bottom of the main hydraulic cylinder is provided with a lower lifting ring, the main piston rod is connected with the damping cylinder, the main piston is squeezed into the main hydraulic cylinder, and the upper end and the lower end of the damping spring are respectively fixed with the damping cylinder and the main hydraulic cylinder; the fluid power-generating device comprises an auxiliary hydraulic cylinder, circular magnets and a central shaft, wherein a coil is arranged into the auxiliary hydraulic cylinder, the auxiliary hydraulic cylinder is communicated with the upper end and the lower end of the main hydraulic cylinder, the circular magnets can move in the coil up and down, and the central shaft is used for connecting the circular magnets in series and is fixed into the auxiliary hydraulic cylinder. The fluid power-generation shock damper solves the problems that the traditional shock damper only has a damping action and wastes energy in a shocking process and has the characteristics of collecting and converting energy generated in the shocking process into electric energy, increasing once-charging running mileage, reducing energy waste, and the like.

Owner:吉林省同创投资有限公司

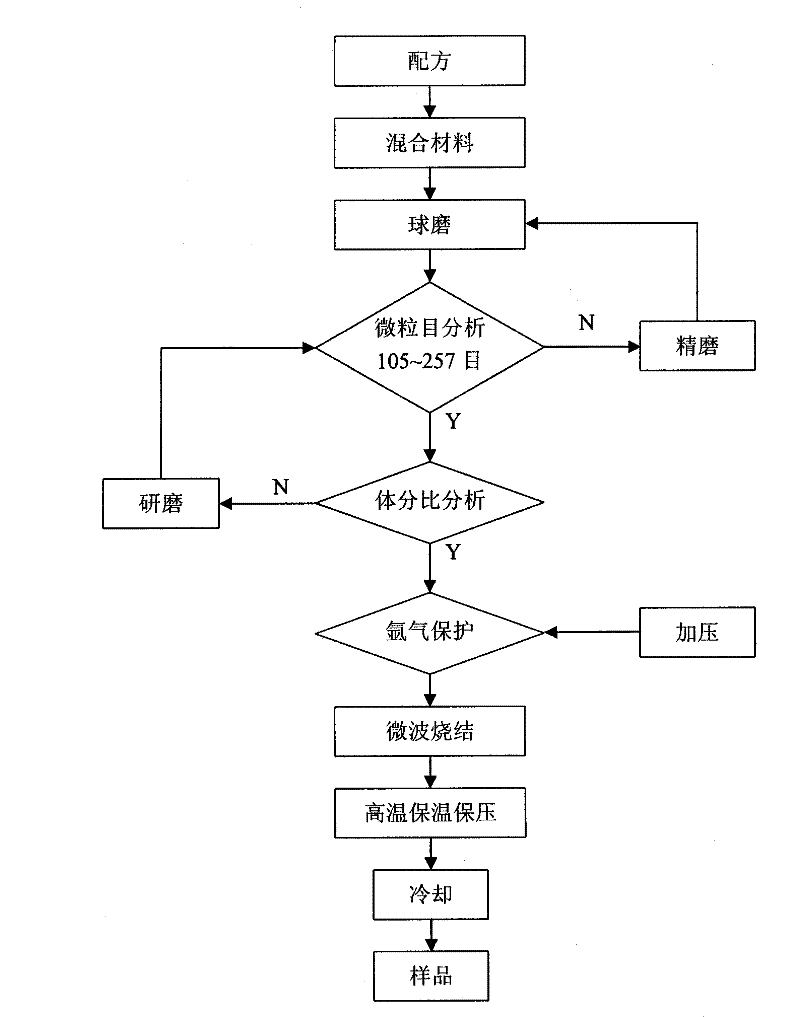

Lead magnesium niobate-lead titanate-bismuth ferrite multiferroic ceramic material and preparation method thereof

InactiveCN107500764AHigh strengthImprove magnetic propertiesInorganic material magnetismComposite ceramicRoom temperature

The invention discloses a lead magnesium niobate-lead titanate-bismuth ferrite multiferroic ceramic material and a preparation method thereof. The lead magnesium niobate-lead titanate-bismuth ferrite multiferroic ceramic material comprises a novel ferroelectric and ferromagnetic composite ceramic material formed by adding bismuth ferrite into lead magnesium niobate (PMN)-lead titanate (PT) serving as a matrix. The material comprises the chemical components: (1-x)[(1-y)Pb(Mg1 / 3Nb2 / 3)O3+yPbTiO3]+xBiFeO3, x is equal to 0.01-0.05, and y is equal to 0.30-0.39. The lead magnesium niobate-lead titanate-bismuth ferrite multiferroic ceramic material is simple in process and low in cost, and the spontaneous polarization intensity and magnetic property of the material can be improved by regulation. The multiferroic ceramic material is relatively low in raw material cost, simple in preparation process and easy to store and use; and the multiferroic magnetoelectric composite can be widely applied to aspects such as sensors, energy converters, filters, oscillators and storages due to a remarkable magnetoelectric effect at room temperature.

Owner:SHANGHAI NORMAL UNIVERSITY

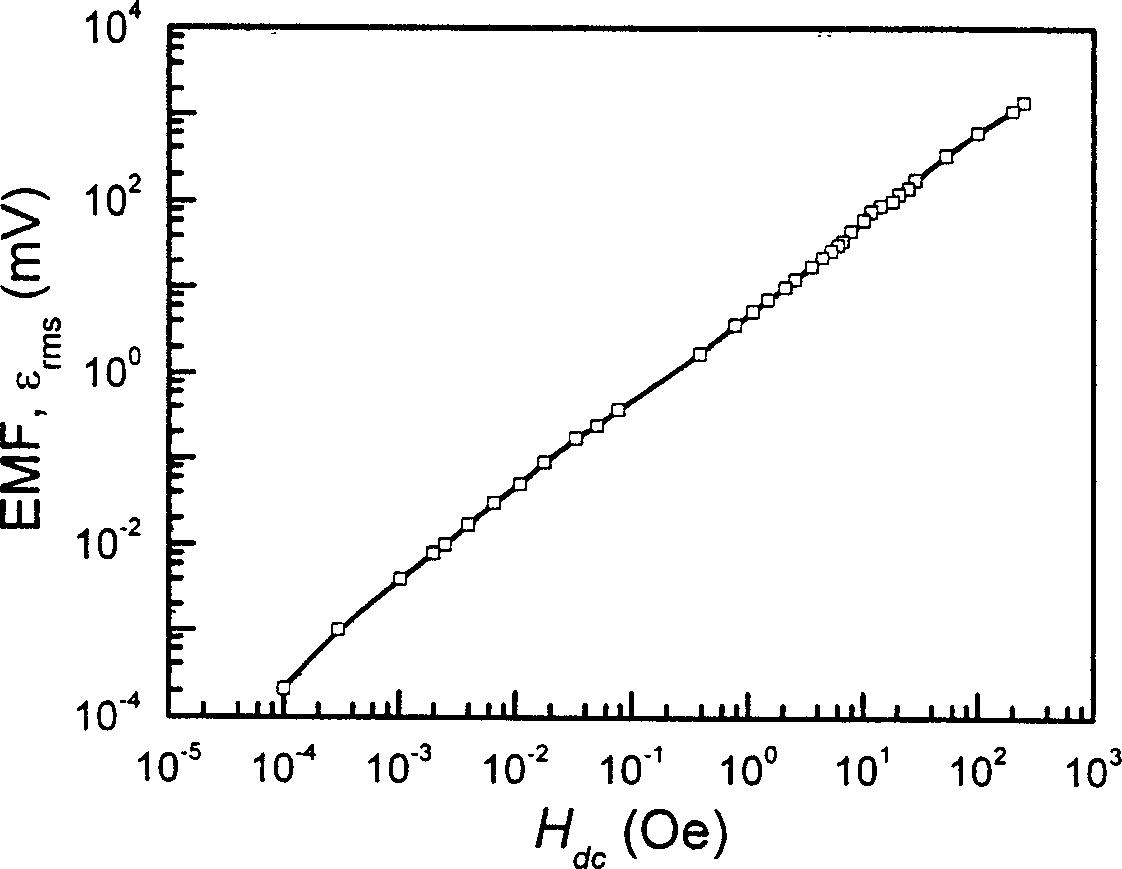

DC magnetic field sensor

InactiveCN1900732ASimple structureEasy to operateMagnetic field measurement using galvano-magnetic devicesMagnetizationElectromotive force

DC magnetic field sensor includes magneto-electric component, and induction coil. Two electrodes of the component are connected to alternation power supply. Characters are that the component is prepared from material of magnetoelectric effect. Induction coil is enwound outside the component. Two ends of the induction coil are output ends of the sensor. Applied alternation electric field makes inside magneto-electric component generate magnetization caused by magnetoelectric effect. The said magnetization generated can be sensitive inducted by external induction coil so as to generate an induction electromotive force (IEF). When the sensor is placed in DC magnetic field since magnetoelectric effect presents regular change along with change of DC magnetic field. Thus, variable magnetized state causes change of IEF of outer induction coil. Therefore, magnitude of DC magnetic field to be detected can be obtained by measuring magnitude of IEF of outer induction coil.

Owner:NANJING UNIV

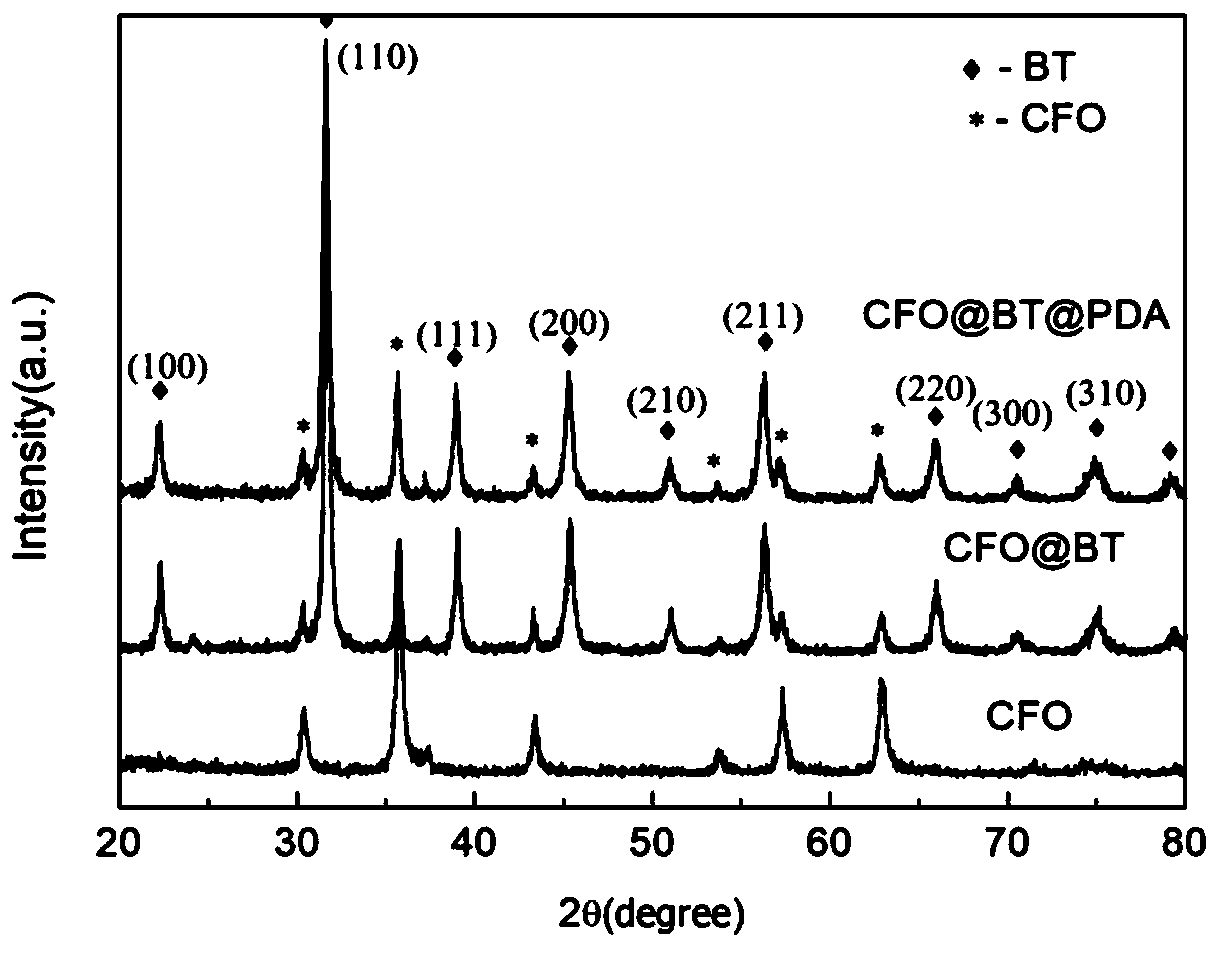

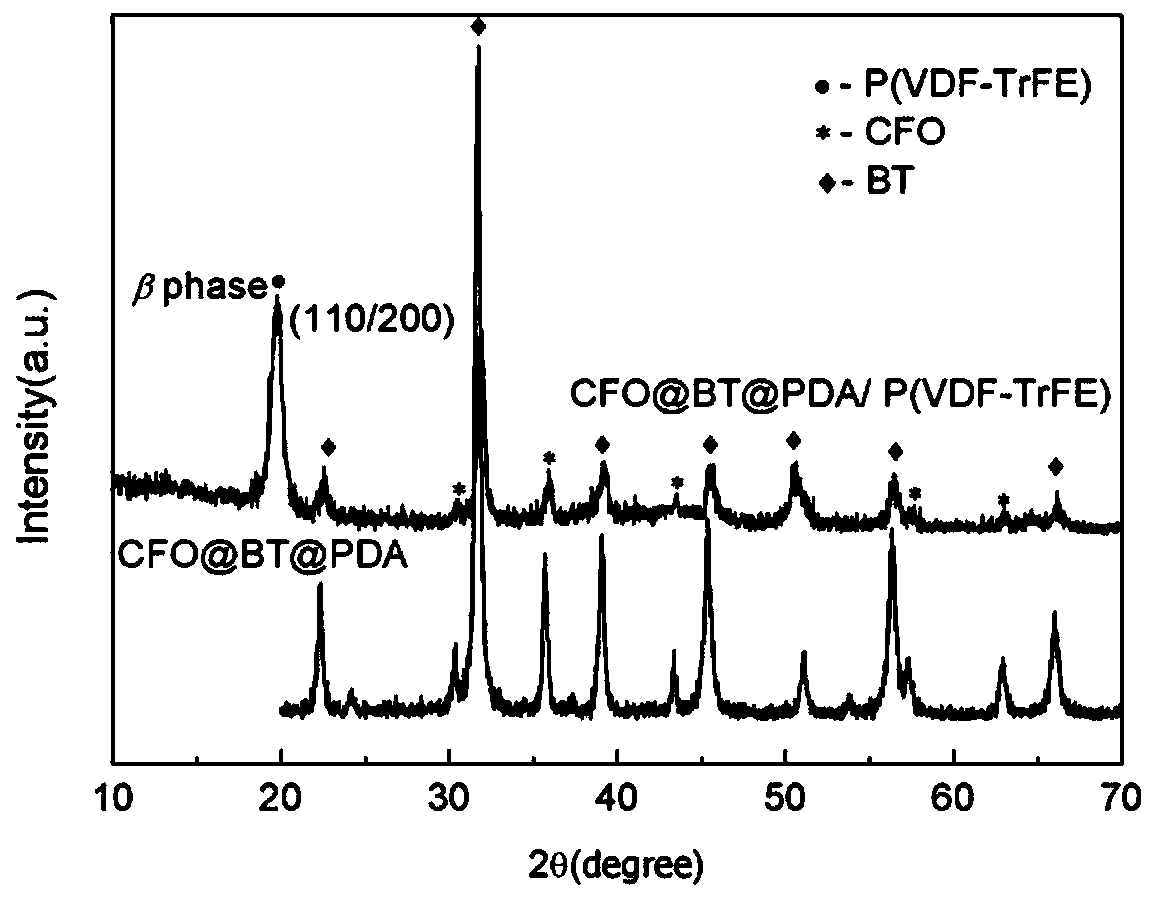

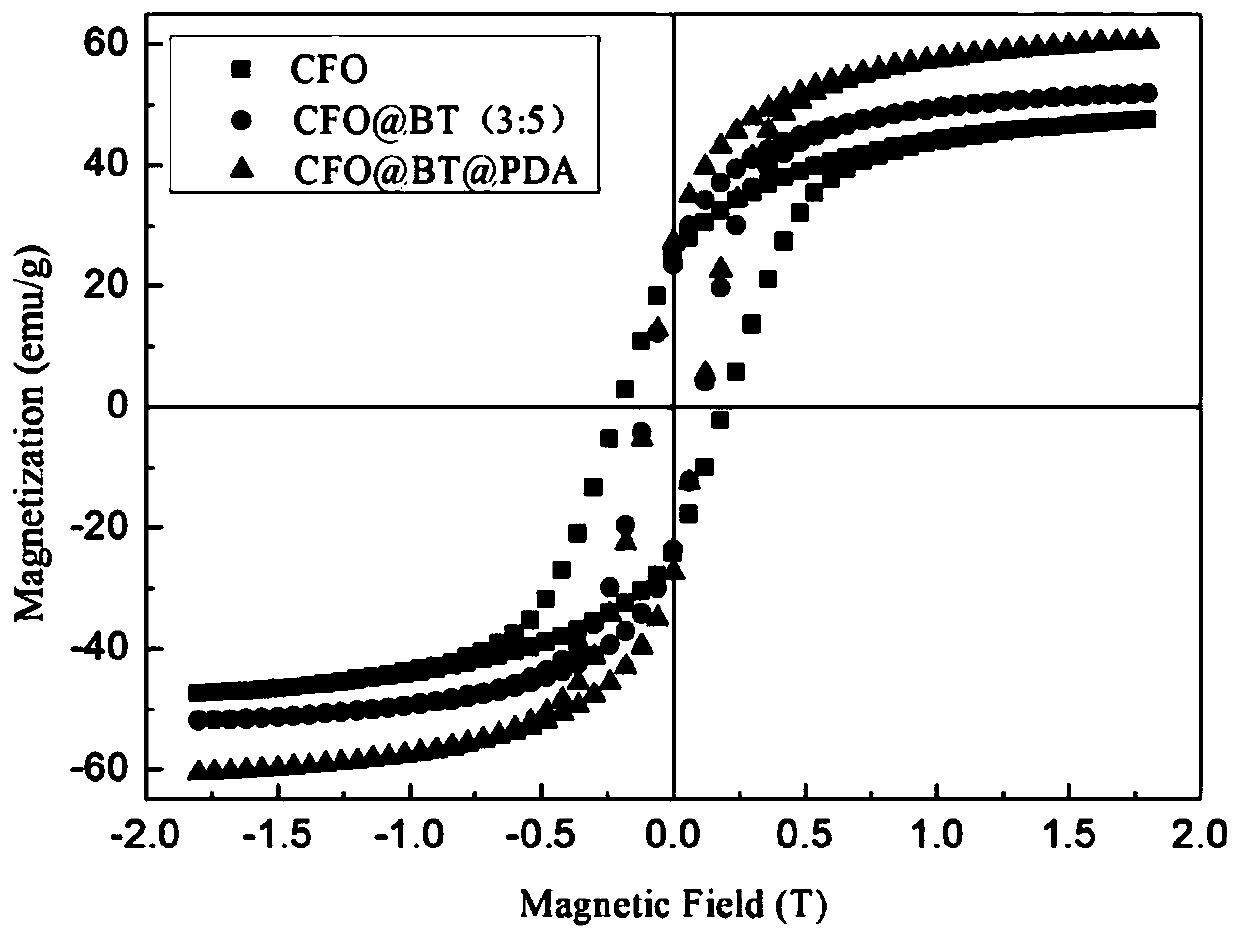

Ferromagnet composite polymer nanofilm and preparation method thereof

The invention discloses a ferromagnet composite polymer nanofilm. CFO serves as a core and is coated with insulated ferroelectric BT nanoparticles and a polydopamine (PDA) organic shell layer, the CFO@BT@PDA nanoparticles of a core-shell structure serve as an inorganic doping phase in a P(VDF-TrFE) polymer-based composite material, the inevitable agglomeration phenomenon of low-resistivity magnetic nanoparticles can be relieved, due to the high piezoelectric constant and dielectric constant of the insulated ferroelectric particles, the electrical performance of the film can be improved to a great extent, and the magnetoelectric effect is further improved.

Owner:贵州贤俊龙彩印有限公司

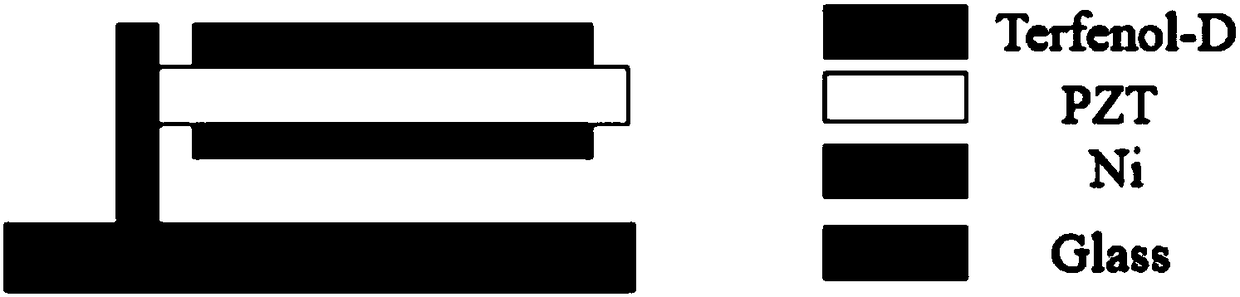

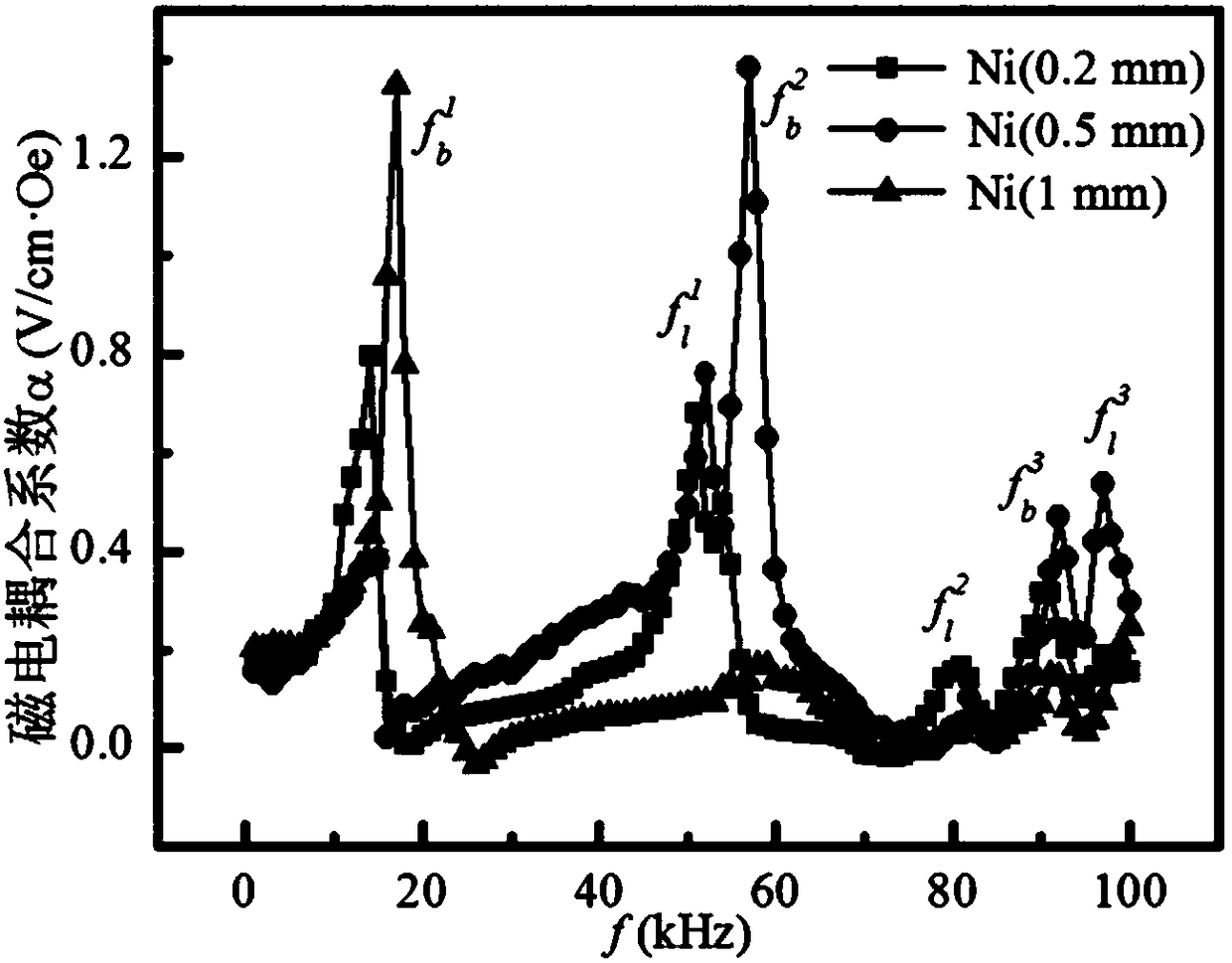

Magnetoelectric coupling composite material with adjustable resonance mode and preparation method thereof

InactiveCN108550692ALow priceSimple preparation processPiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive devicesCouplingResonance

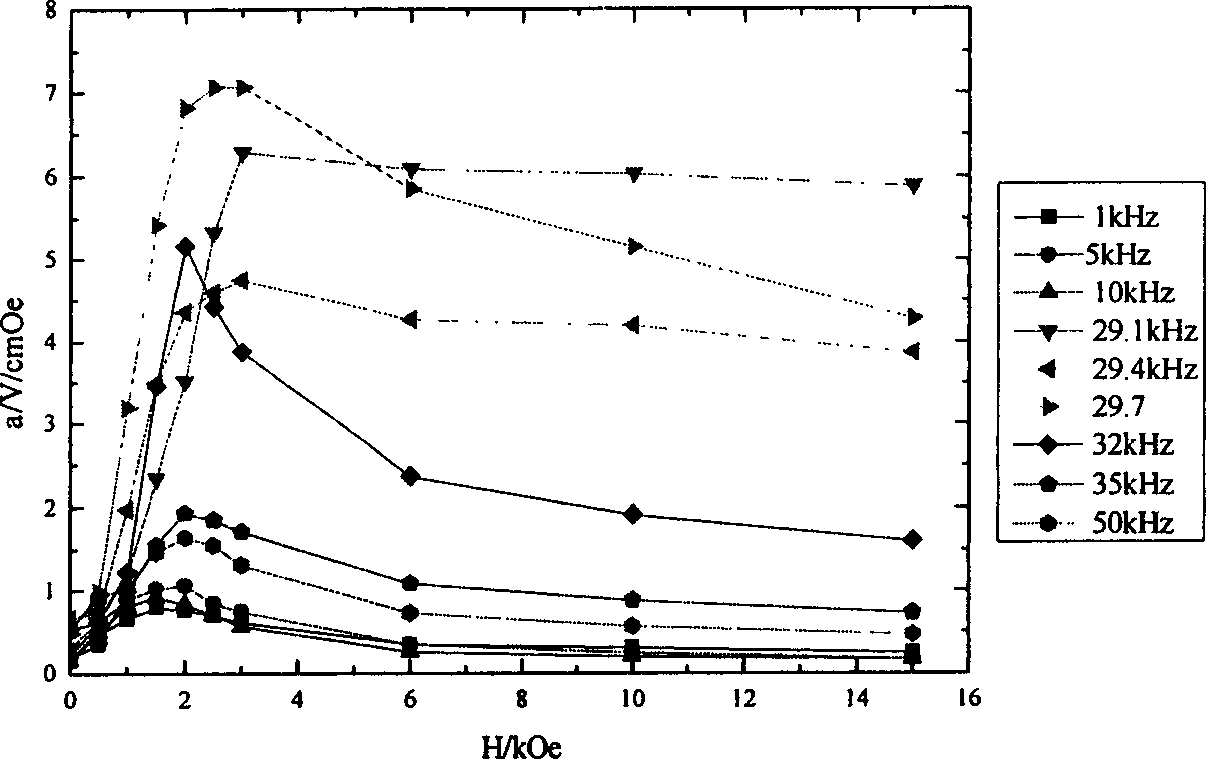

The invention provides a magnetoelectric coupling composite material with an adjustable resonance mode and a preparation method thereof; the magnetoelectric coupling composite material comprises a positive magnetostriction material, a piezoelectric material and a negative positive magnetostriction material layer that are stacked and fixed on a T-type structure glass substrate, thus forming a composite magnetoelectric material with a cantilever structure; the thickness ratio between the positive and negative magnetostriction materials are 1:0.4-2. Under a high or low bias magnetic field effect,the resonance mode will change along with different positive and negative magnetostriction layer thickness ratios; in preparation, the different positive and negative magnetostriction layer thicknessratios can be adjusted so as to obtain different resonance modes. Compared with other magnetoelectric coupling materials with a single resonance mode, the composite material and preparation method can change the positive and negative magnetostriction layer thickness ratios, thus effectively regulating the magnetoelectric effect resonance modes, realizing enhancement of multifrequency magnetoelectric effect under multi-resonance modes, and making contributions for multifrequency device development.

Owner:HUBEI UNIV

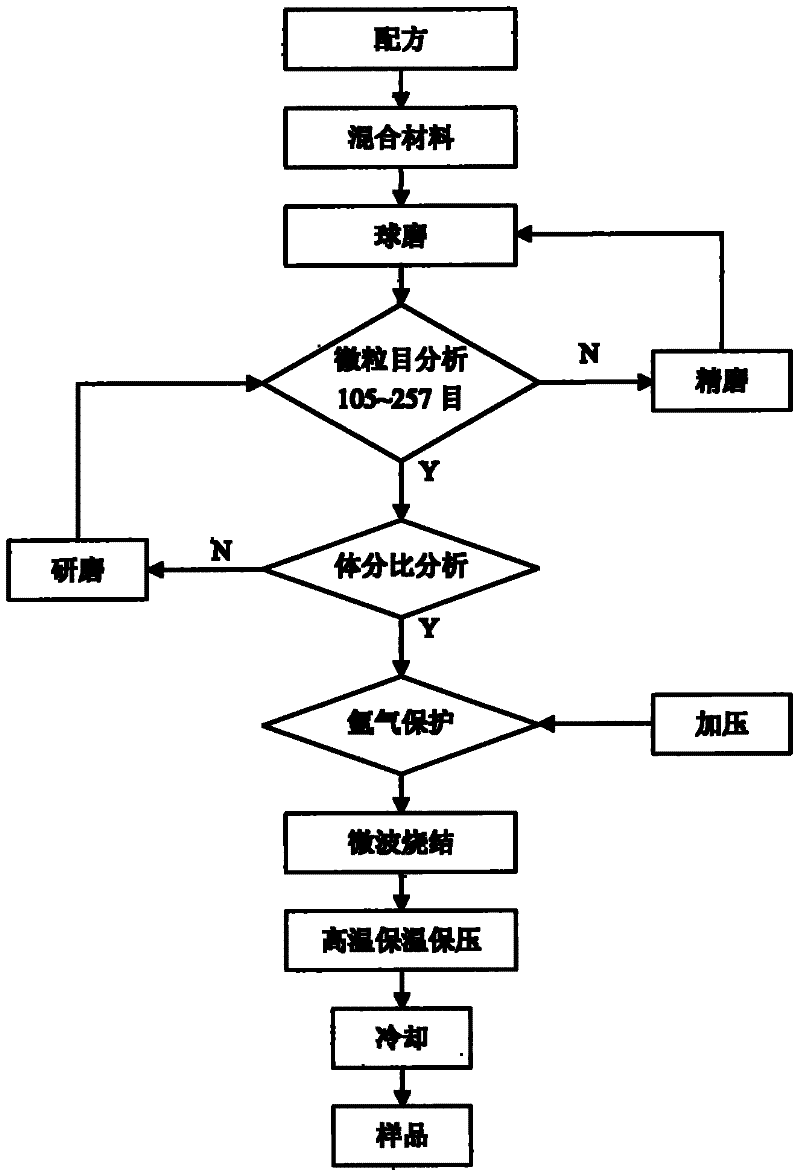

Method for preparing wave-absorbing material

InactiveCN102031446AAchieve refinementMicroscopic morphology changesMagnetic/electric field screeningNitrogen gasQuenching

The invention discloses a method for preparing a wave-absorbing material, which is characterized by comprising the following steps of: 1, performing nanocrystallization treatment on a base material of an iron-based nanocrystalline material prepared by a single-roll quenching method under the protection of nitrogen to obtain an iron-based nanocrystalline material with a nano crystalline phase structure; 2, performing mechanical crushing on the iron-based nanocrystalline material through high-speed cutting to obtain powder; and 3, reprocessing the powder by using a jet mill for 0.5 to 4 hours under the gas pressure of 0.5-2.0MPa. Compared with the prior art, the method has the advantages that: the powder is refined through high-speed collision of the jet mill, and the micromorphology of the powder material is changed by a method for modifying the micromorphology of the nanocrystalline magnetic powder, so that the magneto-electrical properties of the powder are changed and the aim of improving the magnetoelectric effect and wave-absorbing property of the material is fulfilled.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

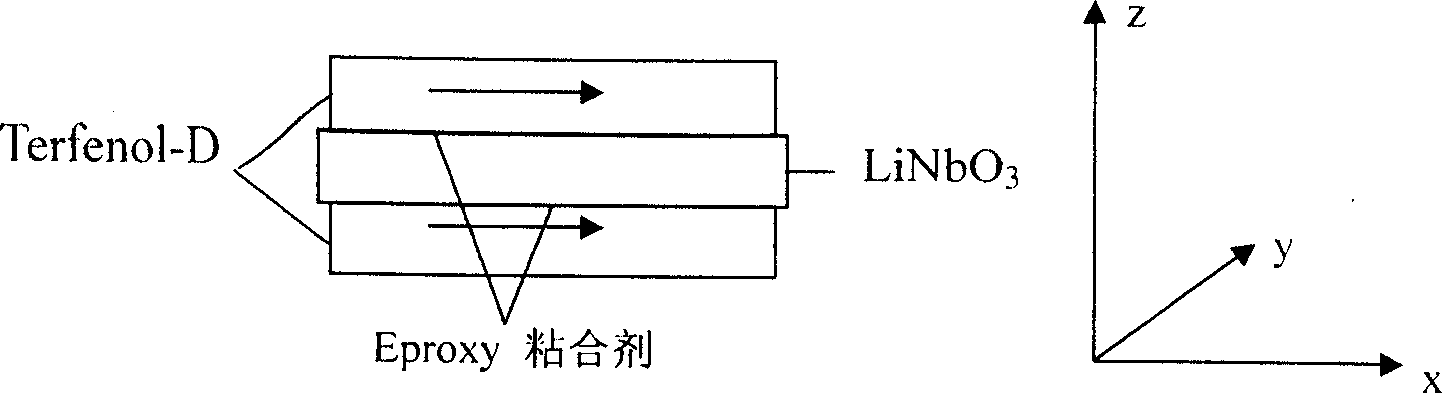

Method for improving magneto-electric effect of composite materials

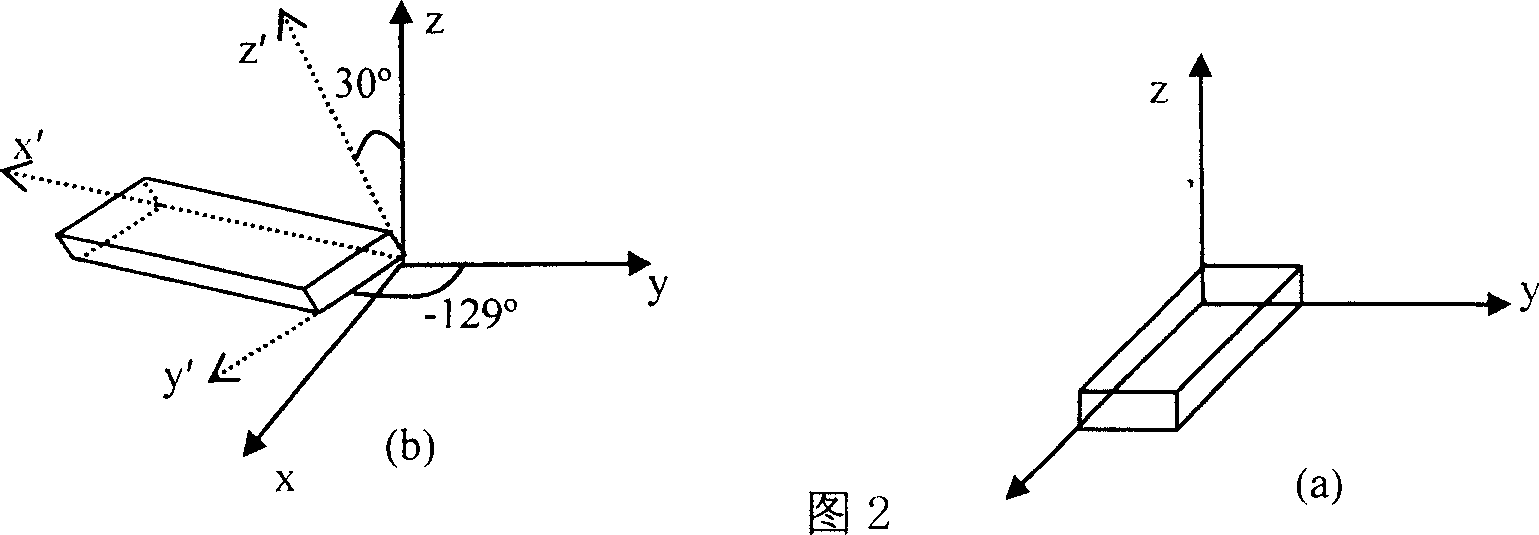

InactiveCN1805165AIncrease magnetoelectric outputPiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblySingle crystalPiezoelectric coefficient

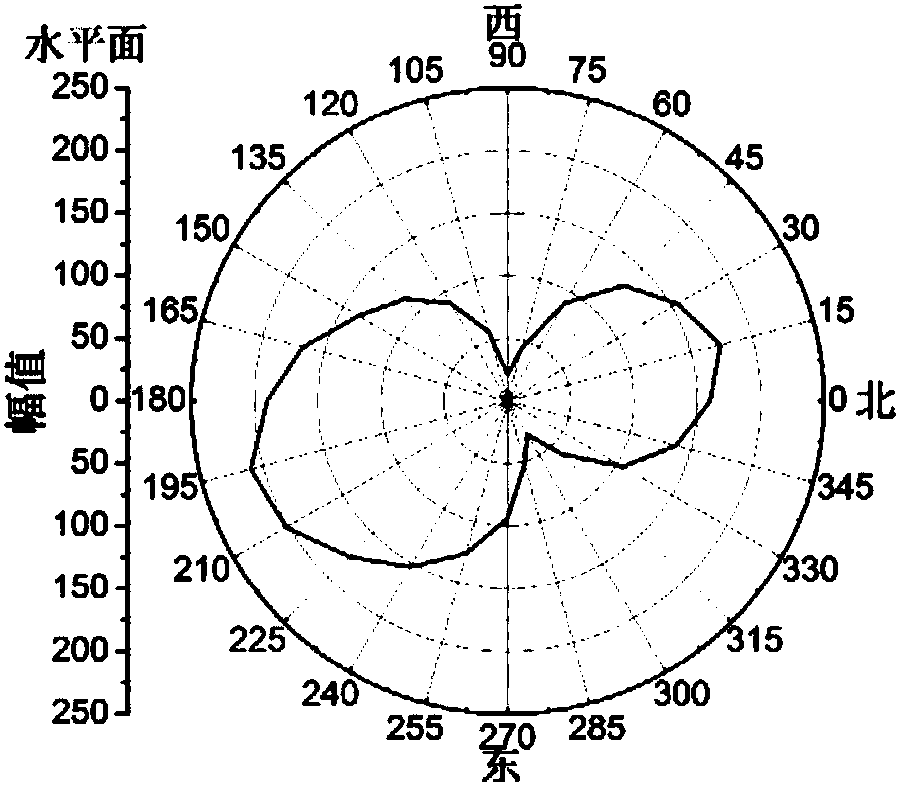

The invention relates to a method for improving the magnetoelectric effect of composite material, which prepares the magnetic deformation and the piezoelectric material into sheet composite material while they are adhered. It designs the cutting shape of piezoelectric single crystal according to the vibration mode of magnetic deformation material under the direct current bias magnetic field and alternating excited magnetic field, to make the cut piezoelectric single crystal attain high piezoelectric output under the strain effect processed by the magnetic deformation material; selecting the cutting shape of standard cut piezoelectric single crystal to attain the maximum piezoelectric factors of crystal; processing coordinate transformation on the piezoelectric tensor matrix of standard piezoelectric single crystal to make the piezoelectric factor integrated valve used in the new cut piezoelectric factor matrix reach maximum, and the new cut piezoelectric single crystal attain maximum piezoelectric output at needed direction to attain the maximum magnetoelectric effect.

Owner:NANJING UNIV

Composite type nano generator and wearable device

InactiveCN106469996APromote sportsImprove electrical signal outputDynamo-electric machinesFriction generatorsNanogeneratorFriction effect

The invention relates to the technical field of nano generators and discloses a composite type nano generator and a wearable device. The composite type nano generator comprises a magneto-electric generator and a friction nano generator. The magneto-electric generator is arranged in a support box and used for generating magneto-electric signals based on the magneto-electric effects under the effects of external force. The friction nano generator is fixed on the outer surface of the support box, comprises a deformable part and a fixed part and is sued for allowing the deformable part to be deformed under the effects of the external force, thereby allowing the deformable part to be in contact with or separated from the fixed part to generate friction electric signals. The wearable device comprises the composite type nano generator. According to the invention, by adoption of coupling of the friction effects and the magneto-electric effects and by use of the design of the contact-separation type element device structure, the composite type nano generator based on electro-magnetic friction is provided, so electric signal output of the nano generator is improved; mechanical energy generated by wrist movement and the like can be converted into electric power; and the composite type nano generator can be used for driving small wearable devices, so life of the people becomes convenient.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

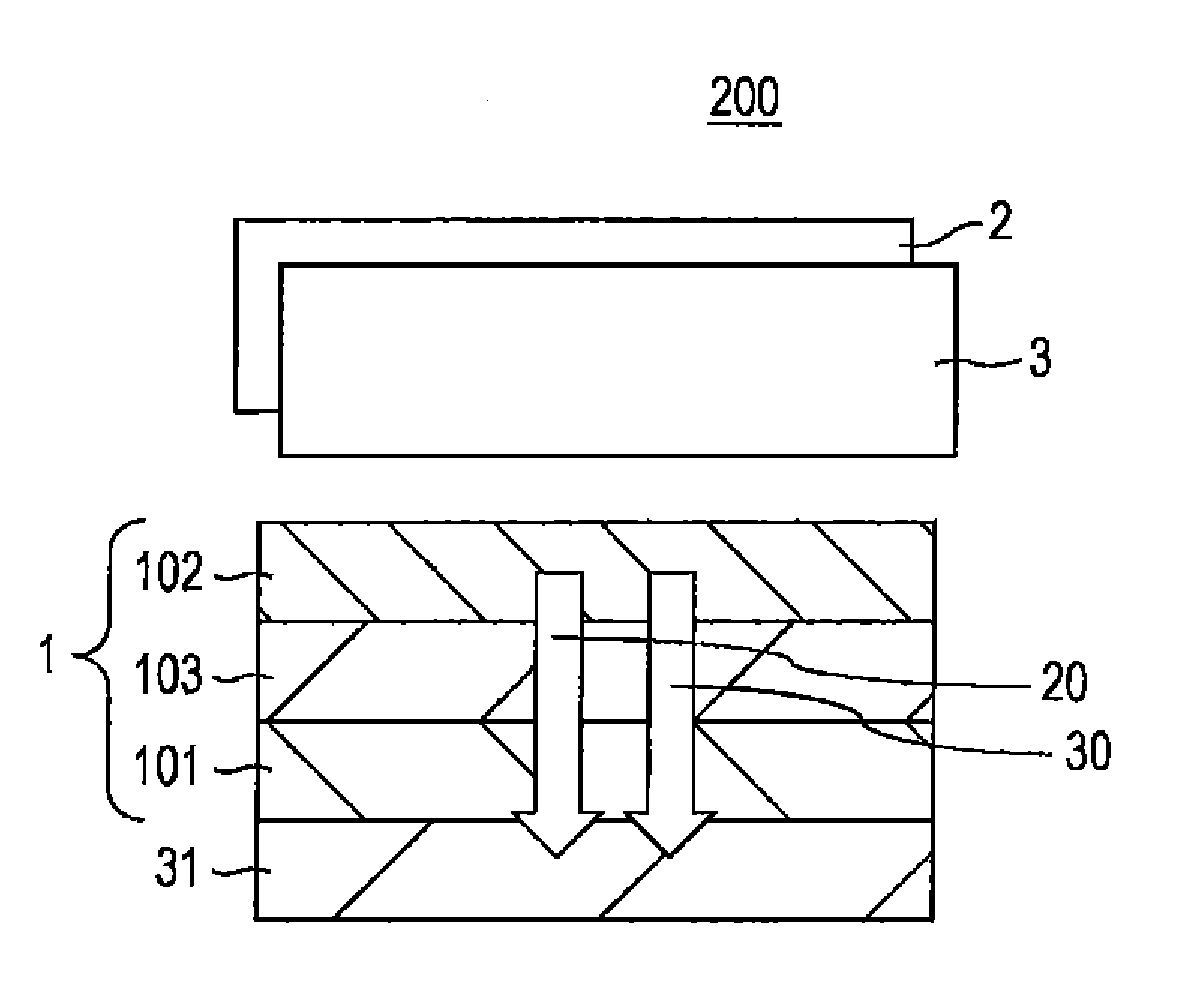

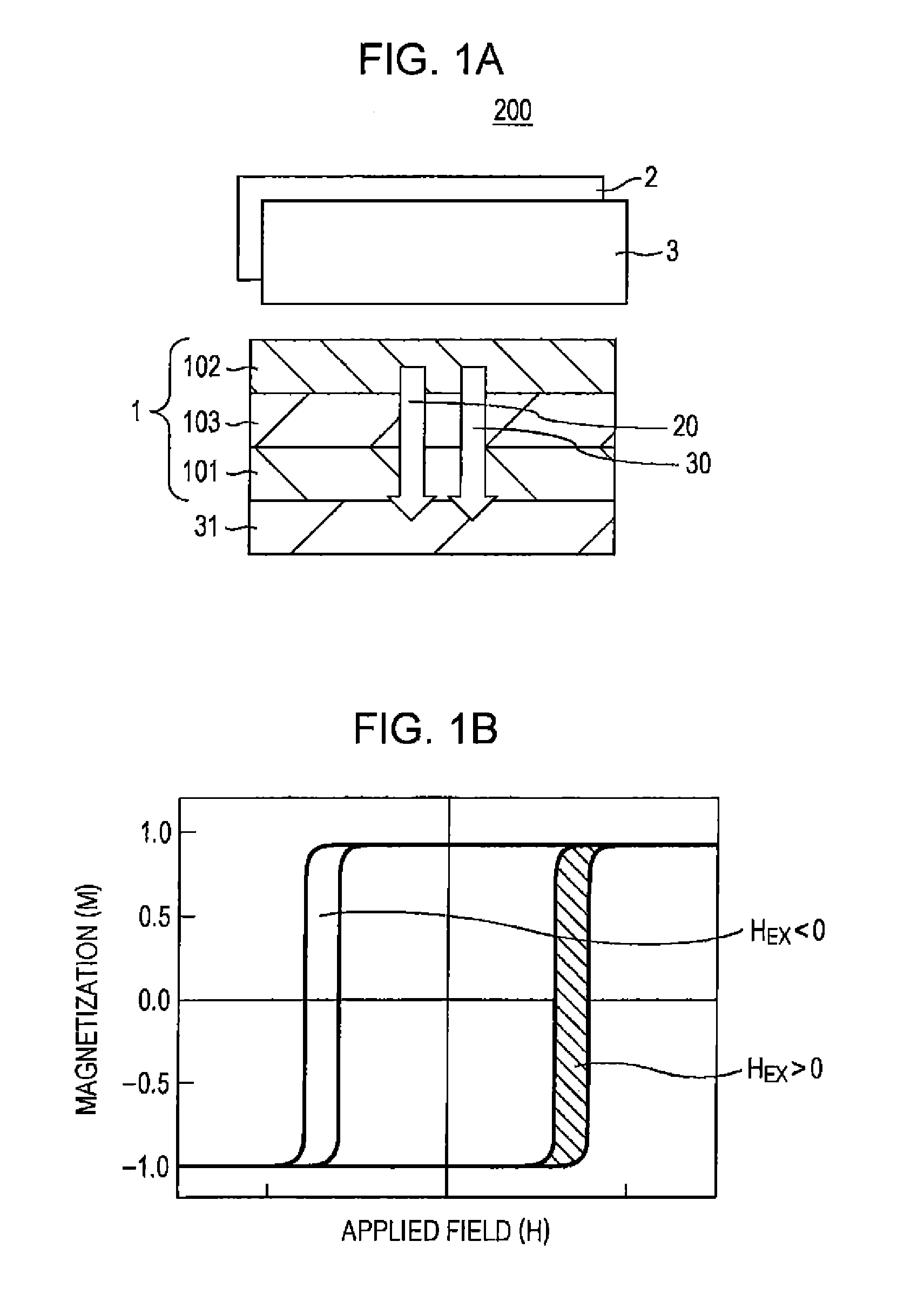

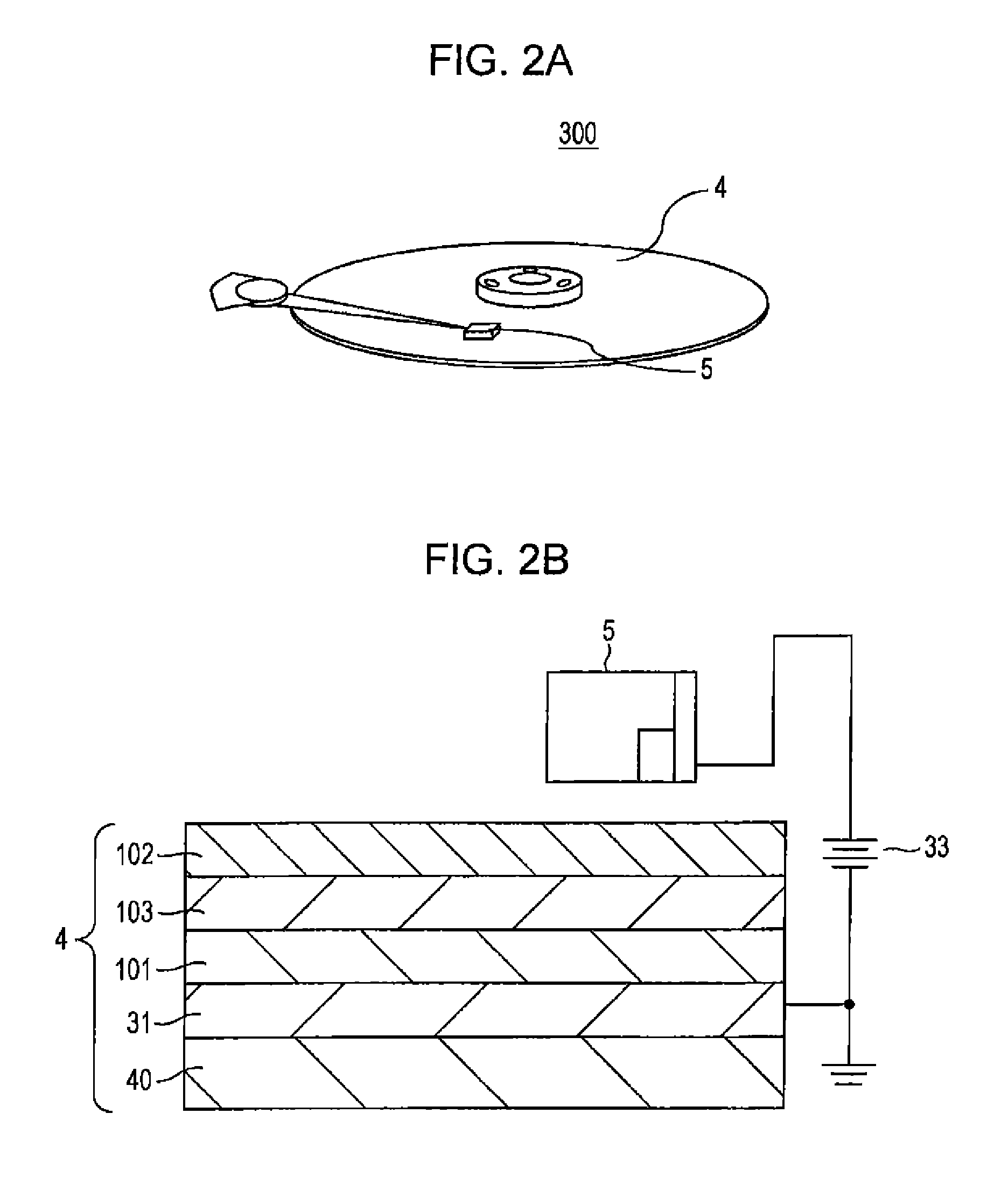

Magnetization controlling element using magnetoelectric effect

ActiveUS9520175B2Avoid natural oxidationRecord information storageRecording/reproducing/erasing methodsPerpendicular magnetizationCoupling

Owner:TDK CORPARATION

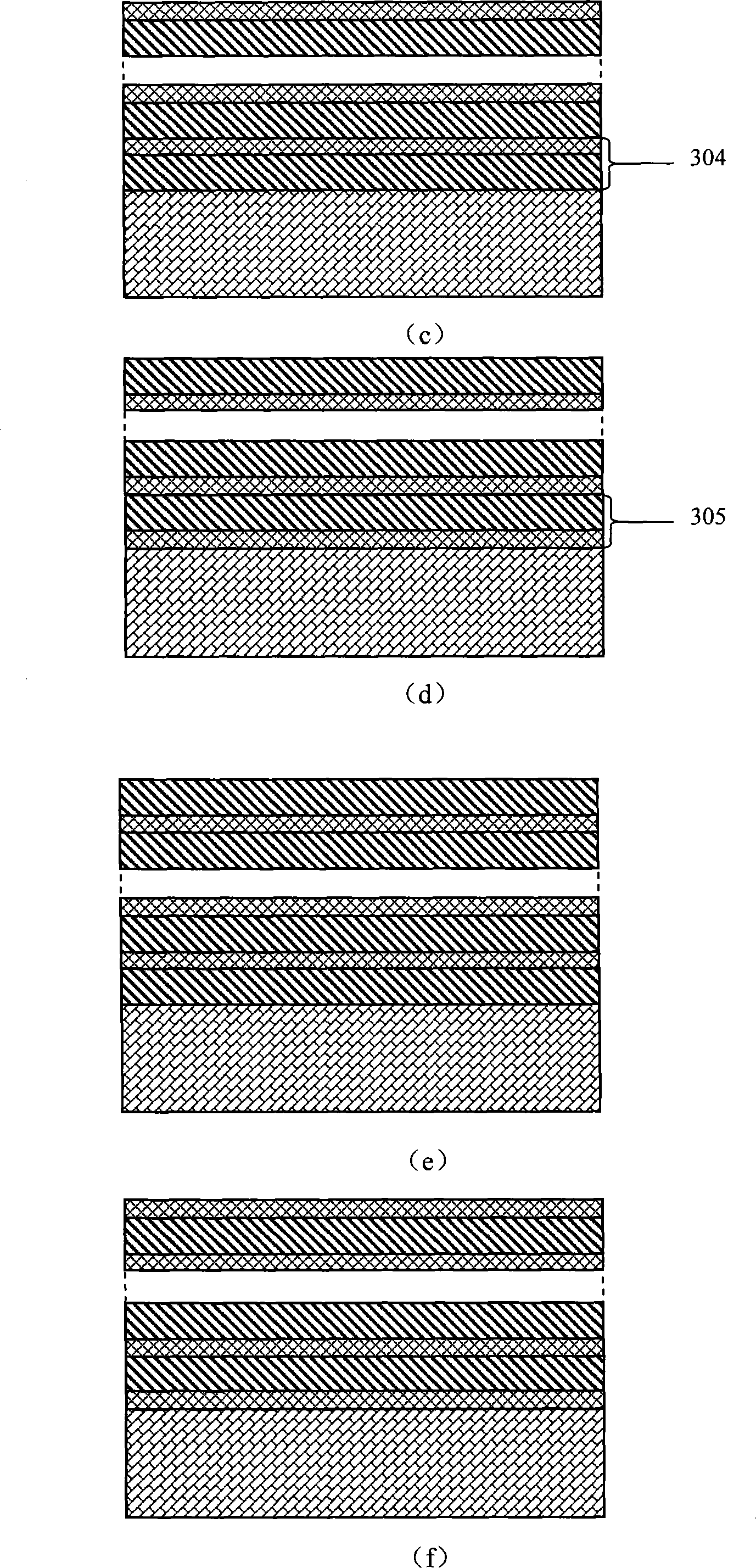

Poly iron performance composed film reading magnetic head based on magnetoelectric effect

InactiveCN101251997ANo energy consumptionSimple structureHeads using thin filmsExternal biasComposite film

The invention relates to a magnetoelectric effect-based multiferroic composite film read magnetic head, which comprises a ferroelectric oxide layer grown on a substrate and a magnetic layer. A plurality of proposals for the structure of the read magnetic head are provided as follows: the ferroelectric oxide layer grown on the substrate serves as the first layer and the magnetic layer as the second layer, which forms the first structural unit; or the magnetic layer grown on the substrate serves as the first layer and the ferroelectric oxide layer as the second layer, which forms the second structural unit; the first structural units are repeatedly stacked on the substrate; the second structural units are repeatedly stacked on the substrate; a ferroelectric oxide layer is then stacked on the first structural units which are repeatedly stacked on the substrate; a magnetic layer is then stacked on the second structural units which are repeatedly stacked on the substrate, and a magnetic layer is grown on the ferroelectric oxide substrate. Compared with a conventional read magnetic head, the multiferroic composite film read magnetic head has the advantages that no external bias magnetic field is needed, the structure is simple, and no energy is consumed.

Owner:TSINGHUA UNIV

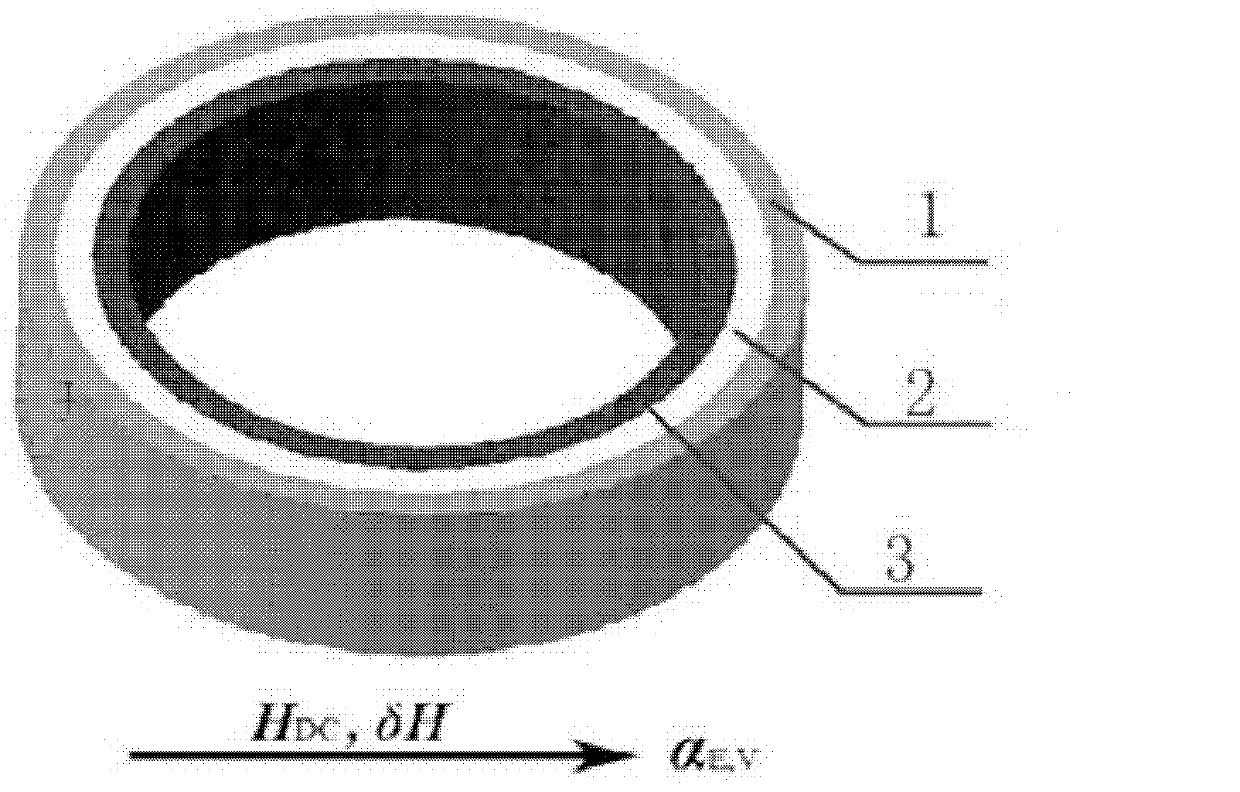

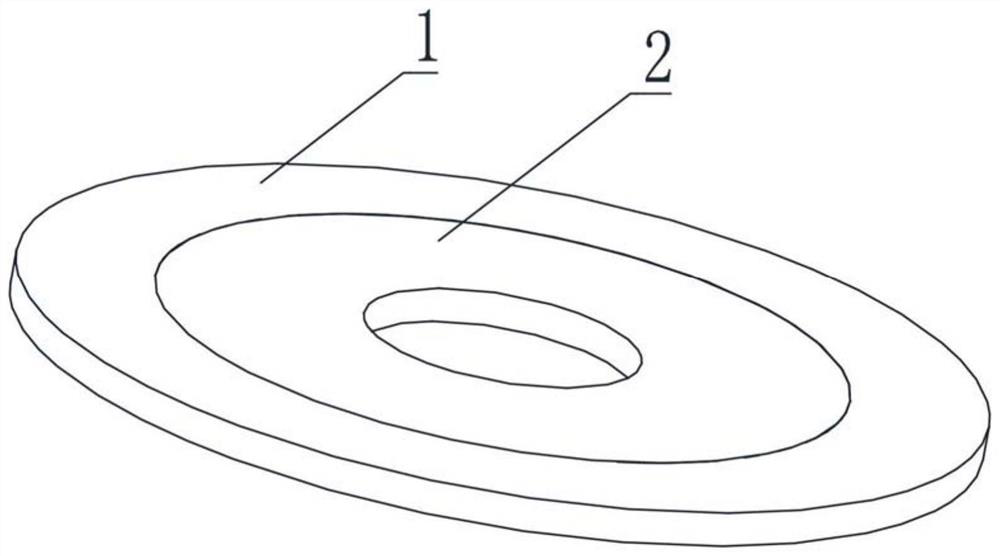

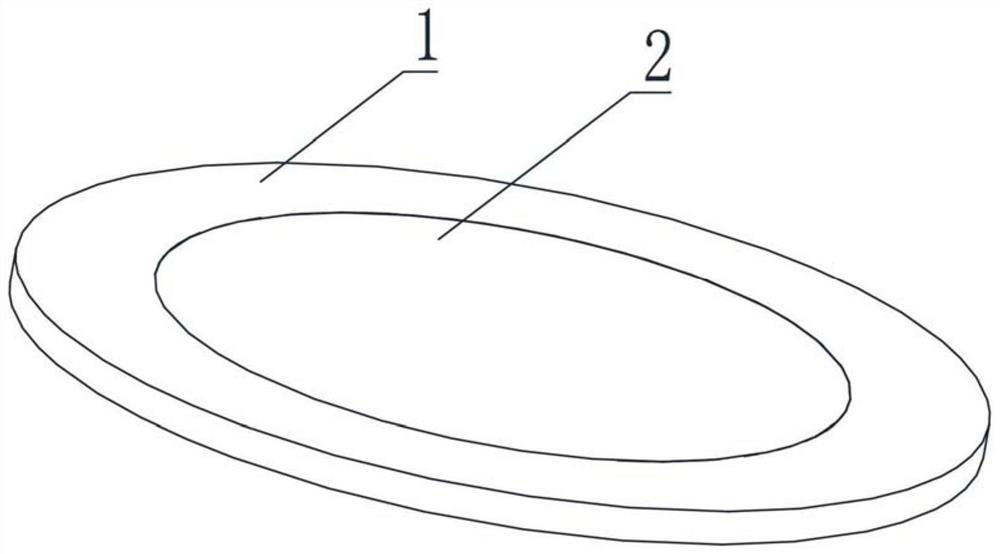

Magnetic-electric composite material and preparation method thereof

InactiveCN102637819AImproved force transmissionLarge magnetoelectric effectMagnetostrictive material selectionSilicon rubberEmery paper

The invention discloses a magnetic-electric composite material and a preparation method thereof. The composite material has a composite structure formed by compounding a radially-polarized ring-shaped piezoelectric material, a negative magnetostriction layer and a positive magnetostriction layer. The preparation method comprises the following steps of: firstly, performing deposition of the positive magnetostriction layer on the ring-shaped piezoelectric material; secondly, polishing and removing the positive magnetostriction layer on the outer side of the piezoelectric material by using a piece of metallographic abrasive paper; thirdly, sealing the inner side of a ring by using a waterproof heat-resistant silicone rubber, and performing deposition of the negative magnetostriction layer on the outer surface; and finally, performing polarization after removing the silicon rubber to obtain the magnetic-electric composite material. According to the magnetic-electric composite material and the preparation method thereof, through co-extrusion on the ring-shaped piezoelectric material by positive and negative magnetostriction materials in different positions, compared with a ring-shaped magnetic-electric composite material which is made of a single positive magnetostriction material with the same type or a ring-shaped magnetic-electric composite material which is made of a single negative magnetostriction material with the same type, the interlayer force transmission is enhanced, and the magnetic-electric composite material has a greater magnetic-electric effect.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Zirconium-enriched lead zirconate titanate-bismuth ferrite multiferroic ceramic material

InactiveCN106145941AImprove magnetic propertiesGood magnetoelectric coupling effectLead zirconate titanateNiobium

The invention relates to the field of functional materials, and in particular relates to a zirconium-enriched lead zirconate titanate-bismuth ferrite multiferroic ceramic material. The zirconium-enriched lead zirconate titanate-bismuth ferrite multiferroic ceramic material is prepared from (1-x)Pb(Zr1-yTiy)O3+z wt%Nb2O5+xBiFeO3, wherein x is equal to 0.005 to 0.10, y is equal to 0.01 to 0.1, and z is equal to 0.5 to 2.0. According to the zirconium-enriched lead zirconate titanate-bismuth ferrite multiferroic ceramic material, a zirconium-enriched lead zirconate titanate system is selected for combining a niobium-doped modified zirconium-enriched Pb(Zr,Ti)O3 material and a BiFeO3 material, the composition and structure are adjusted so as to improve the spontaneous polarization and magnetic properties of the material at room temperature, the coexistence of ferroelecteicity and ferromagnetism at room temperature is realized, and a good magnetoelectric effect is achieved. The multiferroic material has the advantages of relatively low cost of used raw materials, simple preparation process and easiness in storage and use and can be applied to the high technical fields of energy conversion, sensitive detection, modern communication and the like.

Owner:SHANGHAI NORMAL UNIVERSITY +1

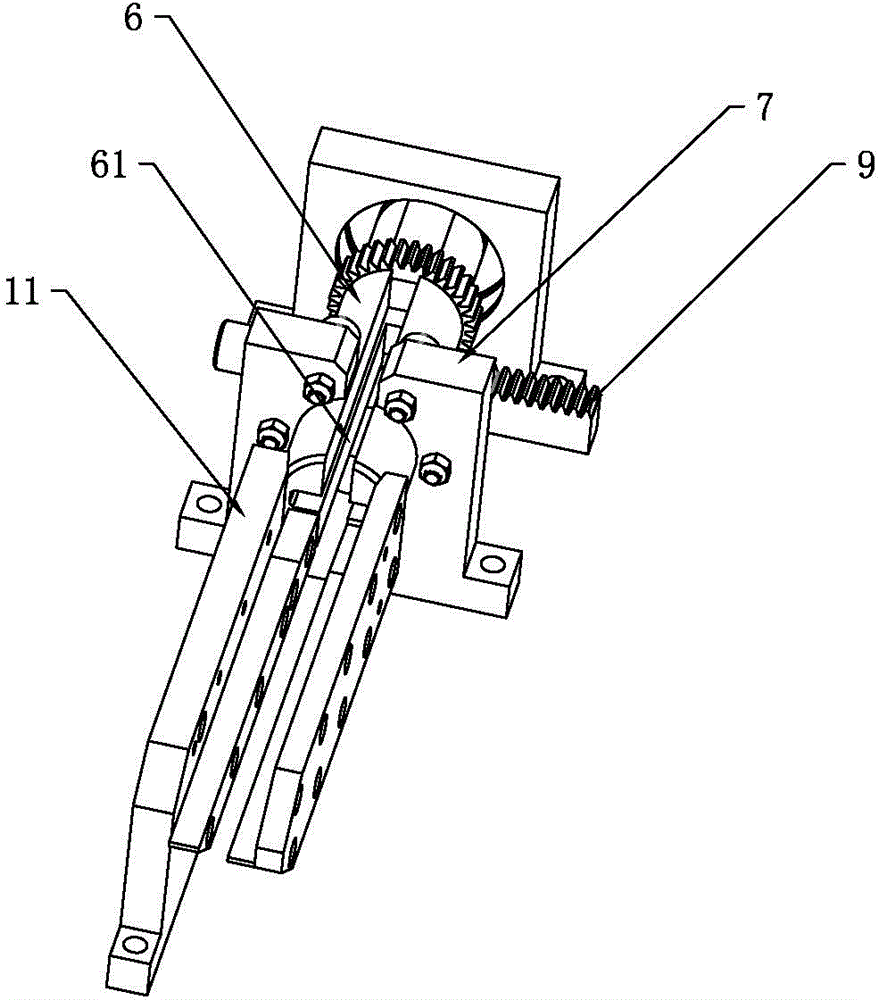

Magnetic shoe feeding method

ActiveCN104787565AAchieve the purpose of flippingEasy to useConveyor partsStructural engineeringMechanical engineering

The invention discloses a magnetic shoe feeding method. A first pushing mechanism is used for pushing a single magnetic shoe in a stacked magnetic shoe pile to a turning mechanism. A Hall sensor senses the magnetoelectric effect caused by the single magnetic shoe, and signals are transmitted to a controller. The controller sends instructions to the turning mechanism according to the signals transmitted by the Hall sensor. The turning mechanism works according to the instructions, so that the purpose that magnetic shoes in different magnetic directions are turned is achieved. Then, a second pushing mechanism pushes the single magnetic shoe in the turning mechanism to a next process. The operation is carried out repeatedly and continuously. The single magnetic shoe in the magnetic shoe pile can be efficiently pushed, and magnetism turning adjusting direction is recognized automatically. Using of magnetic shoes with the same polarity in the next process is convenient.

Owner:GUANGZHOU FIRESTEP SELF CONTROL SPECIAL PURPOSE EQUIP +1

Fluxgate magnetic field sensor based on magnetoelectric effect

InactiveCN108241130ASimple structureLow costMagnetic field measurement using flux-gate principleMagnetic field measurement using galvano-magnetic devicesAudio power amplifierDouble frequency

The invention discloses a fluxgate magnetic field sensor based on a magnetoelectric effect, and relates to a magnetic field sensor. The fluxgate magnetic field sensor is provided with a layered magnetoelectric composite material, an excitation coil and a piezoelectric layer signal output lead. The layered magnetoelectric composite material is an amorphous strip Metal-glass / PVDF layered magnetoelectric composite material. The excitation coil is a symmetric series-opposing excitation coil. The symmetric series-opposing excitation coil is wound on the layered magnetoelectric composite material Metal-glass / PVDF, and a function signal generator outputs an AC sinusoidal voltage signal to drive the excitation coil. A double-frequency output signal of the piezoelectric layer is measured by a lock-in amplifier. When a DC magnetic field passes through the fluxgate magnetic field sensor, the output signal measured by the lock-in amplifier includes the phase and amplitude, and the magnitude and direction of the applied DC magnetic field can be directly reflected. The magnetoelectric composite material is used as the magnetic core, and an electromagnetic coil is used as the excitation coil.

Owner:XIAMEN UNIV

Gradient multiferroic material and preparation method thereof

The invention relates to a gradient multiferroic material with good ferroelectricity and ferromagnetism and strong magnetoelectric coupling effect and a preparation method thereof. The material is characterized in that: the material comprises a ferroelectric material Nb-SrTiO3 and Ni2MnGa alloy ferromagnetic inclusion particles distributed in a gradient mode. The gradient multiferroic material prepared in the present invention has a stronger bearing capability than bearing capabilities of like gradient materials, has the advantages of simple preparation technology and good magnetoelectric effect, and has large application values in the electromagnetic fields of memories, actuators, transmitters and the like and important functions on researching intelligent materials and structures thereof and multi-field coupling materials.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

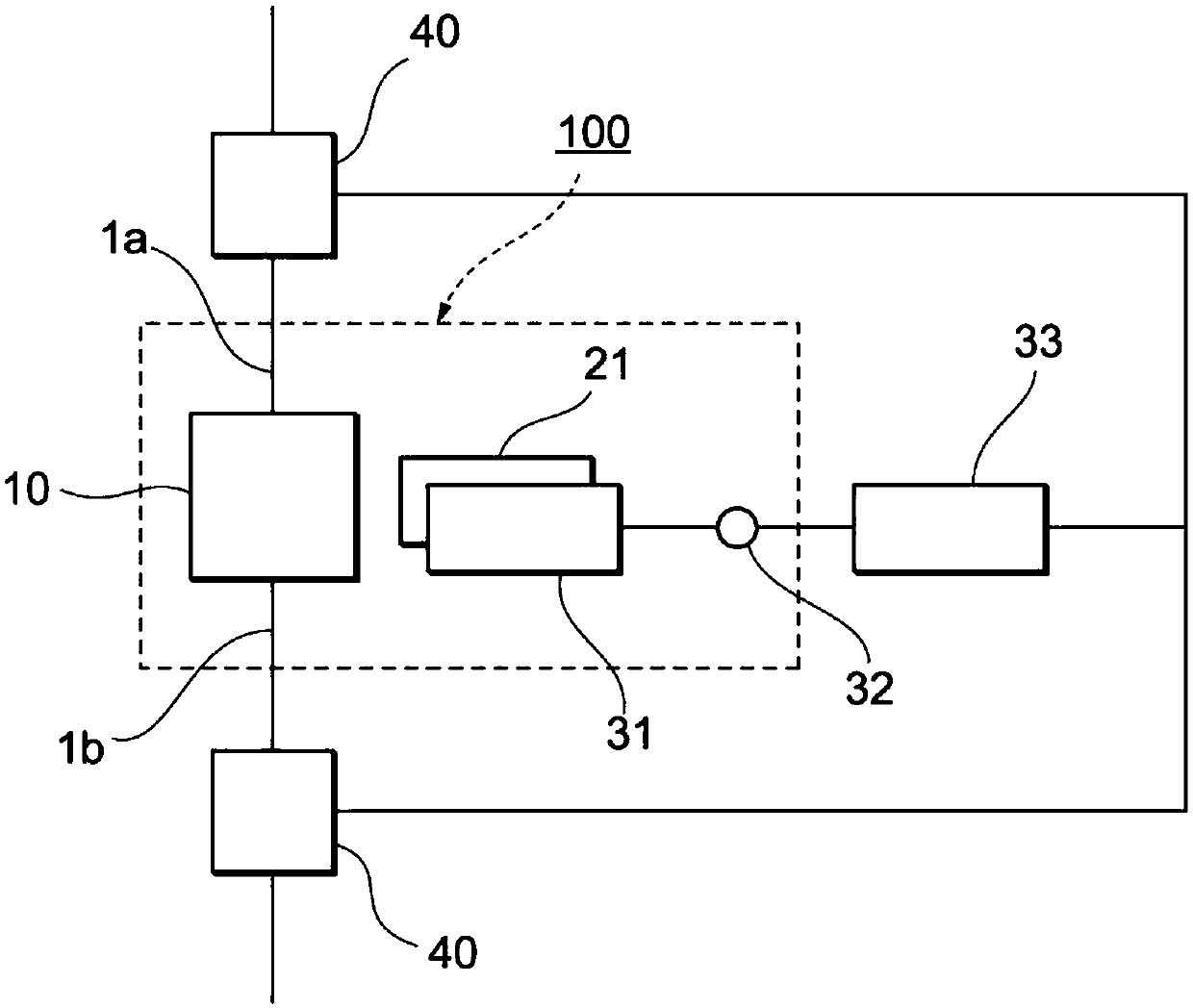

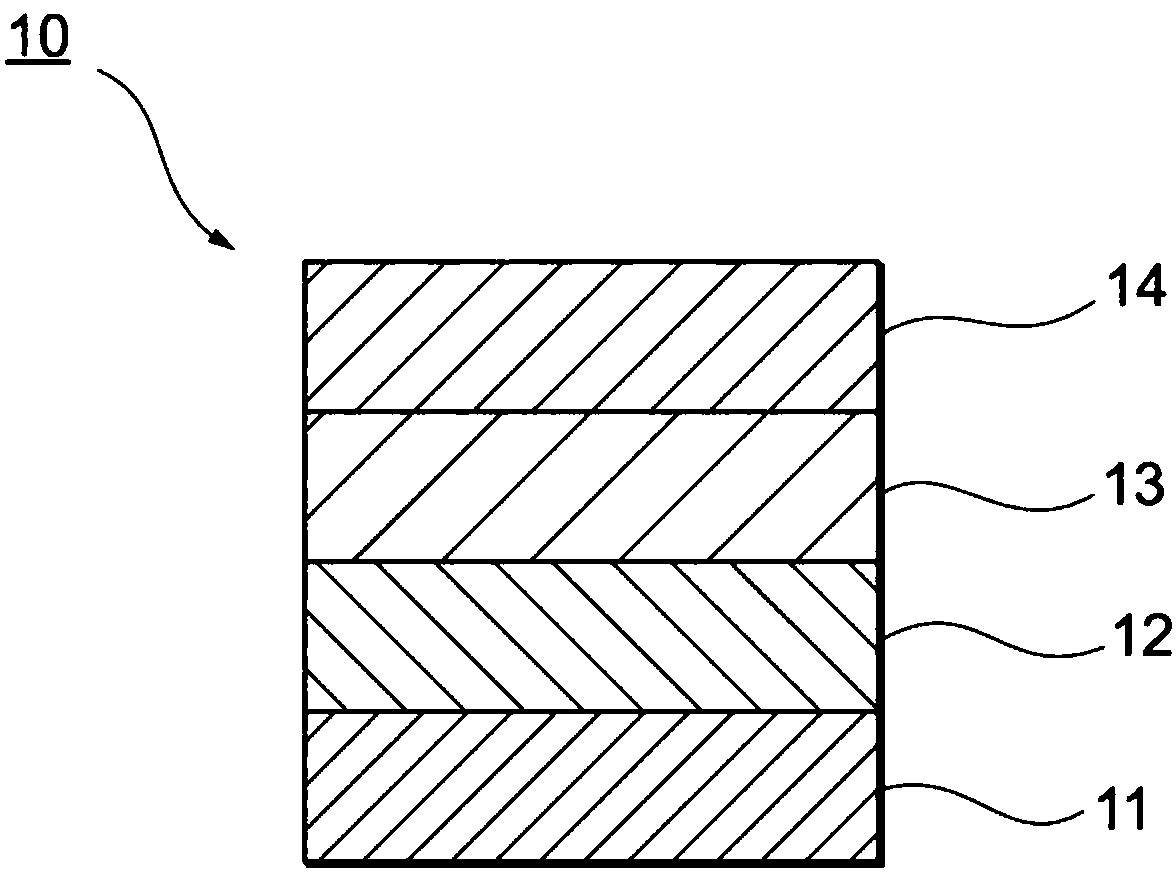

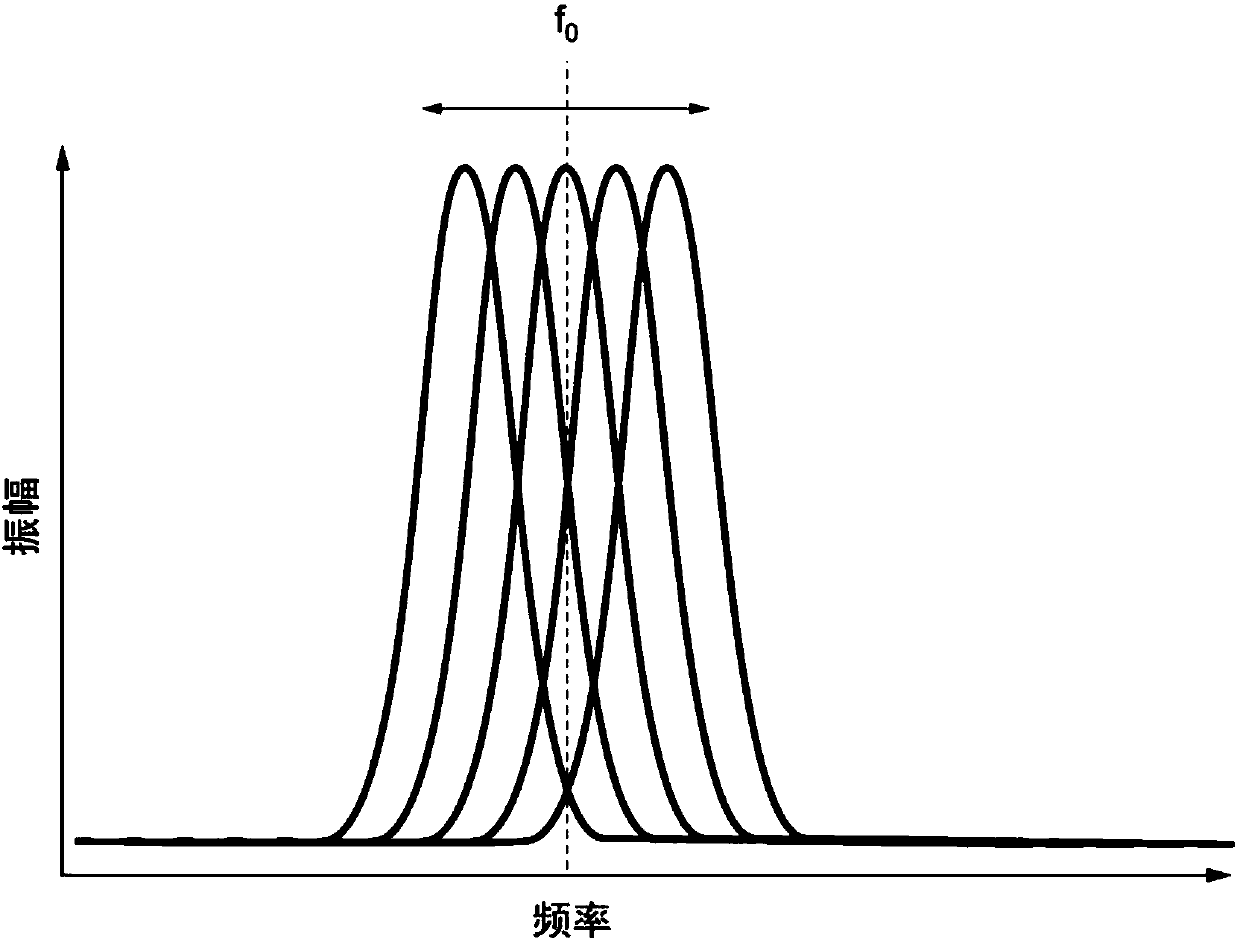

Variable-frequency magnetoresistive effect element and oscillator, detector, and filter using the same

ActiveCN107919434AReduce work energyMagnetic measurementsMagnetic-field-controlled resistorsMagnetic effectElectrical resistance and conductance

The invention aims to provide a variable-frequency magnetoresistive effect element stable in frequency feature and substantially reduced in working energy and a device employing the same. The variable-frequency magnetoresistive effect element includes a magnetoresistive effect element, a magnetic-field applying mechanism that applies a magnetic field to the magnetoresistive effect element, an electric-field applying mechanism that applies an electric field to the magnetoresistive effect element, and a control terminal connected to the electric-field applying mechanism and used for applying a voltage that varies in at least one of magnitude and polarity to the electric-field applying mechanism. The magnetoresistive effect element contains an antiferromagnetic material or ferrimagnetic material having a magnetoelectric effect. A spin torque oscillation frequency or spin torque resonance frequency of the magnetoresistive effect element is controlled by varying the voltage applied via thecontrol terminal in at least one of magnitude and polarity.

Owner:TDK CORPARATION

Variable-frequency magnetoresistive effect element and oscillator, detector, and filter using the same

ActiveUS20180102475A1Reduce energy consumptionLower impedanceMagnetic measurementsMagnetic-field-controlled resistorsResonanceElectrical polarity

A variable-frequency magnetoresistive effect element includes a magnetoresistive effect element, a magnetic-field applying mechanism that applies a magnetic field to the magnetoresistive effect element, an electric-field applying mechanism that applies an electric field to the magnetoresistive effect element, and a control terminal connected to the electric-field applying mechanism and used for applying a voltage that varies in at least one of magnitude and polarity to the electric-field applying mechanism. The magnetoresistive effect element contains an antiferromagnetic material or ferrimagnetic material having a magnetoelectric effect. A spin torque oscillation frequency or spin torque resonance frequency of the magnetoresistive effect element is controlled by varying the voltage applied via the control terminal in at least one of magnitude and polarity.

Owner:TDK CORPARATION

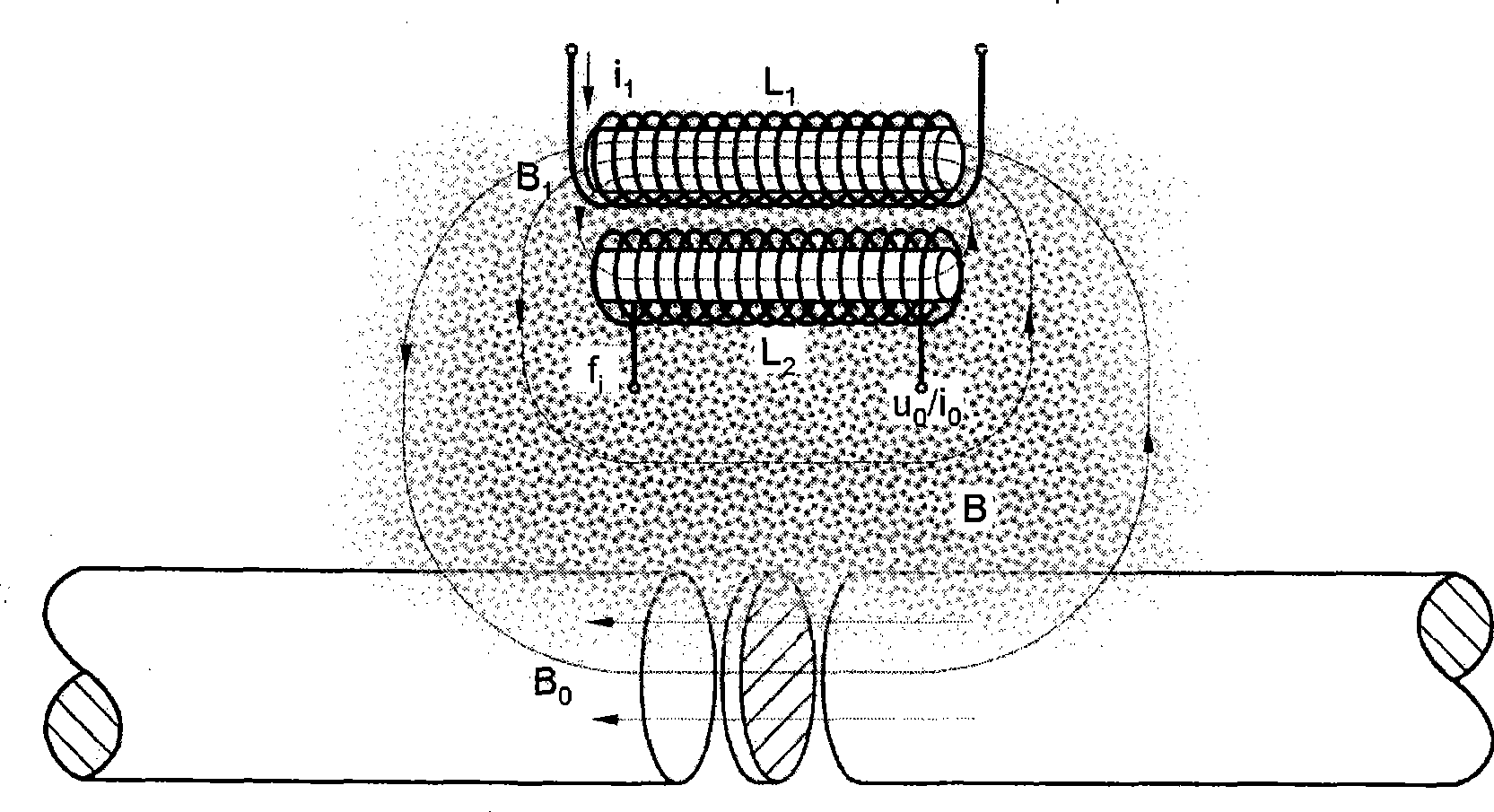

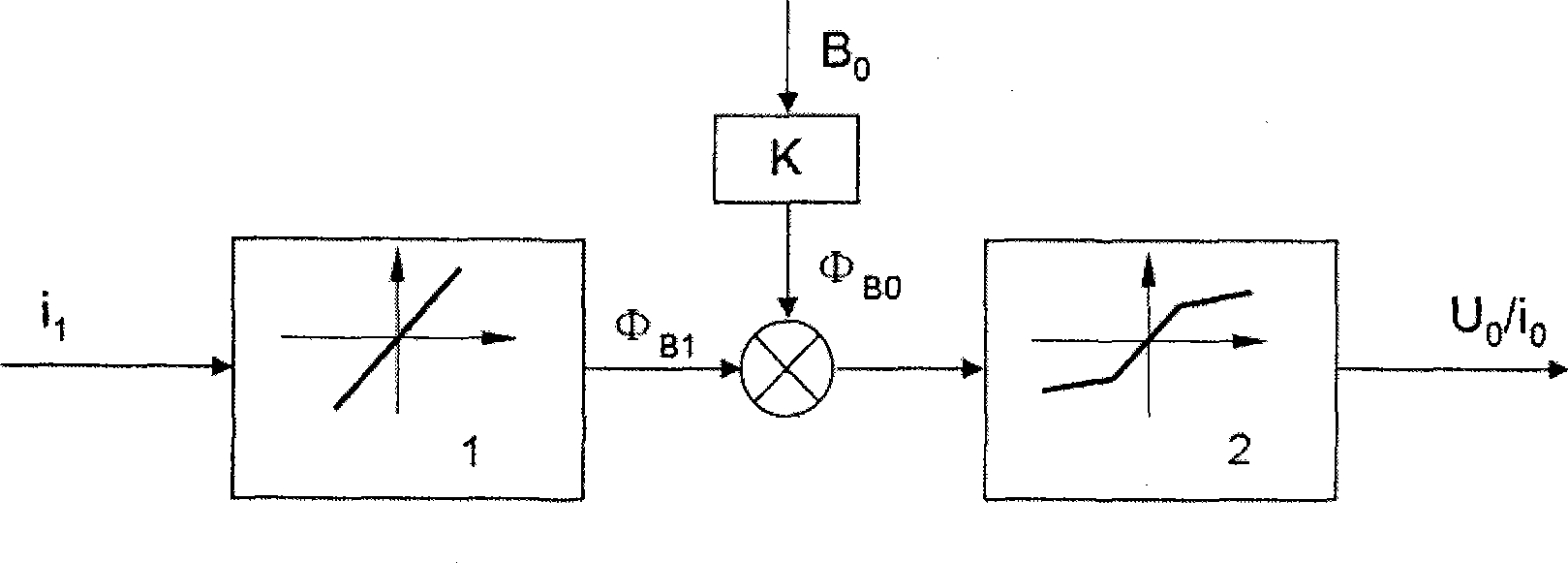

Electromagnetic magnetoelectric-effect type sensor

ActiveCN101520494AGood compatibilityImprove resolutionMagnetic field measurement using flux-gate principleMagnetic property measurementsMagnetic energyResonance spectrum

The invention relates to an electromagnetic magnetoelectric-effect type sensor which comprises electromagnetic energy-release coils and magnetic-energy balance coils. Constant direct current i1 is inputted into a magnetic core of the electromagnetic energy-release coils to generate B1, a stable weak magnetic field B0 of an iron magnetic member generates a correlative magnetic field B, and the magnetic-energy balance coils are in a correlative magnetic sensing field. The detecting information contained in the output power of a weak magnetic sensor includes a frequency-selection amplitude mode and a resonance spectrum mode which can be independently used or used in integration. The invention has reliability, simplicity, economical performance and durability, can be widely used and has high performance and price advantages.

Owner:LUO YANG WIRE ROPE INSPECTION TECH CO LTD

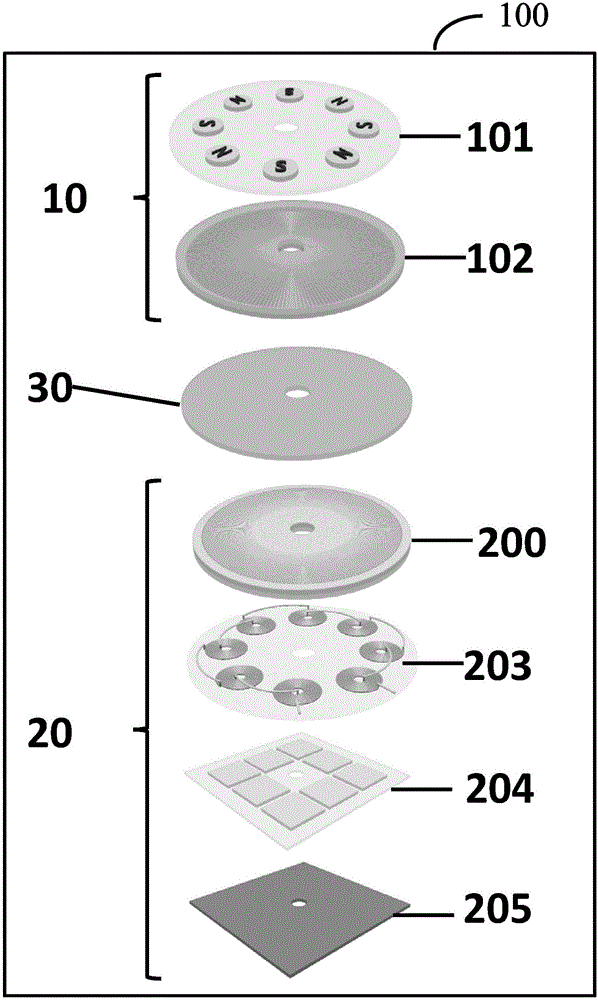

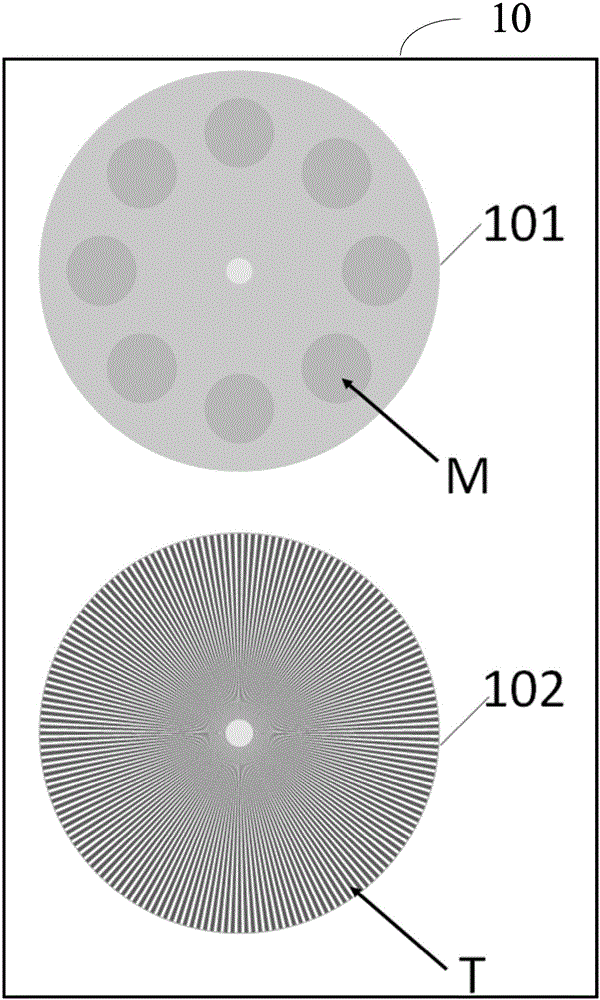

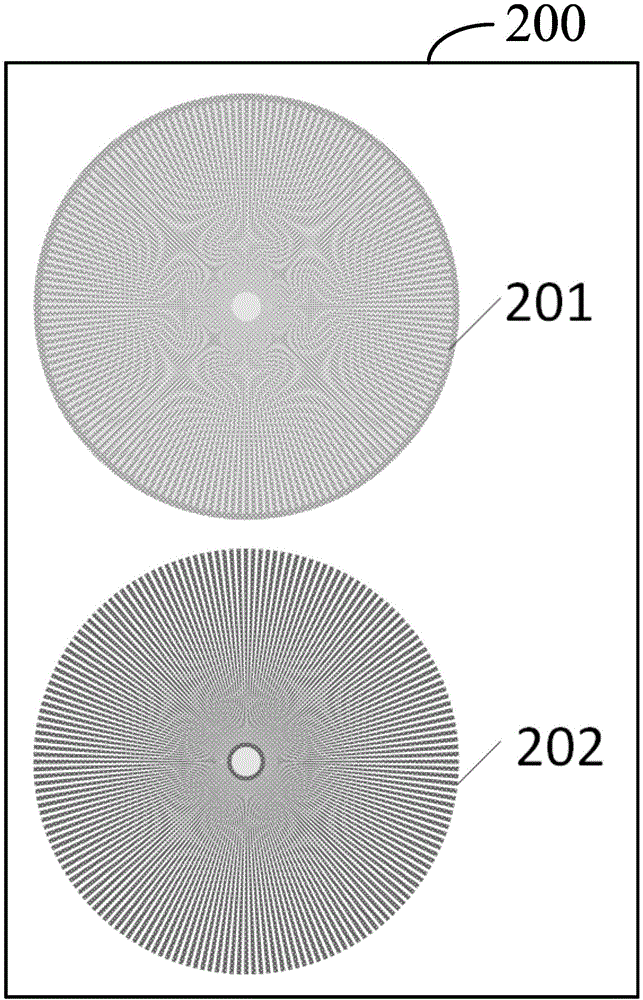

Nanogenerator

The invention relates to the technical field of nano-energy generation, and discloses a nangenerator. The nangenerator comprises a rotor, a stator, and an isolation layer disposed between the rotor and the stator. One part of the rotor, a first part of the stator and the isolation layer form a friction generator. Moreover, the other part of the rotor and the second part of the stator form a magnetoelectric generator, and the third part of the stator form a thermoelectric generator. The nanogenerator achieves the stable DC current output through the coupling of a triboelectric effect, a magnetoelectric effect and a thermoelectric effect, can supply renewable electric energy to various types of electronic equipment, and solves problems that an existing external power supply is limited in storage capacity and causes environment pollution.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

Magnetoelectric mechanical resonant antenna integrated with permanent magnet

PendingCN113422198ASmall sizeEasy to detectRadiating elements structural formsDisturbance protectionEngineeringMechanical resonance

The invention relates to a magnetoelectric mechanical resonant antenna integrated with a permanent magnet, which adopts a magnetostrictive material-piezoelectric material-magnetostrictive material three-layer composite structure, so that the antenna detects, receives and transmits electromagnetic waves through mechanical resonance, and the size and the structure of the antenna are greatly reduced compared with those of a traditional antenna. Meanwhile, by arranging the permanent magnet, the magnetoelectric effect is improved, the detection and transmitting capability of the antenna is improved, and the antenna has the advantages of being small in size, simple in structure and low in manufacturing cost; the antenna can replace a traditional antenna or be matched with the traditional antenna, and is high in universality.

Owner:SHANGHAI TECH UNIV

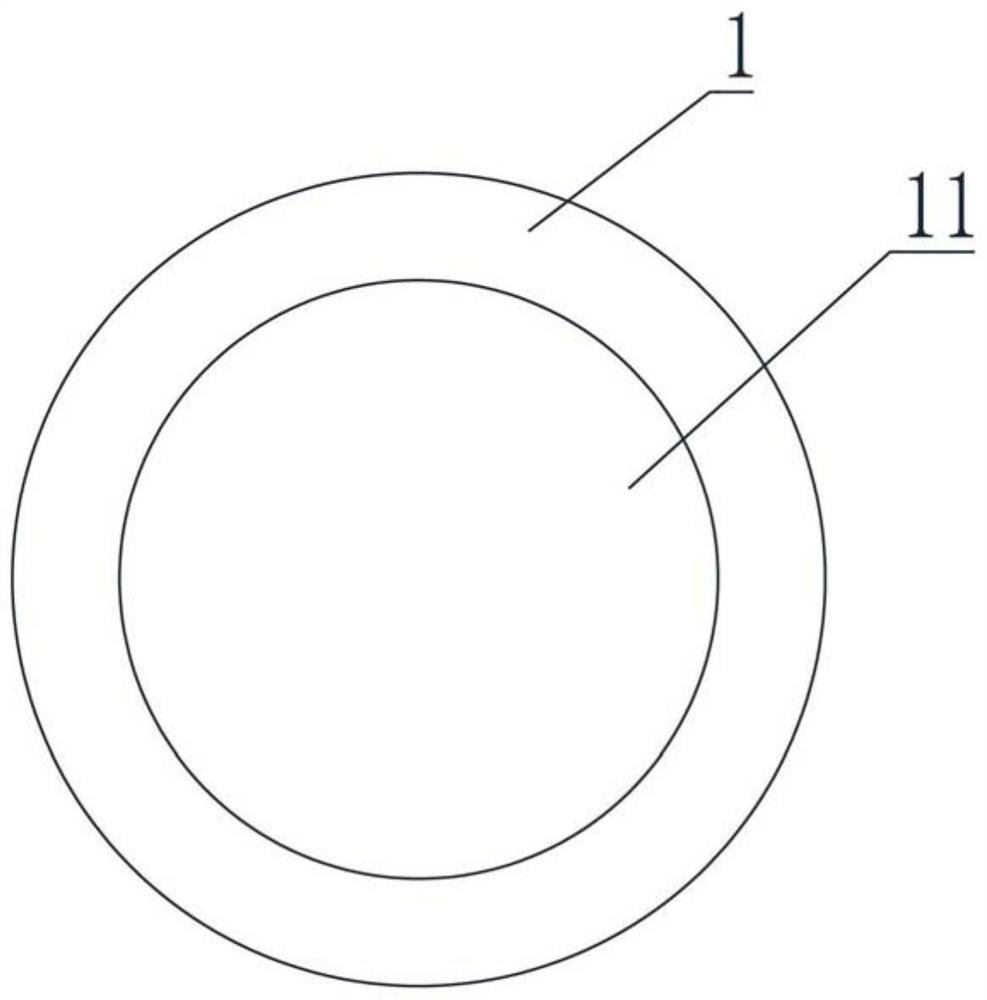

Self-biased magnetoelectric composite material structure and assembly method thereof

PendingCN112490350AStrong magnetoelectric effectSimple structureMagnetostrictive device manufacture/assemblyMagnetostrictive material selectionMagnetic fieldMagnetoelectric effect

The invention relates to the technical field of magnetoelectric composite material structures, in particular to a self-biased magnetoelectric composite material structure and an assembly method thereof. The self-biased magnetoelectric composite material structure comprises a magnetostrictive material and a piezoelectric ceramic material, and the piezoelectric ceramic material is coaxially embeddedin an annular hole of the magnetostrictive material and is in interference fit with the magnetostrictive material. The self-biased magnetoelectric composite material structure can generate a strongermagnetoelectric effect without providing a specific static magnetic field, and the structure is simple. According to the assembly method, the magnetostrictive material is heated to expand, and then the piezoelectric ceramic material is coaxially embedded in the annular hole of the magnetostrictive material, so that the assembly of the self-biased magnetoelectric composite material structure can be better and accurately realized.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com