Method for improving magneto-electric effect of composite materials

A composite material, magnetoelectric effect technology, applied in chemical instruments and methods, manufacturing/assembly of magnetostrictive devices, and manufacturing/assembly of piezoelectric/electrostrictive devices, etc., can solve problems such as inability to meet practical applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

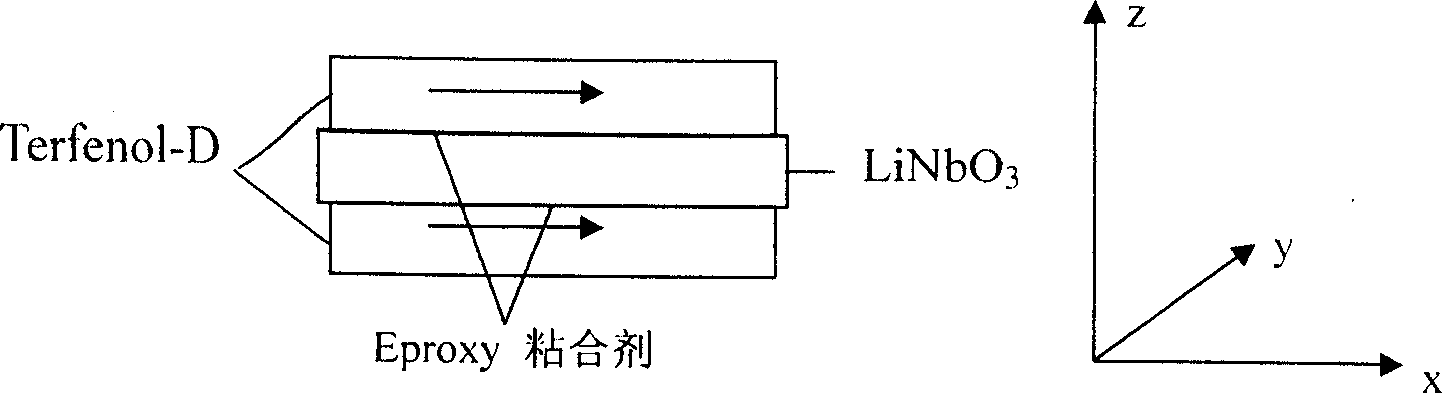

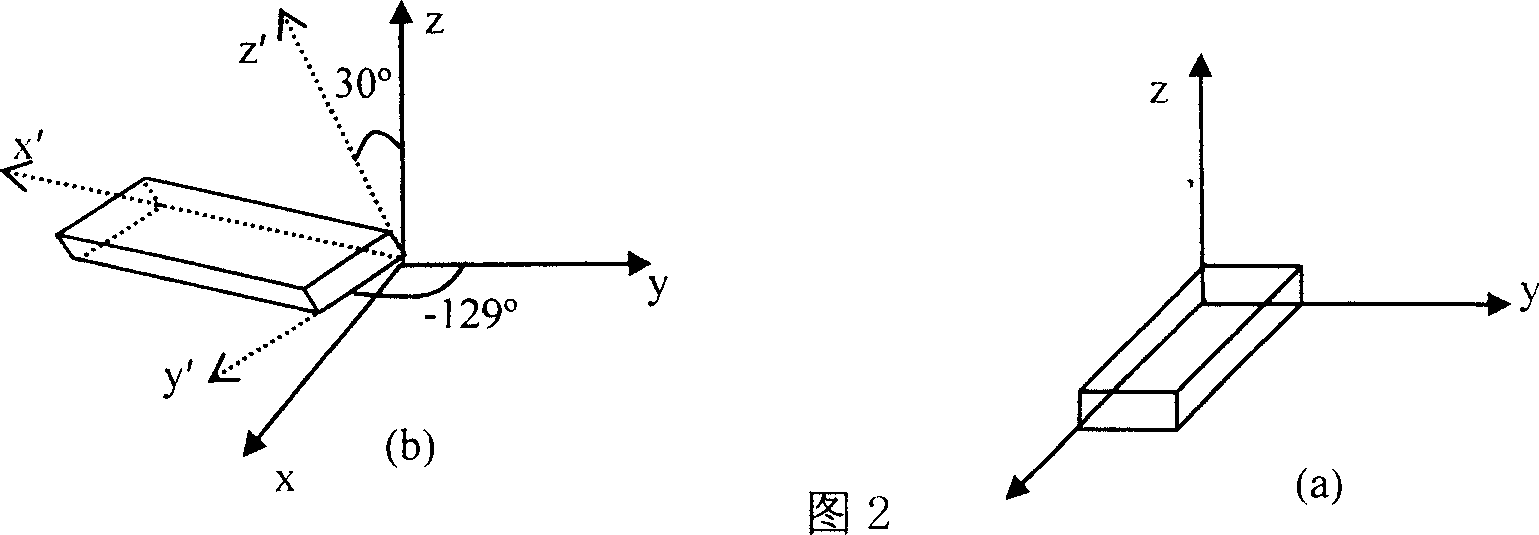

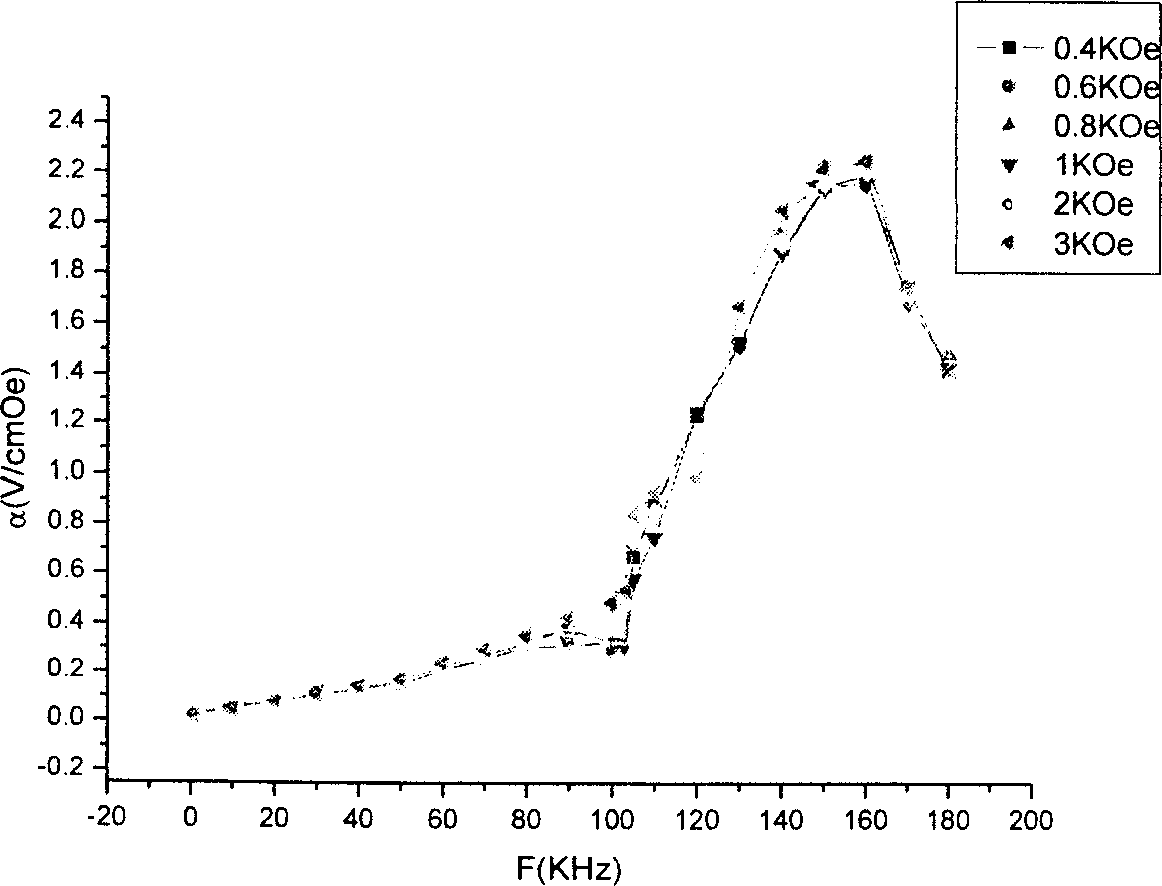

[0027] Such as figure 1 Shown, the object of main application research of the present invention is composite material, and this composite material is made of magnetostrictive material Terfenol-D and piezoelectric material LiNbO 3 Interlayer coupled 2-2 type composites composed of single crystals. Its magnetoelectric coupling is realized through the "product effect" of the magnetostrictive effect and the piezoelectric effect under the synergy of the phase interface, that is, the coupling of magnetism-force and force-electricity. The process can be visualized as: Magnetoele ctric = electric mechanical × mechanical magnetic , Thus we obtain the important characterization parameter of the magnetoelectric coupling effect, namely the magnetoelectric coupling coefficient, α H = ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com