Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

132results about "Device material selection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

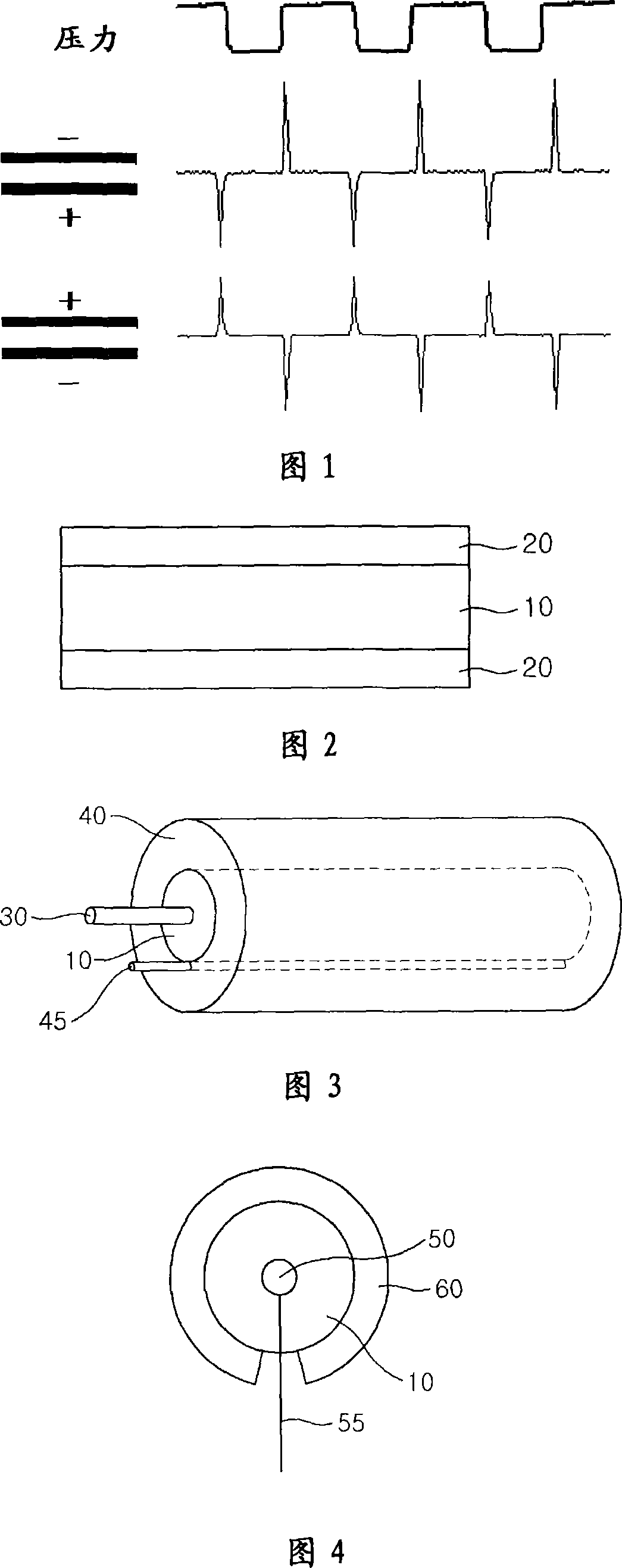

Ternary system sodium-bismuth titanate lead-free piezoelectric ceramics

InactiveCN101200370AExcellent piezoelectric propertiesPracticalDevice material selectionElectricityVolumetric Mass Density

The invention discloses a triple system (Na,Bi)TiO3-based lead-free piezoelectric ceramic material, the formula of the disclosed lead-free piezoelectric ceramic component is denoted with (1-x-y)(Bi0.5Na0.5)TiO3-x(Bi0.5K0.5)TiO3-yBi(Me)O3 and (1-x-y)(Bi0.5Na0.5)TiO3-x(Bi0.5K0.5)TiO-yBi(Me)O3+zM(a)O(b), in the formula x,y and z denote molar fractions, wherein x is bigger than or equal to 0 and smaller than or equal to 1.0, y is bigger than or equal to 0 and smaller than or equal to 0.2, z is bigger than or equal to 0 and smaller than or equal to 0.1, Me is trivalent metal element, M(a)O(b) is one or more oxides, wherein M is +1 to +6 valence and is an element that can be integrated with oxygen to form a solid oxide. The lead-free piezoelectric ceramic has high ceramic density and excellent performance, piezoelectric constant d33 can reach above 180pC per N, Kp can reach above 0.36. The lead-free piezoelectric ceramic adopts traditional electronic ceramic preparation process, and has low sintering temperature, simple and stable manufacture process and is suitable for industrialization production.

Owner:GUILIN UNIV OF ELECTRONIC TECH

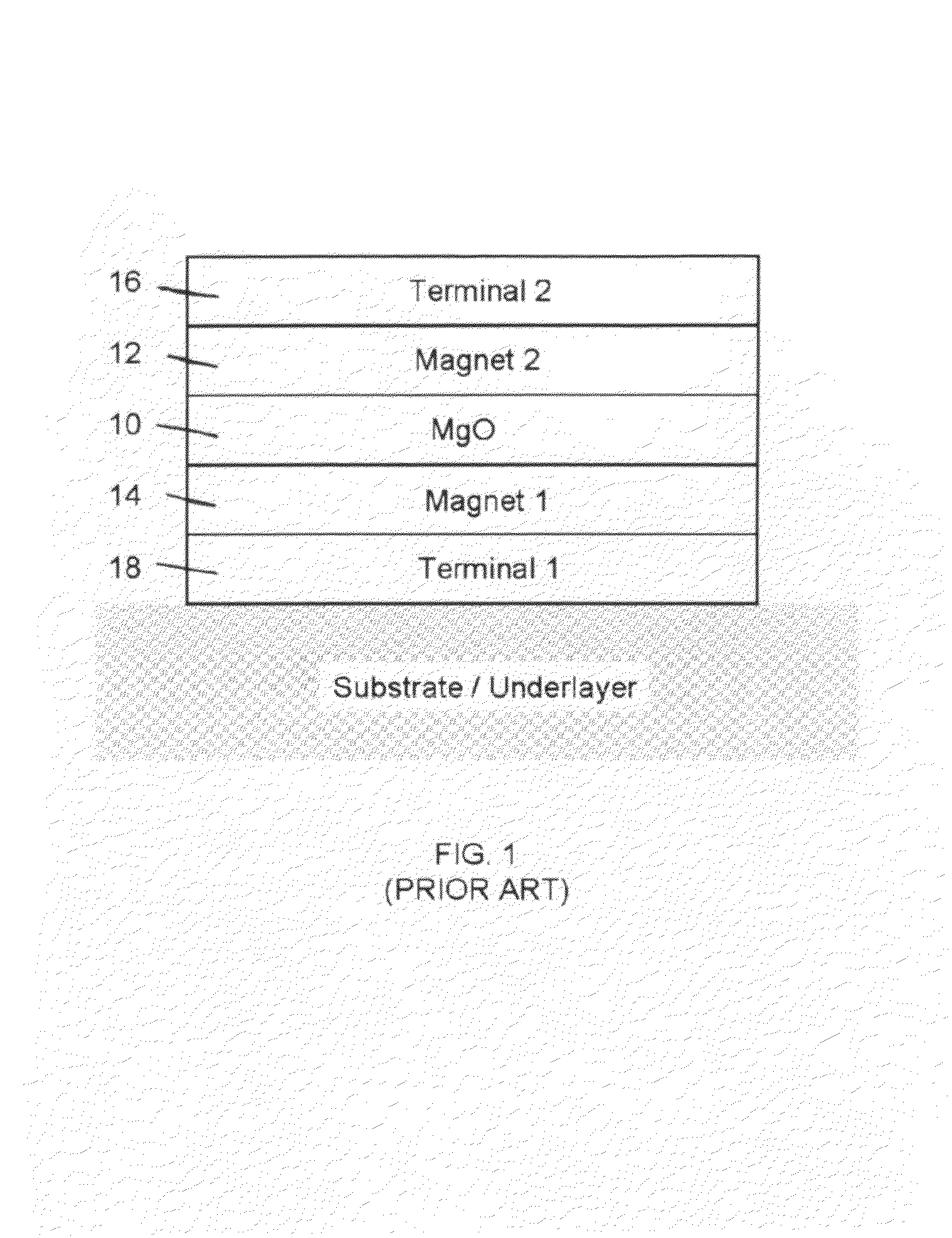

Multiple magneto-resistance devices based on doped magnesium oxide

The present invention provides a low resistance high magnetoresistance (MR) device comprised of a junction of two magnetic elements separated by a magnesium oxide (MgO) layer doped with such metals as Al and Li. Such device can be used as a sensor of magnetic field in magnetic recording or as a storage element in magnetic random access memory (MRAM). The invention provides a high-MR device possessing a diode function, comprised of a double junction of two outer magnetic elements separated by two MgO insulating layer and a center MgO layer doped with such metals as Al and Li. Such device provides design advantages when used as a storage element in MRAM. The invention with MR wherein a gate electrode is placed in electrical or physical contact to the center layer of the double tunnel junction.

Owner:VNK INNOVATION

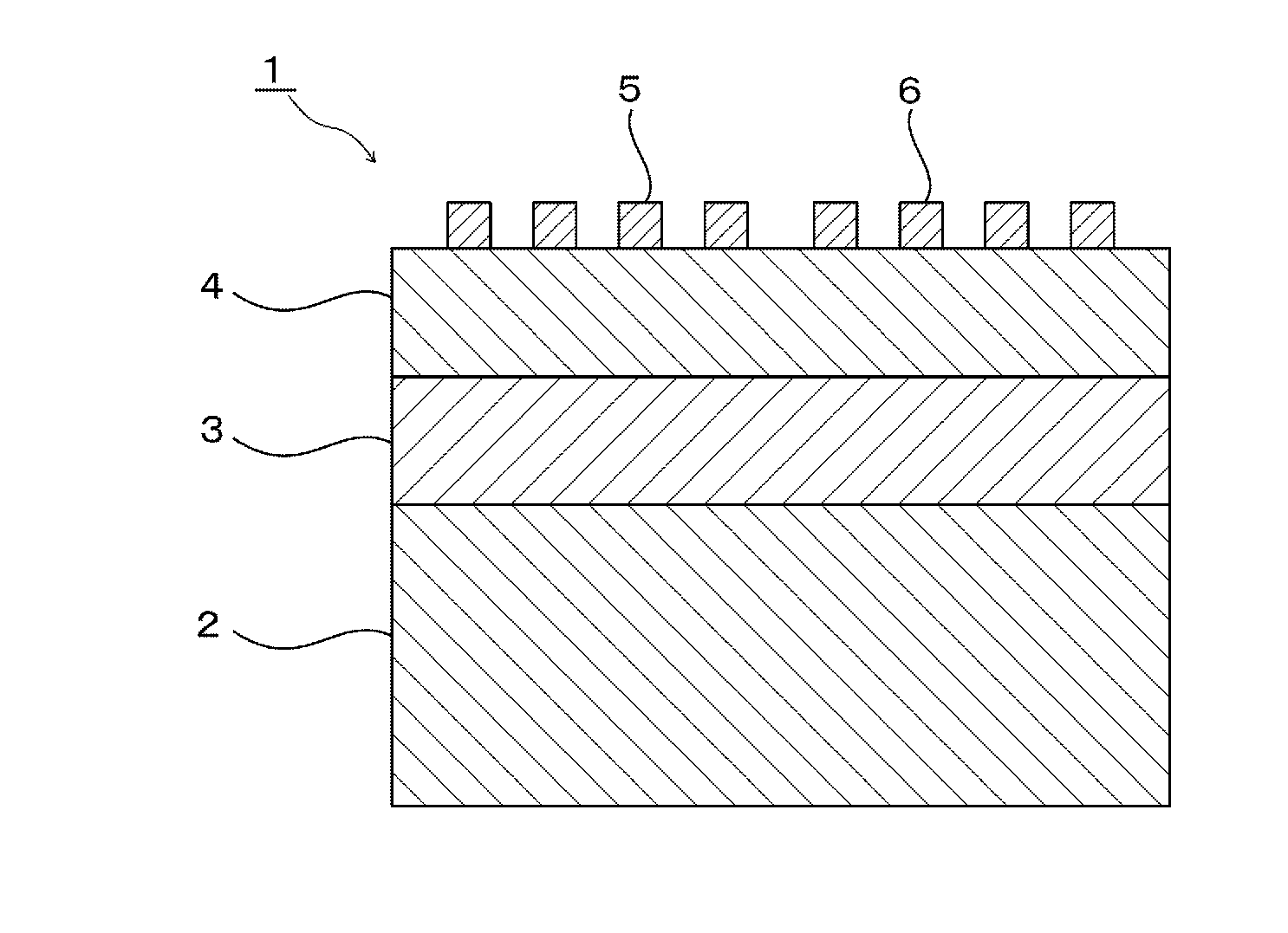

Surface acoustic wave device

ActiveUS20150069882A1Low priceLarger diameter design is achieved with easePiezoelectric/electrostriction/magnetostriction machinesImpedence networksSurface acoustic wave sensorSilicon

A surface acoustic wave device includes a high acoustic velocity film in which a transversal wave propagates at a higher acoustic velocity than in a ScAlN film laminated on a substrate made of silicon or glass. The ScAlN film is laminated on the high acoustic velocity film, and IDT electrodes are laminated on the ScAlN film.

Owner:MURATA MFG CO LTD

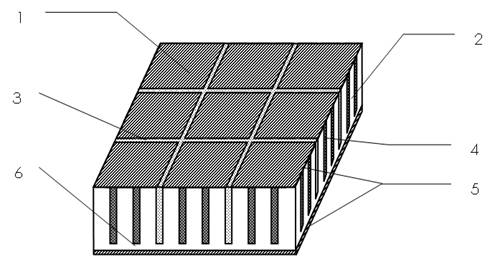

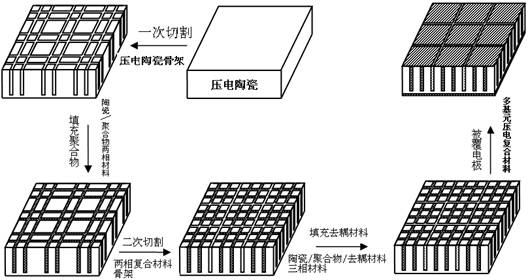

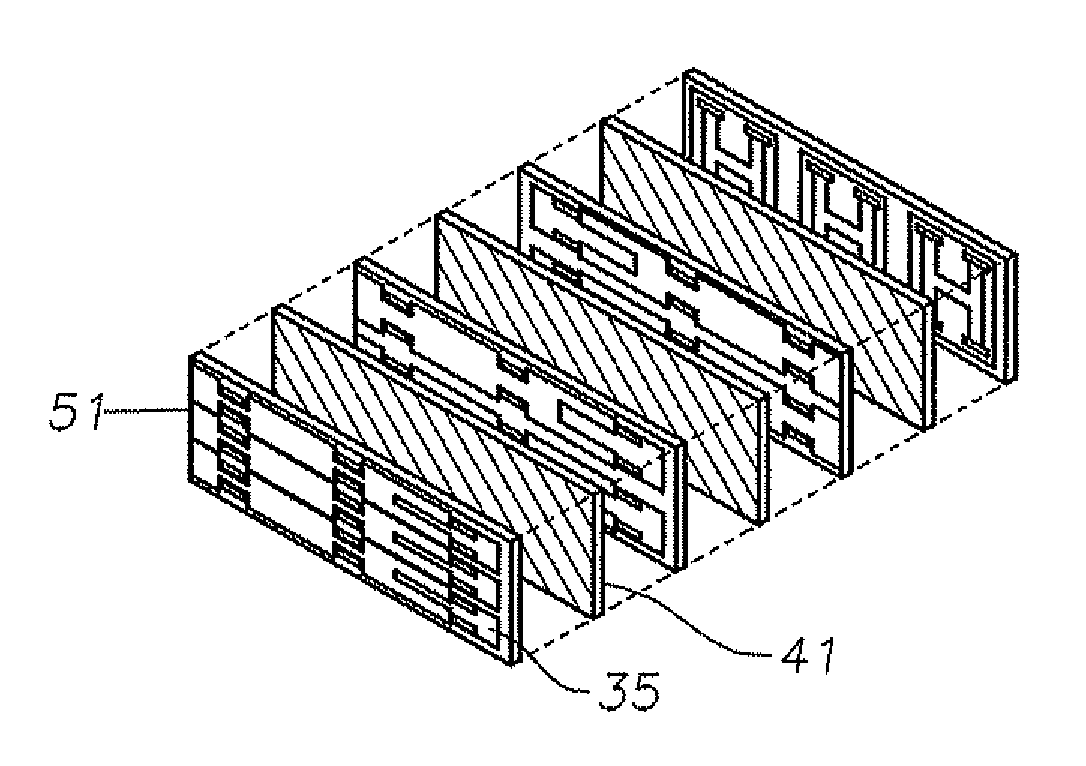

Multi-element piezoelectric composite material and preparation method and application thereof

ActiveCN102427110ASimple preparation processImprove performancePiezoelectric/electrostrictive device manufacture/assemblyDevice material selectionPiezoelectric compositePolymer composite materials

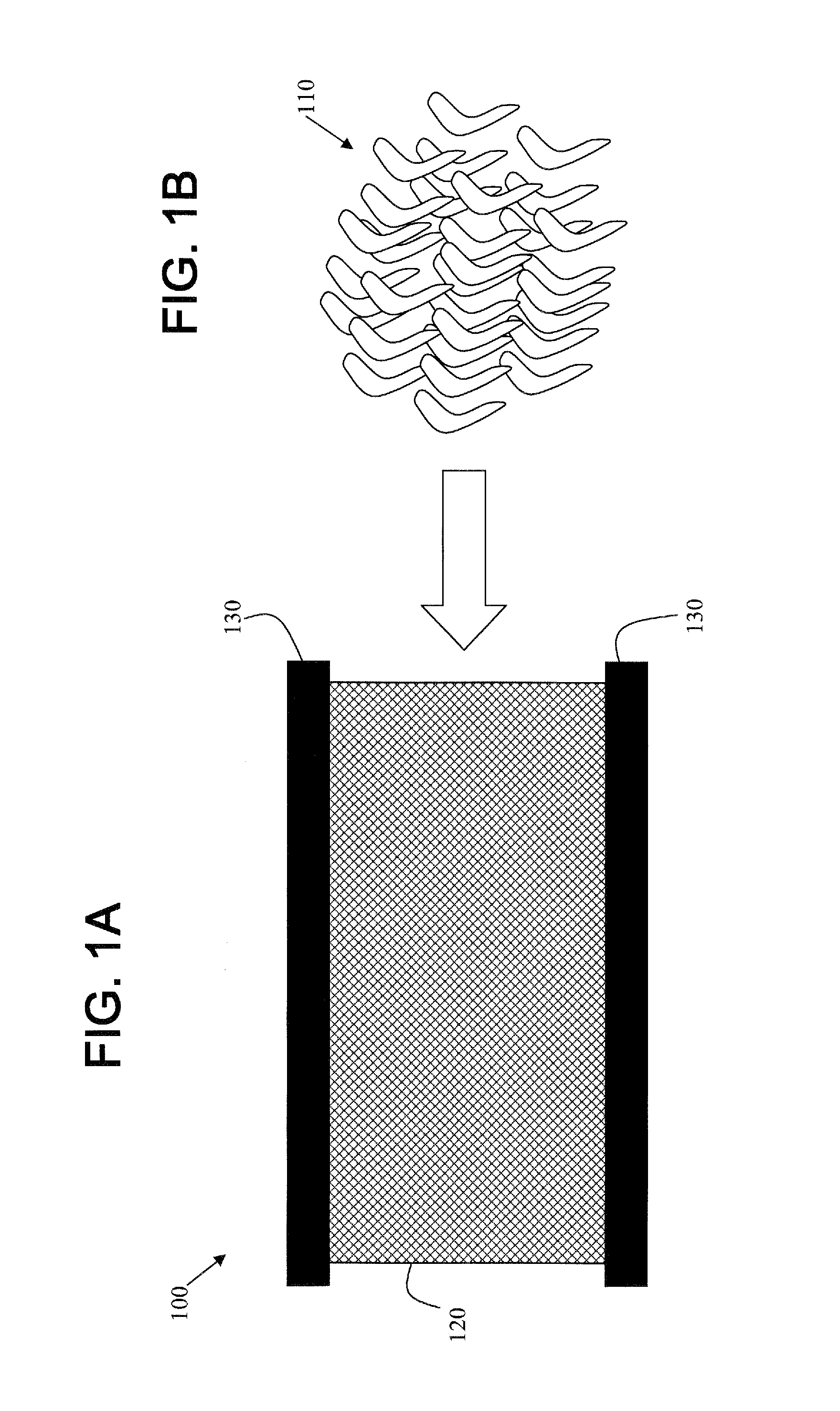

The invention discloses a multi-element piezoelectric composite material and a preparation method. The multi-element piezoelectric composite material is a 1-3-2 type composite material consisting of a piezoelectric ceramic / polymer composite material and a decoupling material, wherein the piezoelectric ceramic / polymer composite material takes piezoelectric ceramic as a skeleton and a polymer as a base body and is attached with an upper electrode and a lower electrode, the piezoelectric ceramic skeleton comprises a substrate and a piezoelectric ceramic column connected to the substrate, the decoupling material is filled in the piezoelectric ceramic / polymer composite material, the piezoelectric ceramic / polymer composite material is divided into a plurality of units of the same structure by the decoupling material, and the upper electrodes of all elements are discontinuous. Through the adding of the decoupling material, the whole composite material is divided into a plurality of units. The preparation technology is simple. The obtained multi-element material has excellent property, good consistency, low coupling and wide application prospect in the field of transducers.

Owner:UNIV OF JINAN

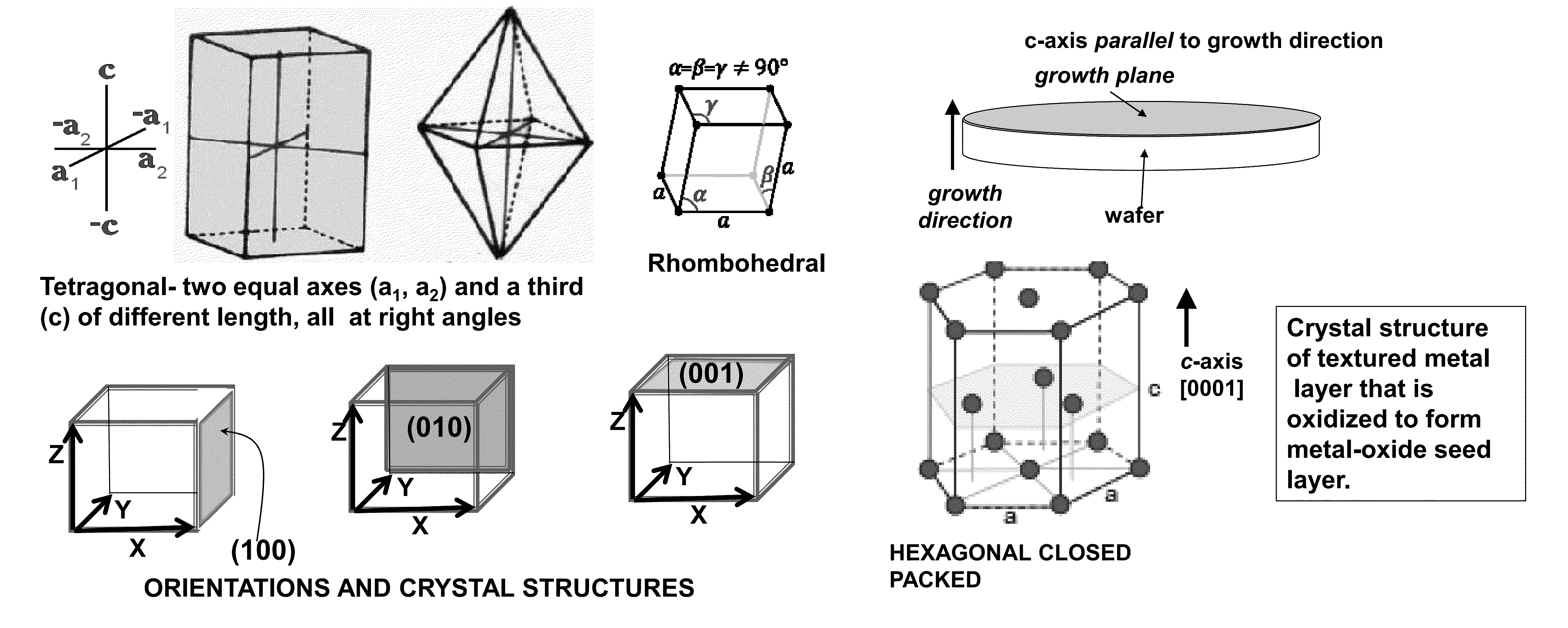

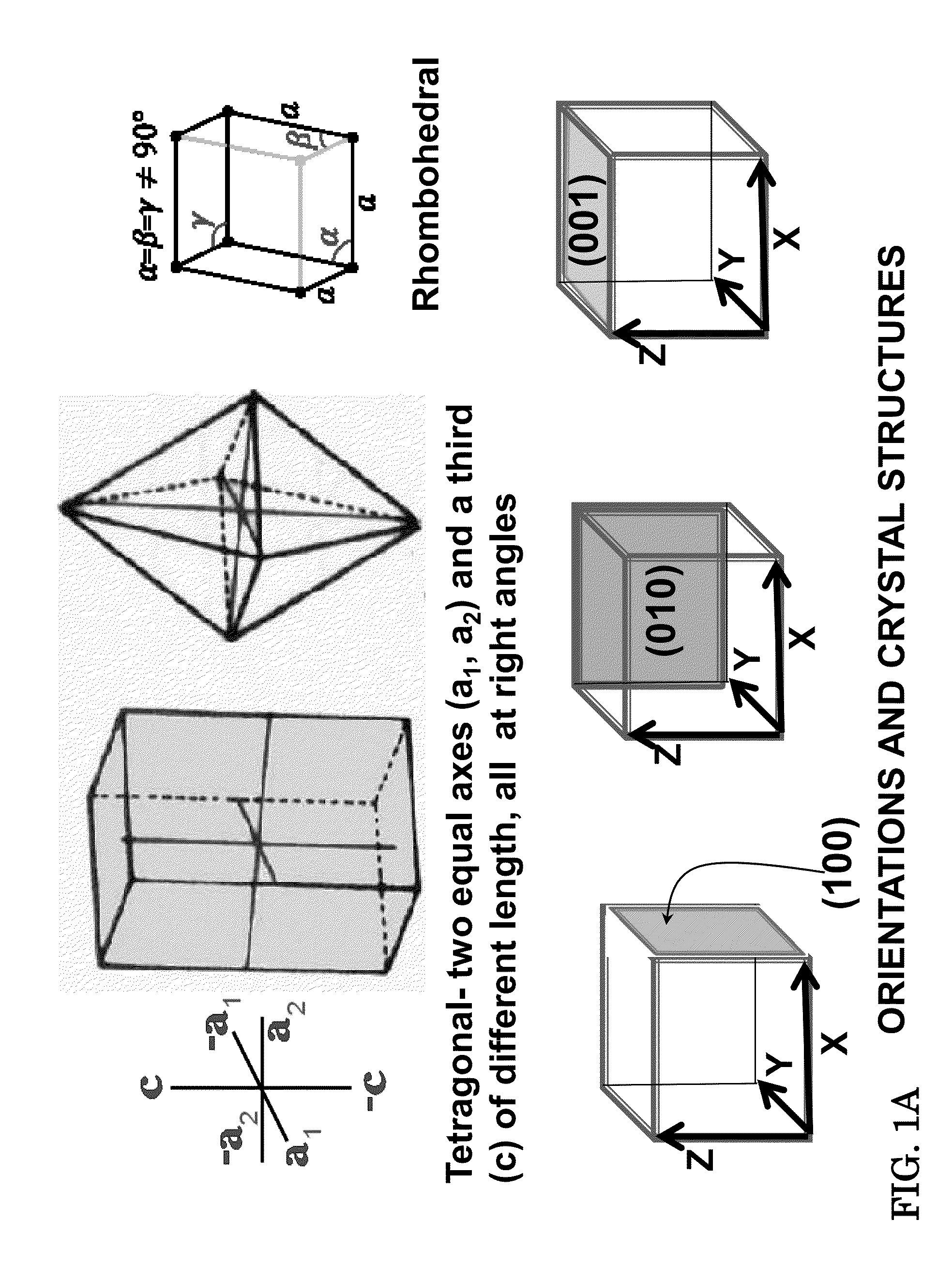

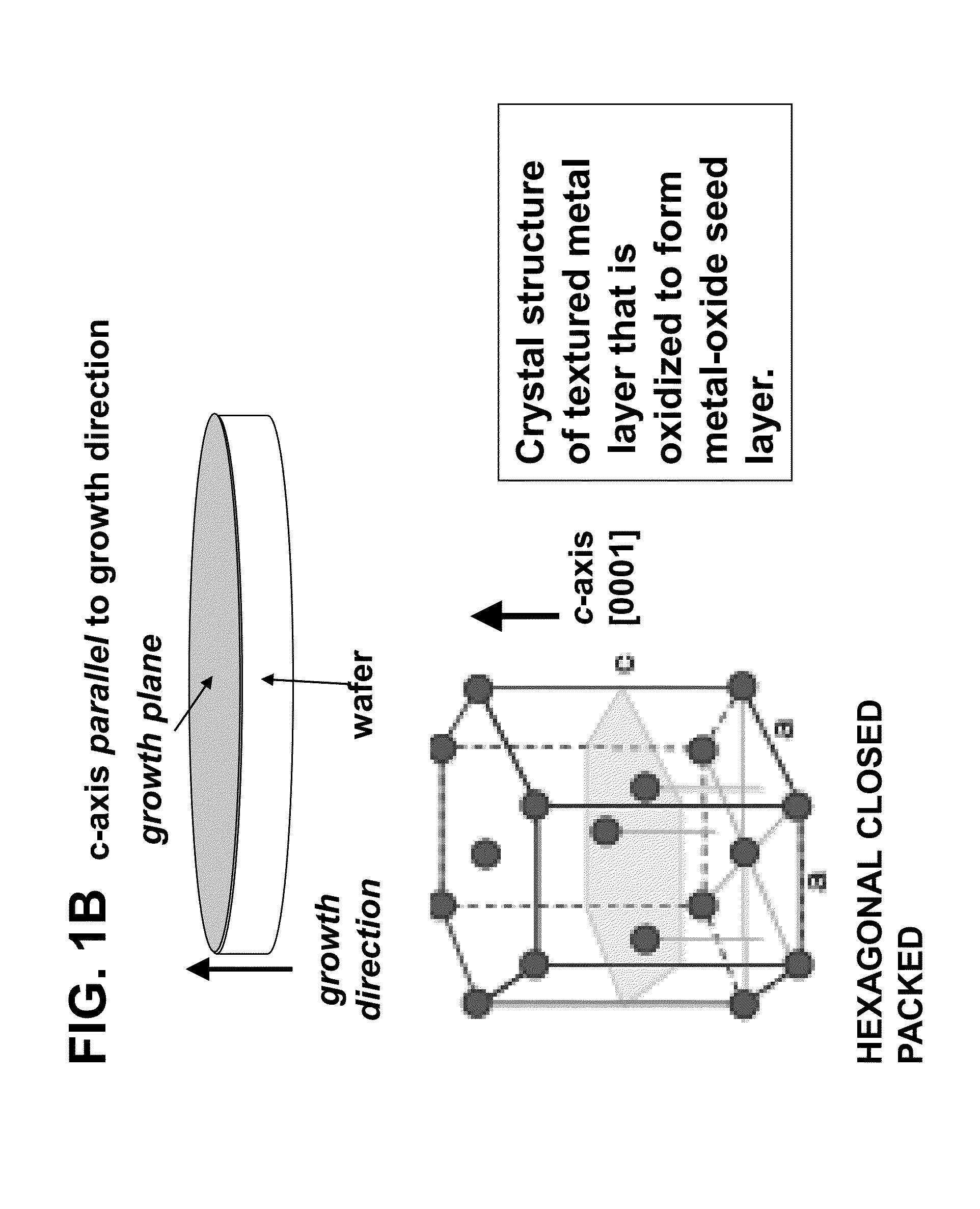

Thermally oxidized seed layers for the production of textured electrodes and pzt devices and method of making

InactiveUS20130093288A1Improve texturePolycrystalline material growthPiezoelectric/electrostriction/magnetostriction machinesCrystallographyFerroelectric thin films

A method for forming an electrical device having a {100}-textured platinum electrode comprising: depositing a textured metal thin film onto a substrate; thermally oxidizing the metal thin film by annealing to convert it to a rocksalt structure oxide with a {100}-texture; depositing a platinum film layer; depositing a ferroelectric film. An electrical device comprising a substrate; a textured layer formed on the substrate comprising metal oxide having a rocksalt structure; a first electrode film layer having a crystallographic texture acting as a template; and at least one ferroelectric material layer exhibiting spontaneous polarization epitaxially deposited on the first electrode film layer whereby the rocksalt structure of the textured layer facilitates the growth of the first electrode film layer with a {100} orientation which forms a template for the epitaxial deposition of the ferroelectric layer such that the ferroelectric layer is formed with an {001} orientation.

Owner:ARMY UNITED STATES GOVERNMENT AS REPRESENTED BY THE SEC OF THE ARMY THE

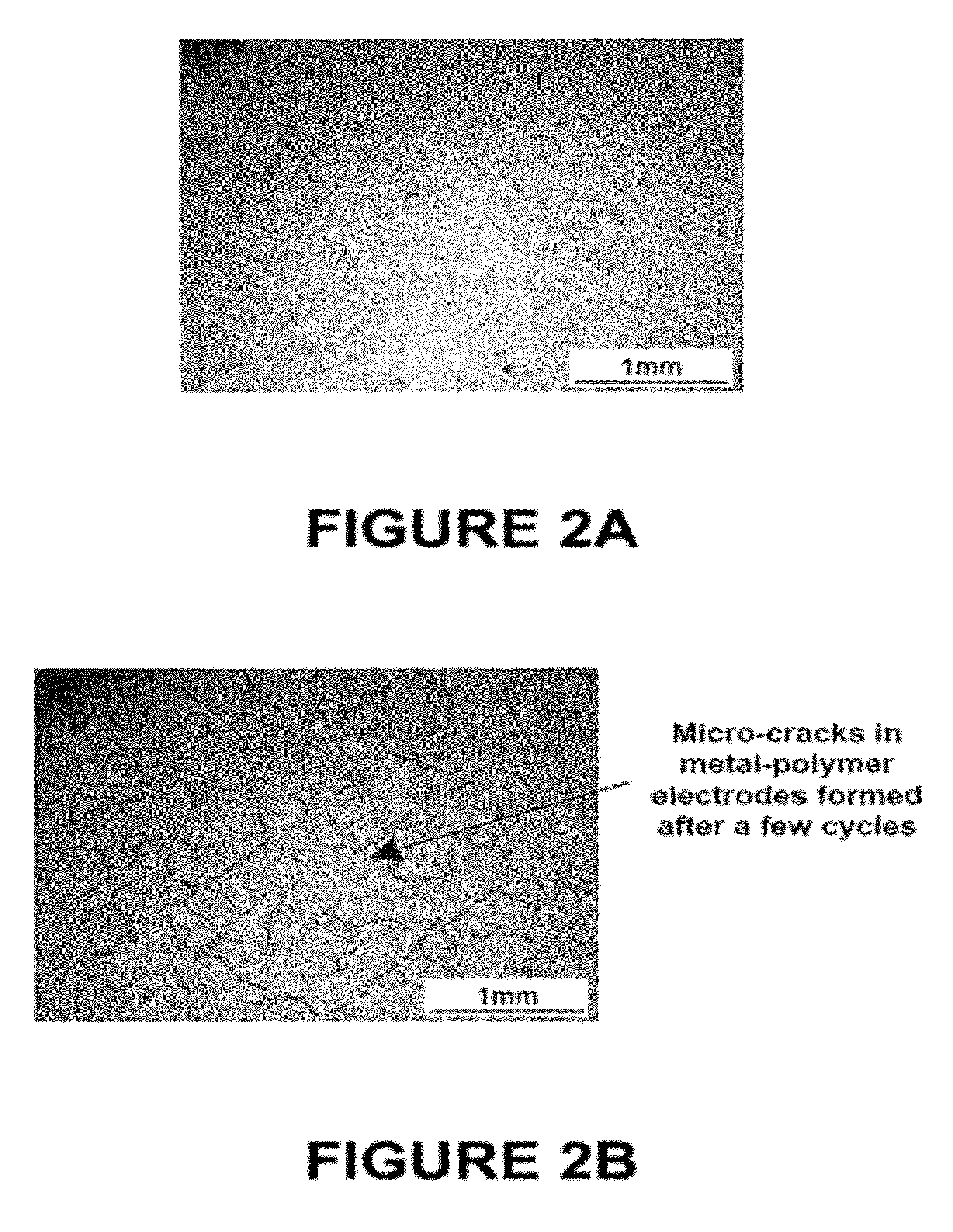

Piezo-electric composite sensor

InactiveCN101194376AExcellent piezoelectric propertiesExcellent dielectric propertiesPiezoelectric/electrostrictive device manufacture/assemblyDevice material selectionProduction rateConductive polymer

The present invention provides a piezoelectric composite sensor comprising a piezoelectric material layer formed of a piezoelectric composite obtained by mixing piezoelectric material powder with a polymer, and electrodes formed of a conductive composite or conductive polymer obtained by mixing conductive filling particles with a polymer matrix and formed on both surfaces of the piezoelectric material layer. The piezoelectric composite sensor of the present invention has advantages of superior piezoelectric and dielectric properties, high mechanical strength, improved reliability and process flexibility, a simplified process and reduced process costs, and improved productivity.

Owner:ATSUDEN

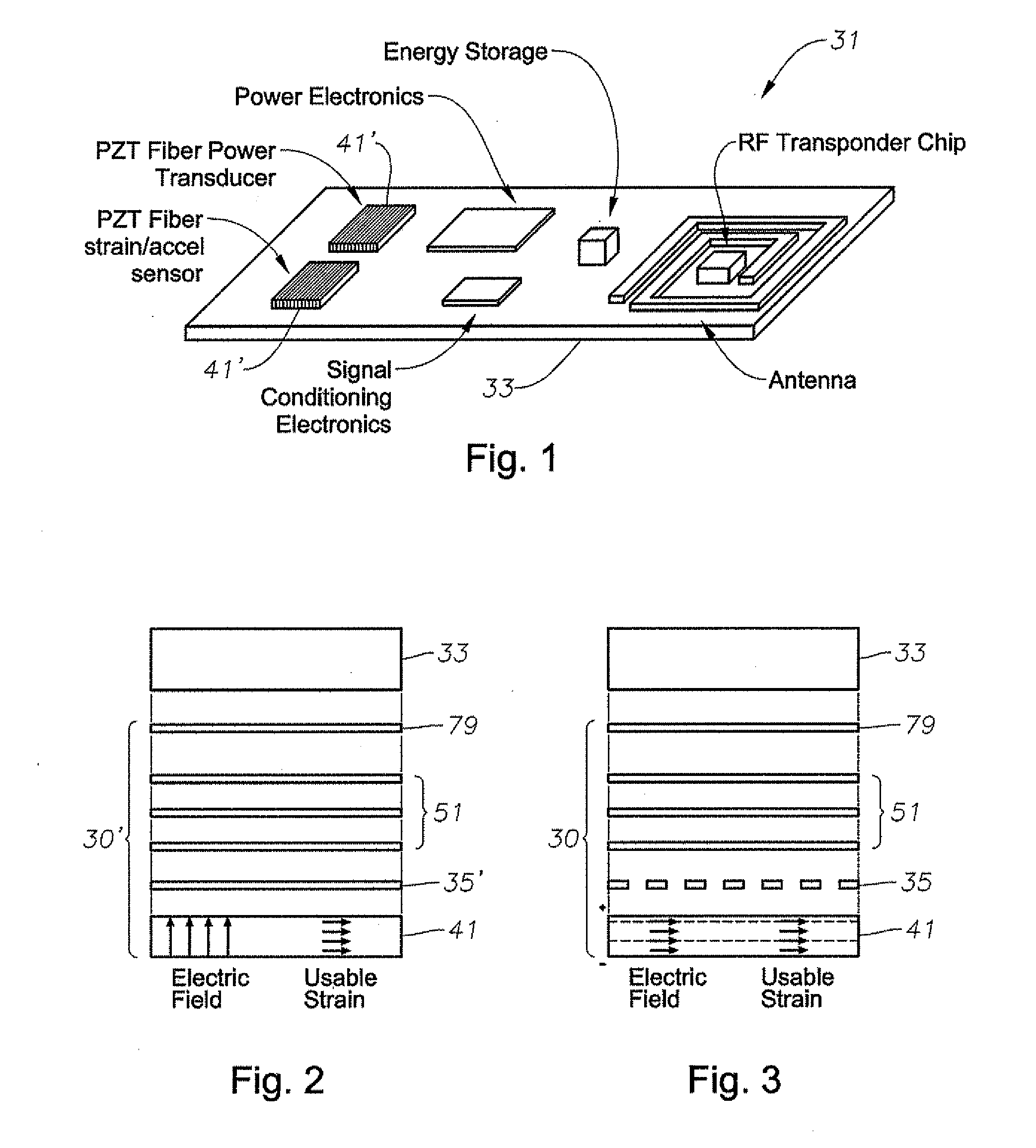

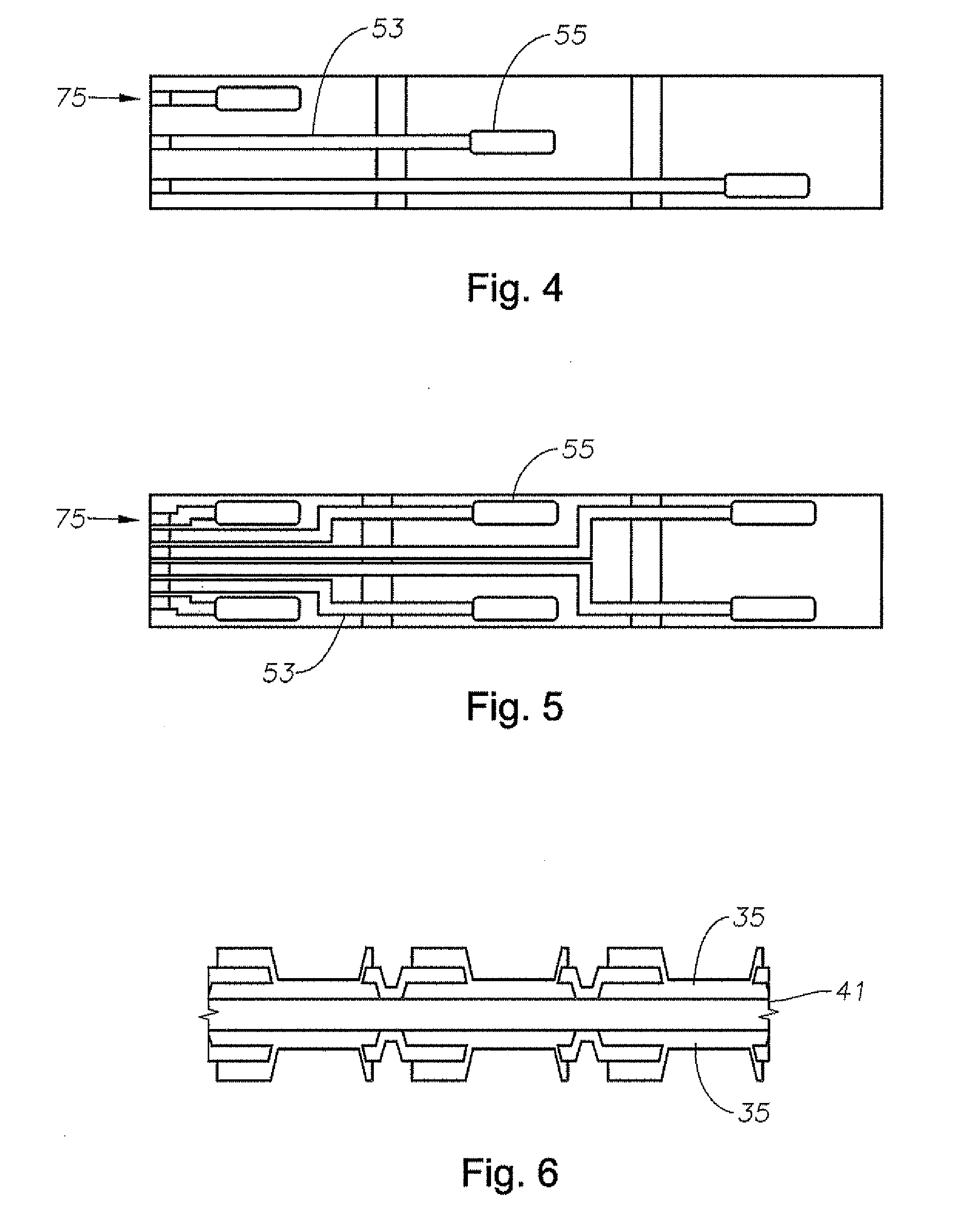

Piezoelectric composite apparatus and related methods

ActiveUS20080143216A1Increase temperatureFacilitate high outputMaterial analysis using sonic/ultrasonic/infrasonic wavesPiezoelectric/electrostriction/magnetostriction machinesElectrical conductorPiezoelectric composite

A piezoelectric planar composite apparatus to provide health monitoring of a structure and associated methods are provided. The piezoelectric planar composite apparatus includes a piezoelectric electric material layer, multiple electrodes positioned in electrical contact with the piezoelectric material layer, and multiple sets of electrode interconnect conductors each positioned in electrical contact with a different subset of the of the electrodes and positioned to form multiple complementary electrode patterns. Each of the complementary electrode patterns is positioned to form an electric field having an electric field axis oriented along a different physical axis from that of an electric field formed by at least one other of the complementary electrode patterns. The interconnect conductors can be distributed over several electrode interconnect conductor carrying layers to enhance formation of the different complementary electrode patterns.

Owner:LOCKHEED MARTIN CORP

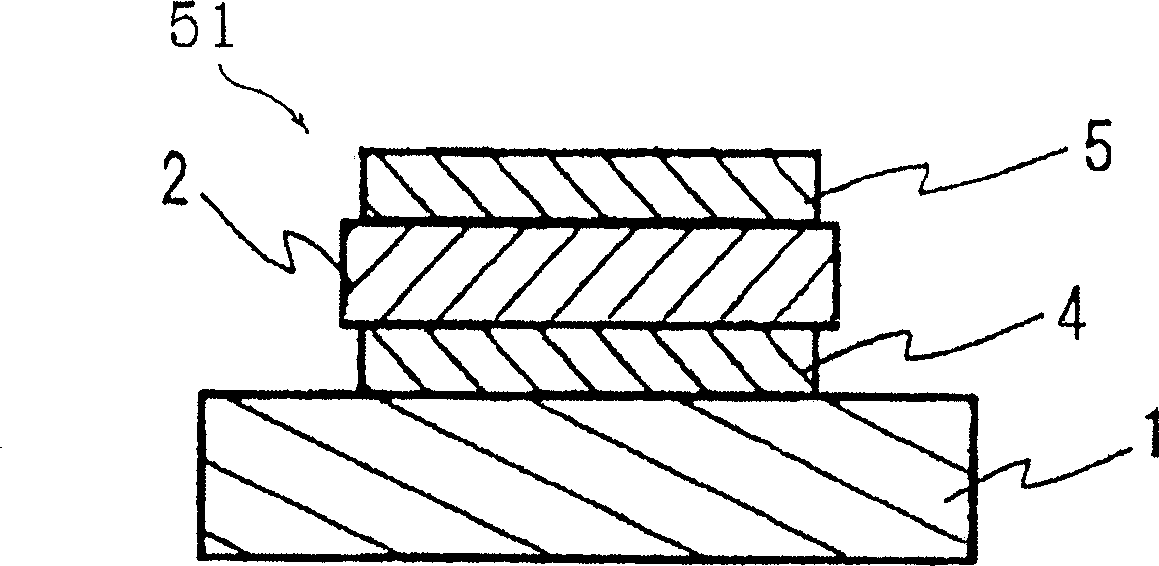

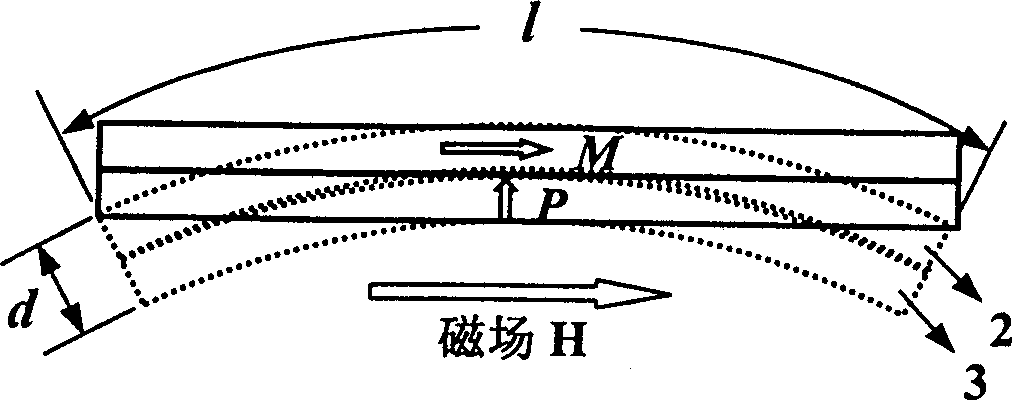

Film magnetoelectric composite material and preparation method thereof

InactiveCN102044626AAvoid reactionAvoid eddy current lossPiezoelectric/electrostrictive device manufacture/assemblyDevice material selectionPhase reactionComposite strength

The invention relates to a film magnetoelectric composite material and a preparation method thereof, and belongs to the technical field of magnetic functional materials and preparation thereof. The magnetoelectric composite material is characterized by being prepared by compounding a magnetostrictive film layer, a conductive film layer and a piezoelectric ceramic substrate. In the preparation method, the magnetostrictive film layer is deposited on the piezoelectric substrate with a prepared electrode by physical vapor deposition (PVD) technology. The magnetoelectric composite material has high interfacial composite strength, a simple structure, a high magnetoelectric conversion coefficient, low high-frequency eddy current loss, stable performance and thin and light size, effectively avoids phase reaction between ferroelectric and ferromagnetic phases, and is particularly suitable for preparing a micro sensor; in addition, the preparation method is simple and feasible, and low in cost, and overcomes the defects of a complicated preparation process, high cost and the like of a laminated magnetoelectric composite material and the conventional film magnetoelectric composite material.

Owner:GRIREM ADVANCED MATERIALS CO LTD

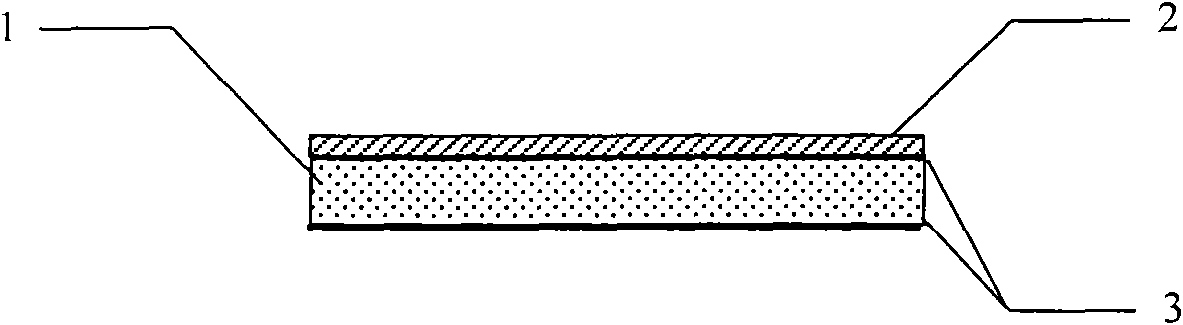

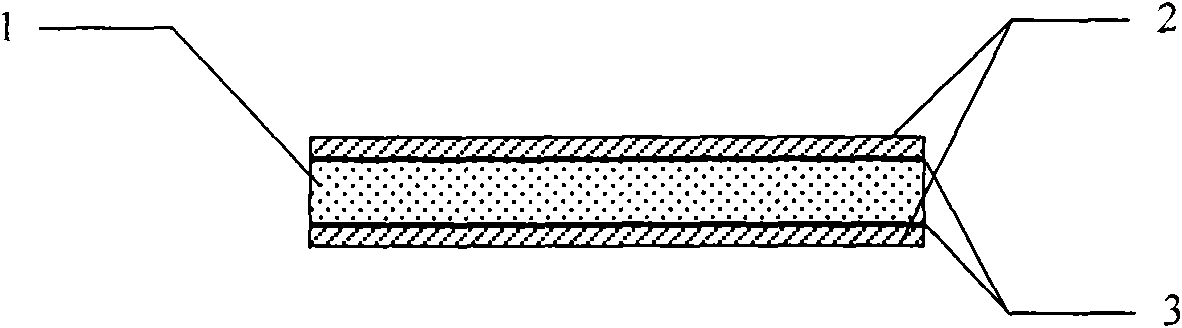

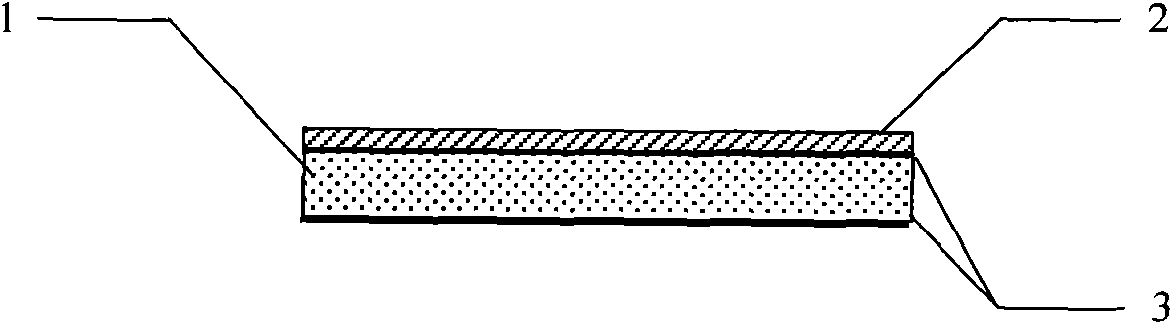

Energy Harvesting Devices Using Carbon Nanotube (CNT)-Based Electrodes

InactiveUS20120043858A1Piezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesEpoxyCarbon nanotube

Energy harvesting elements or membranes are provided that use a layer of electrodes with a mixture of carbon nanotubes (CNT). The energy harvesting device of this type can be used as in sensor-based system in which on application of a bending load, the energy harvesting device produces a voltage across the electrodes. The energy harvesting device may include an electrode coating including carbon nanotubes (CNT) substantially homogenously dispersed in epoxy resin system to form a CNT-epoxy electrode coating. The CNT-epoxy electrode can be realized by dispersing about 5% CNT (by weight) in an epoxy-resin system, followed by mixing the system to achieve a near-homogenous dispersion resulting in a CNT-epoxy mixture. The CNT-epoxy mixture can then be uniformly coated on surfaces of a polymer to form electrodes.

Owner:INDIAN INSTITUTE OF SCIENCE

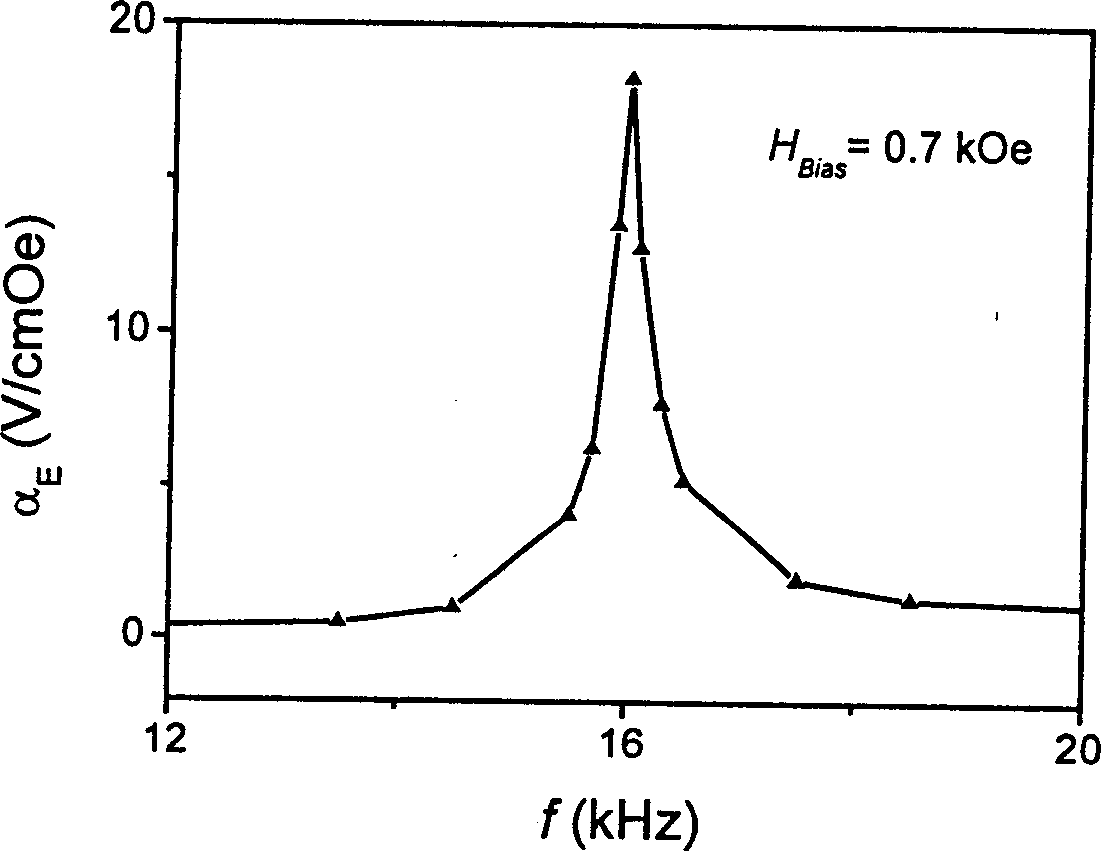

Magnetoelectric devices and methods of using same

ActiveUS20050218729A1Piezoelectric/electrostriction/magnetostriction machinesDevice material selectionElectricityEddy current

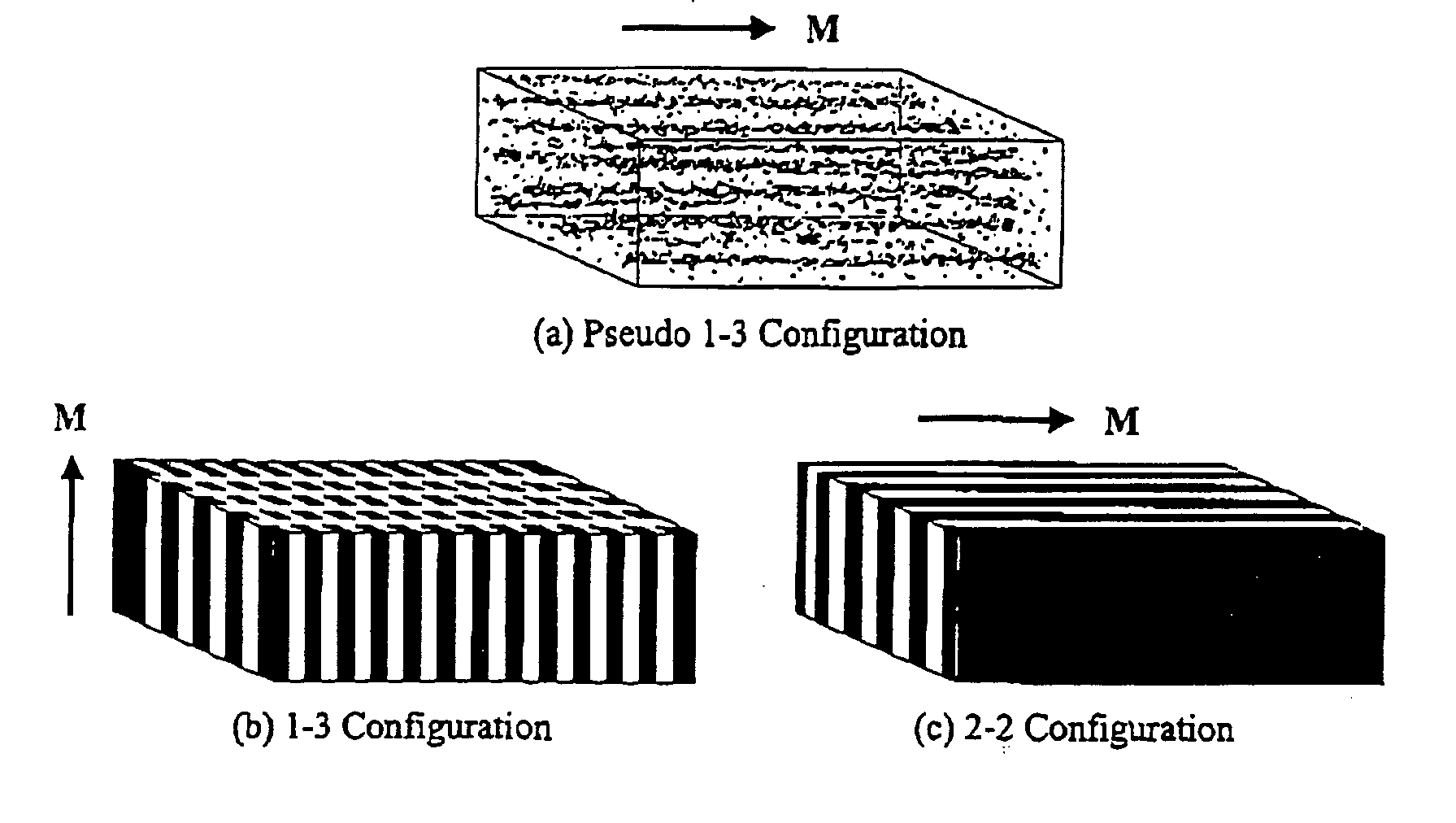

Existing magnetoelectric materials relying on the use of metallic or ceramic magnetostrictive materials and ceramic piezoelectric materials as their constituent phases may have three problems. First, the operational frequency may be limited to a few kilohertz due to the presence of eddy-current losses in the metallic magnetostrictive phase. Secondly, it may be difficult to machine and fabricate devices due to the mechanical brittleness of the ceramic and some metallic magnetostrictive phases as well as of the ceramic piezoelectric phase. Thirdly, it may be difficult to tailor and optimize the properties (i.e., magnetoelectric voltage coefficient αE, etc.) of the devices due to the limitation of the types of the constituent materials. This invention provides a magnetoelectric element including at least one set of alternative piezoelectric layer and magnetostrictive composite layer. The magnetostrictive composite layer includes at least one magnetostrictive material dispersed in first concentrated zones within a first polymer matrix, wherein all of said concentrated zones are orientated along a first direction. It is found that the conversion efficiency (i.e., αE) varies in accordance with applied magnetic control field Hcontrol in magnetoelectric devices made of such a magnetoelectric element.

Owner:THE HONG KONG POLYTECHNIC UNIV

Film forming method and film forming apparatus

InactiveUS20060068105A1Improve propertiesIncrease valuePretreated surfacesMagnetic film to substrate applicationProperty valueCrystal orientation

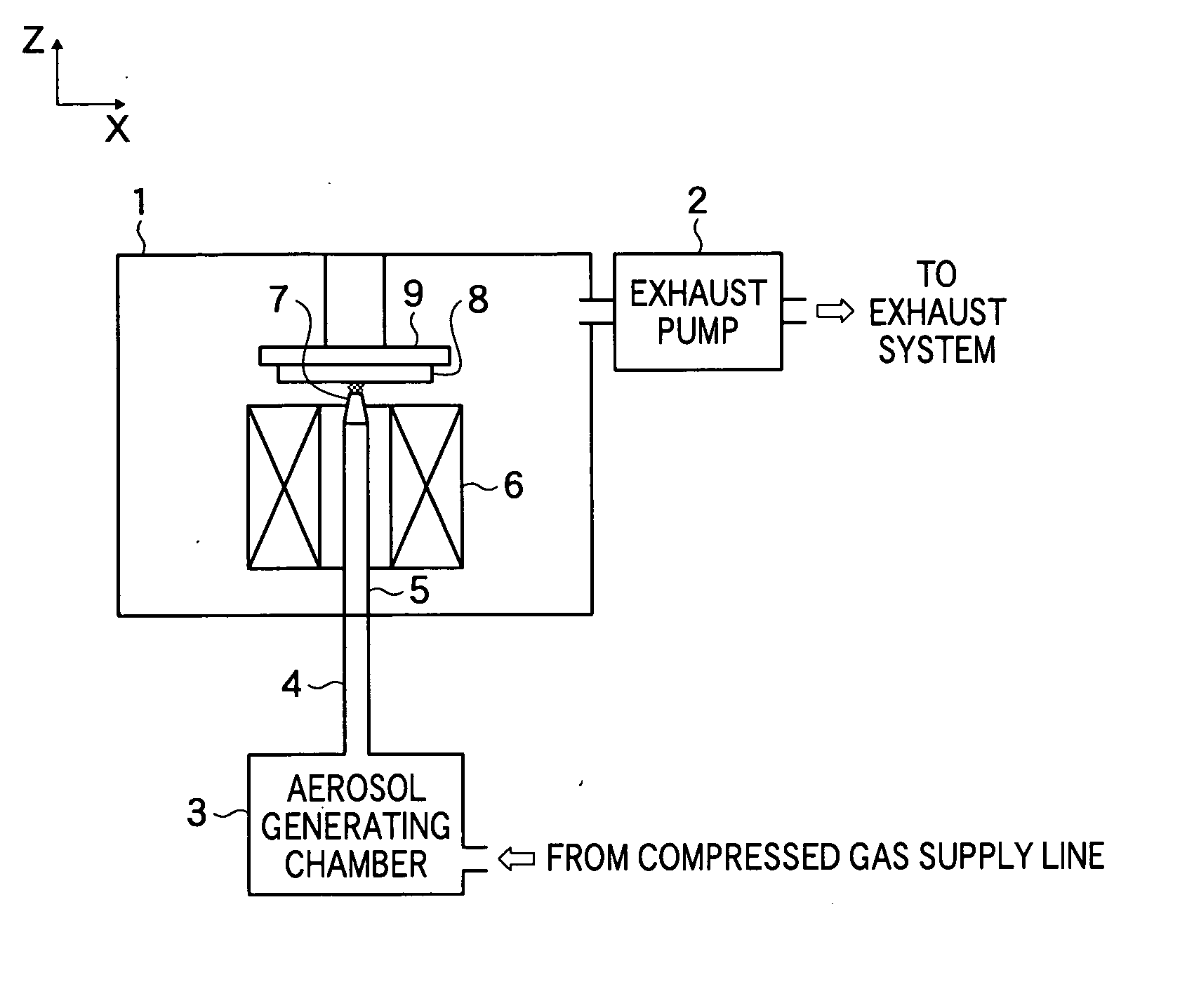

A film forming apparatus by which property values in a film formed by the AD method can be improved. The film forming apparatus includes: a chamber having a substrate stage for holding a substrate on which a film is to be formed; an aerosol generating unit for generating an aerosol by dispersing a raw material powder into a gas; a magnetic field applying device for applying a magnetic field to a flow path of the aerosol generated by the aerosol generating unit so as to orient crystal orientation in the raw material powder in an aerosol state; and an injection nozzle for spraying the aerosol applied with the magnetic field by the magnetic field applying device to the substrate so as to deposit the raw material powder, in which the crystal orientation is oriented, on the substrate.

Owner:FUJIFILM CORP +1

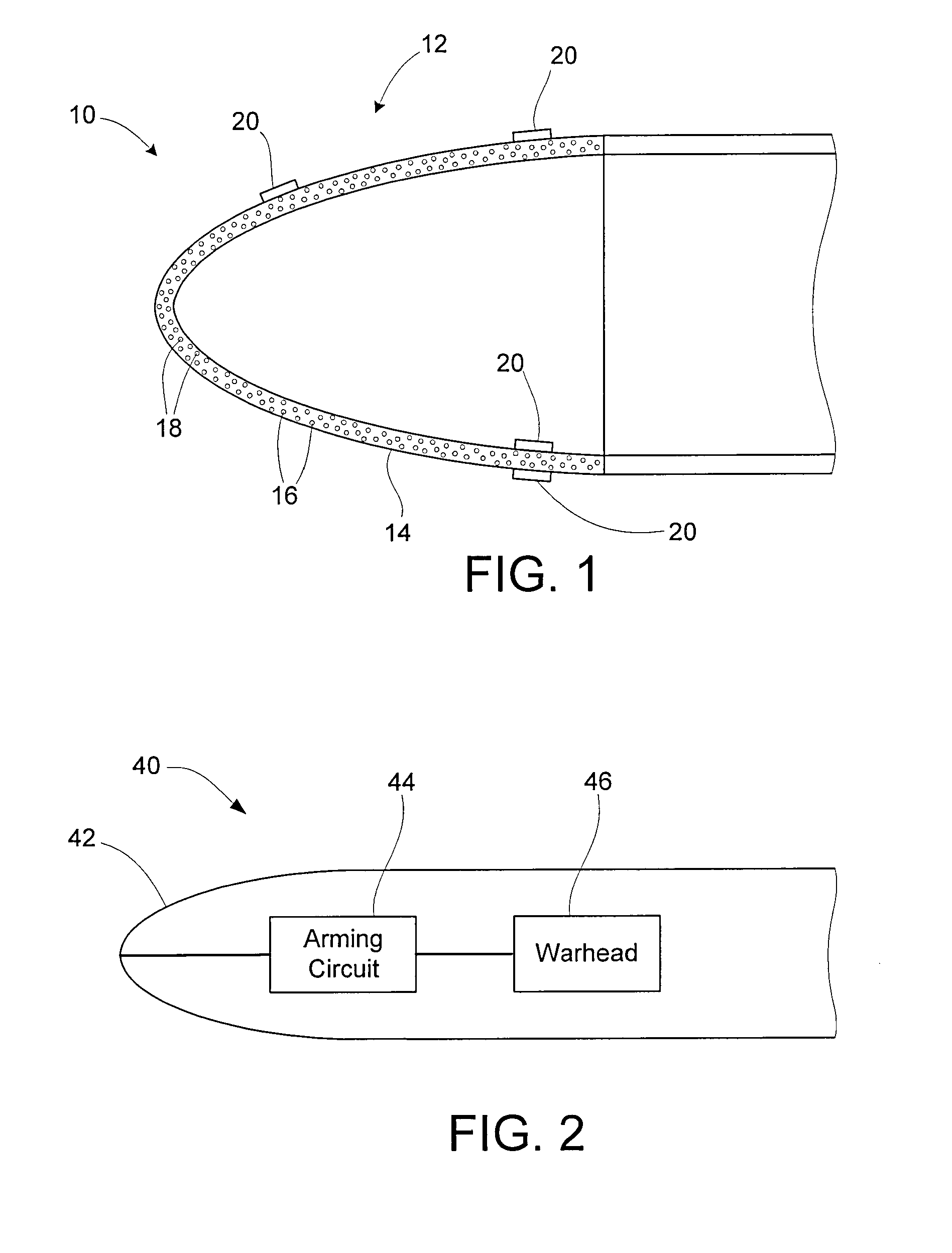

Structural material with piezoelectric material particles

ActiveUS20080179993A1Vibration measurement in solidsAcceleration measurement using interia forcesElectricityStructural health monitoring

A load-bearing structural member has a continuous structural material with piezoelectric material particles mixed in throughout. The structural material may be any of a variety of suitable materials, such as polymer materials, composite materials, ceramic materials, or concrete. The piezoelectric material particles may be used for evaluating the soundness of the structural member, such as in quality control or structural health monitoring processes. The structural member may include one or more conductive pickups used for receiving signals from the structural member. The signals may be induced by introducing ultrasonic signals or vibrational resonance signals into the structural member. The response from such induced signals may be used for quality control purposes or structural health monitoring. Piezomagnetic, electro-strictive, or magneto-strictive material particles may also be spread throughout the structural material, to amplify and otherwise enhance the signals from the piezoelectric material particles.

Owner:RAYTHEON CO

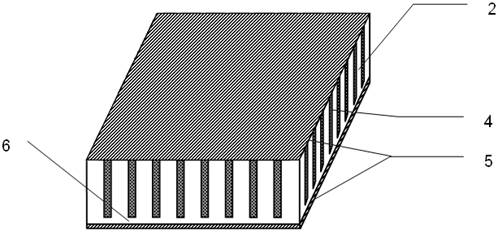

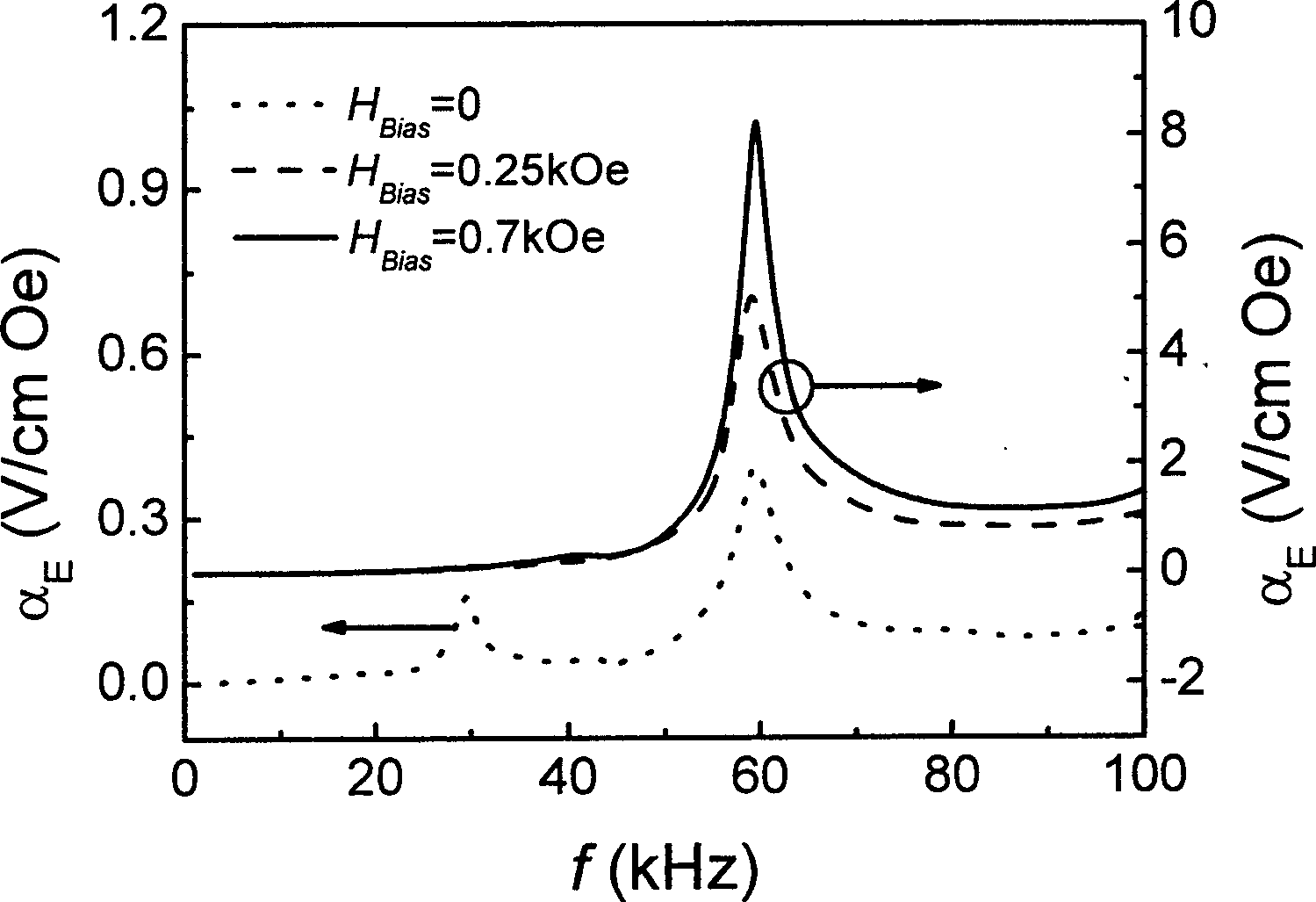

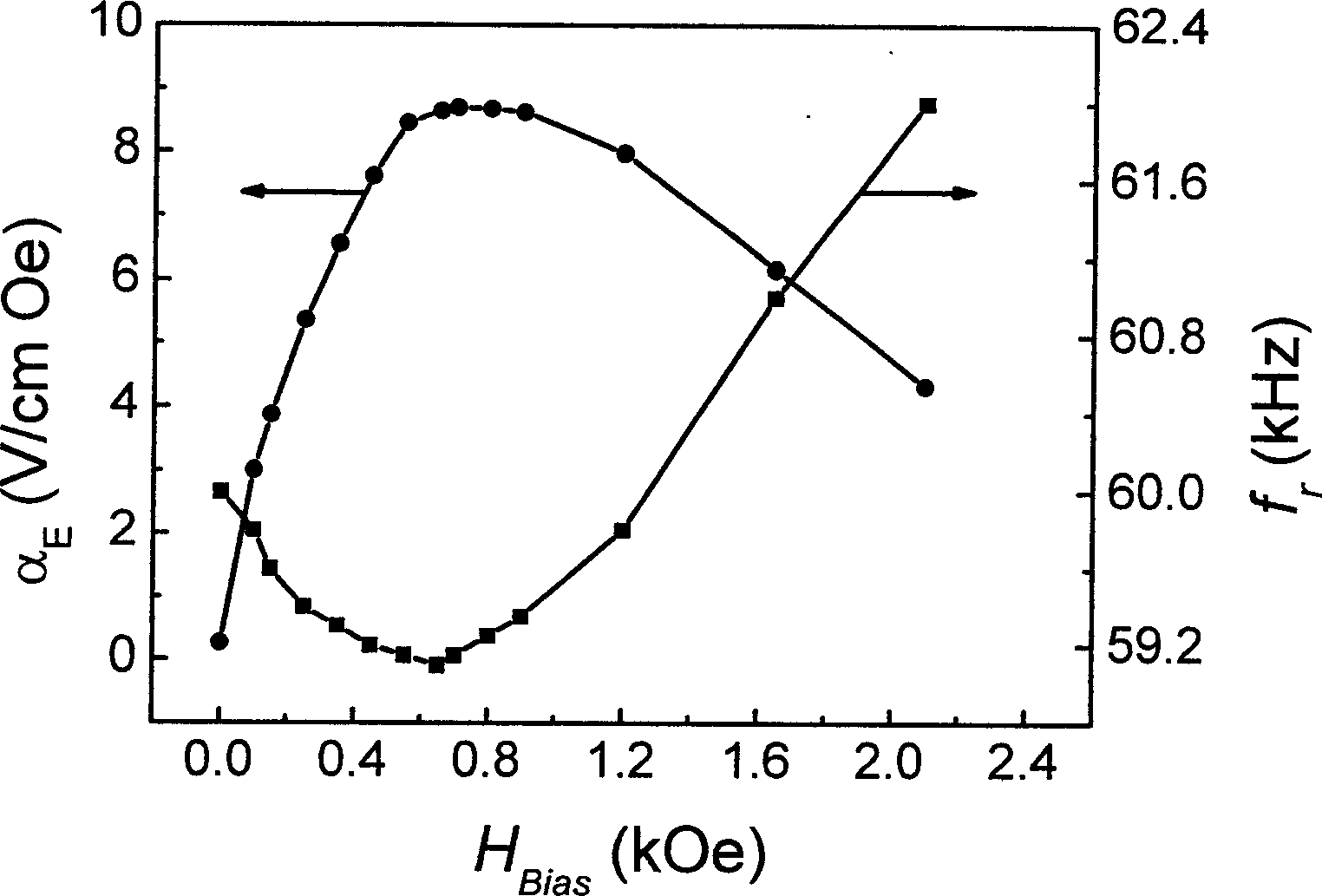

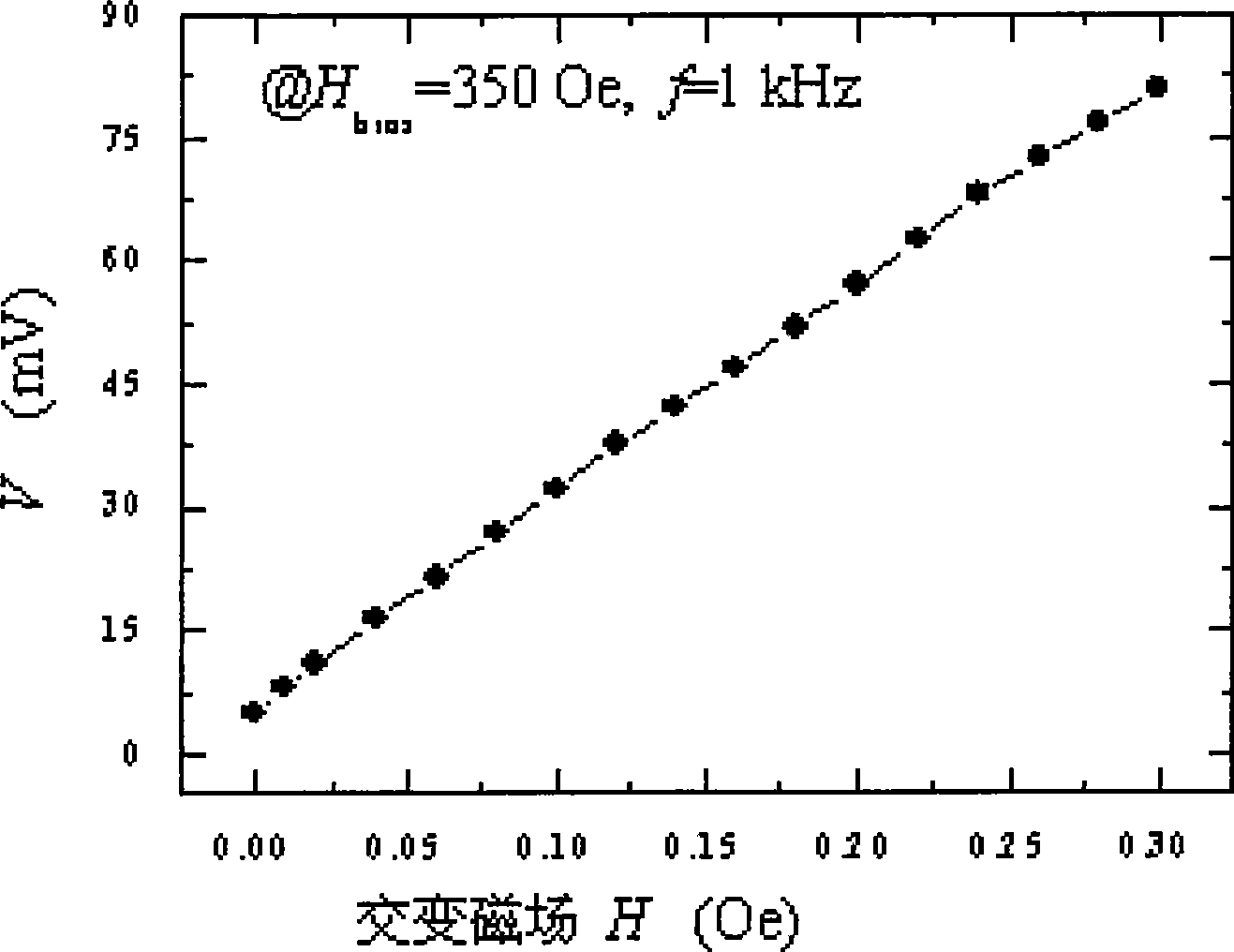

Magne to electric composite material and manufacturing method thereof

InactiveCN1489227AReduce lossImprove conversion efficiencyPiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyResonanceAlloy

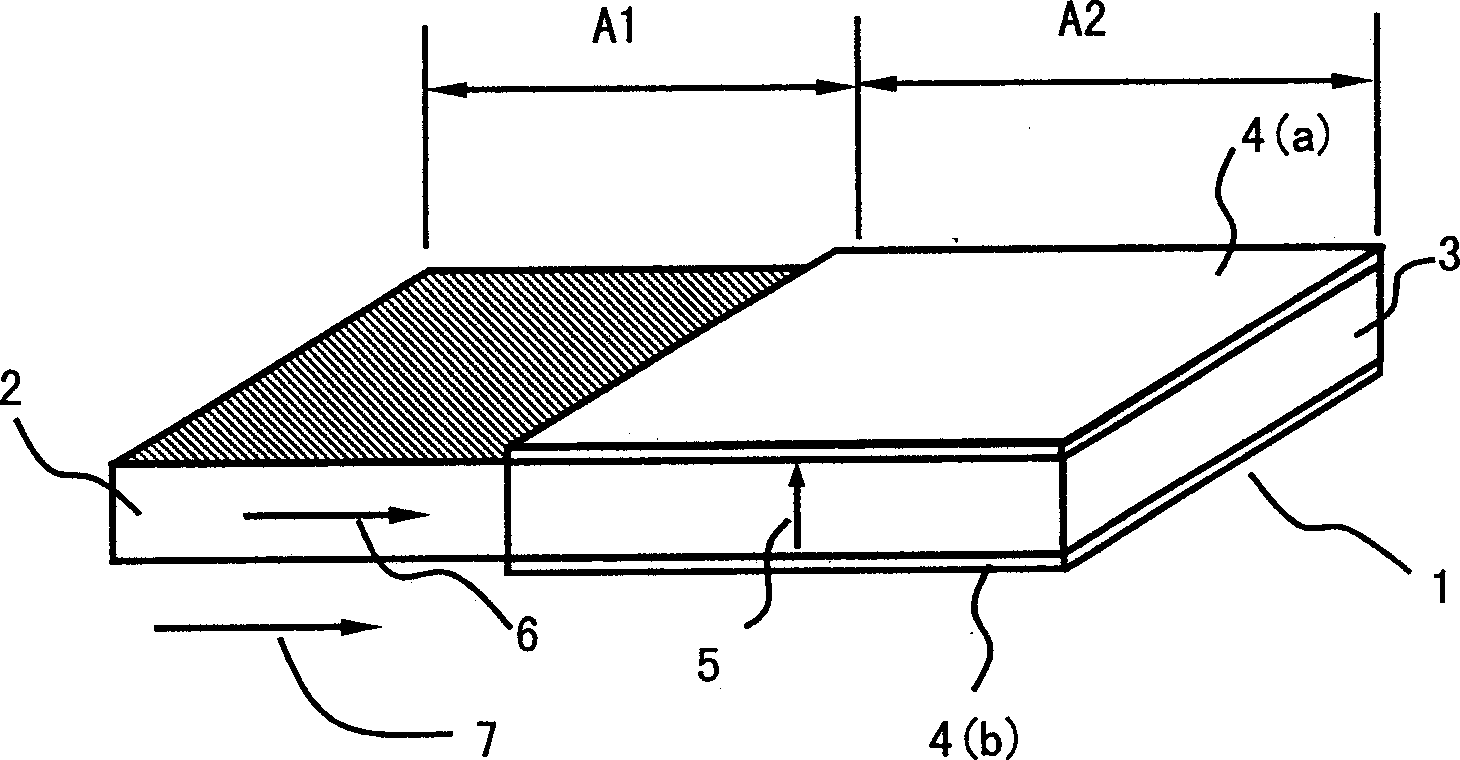

The magnetoelectricity composite material is a rectangle piece (1) divided into two areas A1 and A2 along longitudinal direction. A1 is made from magnetostrictive material, and A2 is made from piezodielectric material. A1 and A2 are combined through agglomerant. A pair of flat pole (4a and 4b) is in the A2 area. The piezodielectric material is polarized along thick direction. The said magnetostrictive material is magnetostrictive alloy, oxide or their composite material with polymer. The said piezodielectric material is piezoelectric ceramic or a composite material formed from piezoelectric ceramic and polymer. When dc magnetic biasing field and AC magnetic field with small signal are applied to rectangle piece 2 of magnetostrictive material along longitudinal direction, the rectangle piece (1) of magnetoelectricity generates resonance near to 60kHz, and voltage is output through rectangle piece 3 of piezodielectric composite material so as to realize magneto-electric coupling.

Owner:NANJING UNIV

Piezoelectric/electrostrictive porcelain composition and its application

InactiveCN1754858AExcellent piezoelectric/electrostrictive propertiesImpedence networksDevice material selectionSolid solutionMaterials science

There is provided a piezoelectric / electrostrictive porcelain composition capable of manufacturing a piezoelectric / electrostrictive article or a piezoelectric / electrostrictive portion which exhibits superior piezoelectric / electrostrictive characteristics without containing lead (Pb). The piezoelectric / electrostrictive porcelain composition contains as a main component a binary solid solution represented by the general formula (1): €ƒ€ƒ€ƒ€ƒ€ƒ€ƒ€ƒ€ƒ (1-n)(Ag 1-a-b-c Li a Na b K c ) (Nb 1-x-y-z Ta x Sb y V z O 3 + nM 1 M 2 O 3 wherein 0 ‰¤ a ‰¤ 0.2, 0 ‰¤ b ‰¤ 0.95, 0 ‰¤ c ‰¤ 0.95, 0 < (1 - a - b - c) ‰¤ 1, 0 ‰¤ x ‰¤ 0.5, 0 ‰¤ y ‰¤ 0.2, 0 ‰¤ z ‰¤ 0.2, 0 ‰¤ (y+z) ‰¤ 0.3, 0 ‰¤ n ‰¤ 0.2, wherein in the general formula (1), M 1 and M 2 are combinations of metal elements which satisfy predetermined conditions.

Owner:NGK INSULATORS LTD

Magnetoelectric composites

ActiveUS20130252030A1High ME compositesHigh sensitivityDevice material selectionLaminationResonanceCrystal orientation

Disclosed is a magnetoelectric (ME) composite including both a piezoelectric material and a magnetostrictive material, wherein a piezoelectric single crystal material having high piezoelectric properties is used as the piezoelectric material, and a metal magnetostrictive material having high magnetostrictive properties is used as the magnetostrictive material, thus achieving an ME composite having a layered structure via adhesion. When the ME layered composite is manufactured such that a <011> crystal orientation of the piezoelectric single crystal material is set to a thickness direction, high ME voltage coefficient, which is at least doubled, compared to a conventional <001> crystal orientation, can be obtained, and such an effect is further maximized in the resonance of the composite.

Owner:KOREA INST OF MATERIALS SCI

Non-contact type current/voltage converter

InactiveCN101369484ATransformersDevice material selectionTransimpedance amplifierElectromagnetic induction

The invention relates to a non-contact type current / voltage converter comprising a composite magnetoelectric material (1), a bias magnet (3), a shielding casing (4), a grounding electrode (5), an voltage input / output electrode (6) and belonging to electric device field, in which, the composite magnetoelectric material is of layer-shaped sandwich structure composed of magnetostrictive material-piezoelectric material-magnetostrictive material; the bias magnet using one block of the magnet for providing the bias magnetic field on one end or two blocks of magnets distributed left and right symmetrically for providing the even bias magnetic field; the shielding casing enwraps the composite magnetoelectric material; the shielding casing is connected with the total ground wire. The device realizes bilateral conversion among voltage-magnetic field strength-current by magnetoelectric, reverse magnetoelectric effects and Faraday electromagnetic induction effect. Compared with the traditional current / voltage converter based on electric circuit, the device has advantages of passive, bidirectional reversibility, inactive mode, fast response speed, safety, isolation, simple design, low cost and good compatibility with other devices.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Piezoelectric thin film element

ActiveUS20140049138A1Improve featuresExcellent electrical propertiesPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesOptoelectronicsPiezoelectric thin films

A piezoelectric thin film element that includes a substrate, a lower electrode on the substrate, a piezoelectric film on the lower electrode, and an upper electrode on the piezoelectric film. The piezoelectric film is a potassium sodium niobate film represented, as its main constituent, by the general formula (1−n)(K1-xNax)NbyO3-nM1M2O3 in which M1 is any one of Ca, Sr, and Ba, and M2 is Zr, and x, y, and n respectively are within the ranges of: 0.25≦x≦1.00; 0.85≦y≦1.10; and 0.01≦n≦0.10. Alternatively, M2 is any one of Sn and Hf, and x, y, and n respectively are within the ranges of: 0.25≦x≦1.00; 0.90≦y≦1.05; and 0.01≦n≦0.10.

Owner:MURATA MFG CO LTD

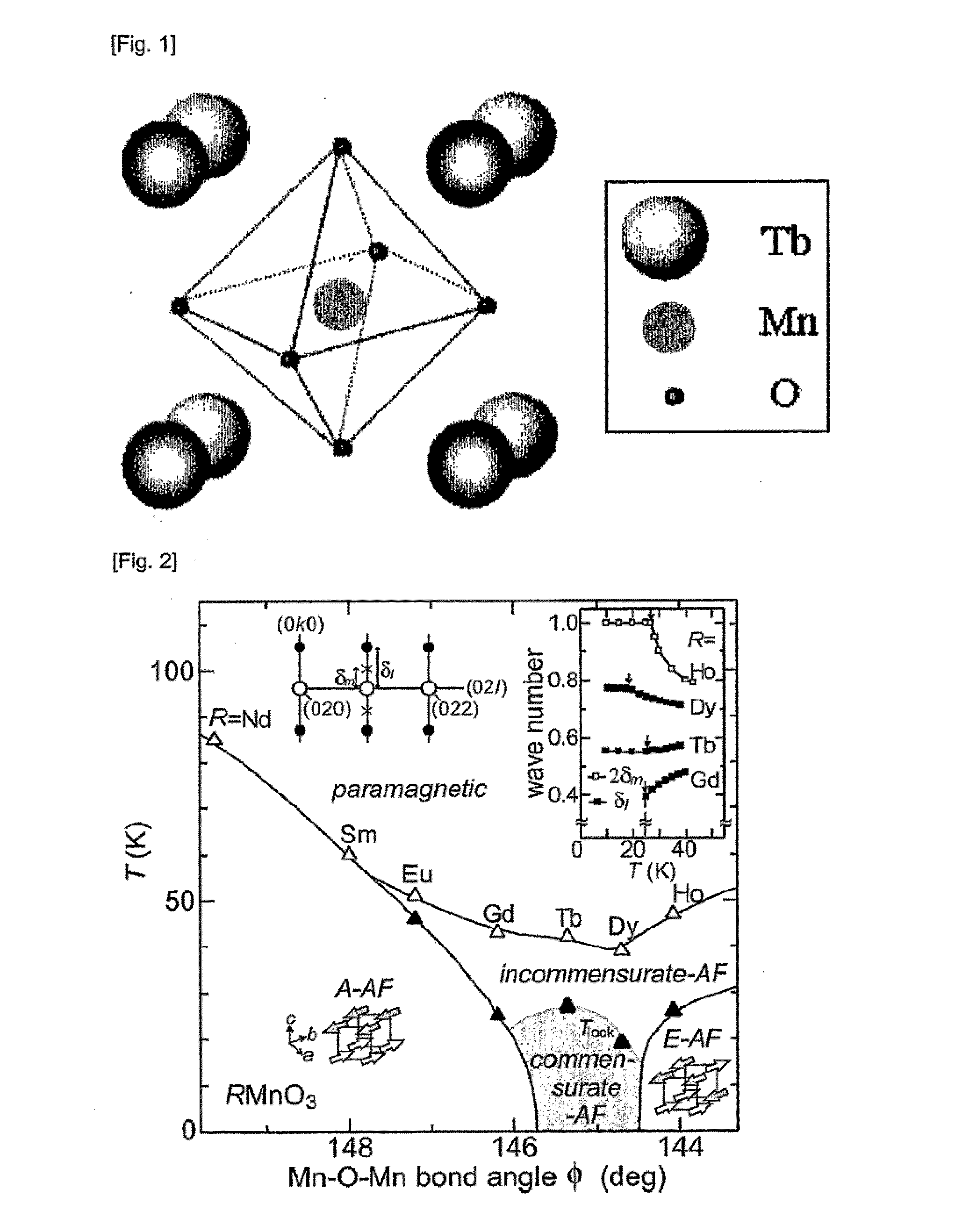

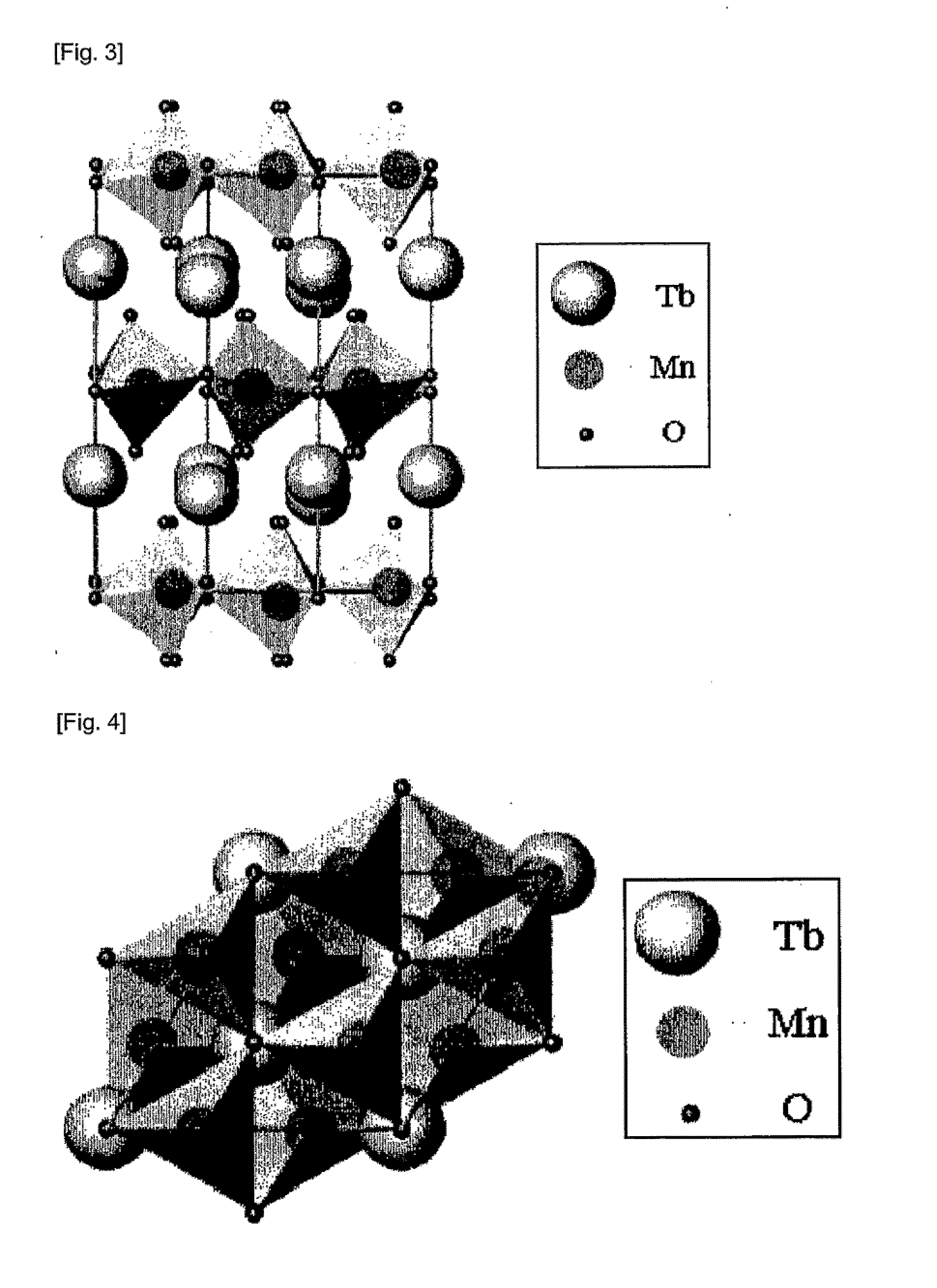

Multiferroic layer, structure including the layer, and methods of forming the layer and the structure

ActiveUS20090246543A1Improve multiferroic performanceSolid-state devicesSemiconductor/solid-state device manufacturingPolymer scienceLanthanide

The present invention relates to forming the material represented by the following formula (1) into a layer having hexagonal crystalline structure, which is different from the orthorhombic crystalline structure of the material in bulk phase, so that the material can be used more effectively in various fields requiring multiferroic properties by obtaining multiferroic properties enhanced than the conventional multiferroic materials. RMnO3, (R=Lanthanide) . . . (1)

Owner:SEOUL NAT UNIV R&DB FOUND

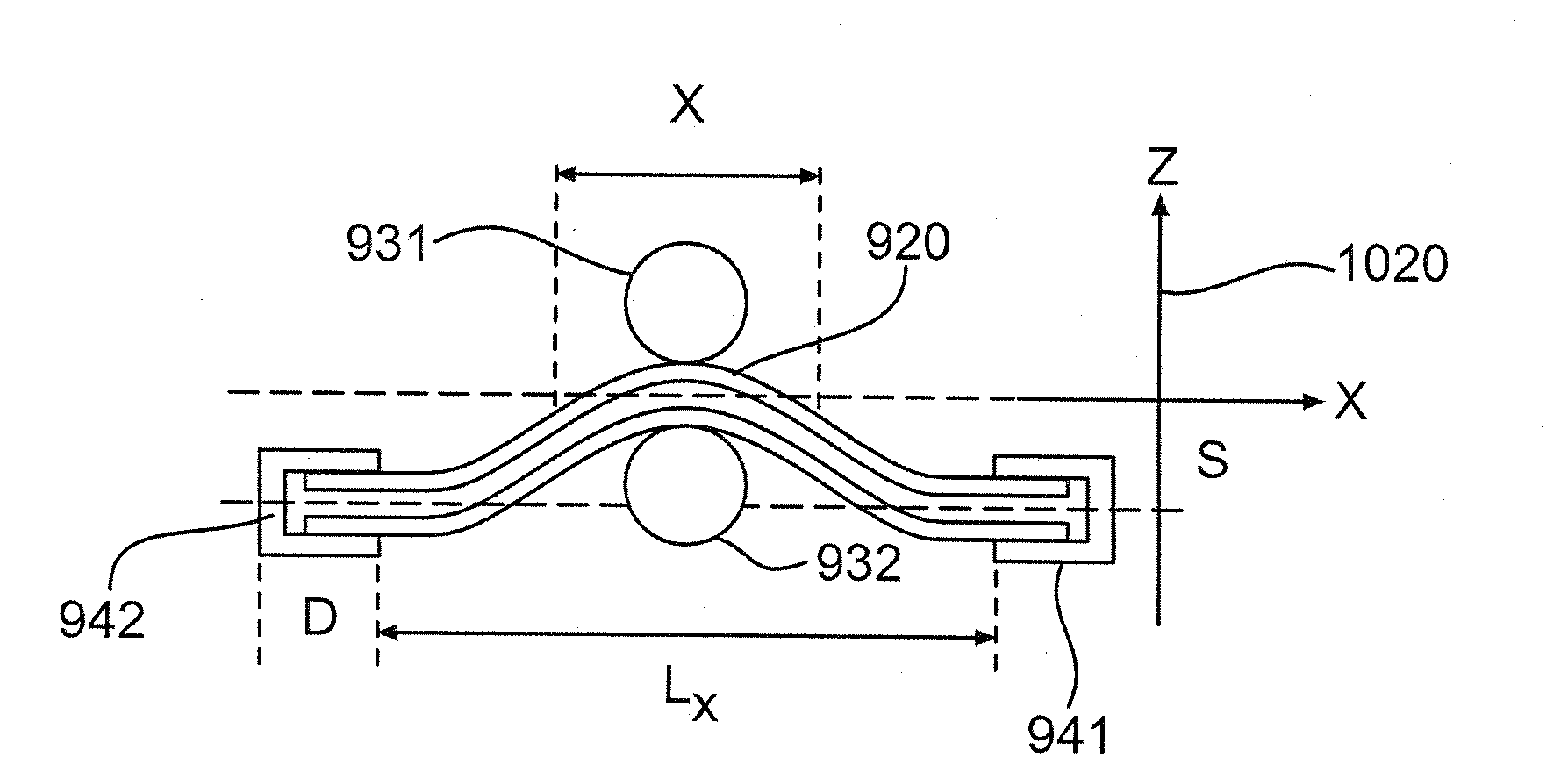

Devices and methods for energy conversion basedon the giant flexoelectric effect in non-calamitic liquid crystals

InactiveUS20080303376A1Light weightLow costPiezoelectric/electrostrictive device manufacture/assemblyWave amplification devicesTransducerMechanical energy

Devices and methods for energy conversion based on the giant flexoelectric effect in non-calamitic liquid crystals. By preparing a substance comprising at least one type of non-calamitic liquid crystal molecules and stabilizing the substance to form a mechanically flexible material, flexible conductive electrodes may be applied to the material to create an electro-mechanical energy conversion device which relies on the giant flexoelectric effect to produce electrical and / or mechanical energy that is usable in such applications as, for example, power sources, energy dissipation, sensors / transducers, and actuators. The ability to directly and accurately measure the giant flexoelectric effect for different types of non-calamitic liquid crystal molecules is important for identifying molecules that may be effective for particular applications.

Owner:KENT STATE UNIV

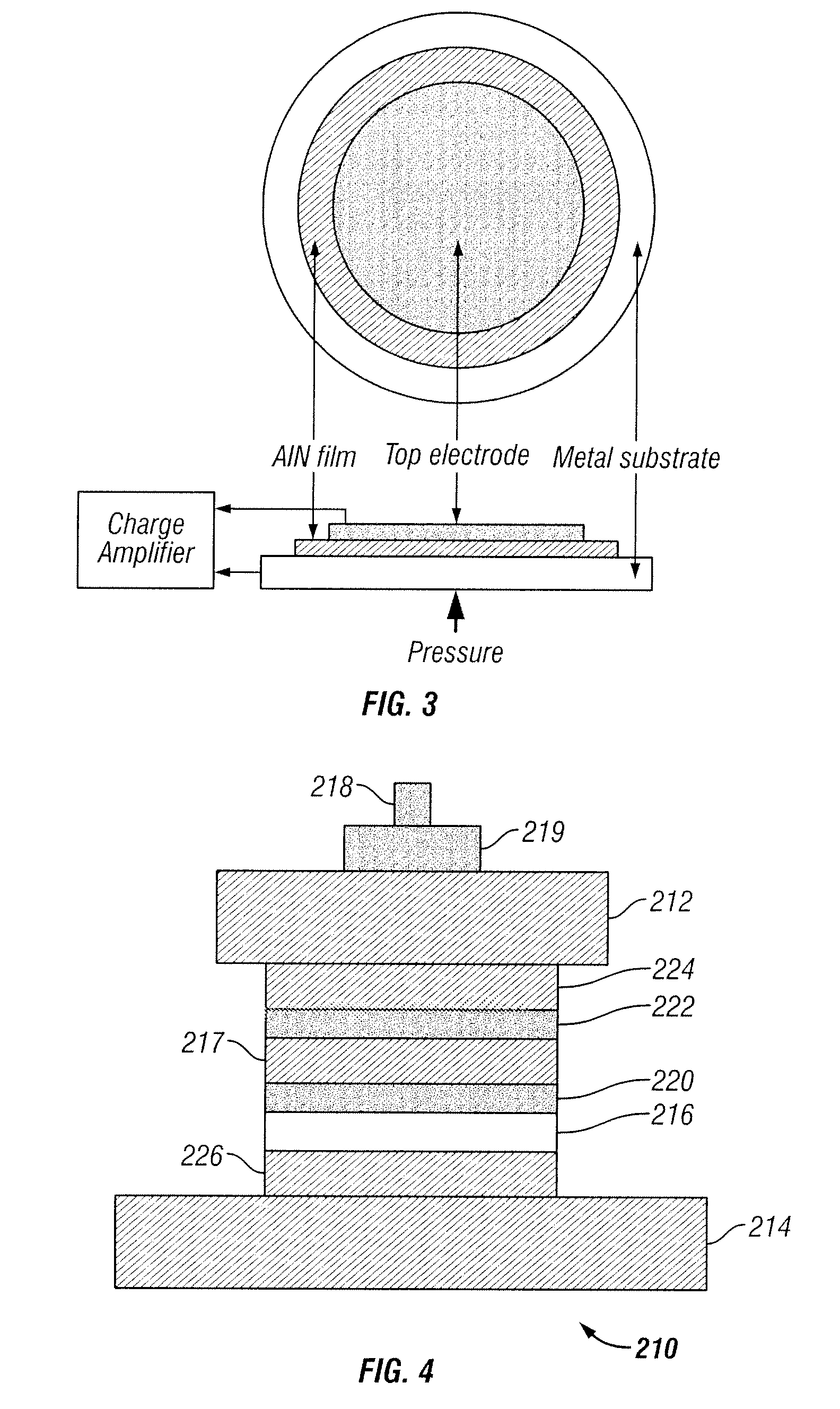

High temperature sustainable piezoelectric sensors using etched or micromachined piezoelectric films

InactiveUS20080129150A1Extended temperature rangeAcceleration measurement using interia forcesPiezoelectric/electrostriction/magnetostriction machinesSensor arrayHigh resolution ultrasound

The present invention is directed to sensors that use wide band gap piezoelectric films such as aluminum nitride and zinc oxide. The films can be deposited with chemical and physical methods and etched or micro machined into miniature and micro sensing elements. Various piezoelectric sensing structures such as compression mode and cantilever-type accelerometers, diaphragm-type pressure sensors, and micro sensor arrays can be manufactured with the sensing elements. They can be used in the measurements of vibration, shock, dynamic pressure, stress, and high resolution ultrasound non-destructive test at high temperature up to 800-1000° C.

Owner:ENDEVCO

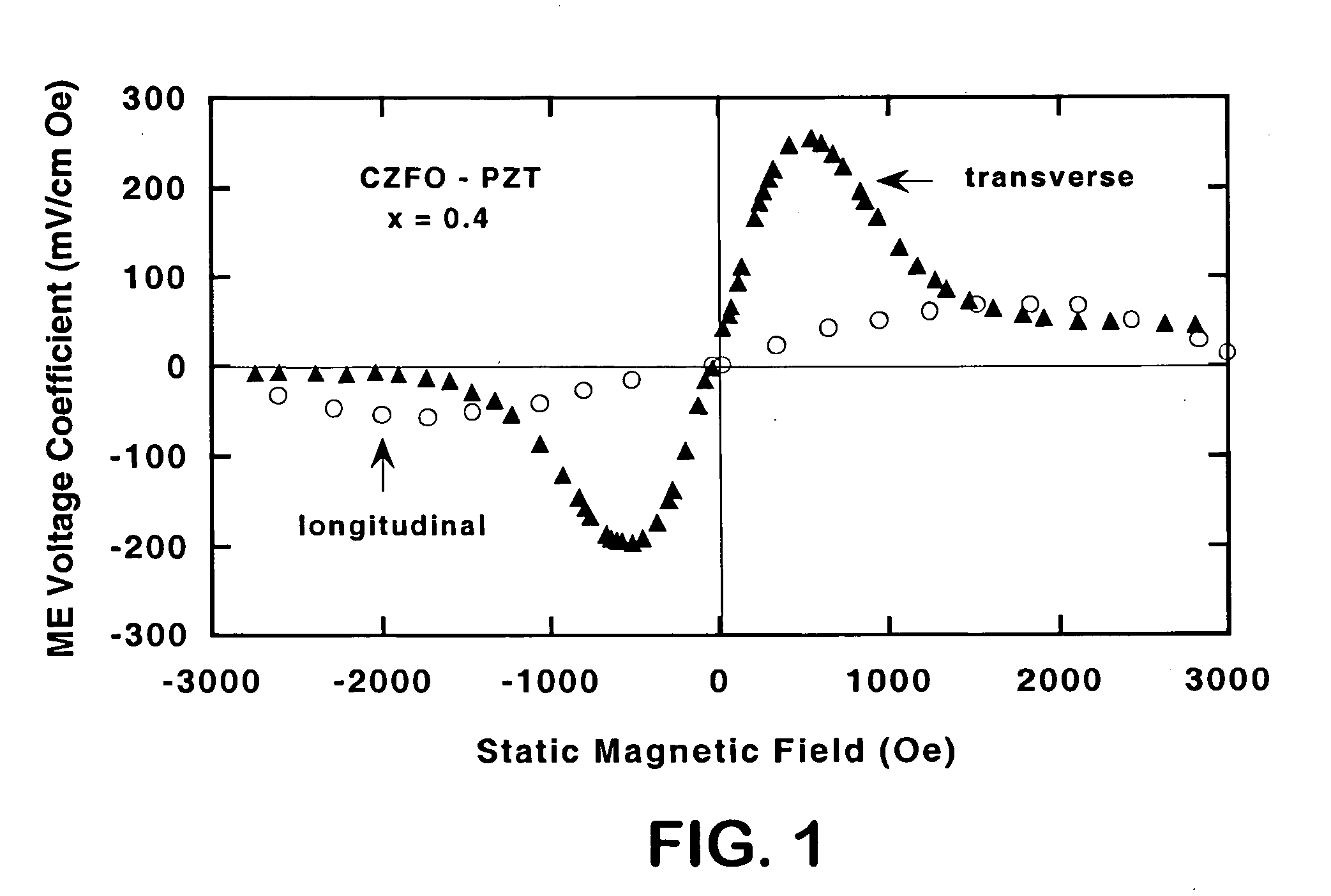

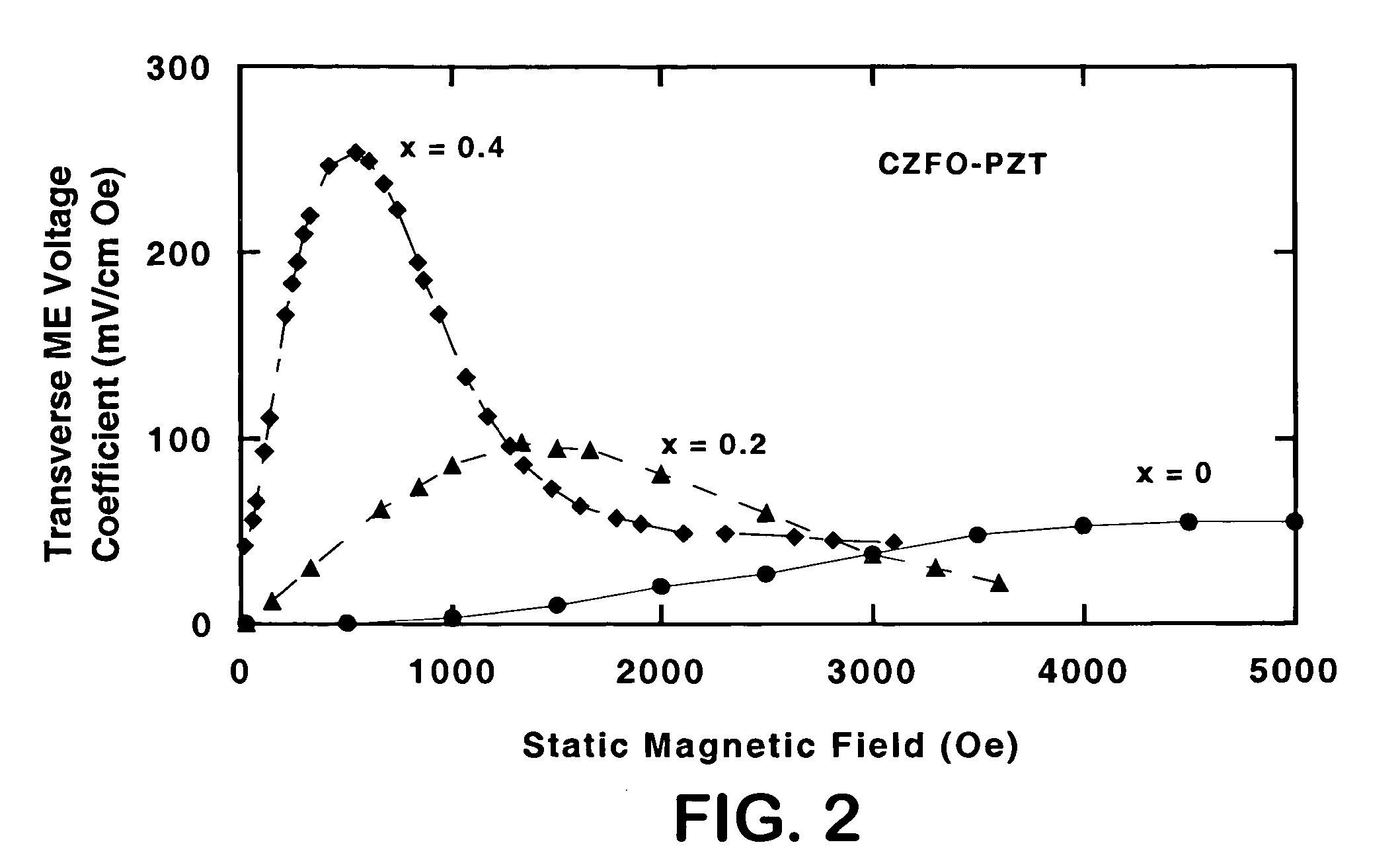

Magnetoelectric multilayer composites for field conversion

InactiveUS20050104474A1Large ME effectMaximum efficiencyPiezoelectric/electrostriction/magnetostriction machinesDevice material selectionMagnetic storageCobalt

Magnetoelectric multilayer composites comprising alternate layers of a bimetal ferrite wherein one of the metals is zinc and a piezoelectric material for facilitating conversion of an electric field into a magnetic field or vice versa. The preferred composites include cobalt, nickel, or lithium zinc ferrite and PZT films which are arranged in a bilayer or in alternating layers, laminated, and sintered at high temperature. The composites are useful in sensors for detection of magnetic fields (10); sensors for measuring rotation speed, linear speed, or acceleration; read-heads in storage devices by converting bits in magnetic storage devices to electrical signals; magnetoelectric media for storing information; and high frequency devices for electric field control of magnetic devices or magnetic field control of electric devices.

Owner:OAKLAND UNIVESITY

Fe-Ga base magnetic striction wire and preparation method thereof

InactiveCN101418415AExcellent process repeatabilityExcellent process stabilityDevice material selectionFurnace typesLinearityNano crystalline

The invention relates to a Fe-Ga-based magnetostrictive wire and a method for preparing the same. The alloy composition (atom fraction) used in the method is Fe1-x-y-zGaxAlyMz, wherein M is selected from one or more than one of Co, B, Cr, V, Nb, Zr, Be, Y, Ti and the like; x is equal to between 0.10 and 0.30; y is equal to between 0.01 and 0.15; z is equal to between 0.000 and 0.1, and the balance is Fe. The invention makes use of a rotating water spinning method to prepare a Fe-Ga-based magnetostrictive microcrystalline or amorphous wire; and the method has the advantages of simple and convenient process, high wire-forming rate, good process repeatability and stability and the like. The wire prepared by the method has good roundness and linearity, and has higher magnetostrictive coefficient, good corrosion resistance and good mechanical property at the same time. The diameter of the prepared Fe-Ga-based magnetostrictive microcrystalline or amorphous wire is between 0.01 and 0.5 millimeter, and the amorphous wire can be made into an alloy wire with a nano-crystalline structure after heat treatment. Under a low magnetic field condition, the magnetostrictive property of the Fe-Ga-based magnetostrictive wire can reach 160 * 10<-6>.

Owner:UNIV OF SCI & TECH BEIJING

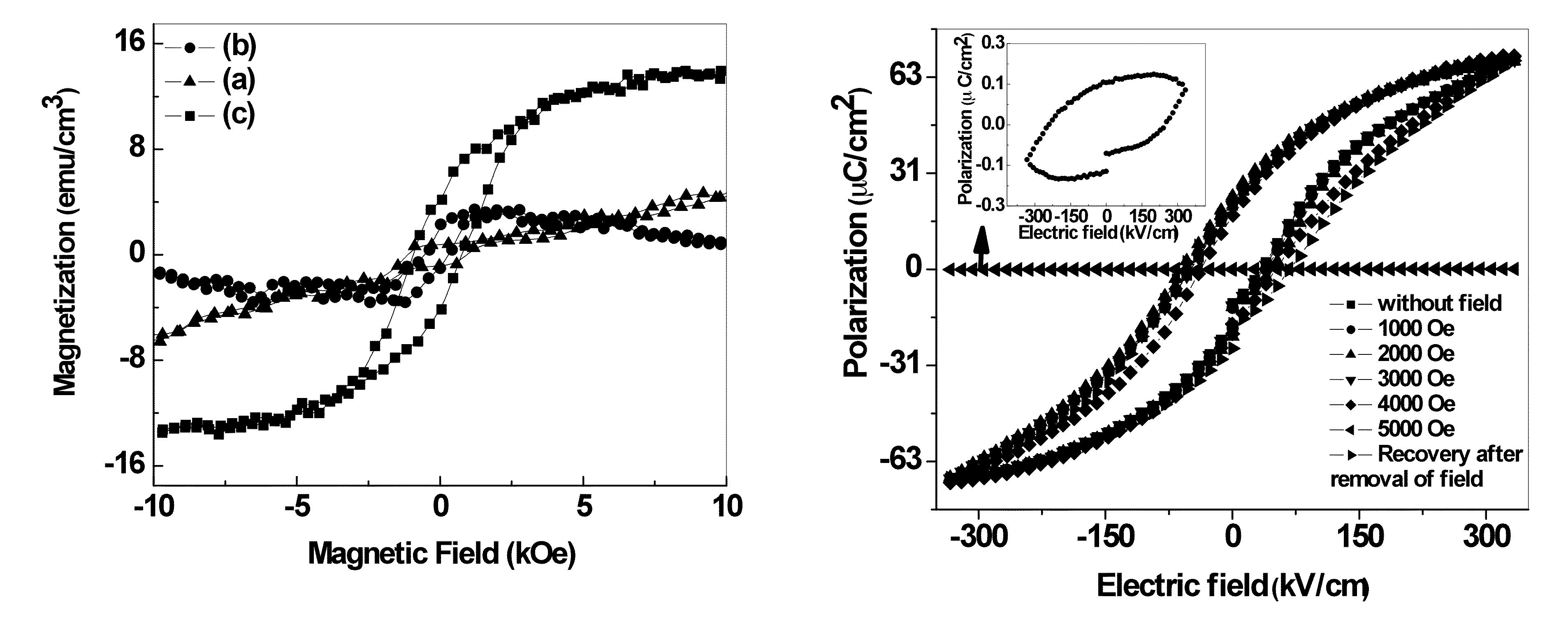

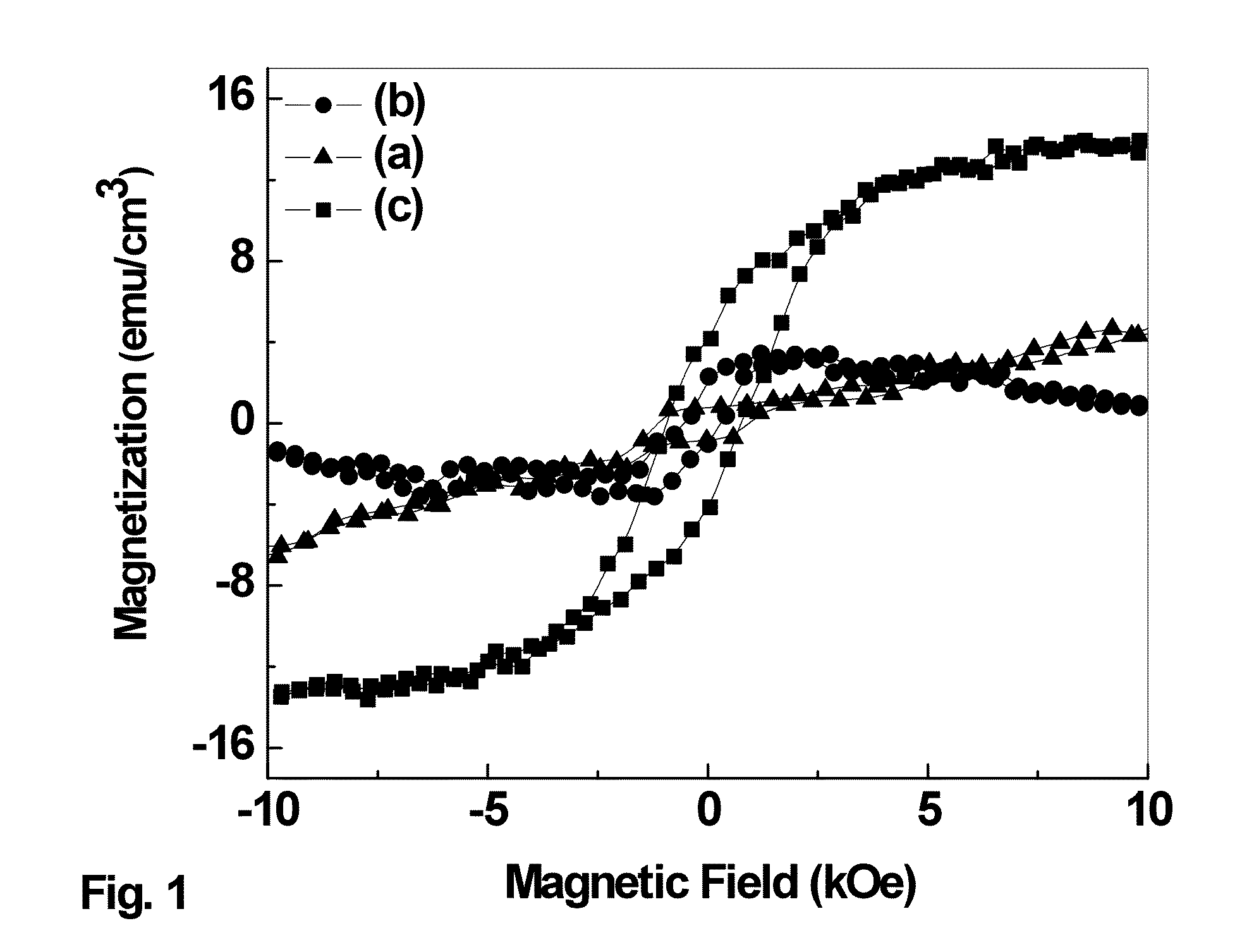

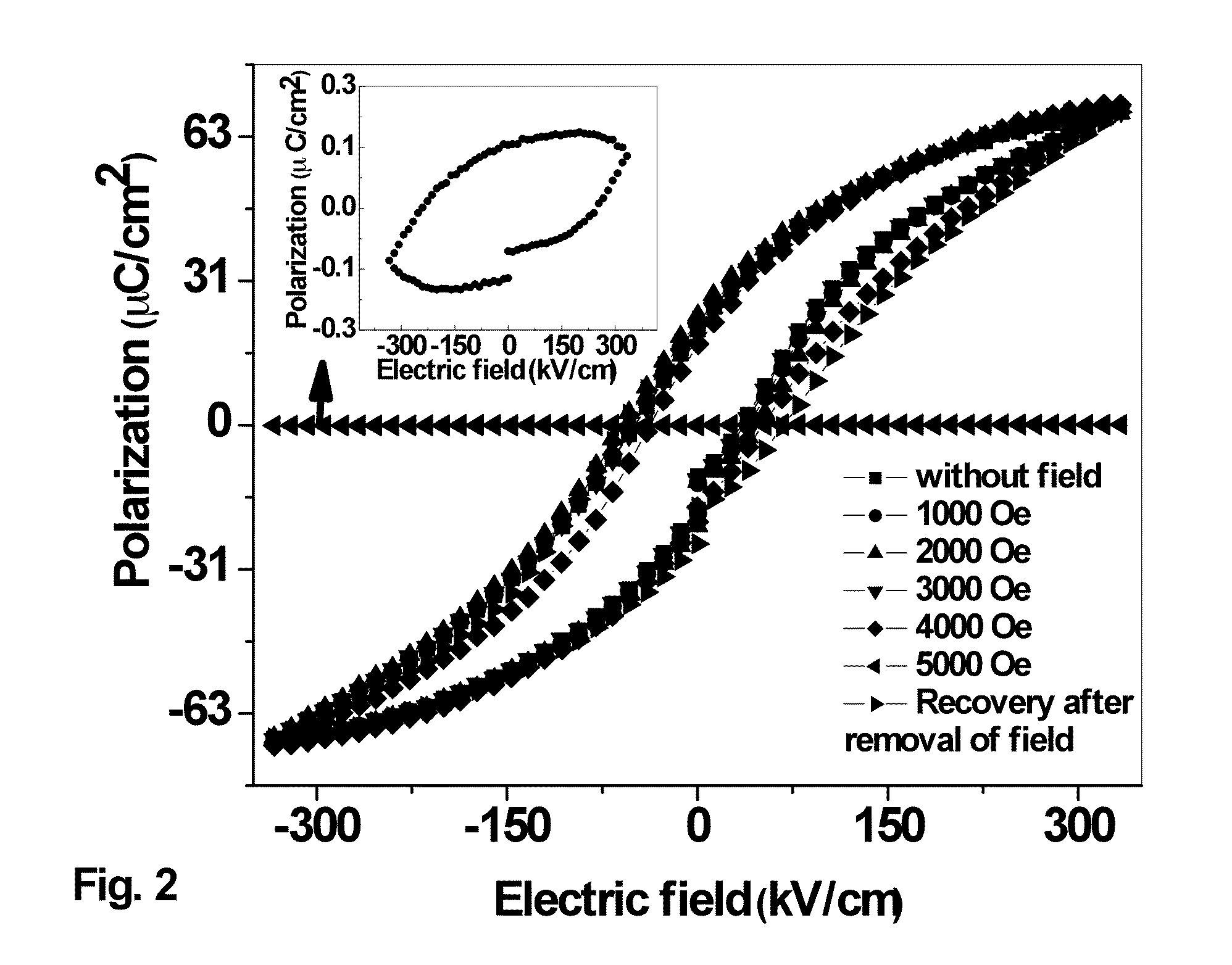

Room-temperature magnetoelectric multiferroic thin films and applications thereof

ActiveUS8803264B1Well behaved and saturated C(V) hysteresisReduce leakageTransistorDevice material selectionDielectric lossRoom temperature

The invention provides a novel class of room-temperature, single-phase, magnetoelectric multiferroic (PbFe0.67W0.33O3)x (PbZr0.53Ti0.47O3)1-x (0.2≦x≦0.8) (PFWx−PZT1-x) thin films that exhibit high dielectric constants, high polarization, weak saturation magnetization, broad dielectric temperature peak, high-frequency dispersion, low dielectric loss and low leakage current. These properties render them to be suitable candidates for room-temperature multiferroic devices. Methods of preparation are also provided.

Owner:UNIVERSITY OF PUERTO RICO

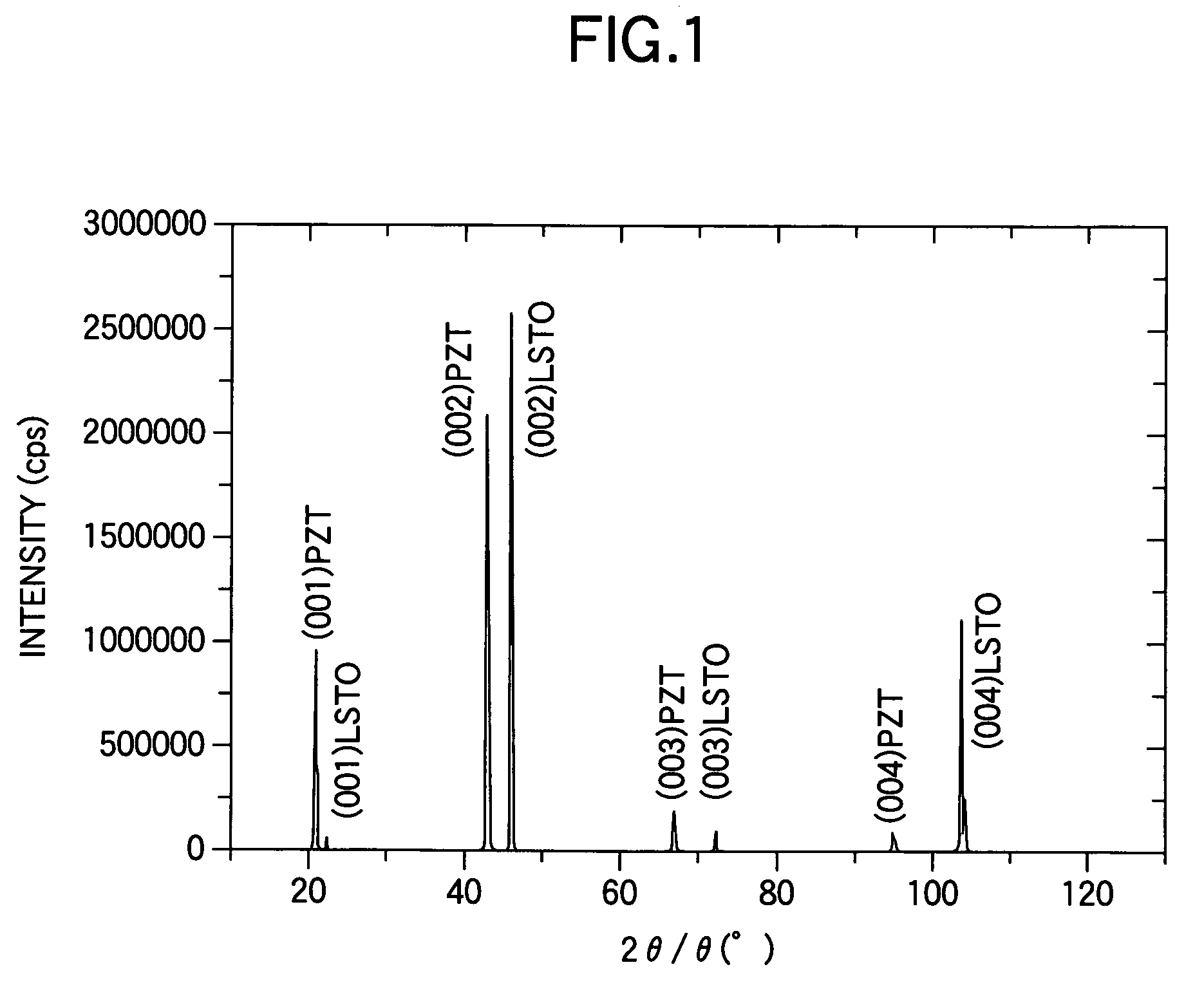

Ferroelectric thin film element, piezoelectric actuator and liquid discharge head

InactiveUS7215067B2High spontaneous polarizationImprove featuresPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesFerroelectric thin filmsPiezoelectric actuators

A ferroelectric thin film element comprises a substrate and an epitaxial ferroelectric thin film provided on the substrate. The thin film satisfies z / z0>1.003 and 0.997≦x / x0≦1.003, where a crystal face of said thin film parallel to a crystal face of a surface of the substrate is taken as a Z crystal face, a face spacing of the Z crystal face is taken as z, a face spacing of the Z crystal face of a material constituting the thin film in a bulk state is taken as z0, a crystal face of the thin film perpendicular to the Z crystal face is taken as an X crystal face, a face spacing of the X crystal face is taken as x and a face spacing of the X crystal face of the material constituting the thin film in a bulk state is taken as x0.

Owner:CANON KK

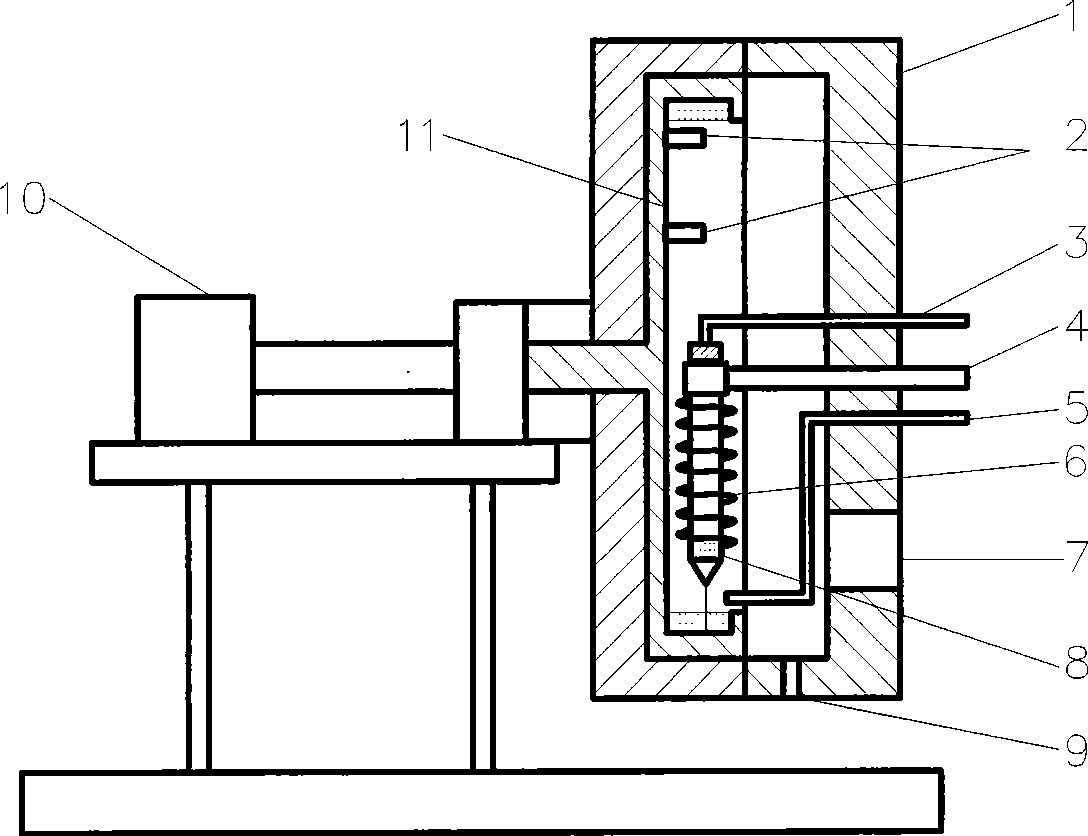

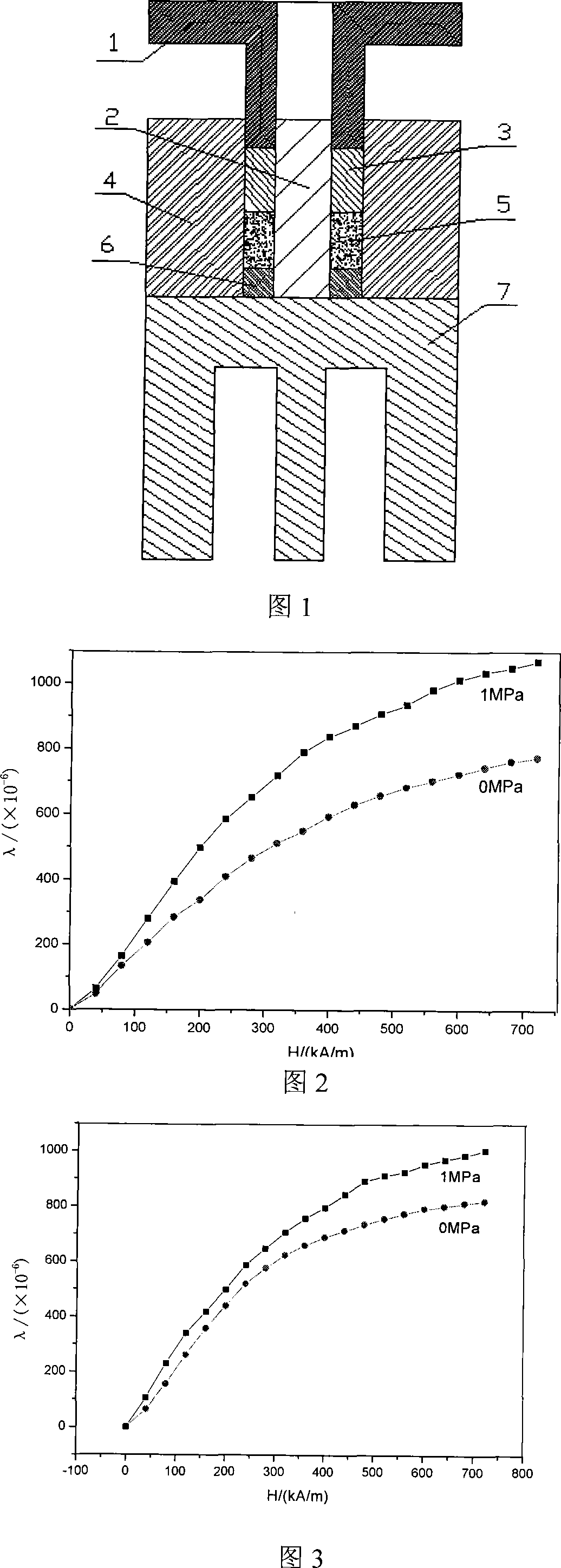

High-performance ring shaped agglutinate rare earth ultra-magnetostriction material, manufacturing method and device thereof

The invention discloses ring bonding rare earth giant magnetostriction materials and a preparation method and a device for the ring bonding rare earth giant magnetostriction materials; wherein, an alloy ingot of TbxDy1-xFe2-y is placed into anhydrous alcohol protective media to be mechanically crushed for milling, and after the anhydrous alcohol is extracted by low boiling organic solvents and the powders go through the natural drying sieving, epoxy resin, curing agents and alloy powders are uniformly mixed according to certain mass ratio; the materials are molded by compressing of a ring cavity molding die of the invention, and are prepared by solidification and knockout after standing the die for 24 hours at room temperature, or 1 to 4 hours at the temperature of 80 to 120 DEG C. The invention has the advantages of low cost, simple technique, easy operation and especially being capable of manufacturing the present ring bonding rare earth giant magnetostriction materials which are obtained by using special methods and devices and have similar performance.

Owner:GUILIN UNIV OF ELECTRONIC TECH

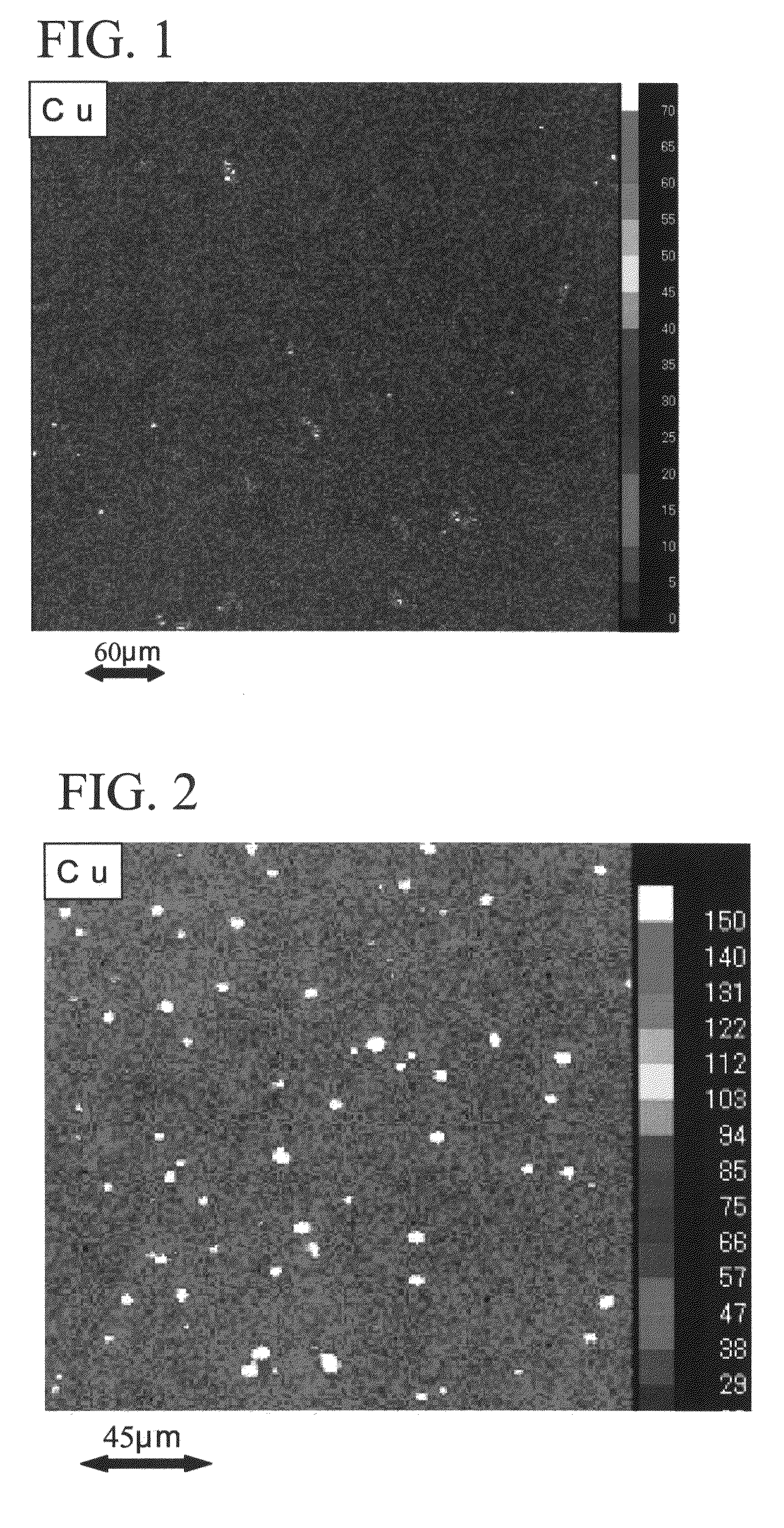

Piezoelectric ceramic composition and laminated piezoelectric element

InactiveUS20080129155A1Sufficient displacementPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesComposite oxideCarbonate

A piezoelectric ceramic composition includes: a composite oxide, as a main component thereof, represented by the composition formula,Pba[(Zn1 / 3Nb2 / 3)xTiyZrz]O3,wherein a, x, y and z satisfy the followingrelations, 0.96≦a≦1.03, 0.005≦x≦0.047,0.42≦y≦0.53, 0.45≦z≦0.56, and x+y+z=1, and the following additives in the indicated percentages by mass in relation to the main component,Cu as a first additive, in a content α, in terms of Cu2O, falling within a range 0<α≦0.5%;at least one of Li, Co, Ni, Ga and Mg, as a second additive, in a content β, in terms of carbonate for Li, falling within a range 0<β≦0.1%, in a content δ1, in terms of oxide for Co, Ni and Ga, falling within a range 0<δ1≦0.2%, and in a content δ2, in terms of carbonate for Mg, falling within a range 0<δ2≦0.2%;and at least one of Ta, Nb, W and Sb, as a third additive, in a content γ, in terms of oxide, falling within a range 0<γ≦0.6%.

Owner:TDK CORPARATION

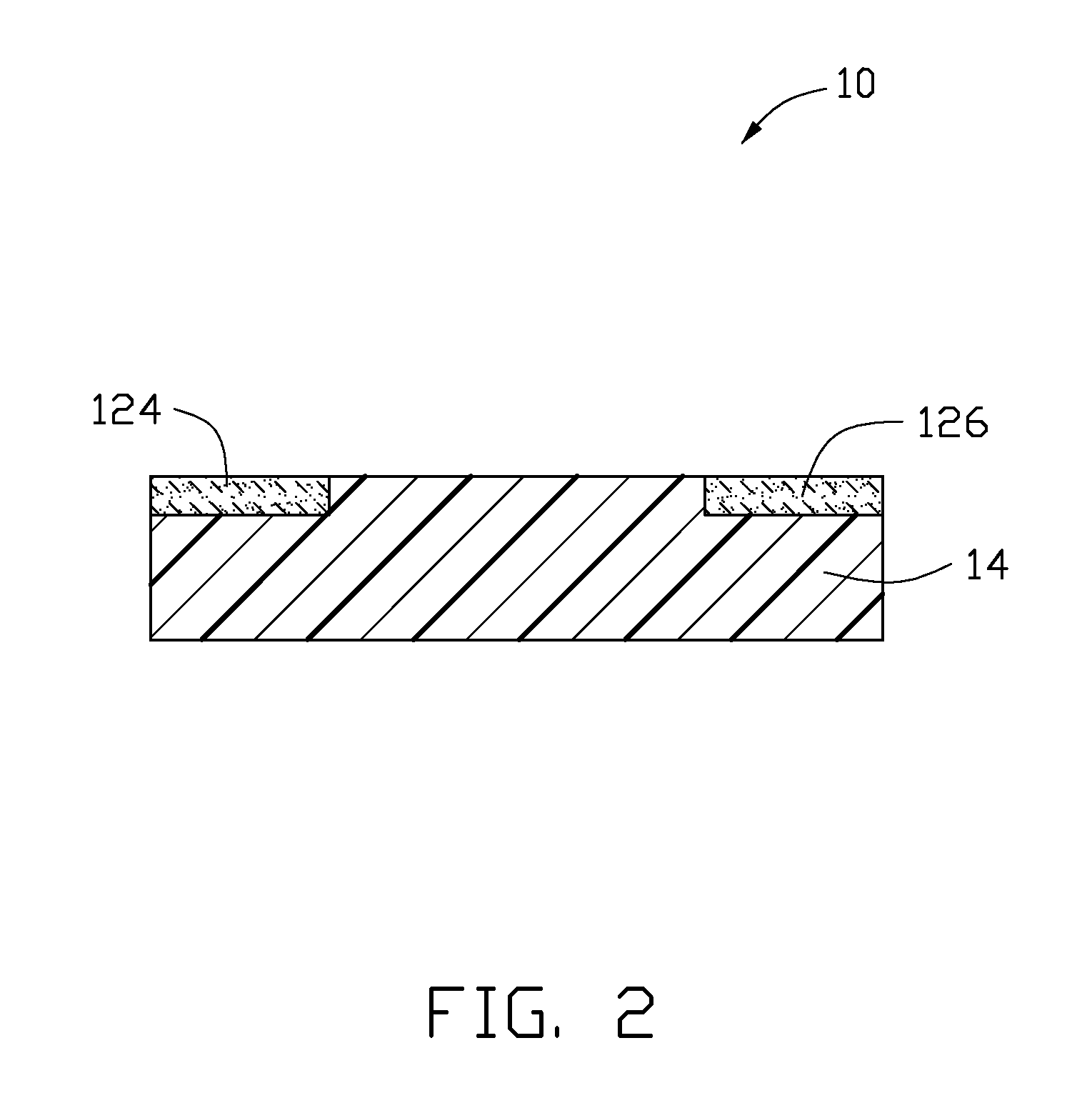

Piezoelectric actuator, liquid jetting head and liquid jetting device using the same

InactiveUS6943485B2Improve featuresAdhesive layerInking apparatusPiezoelectric/electrostriction/magnetostriction machinesLiquid jetDielectric

It is an object of the present invention to provide a piezoelectric actuator which uses strontium ruthenate as the material of the bottom electrode, and which uses PMN-PT as the material of the piezoelectric layer. This piezoelectric actuator comprises a base layer (31, 20) of SiO2 or Si ((100) orientation or (110) orientation), a buffer layer (41) constituted by strontium ruthenate (SRO), and a piezoelectric layer (44) constituted by a relaxor dielectric (PMN-PT) with a rhombohedral or quasi-cubic crystal structure oriented in the (001) direction at room temperature.

Owner:SEIKO EPSON CORP

Electrostrictive structure incorporating carbon nanotubes and electrostrictive actuator using the same

ActiveUS8421315B2Piezoelectric/electrostriction/magnetostriction machinesDevice material selectionCarbon nanotubeActuator

An electrostrictive structure includes a flexible polymer matrix and a carbon nanotube film structure at least partly embedded into the flexible polymer matrix. The carbon nanotube film structure includes a number of carbon nanotubes combined by van der Waals attractive force therebetween. The carbon nanotube film structure extends in a curve in the flexible polymer matrix.

Owner:TSINGHUA UNIV +1

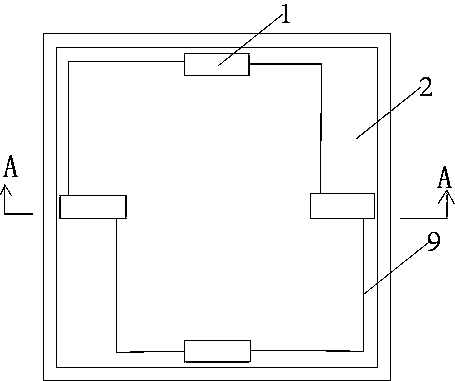

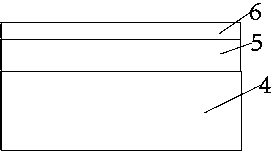

Wheatstone-bridge-based pressure sensor and manufacturing method thereof

ActiveCN107732001AGood high temperature characteristicsIncrease electron concentrationPiezoelectric/electrostrictive device manufacture/assemblyDevice material selectionGallium nitrideForce sensor

The invention discloses a Wheatstone-bridge-based pressure sensor and a manufacturing method thereof, which relate to the technical field of semiconductor pressure sensors. The pressure sensor comprises a bonding wafer, a bonding medium, a substrate, a buffer layer, a barrier layer, metal lead wires, a barrier layer, an empty cavity and ohmic electrodes, wherein the material of the buffer layer isgallium nitride, and the material of the barrier layers is In<x>Al<y>Ga<1 x y>N. The pressure sensor ensures the stability of resistance, is simple in manufacturing method, improves the manufacturingprecision of products, and can be used in a high-temperature environment.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

Bending resonance type magnetoelectric composite material and its manufacturing method

InactiveCN1794480AMiniaturizationLow bending resonance frequencyMagnetostrictive device manufacture/assemblyDevice material selectionResonanceMiniaturization

An electromagnetic compound material is formed by laminating a rectangular plate of magnetostrictive material and rectangular plates of piezoelectric materials in a same shape having a pair of plane electrodes and being polarized along the thickness direction, in which, the electromagnetic compound rectangular plate is applied with an AC magnetic field and a DC bias magnetic field along the length direction, when the frequency of the AC magnetic field equals to a stage curved resonance frequency of the electromagnetic complex material rectangular plate, the plate will generate bend resonance and the piezoelectric layer will output voltages to realize the transformation from magnetic energy to electric energy, when the applied DC bias magnetic field strength is suitable, the voltage output by the piezoelectric layer reaches to the maximum and the energy conversion efficiency is the maximum.

Owner:NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com