Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Adhesive layer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

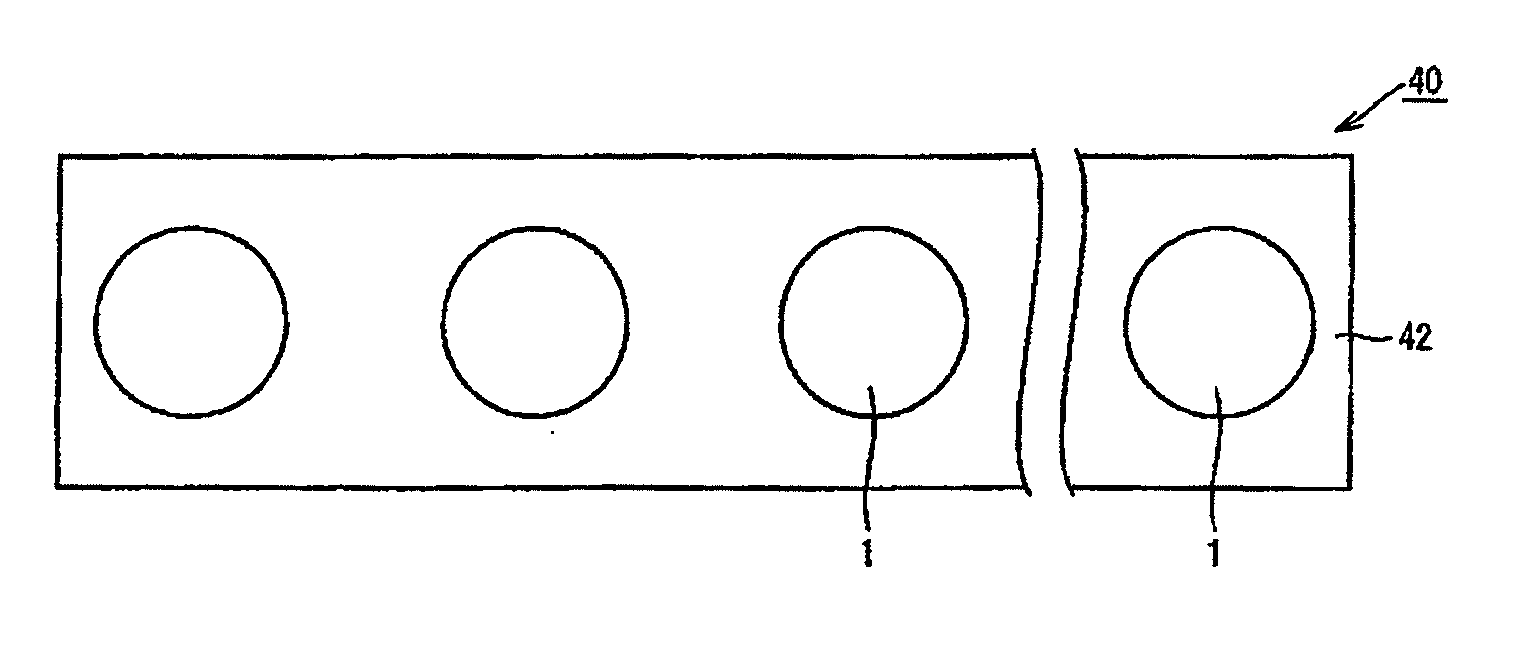

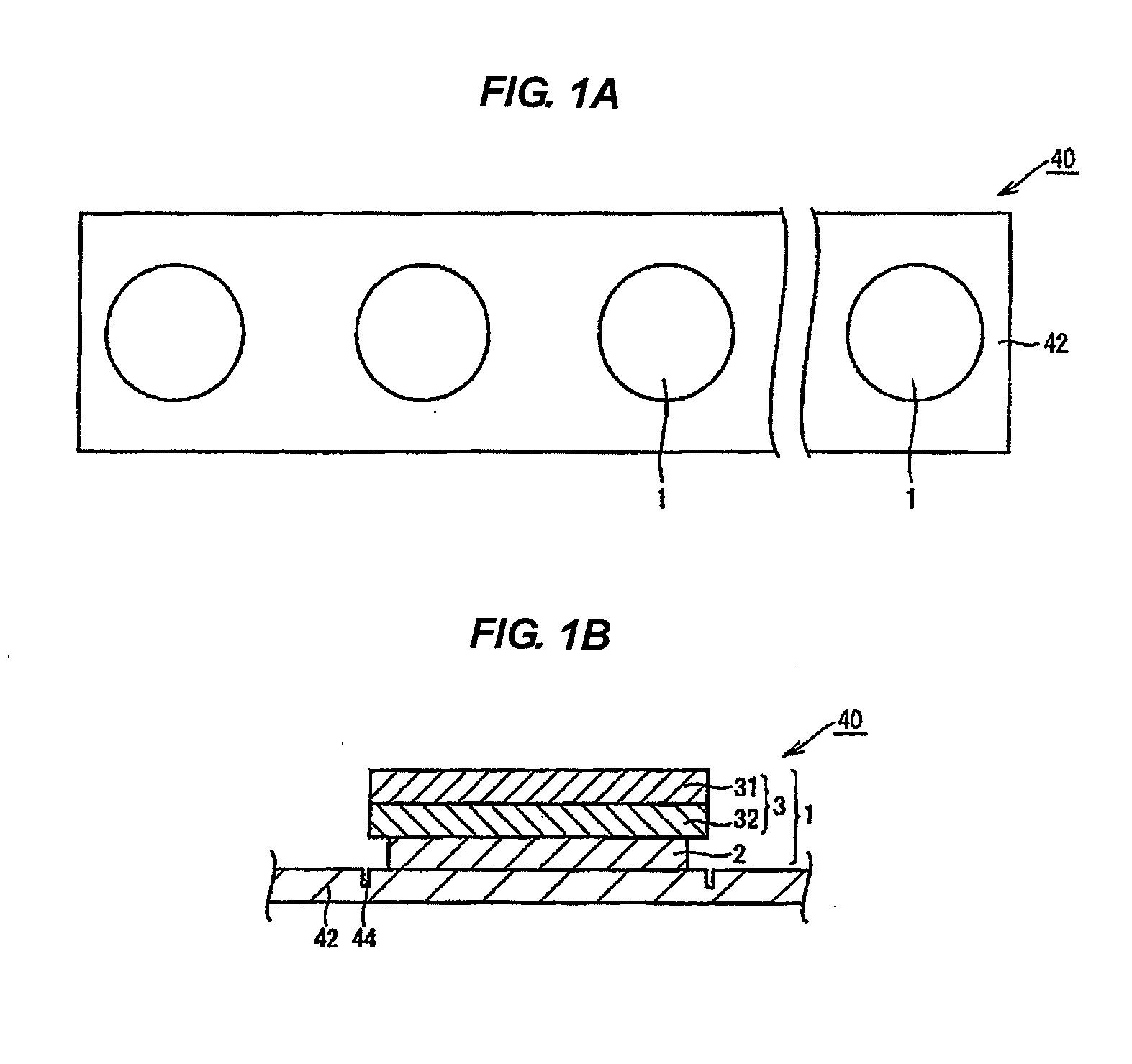

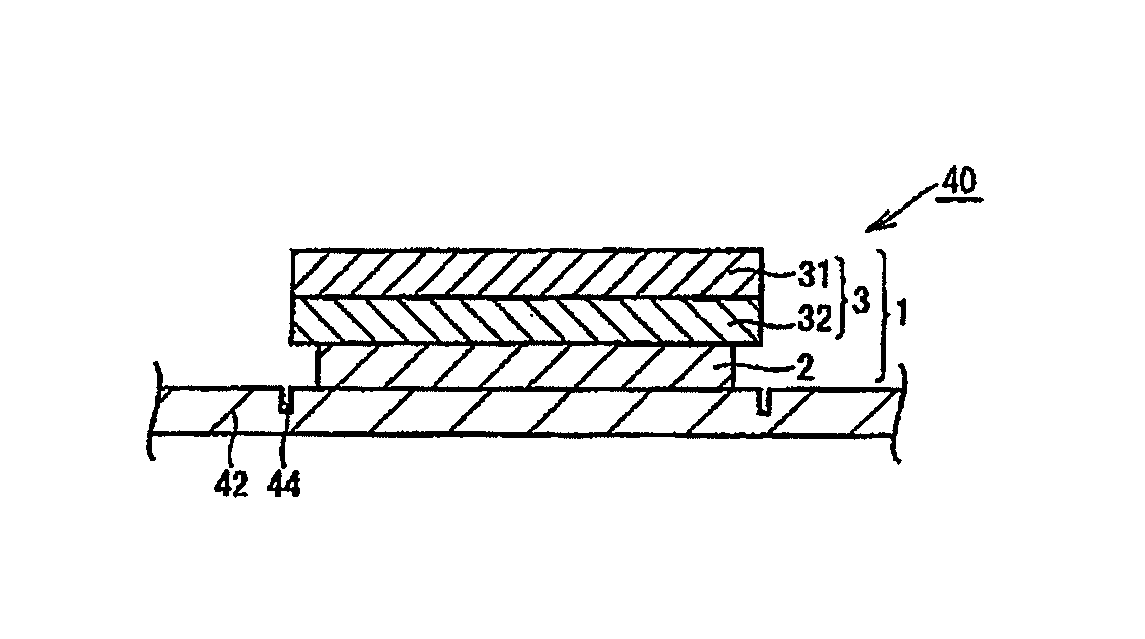

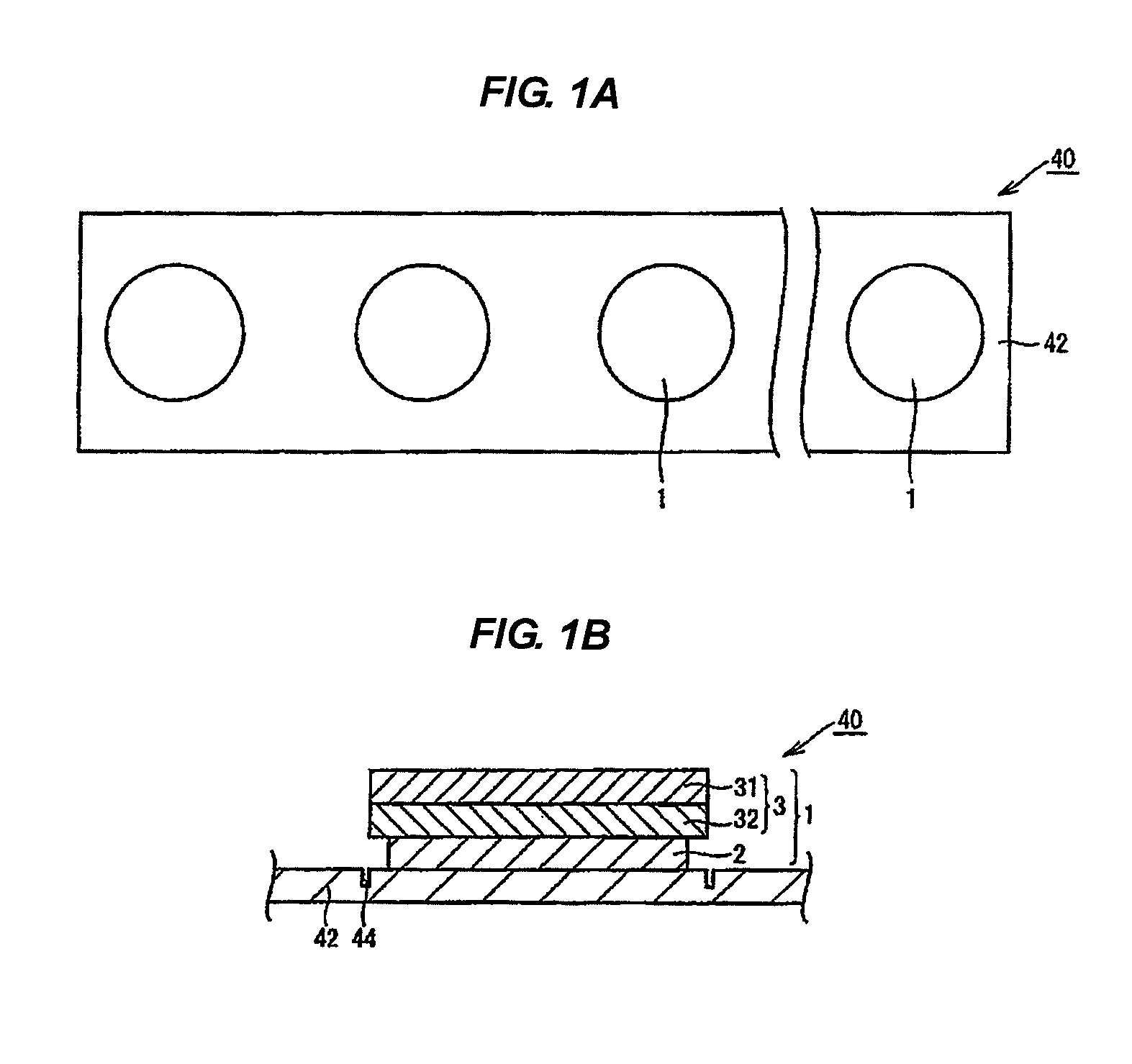

Multi-layer wiring board and method of manufacturing the same

InactiveUS20090242245A1High bonding strengthEasy to processFinal product manufactureSemiconductor/solid-state device detailsResistMetallic materials

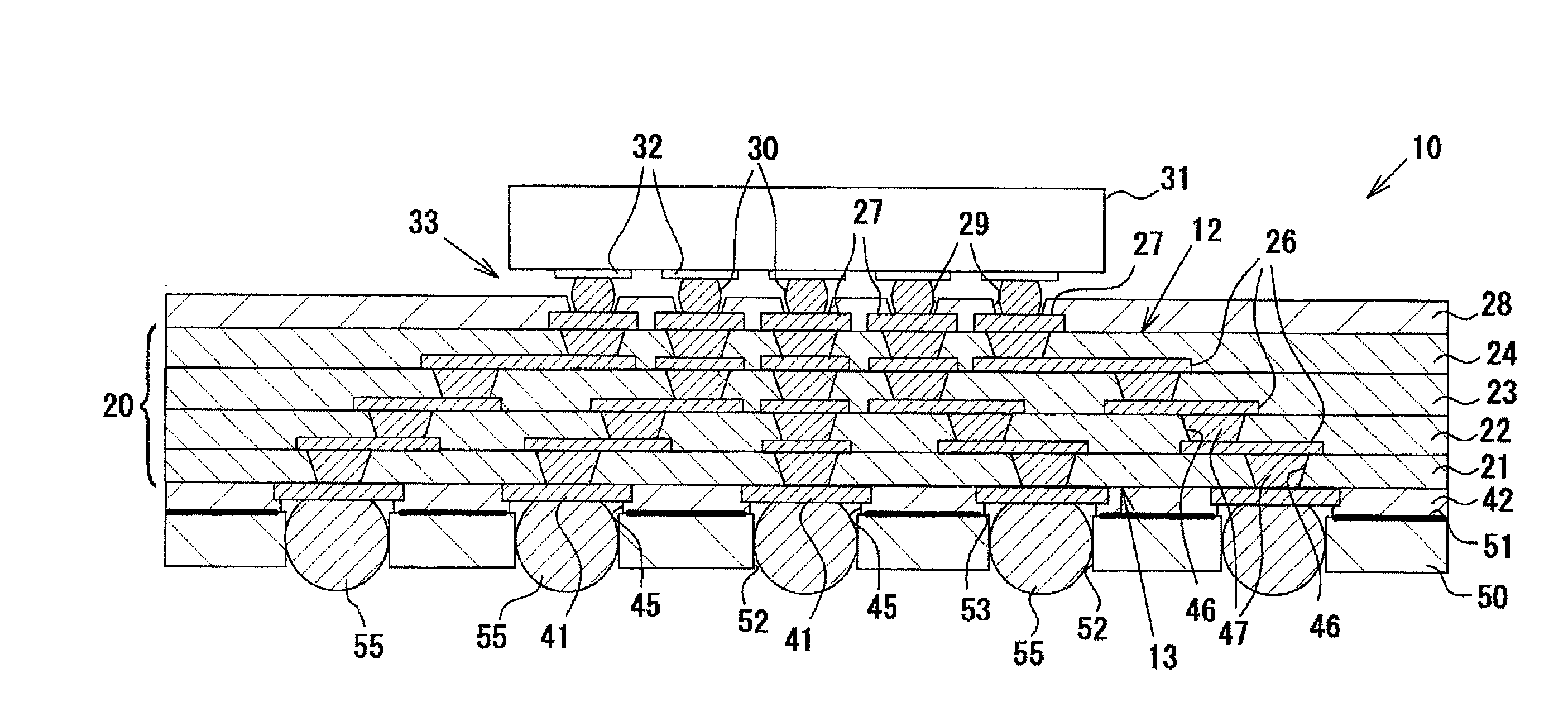

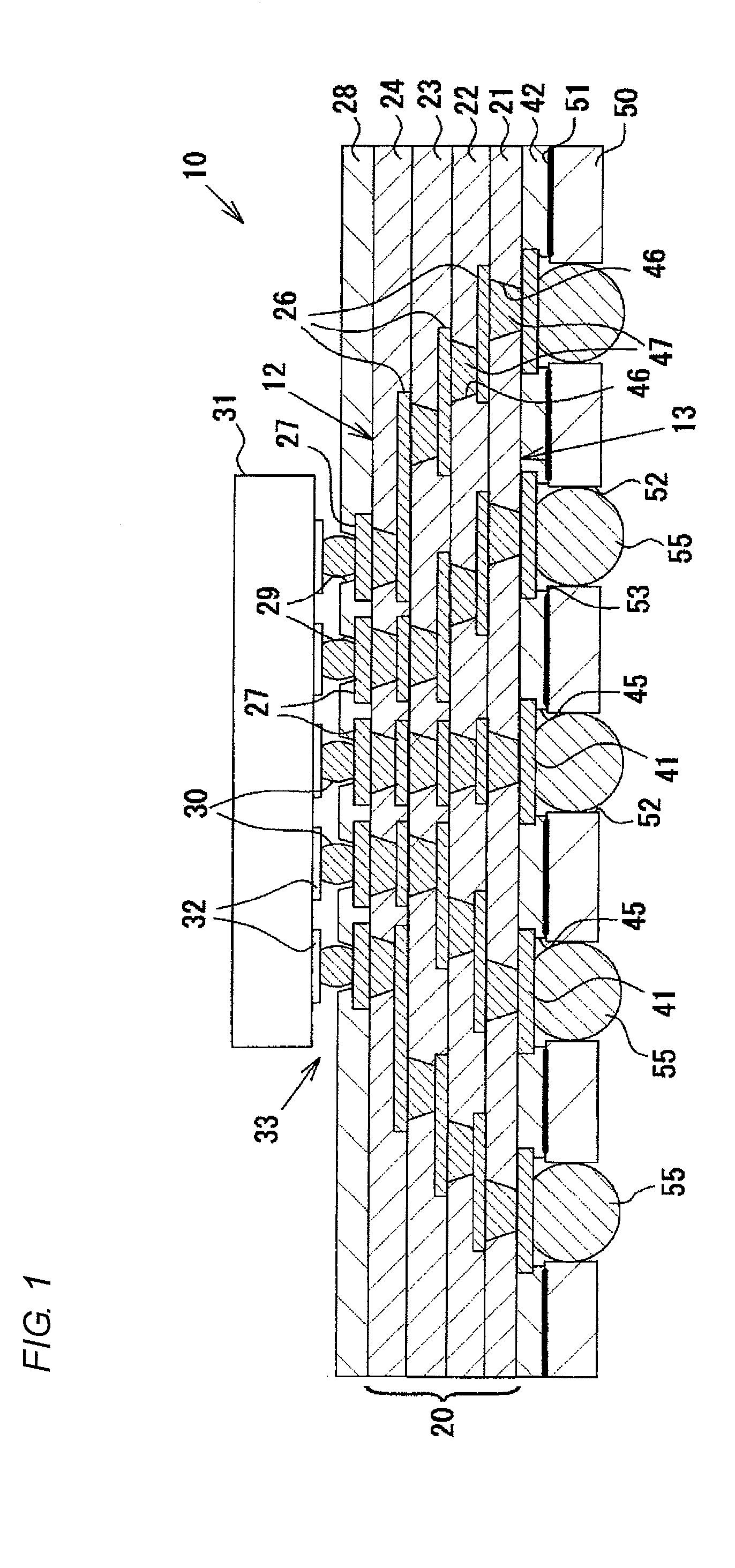

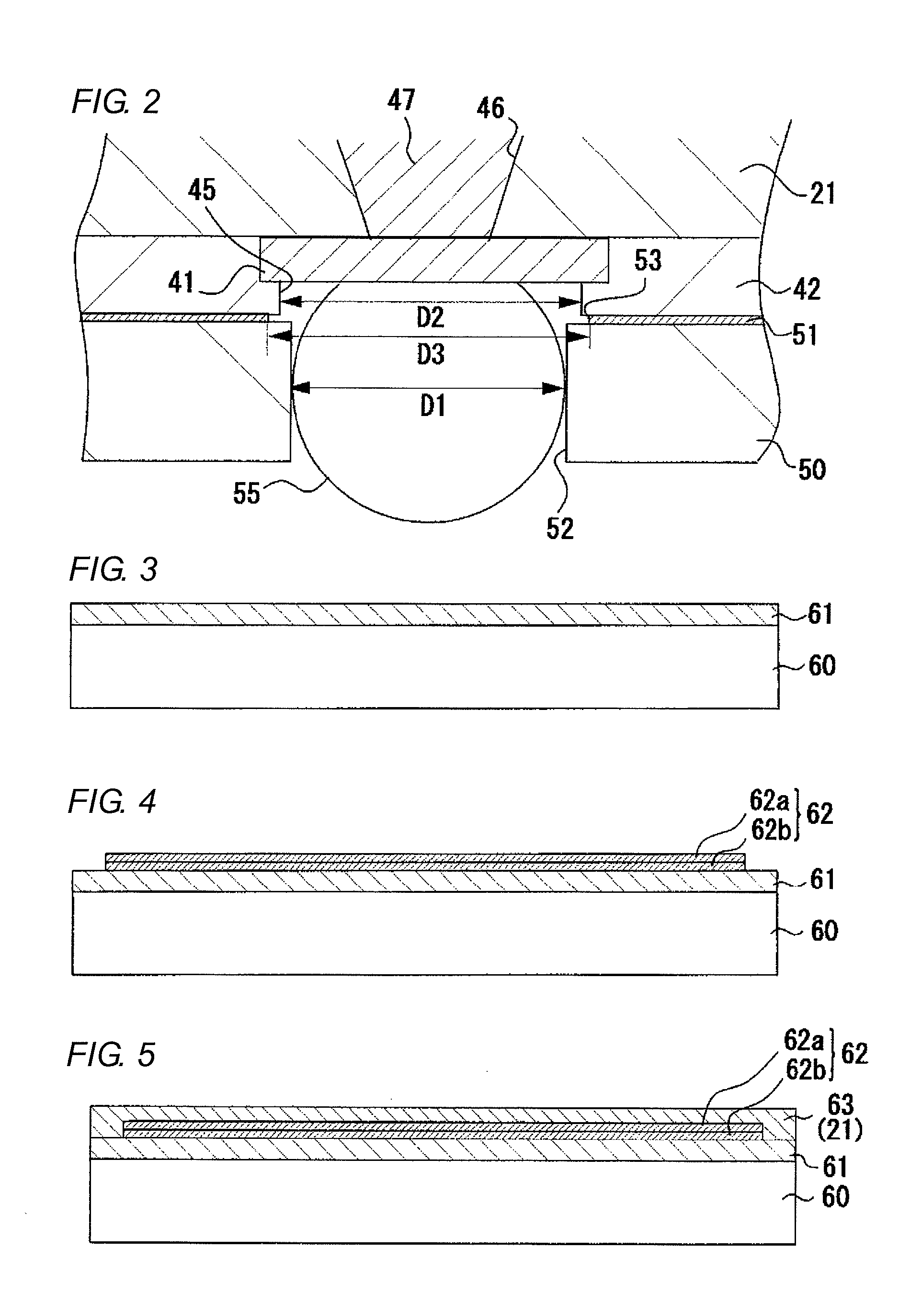

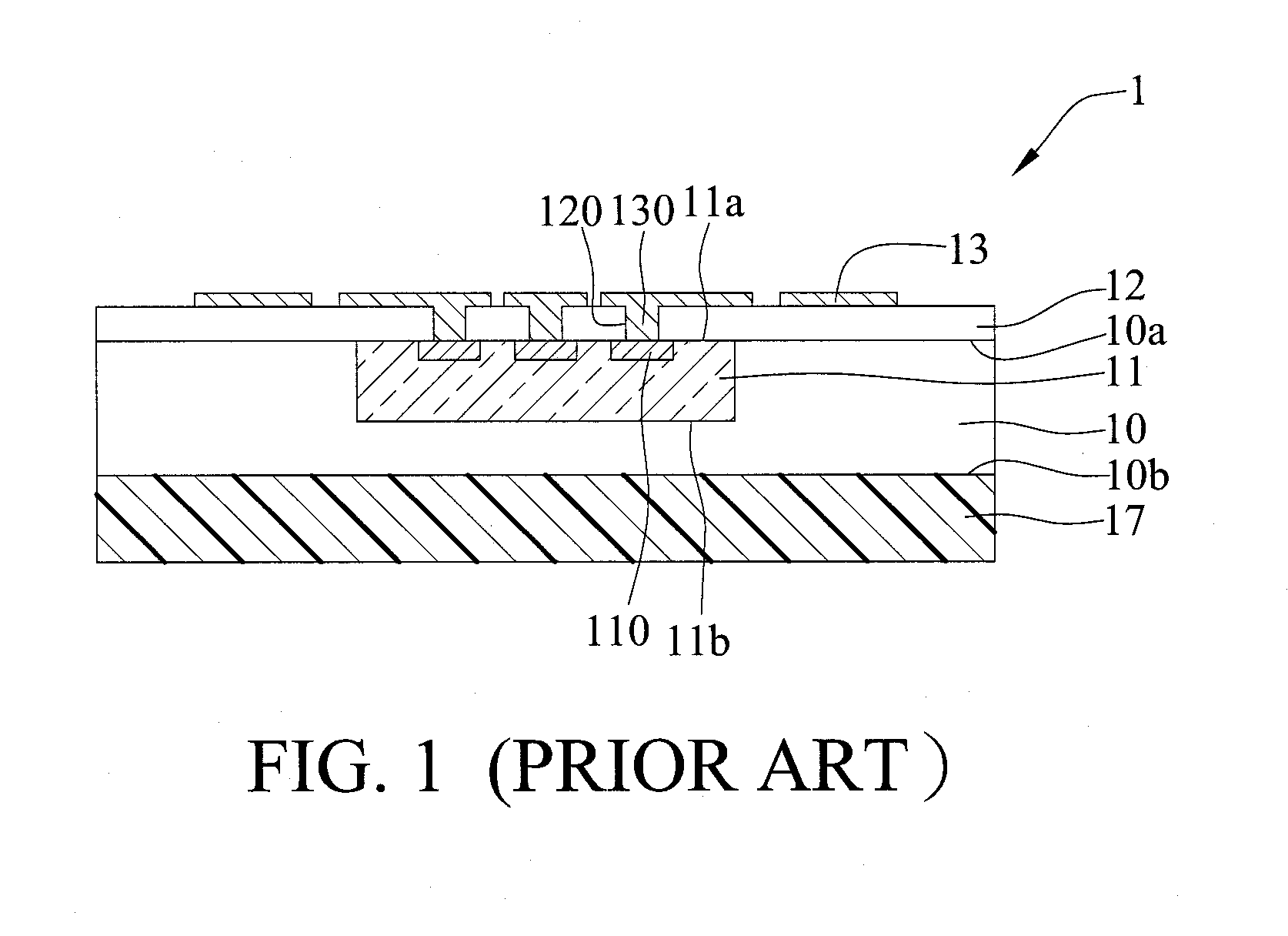

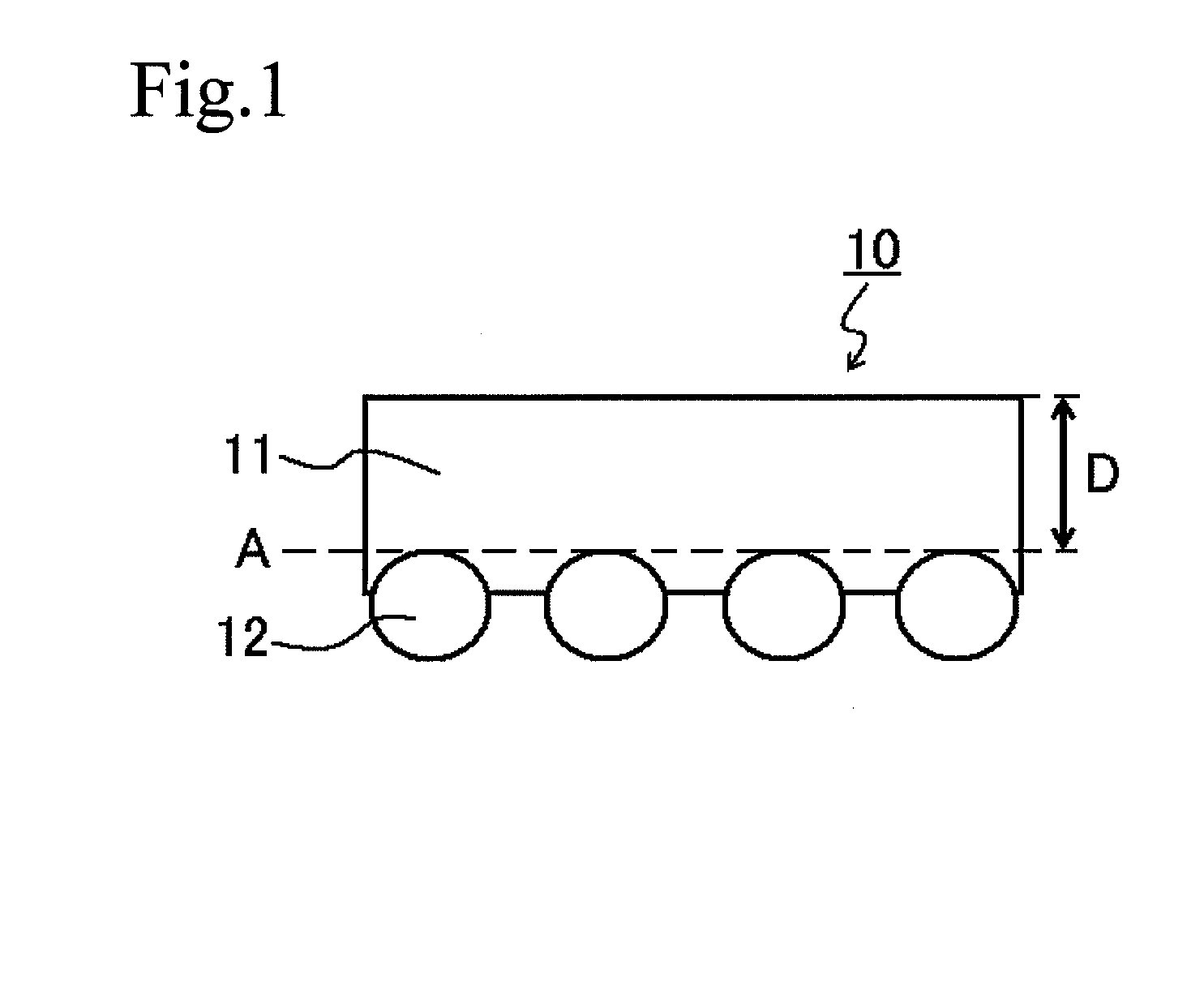

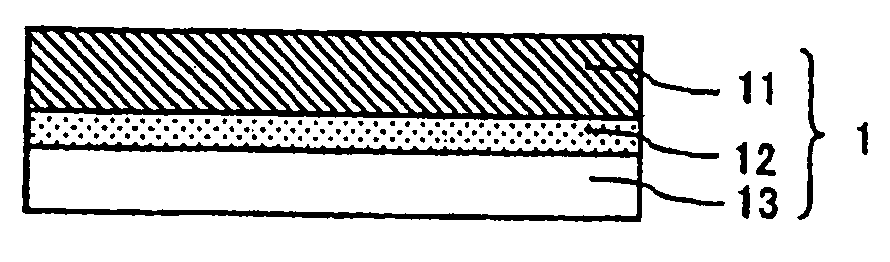

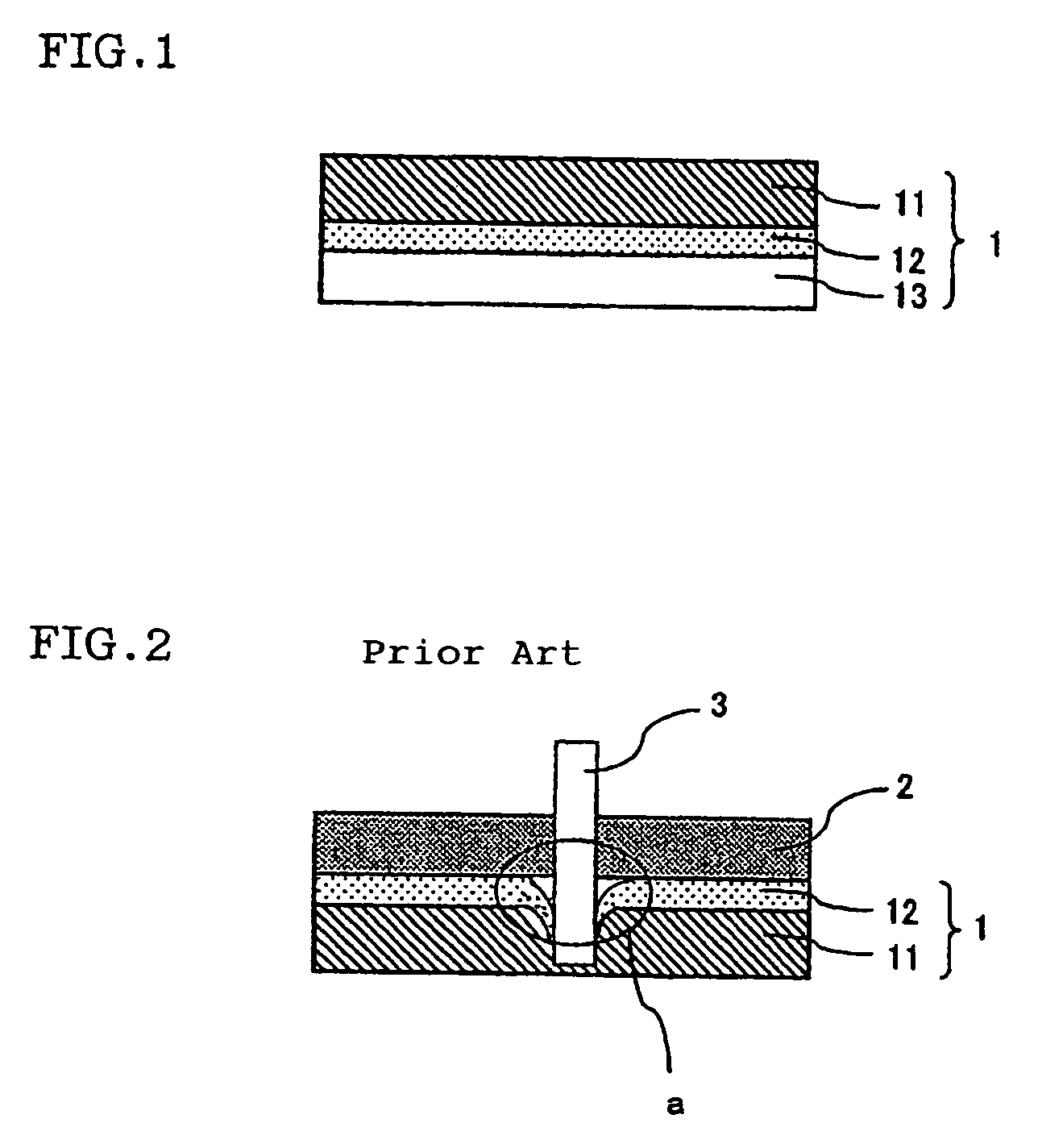

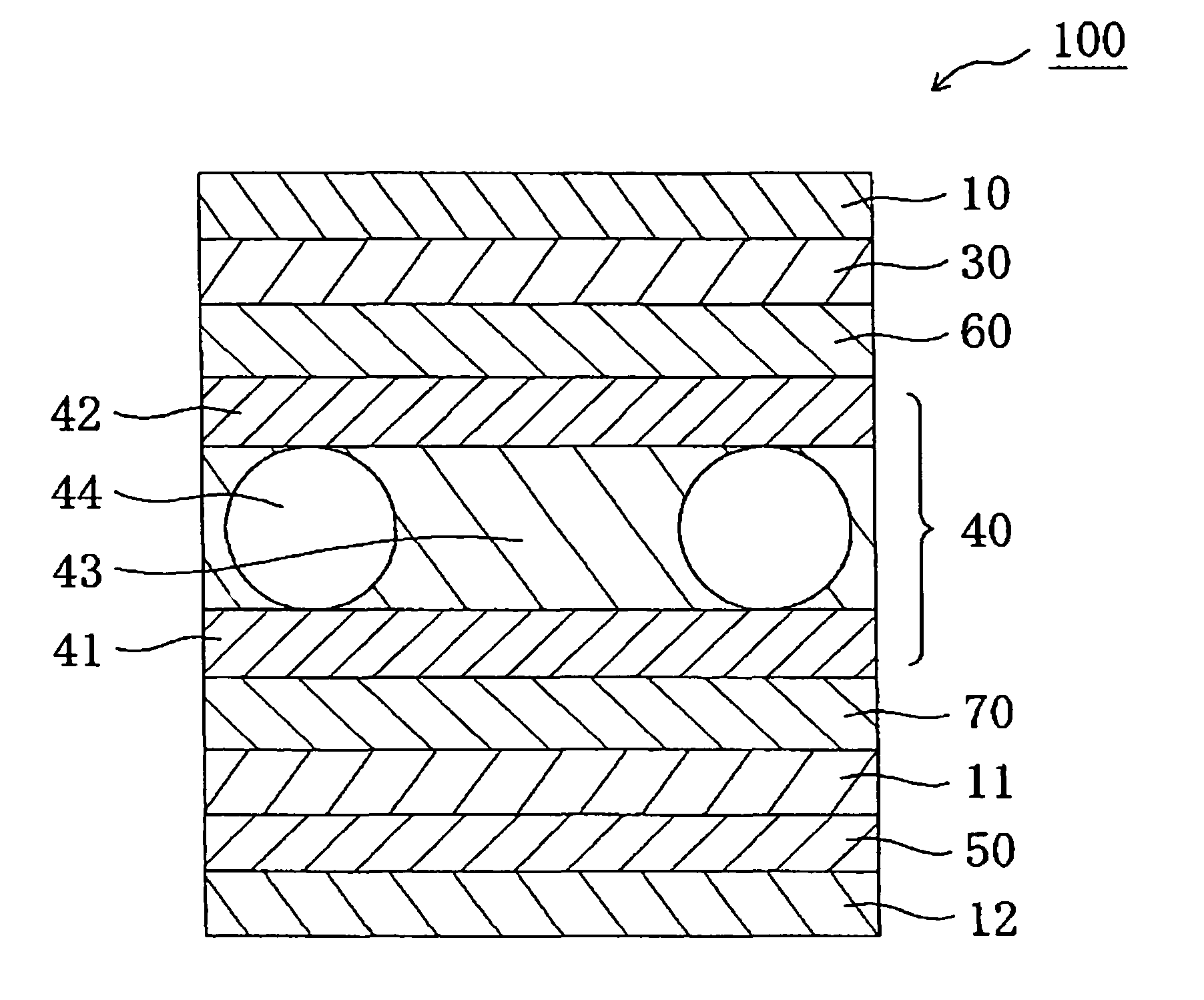

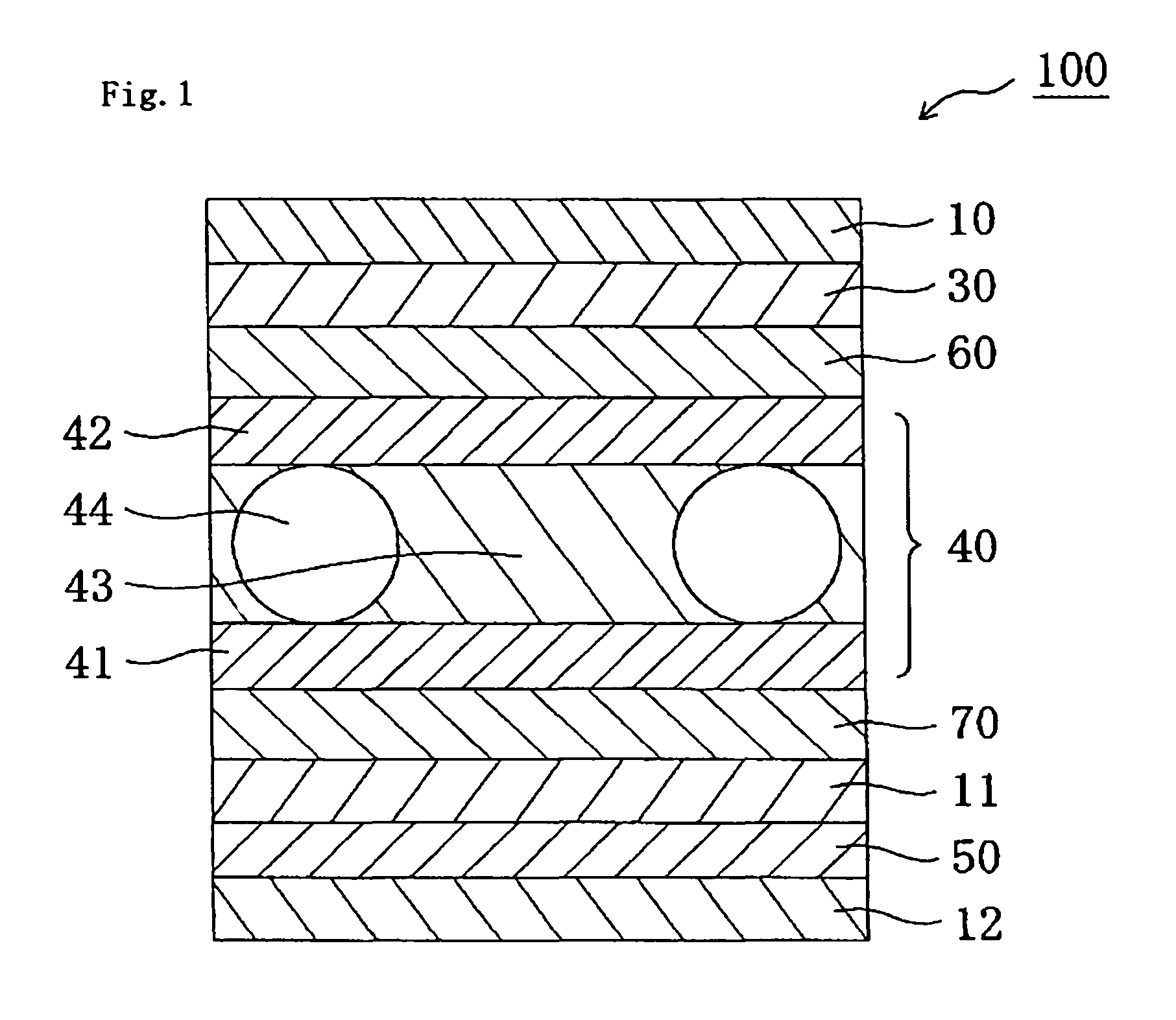

A multi-layer wiring board without a core substrate includes: a multi-layer laminated structure; first terminals provided on a front surface of the multi-layer laminated structure; second terminals provided on a rear surface of the multi-layer laminated structure; a solder resist which covers the rear surface and which has solder resist openings formed at positions corresponding to the second terminals; a reinforcing plate which is made of a non-metal material and which has reinforcing plate openings formed at positions corresponding to the second terminals; and an adhesive layer interposed between the solder resist and the reinforcing plate to fix the reinforcing plate to the solder resist and which includes adhesive layer openings formed at positions corresponding to the second terminals. A diameter of the solder resist openings and a diameter of the reinforcing plate openings are smaller than that of the adhesive layer openings.

Owner:NGK SPARK PLUG CO LTD

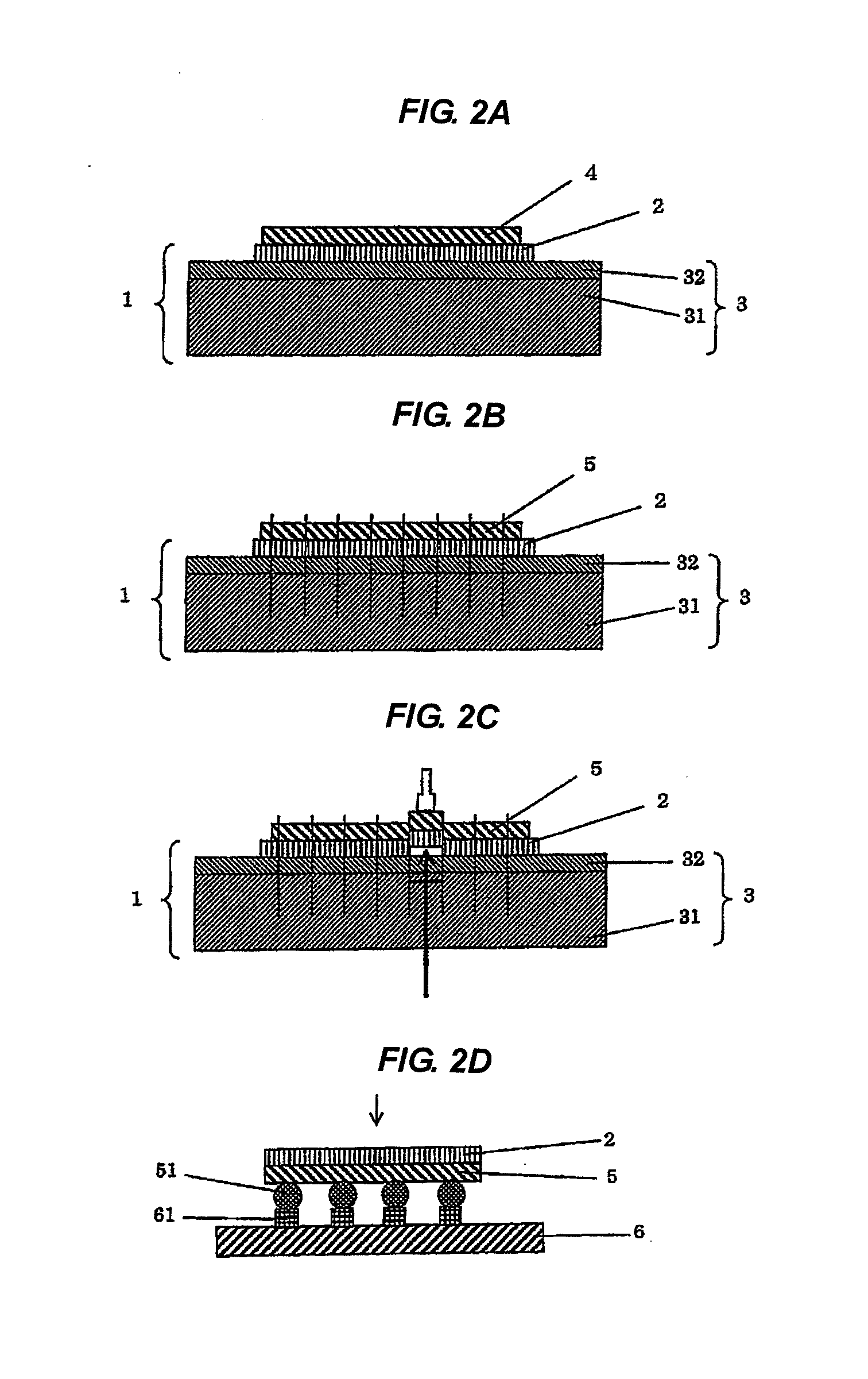

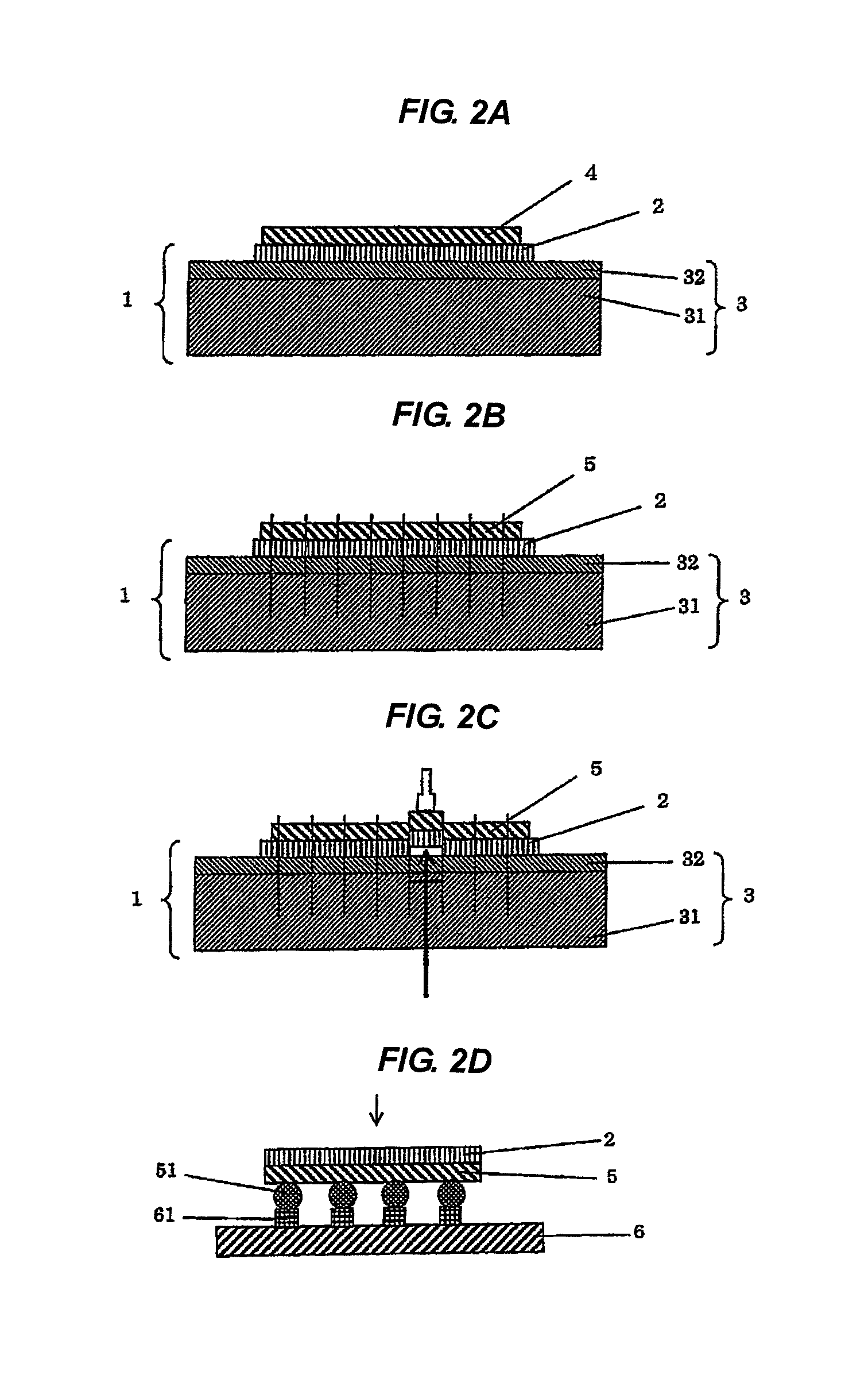

Chip-scale package

InactiveUS20120313243A1Equally distributedImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesComputational physicsDielectric layer

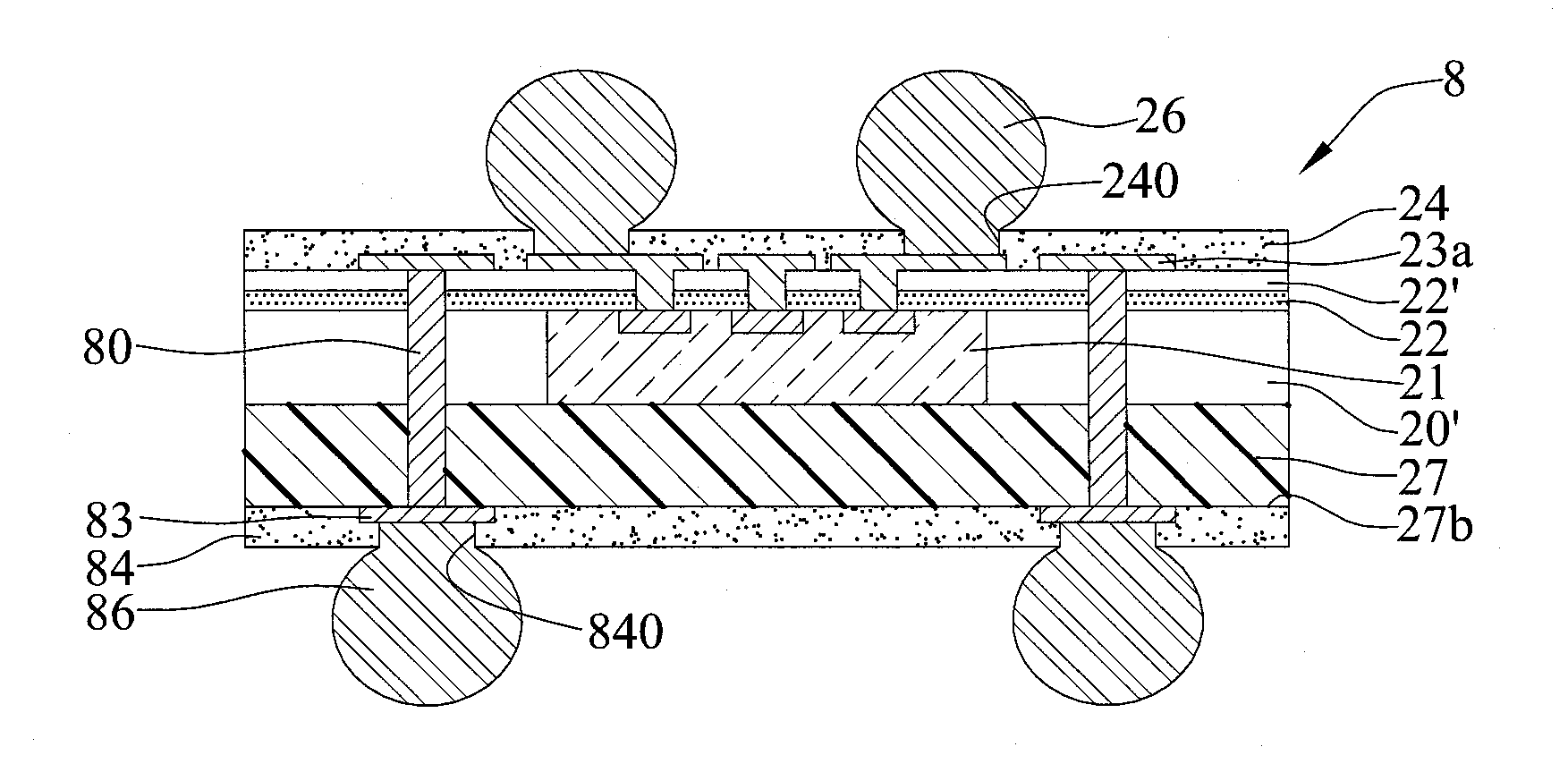

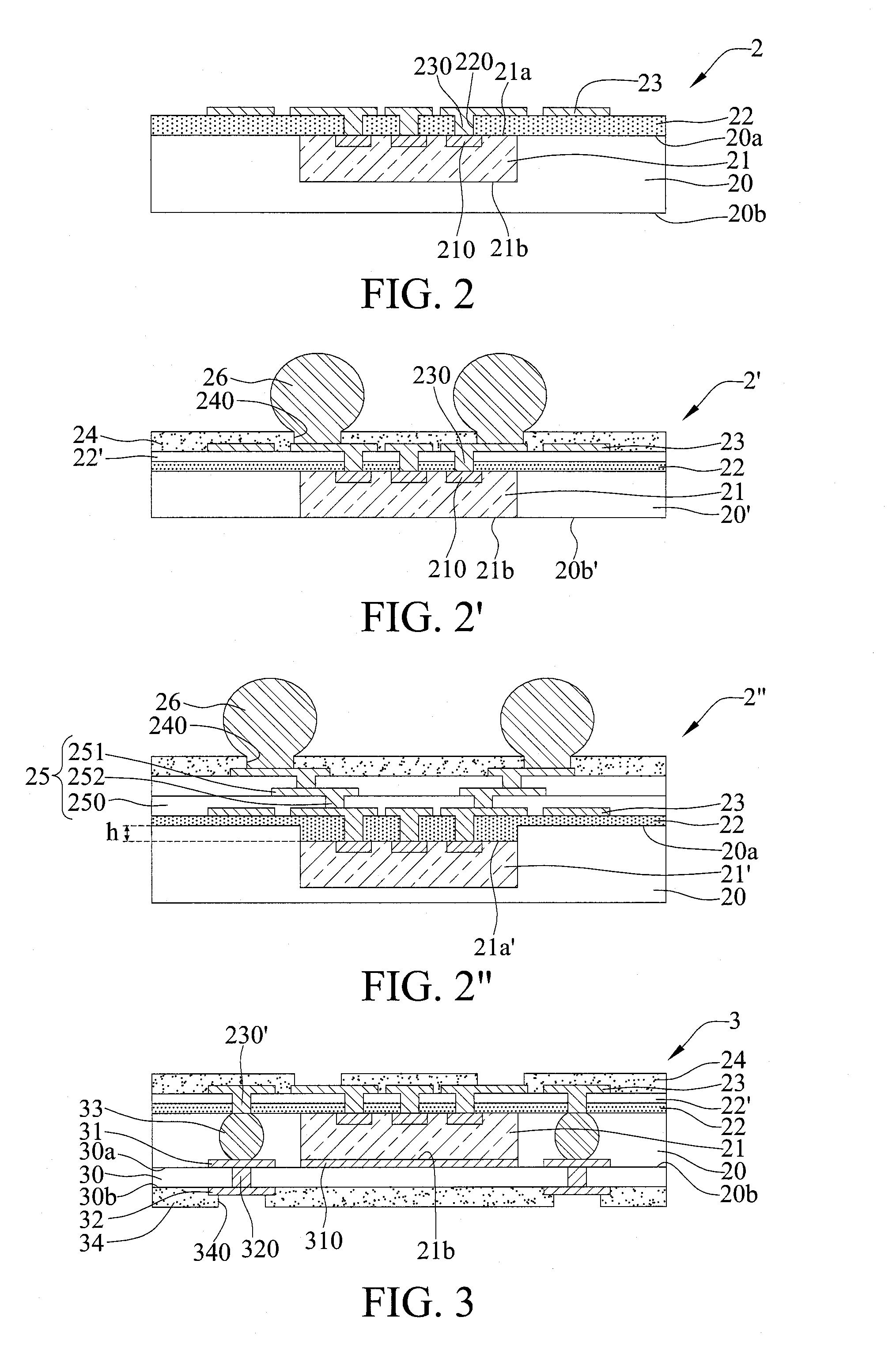

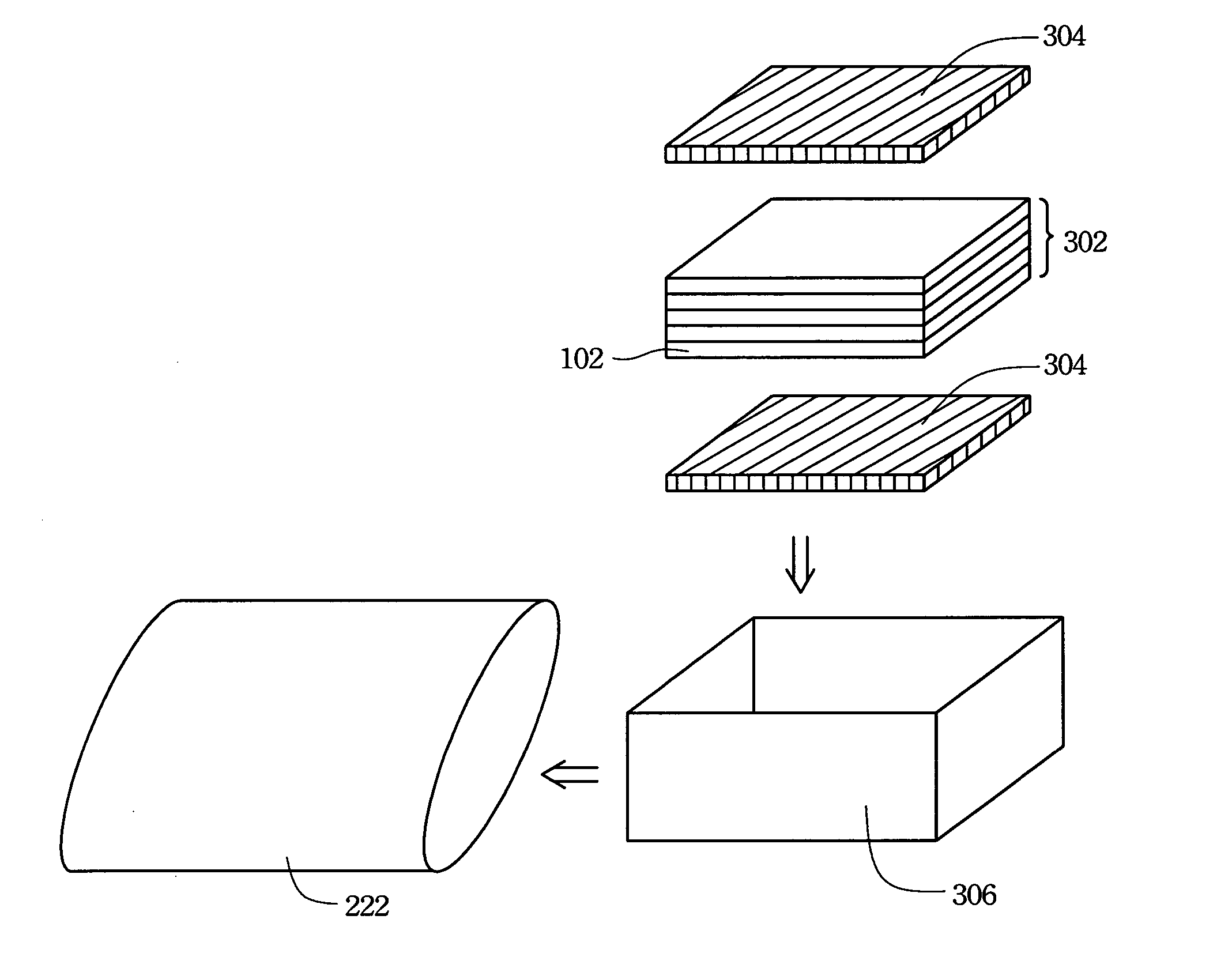

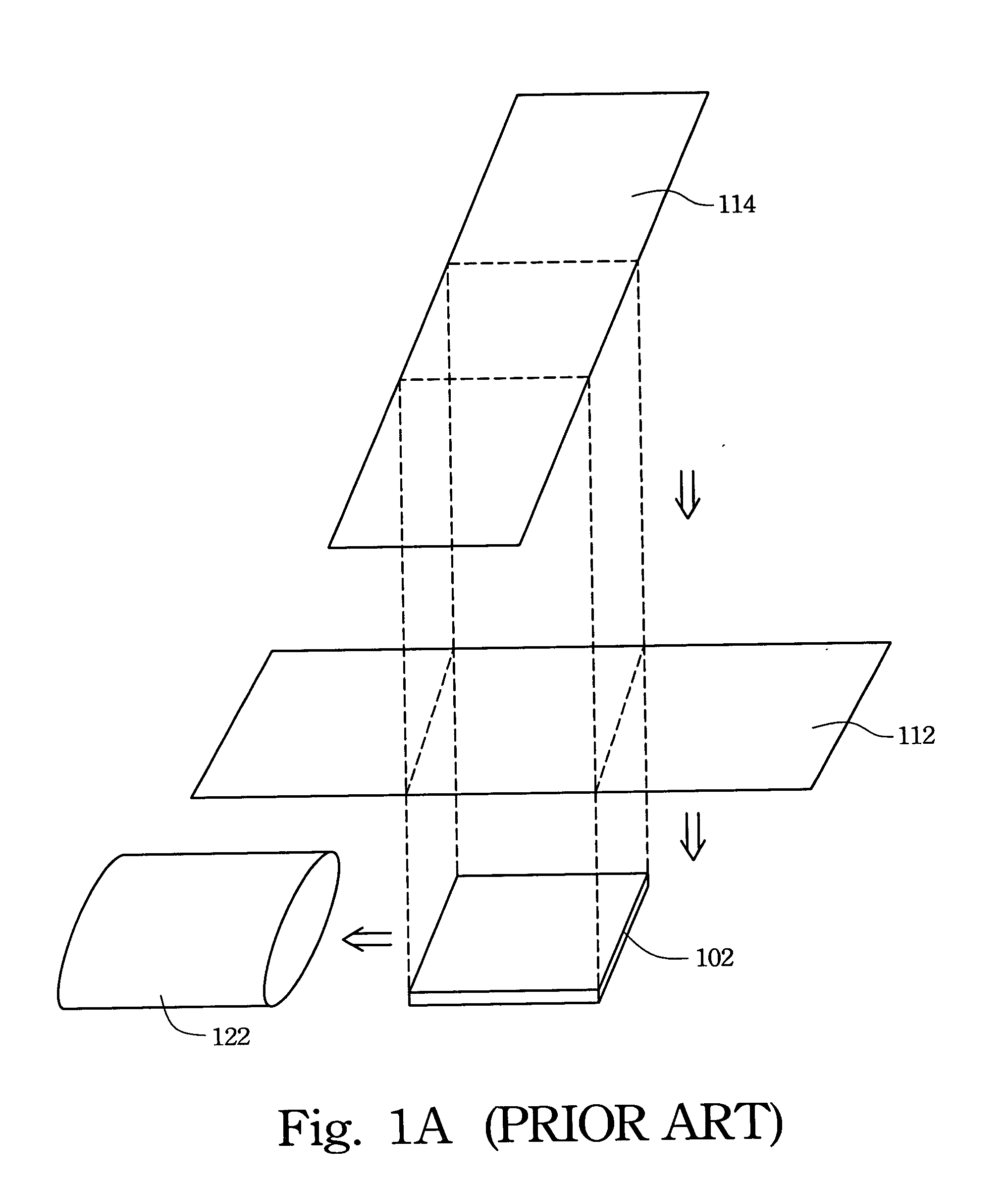

A chip-scale package includes an encapsulating layer, a chip embedded in the encapsulating layer and having an active surface exposed from the encapsulating layer, a buffering dielectric layer formed on the encapsulating layer and the chip, a build-up dielectric layer formed on the buffering dielectric layer, and a circuit layer formed on the build-up dielectric layer and having conductive blind vias penetrating the build-up dielectric layer and being in communication with the openings of the buffering dielectric layer and electrically connected to the chip, wherein the build-up dielectric layer and the buffering dielectric layer are made of different materials. Therefore, delamination does not occur between the buffering dielectric layer and the encapsulating layer, because the buffering dielectric layer is securely bonded to the encapsulating layer and the buffering dielectric layer is evenly distributed on the encapsulating layer.

Owner:SILICONWARE PRECISION IND CO LTD

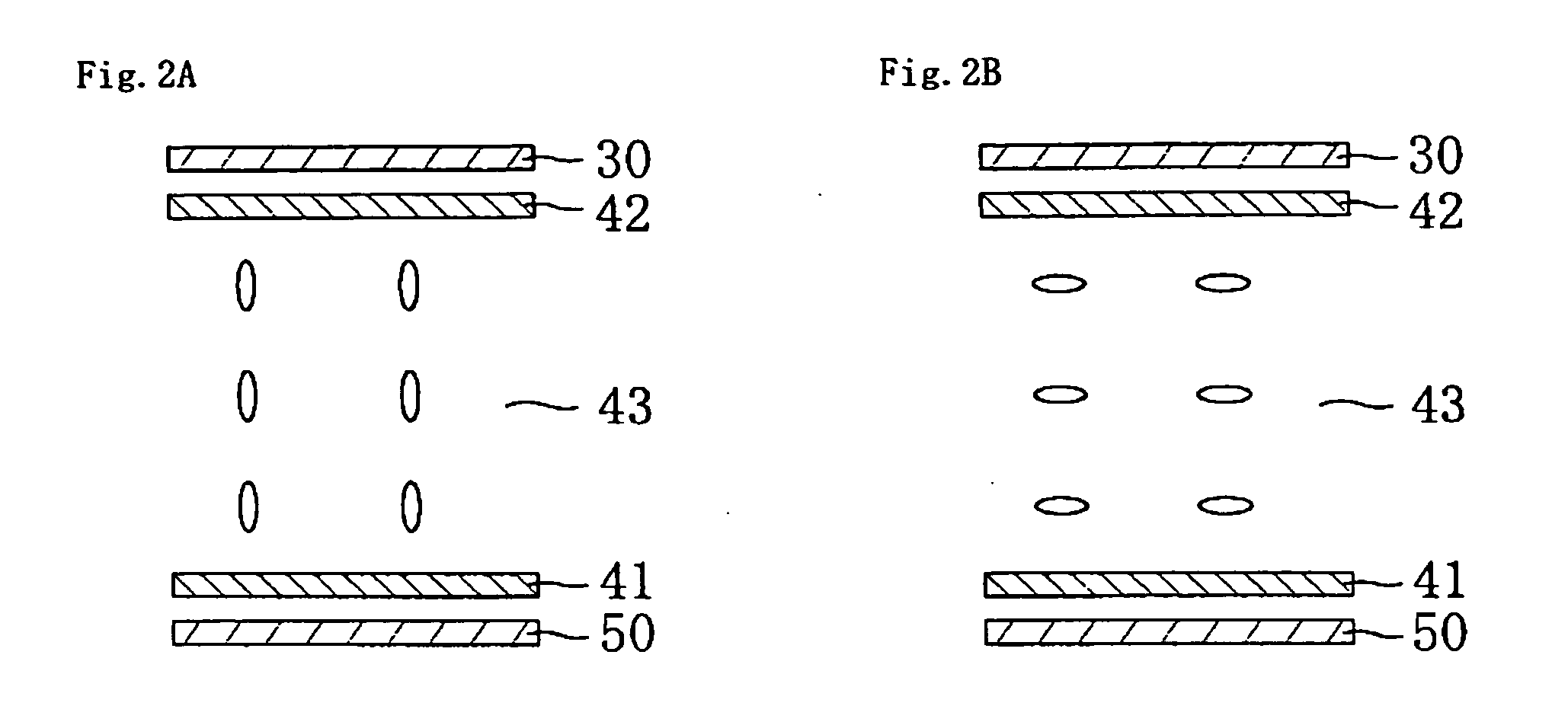

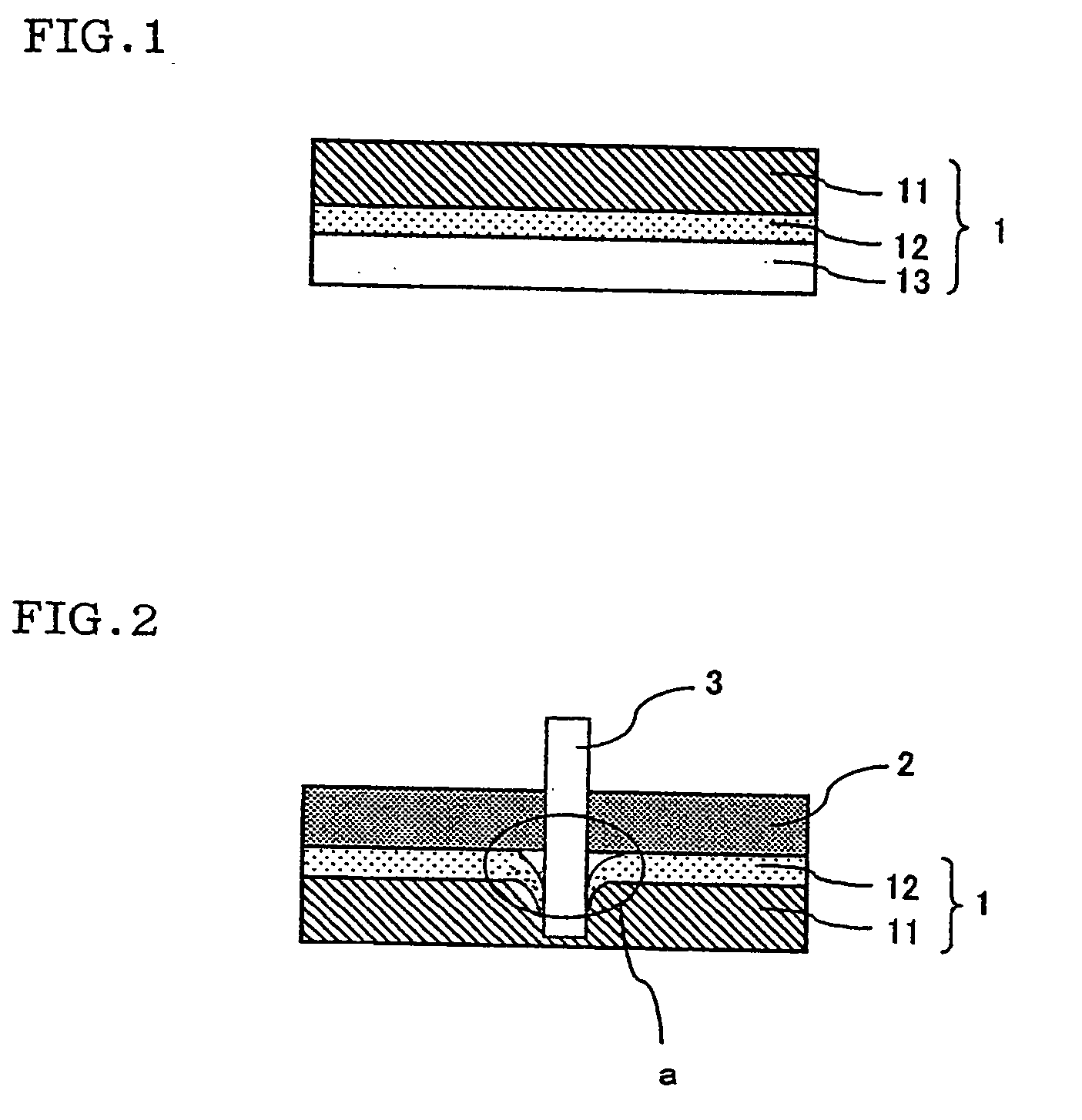

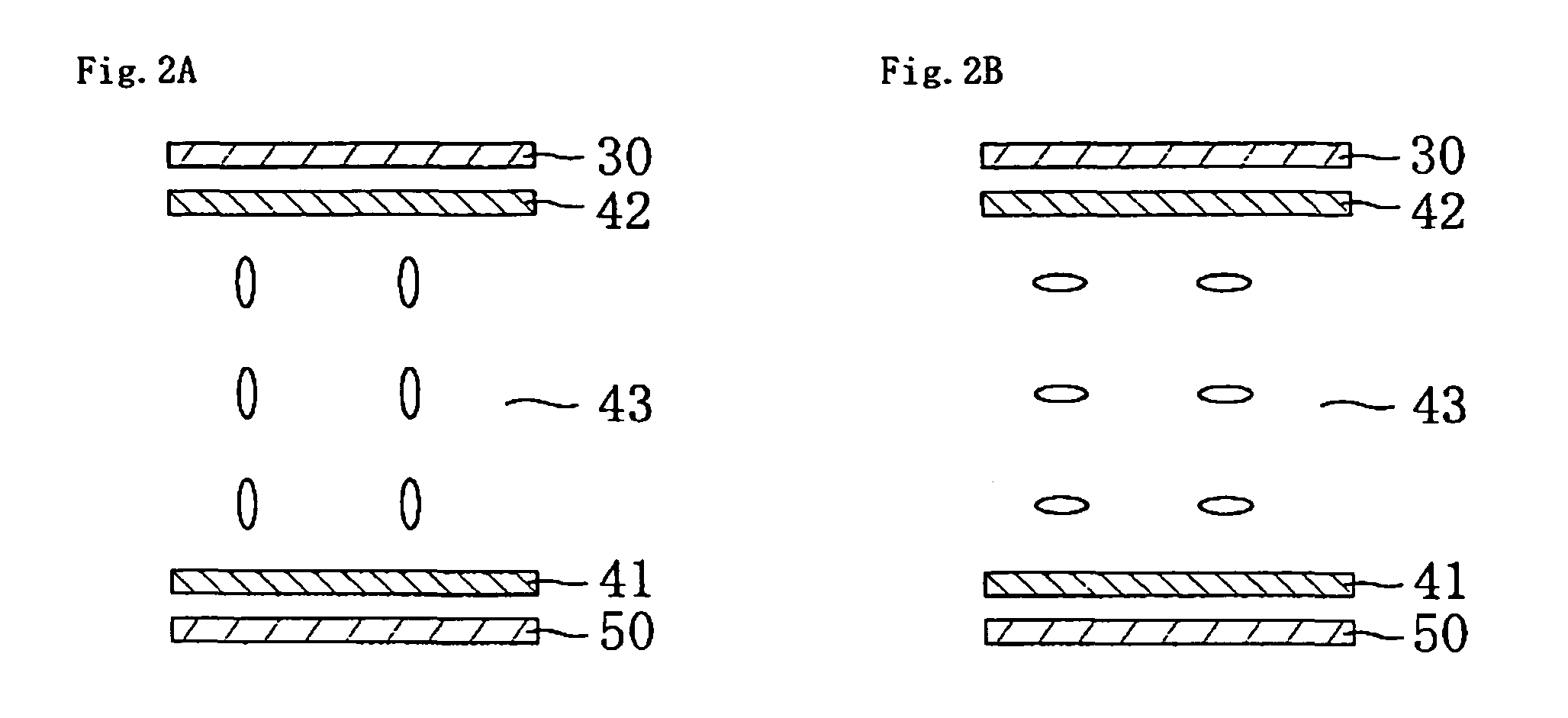

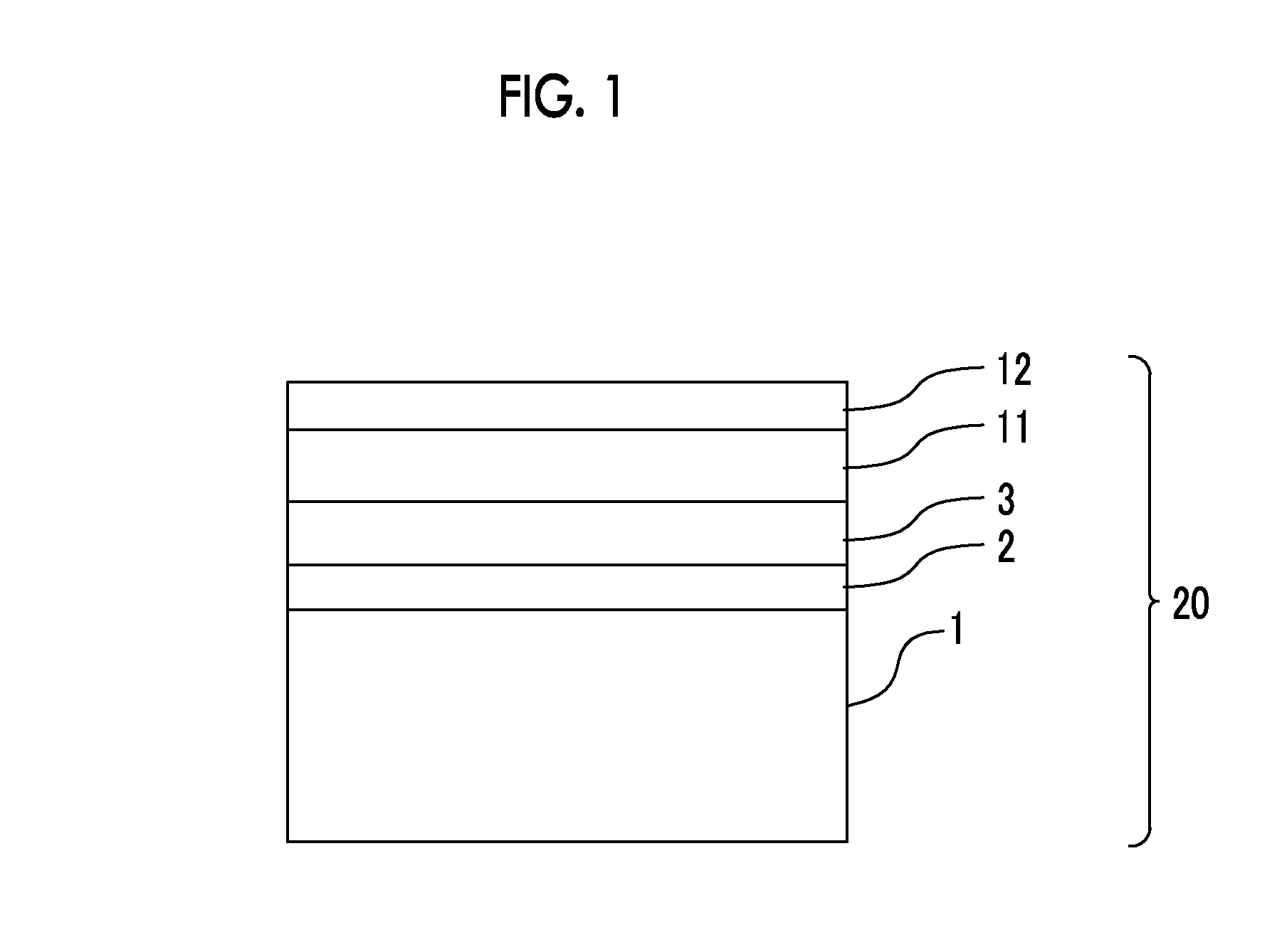

Optical film, liquid crystal panel, and liquid crystal display apparatus

ActiveUS20060238681A1Reduce thicknessAdhesive layerNon-linear opticsTectorial membraneLiquid-crystal display

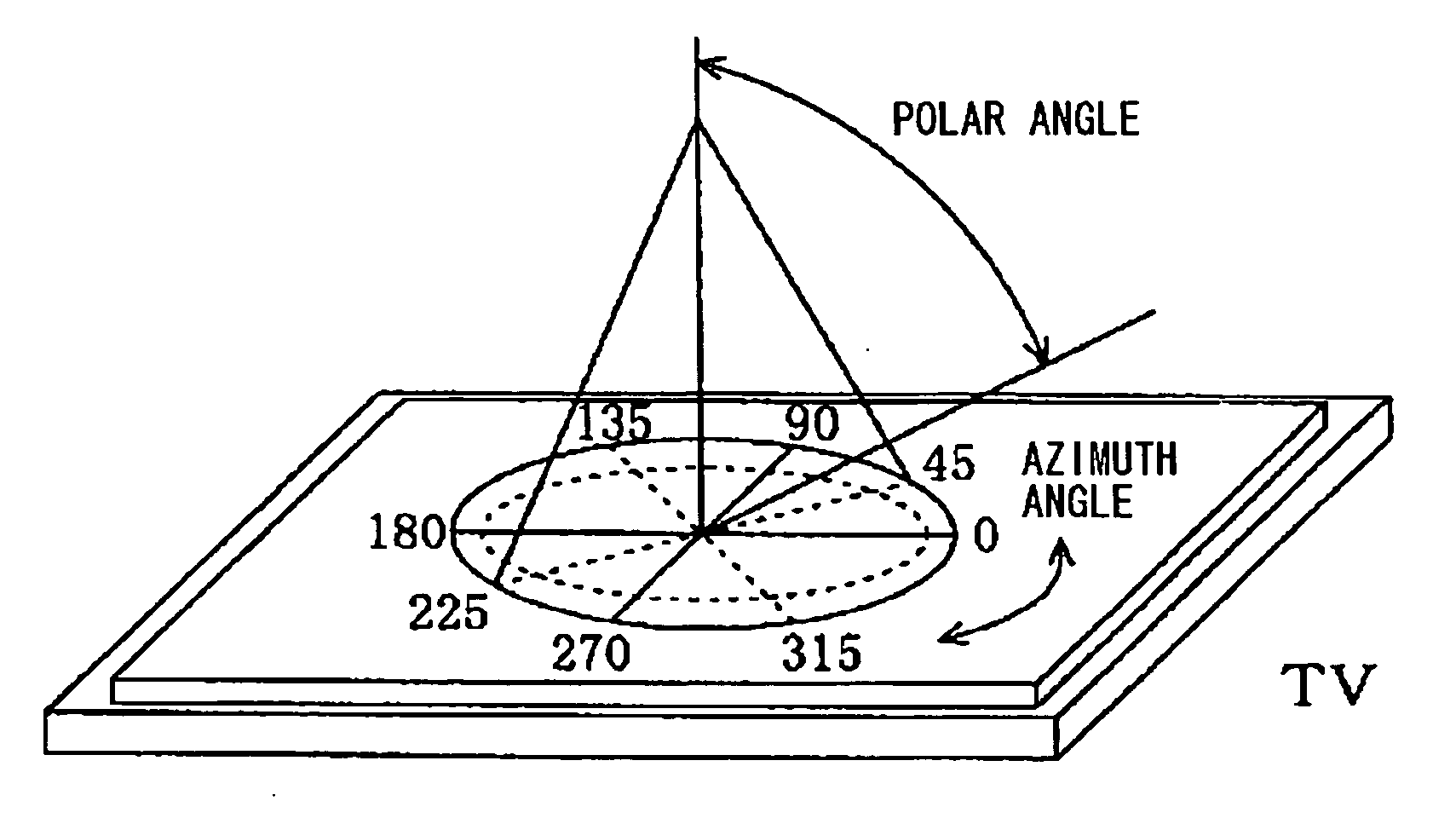

There is provided: an optical film suitable for a liquid crystal display apparatus providing a colorless neutral display in all azimuth angle directions; a liquid crystal panel employing the optical film; and a liquid crystal display apparatus employing the liquid crystal panel. An optical film includes a transparent protective film, a polarizer, and a birefringent layer having a relationship of nx>ny=nz and positive uniaxial property, in the stated order, in which the polarizer and the birefringent layer are laminated directly through one of a pressure-sensitive adhesive and an adhesive.

Owner:NITTO DENKO CORP

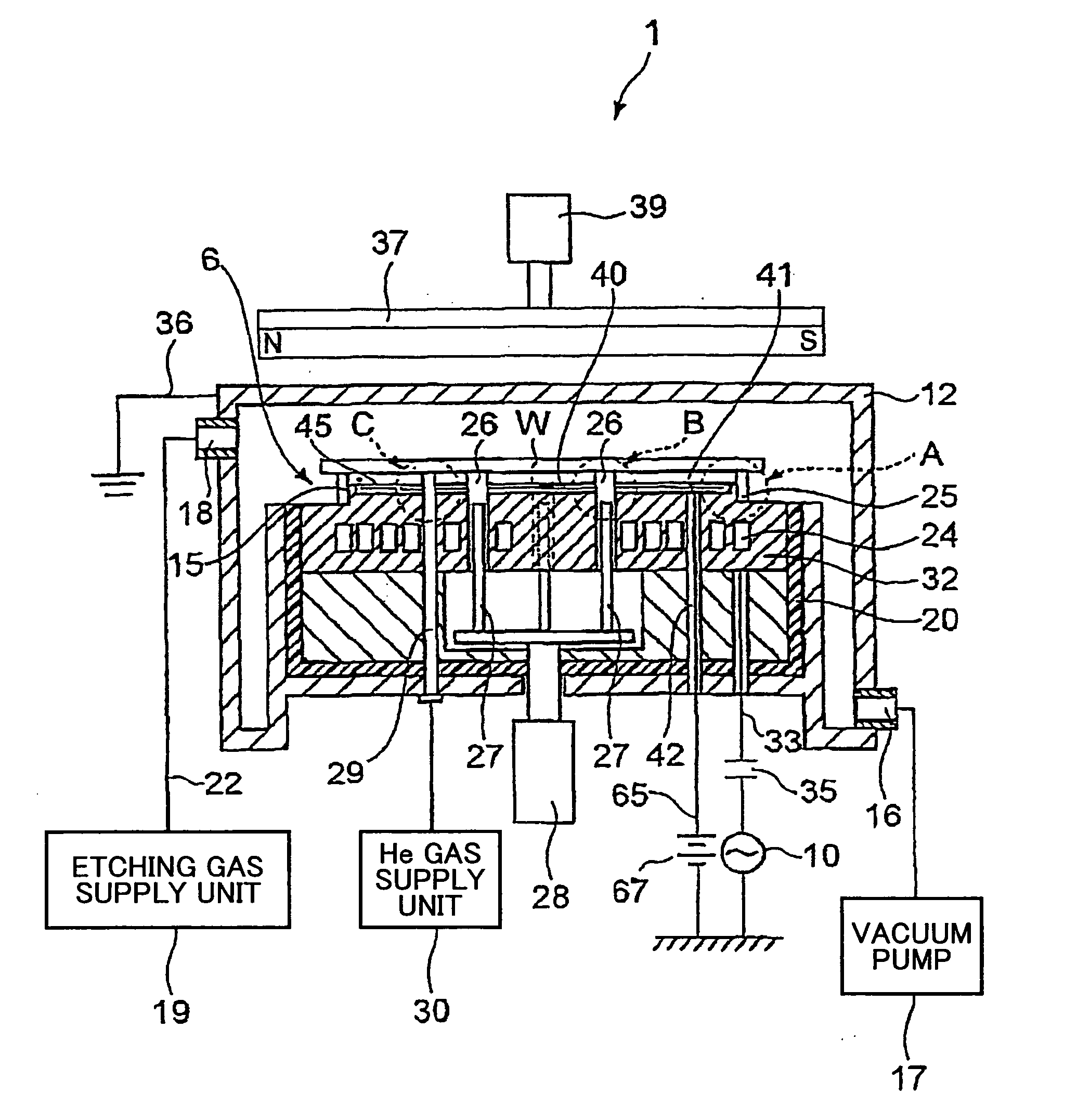

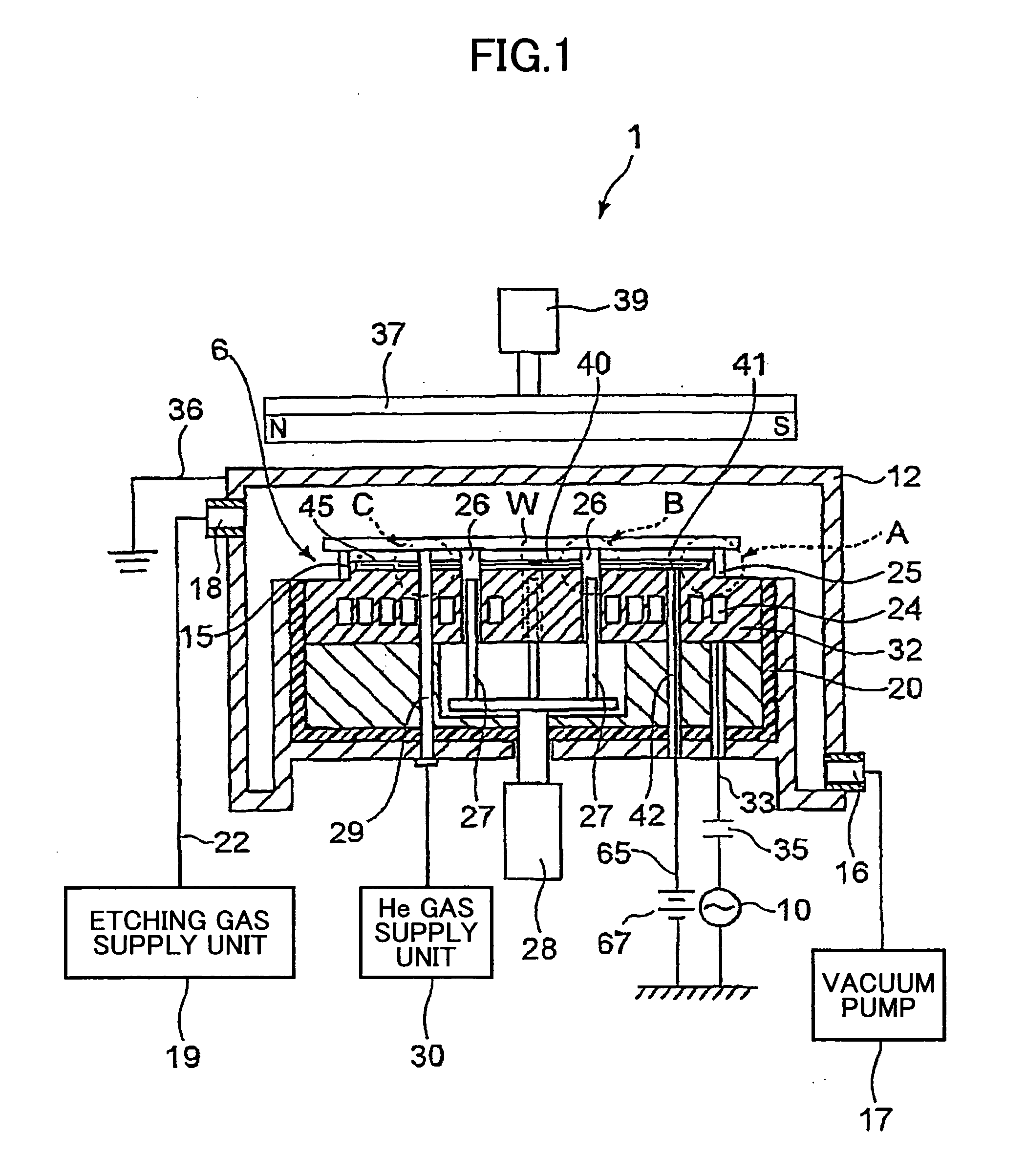

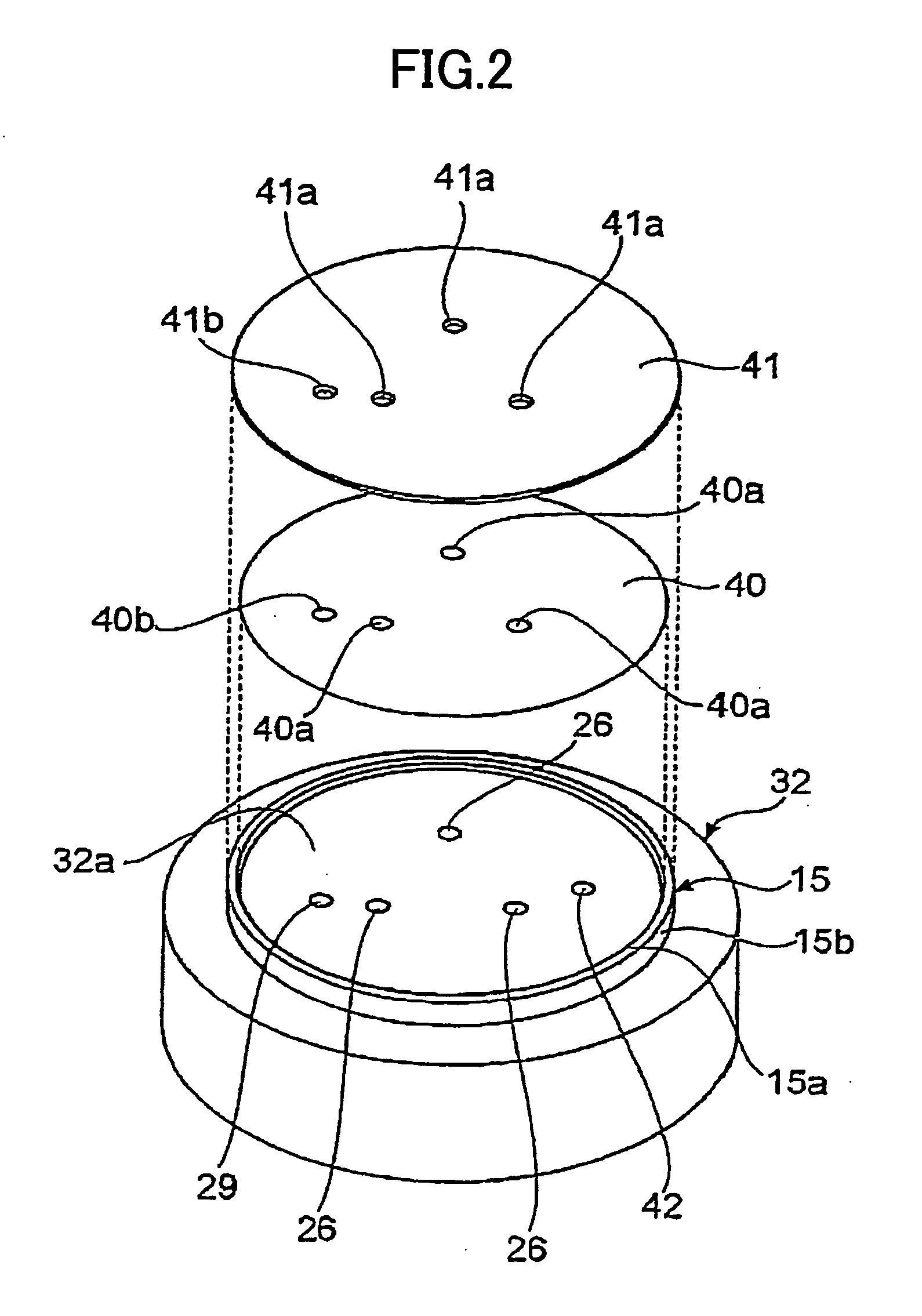

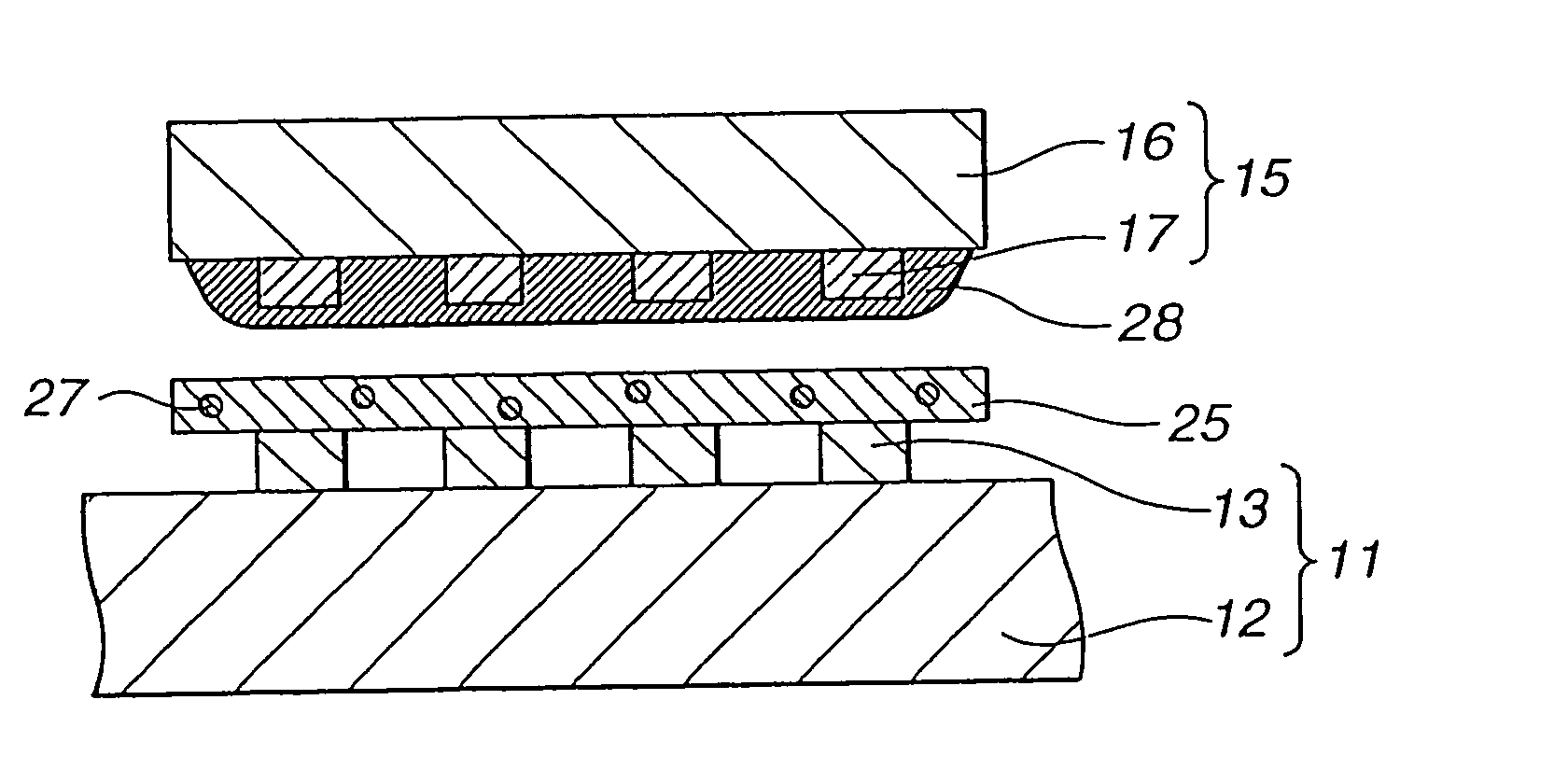

Substrate holding mechanism using electrostaic chuck and method of manufacturing the same

InactiveUS20060175772A1Avoid layeringExtended service lifeSleeve/socket jointsLamination ancillary operationsEngineeringMechanical engineering

A substrate holding apparatus includes a stage configured to support a substrate to be processed, the stage including a surface, and a continuous convex portion surrounding a predetermined region of the surface which convex portion includes a periphery surface and an upper surface that is positioned higher than the surface of the stage; an electrostatic attraction sheet configured to attract a substrate with electrostatic force, the electrostatic attraction sheet being arranged on the surface of the stage within the region surrounded by the convex portion; a first protection member configured to protect the electrostatic attraction sheet, the first protection member being arranged on the electrostatic attraction sheet and including a side surface and a portion that is arranged to face opposite the upper surface of the convex portion; an adhesive layer that is arranged at least between the electrostatic attraction sheet and the first protection member and is configured to bond the electrostatic attraction sheet and the first protection member; and a second protection member that covers at least the outer peripheral surface of the convex portion and the side surface of the first protection member to conceal at least the adhesive layer.

Owner:TOKYO ELECTRON LTD

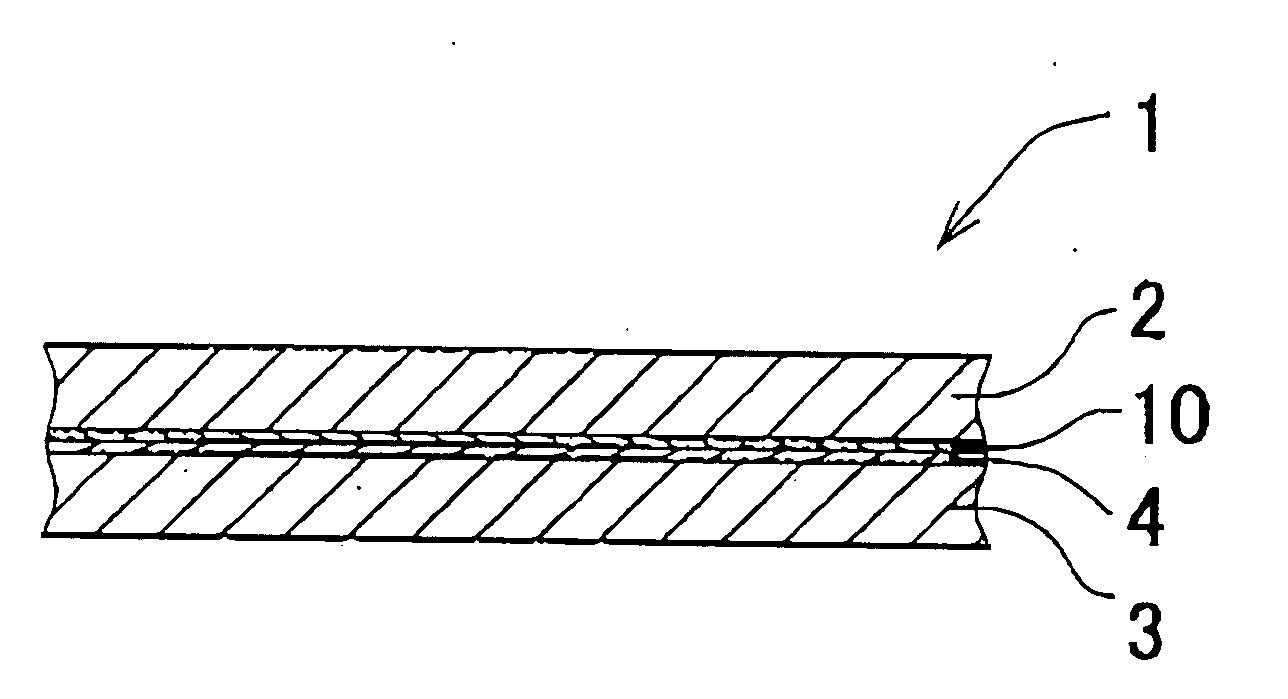

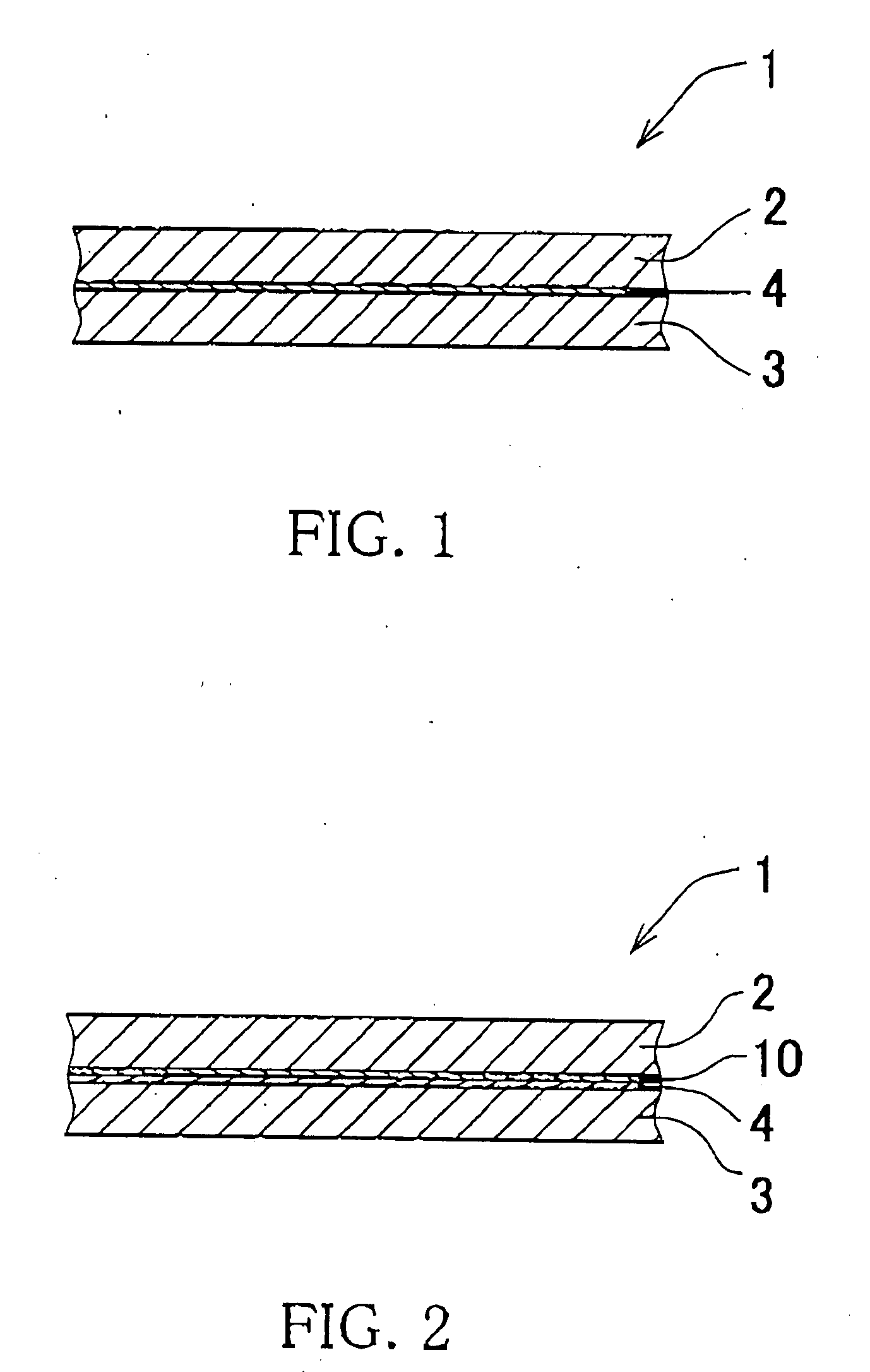

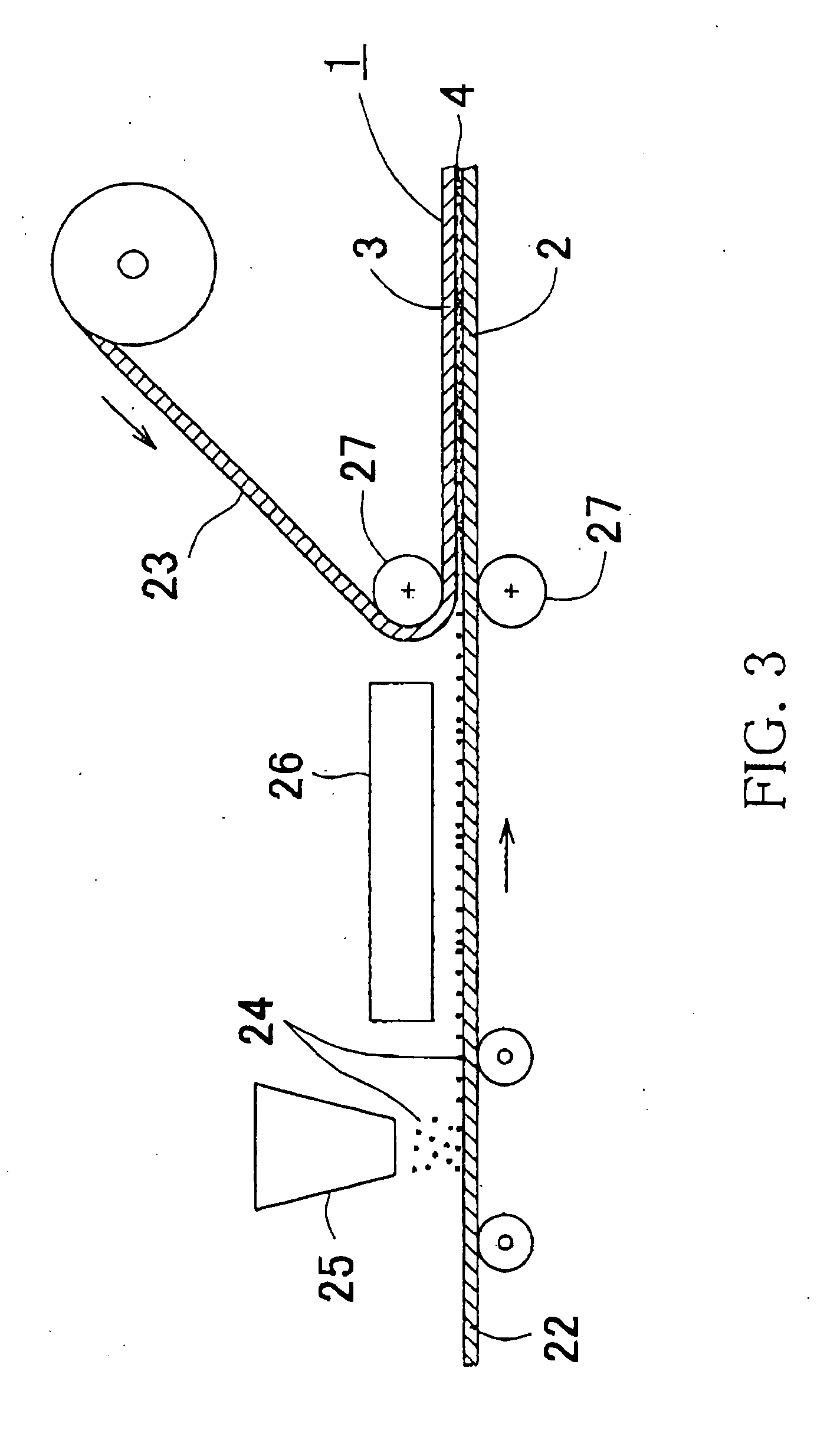

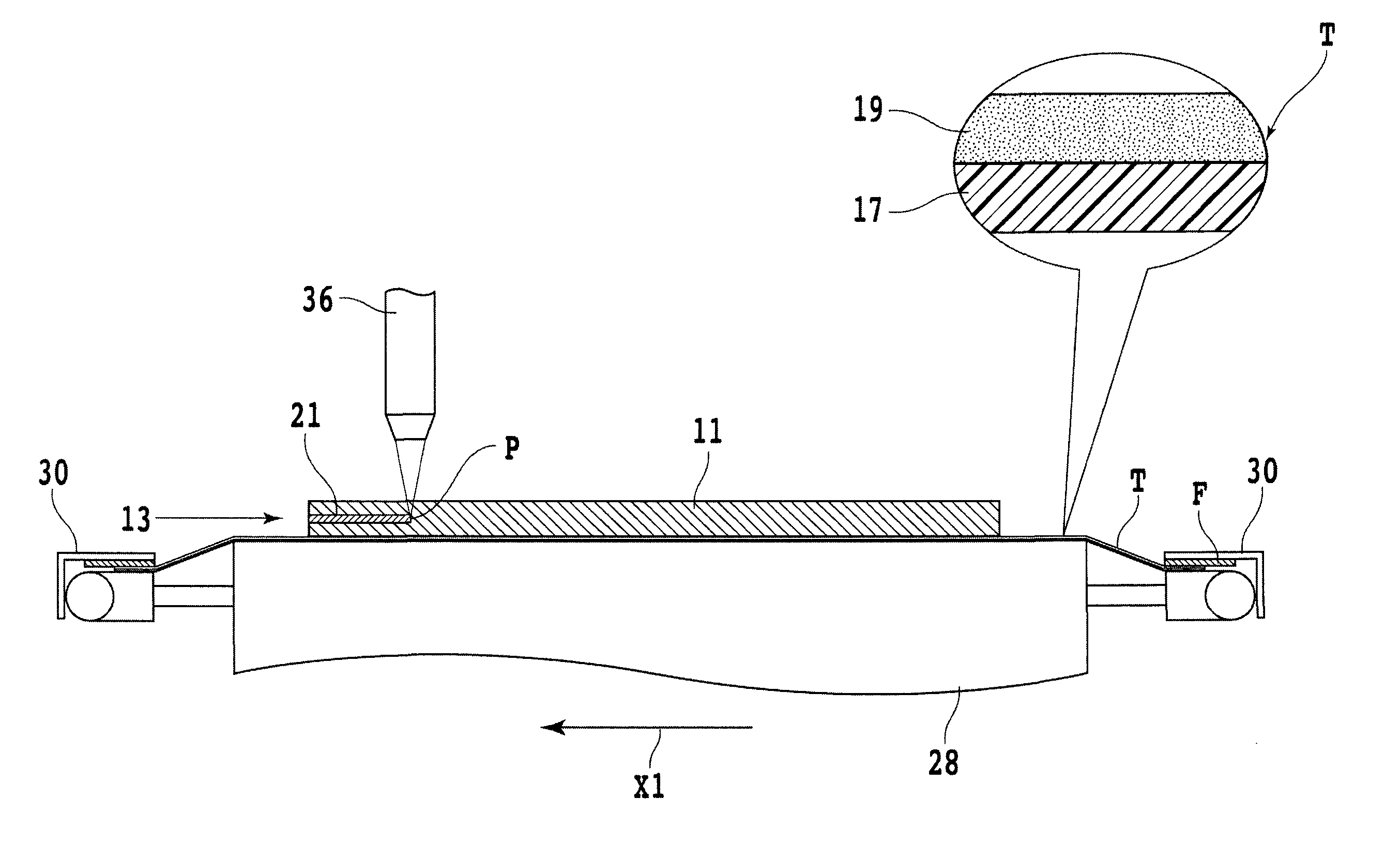

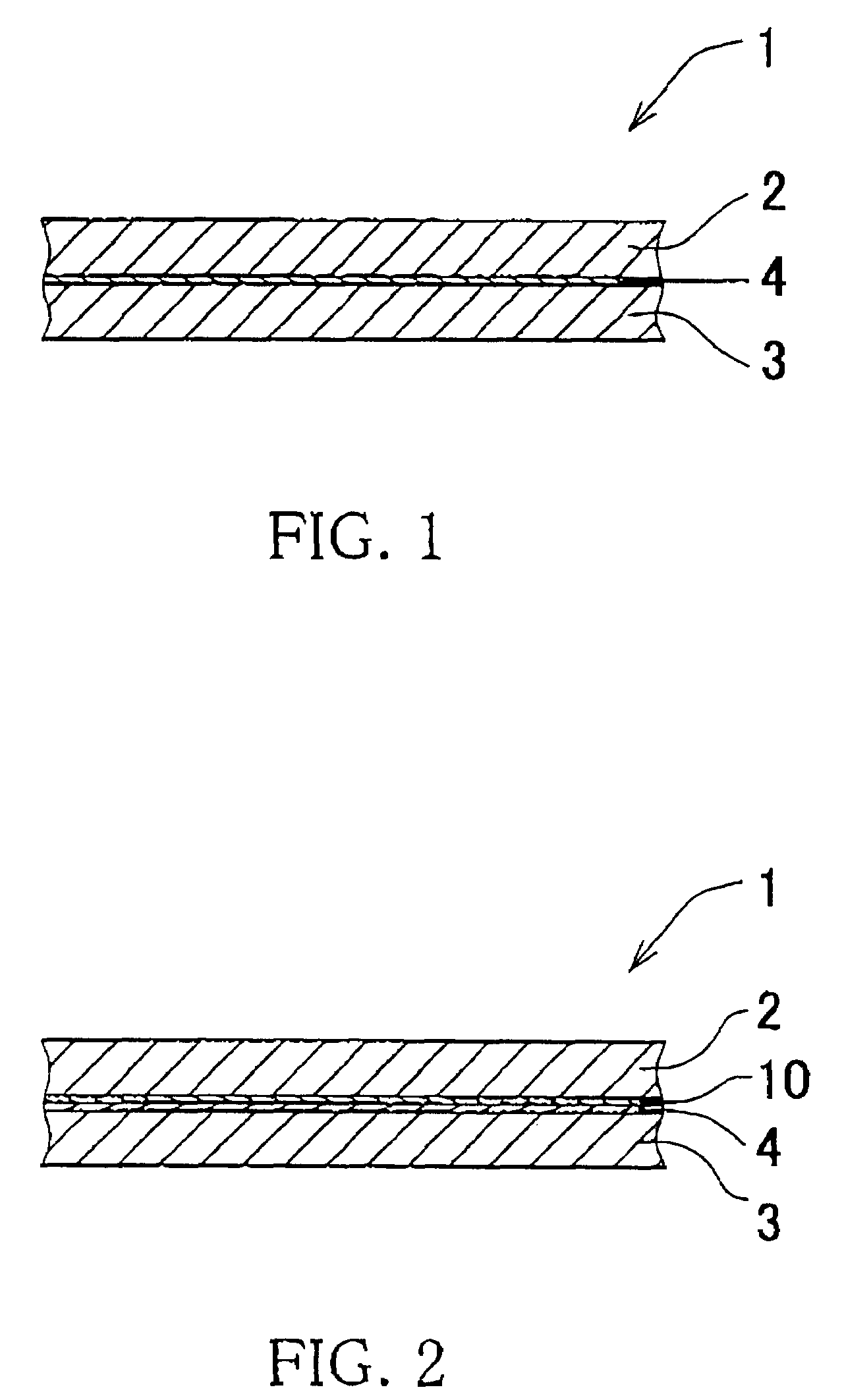

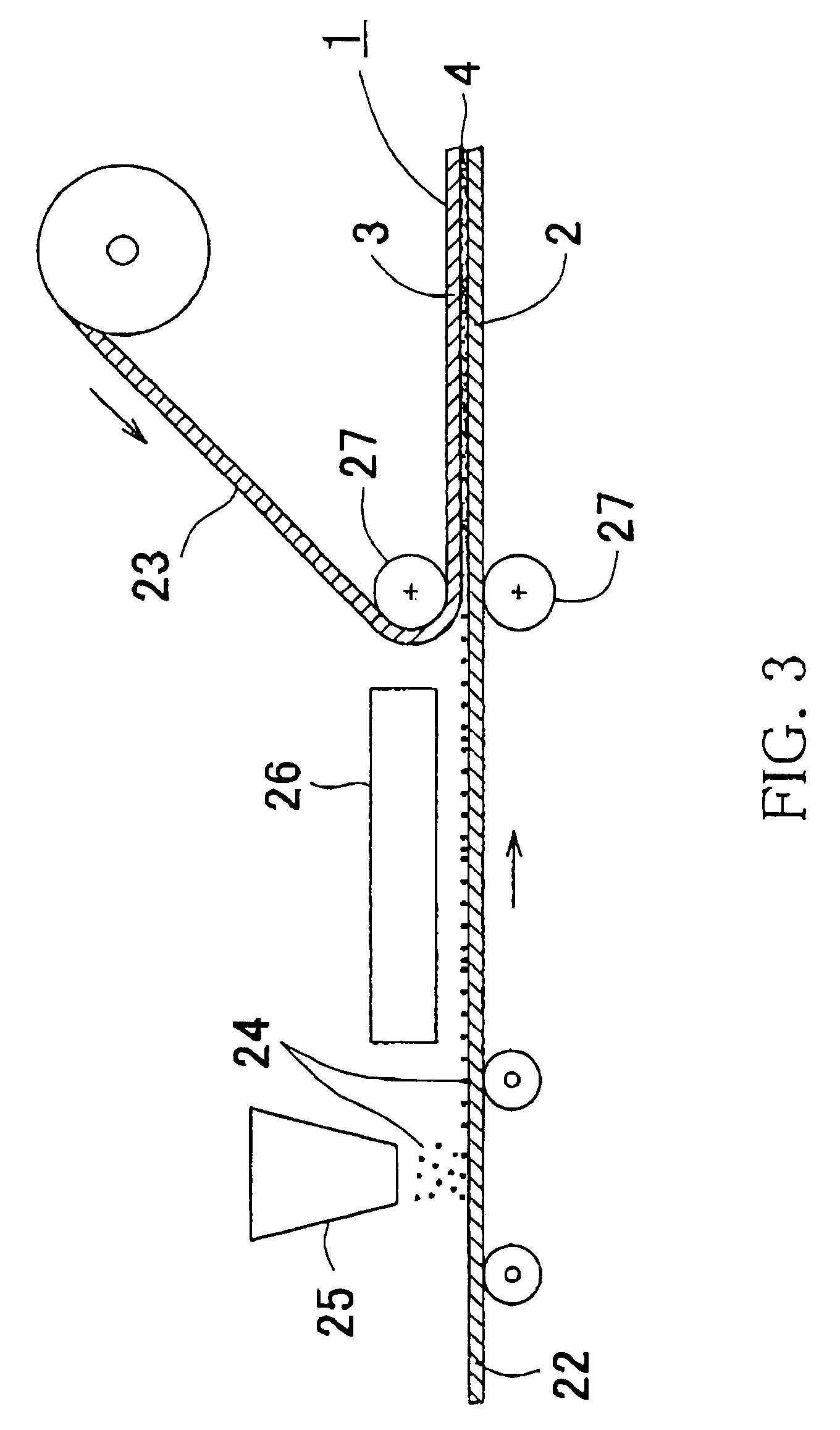

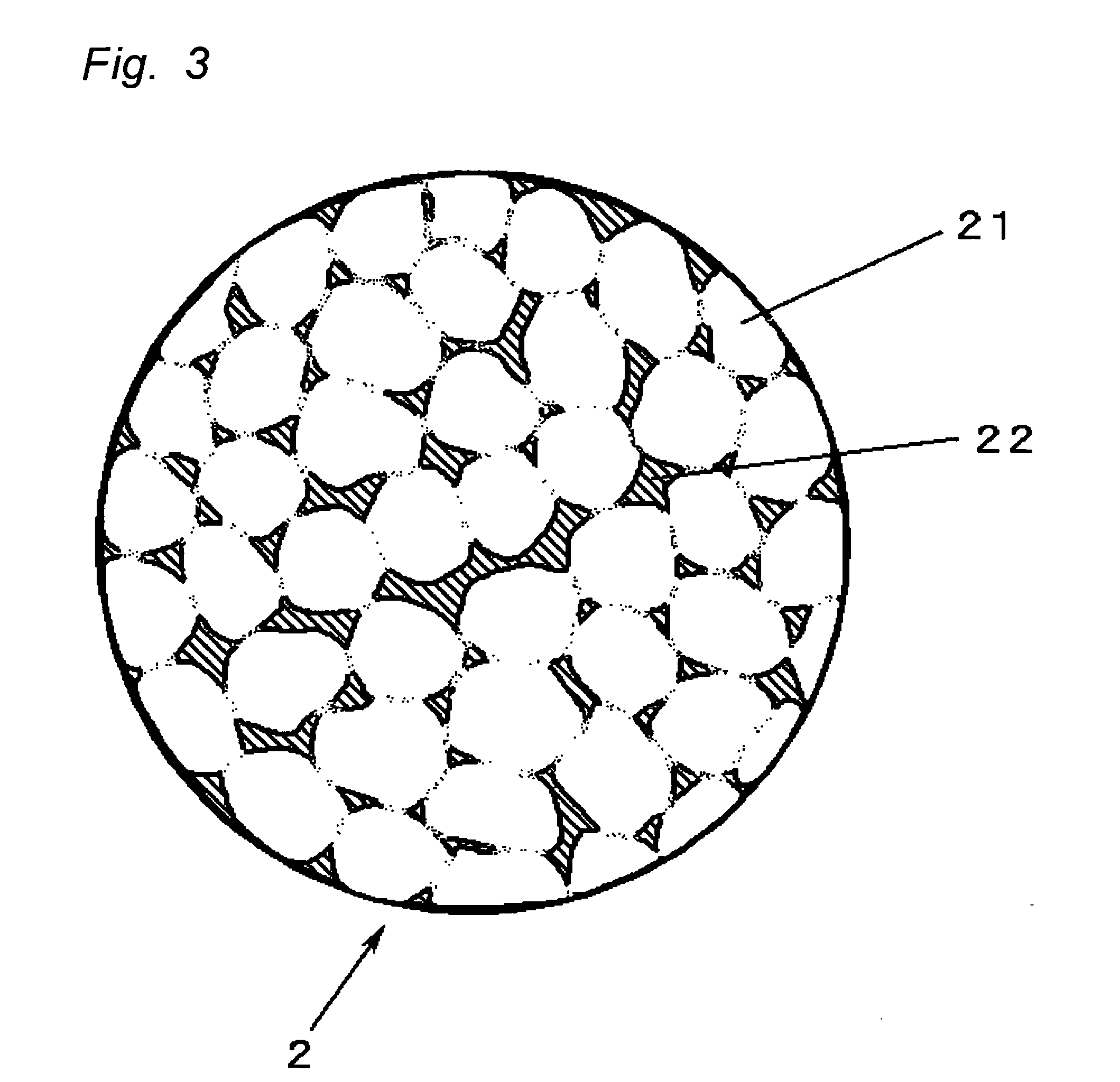

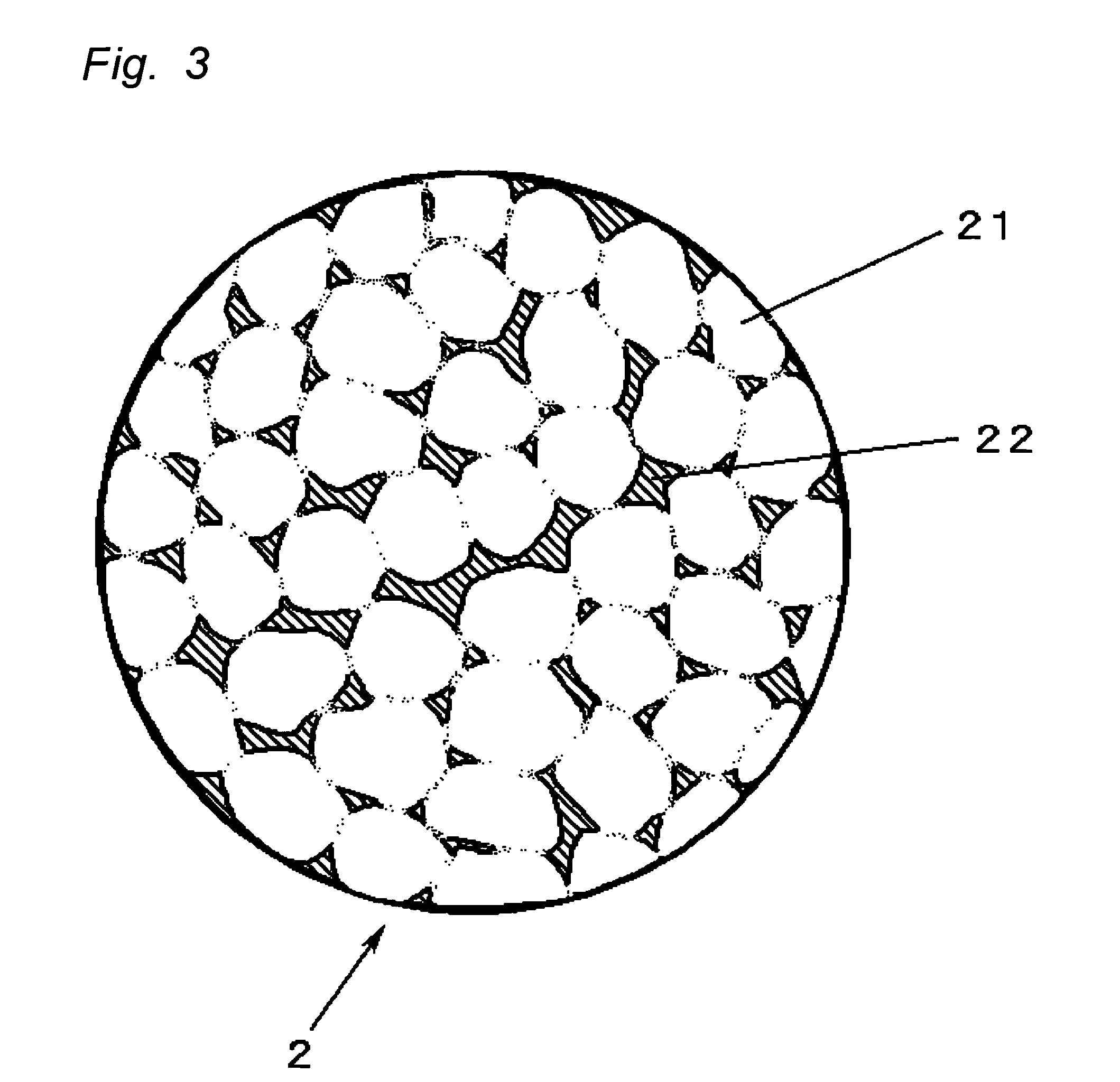

Carpet for vehicles

InactiveUS20080131647A1Sufficient quietnessImprove sound absorptionVehicle arrangementsLayered productsInterior spaceEngineering

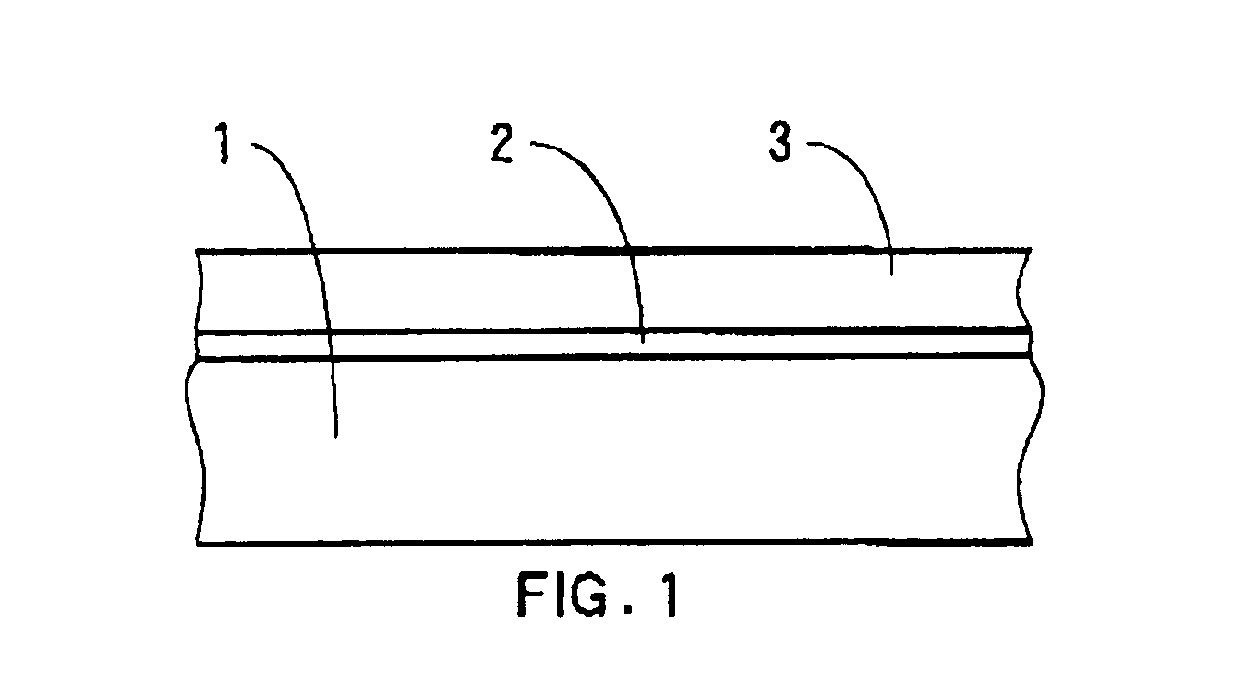

According to one aspect of a preferred embodiment of the present invention, a carpet for vehicles comprises a surface skin layer 2 and a sound absorption layer 3 made of a nonwoven fabric integrally bonded to the surface skin layer 2 via an adhesive resin layer 4. The adhesive resin layer 4 is constituted by an air permeable resin layer formed by melting thermoplastic resin powder having a particle diameter of not smaller than 320 μm but not larger than 1,000 μm. An adhered amount of the thermoplastic resin powder is 180 to 500 g / m2. Air permeability of the entire carpet in a thickness direction thereof is 10 to 26 cm3 / cm2·sec. With this structure, excellent sound absorption performance can be exerted against noise entering into an inside space of a vehicle from the above side, such as, the roof, doors, or windows, as well as noise entering from the lower side.

Owner:SUMINOE TEXTILE CO LTD

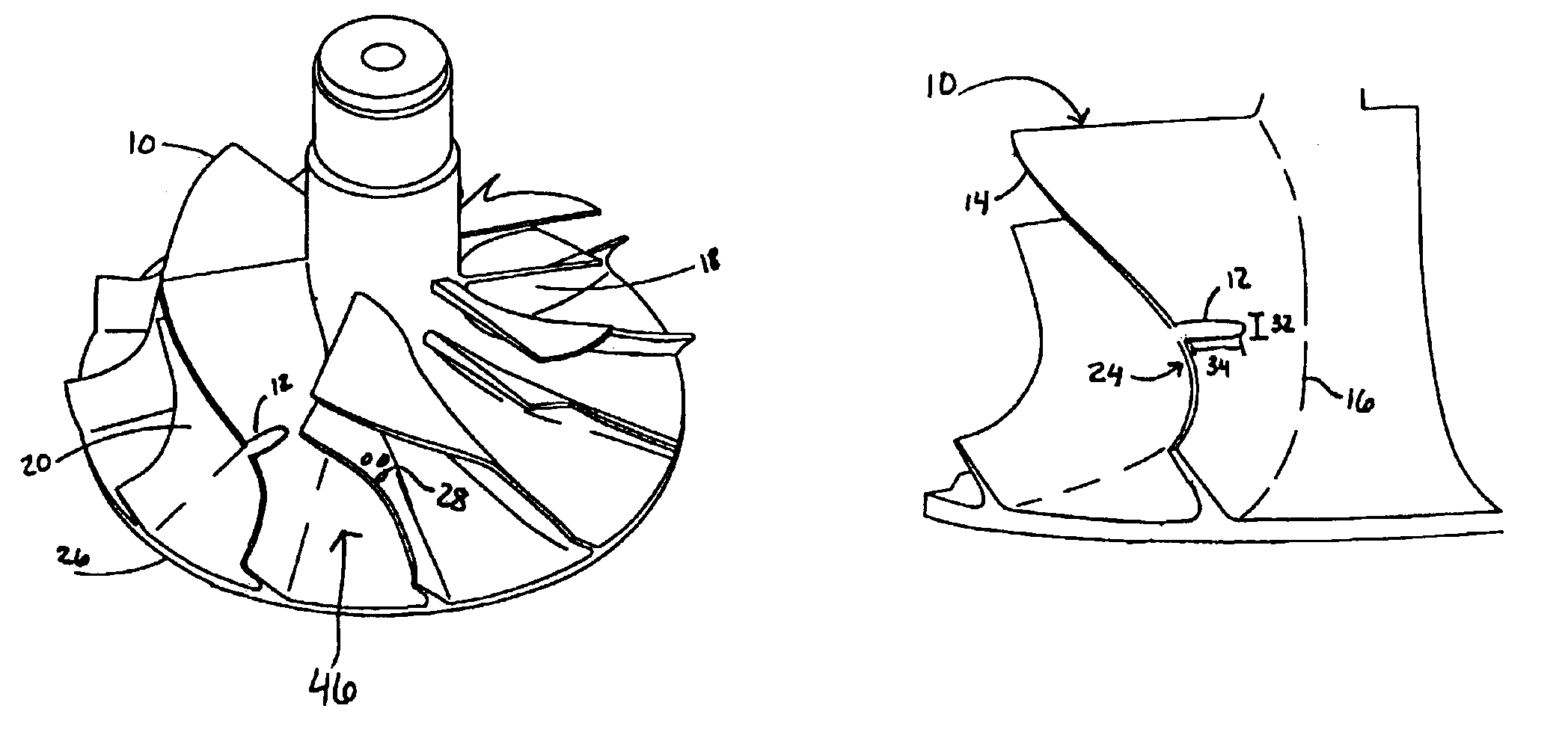

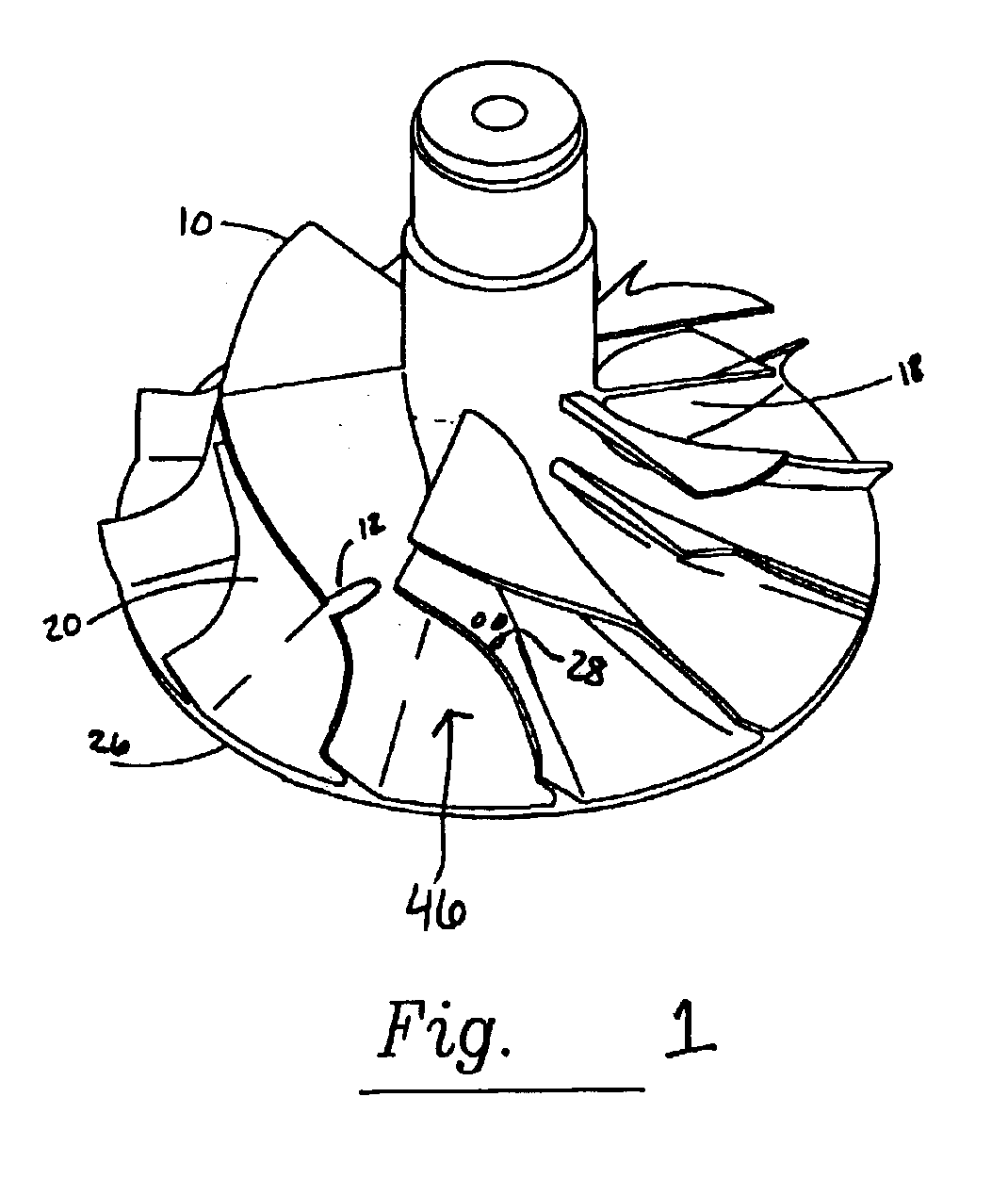

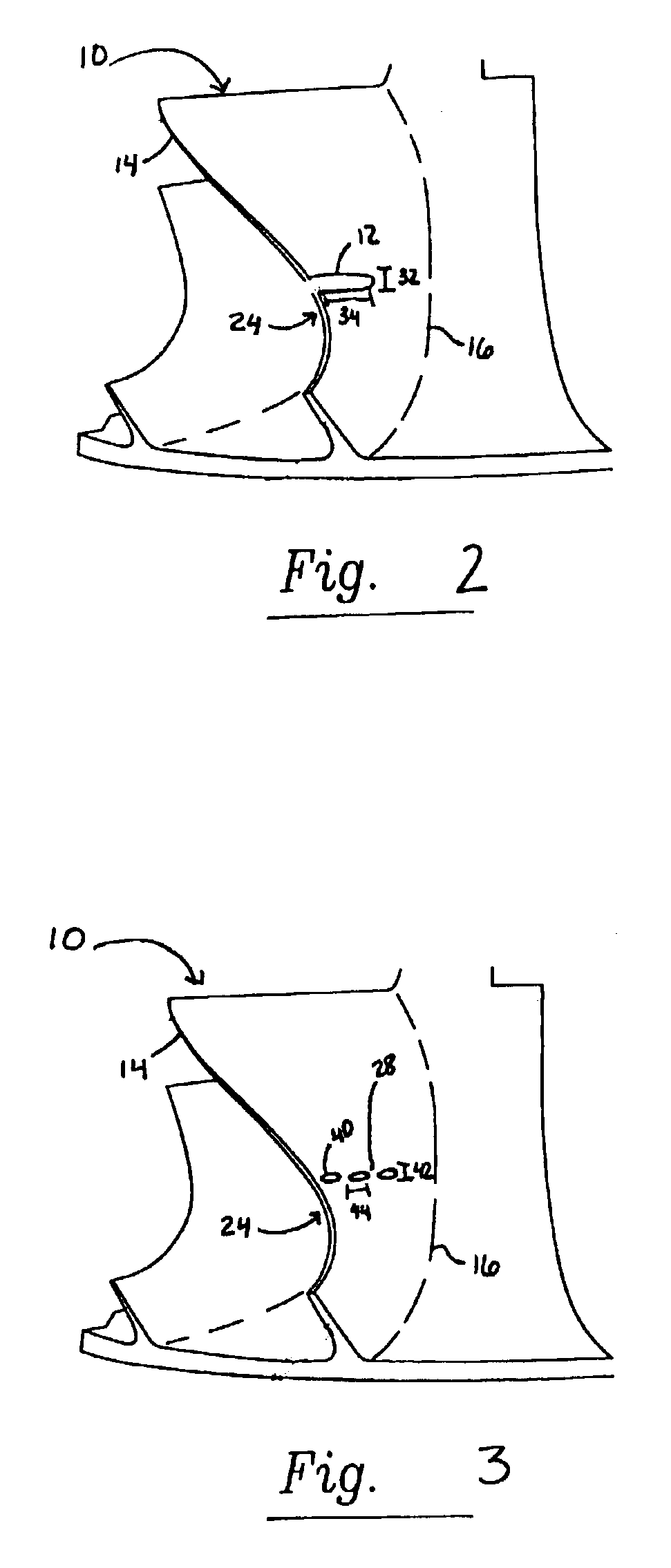

Centrifugal compressor wheel

InactiveUS6860715B2Weaken structural integrityLow efficiencyPump componentsBlade accessoriesMomentumEngineering

As air passes through the airflow channels (46) between the blades (10) of a compressor impeller, boundary layers build up on the blade (10) surfaces. These low momentum masses of air are considered a blockage and loss generators. Ultimately, the boundary layer on the suction side of the blade (20) will separate, causing stall and reversed flow. Reversed flow will occur until a stable pressure ratio with positive volume flow rate is reached. When the pressure ratio becomes unstable again, the cycle will repeat. Introducing a slit (12) or a series of perforations (28) on the compressor wheel blade (10) allows the air to communicate between the pressure side (18) and the suction side (20) of the blade, which allows the boundary layer to stay attached longer. The invention allows for various shapes, positions, lengths and widths, locations, and arrangements of either a slit (12) or a series of perforations (28) on the compressor blade (10) in order to accomplish the objectives of delaying surge conditions by prolonging the boundary layer adherence to the suction side (20) of the compressor blade (10) and of maintaining a low level of noise emission, ease of manufacturing, and structural integrity.

Owner:BORGWARNER INC

Multilayer Film

InactiveUS20110097548A1Improve adhesionAssures adhesionWrappersOrnamental structuresPolymer resinPlasticizer

A multilayered formable packaging film and a method of manufacturing the film are disclosed. The film is suitable for making blisters either by thermoforming or cold forming. The visible surface of the film has unique features preventing counterfeiting, which features are retained on the film even after blister formation. The film has a thickness not exceeding 1050 microns. The film substrate has a 10-500 micron thickness, is devoid of plasticizer and comprises at least one polymeric resin. A coat of an ester acrylic based primer having a 0.1-1 micron thickness is on a first surface of the substrate. A metallized layer with non-uniform thickness between 0.001 to 0.3 micron is deposited on the coat and embossed. A base having a thickness of 50-1000 microns is on the second surface, the base comprising at least one polymeric resin.

Owner:BILCARE

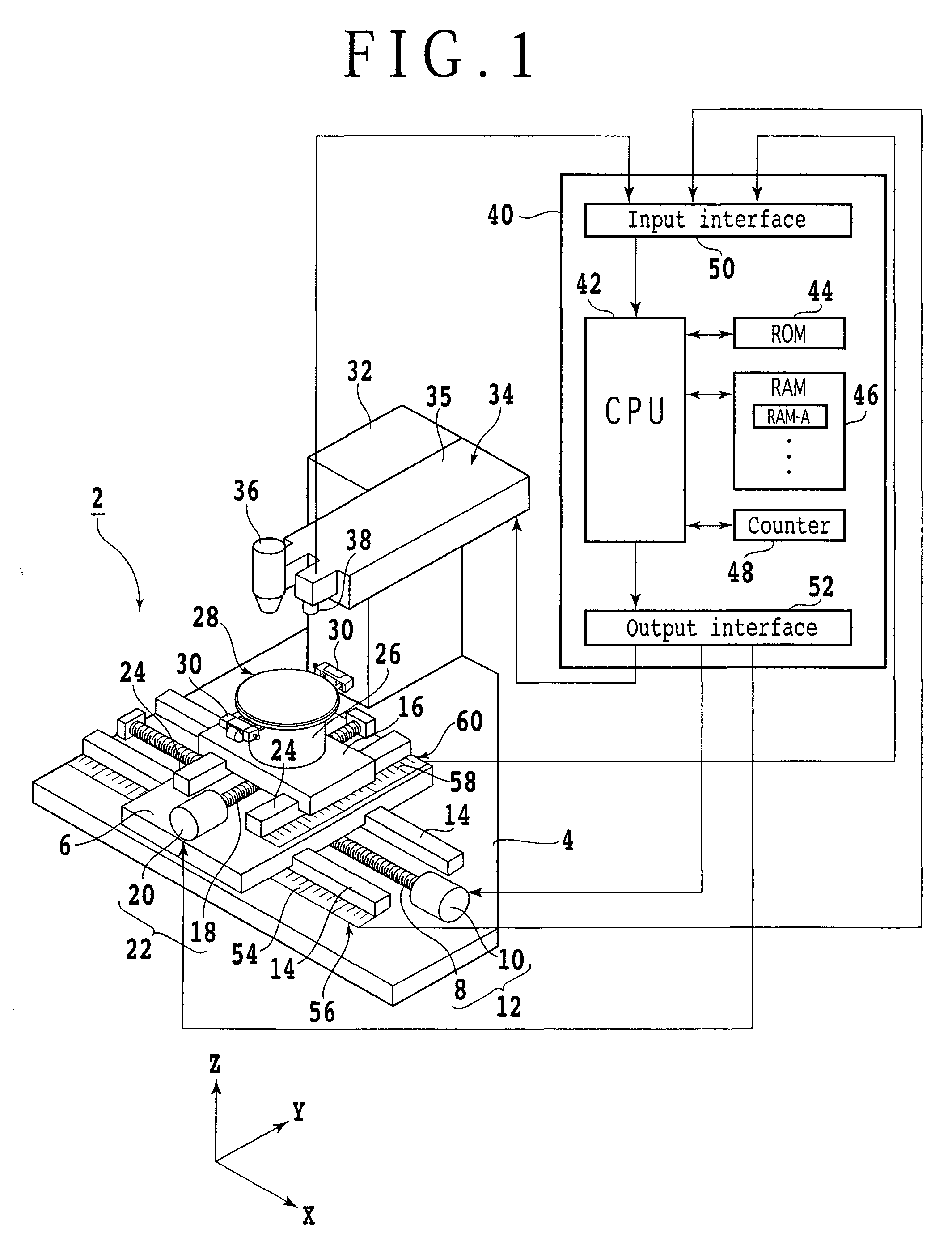

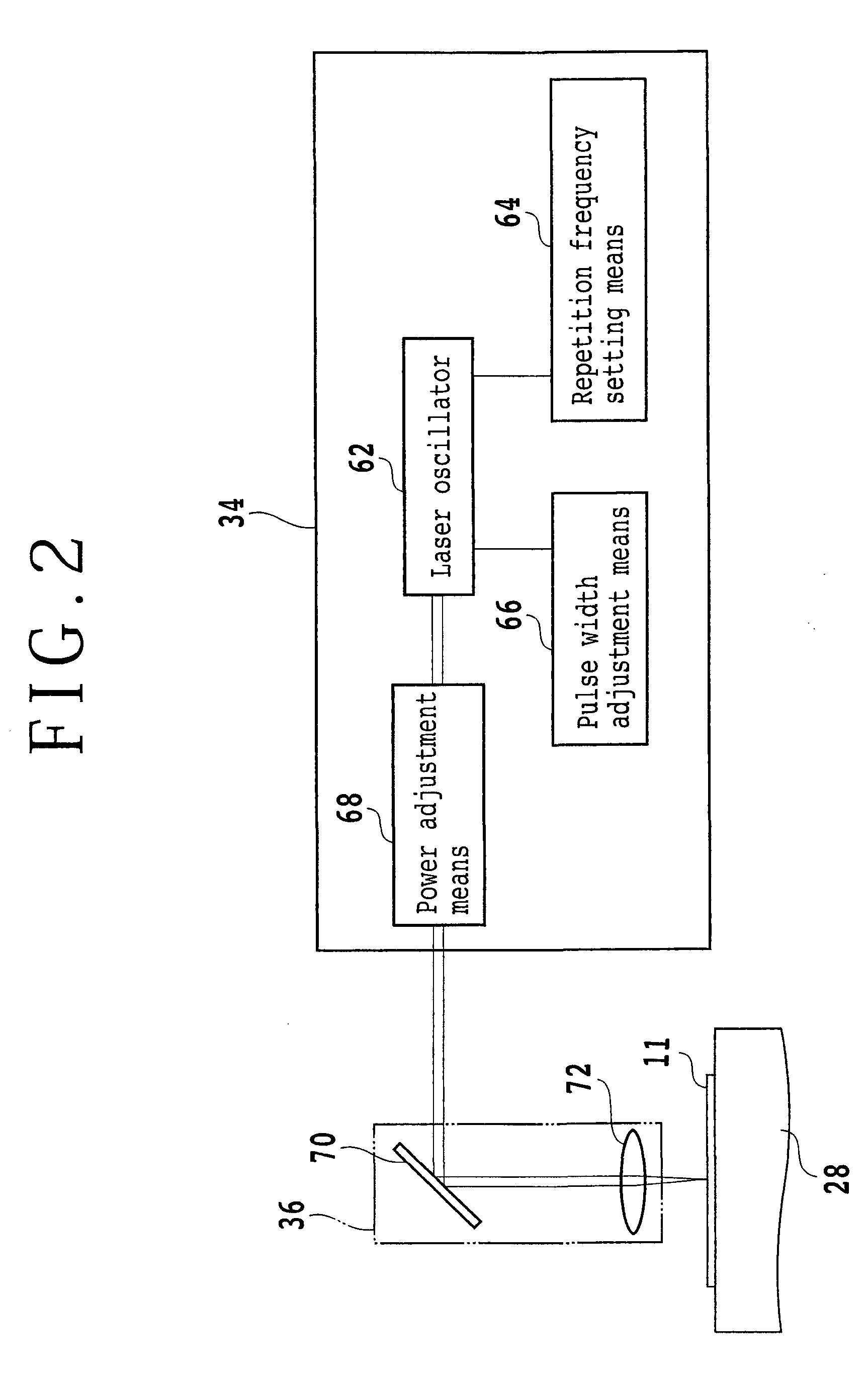

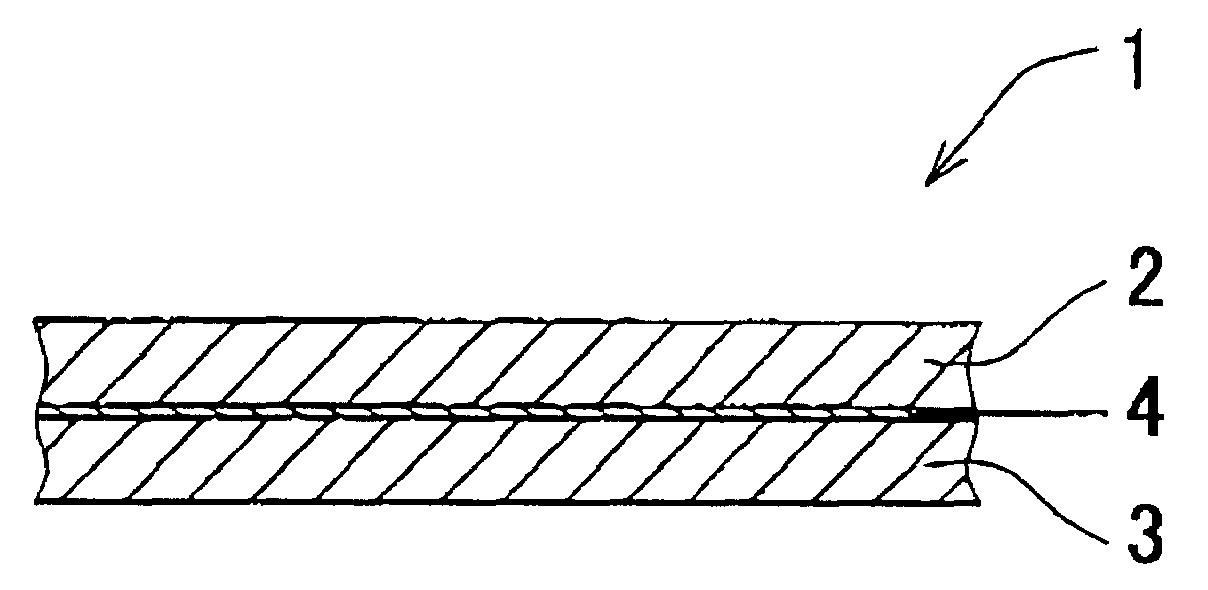

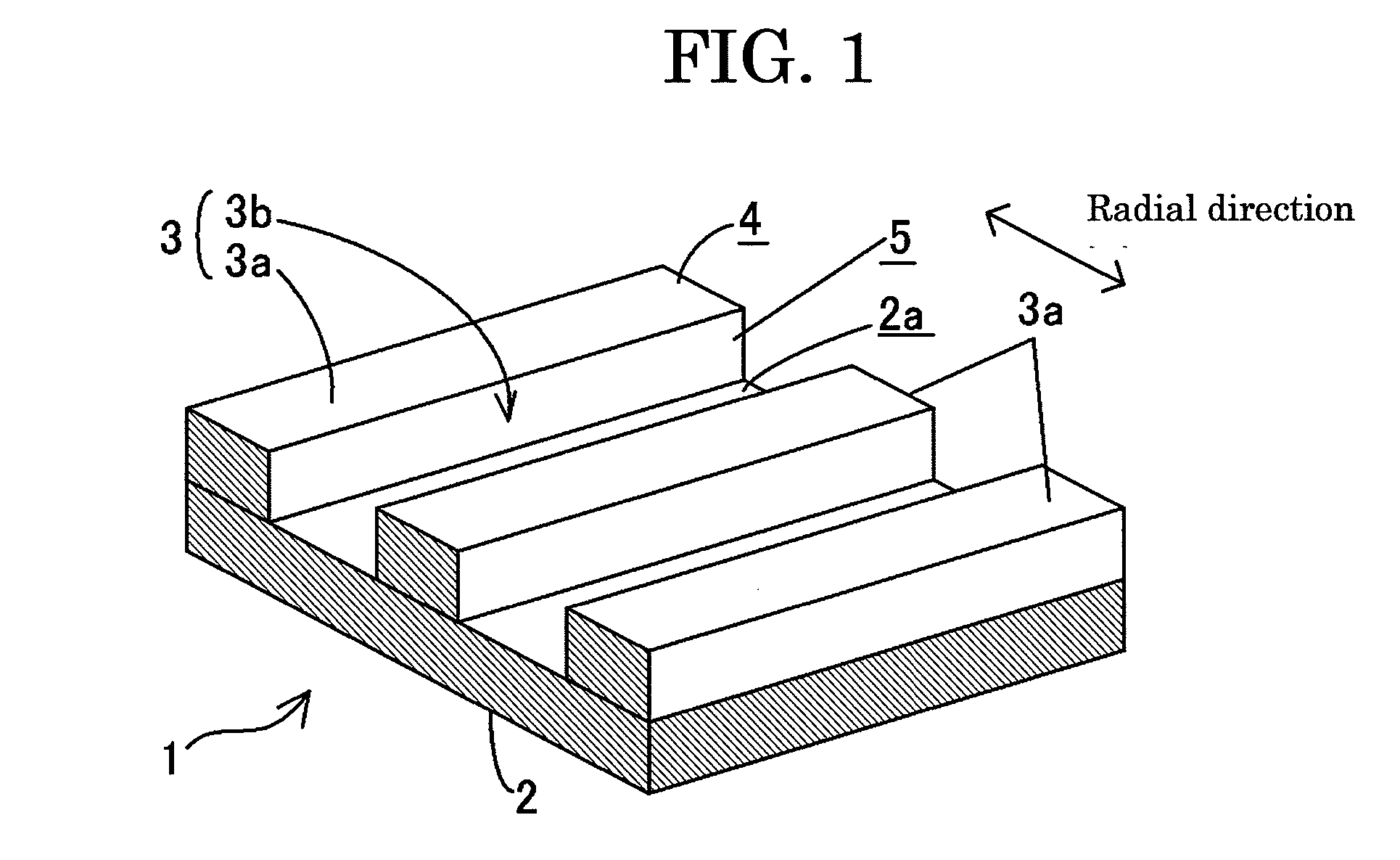

Wafer dividing method

ActiveUS8415234B2Avoid quality lossRule out the possibilitySolid-state devicesSemiconductor/solid-state device manufacturingSplit linesEngineering

Owner:DISCO CORP

Carpet for vehicles

InactiveUS7563498B2Sufficient quietnessImprove sound absorptionVehicle arrangementsLayered productsInterior spaceEngineering

According to one aspect of a preferred embodiment of the present invention, a carpet for vehicles comprises a surface skin layer 2 and a sound absorption layer 3 made of a nonwoven fabric integrally bonded to the surface skin layer 2 via an adhesive resin layer 4. The adhesive resin layer 4 is constituted by an air permeable resin layer formed by melting thermoplastic resin powder having a particle diameter of not smaller than 320 μm but not larger than 1,000 μm. An adhered amount of the thermoplastic resin powder is 180 to 500 g / m2. Air permeability of the entire carpet in a thickness direction thereof is 10 to 26 cm3 / cm2·sec. With this structure, excellent sound absorption performance can be exerted against noise entering into an inside space of a vehicle from the above side, such as, the roof, doors, or windows, as well as noise entering from the lower side.

Owner:SUMINOE TEXTILE CO LTD

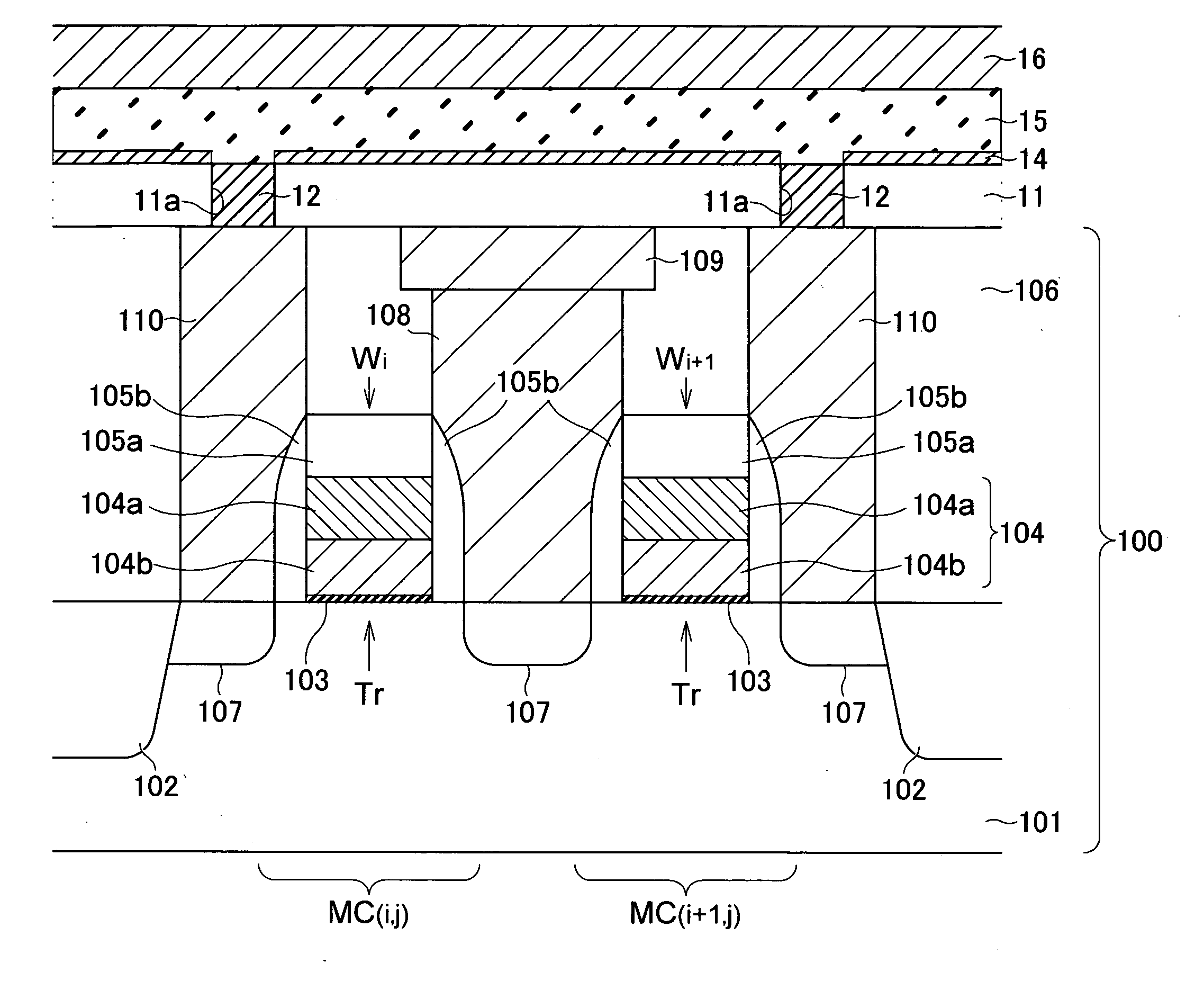

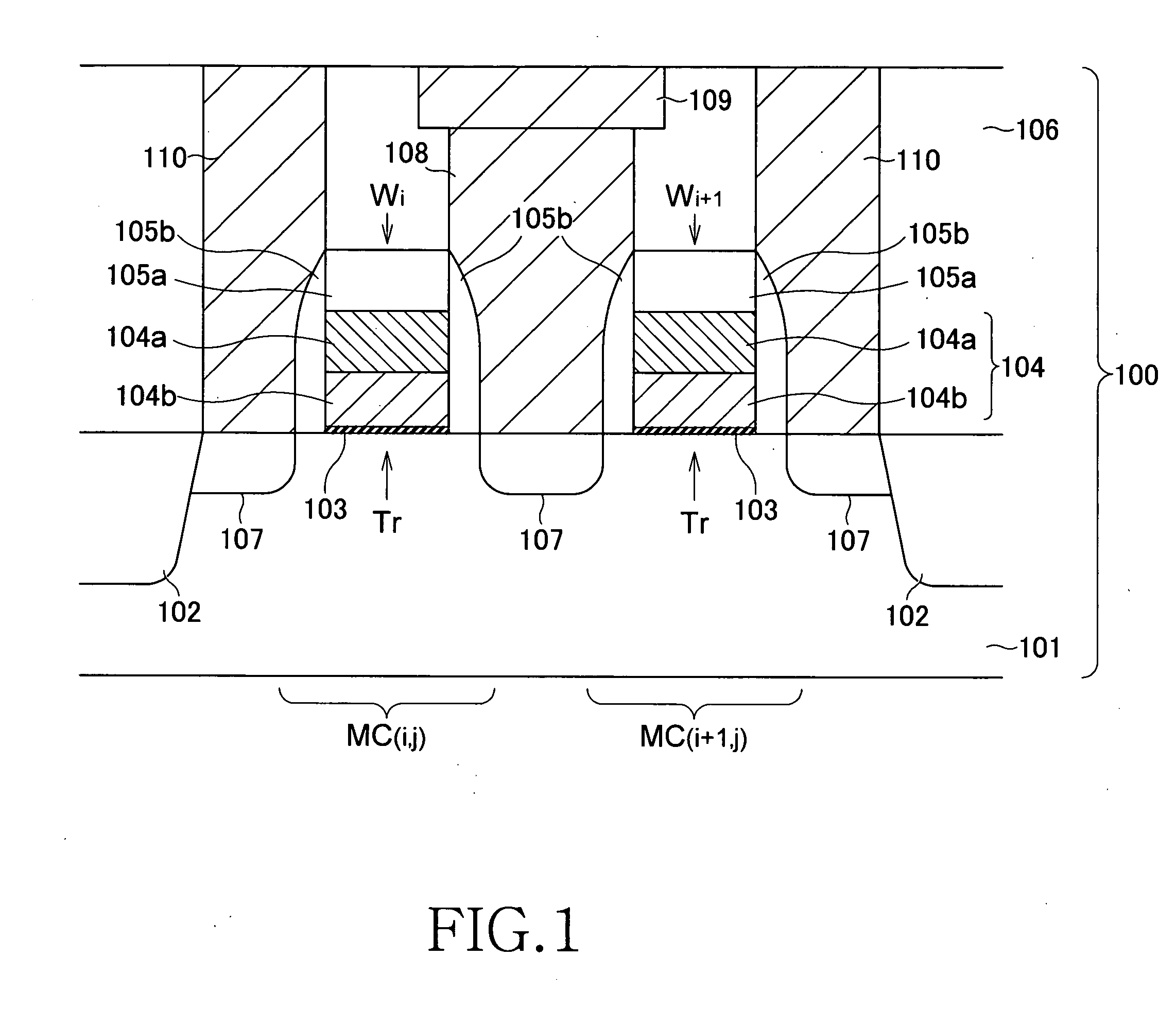

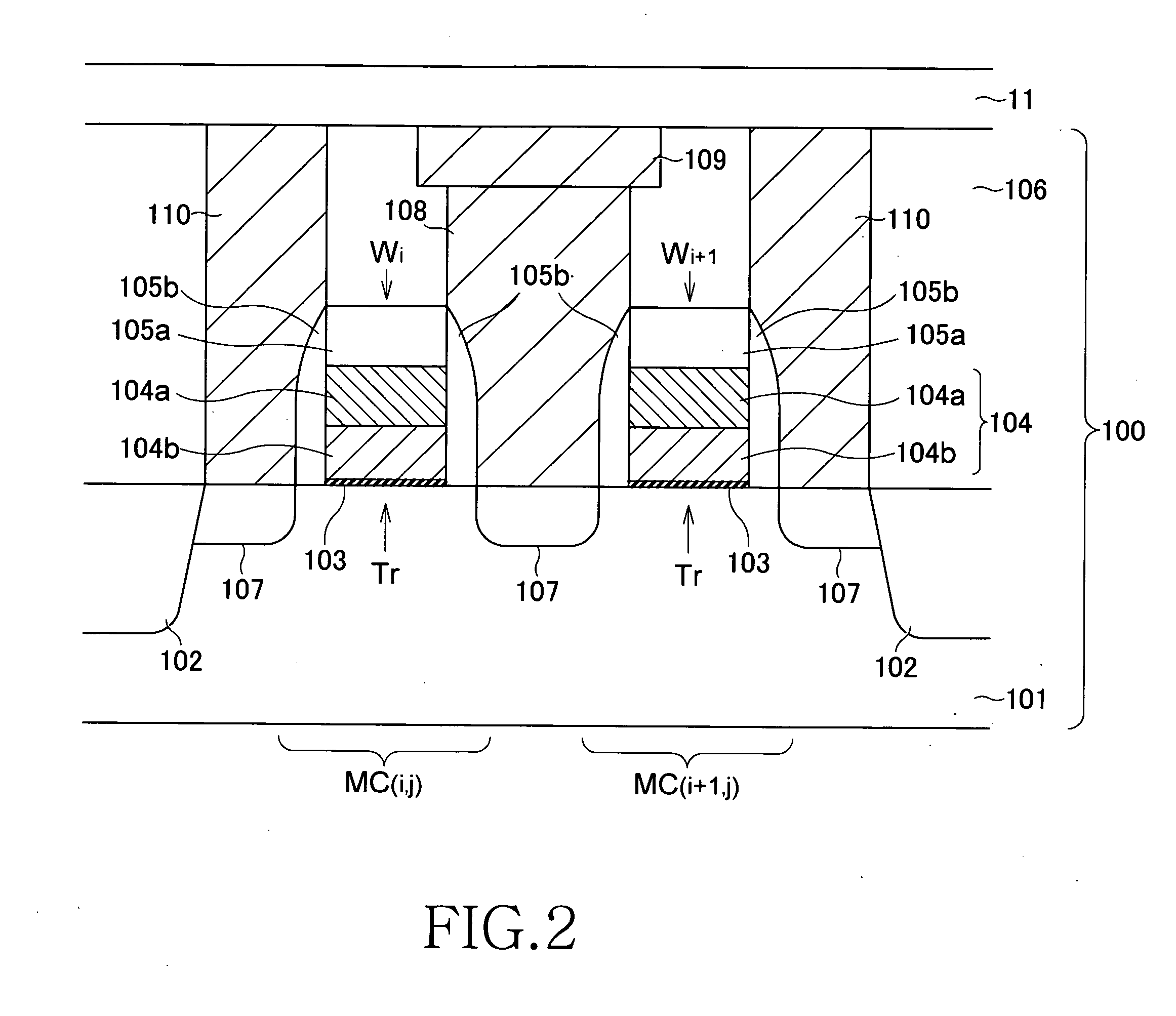

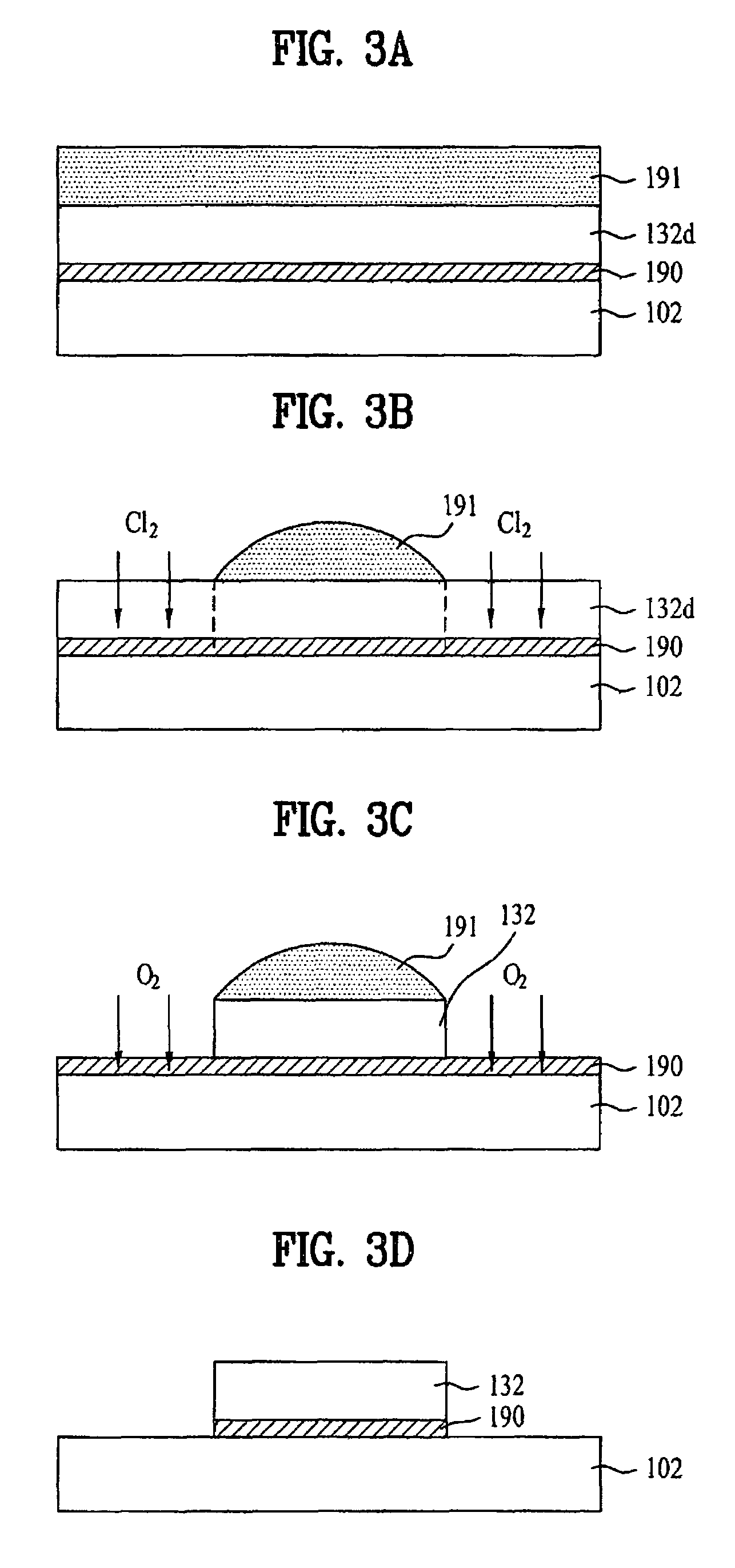

Method of manufacturing non-volatile memory element

InactiveUS20070141786A1Total current dropEffect disappearSolid-state devicesSemiconductor/solid-state device manufacturingElectrical connectionEngineering

A method of manufacturing a non-volatile memory element in the present invention comprises a first step for forming an adhesion layer on an interlayer insulating film so that an electrical connection is established with a lower electrode, a second step for forming a recording layer containing a phase change material on the adhesion layer, a third step for forming an upper electrode that is electrically connected to the recording layer, and a fourth step for diffusing in the recording layer some of the adhesion layer positioned between at least the lower electrode and the recording layer.

Owner:ELPIDA MEMORY INC

Dicing adhesive sheet and dicing method

InactiveUS20050000638A1High peel adhesionSuppress and prevent deformationLamination ancillary operationsSolid-state devicesSemiconductorSilicon

A dicing adhesive sheet having a base film and an adhesive layer formed on the base film is characterized in that the thickness of the adhesive layer ranges from 1 to 10 μm and the adhesive layer has an sticking temperature such that the adhesion measured when 180° peeling at 23° C. of the dicing sheet is conducted (the peeling rate is 300 mm / min) after it is applied to a silicon mirror wafer is 10 N / 25 mm or more. In a dicing method using such a dicing adhesive sheet, the production yield of a diced body such as a semiconductor wafer is high, and chipping the dicing is prevented.

Owner:NITTO DENKO CORP

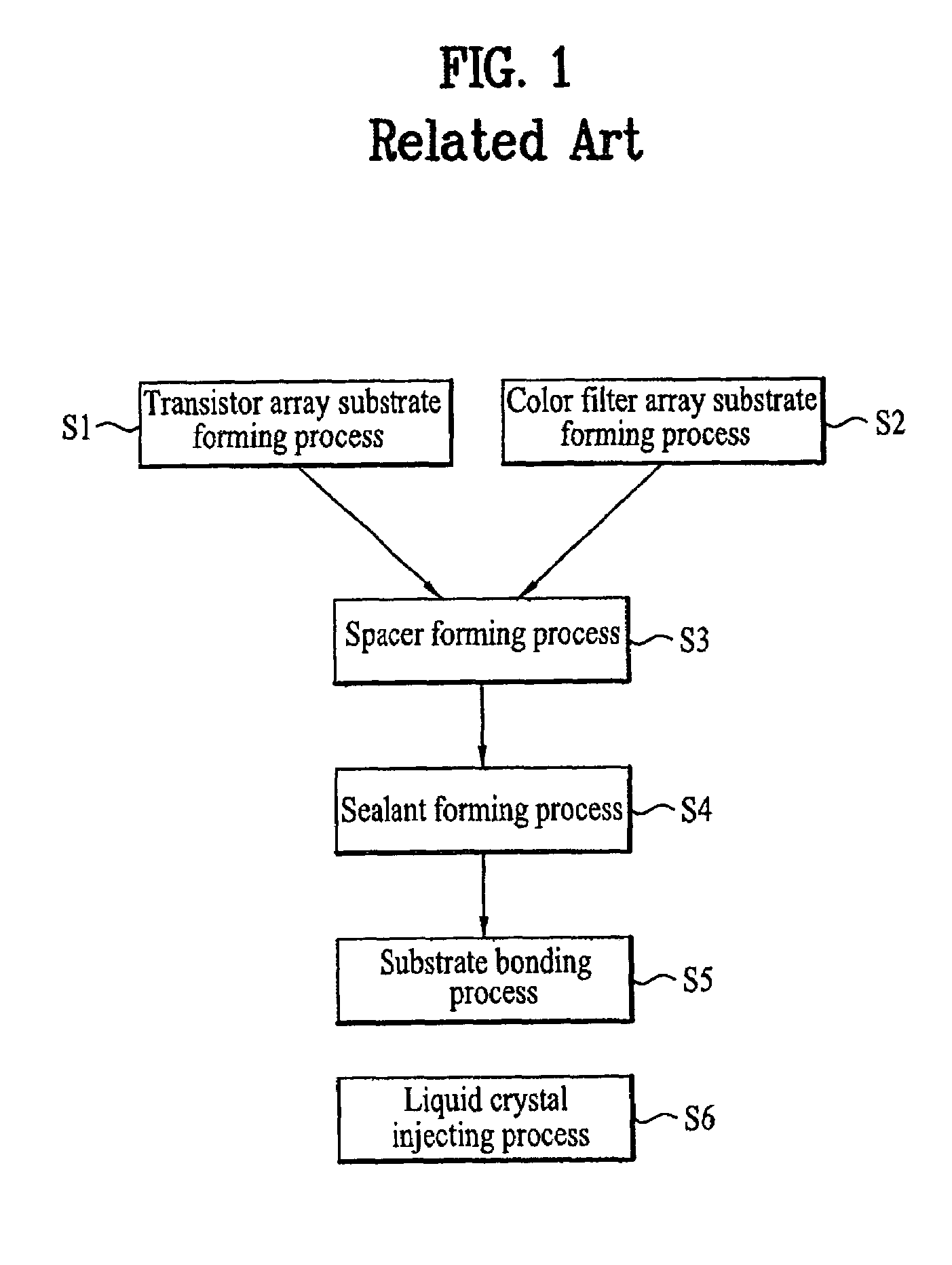

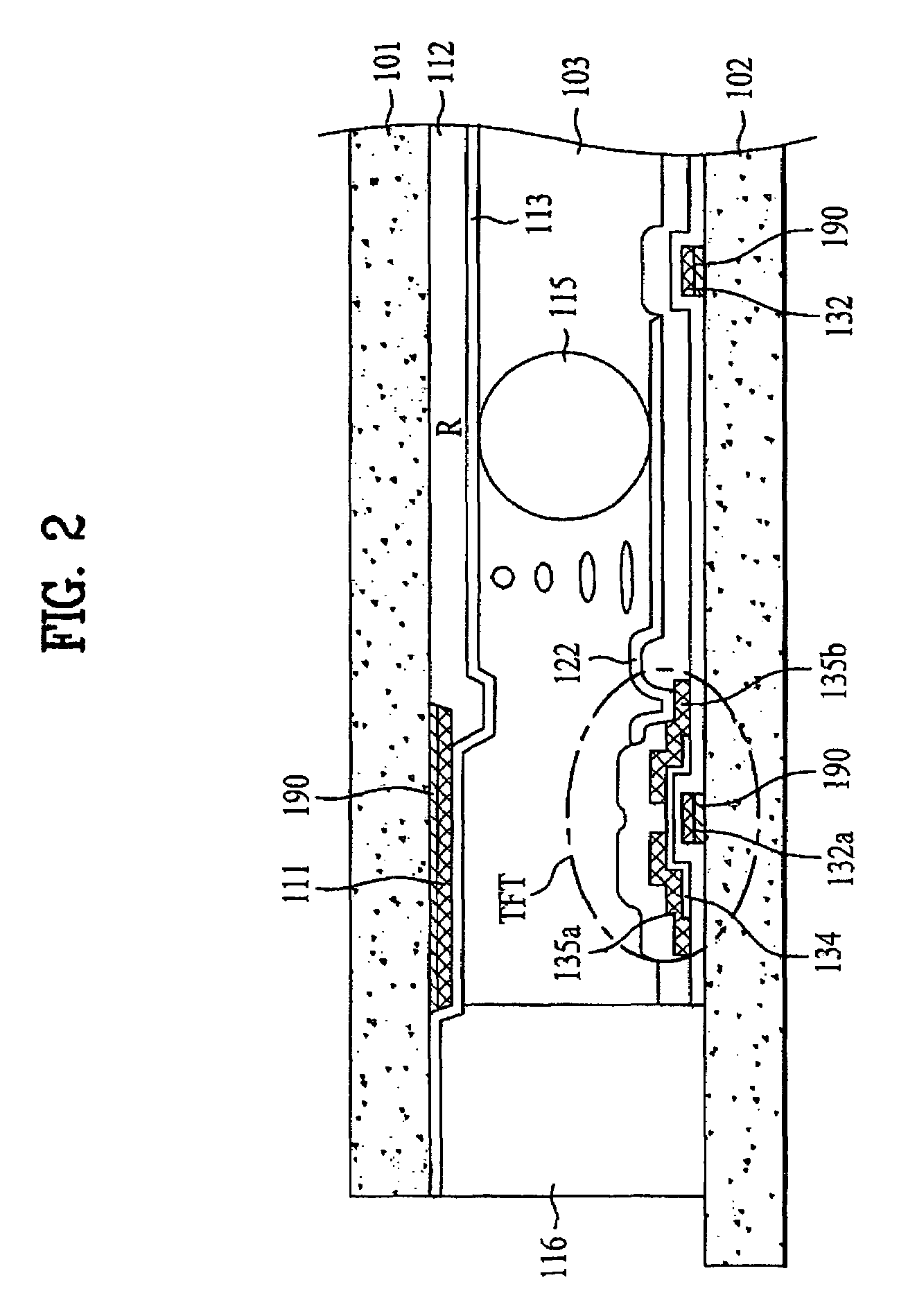

Liquid crystal display device and method for manufacturing the same

ActiveUS7501163B2Reduce generationImprove equipment reliabilityLiquid crystal compositionsPhotosensitive materialsPolymer adhesiveLiquid-crystal display

A liquid crystal display device having a polymer adhesive layer interposed between a substrate and a pattern or between one pattern and another pattern, and a method for manufacturing the same are disclosed. The polymer adhesive layer is interposed where peeling problems occur. The polymer adhesive layer reduces process errors and improves reliability. The device includes: a first substrate; gate lines, data lines, TFTs, and pixel electrodes on a surface of the first substrate; a second substrate bonded to the first substrate; a liquid crystal layer between the first and second substrates; a black matrix layer and a color filter layer on a surface of the second substrate; a sealant formed along an edge of a substrate that bonds the first and second substrates to each other; spacers that maintain a cell gap between the first and second substrates; and a polymer adhesive layer that improves adhesive characteristics.

Owner:LG DISPLAY CO LTD

Film for semiconductor device production, method for producing film for semiconductor device production, and method for semiconductor device production

The present invention relates to a film for semiconductor device production, which includes: a separator; and a plurality of adhesive layer-attached dicing tapes each including a dicing tape and an adhesive layer laminated on the dicing tape, which are laminated on the separator at a predetermined interval in such a manner that the adhesive layer attaches to the separator, in which the separator has a cut formed along the outer periphery of the dicing tape, and the depth of the cut is at most ⅔ of the thickness of the separator.

Owner:NITTO DENKO CORP

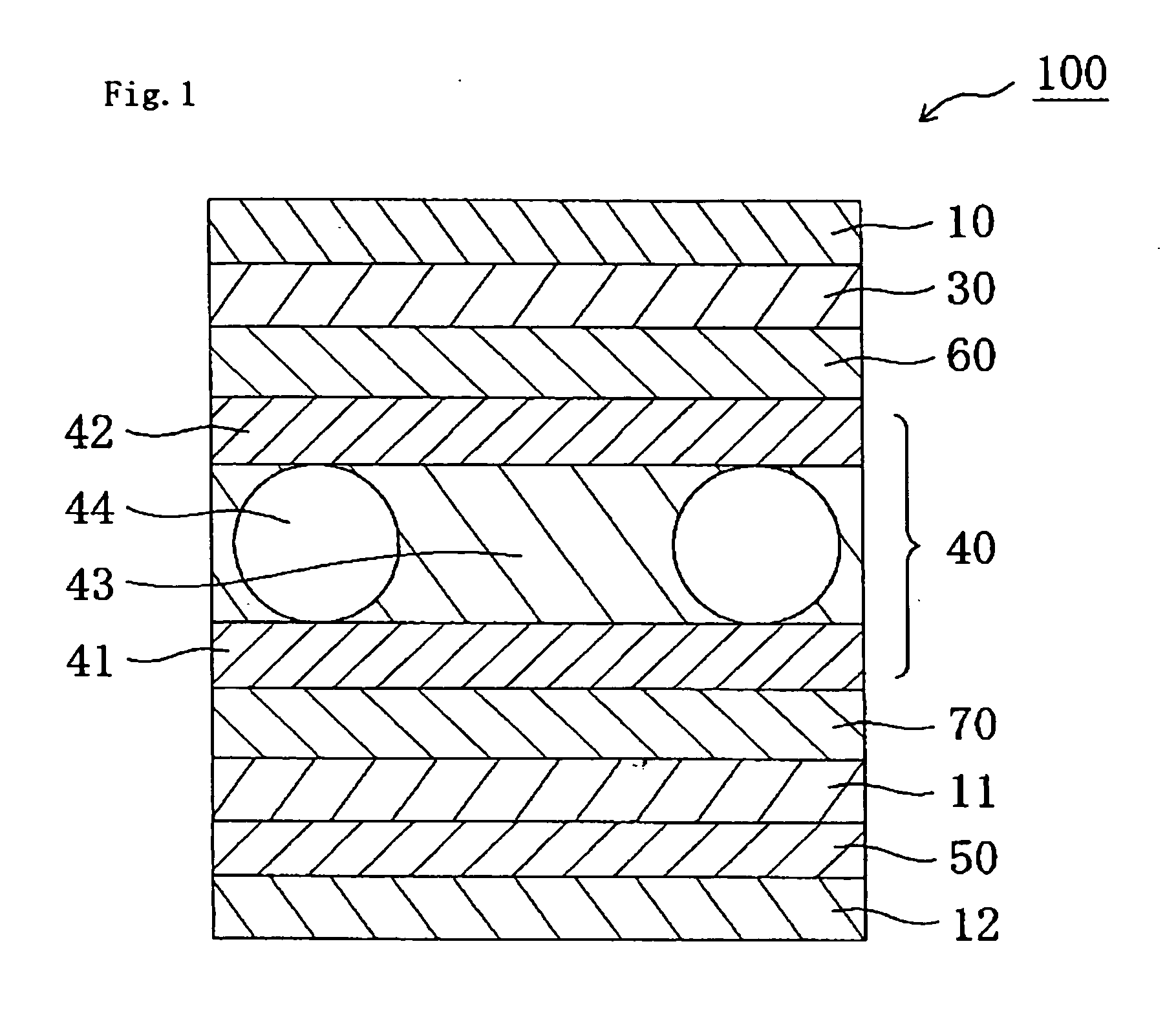

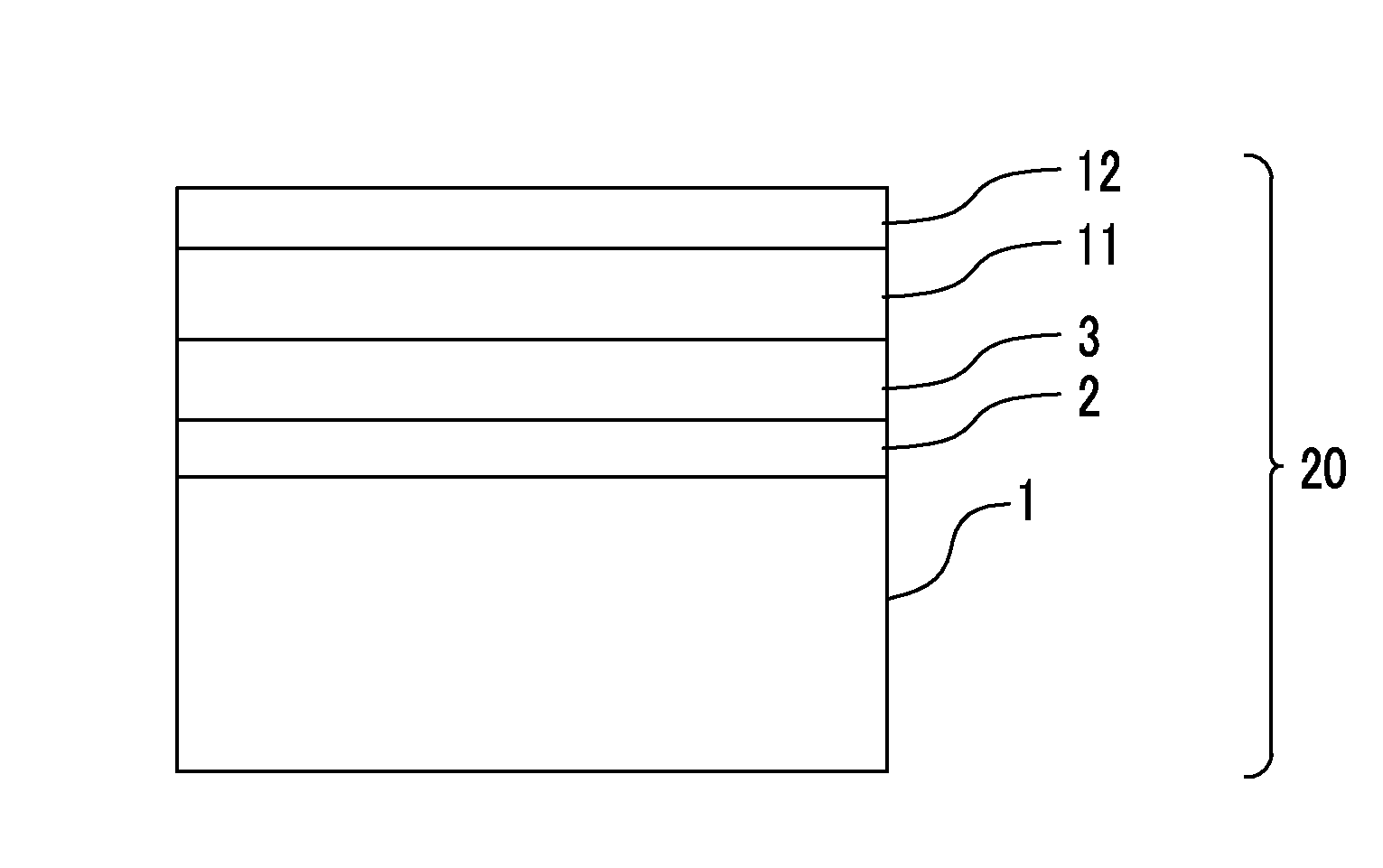

Liquid crystal panel and liquid crystal display device

ActiveUS20180157111A1Inhomogeneous suppressionImprove adhesionPolarising elementsNon-linear opticsLiquid-crystal displayStress relaxation

The liquid crystal panel has a front-surface plate, a front-side polarizing plate, a liquid crystal display element, and a rear-side polarizing plate in an integrally laminated state, in which the front-surface plate and the front-side polarizing plate are in the state of being laminated with each other via an adhesive layer having a thickness of 2 μm or more, and the liquid crystal panel satisfies Formula A-1: 2020>ECp×dCp×εCp×(100−P)+(Ef×df×εf)−(Er×dr×εr)>0 (ECp is the modulus of elasticity, dCp is the thickness, and εCp is the humidity dimensional change rate, of the front-surface plate, Ef is the modulus of elasticity, df is the thickness, and εf is the humidity dimensional change rate, of the front-side polarizing plate, Er is the modulus of elasticity, dr is the thickness, and εr is the humidity dimensional change rate, of the rear-side polarizing plate, P is the stress relaxation rate of the adhesive layer).

Owner:FUJIFILM CORP

Adhesive sheet for water jet laser dicing

InactiveUS20090311474A1Smooth penetrationAvoid precisionFilm/foil adhesivesLayered productsFiberEngineering

An object of the present invention is to provide an adhesive sheet which, through improvement in the permeability of liquids originating in a liquid stream during water jet laser dicing, allows chips, IC components, or the like to be detached, prevents machining precision from being compromised such as by chipping or the scattering of chips and the like, and allows extremely thin semiconductor wafers or materials to be processed. The adhesive sheet for water jet laser dicing of the present invention comprises an adhesive layer laminated on a base film, the base film made of mesh fiber.

Owner:NITTO DENKO CORP

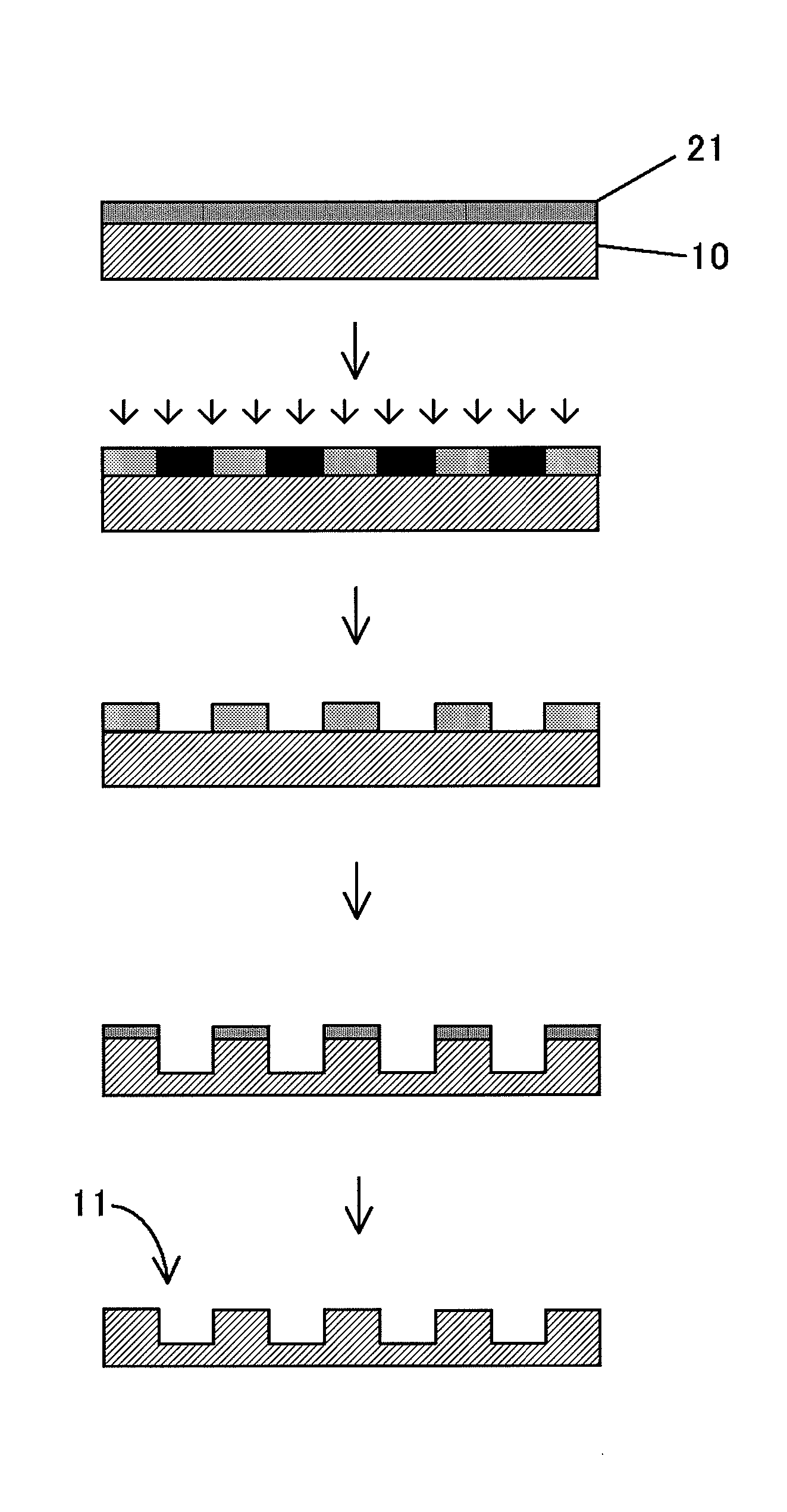

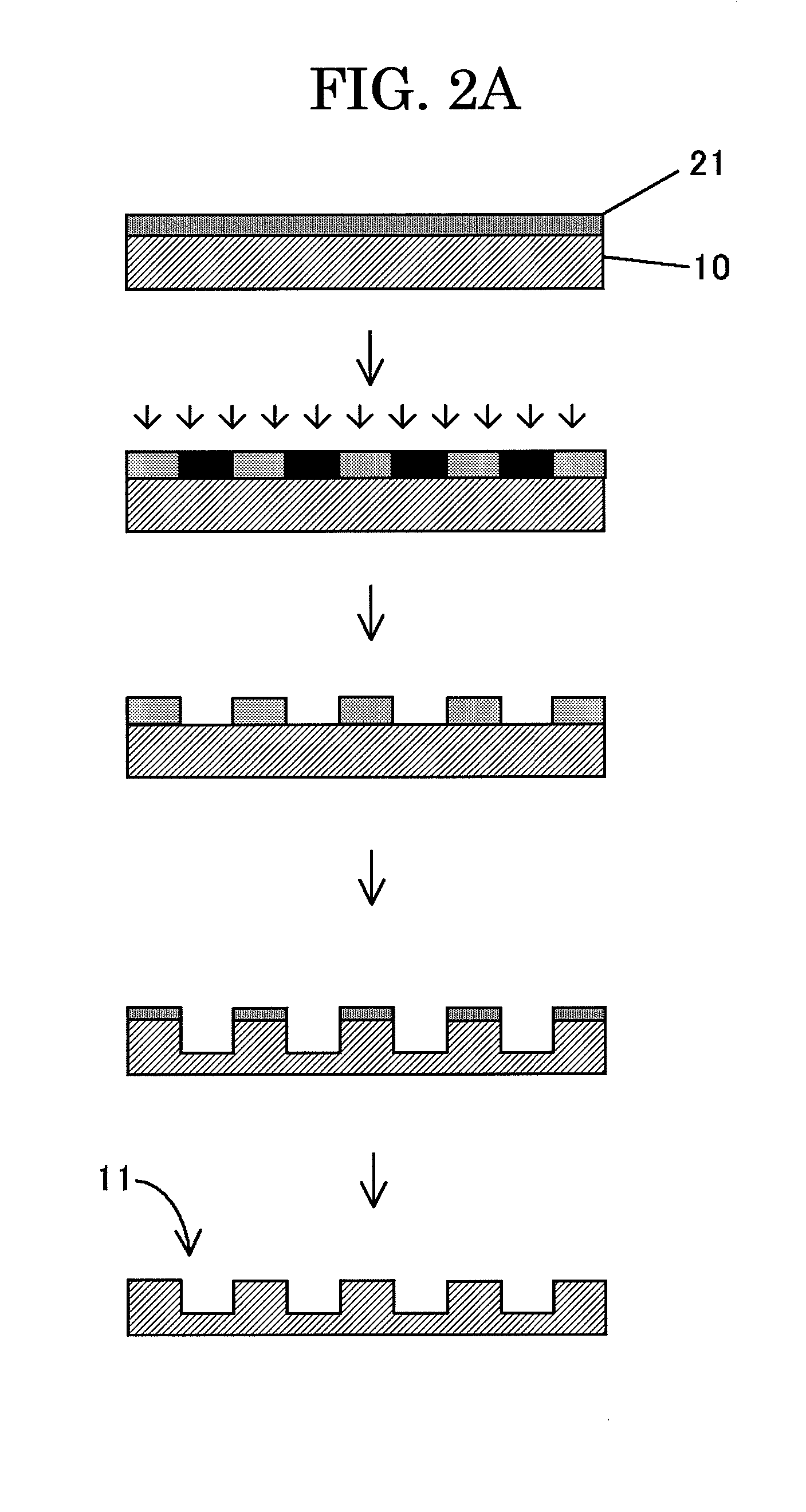

Mold structure, imprinting method using the same, magnetic recording medium and production method thereof

InactiveUS20080248334A1Improve transmission qualityEasy to separateNanoinformaticsPhotomechanical apparatusResistPatterned media

To provide a mold structure which is excellent in the transfer quality of a pattern to a substrate and superior in its separability from an imprint resist layer and which allows a high-quality pattern to be transferred and formed on discrete track media and patterned media. Specifically, there is a mold structure including: convex portions and concave portions formed on its surface, wherein the mold structure is used for transferring a concavo-convex pattern onto an imprint resist layer formed on a surface of a substrate having a thickness of 0.3 mm to 2.0 mm by pressing the convex portions and the concave portions against the imprint resist layer, and wherein a ten-point average roughness Rz1 of apical portions of the convex portions and a ten-point average roughness Rz2 of bottom portions of the concave portions are in the range of 0.5 nm to 20 nm each.

Owner:FUJIFILM CORP

Dicing adhesive sheet and dicing method

InactiveUS7183007B2High peel adhesionSuppress and prevent deformationPaper/cardboard articlesSolid-state devicesSiliconSemiconductor

A dicing adhesive sheet having a base film and an adhesive layer formed on the base film is characterized in that the thickness of the adhesive layer ranges from 1 to 10 μm and the adhesive layer has an sticking temperature such that the adhesion measured when 180° peeling at 23° C. of the dicing sheet is conducted (the peeling rate is 300 mm / min) after it is applied to a silicon mirror wafer is 10 N / 25 mm or more. In a dicing method using such a dicing adhesive sheet, the production yield of a diced body such as a semiconductor wafer is high, and chipping the dicing is prevented.

Owner:NITTO DENKO CORP

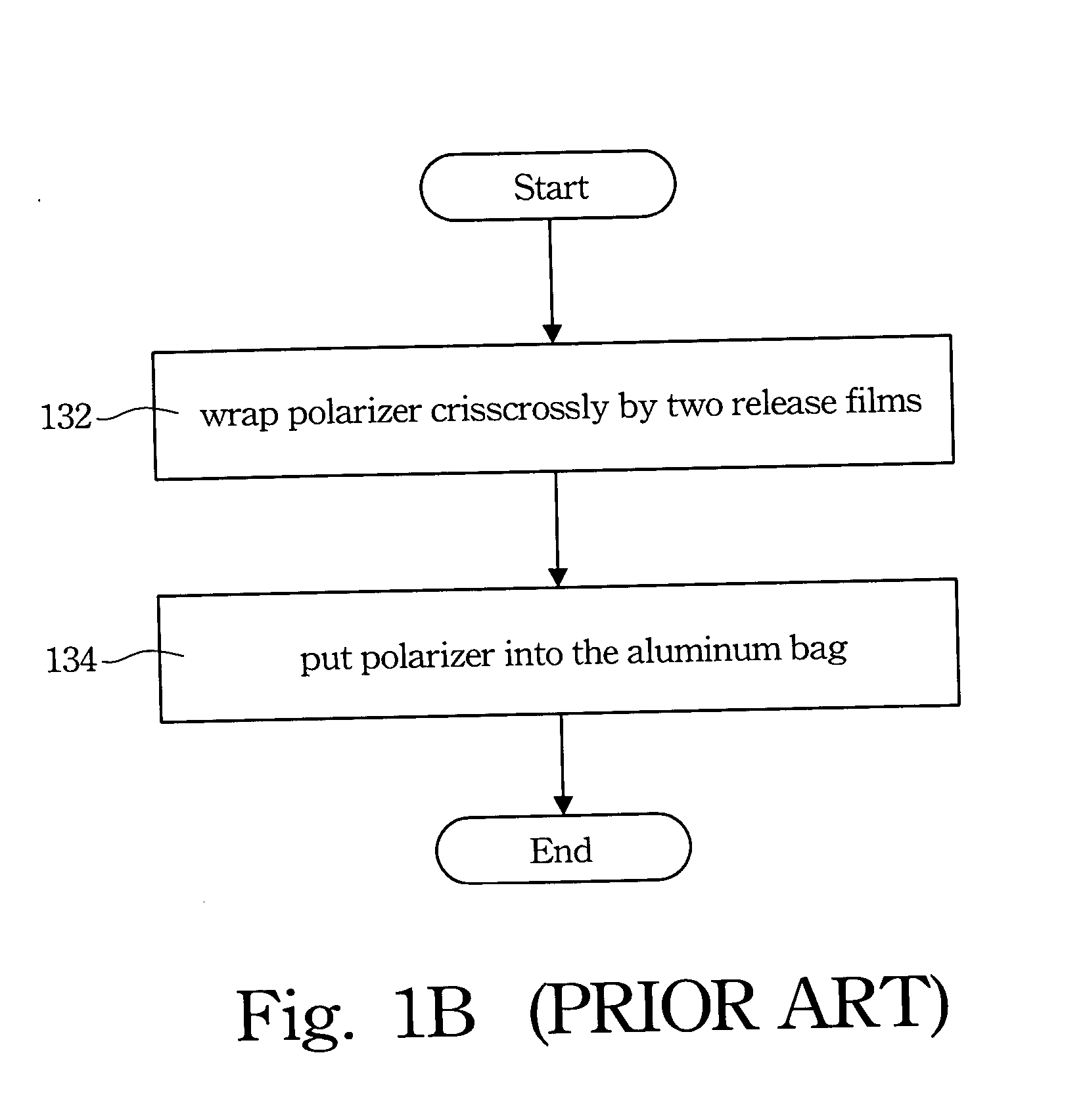

Packaging for an optical sheet and a packaging method of the same

InactiveUS20050145524A1Reduce in quantityReduce material costsOther accessoriesContainer/bottle contructionPolyethylene terephthalateEngineering

An optical sheet having an adhesive layer is wrapped by a first packaging component of which the material includes a plastic base mixed with silicone. A second packaging component then wraps the first packaging component, and the second packaging component is opaque. The plastic base can be polyethylene or polyethylene terephthalate, and the weight percent of the silicone to the plastic base is less than 5, preferably less than 3.

Owner:OPTIMAX TECHNOLOGY CORPORATION

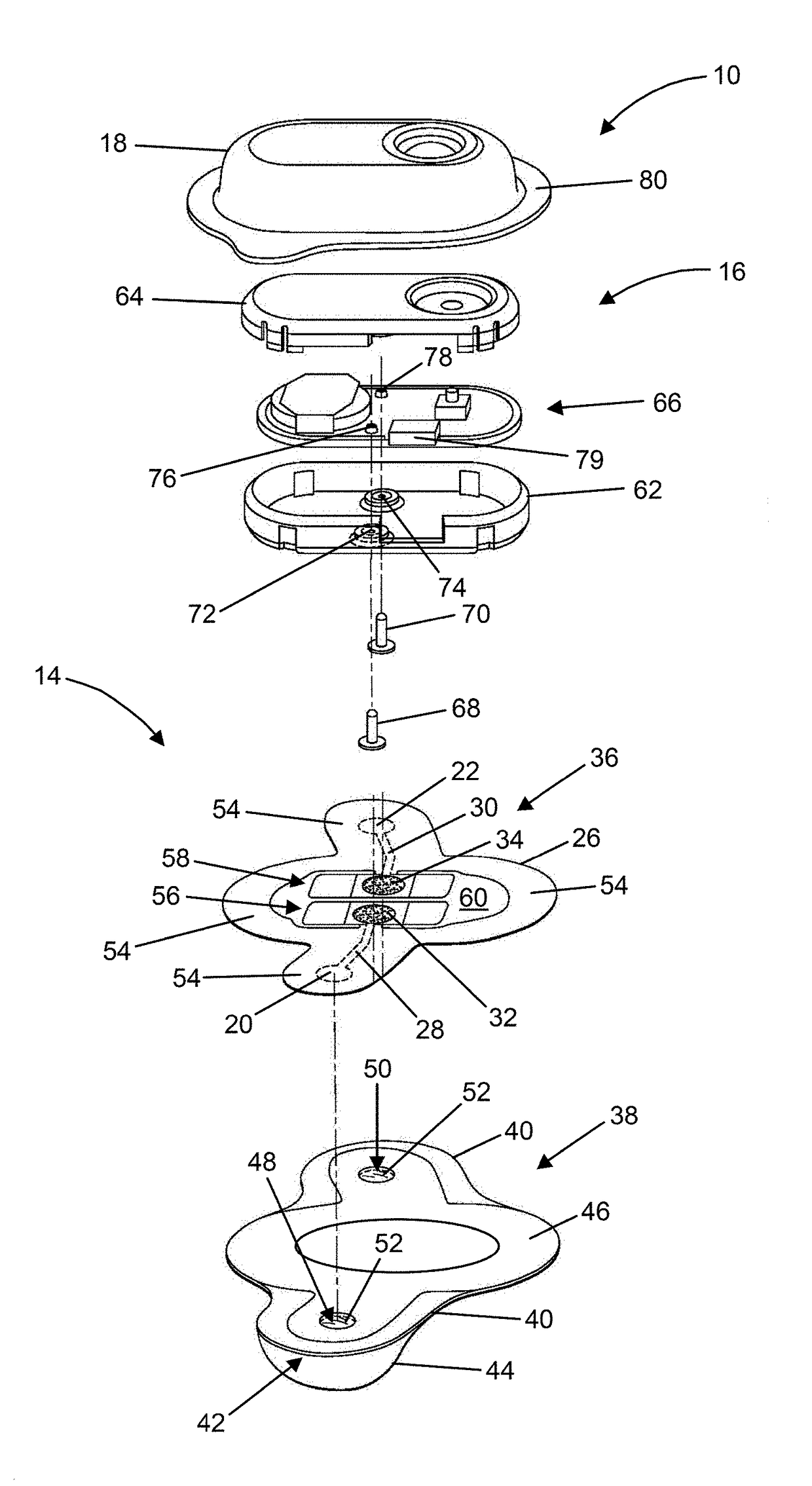

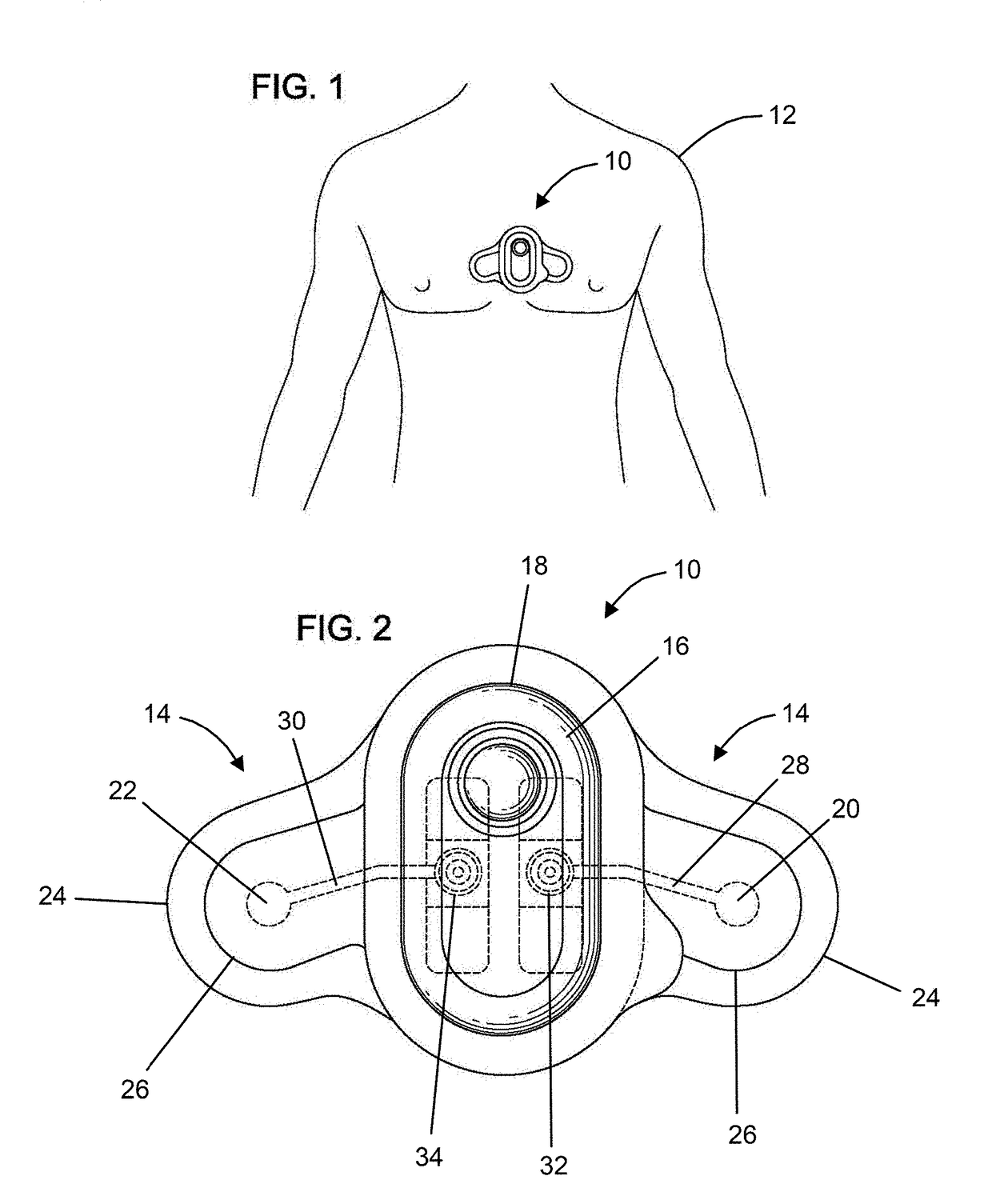

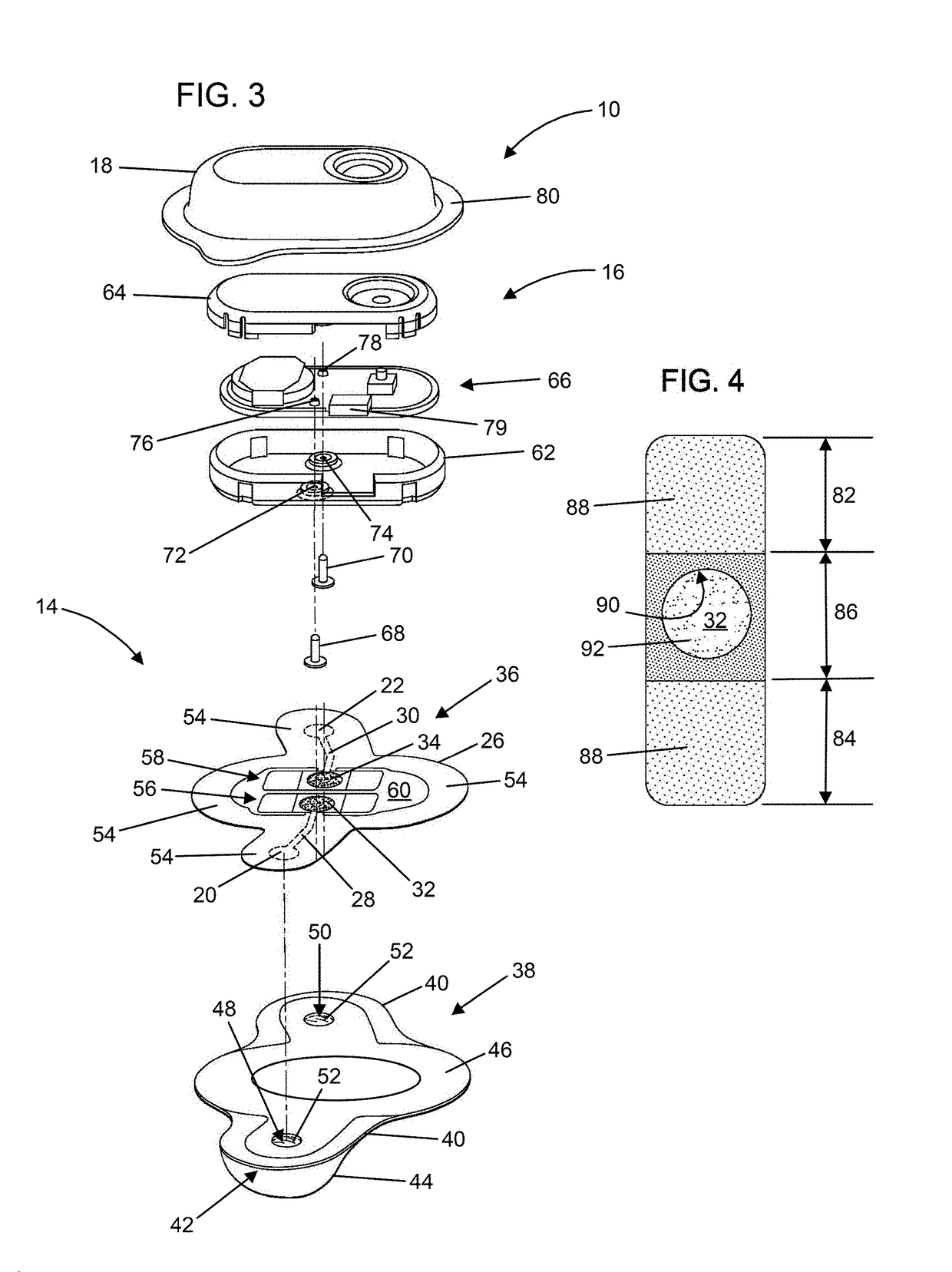

Ambulatory monitor with conductive adhesive and related methods

InactiveUS20180125387A1Inhibit electrical shortingAdhesive layerElectrocardiographySensorsEngineeringData recording

Ambulatory monitors and related methods employ an adhesive layer with conductive and non-conductive regions to improve electrical isolation of electrodes. An ambulatory monitor includes a biocompatible layer, first and second electrodes, an adhesive layer, and a physiological data recording module. The adhesive layer is interfaced with the biocompatible layer and configured to adhere the biocompatible layer to the user's skin. The adhesive layer has a first conductive adhesive region comprising a conductive adhesive electrically coupled with the first electrode, a second conductive adhesive region comprising a conductive adhesive electrically coupled with the second electrode, and a non-conductive adhesive region comprising a non-conductive adhesive. The non-conductive adhesive region serves as an electrical insulator between the first conductive adhesive region and the second conductive adhesive region. The physiological data recording module is configured to store physiological data of the user generated from an electrical signal from the first and second electrodes.

Owner:CARDIAC INSIGHT

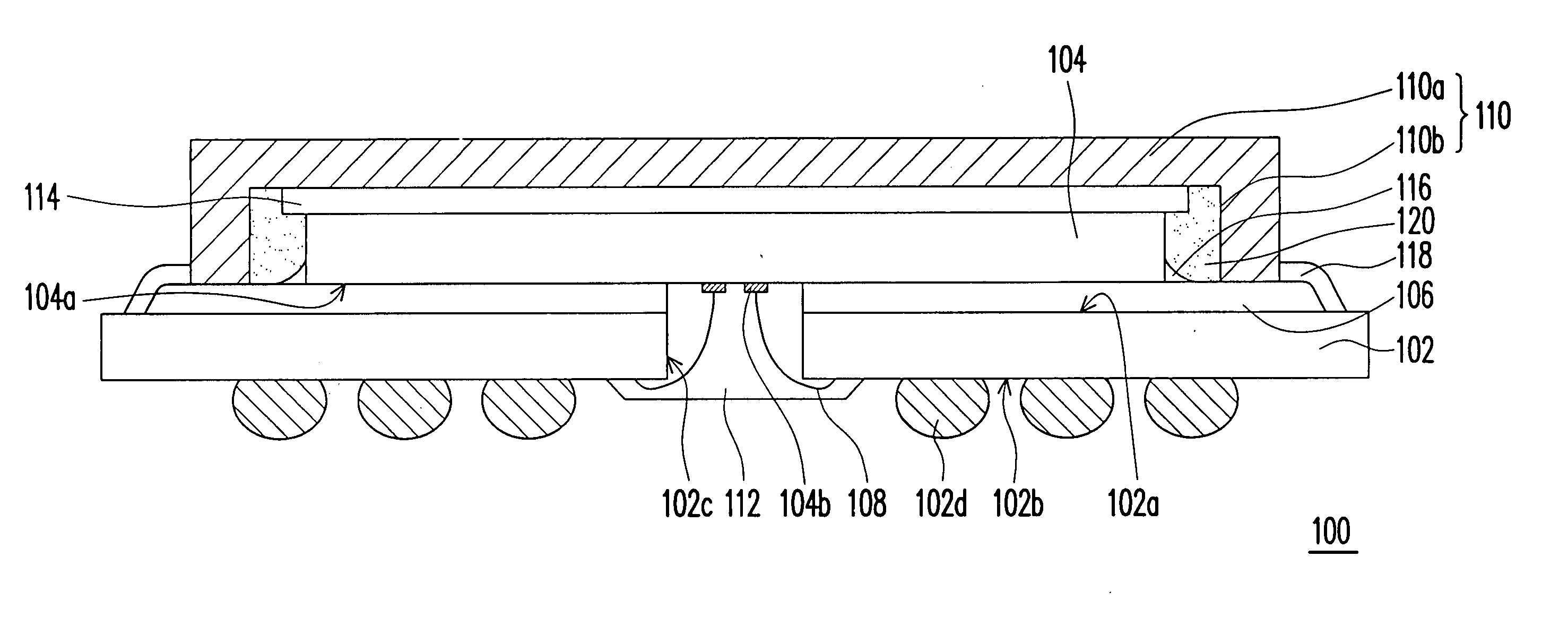

Chip package structure

InactiveUS20070045835A1Improve yield rateFacilitate heat dissipationSemiconductor/solid-state device detailsSolid-state devicesAdhesiveEngineering

A chip package structure includes a substrate, a chip, a first B-stage adhesive, bonding wires, a heat sink and a molding compound. The substrate comprises a first surface, a second surface and a through hole. The chip is arranged on the first surface of the substrate and electrically connected thereto while the through hole of the substrate exposes a portion of the chip. The first B-stage adhesive is arranged between the chip and the first surface of the substrate, and the chip is attached to the substrate through the first B-stage adhesive. The bonding wires are connected between the chip exposed by the through hole and second surface of the substrate. The heat sink is arranged on the first surface of the substrate, covering the chip. The molding compound is arranged on the second surface of the substrate, covering a portion of the substrate and bonding wires.

Owner:CHIPMOS TECH INC

Production method for flexible printed board

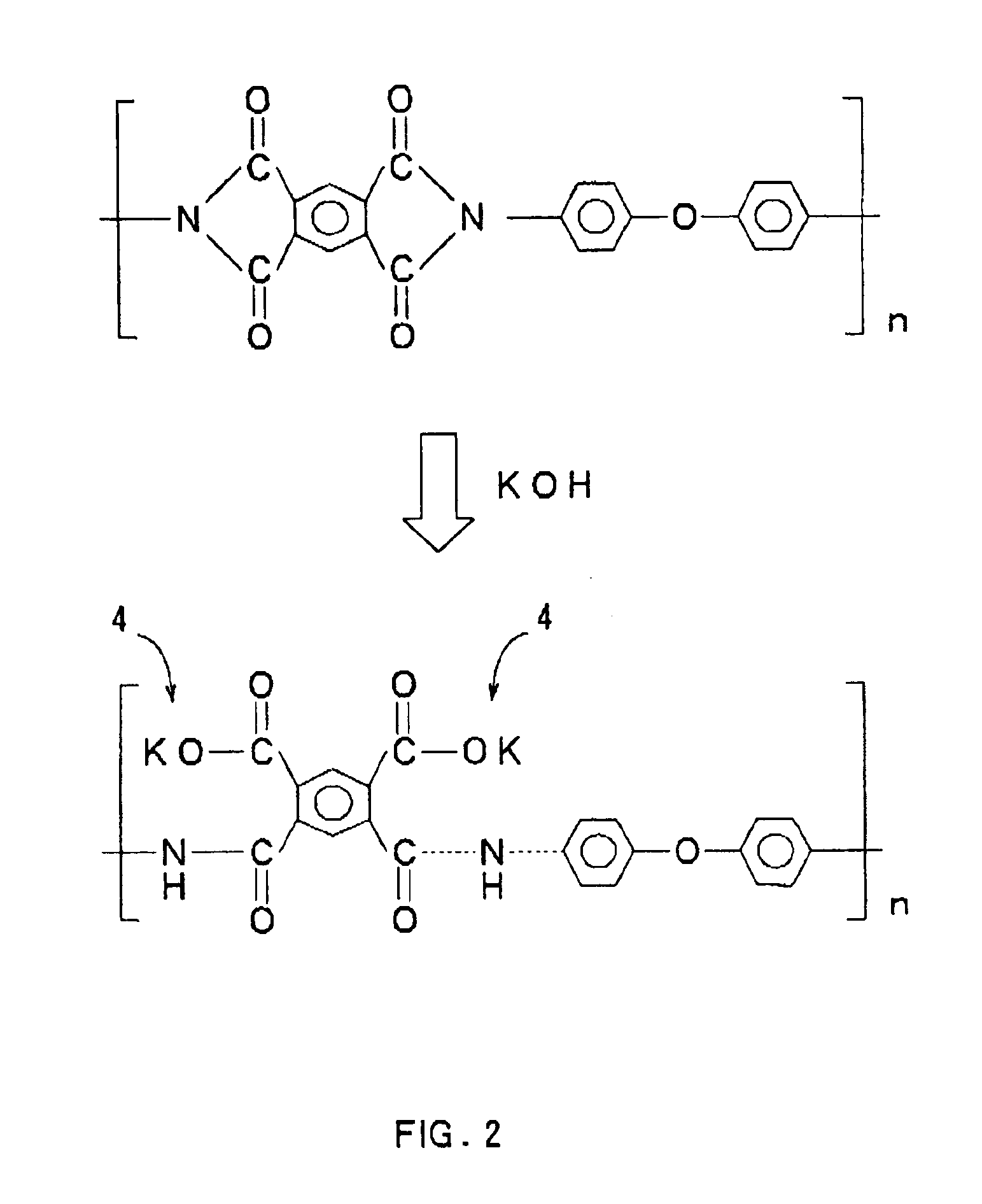

ActiveUS6951604B2Improve adhesionEfficiently and uniformly activatedInsulating substrate metal adhesion improvementLiquid/solution decomposition chemical coatingUltravioletUltraviolet radiation

A flexible printed board production method which ensures higher adhesion of copper, excellent workability, easier continuous production and lower costs. The flexible printed board production method comprises the steps of: treating a surface of a polyimide resin film with plasma or short wavelength ultraviolet radiation; activating the treated surface with the use of an alkali metal hydroxide; electrolessly plating the surface of the polyimide resin film with nickel; and electroplating the electrolessly plated surface of the polyimide resin film with copper, whereby a copper layer is formed on the surface of the polyimide resin film.

Owner:OKUNO CHEM IND CO LTD +1

Optical film, liquid crystal panel, and liquid crystal display apparatus

ActiveUS8199289B2Adhesive layerReduce thicknessNon-linear opticsLiquid-crystal displayAzimuth direction

Owner:NITTO DENKO CORP

Resin composition for protective layer transfer sheets

ActiveUS20120321861A1Easy to storeMaintain good propertiesLayered productsDecorative surface effectsPolyolAlcohol

The present invention relates to a resin composition for protective layer transfer sheets which includes a polyester resin produced by polycondensing a polyhydric alcohol component containing a hydrogenated bisphenol A in an amount of 30 mol % or more and a polycarboxylic acid component containing a benzenedicarboxylic acid in an amount of 50 mol % or more.

Owner:KAO CORP +1

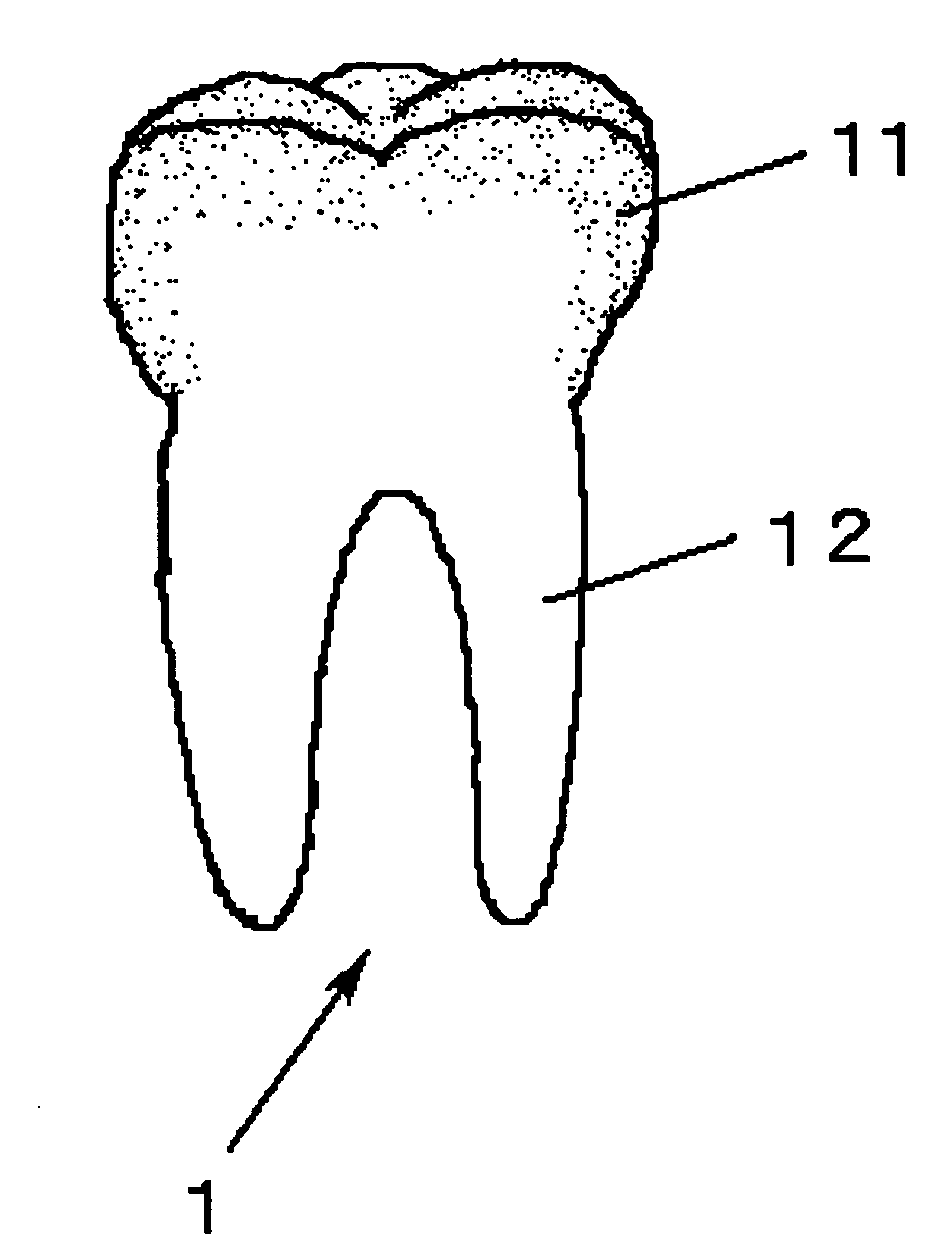

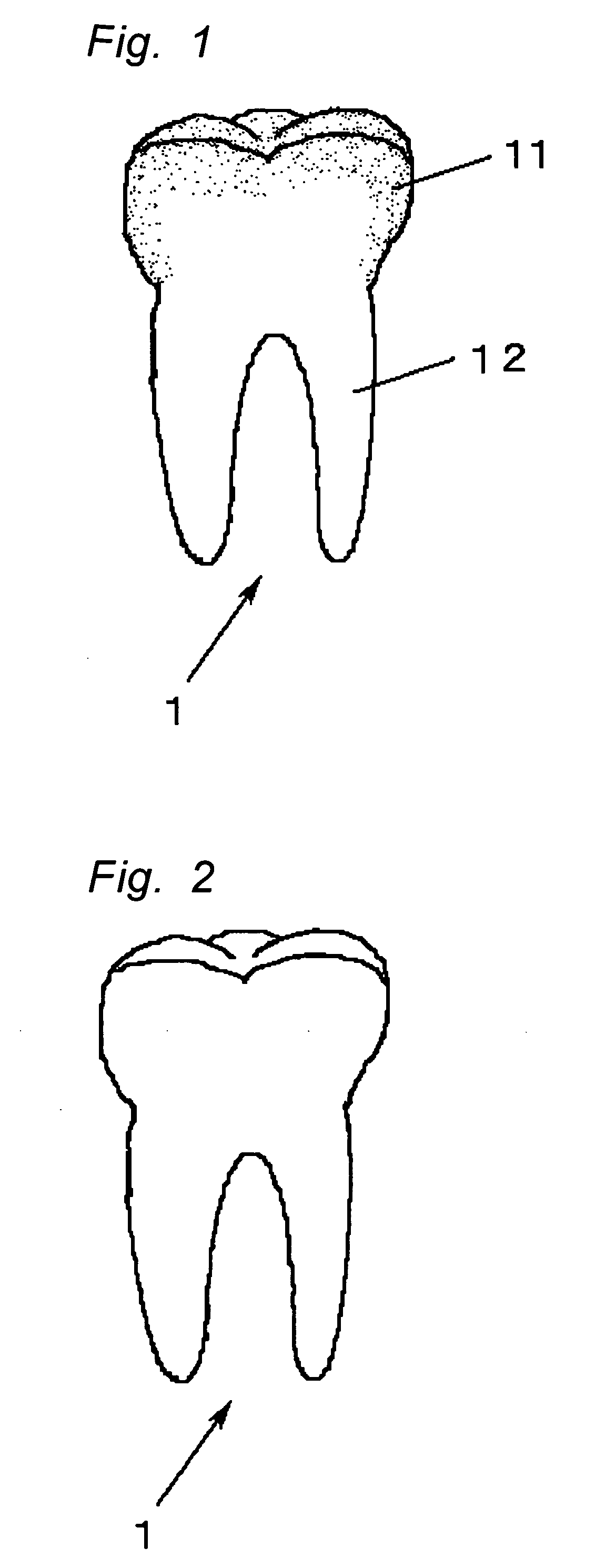

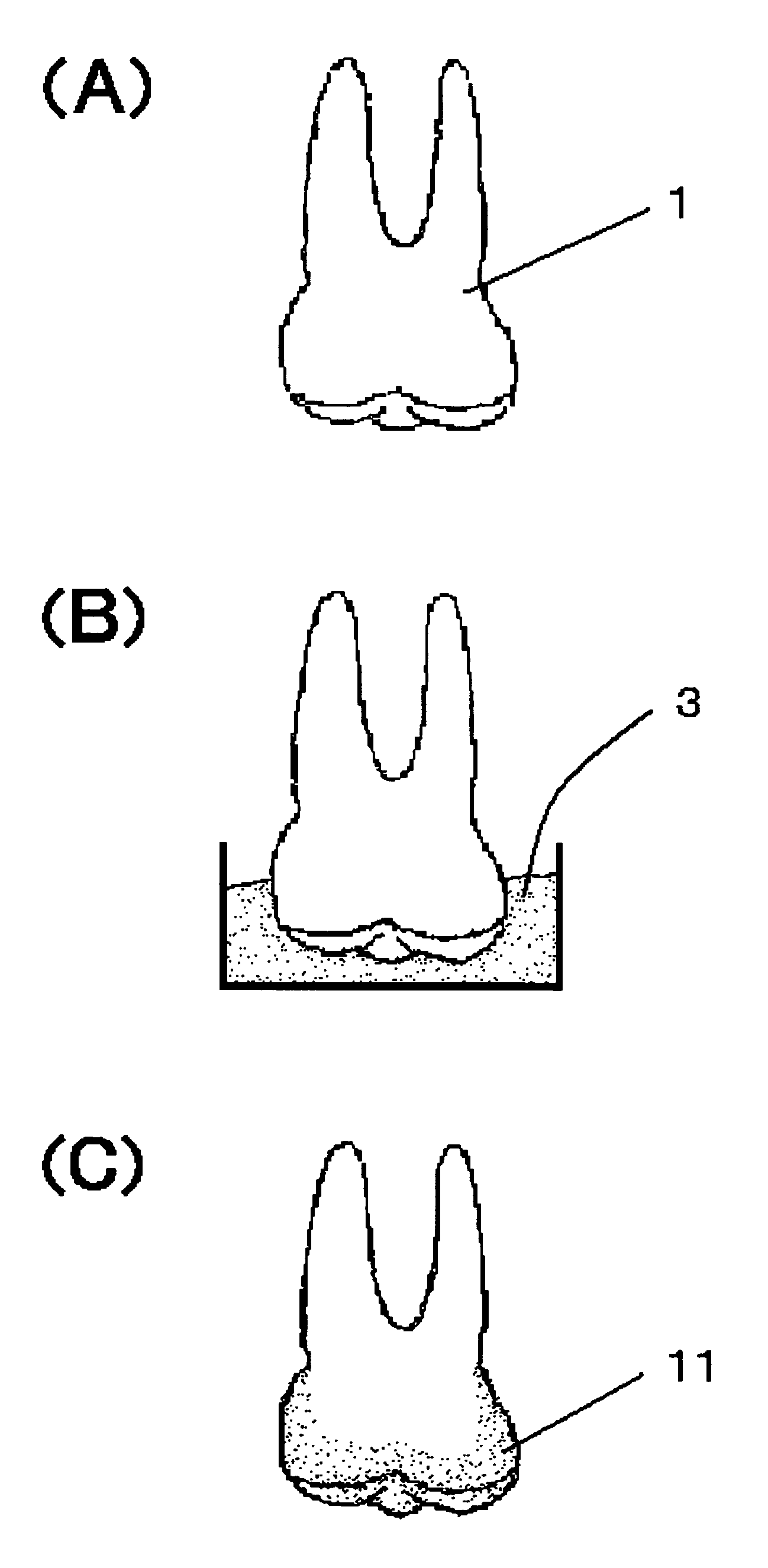

Tooth for tooth model, comprising enamel portion impregnated with resin or low melting point glass, and method for producing the same

ActiveUS20090035738A1Process stabilityAdhesive layerArtificial teethEducational modelsNatural toothTooth enamel

An object of the present invention is to provide a tooth model capable of exhibiting grinding feel similar to that of a natural tooth, with which students aspiring to become dentists experience intraoral work and perform training related to a treatment, and also experience formation of an abutment tooth, formation of cavity or the like. A difference in the grinding feel between tooth enamel and dentin, which constitute a natural tooth, is reproduced by impregnating a sintered body formed integrally of an inorganic powder such as alumina with a thermosetting resin or a low melting point glass to form an enamel portion.

Owner:SHOFU INC

Film for semiconductor device production, method for producing film for semiconductor device production, and method for semiconductor device production

ActiveUS8986486B2Easy to peelAdhesive layerLamination ancillary operationsPaper/cardboard articlesDicing tapeEngineering

The present invention relates to a film for semiconductor device production, which includes: a separator; and a plurality of adhesive layer-attached dicing tapes each including a dicing tape and an adhesive layer laminated on the dicing tape, which are laminated on the separator at a predetermined interval in such a manner that the adhesive layer attaches to the separator, in which the separator has a cut formed along the outer periphery of the dicing tape, and the depth of the cut is at most ⅔ of the thickness of the separator.

Owner:NITTO DENKO CORP

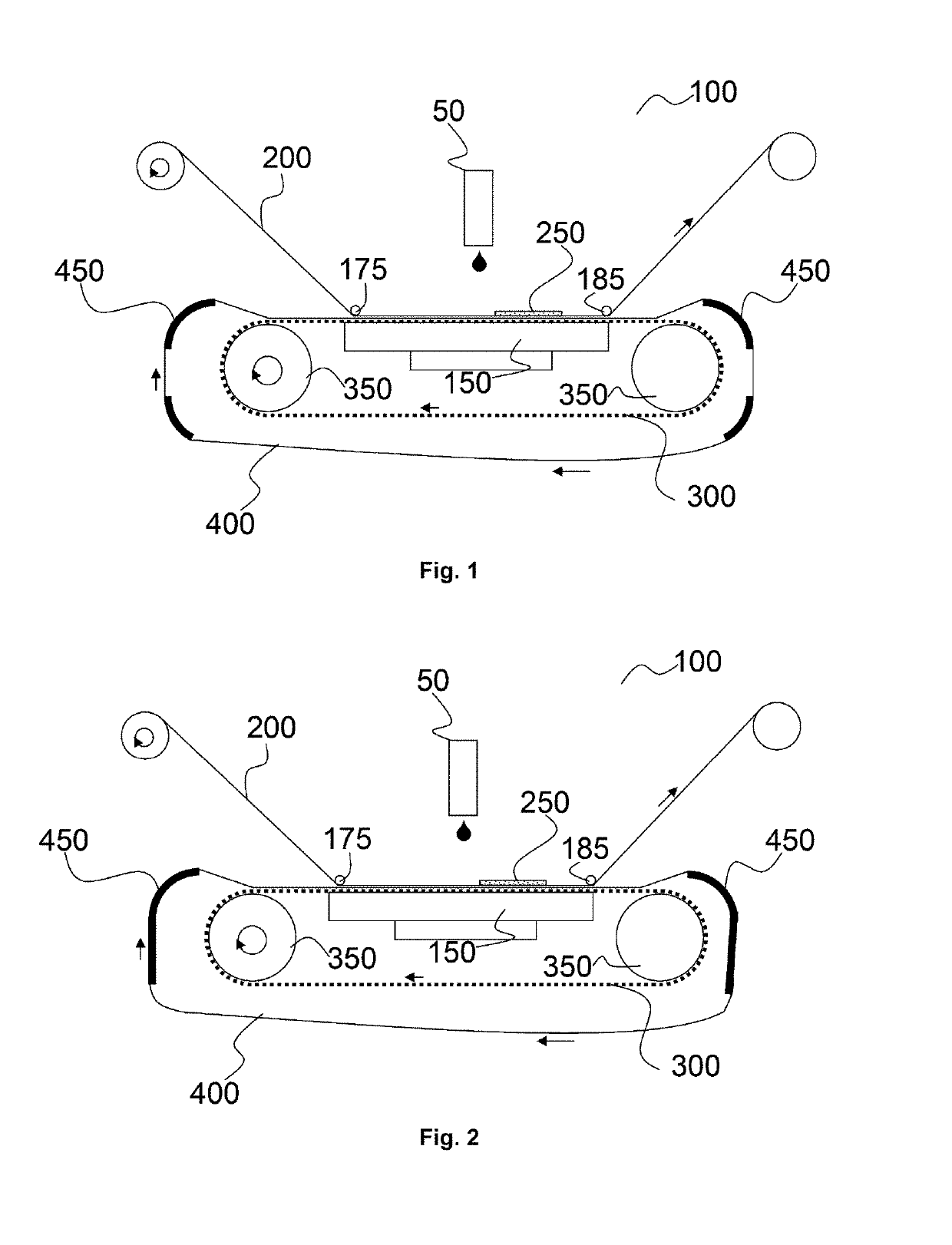

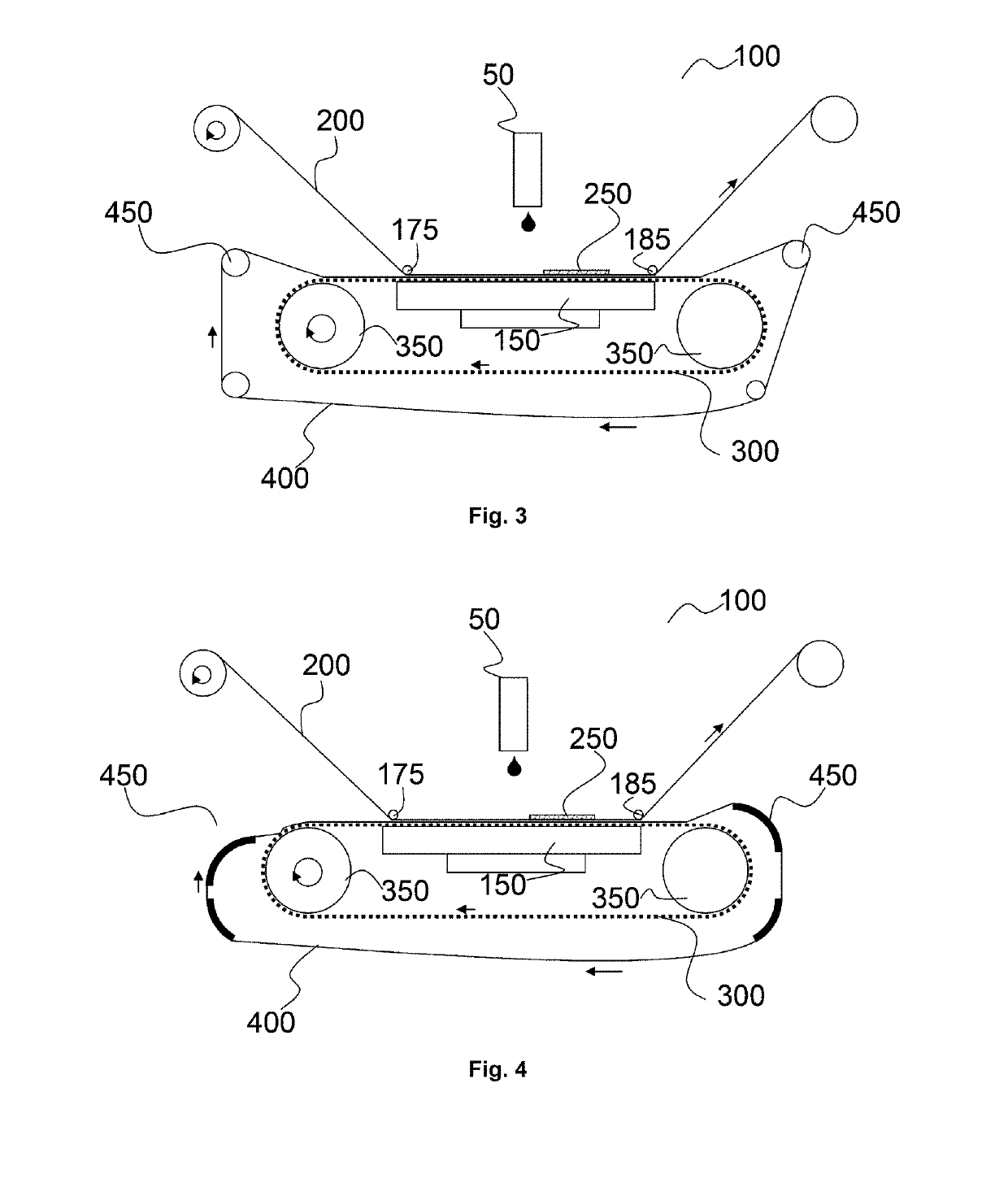

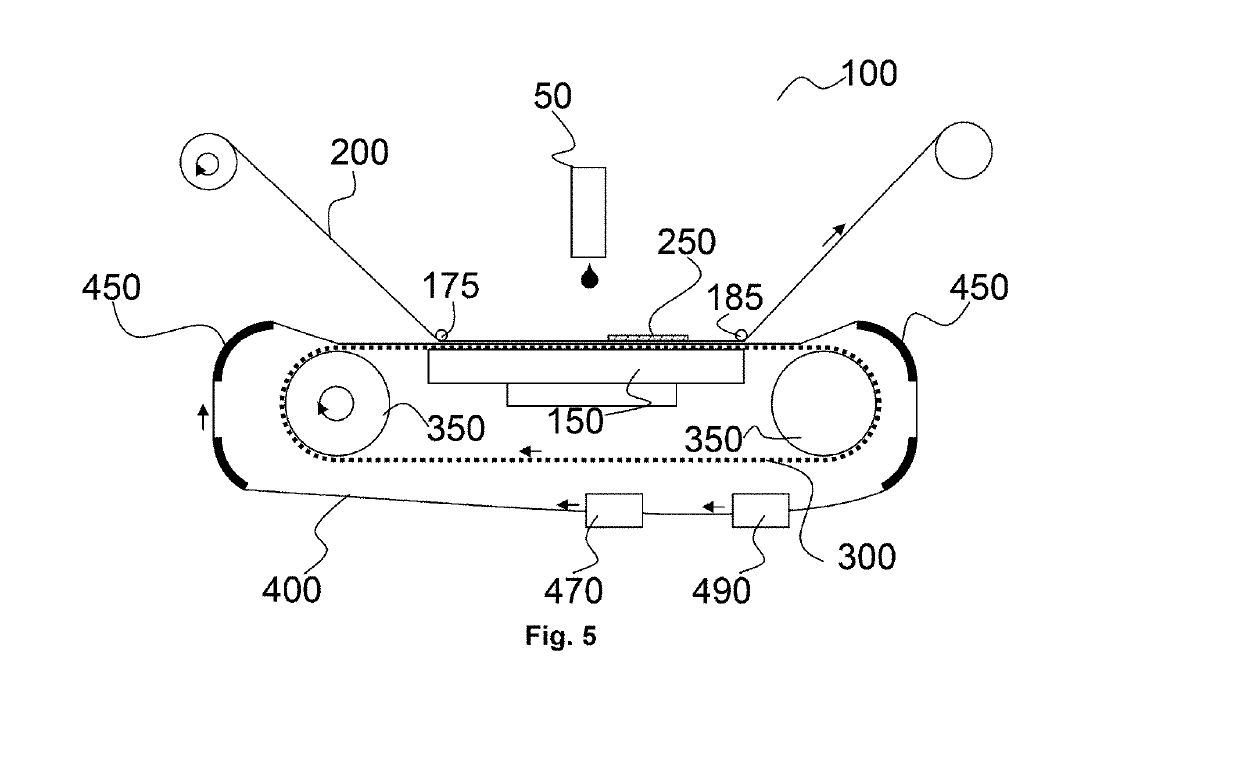

Printing device with conveyor belt

ActiveUS20190270320A1Easy to handleImprove versatilityTypewritersOther printing apparatusInk printerConveyor belt

An inkjet printer, and a printing method with the inkjet printer, includes a first conveyor belt wrapped around a vacuum table and supported by an upstream pulley and a downstream pulley and a vacuum area on the first conveyor belt, and a second conveyor belt wrapped-around the first conveyor belt and supported by an upstream sliding support and a downstream sliding support. The second conveyor belt is adhered in the vacuum area by vacuum power and a print receiver is attached to the second conveyor belt for conveying and printing.

Owner:AGFA NV

Tooth for tooth model, comprising enamel portion impregnated with resin or low melting point glass, and method for producing the same

ActiveUS8221128B2Process stabilityAdhesive layerArtificial teethEducational modelsNatural toothTooth enamel

An object of the present invention is to provide a tooth model capable of exhibiting grinding feel similar to that of a natural tooth, with which students aspiring to become dentists experience intraoral work and perform training related to a treatment, and also experience formation of an abutment tooth, formation of cavity or the like. A difference in the grinding feel between tooth enamel and dentin, which constitute a natural tooth, is reproduced by impregnating a sintered body formed integrally of an inorganic powder such as alumina with a thermosetting resin or a low melting point glass to form an enamel portion.

Owner:SHOFU INC

Film, method for producing same, transparent conductive film, and touch panel

ActiveUS20160244580A1High interlayer adhesivenessWet adhesivenessSynthetic resin layered productsElectrical equipmentTransparent conducting filmFluorine containing

A film includes a substrate including a cyclic olefin-based resin; and an easily adhesive layer adjacent to the substrate, in which a content of a fluorine-containing polymer in the easily adhesive layer is greater than 20 mass % with respect to a total mass of the easily adhesive layer. This film is used in a transparent conductive film, and this transparent conductive film is used in a touch panel. A method for producing a film includes laminating an easily adhesive layer by directly applying a coating liquid for forming an easily adhesive layer on a substrate including a cyclic olefin-based resin, in which a content of a fluorine-containing polymer in the coating liquid for forming the easily adhesive layer is greater than 20 mass % with respect to a total mass of the coating liquid for forming the easily adhesive layer.

Owner:FUJIFILM CORP

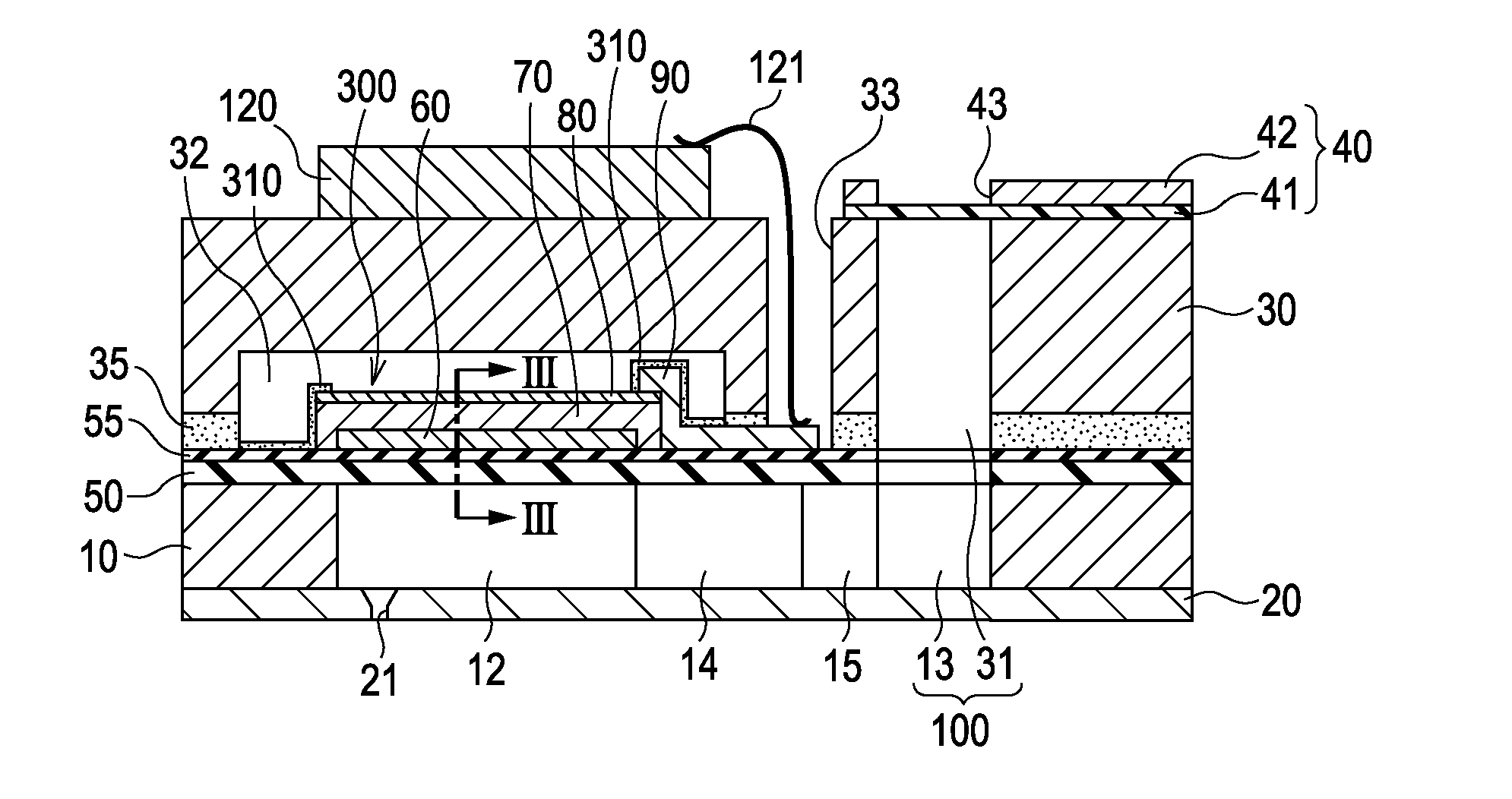

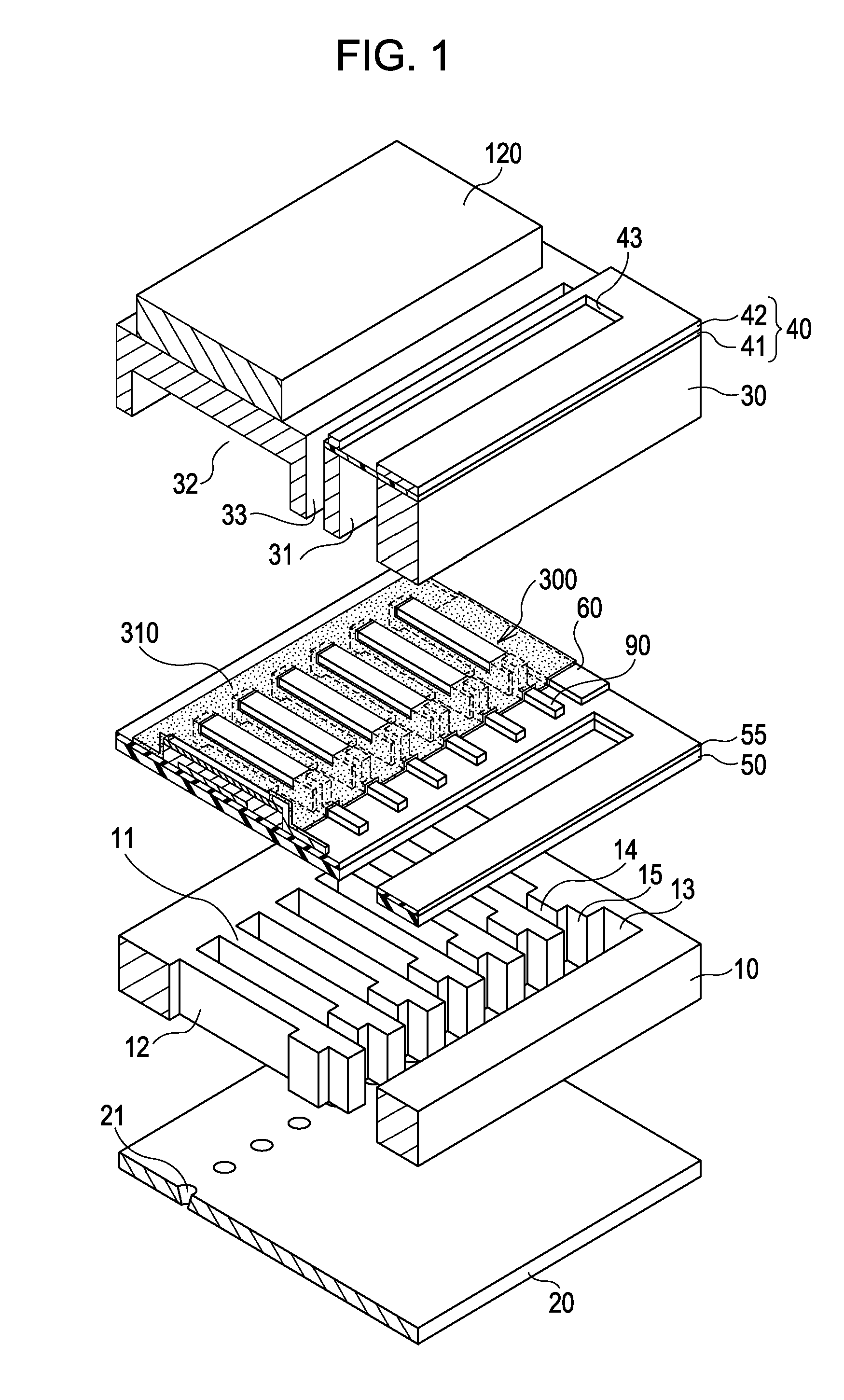

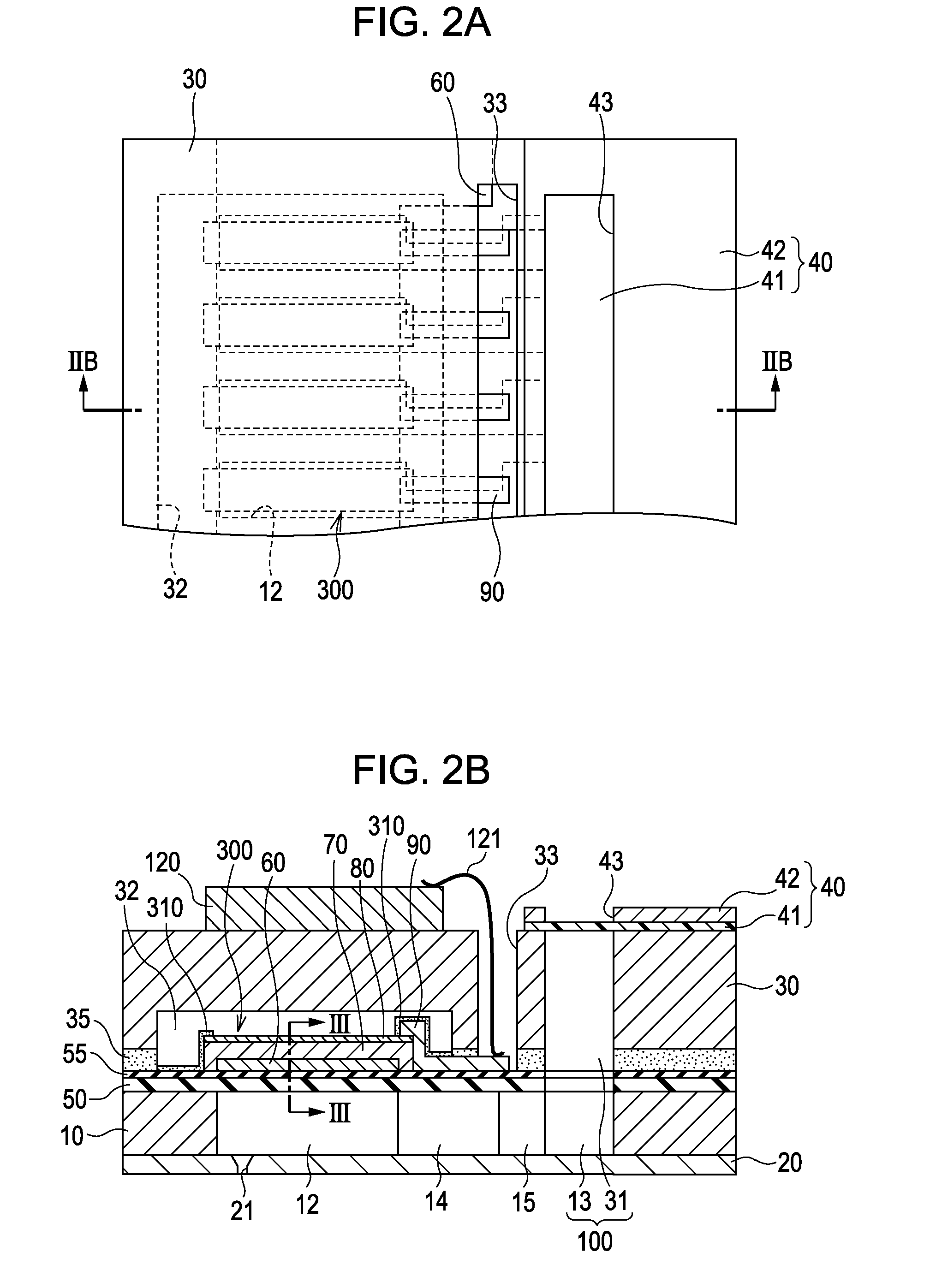

Liquid ejecting head, piezoelectric element, and liquid ejecting apparatus

ActiveUS20090244214A1Increase the areaPrevent degradationPrintingEngineeringElectrical and Electronics engineering

A liquid ejecting head includes a piezoelectric element in which a lower electrode, a piezoelectric layer, and an upper electrode are laminated in this order, and a flow path forming substrate in which the piezoelectric element is formed above one surface thereof and a pressure generating chamber being communicated with a nozzle opening is provided, in which the upper electrode is formed so as to extend over an upper surface of the piezoelectric layer and an upper portion of side faces of the piezoelectric layer, and a protective film is formed above portions of the piezoelectric layer, which are not covered by the upper electrode.

Owner:SEIKO EPSON CORP

Process for producing electrical apparatus

InactiveUS20050257886A1Resolution problemEasy to producePrinted circuit assemblingAdhesive processes with surface pretreatmentLiquid-crystal displayCationic polymerization

Disclosed is a method for producing an electrical device by electrically and mechanically interconnecting two objects for bonding. When an adhesive layer (25) provided to an LCD (11) and a layer of a second curing agent (28) provided to a TCP (15) are brought into tight contact with each other and thrust in this state to each other under heating, a first curing agent in the adhesive layer (25) and a second curing agent forming the layer of the second curing agent react with each other so that the thermosetting resin in the adhesive layer is polymerized to bond the LCD (11) and the TCP (15) together to produce an electrical device. In case a metal chelate or a metal alcoholate and a silane coupling agent are used as the first and second curing agents, respectively, the silane coupling agent and the metal chelate react with each other to yield cations and, by these cations, the thermosetting resin undergoes cationic polymerization. The adhesive may be cured to bond the LCD (11) and the TCP (15) together in a shorter time at a lower temperature than in case the conventional adhesive is used.

Owner:DEXERIALS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com