Piezo-electric composite sensor

A piezoelectric composite and piezoelectric composite material technology, which is applied in the field of piezoelectric sensors using piezoelectric composite materials, can solve the problems of limited adjustment range of electrode thickness, weakened electrical properties of thin film layers, and fragile electrodes, and achieves excellent performance. Piezoelectric and dielectric properties, ease of processing, effect of reducing process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

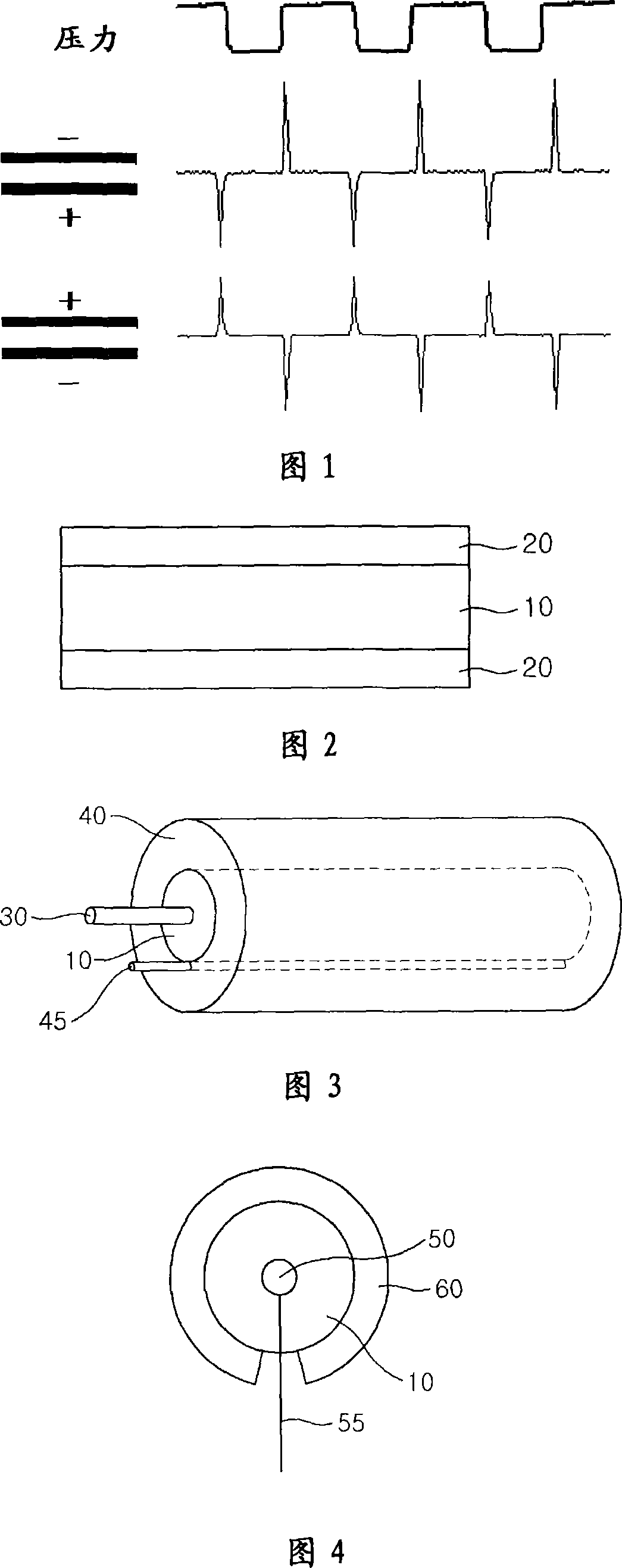

[0049] [46] Preferred embodiments of the piezoelectric composite sensor according to the present invention will be described below with reference to the drawings.

[0050] [47] FIG. 2 is a sectional view showing a piezoelectric composite sensor according to a preferred embodiment of the present invention.

[0051] [48] Referring to the figure, the piezoelectric composite sensor includes a piezoelectric material layer 10 and electrodes 20 formed on both surfaces of the piezoelectric material layer.

[0052] [49] Ceramic materials or electrodes in traditional products are easily broken, when the piezoelectric composite sensor constructed as shown in Figure 2 is applied to traditional products, it can improve product reliability and durability, and prolong product life. For example, the advantageous features of the present embodiment can be effectively applied to an automobile tire pressure management system, which functions to notify dangerous situations in advance by sensing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com