(1-x)(ba,bi,na)tio3-xcofe2o4 composite multi-iron ceramic and preparation method thereof

A multiferroic ceramic, fe2o3 technology, applied in the field of material science, can solve the problems of not meeting the application requirements, small magnetoelectric coupling coefficient, etc., achieve good ferroelectricity, simple equipment and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

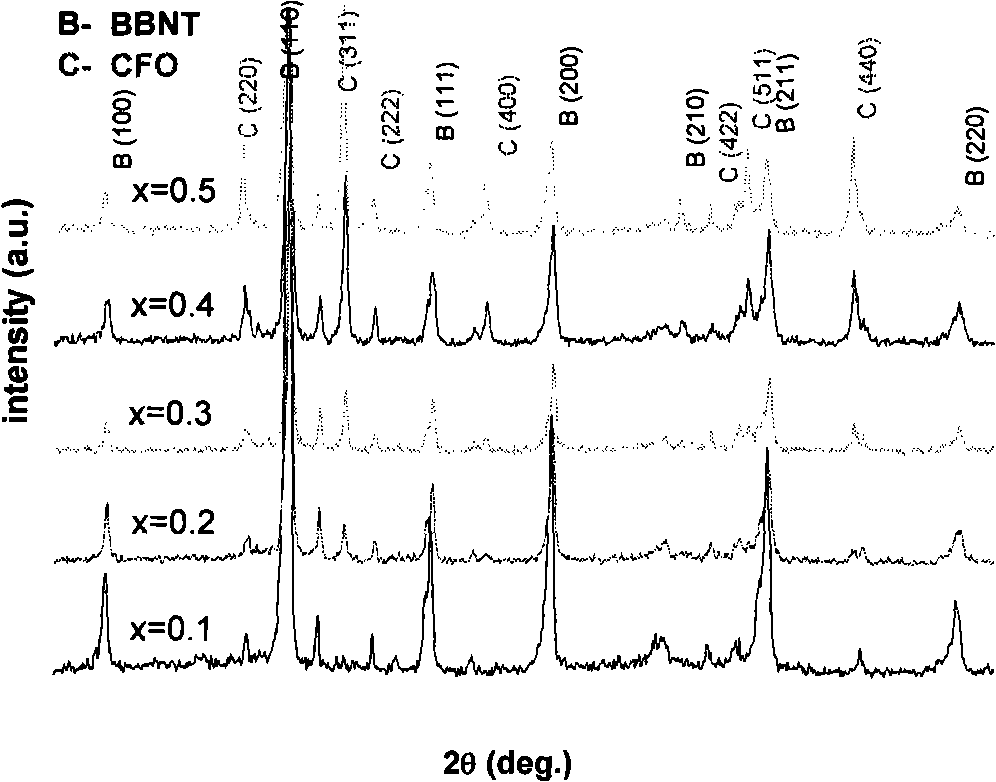

[0029] The first step: first determine the value of x (in this experiment, x is respectively 0.1, 0.2, 0.3, 0.4, 0.5). According to the chemical formula (1-x) BBNT-xCFO, weigh the dried Bi with a purity greater than or equal to 99.0%. 2 o 3 、Na 2 CO 3 , BaTiO 3 、Co 2 o 3 and Fe 2 o 3 powder, add alcohol to the mixture of the five powders, and then ball mill (350 rpm, 12 hours) to make the five powders mix evenly.

[0030] The second step: After drying the powder obtained in the first step, put it into Al 2 o 3 crucible, and covered with Al 2 o 3 The crucible lid is placed in a heating furnace for sintering. The heating rate is 5°C / min, and sintering is performed at 800°C for 2 hours.

[0031] Step 3: Add alcohol to the pre-burned powder and perform ball milling (350 rpm, 12 hours) to refine the powder particles.

[0032] Step 4: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com