Wheatstone-bridge-based pressure sensor and manufacturing method thereof

A technology of a pressure sensor and a manufacturing method, which is applied in the manufacture/assembly of piezoelectric/electrostrictive devices, components of piezoelectric devices or electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc. , can solve the problems of high Si diffusion resistance process requirements, difficult to guarantee process accuracy, uniformity, poor temperature characteristics of Si materials, etc., to achieve the effect of improving product manufacturing accuracy, simple preparation method and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

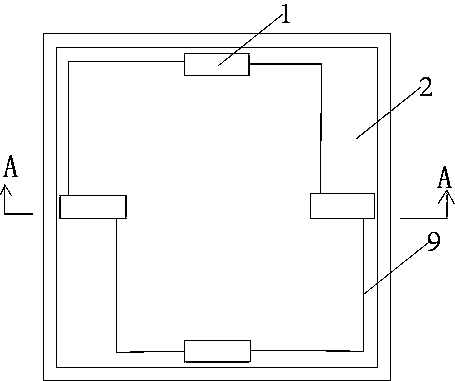

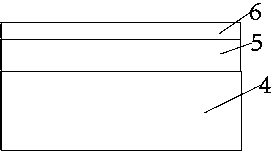

[0030] Such as figure 2 As shown, it is an embodiment of a pressure sensor based on a Wheatstone bridge structure and its manufacturing method in the present invention, including bonding wafers, bonding media, substrates, buffer layers, metal wires, barrier layers, The cavity and the ohmic electrode, the material of the buffer layer is gallium nitride, and the material of the barrier layer is In x al y Ga 1-x-y N multi-component compound, according to which the bridge resistance is obtained.

[0031] figure 1 Including metal wire 9 , cavity film 2 and GAN device 1 .

[0032] Gallium nitride is used as the buffer layer, and the GaN bandgap width is 3.4eV, which is three times that of Si material. The wide bandgap determines the good high-temperature characteristics of the material. Reports have confirmed that GaN material devices...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com