Piezoelectric/electrostrictive porcelain composition and its application

A ceramic composition, a technology of compression, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problem of difficulty in obtaining piezoelectric bodies, and achieve excellent piezoelectric/electrostrictive Effects of Features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4、 comparative example 1

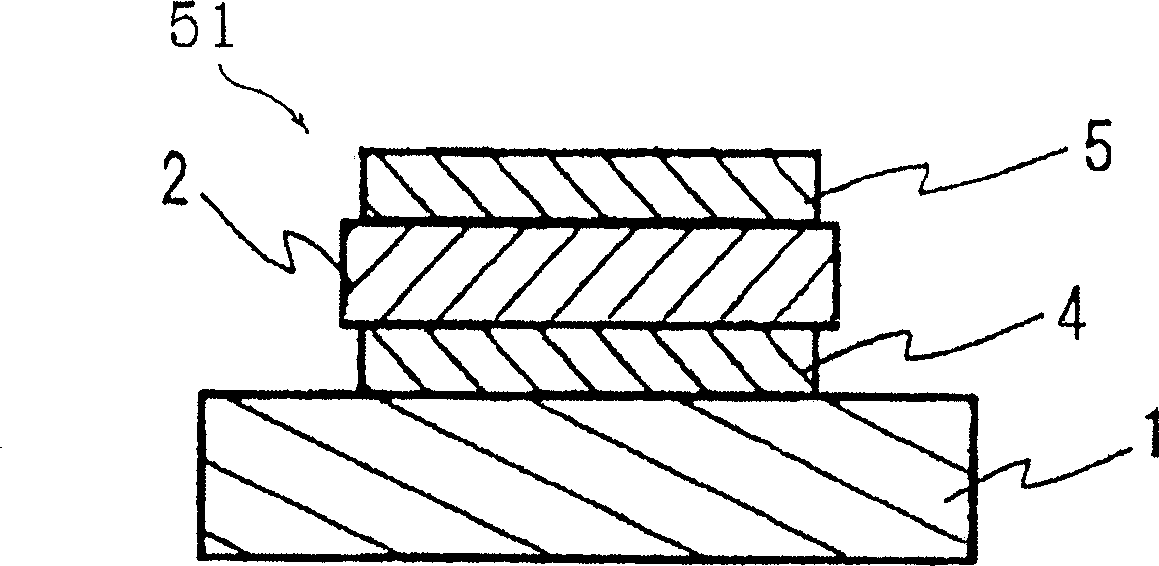

[0091] After forming and firing by using the printed circuit board lamination method, and then using yttrium oxide (Y 2 o 3 ) stabilized zirconia (ZrO 2 ) on a substrate (1.6×1.1mm×thickness 10μm), a lower electrode film (1.2×0.8mm×thickness 3μm) made of platinum (Pt) was formed by screen printing method, and heat treatment at 1300°C for 2 hours integrated with the substrate. A piezoelectric / electrostrictive ceramic composition represented by the composition formula shown in Table 1 was laminated on the lower electrode film with a size of 1.3×0.9 mm×15 μm in thickness by screen printing, and fired at 1200° C. for 3 hours. Furthermore, an upper electrode film (1.2 x 0.8 mm x thickness 0.5 μm) made of gold (Au) was laminated thereon by a screen printing method, and at the same time heat-treated to obtain a piezoelectric / electrostrictive film type element ( Embodiment 1~4, comparative example 1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com