Piezoelectric/electrostrictiven ceramic composition

A ceramic composition and stretching technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve the problems of easy deformation, low compactness, Problems such as piezoelectric properties cannot be obtained, and the effects of dense crystallinity and excellent piezoelectric/electrostrictive properties can be achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] According to the following composition (formula (2)) weigh the PbO powder, Bi 2 o 3 powder, NiO powder, Nb 2 o 5 Powder, TiO 2 Powder, ZrO 2 Powder, wet mixed for 40 hours using a ball mill.

[0037] xBi(Ni 2 / 3 Nb 1 / 3 )O 3 —(1—x)Pb(Zr 1-y Ti y )O 3

[0038] x=0.20, y=0.625...(2)

[0039] The mixed powder was dried and pre-fired at 800°C for 2 hours in the air. Then, the powder that was pulverized and dried by a wet ball mill until a specific surface area was passed through a sieve was granulated, formed into a disk shape by a uniaxial press and a hydrostatic press, sealed in a ceramic shell, and carried out at 950°C. burnt.

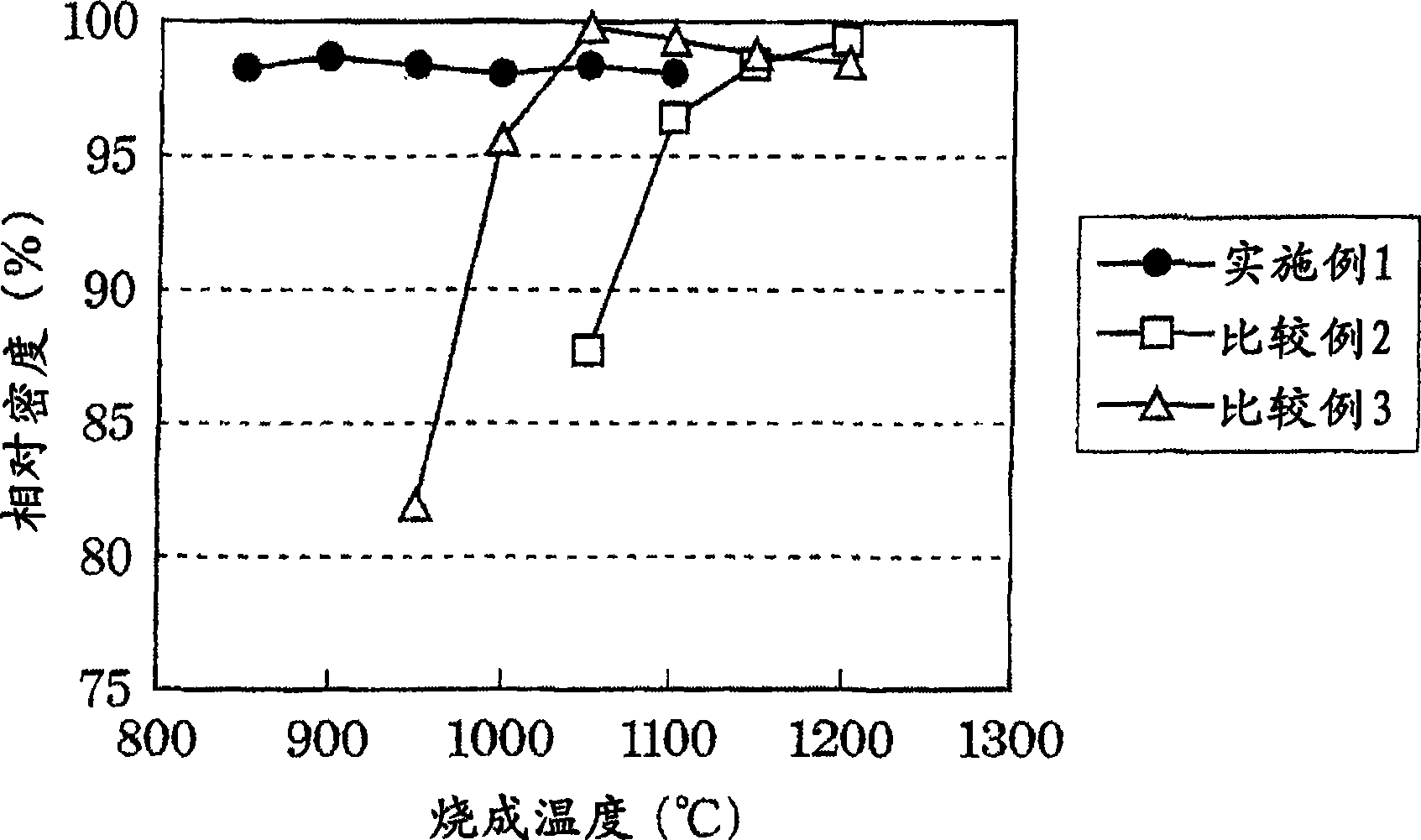

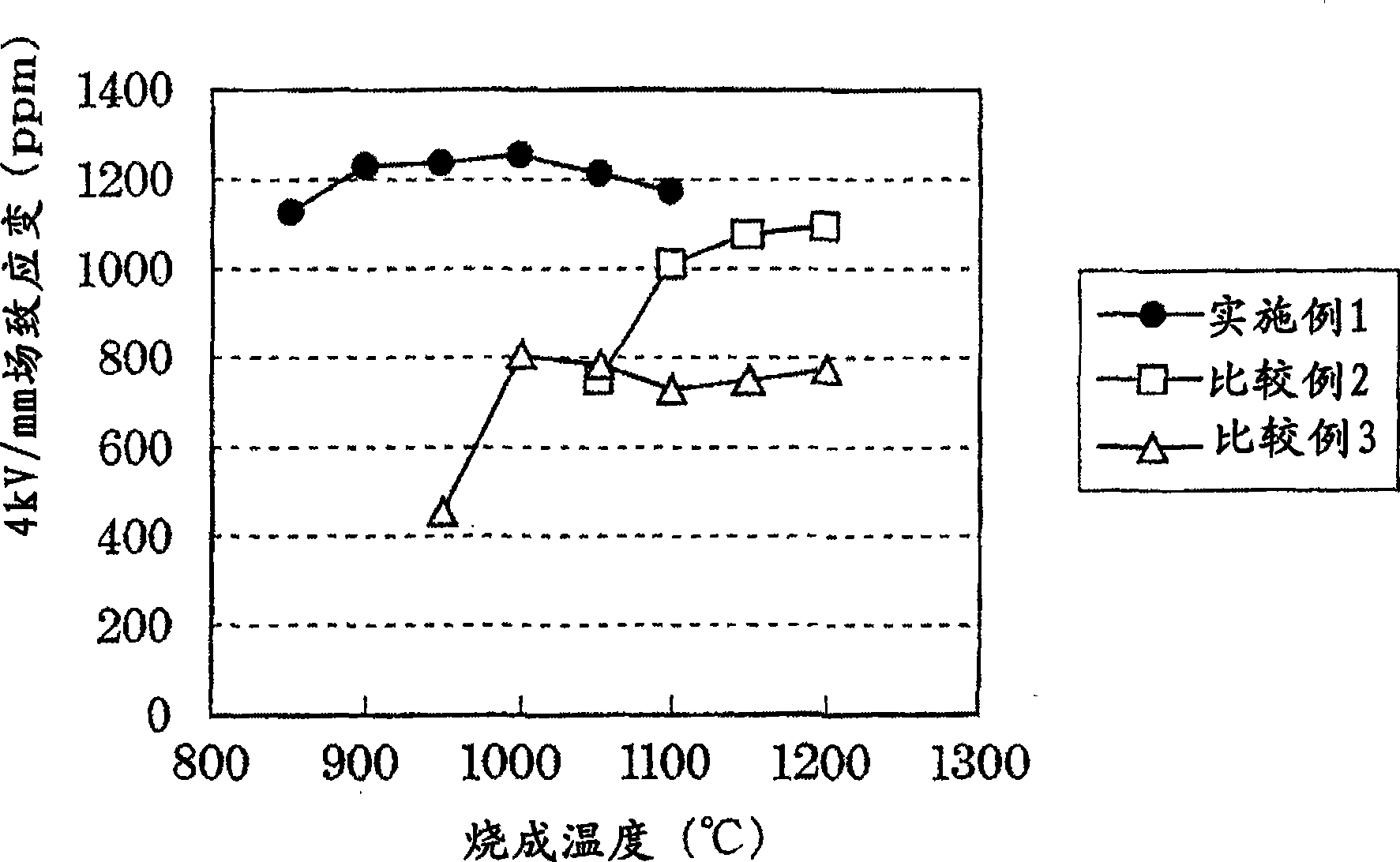

[0040] The density of the sintered body was measured, and the microstructure and crystal structure were evaluated. In order to evaluate the electrical characteristics, the sintered body was cut into short strips with a thickness of 1 mm, Ag paste was coated on both sides, and fired at 600° C. to form electrodes....

Embodiment 2~12

[0043] By the same manufacturing method as Example 1, it produced with the composition shown in Table 1, and performed the same evaluation as Example 1. As a result, in any case, densification can be performed at 1000° C. or lower, and good piezoelectric characteristics can be obtained.

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com