Method for preparing wave-absorbing material

A technology of wave-absorbing materials and base materials, applied in the direction of electrical components, magnetic field/electric field shielding, etc., can solve problems such as difficult breakthroughs in the performance of wave-absorbing materials, and achieve the effect of improving wave-absorbing performance and magnetoelectric effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

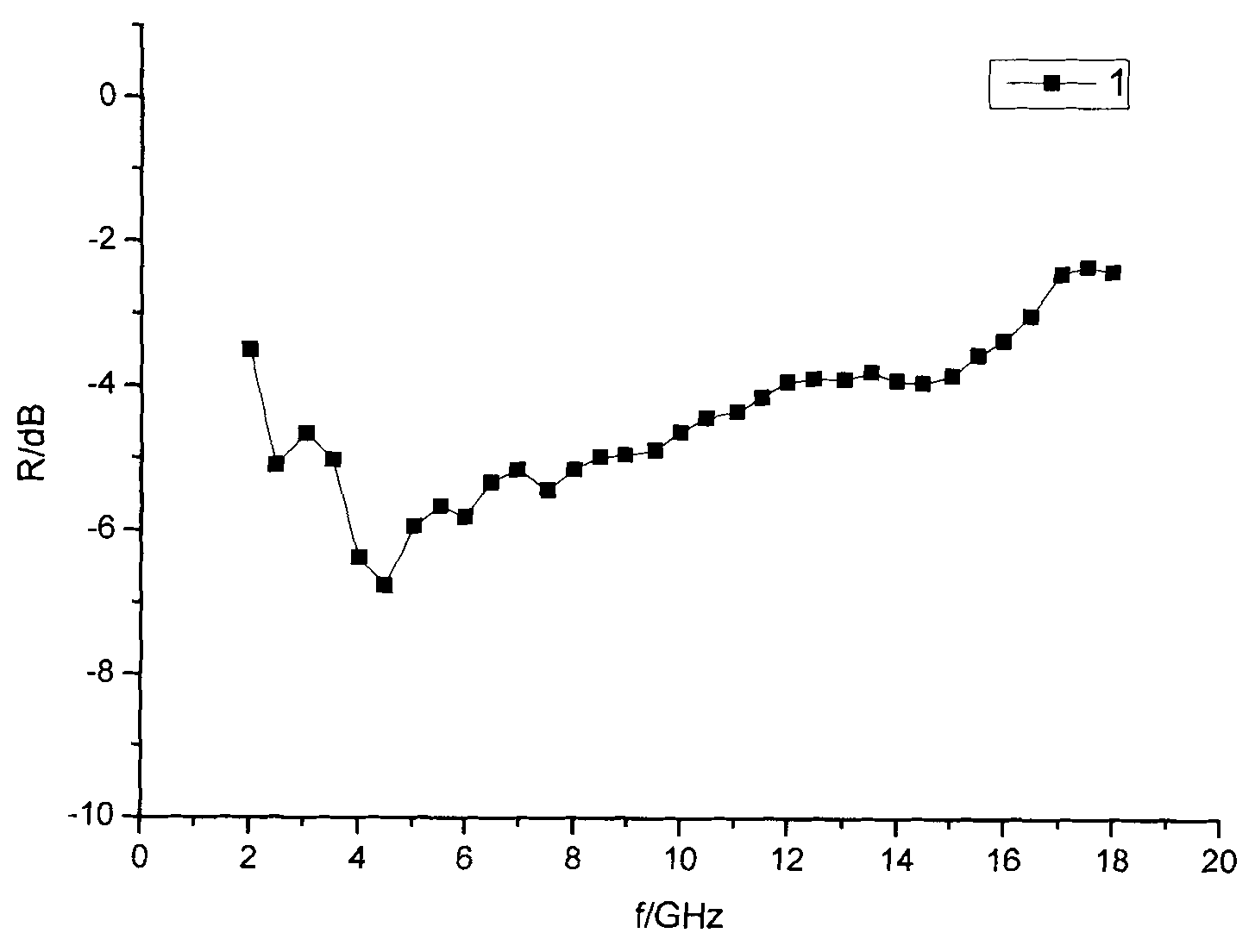

[0021] The material composition of this example is Fe 72 Cu 1 Nb 3 Si 15 B 9 , the iron-based nanocrystalline material base material is prepared by a single-roll chilling method, and the material is subjected to nanocrystallization treatment under the protection of high-purity nitrogen gas to obtain a nanocrystalline material with a nanocrystalline phase structure. The iron-based nanocrystalline material is mechanically crushed by a high-speed cutting method to prepare a nanocrystalline material powder, and the powder is sieved to obtain a graded powder of 45 μm to 60 μm. The powder is reprocessed with jet mill equipment, the gas working pressure is 0.5MPa, the treatment time is 1h, and then its absorbing performance is measured. Such as figure 1 As shown, it can be seen that the reflectance R=-3.5dB at 2GHz, and the maximum emissivity appears at the frequency point of 4.5GHz, which is -6.7dB. In the frequency range of 2GHz to 18GHz, the bandwidth of reflectivity greater ...

Embodiment 2

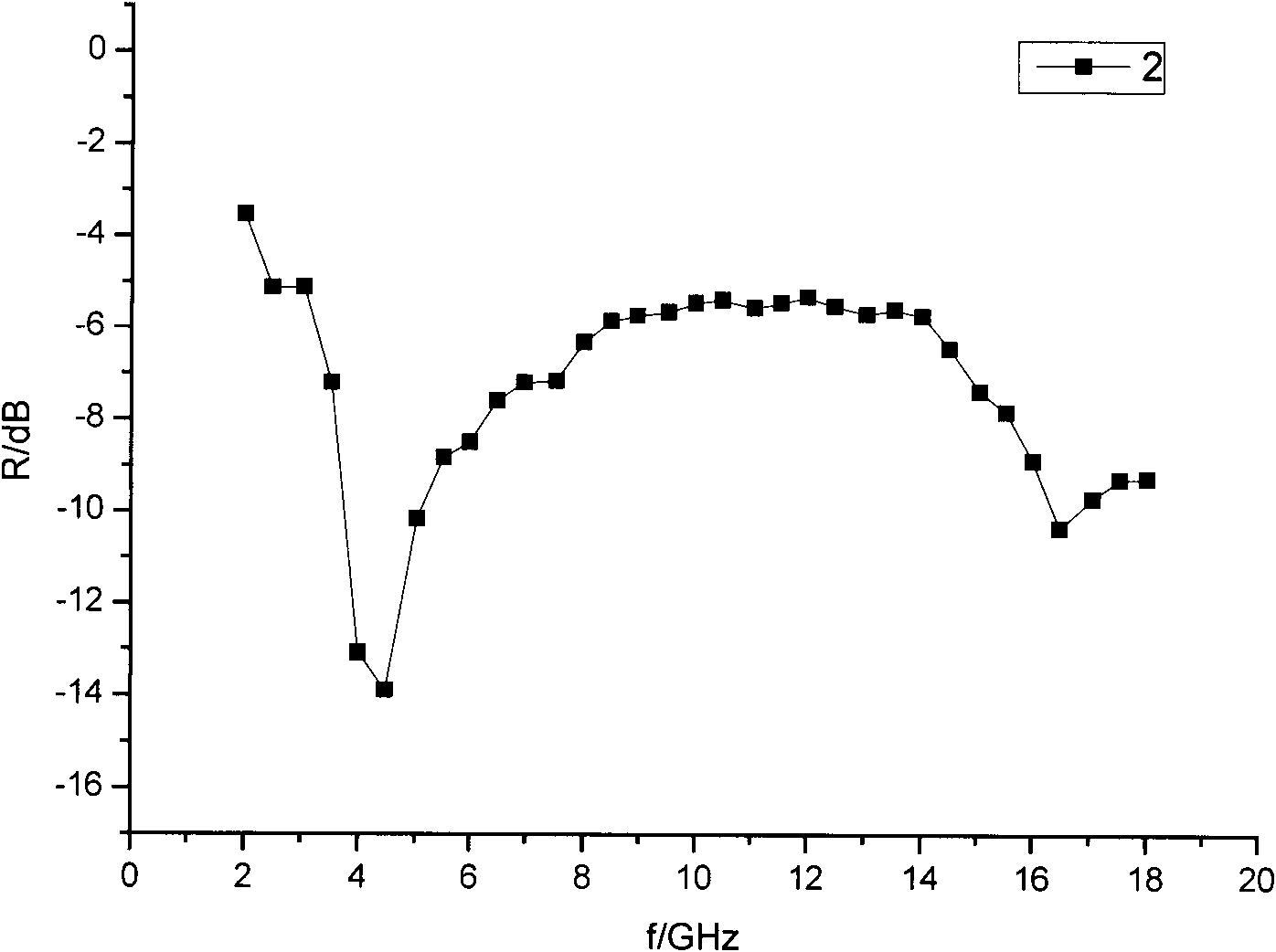

[0023] The material composition of this example is Fe 72.5 Cu 1 Nb 2 V 2 Si 13.5 B 9 , the iron-based nanocrystalline material base material is prepared by a single-roll chilling method, and the material is subjected to nanocrystallization treatment under the protection of high-purity nitrogen gas to obtain a nanocrystalline material with a nanocrystalline phase structure. The iron-based nanocrystalline material is mechanically crushed by a high-speed cutting method to prepare a nanocrystalline material powder, and the powder is sieved to obtain a graded powder of 45 μm to 60 μm. The powder is reprocessed with jet mill equipment, the gas working pressure is 1.0MPa, the treatment time is 3h, and then its absorbing performance is measured, such as figure 2 As shown, it can be seen that the reflectivity R=-3.5dB at 2GHz, and the maximum reflectivity appears at the frequency point of 4.5GHz, which is -13.9dB. In the frequency range of 2GHz to 18GHz, the bandwidth with reflec...

Embodiment 3

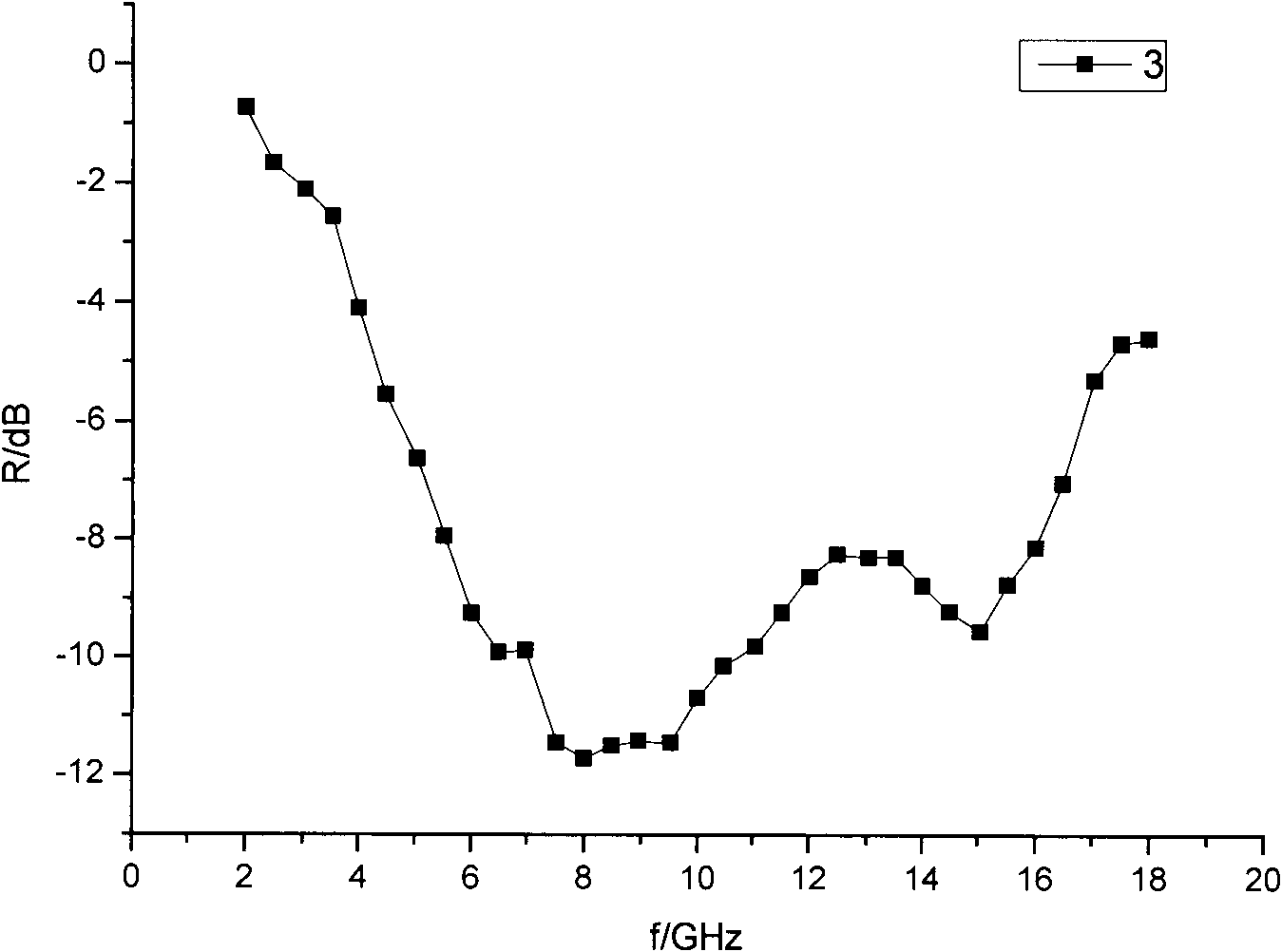

[0025] The material composition of this example is Fe 73.5 Cu 1 Nd 3 Si 13.5 B 9 , the iron-based nanocrystalline material base material is prepared by a single-roll chilling method, and the material is subjected to nanocrystallization treatment under the protection of high-purity nitrogen gas to obtain a nanocrystalline material with a nanocrystalline phase structure. The iron-based nanocrystalline material is mechanically crushed by a high-speed cutting method to prepare a nanocrystalline material powder, and the powder is sieved to obtain a graded powder with a level of 30 μm to 45 μm. The powder is reprocessed with jet mill equipment, the gas working pressure is 1.0MPa, the treatment time is 3h, and then its absorbing performance is measured, such as image 3 As shown, it can be seen that the reflectivity R=-0.75dB at 2GHz, and the maximum reflectivity appears at the frequency point of 8GHz, which is -11.7dB. In the frequency range of 2GHz to 18GHz, the bandwidth with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reflectivity | aaaaa | aaaaa |

| Emissivity | aaaaa | aaaaa |

| Reflectivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com