Variable-frequency magnetoresistive effect element and oscillator, detector, and filter using the same

一种磁电阻、效应的技术,应用在功率振荡器、磁场控制的电阻器、电气元件等方向,能够解决占有面积增加、元件工作能量增加等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

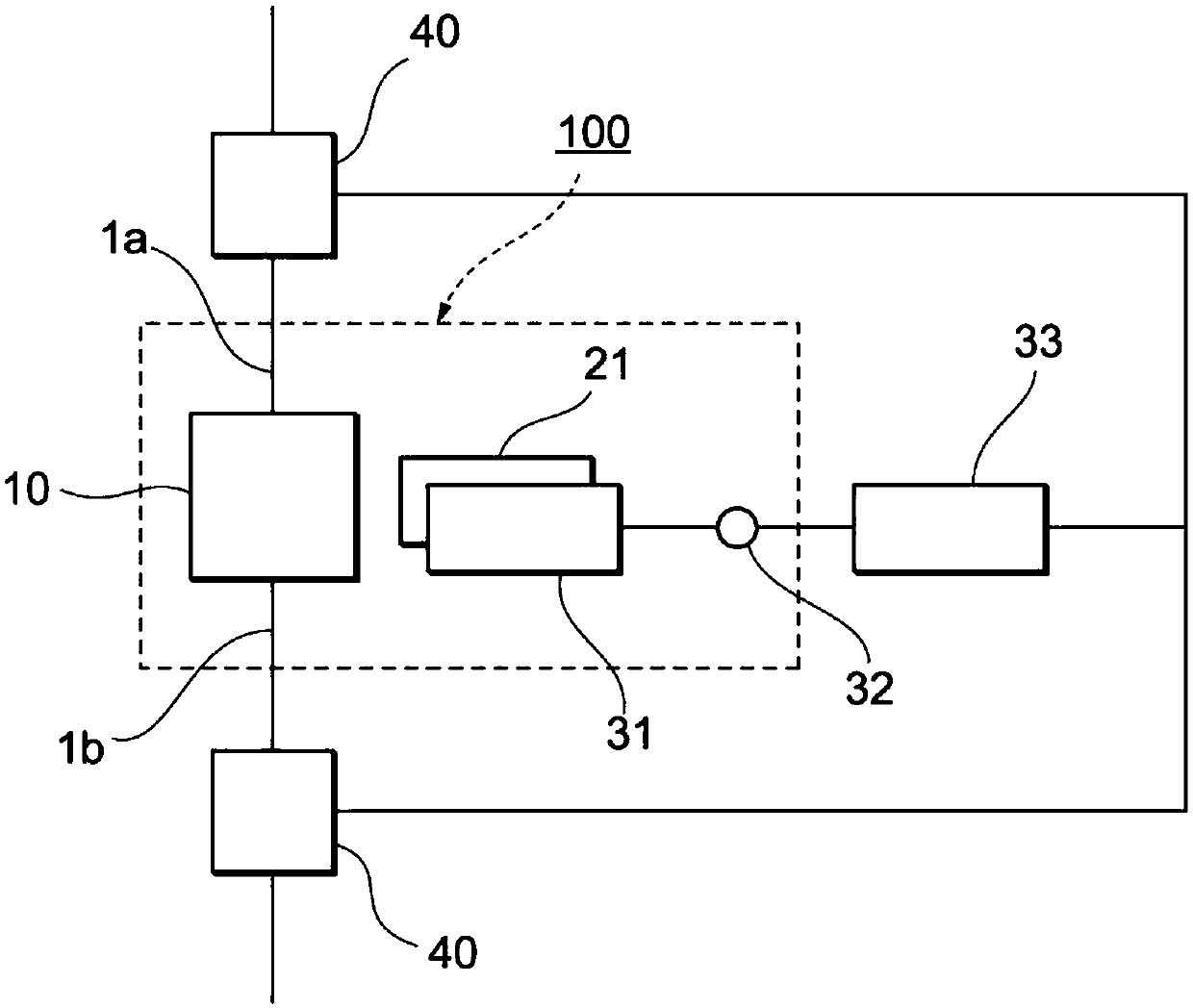

[0090] figure 1 It is a schematic diagram showing the configuration of the frequency variable magnetoresistance effect element 100 according to the first embodiment of the present invention. The frequency variable magnetoresistance effect element 100 includes a magnetoresistance effect element 10 , a magnetic field applying mechanism 21 , an electric field applying mechanism 31 and a control terminal 32 . The input signal line 1 a and the output signal line 1 b are connected to the magnetoresistance effect element 10 . The input signal line 1a and the output signal line 1b are respectively used for transmitting input signals and output signals. The control terminal 32 is connected to the electric field applying mechanism 31 , and by applying positive or negative voltage from the control terminal 32 , an electric field having a predetermined magnitude and direction can be applied to the magnetoresistance effect element via the electric field applying mechanism 31 . In this em...

no. 2 approach

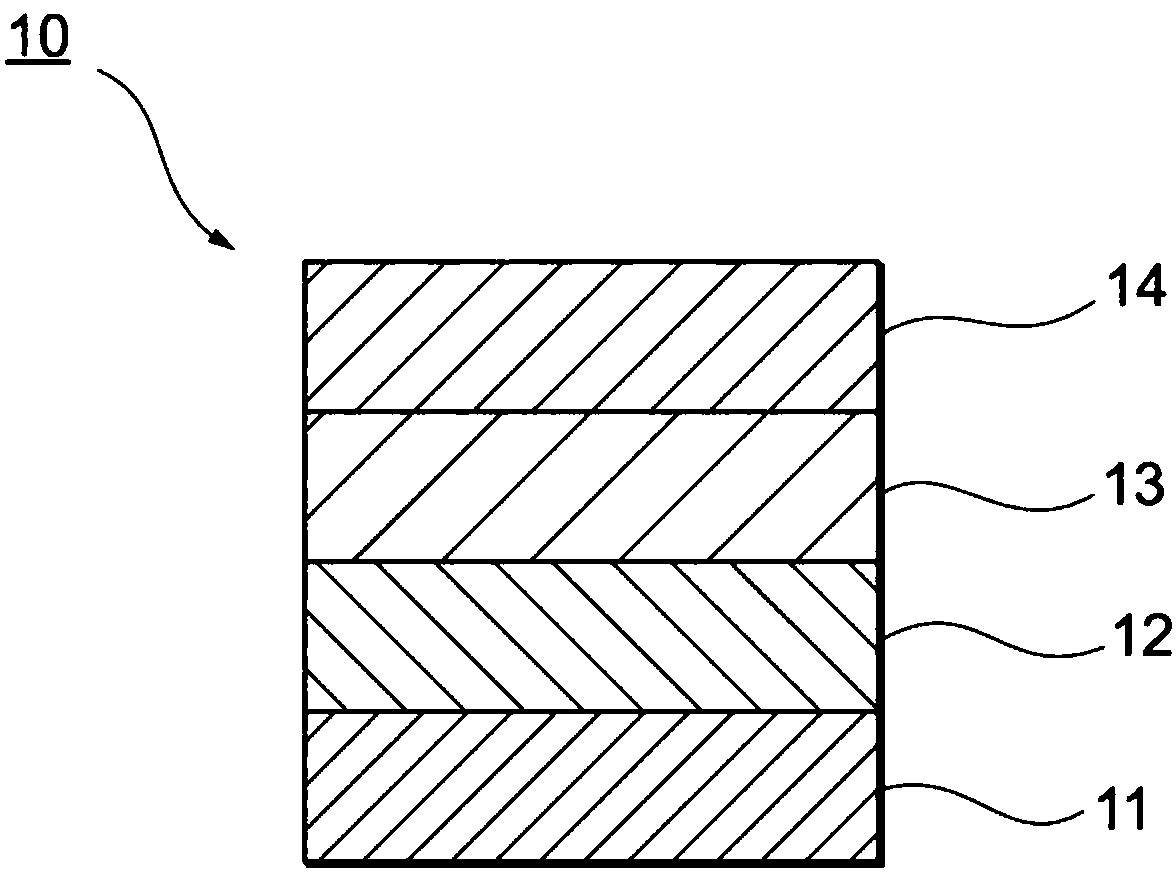

[0133] Figure 4 It is a schematic diagram showing the positional relationship among the magnetoresistance effect element 10 , the magnetic field applying mechanism 21 and the electric field applying mechanism 31 according to the second embodiment of the present invention. The magnetoresistance effect element 10 includes a control layer 11 , a magnetization free layer 12 with a variable magnetization direction, an intermediate layer 13 and a magnetization fixed layer 14 with a constant magnetization direction. The magnetization fixed layer 14 is made of a ferromagnetic material, and its magnetization direction is actually fixed to one direction in the plane of the magnetization fixed layer. The magnetic field applying mechanism 21 has a function of applying a magnetic field to the control layer 11 in a direction perpendicular to the stacking direction. The electric field applying mechanism 31 has a function of applying an electric field to the control layer 11 in a direction ...

no. 3 approach

[0138] Figure 5 It is a schematic diagram showing the positional relationship among the magnetoresistance effect element 10 , the magnetic field applying mechanism 21 and the electric field applying mechanism 31 according to the third embodiment of the present invention. The magnetoresistance effect element 10 includes a control layer 11 , a magnetization free layer 12 with a variable magnetization direction, an intermediate layer 13 and a magnetization fixed layer 14 with a constant magnetization direction. The magnetization fixed layer 14 is made of a ferromagnetic material, and its magnetization direction is actually fixed to one direction in the plane of the magnetization fixed layer. The magnetic field applying mechanism 21 has a function of applying a magnetic field to the control layer 11 in a direction perpendicular to the plane. The electric field applying mechanism 31 has a function of applying an electric field to the control layer 11 in a direction perpendicular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com