Ferromagnet composite polymer nanofilm and preparation method thereof

A composite polymer and nano-film technology, applied in the preparation of the nano-film and the field of ferromagnetic composite polymer nano-film, can solve the problems of large leakage current, reduced magnetoelectric performance, weak magnetoelectric effect, etc., and achieve inevitable improvement. The effect of increasing the magnetoelectric effect and improving the agglomeration phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

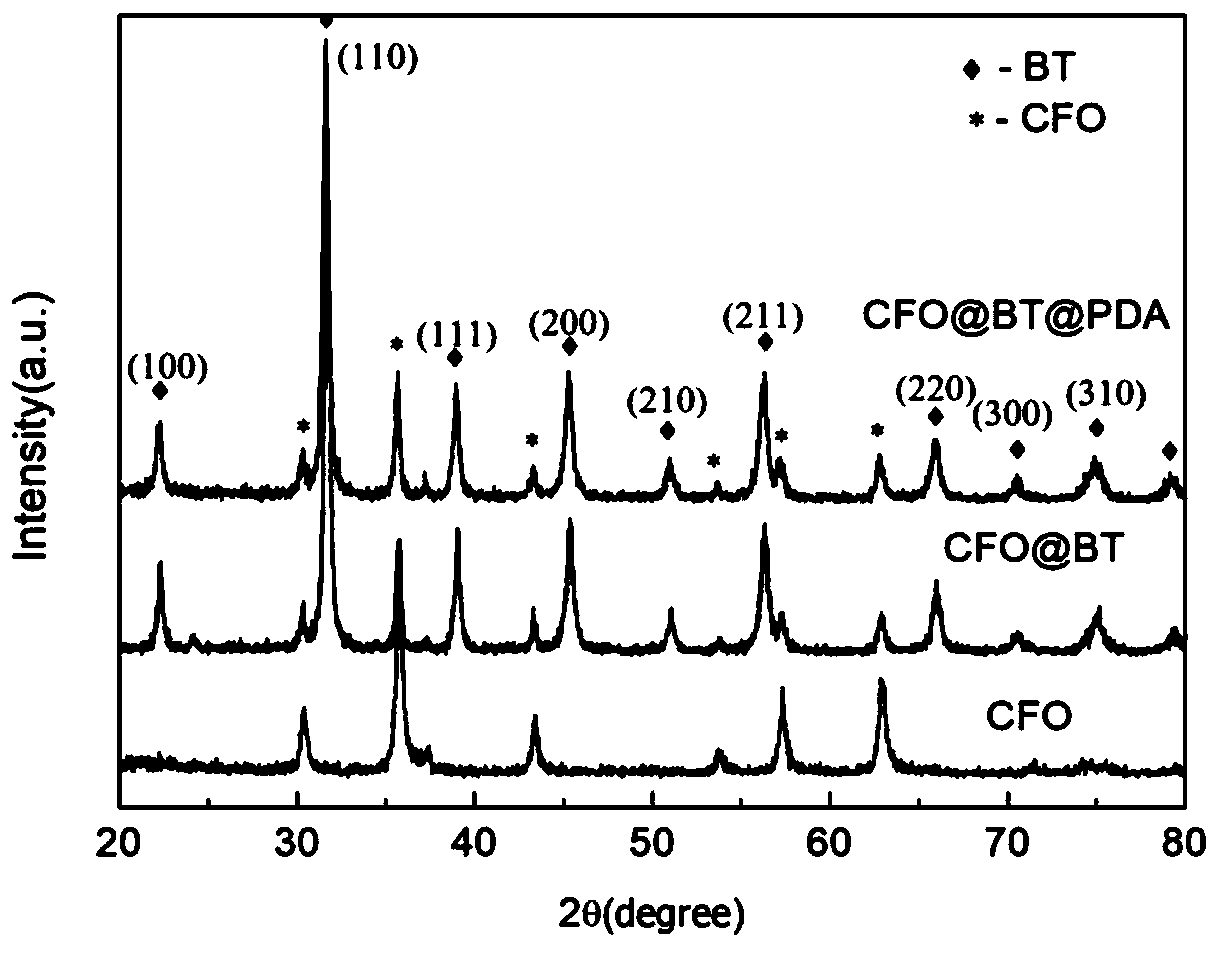

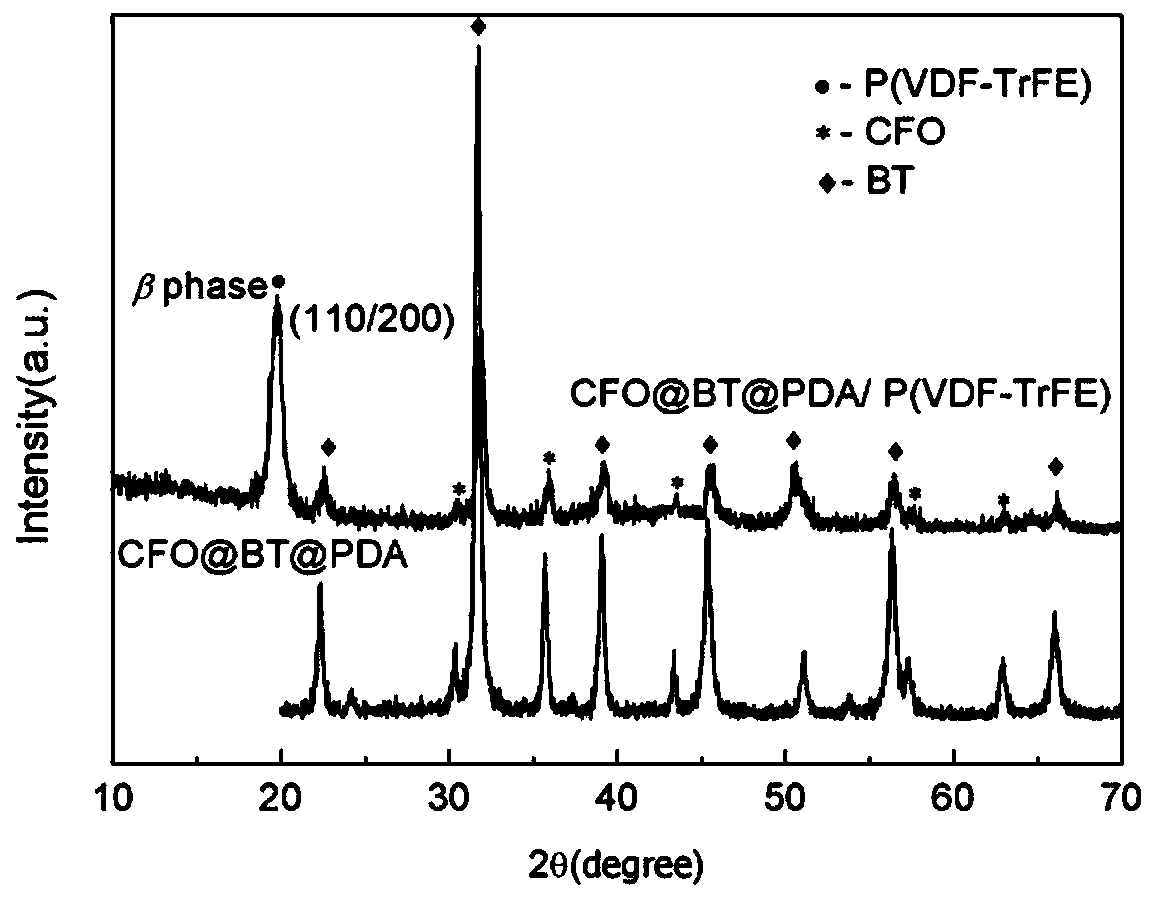

Image

Examples

Embodiment 1

[0045] A preparation method of a ferromagnetic composite polymer nano film, specifically implemented according to the following steps:

[0046] 0.05gCoFe 2 o 4 Nanoparticles were added to 18ml of deionized water, and ultrasonically dispersed to form a suspension; then the suspension was stirred in a water bath and heated to 78°C, and oleic acid with a mass percentage of 25% of the suspension was added dropwise to the suspension, Stir while adding dropwise, raise the temperature to 90°C, keep it warm for 1h, and after naturally cooling down to room temperature, take out the precipitate, wash it twice with absolute ethanol and deionized water, put it in an oven and dry it under vacuum at 65°C for 24h to obtain modified CoFe 2 o 4 Nanoparticles, namely modified CFO nanoparticles.

[0047] According to the molar ratio Ba:Ti=1:1, titanium isopropoxide and citric acid were continuously stirred in 50ml ethanol, and heated at 90°C for 20min to obtain a titanium citrate solution; 0....

Embodiment 2

[0052] A preparation method of a ferromagnetic composite polymer nano film, specifically implemented according to the following steps:

[0053] 0.052gCoFe 2 o 4 Nanoparticles were added to 20ml of deionized water, and ultrasonically dispersed to form a suspension; then the suspension was stirred in a water bath and heated to 79°C, and oleic acid with a mass percentage of 25% of the suspension was added dropwise to the suspension, Stir while adding dropwise, raise the temperature to 90°C, keep it warm for 1h, and after naturally cooling down to room temperature, take out the precipitate, wash it twice with absolute ethanol and deionized water, put it in an oven and dry it under vacuum at 65°C for 24h to obtain modified CoFe 2 o 4 Nanoparticles, namely modified CFO nanoparticles.

[0054] According to the molar ratio Ba:Ti=1:1, titanium isopropoxide and citric acid were continuously stirred in 50ml ethanol, and heated at 90°C for 20min to obtain a titanium citrate solution; 0...

Embodiment 3

[0059] A preparation method of a ferromagnetic composite polymer nano film, specifically implemented according to the following steps:

[0060] 0.056gCoFe 2 o 4 Nanoparticles were added to 20ml of deionized water, and ultrasonically dispersed to form a suspension; then the suspension was stirred in a water bath and heated to 80°C, and oleic acid with a mass percentage of 25% of the suspension was added dropwise to the suspension, Stir while adding dropwise, raise the temperature to 90°C, keep it warm for 1h, and after naturally cooling down to room temperature, take out the precipitate, wash it twice with absolute ethanol and deionized water, put it in an oven and dry it under vacuum at 65°C for 24h to obtain modified CoFe 2 o 4 Nanoparticles, namely modified CFO nanoparticles.

[0061] According to the molar ratio Ba:Ti=1:1, titanium isopropoxide and citric acid were continuously stirred in 50ml ethanol, and heated at 90°C for 20min to obtain a titanium citrate solution; 0...

PUM

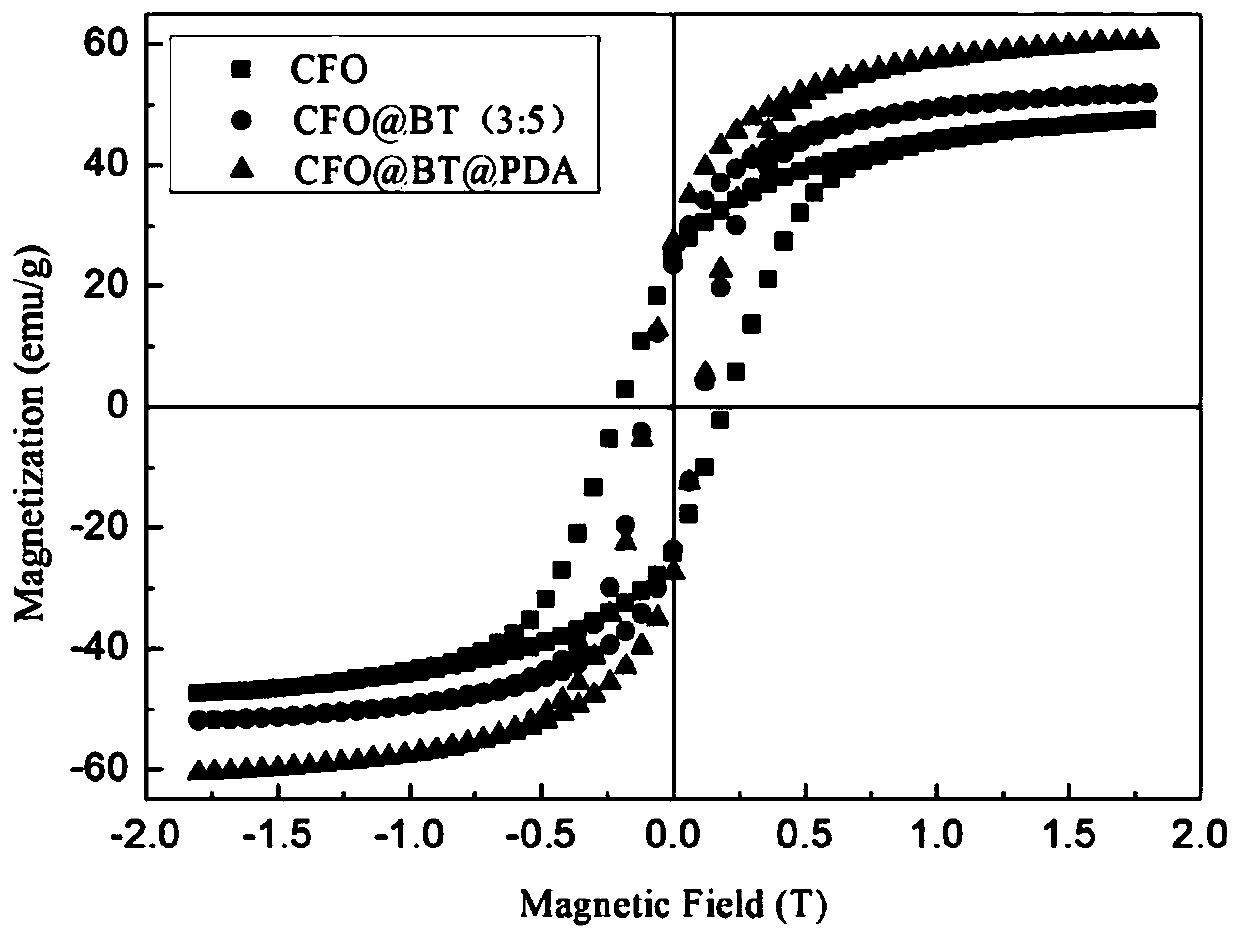

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com