Method multi-field coupling preparation magnetoelectric composite

A magnetoelectric composite material and mixed powder technology, which is applied in the field of magnetoelectric composite materials to achieve the effect of improving magnetoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

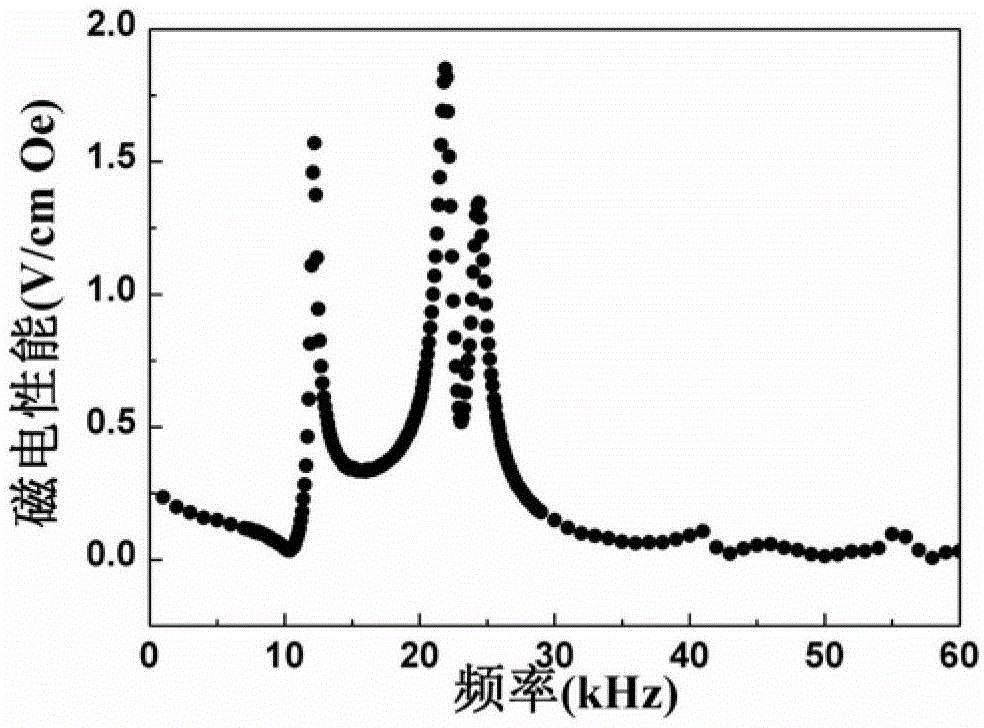

Embodiment 1

[0022] Put Terfenol-D rare earth giant magnetostrictive material powder less than 250 μm in proportion with epoxy resin E-12 binder and silane (KH550) coupling agent into a closed container and mix uniformly to obtain a mixed powder, in which The weight of the agent is 3% of the weight of the rare earth giant magnetostrictive material powder, and the weight of the coupling agent is 0.1% of the weight of the rare earth giant magnetostrictive powder; put the mixed powder into the forming mold, keep it warm for 1 minute, and apply a prefabricated pressure of 5MPa , wherein the forming mold is kept at room temperature; under a DC magnetic field with an orientation magnetic field of 0 Tesla and a forming pressure of 80 MPa, keep the pressure for 2 minutes to obtain a bonded magnet body; put the bonded magnet body into an 80°C incubator Curing for 2 hours to obtain a bonded magnet; the bonded magnet and the polarized piezoelectric ceramic sheet were glued with 914AB glue produced by ...

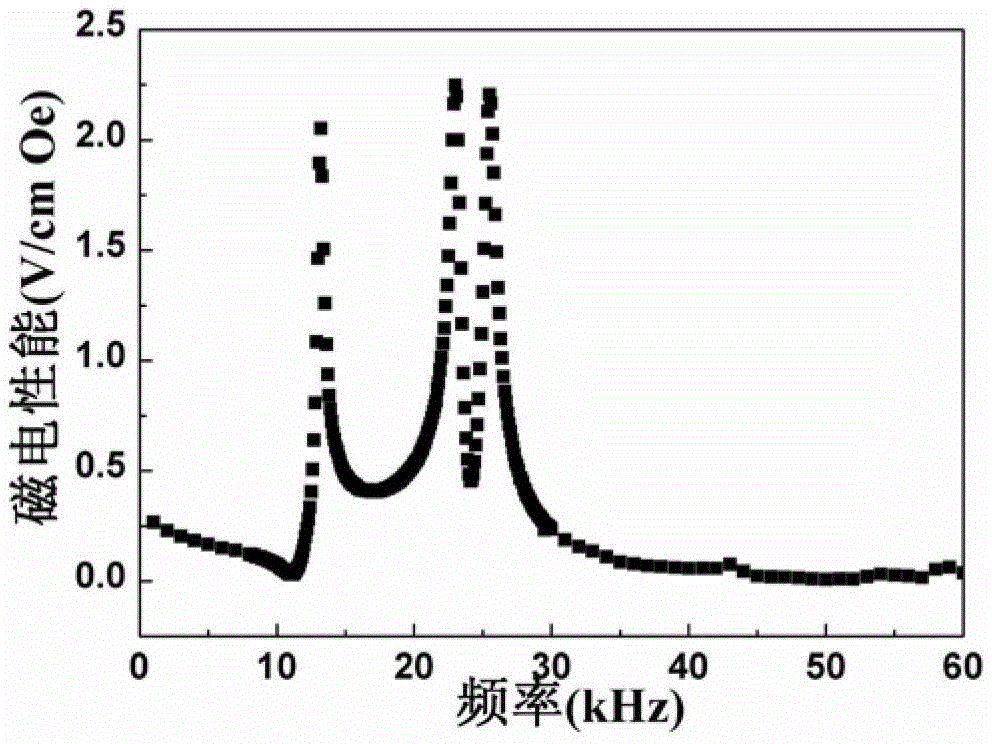

Embodiment 2

[0024] Put Terfenol-D rare earth giant magnetostrictive material powder less than 250 μm in proportion with epoxy resin E-12 binder and silane (KH550) coupling agent into a closed container and mix uniformly to obtain a mixed powder, in which The weight of the agent is 50% of the weight of the rare earth giant magnetostrictive material powder, and the weight of the coupling agent is 0.3% of the weight of the rare earth giant magnetostrictive powder; put the mixed powder into the forming mold, keep it warm for 5 minutes, and apply a prefabricated pressure of 5MPa , wherein the forming mold is maintained at 130°C; under a DC magnetic field with an orientation magnetic field of 0 Tesla and a forming pressure of 300MPa, keep the pressure for 20 seconds to obtain a bonded magnet body; put the bonded magnet body at 100°C for heat preservation The bonded magnet was obtained by curing in the box for 24 hours; the bonded magnet and the polarized piezoelectric ceramic sheet were glued wi...

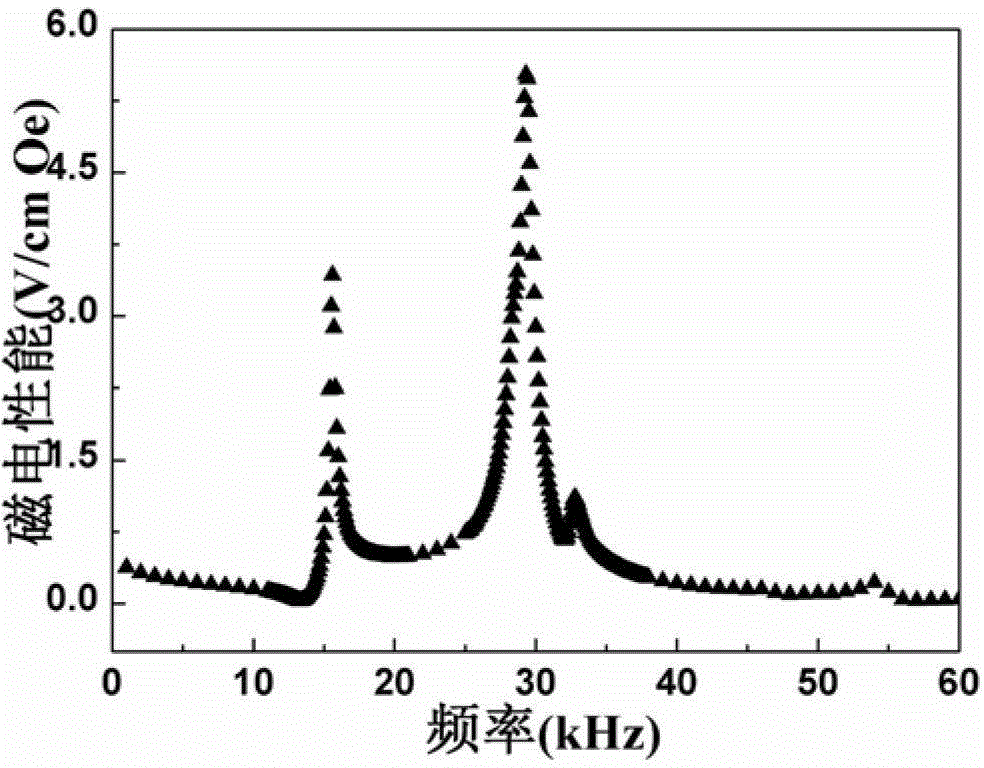

Embodiment 3

[0026] Put Terfenol-D rare earth giant magnetostrictive material powder less than 250 μm in proportion with epoxy resin E-12 binder and silane (KH550) coupling agent into a closed container and mix uniformly to obtain a mixed powder, in which The weight of the agent is 23% of the weight of the rare earth giant magnetostrictive material powder, and the weight of the coupling agent is 0.2% of the weight of the rare earth giant magnetostrictive powder; put the mixed powder into the forming mold, keep it warm for 3 minutes, and apply a prefabricated pressure of 5MPa , wherein the forming mold is kept at room temperature; under a DC magnetic field with an orientation magnetic field of 2 Tesla and a forming pressure of 200 MPa, keep the pressure for 1 minute to obtain a bonded magnet body; put the bonded magnet body into a 90°C incubator Solidified for 12 hours to obtain a bonded magnet; the bonded magnet and the polarized piezoelectric ceramic sheet were glued with 914AB glue produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com