Circular cylinder-shaped composite material with giant magnetoelectric effect and method for making same

A magnetoelectric composite material, cylindrical technology, applied in the manufacture/processing of electromagnetic devices, manufacture/assembly of magnetostrictive devices, manufacture/assembly of piezoelectric/electrostrictive devices, etc., can solve the transmission of force It is not very ideal, and the process conditions are easy to control, the magnetic and electrical properties are improved, and the elastic loss is avoided.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

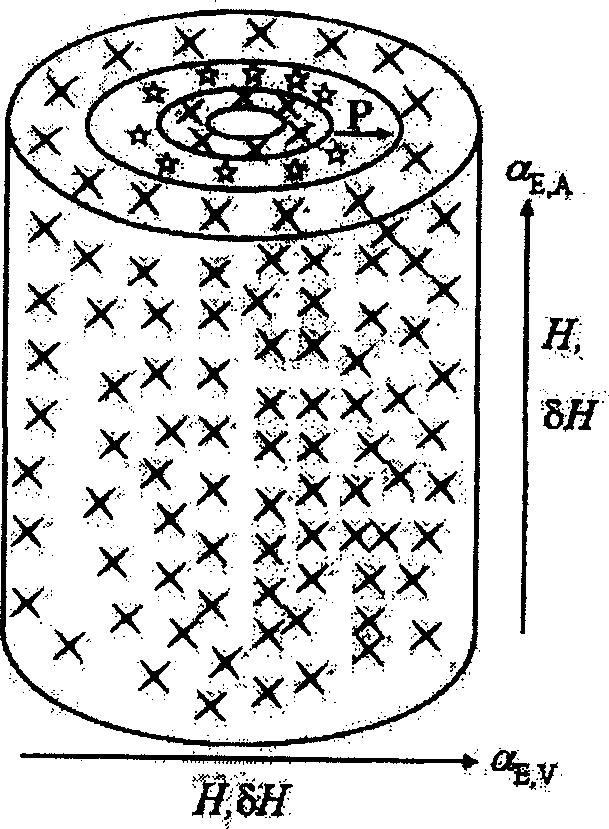

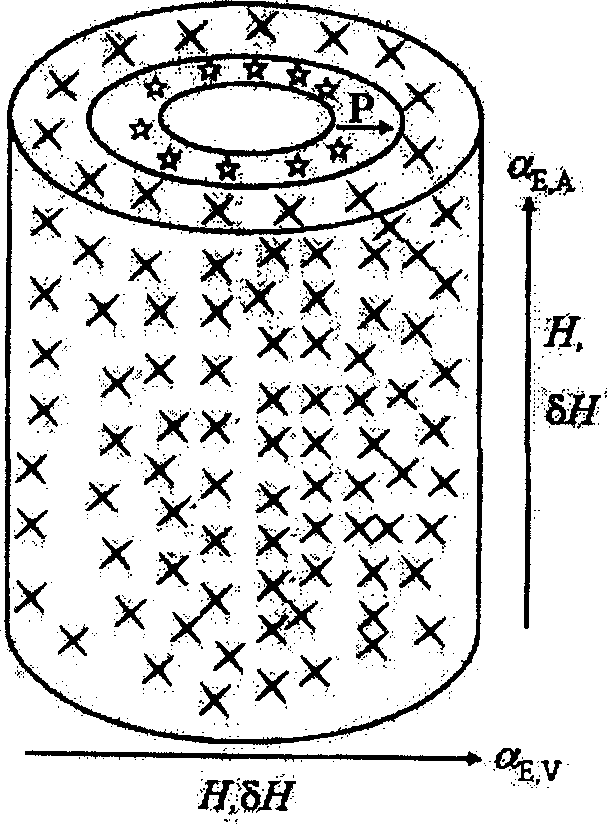

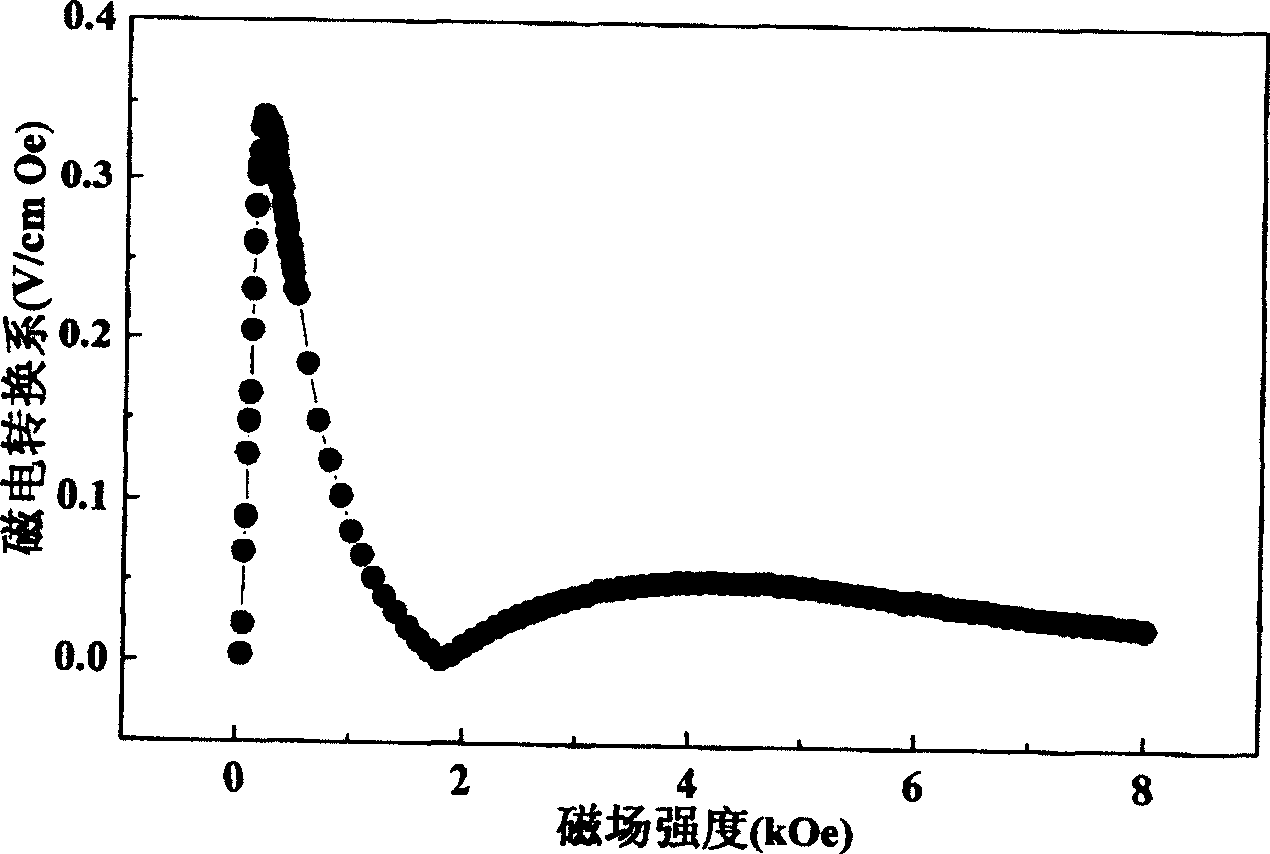

[0023] The PZT is cold-pressed and sintered into a cylindrical shape of 8×φ18×φ20mm, where 8mm is the height of the cylinder, and φ18 and φ20 are the inner and outer diameters of the cylinder, respectively, with electrodes on both sides. Then polarize the PZT with the prepared electrode in the silicone oil at 150°C with an electric field of 50kv / cm, the polarization direction is along the radial direction of the cylinder, from the inside to the outside, keep the electric field and temperature for 30 minutes, and then cool with the oil to room temperature. The polarized sample was ultrasonically cleaned with acetone until the surface silicone oil and organic matter were removed, and rinsed with deionized water. The cleaned samples were plated with Ni electrodes by electroless plating, and wires were welded on the surfaces of the two electrodes. Put the sample into the prepared electroplating solution for electroplating.

[0024] Temperature control and magnetic stirring are r...

Embodiment 2

[0028] The PZT is cold-pressed and sintered and cut into a 3×φ18×φ20mm cylinder, where 8mm is the height of the cylinder, and φ18 and φ20 are the inner and outer diameters of the cylinder, respectively, with electrodes on both sides. Then polarize the PZT with the prepared electrode in the silicone oil at 150°C with an electric field of 50kv / cm, the polarization direction is along the radial direction of the cylinder, from the inside to the outside, keep the electric field and temperature for 30 minutes, and then cool with the oil to room temperature. The polarized sample was ultrasonically cleaned with acetone until the surface silicone oil and organic matter were removed, and rinsed with deionized water. The cleaned samples were plated with Ni electrodes by electroless plating, and wires were welded on the surfaces of the two electrodes. Seal the inner surface of the cylinder with 704 silicone rubber produced by Nanjing University, put the sample into the prepared electropl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com