Crystalline modified method for transfering phase polymer in magnetic-force-electro-coupling effect

A polymer and crystalline polymer technology, applied in the direction of device material selection, etc., can solve the problems of low piezoelectric performance and magnetoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

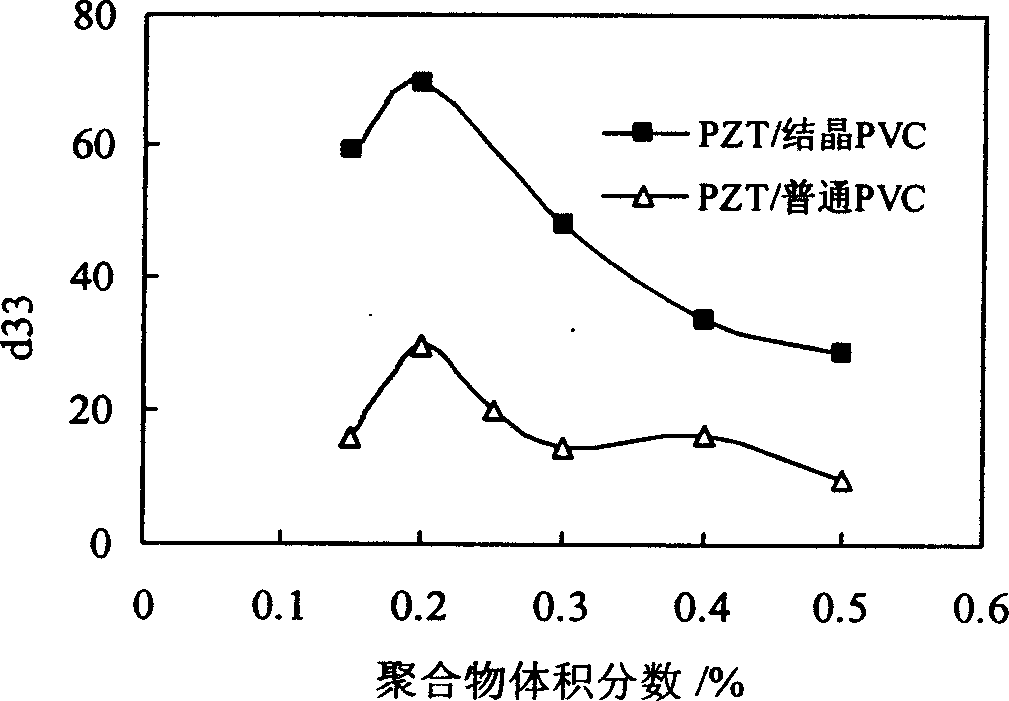

[0019] Dissolve isotactic PVC with cyclohexanone solvent, use the solution to spray dry ordinary PVC powder, and heat-treat at 100°C for 4 hours to obtain crystalline PVC powder. The crystalline PVC is pulverized by a jet mill to obtain nanocrystalline PVC powder of 5-20 μm, wherein the crystal grains in the nanocrystalline PVC powder are less than 100 nm. Hot press molding, the hot press molding time is 25min, and the pressure is 10MPa. Piezoelectric constant d of crystalline PVC and PZT composites and common PVC and PZT composites 33 The relationship curve with polymer volume fraction is shown in figure 1 . It can be seen from the figure that the piezoelectric performance of crystalline PVC and PZT composites is higher than that of ordinary PVC and PZT composites.

Embodiment 2

[0021] Dissolve isotactic PVC with cyclohexanone solvent, use the solution to spray dry ordinary PVC powder, heat treat at 120°C for 2 hours, and obtain crystalline PVC powder. The crystalline PVC is pulverized by a jet mill to obtain 5-20 μm nanocrystalline PVC micropowder, wherein the crystal grains in the nanocrystalline PVC micropowder are less than 100 nm, and crystalline PVC with a crystallinity of 15-30% is obtained. The crystalline PVC, PZT and terfenol-D (Terfenol-D) were hot-pressed at 155°C at a volume ratio of 30:64:6, the molding time was 10min, the pressure was 20MPa, and the magnetoelectric conversion coefficient of the composite material αE 33 It is 60mV / cm Oe, and the composite material composed of ordinary PVC, PZT and Terfenol-D cannot be tested for magnetic and electrical properties.

Embodiment 3

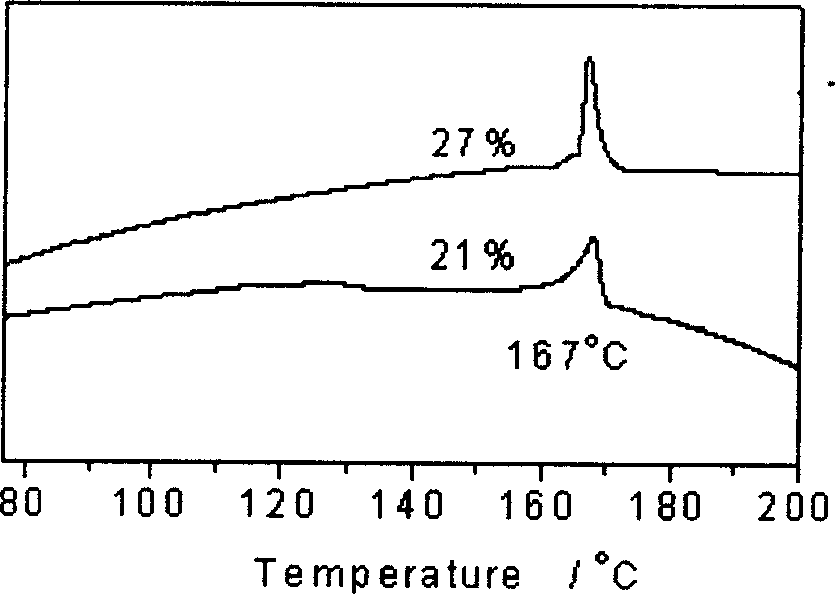

[0022] Example 3: PVDF and PZT are hot-pressed at 170°C according to the volume ratio of 30:70, the time is 30min, and the pressure is 10MPa. After forming, it is divided into two parts, and one part of the composite material is quenched, and the crystallization of PVDF in the PZT and PVDF composite material degree at 21%, see figure 2 , the piezoelectric constant d of the composite 33 is 40pC / N; another composite material was annealed at 120°C for 6 hours under pressure at 10MPa, and the crystallinity of PVDF in the obtained PZT and PVDF composite material was 27%, see figure 2 , the piezoelectric constant d of the composite 33 It is 75pC / N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com