Magnetoelectric composite film and its preparation method

A composite film and magnetoelectric composite technology, which is applied in the direction of the magnetism of inorganic materials, can solve problems that do not involve the measurement of the magnetoelectric effect of composite films, and achieve good ferroelectricity and ferromagnetism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

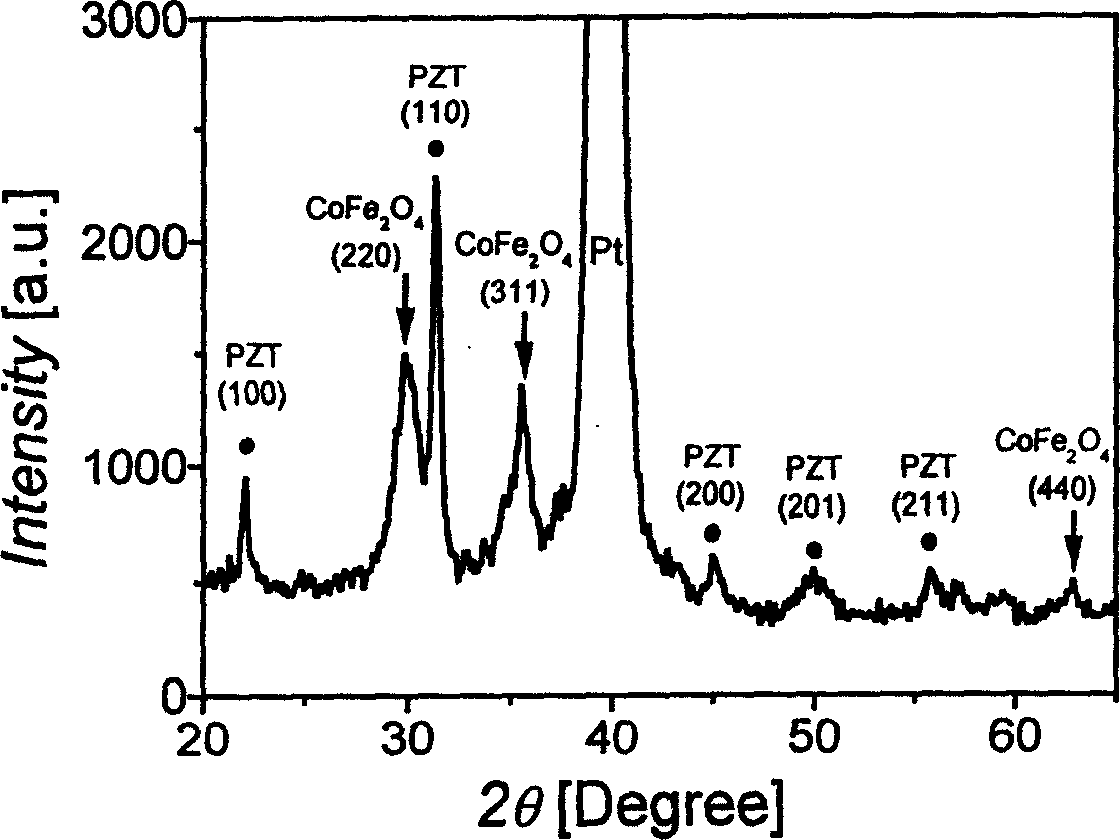

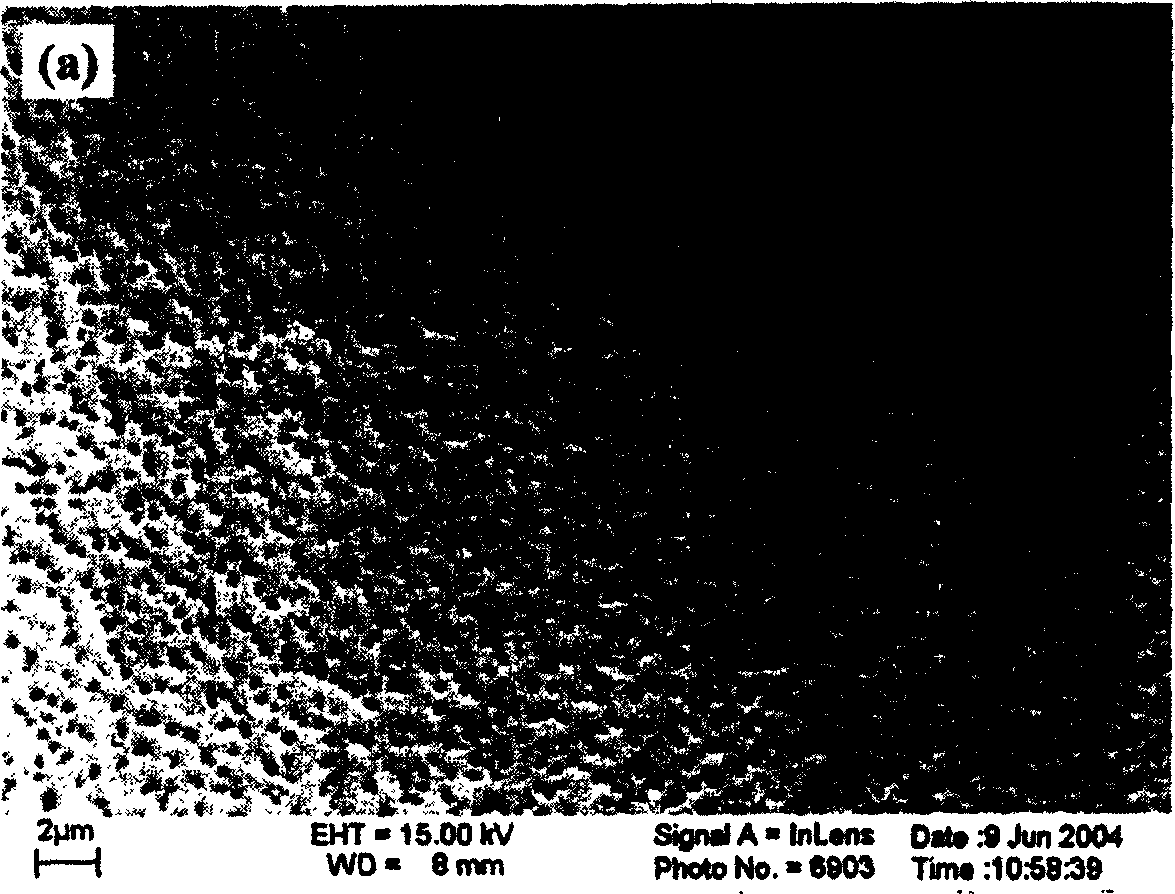

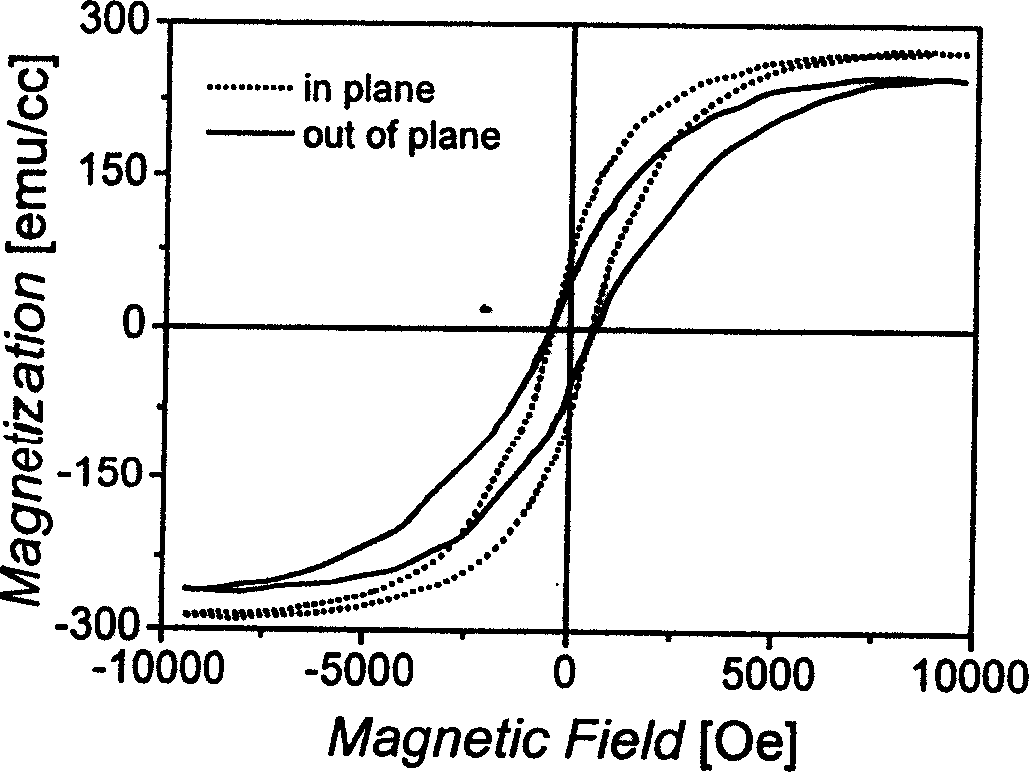

[0034] Example 1: 0.5CoFe 2 o 4 -0.5PZT composite film

[0035] (1) Raw materials:

[0036] Cobalt acetate [Co(CH 3 COO) 2 4H 2 O], iron nitrate [Fe(NO 3 ) 3 9H 2 O], lead acetate [Pb(CH 3 COO) 2 ·3H 2 O], zirconium nitrate [Zr(NO 3 )·5H 2 O], butyl titanate [Ti(C 4 h 9 O) 4 ], ethylene glycol methyl ether, glacial acetic acid.

[0037] Platinum-coated silicon wafer (Pt / Ti / SiO 2 / Si).

[0038] (2) Preparation process:

[0039] a. Preparation of CoFe 2 o 4 Precursor solution:

[0040] Weigh 0.03mol cobalt acetate, 0.06mol ferric nitrate and 100ml ethylene glycol methyl ether. The preparation process is as follows: first put the weighed cobalt acetate and ferric nitrate into two beakers respectively, add 30ml and 50ml of ethylene glycol methyl ether, respectively, stir with a magnetic stirrer at 40°C until completely dissolved, and then put Mix the solutions in the above two beakers with each other and add the remaining ethylene glycol methyl ether. The mi...

Embodiment 2

[0057] Example 2: 0.33CoFe 2 o 4 -0.67PZT composite film

[0058] (1) Raw materials:

[0059] Cobalt acetate [Co(CH 3 COO) 2 4H 2 O], iron nitrate [Fe(NO 3 ) 3 9H 2 O], lead acetate [Pb(CH 3 COO) 2 ·3H 2 O], zirconium nitrate [Zr(NO 3 )·5H 2 O], butyl titanate [Ti(C 4 h 9 O) 4 ], ethylene glycol methyl ether, glacial acetic acid.

[0060] Platinum-coated silicon wafer (Pt / Ti / SiO 2 / Si).

[0061] (2) Preparation process:

[0062]a. Preparation of CoFe 2 o 4 Precursor solution:

[0063] Weigh 0.02mol cobalt acetate, 0.04mol iron nitrate and 100ml ethylene glycol methyl ether. The preparation process is as follows: first put the weighed cobalt acetate and ferric nitrate into the beaker respectively, add 25ml and 40ml of ethylene glycol methyl ether, respectively, stir with a magnetic stirrer at 45°C until completely dissolved, and then mix the above The solutions in the two beakers were mixed with each other and the remaining ethylene glycol methyl ether wa...

Embodiment 3

[0069] Example 3: 0.6CoFe 2 o 4 -0.4PZT composite film

[0070] (1) Raw materials:

[0071] Cobalt acetate [Co(CH 3 COO) 2 4H 2 O], iron nitrate [Fe(NO 3 ) 3 9H 2 O], lead acetate [Pb(CH 3 COO) 2 ·3H 2 O], zirconium nitrate [Zr(NO 3 )·5H 2 O], butyl titanate [Ti(C 4 h 9 O) 4 ], ethylene glycol methyl ether, glacial acetic acid.

[0072] Platinum-coated silicon wafer (Pt / Ti / SiO 2 / Si).

[0073] (2) Preparation process:

[0074] a. Preparation of CoFe 2 o 4 Precursor solution:

[0075] Weigh 0.04mol cobalt acetate, 0.08mol iron nitrate and 100ml ethylene glycol methyl ether. The preparation process is as follows: first, put the weighed cobalt acetate and ferric nitrate into two beakers respectively, add 30ml and 60ml of ethylene glycol methyl ether, respectively, stir with a magnetic stirrer at 50°C until completely dissolved, and then put Mix the solutions in the above two beakers with each other and add the remaining ethylene glycol methyl ether. The mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com