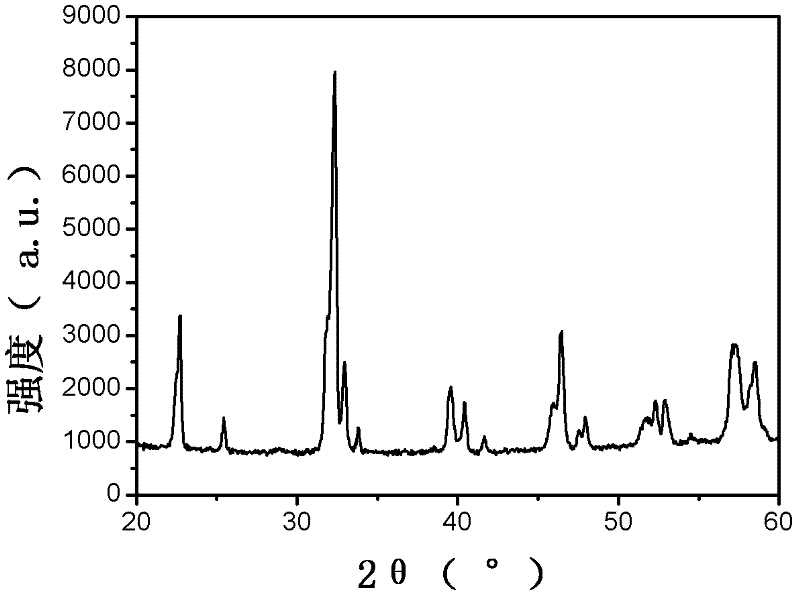

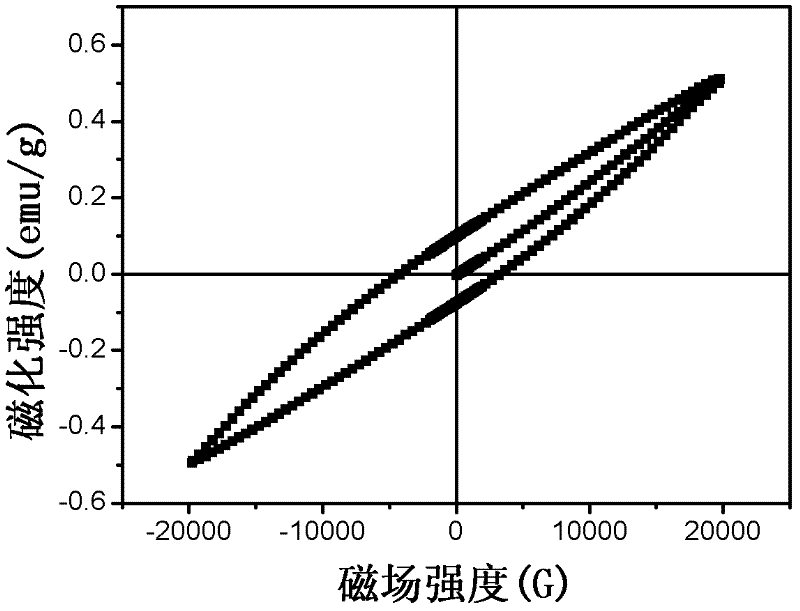

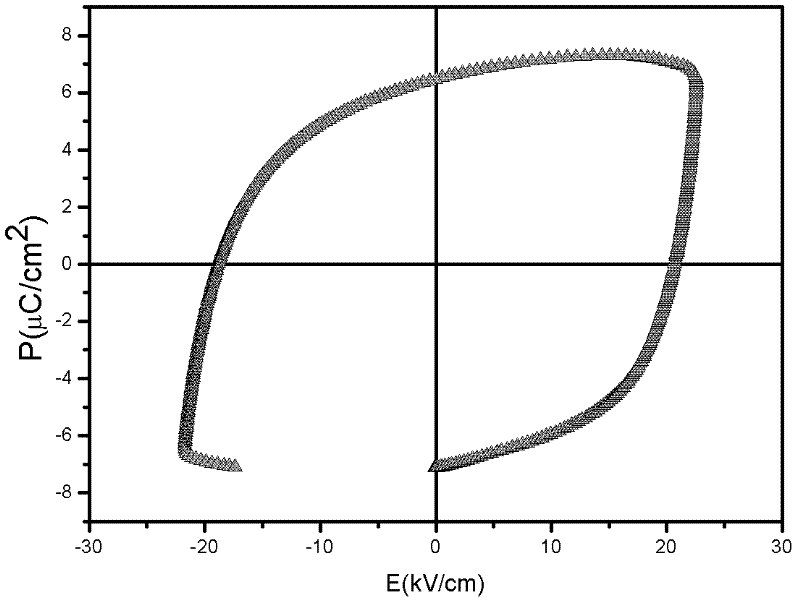

Dysprosium-doped BiFeO3 multi-ferroic ceramic block and preparation method thereof

A multiferroic and bulk technology, applied in the field of functional ceramics, can solve the problems of large leakage current and difficulty in displaying macroscopic magnetic moments, and achieve the effects of good ferroelectricity, low cost, good ferromagnetism and ferroelectricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A BiFeO 3 A method for preparing a multiferroic bulk ceramic, the method is carried out according to the following steps:

[0031] Step 1, take by weighing 30.559g of Bi(NO 3 ) 3 ·5H 2 O was added with 100ml of glacial acetic acid, heated to 65°C with a magnetic stirrer and stirred to dissolve to obtain solution 1; weigh 24.24g of Fe(NO 3 ) 3 9H 2 O was dissolved in 50ml deionized water to obtain solution 2.

[0032] Step 2, mixing the solutions 1 and 2 to obtain a mixed solution, making the Bi in the mixed solution 3+ The ion concentration is 0.4mol / L; add 12.923g citric acid to the mixed solution, heat to 85°C with a magnetic stirrer and stir, add 10% ammonia water dropwise during heating and stirring to adjust the pH=1 of the mixed solution; continue Heat and stir until a gel is obtained.

[0033] Step 3: Bake the gel at 130°C for 12 hours to foam to obtain an airgel; grind the airgel with an agate mortar to obtain a nanoscale powder; heat the powder and slow...

Embodiment 2

[0040] A Dy-doped BiFeO 3 A method for preparing a multiferroic bulk ceramic, the method is carried out according to the following steps:

[0041] Step 1, take by weighing 29.254g of Bi(NO 3 ) 3 ·5H 2 O was dissolved in 100ml of glacial acetic acid, heated to 70°C with a magnetic stirrer and stirred to dissolve to obtain solution 1; weigh 0.224g of Dy 2 o 3 Adding 20ml concentration is that 5% dilute nitric acid aqueous solution dissolves and obtains solution 2; Fe(NO 3 ) 3 9H 2 O was dissolved in 30ml deionized water to obtain solution 3.

[0042] Step 2, mixing the solutions 1, 2 and 3 to obtain a mixed solution, making Bi in the mixed solution 3+ The ion concentration is 0.4mol / L; add 12.914g citric acid to the mixed solution, heat to 85°C with a magnetic stirrer and stir, add 10% ammonia water dropwise during heating and stirring to adjust the pH of the mixed solution to 1.5, and continue Heat and stir until a gel is obtained.

[0043] Step 3: Bake the gel at 130...

Embodiment 3

[0050] A Dy-doped BiFeO 3 A method for preparing a multiferroic bulk ceramic, the method is carried out according to the following steps:

[0051] Step 1, take by weighing 29.031g of Bi(NO 3 ) 3 ·5H 2 O was dissolved in 100ml of glacial acetic acid, heated to 80°C with a magnetic stirrer and stirred to dissolve to obtain solution 1; weigh 1.119g of Dy 2 o 3 Adding 20ml concentration is that 5% dilute nitric acid aqueous solution dissolves and obtains solution 2; Fe(NO 3 ) 3 9H 2 O was dissolved in 50ml deionized water to obtain solution 3.

[0052] Step 2, mixing solutions 1, 2 and 3 to obtain a mixed solution, making the Bi in the mixed solution 3+ The ion concentration is 0.4mol / L; add 12.908g citric acid to the mixed solution, heat to 90°C with a magnetic stirrer and stir, add 10% ammonia water dropwise to adjust the pH of the mixed solution to 1, and continue heating and stirring until the condensate is obtained. glue.

[0053] Step 3: Bake the gel at 130°C for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com