Single-phase ceramic target and preparation method and application thereof

A single-phase ceramic and target material technology, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of bismuth element loss, difficulty, high sintering temperature, etc., and achieve high saturation magnetization and equipment requirements The effect of low, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

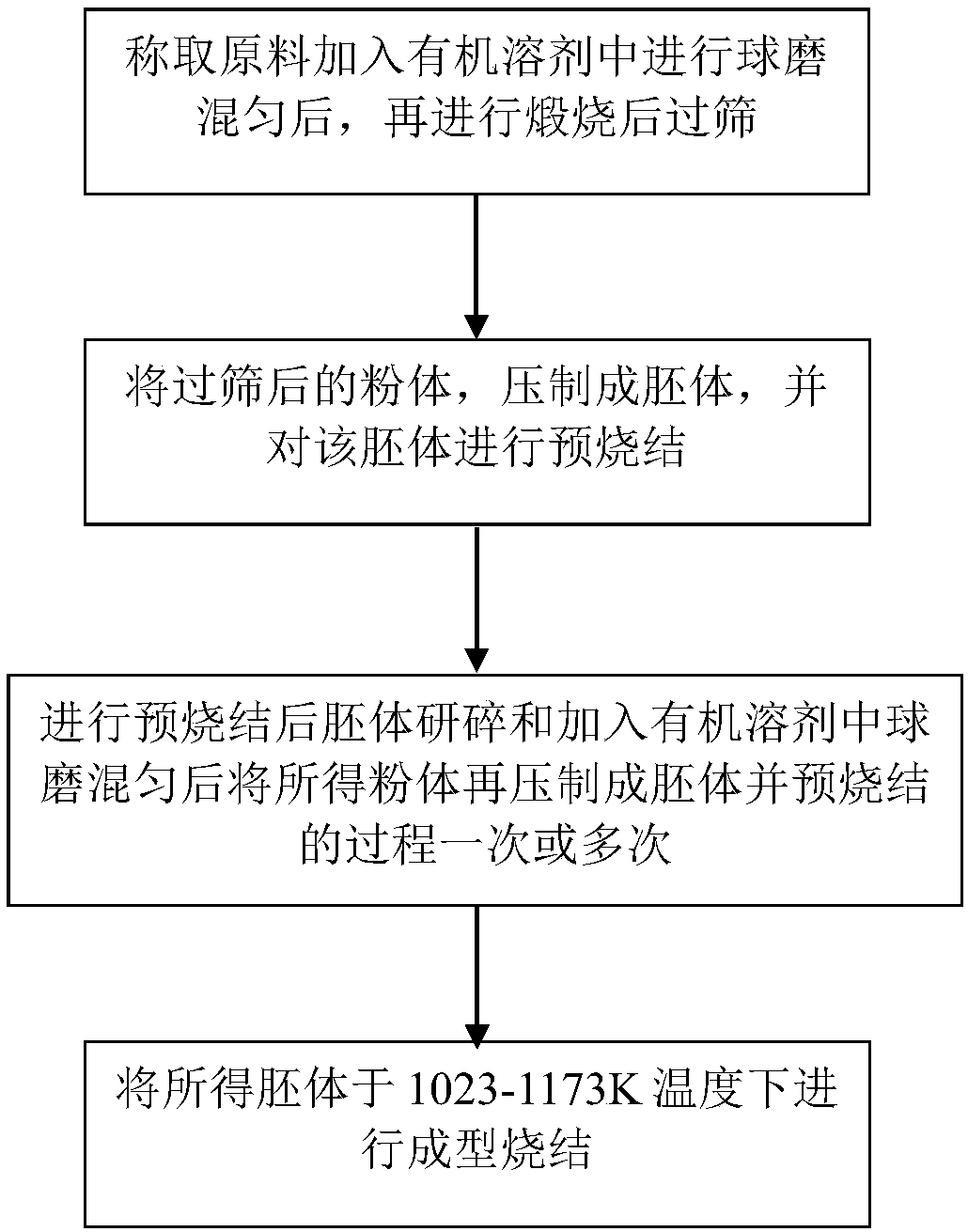

[0031] The present invention provides a single-phase ceramic target preparation method. The preparation method may include: first weighing raw materials according to an appropriate calculated amount, mixing the weighed raw materials, adding an organic solvent therein, and then performing ball milling and mixing; Calcining the powder obtained after ball mill mixing, and sieving after calcination; pressing the powder obtained after sieving into an embryo body, and pre-sintering the embryo body; then grinding the pre-sintered embryo body crushed, and adding an organic solvent to it for ball milling and mixing; the powder obtained after ball milling and mixing is pressed again into an embryo body. The whole process of pre-sintering and grinding the green body after pre-sintering, adding an organic solvent for ball milling and mixing to form the green body can be repeated once or more times. Finally, the obtained green body is pre-sintered at a low temperature and then shaped and s...

Embodiment 1

[0051] 1. Make Bi with a purity of more than 99.99% 2 o 3 、TiO 2 , Fe 2 o 3 , MgO, CaCO 3 Equal high-purity powders are weighed and dosed according to the stoichiometric ratio, because Bi 2 o 3 It is easy to volatilize during the sintering process, and it needs to add 7% more than the stoichiometric ratio.

[0052] 2. Add the ingredients in step 1 to anhydrous ethanol to make them evenly mixed, and use a ball mill to fully grind them for 45 minutes to make the raw materials mix evenly.

[0053] 3. Calcining the powder obtained in step 2, the calcination temperature is 675-750K, the sintering time is 2h, and the powder is sieved after calcination.

[0054] 4. Put the powder obtained in step 3 into a mold, and use cold isostatic pressing to form an embryo, and the pressure is 40-70Mpa.

[0055] 5. Put the ceramic embryo obtained in step 4 into a muffle furnace for pre-sintering, the sintering temperature is 850-900K, and the sintering time is 3 hours.

[0056] 6. Grind ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com