Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Excellent ferroelectric" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing bismuth ferrite based multifunctioanl oxide ceramic material

InactiveCN101050120ARoom temperature ferromagneticInhibition of price changeRare-earth elementOxide ceramic

This invention relates to a method for preparing BiFeO3-based multifunctional oxide ceramic. The method comprises: (1) pre-pressing BLTFO8 powder into a disc, loading oxide protective powder (Al2O3, CeO2, ZrO2 or FeO) into a graphite mold, and pressing; (2) transferring the BLTFO8 disc onto the oxide protective powder layer in the mold; (3) continuing adding oxide protective powder into the mold to embed the BLTFO8 disc, and pressing; (4) transferring the mold into an SPS sintering furnace, heating to 600 deg.C within 3 min, then heating to the sintering temperature at a rate of 50 deg.C / min, keeping the temperature, and sintering. Since BiFeO3 has G-type antiferromagnetic structure, doping with rare earth element such as La or Tb, or metal element such as Ba or K can alter its antiferromagnetic structure, and the obtained BiFeO3-based multifunctional oxide ceramic has ferromagnetism at room temperature. The method can inhibit the valency change of the elements and reduce loss, and the BiFeO3-based multifunctional oxide ceramic has good ferroelectric and ferromagnetic properties at room temperature.

Owner:TSINGHUA UNIV

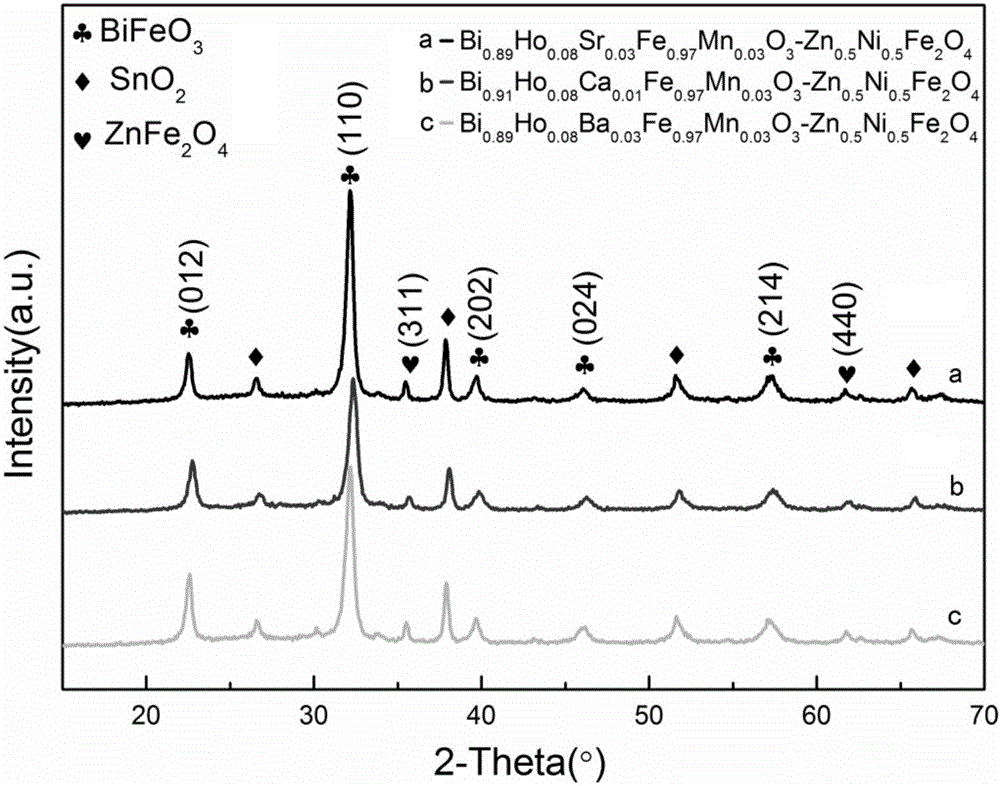

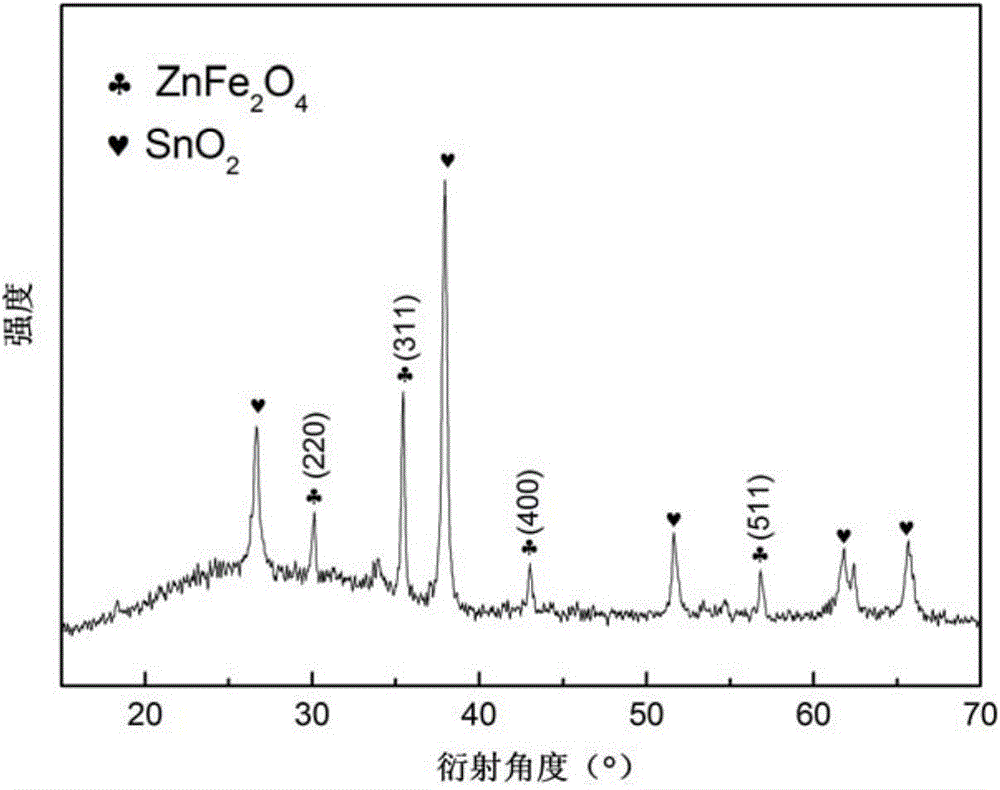

Bi0.92-xHo0.08AExFe0.97Mn0.03O3-Zn1-yNiyFe2O4 ferromagnetic composite film and preparation method thereof

InactiveCN105837196AReduce contentHigh polarizationCeramic layered productsMagnetic layerMagnetic composite

The invention provides a Bi0.92-xHo0.08AExFe0.97Mn0.03O3-Zn1-yNiyFe2O4 ferromagnetic composite film and a preparation method thereof. The ferromagnetic composite film comprises a Bi0.92-xHo0.08AExFe0.97Mn0.03O3 crystalline film and a Zn1-yNiyFe2O4 crystalline film, which are compounded together. The preparation method is as below: first respectively preparing a Zn1-yNiyFe2O4 precursor solution and a Bi0.92-xHo0.08AExFe0.97Mn0.03O3 precursor solution, wherein AE is Sr, Ca, Ba or Pb, x equals to 0.01-0.04, and y equals to 0.1-0.9; preparing a plurality of Zn1-yNiyFe2O4 films on a substrate by spin coating; and then preparing plurality of Bi0.92-xHo0.08AExFe0.97Mn0.03O3 films on the Zn1-yNiyFe2O4 films by spin coating, so as to obtain the ferromagnetic composite film. The method regulates the crystal structure of BiFeO3 by doping, and uses ferromagnetic Zn1-yNiyFe2O4 as the magnetic layer, so as to substantially increase the ferroelectric and ferromagnetic properties of the film, and effectively reduce the leakage current density of the film.

Owner:SHAANXI UNIV OF SCI & TECH

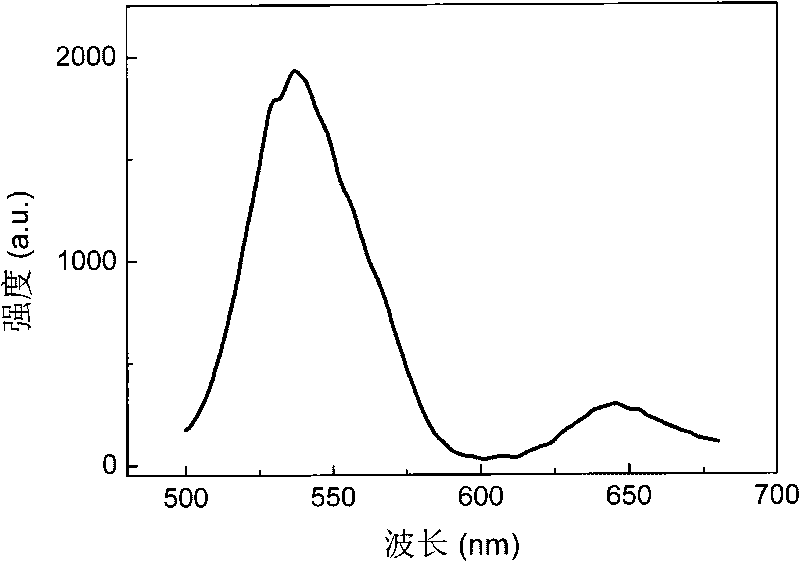

Rare earth doped bismuth titanate up-conversion luminescence ferroelectric film and preparation method thereof

InactiveCN101717201AEfficient up-conversion luminescenceEnhanced upconversion luminescenceFilm materialBismuth titanate

The invention discloses a rare earth doped bismuth titanate up-conversion luminescence ferroelectric film and a preparation method thereof. The rare earth doped bismuth titanate up-conversion luminescence ferroelectric film has the molecular formula of (Bi4-x-yErxYby)Ti3O12, wherein 0<x<=0.85, 0<y<=0.85, and 0<x+y<=0.85. The invention adopts a chemical solution-deposition method to prepare (Bi4-x-yErxYby)Ti3O12 films, the film components are easily controlled, the operation is convenient, and the invention is convenient for scale production. Besides good ferroelectric, dielectric and optical transmittance properties, the (Bi4-x-yErxYby)Ti3O12 film further has efficiently enhanced up-conversion luminescence property, is a novel important multifunctional film material, and has wide application prospect in the field of photoelectric material.

Owner:SUN YAT SEN UNIV

Preparation method of sodium bismuth titanate-based ferroelectric film

InactiveCN101805181AExcellent ferroelectricExcellent dielectric propertiesLayered productsChemistrySol-gel

The invention belongs to the field of electronic functional materials and devices, and particularly relates to a preparation method of a sodium bismuth titanate-based ferroelectric film. The invention provides the preparation method of the sodium bismuth titanate-barium titanate ferroelectric film, which is a chemical preparation method, i.e. a sol-gel method, wherein Pt / Ti / SiO2 / Si is adopted as a substrate, the concentration of a precursor solution is controlled to be 0.1 to 0.3M, clear and transparent sodium bismuth titanate-barium titanate sol is obtained through adding a novel chelating agent-ammonia water, and the ferroelectric film is prepared. In the method of the invention, the sodium bismuth titanate-barium titanate ferroelectric film is prepared by adopting the novel chelating agent-ammonia water, so that the performance of the film can be optimized.

Owner:TONGJI UNIV

Wet chemical prepn process of leadless functional barium titanate ceramic film

InactiveCN1350071AGood dielectricExcellent ferroelectricPiezoelectric/electrostrictive device manufacture/assemblyLiquid/solution decomposition chemical coatingBarium titanateSolvent

The method for preparing barium zirconate titanate (BZT) film belongs to the field of functional ceramic film. Its precursor liquor for preparing BZT is made up by using barium acetate, zirconium propylate and butyl titanate as raw material, using glycol methyl ether as solvent and using acetylacetone and glacial acetic acid as stabilizing agent according to the gran molecular concentration mixing ratio of Ba:Zr:Ti=I:X:1-X (X is greater than or equal to O and is less than or equal to 1), and its concentration is 0.2-0.3M. The above-mentioned precursor is undergone the process of filting, film-forming, whirl coating (its speed is 3000-4000 rpm and time is 30 sec.), pretreating, multiple film-forming, pretreating and film-forming to reach to required thickness, and annealing at 650-750 deg.c so as to obtain the invented product. The lead-free BZT functional film prepared by said ivnention possesses good dielectric feeraelectric and piezoelectric properties.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

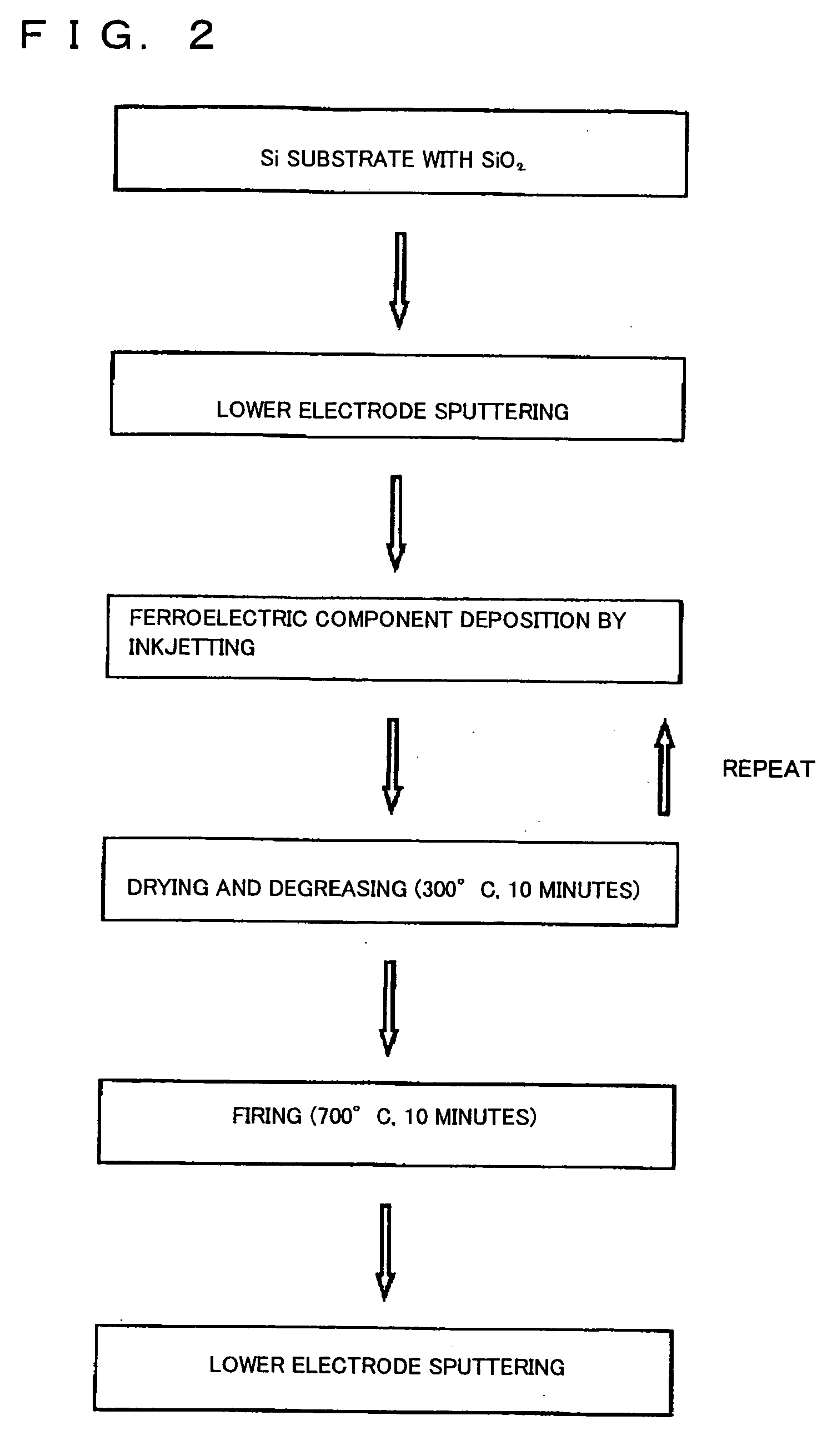

Method for making ferroelectric thin film

InactiveUS20040101980A1Excellent ferroelectricPrevent materialPiezoelectric/electrostrictive device manufacture/assemblySolid-state devicesIn planeFerroelectric thin films

Owner:SEIKO EPSON CORP

Preparation method of Barium Titanate nano-powder

InactiveCN101786656ALow purityLow implementation costNanostructure manufactureTitanium compoundsForeign matterAlcohol

The invention provides a preparation method of Barium Titanate nano-powder, which comprises the following steps that: soluble barium salt is added into H2O2 solution to be mixed continuously, the pH value of the solution is adjusted with ammonia water, and the mixed solution is held statically, filtered, washed and vacuum-dried to obtain a precursor BaO2. H2O2 powder; then the BaO2.H2O2 and H2TiO3 are mixed and ground, KOH and KNO3 are added to be used as a flux, then absolute ethyl alcohol is added for grinding, the ultrasonic treatment on the mixed ground powder is undertaken, and after being dried and removed ethanol, the mixture is dissolved with deionized water, centrifugally separated and washed with deionized water after being roasted and cooled; and finally the sample is put into thin HNO3 solution to be immersed so as to remove the foreign matters, and the sample is centrifugally separated, washed and dried to obtain the barium titanate powder with the granularity of about 15 to 40 nm. The barium titanate powder prepared with the method has the advantages of small power granularity, uniform particles, low roasting temperature, simple production process, safe production process, difficult accumulation of the product particles, high purity of the product, high production efficiency and low implementation cost, and can be widely used for the preparation of different inorganic nano functional materials.

Owner:XIANGTAN UNIV

Multiferroic Bi(0.98-x)Sr0.02RExFe0.97Mn0.03O3-CuFe2O4 composite film and preparation method thereof

The invention discloses a multiferroic Bi(0.98-x)Sr0.02RExFe0.97Mn0.03O3-CuFe2O4 composite film and a preparation method thereof. The composite film comprises Bi(0.98-x)Sr0.02RExFe0.97Mn0.03O3 crystal films and CuFe2O4 crystal films which are composited together. The preparation method comprises the following steps: firstly, preparing a Bi(0.98-x)Sr0.02RExFe0.97Mn0.03O3 precursor solution and a CuFe2O4 precursor solution respectively; secondly, preparing multiple layers of CuFe2O4 films on a substrate by spin coating, and preparing multiple layers of Bi(0.98-x)Sr0.02RExFe0.97Mn0.03O3 films on the CuFe2O4 films by spin coating to obtain a target product. The equipment requirement is simple, the uniformity of the prepared film is high, the doping amount is easy to control, the ferroelectric and ferromagnetic properties of the film are improved, and the leakage current density of the film is effectively reduced.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of size-controllable nanoscale cubic-phase super-fine barium titanate powder

InactiveCN105329939AReduce reunionHigh reactivityMaterial nanotechnologyTitanium compoundsBarium titanateBarium nitrate

The invention discloses a preparation method of size-controllable nanoscale cubic-phase super-fine barium titanate powder. Relatively cheap titanium tetrachloride is used for preparing a titanium precursor solution TiClO2 through hydrolysis, the precursor solution is dropwise added into a mineralizing agent and dispersant solution, and continuous stirring is performed to obtain a titanium precursor gel solution; then centrifugal gel washing is performed to remove chloride ions, the prepared H4TiO4 gel and barium hydroxide or barium nitrate are grinded and dispersed with water and a dispersant according to a certain proportion to prepare mixed dispersed slurry, the mixed dispersed slurry is put into a reaction kettle for hydrothermal reaction, and then washing and drying are performed to obtain the nanoscale cubic-phase super-fine barium titanate powder good in dispersion and centralized in particle size, the average particle size of the power is smaller than 100 nm, and the specific surface area is within the range of 12.5-15.0 m<2> / g.

Owner:安徽凯盛应用材料有限公司 +1

Rear earth doped non-fullness tungsten bronze luminescence ferroelectric material and preparation method thereof

InactiveCN105016728AGood luminous performanceGood monochromaticitySolid state reaction methodMaterials science

The invention discloses a rear earth doped non-fullness tungsten bronze luminescence ferroelectric material and a preparation method thereof. The chemical formula of the rear earth doped non-fullness tungsten bronze luminescence ferroelectric material is Ba1La[1-x]EuxTiNb9O30, wherein x is larger than or equal to 0 and less than or equal to 1. According to the invention, Ba1La[1-x]EuxTiNb9O30 porcelain is prepared by adopting a simple solid-phase reaction method, so cost is low, operation is convenient, and large-scale production is facilitated. The Ba1La[1-x]EuxTiNb9O30 porcelain has good luminescence performance and also has good dielectric property and ferroelectric property, is a novel and important multifunctional porcelain material and has wide application prospect in the field of photoelectric materials.

Owner:CIVIL AVIATION UNIV OF CHINA

Method for preparing micro crystalline powder of pure potassium strontium niobite

InactiveCN1686939AUniform particlesGood dispersionSodium/potassium compoundsNiobium compoundsStrontium carbonatePotassium

The present invention relates to a pure strontium potassium niobate microcrystal powder body and its preparation method. Said method includes the following steps: mixing strontium carbonate and columnbium pentoxide according to the ratio of 4:5, grinding potassium chloride, fully mixing said ground potassium chloride and mixture of strontium carbonate and columnbium pentoxide according to 1.2-2:1, roasting for 2-6 hr at 1150 deg.C, repeatedly washing the roasted product, until when the roaste dproduct has not chlorine ion, drying so that the obtained powder body is the strontium potassium niobate microcrystal powder and tetragonal tungsten bronze structure.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

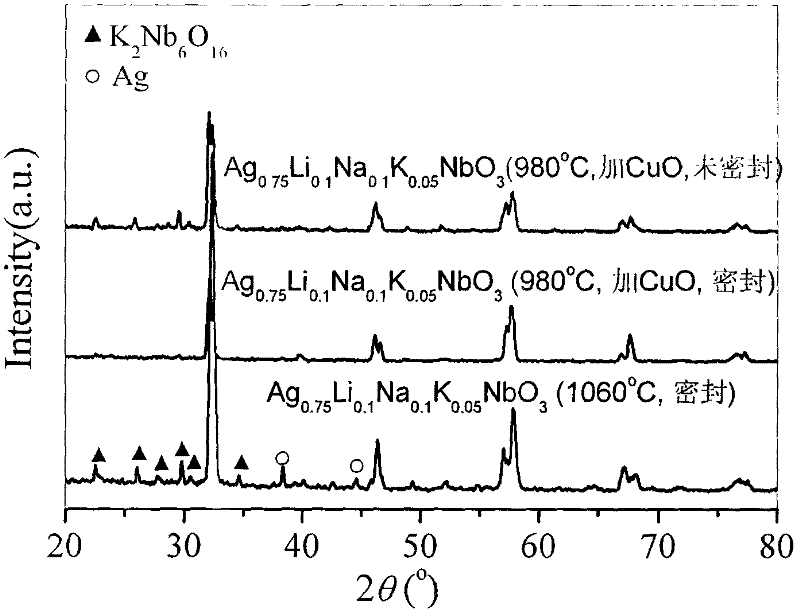

Silver niobate-based lead-free piezoelectric ceramic and preparation method thereof

InactiveCN102249677AExcellent ferroelectricExcellent piezoelectric propertiesElectricityCurie temperature

The invention relates to silver-niobate-based lead-free piezoelectric ceramic and a preparation method thereof, which belong to the field of piezoelectric materials. The composition of the piezoelectric ceramic can be represented by using a general formula (Ag1-x-y-zLixNayKz) (Nb1-m-nTamSbn)O3+wMalphaObeta, x, y, z, m and n in the formula are mole ratios of corresponding components, MalphaObeta is one or multiple cosolvents, M is an element which has +2-+4 valency and can form a solid oxide with oxygen, alpha and beta respectively represent the atom numbers of the element M and the oxygen, w represents the mass percent of MalphaObeta to the total weight of raw materials, 0<=x<=0.2, 0<=y<=0.2, 0<=z<=0.2, 0<=m<=0.1, 0<=n<=0.1, and 0<=w<=5%. The invention further provides a two-step synthesis technology and a low temperature seal sintering mode. Silver-niobate-based lead-free piezoelectric ceramic is made in the air with a traditional ceramic technology. The mechanical quality factor Qm of the series ceramic can reach 1330, the remanent polarization strength Pr reaches 22muC / cm<2>, the piezoelectric coefficient d33 reaches 65pC / N, the Curie temperature Tc reaches 340 DEG C, and the temperature stability is good.

Owner:SOUTHWEAT UNIV OF SCI & TECH

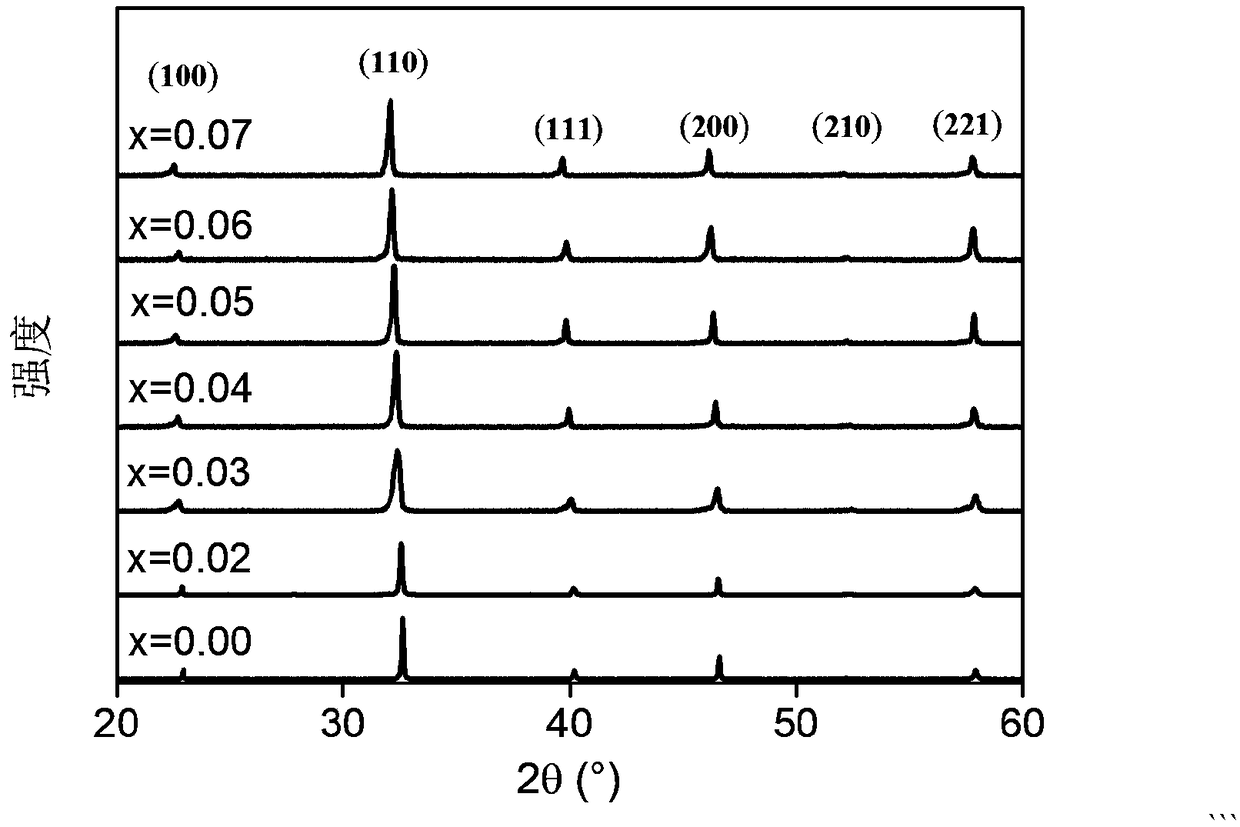

Narrow band gap sodium bismuth titanate-nickel barium titanate ferroelectric material, and preparation method and application thereof

ActiveCN109485413AIncreased photocurrent densityExcellent piezoelectricityGalvano-magnetic material selectionElectricityBarium titanate

The invention provides a narrow band gap sodium bismuth titanate-nickel barium titanate ferroelectric material, and a preparation method and application thereof. The general formula of the ferroelectric material is (1-x)(Na0.5Ba0.5)TiO3-xBa(Ti0.5Ni0.5)O2.5, wherein the value range of the x is 0.01 to 0.09. According to the narrow band gap high-piezoelectric ferroelectric material provided by the invention, acquisition and response of light, heat and mechanical energy can be realized simultaneously; and the narrow band gap high-piezoelectric ferroelectric material provided by the invention canbe applied to the devices of multi-energy acquisition, multifunctional sensing and the like, has high optical response current in near-infrared light, and can be applied to the fields of infrared detectors, optical communication devices and the like.

Owner:SHANGHAI JIAO TONG UNIV

Bi0.92Ho0.08Fe0.97Mn0.03O3-Zn1-xNixFe2O4 multiferroic composite film and preparation method thereof

The invention discloses a Bi0.92Ho0.08Fe0.97Mn0.03O3-Zn1-xNixFe2O4 multiferroic composite film and a preparation method thereof. The composite film comprises a Bi0.92Ho0.08Fe0.97Mn0.03O3 crystalline film and a Zn1-xNixFe2O4 crystalline film, which are compounded together. The method comprises the following steps: firstly, respectively preparing a Bi0.92Ho0.08Fe0.97Mn0.03O3 polymeric precursor solution and a Zn1-xNixFe2O4 precursor solution during preparation; spinning on a substrate, and preparing a multi-layer Zn1-xNixFe2O4 film; and spinning on the Zn1-xNixFe2O4 film and preparing a multi-layer Bi0.92Ho0.08Fe0.97Mn0.03O3-Zn1-xNixFe2O4 film, so as to obtain a target product. The method disclosed by the invention is simple in demands on equipment; the prepared film is good in uniformity; the doping amount is easy to control; the ferroelectric properties and the ferromagnetic properties of the film are improved; and meanwhile, the leakage current density of the film is effectively reduced.

Owner:SHAANXI UNIV OF SCI & TECH

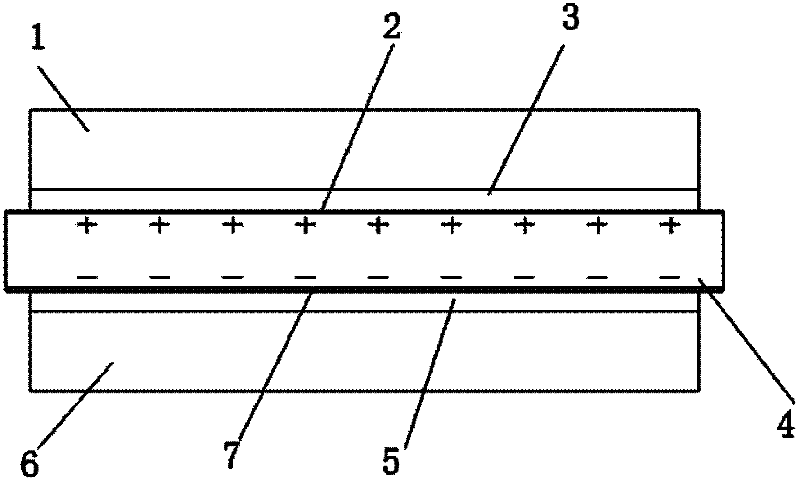

Novel intelligent vibration isolation noise reduction composite structure system and usage method thereof

ActiveCN102413401AReduce noise radiationVibration isolation is effectiveTransducers for subaqueous useFrequency/directions obtaining arrangementsNoise reductionInstrumentation

The invention provides a novel intelligent vibration isolation noise reduction composite structure system and a usage method thereof. The system comprises: a feedback piezoelectricity sensing element, an upper insulation transition layer, an upper flexible electrode, an actuator unit, a lower flexible electrode, a lower insulation transition layer and a piezoelectric sensing element. The feedback piezoelectricity sensing element, the actuator unit and the piezoelectric sensing element are connected with a controller through a line. When one sensor perceives external vibration, the controller adds a control voltage to the electrode coated on electroactive polymer surface according to different controlled objects and a control algorithm so that the actuator performs inverse deformation to control vibration transmission. And the other feedback piezoelectricity sensing element is taken as a feedback element which plays a supervision role. A small block which uses the structure is made to firmly stick on a submarine surface. Because of the inverse deformation, the control actuator can control sound radiation of a submarine. By using the system and the method of the invention, vibration isolation and noise abatement in high, middle and low frequency system can be completed. The system and the method can be widely used in the submarine, aerospace, precise instrument equipment vibration isolation field.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Preparation method for necklace shaped lead titanate nano wire

The invention provides a method for preparing the necklace-shaped lead titanate nano-wire, which comprises the following steps: firstly after the titanic acid ester or soluble titanium salt is reacted with oxalic acid solution to form the complex ion [TiO(C2O4)2]<2->, surface active agent, cosurfactant and fat phase are used to be mixed with the soluble lead salt solution and the [TiO(C2O4)2]<2-> solution to respectively form two uniform and transparent microemulsions containing Pb<2+> and TiO(C2O4)2]<2->; two microemulsions are mixed and reacted, and then are aged, centrifuged and separated, and washed, dried and calcined to get the necklace-shaped lead titanate nano-wire with the length about 450 nm to 2200 nm, and the wider diameter about 60 to 145 nm and the narrower diameter about 40 to 115 nm. The method can conveniently control the size and the shape of the particles of the product, and has the advantages of simple production craftwork, safe production process, uneasy reunion and damage of the particles of the product, high purity of the product, high production efficiency and low implementation cost, and can be widely used for preparing the nano materials with different shapes.

Owner:XIANGTAN UNIV

Material with excellent piezoelectric property and preparation method of material

InactiveCN103121841AExcellent piezoelectricExcellent ferroelectric grinderChemical structureTableting

The invention discloses a material with excellent piezoelectric property and a preparation method of the material, belonging to the field of piezoceramic materials. A chemical structure general formula of the material with excellent piezoelectric property is (1-x)BiMeO3-xPbTiO3, wherein Me=Ni1 / 2Hf1 / 2 or Ni1 / 2Zr1 / 2; and 0.5<x<1. The preparation method comprises the following steps of: based on Bi2O3, NiO, HfO2, ZrO2, PbO and TiO2 as raw materials, weighing Bi2O3, NiO, HfO2 or ZrO2, PbO and TiO2 which accord with the chemical dose ratio according to the chemical structure general formula, uniformly grinding, calcining a sample after grinding for 1-10h at the temperature of 600-1000 DEG C, then tabletting the sample, and sintering the tabletted sample for 1-15h at the temperature of 800-1500 DEG C to obtain the material with excellent piezoelectric property. The material is low in preparation cost and simple in synthetic process, thus having larger scientific research and practical values.

Owner:UNIV OF SCI & TECH BEIJING

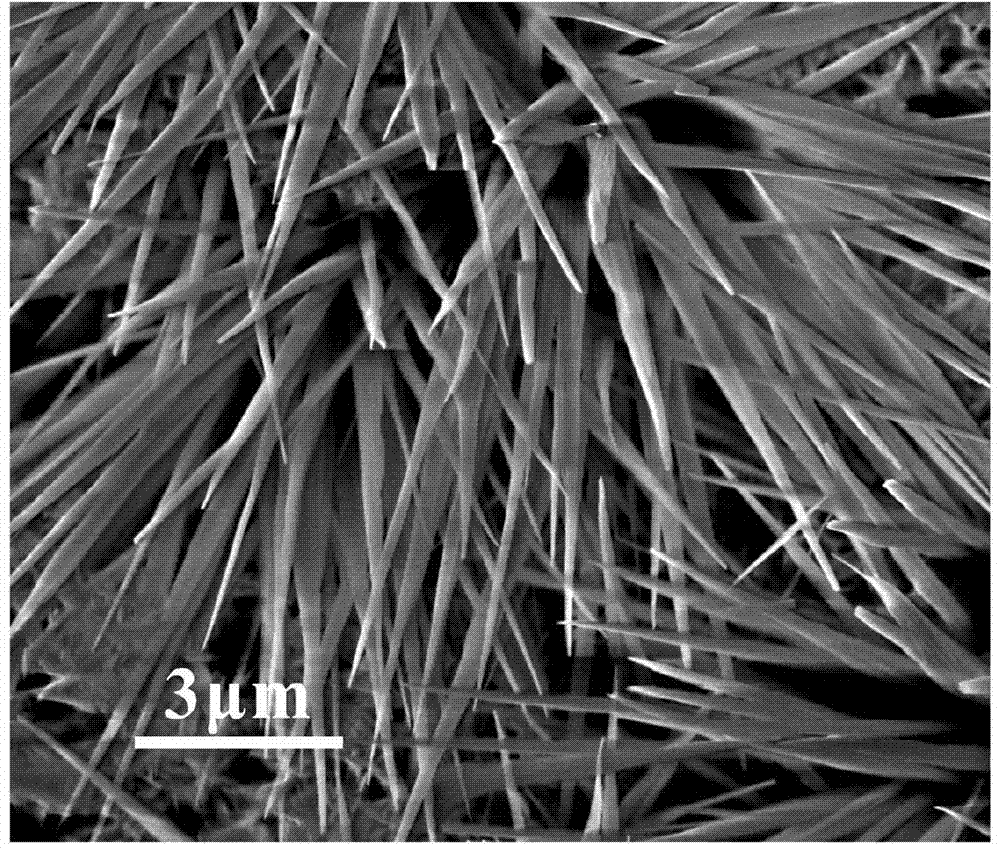

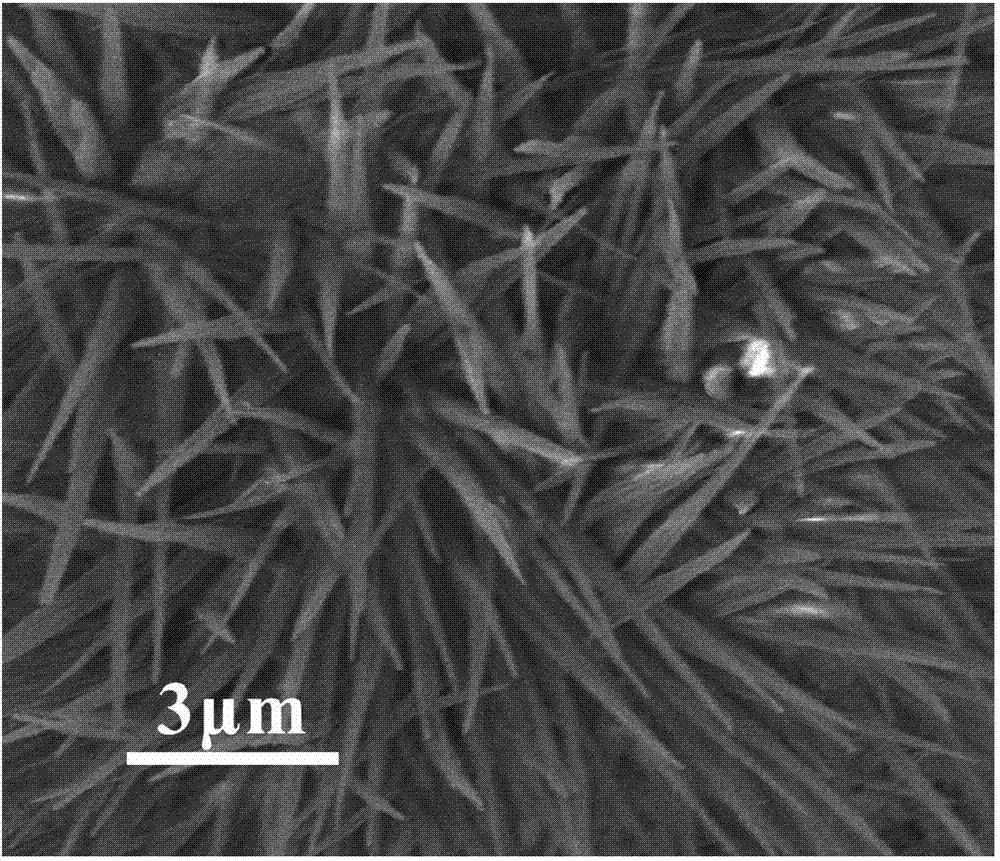

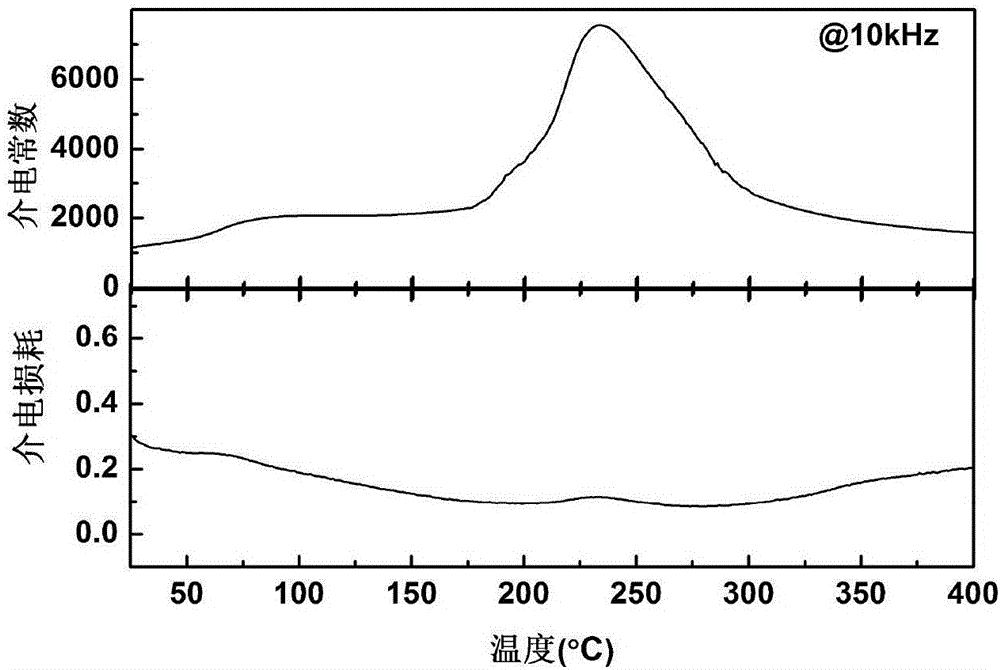

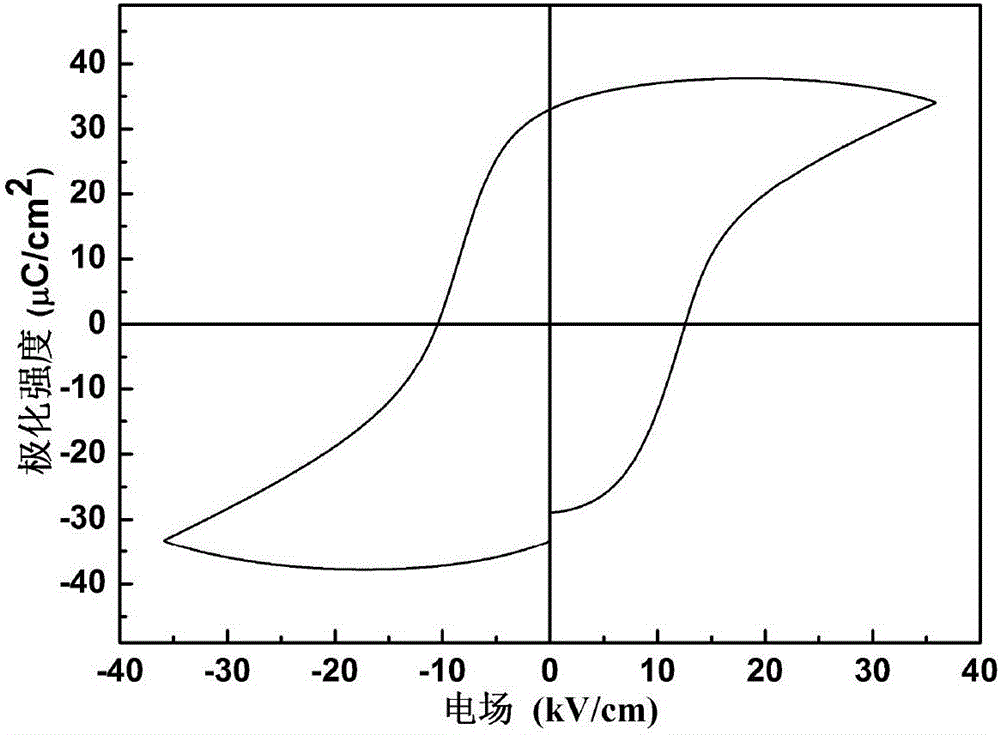

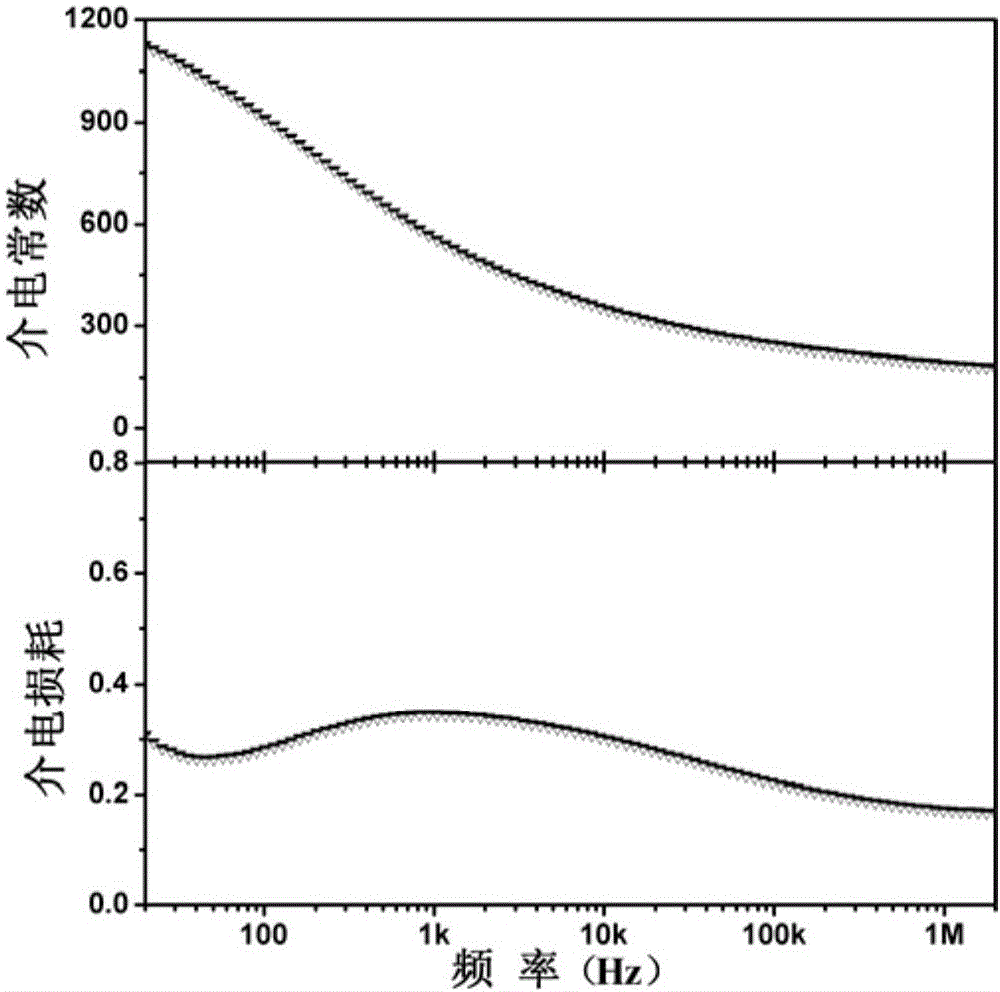

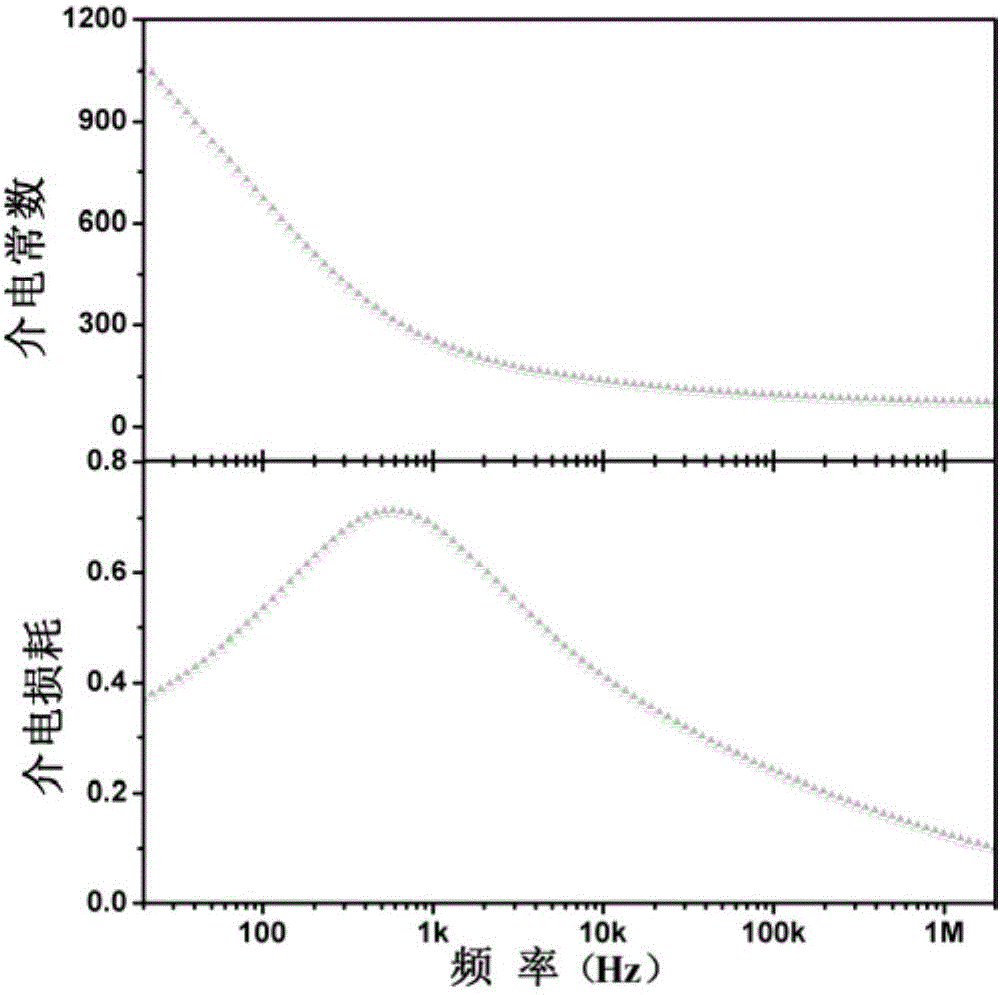

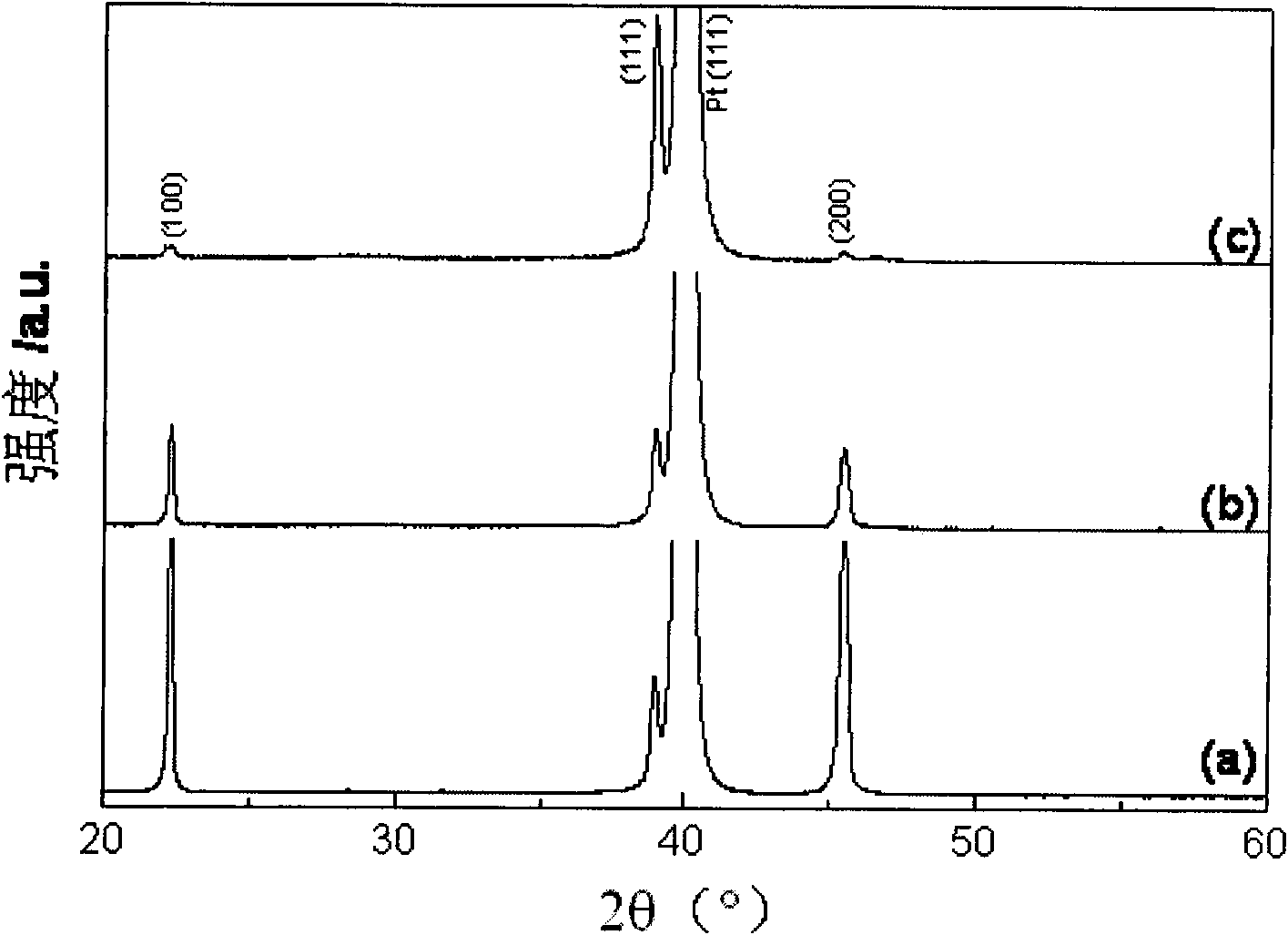

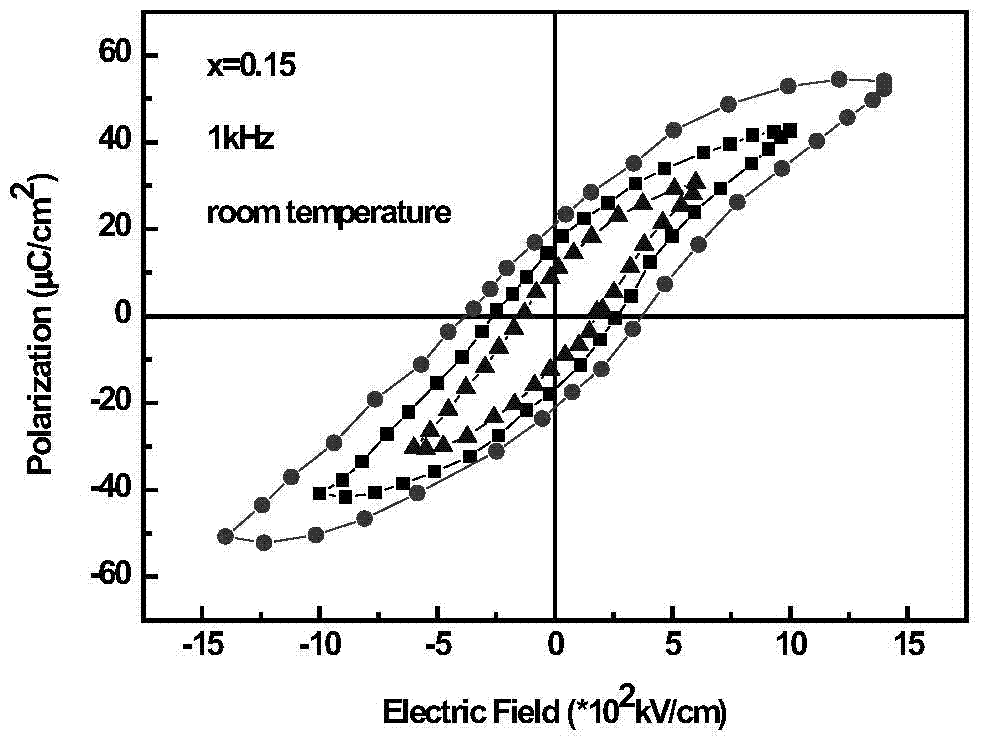

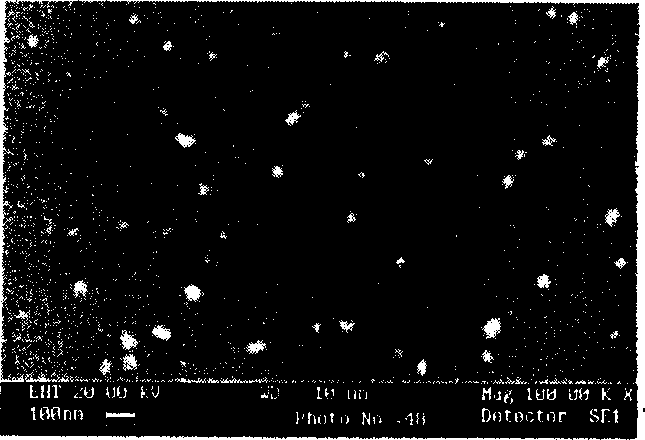

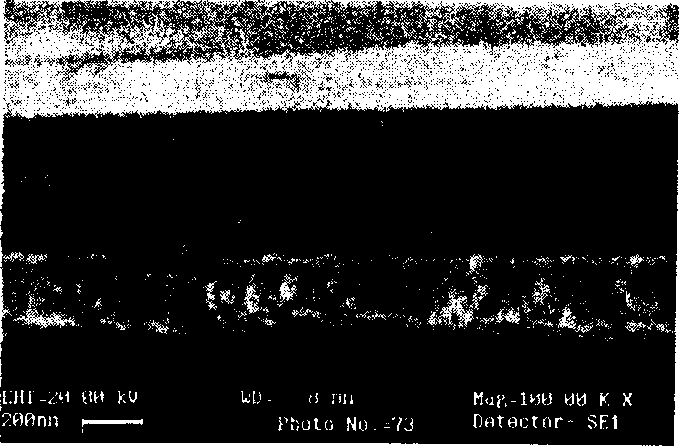

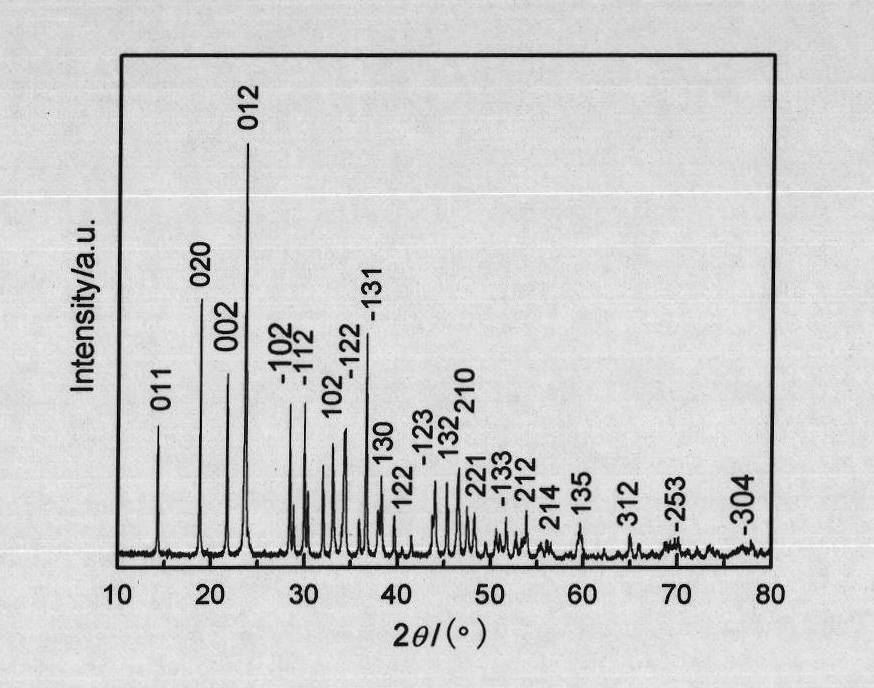

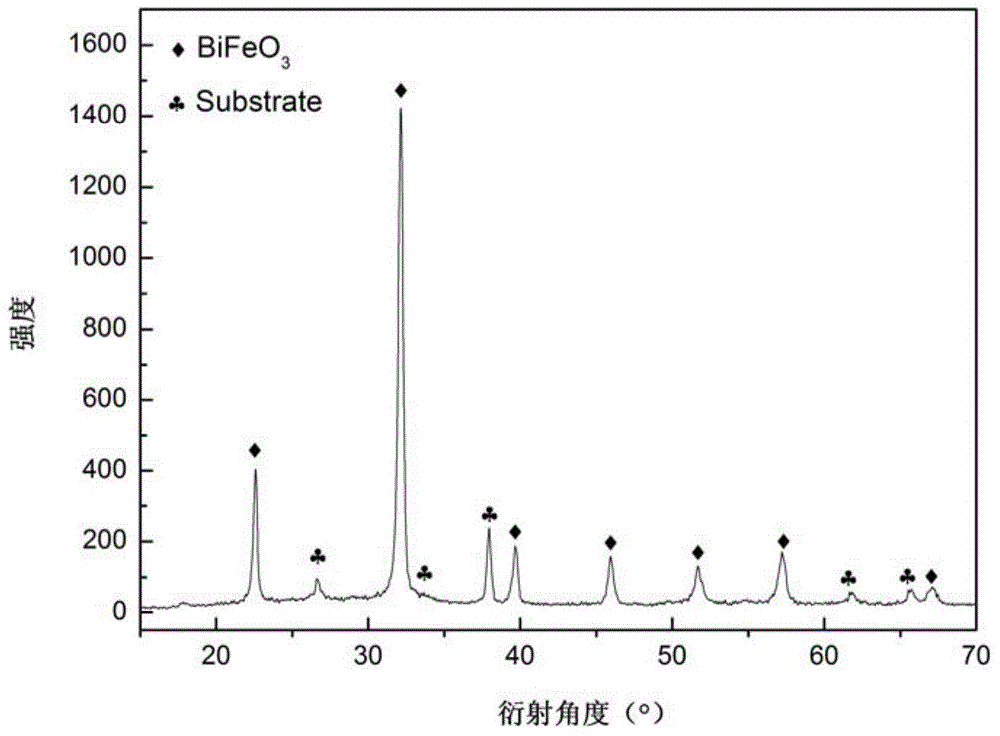

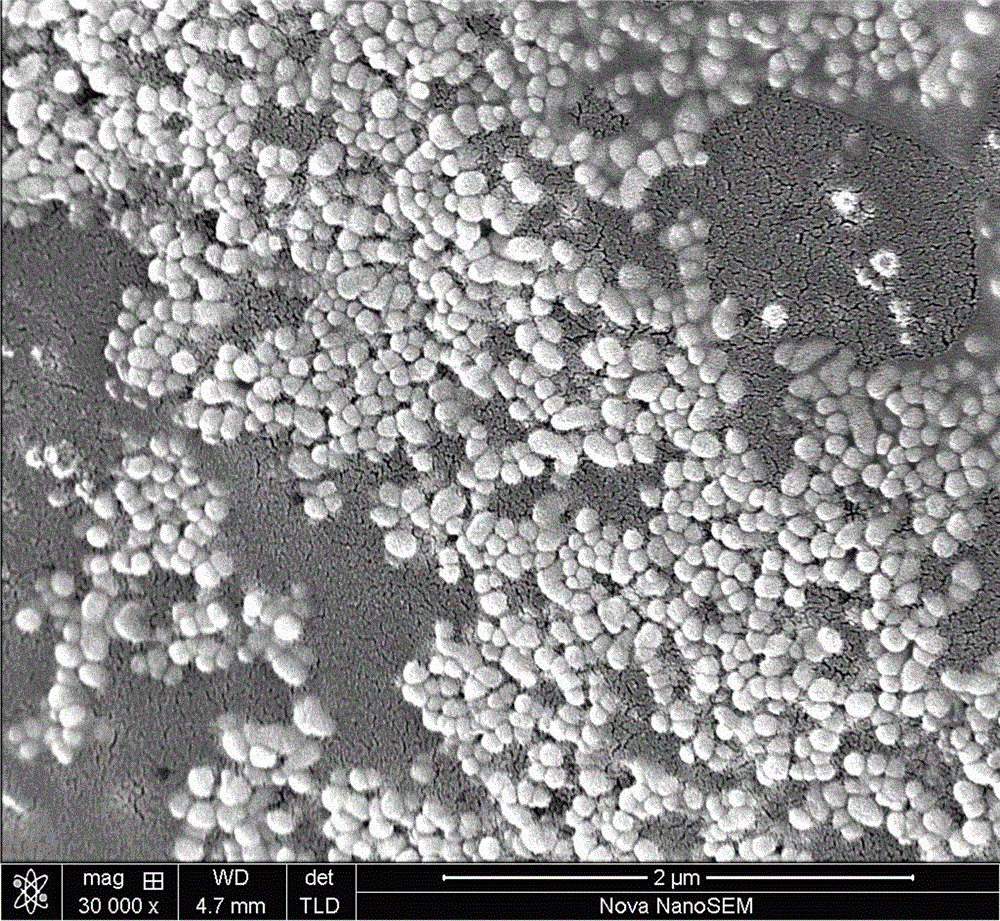

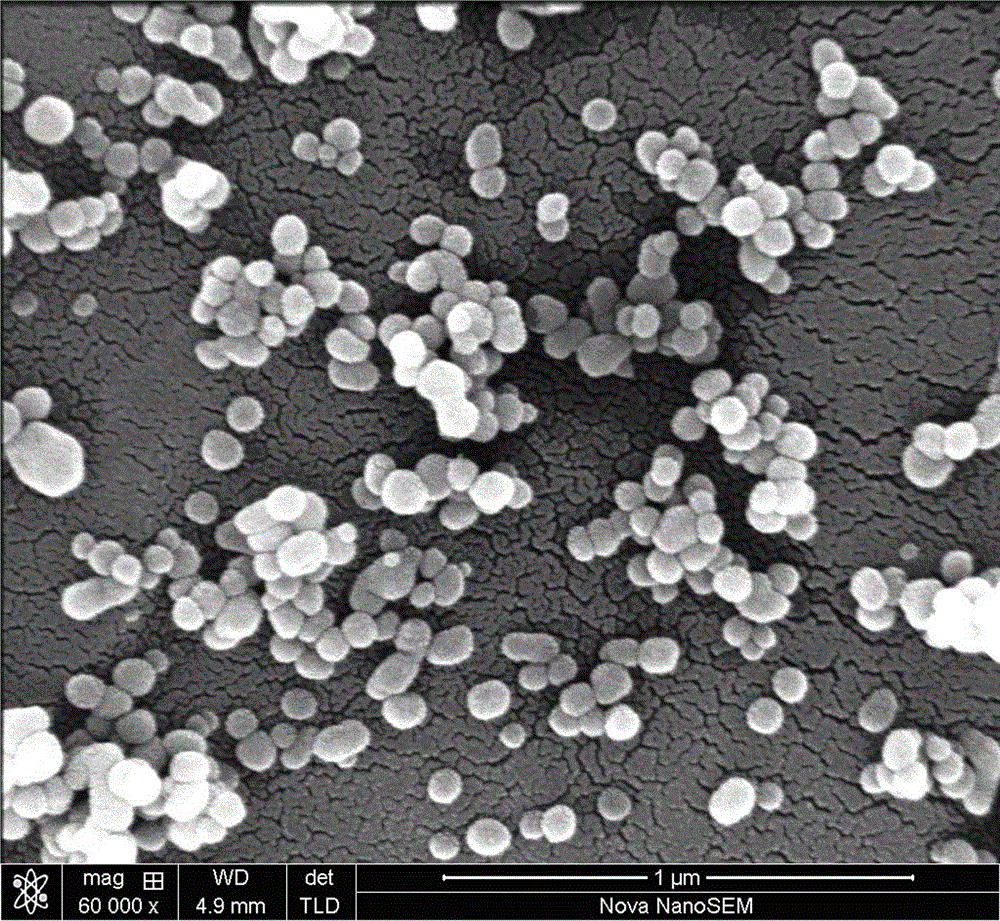

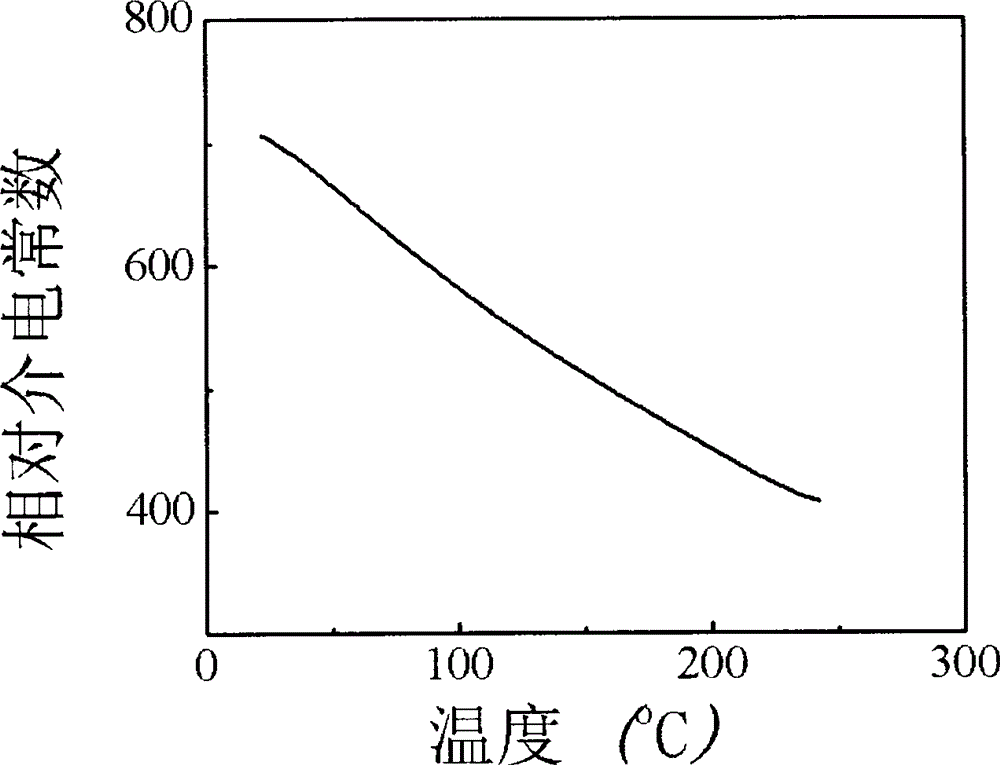

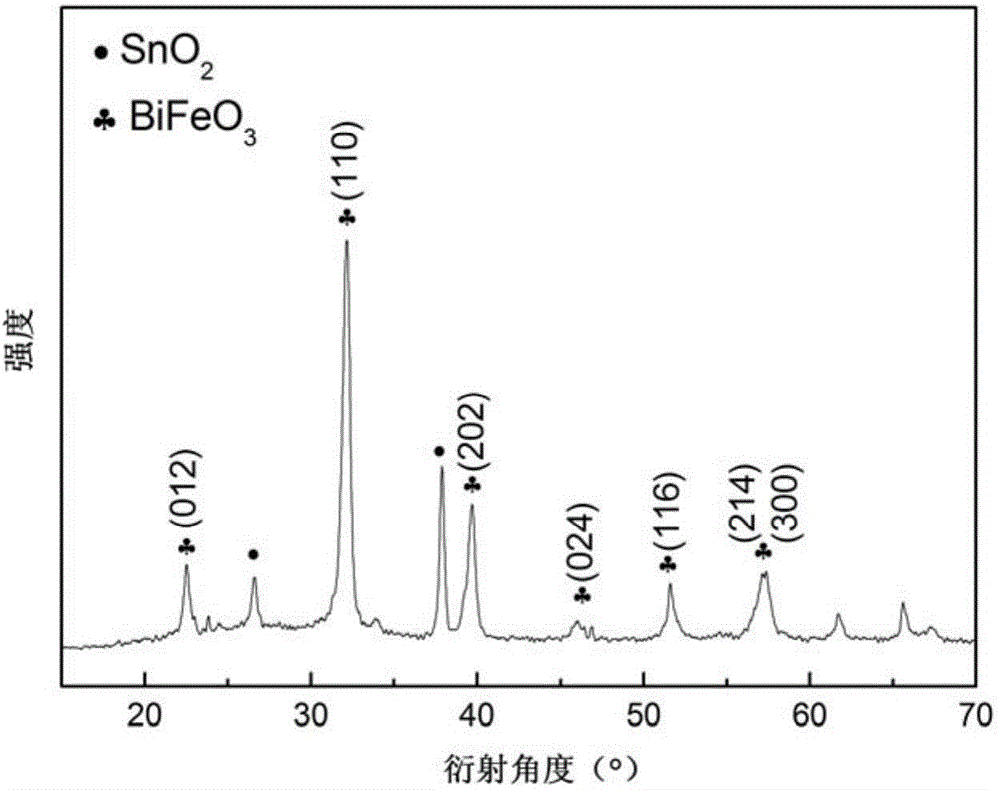

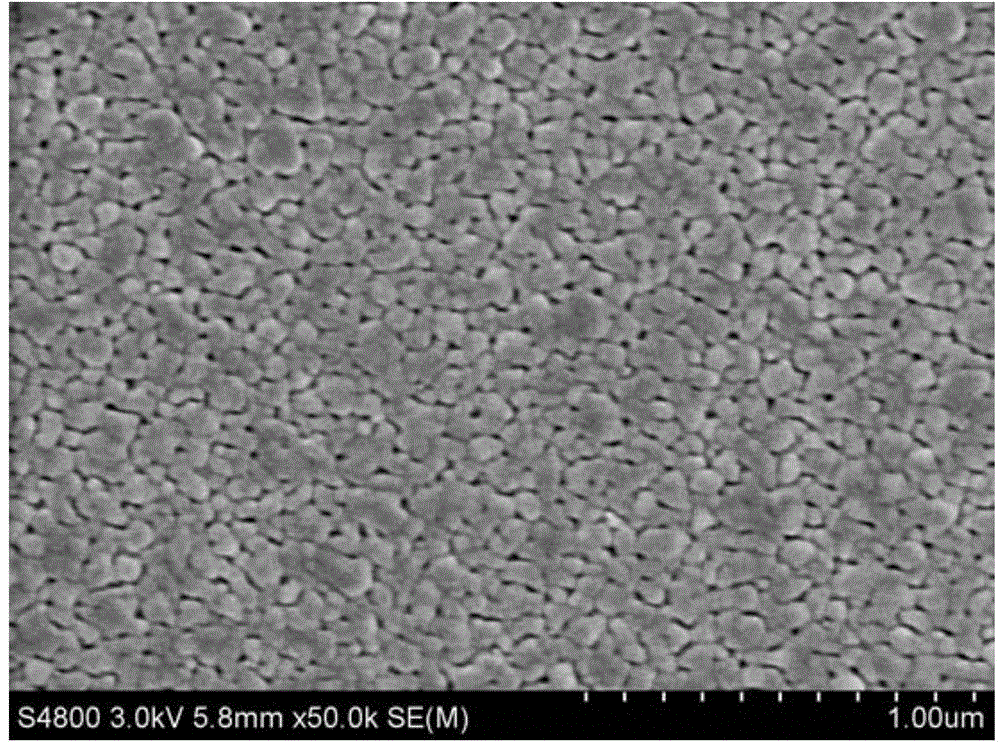

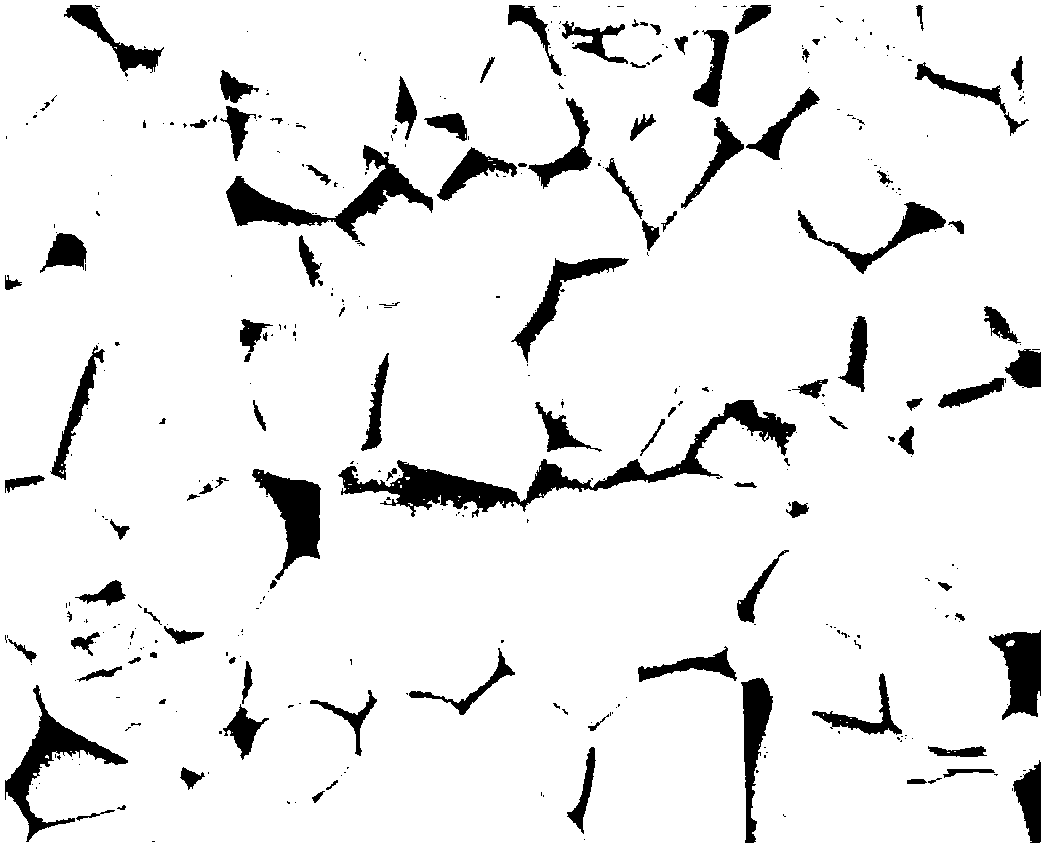

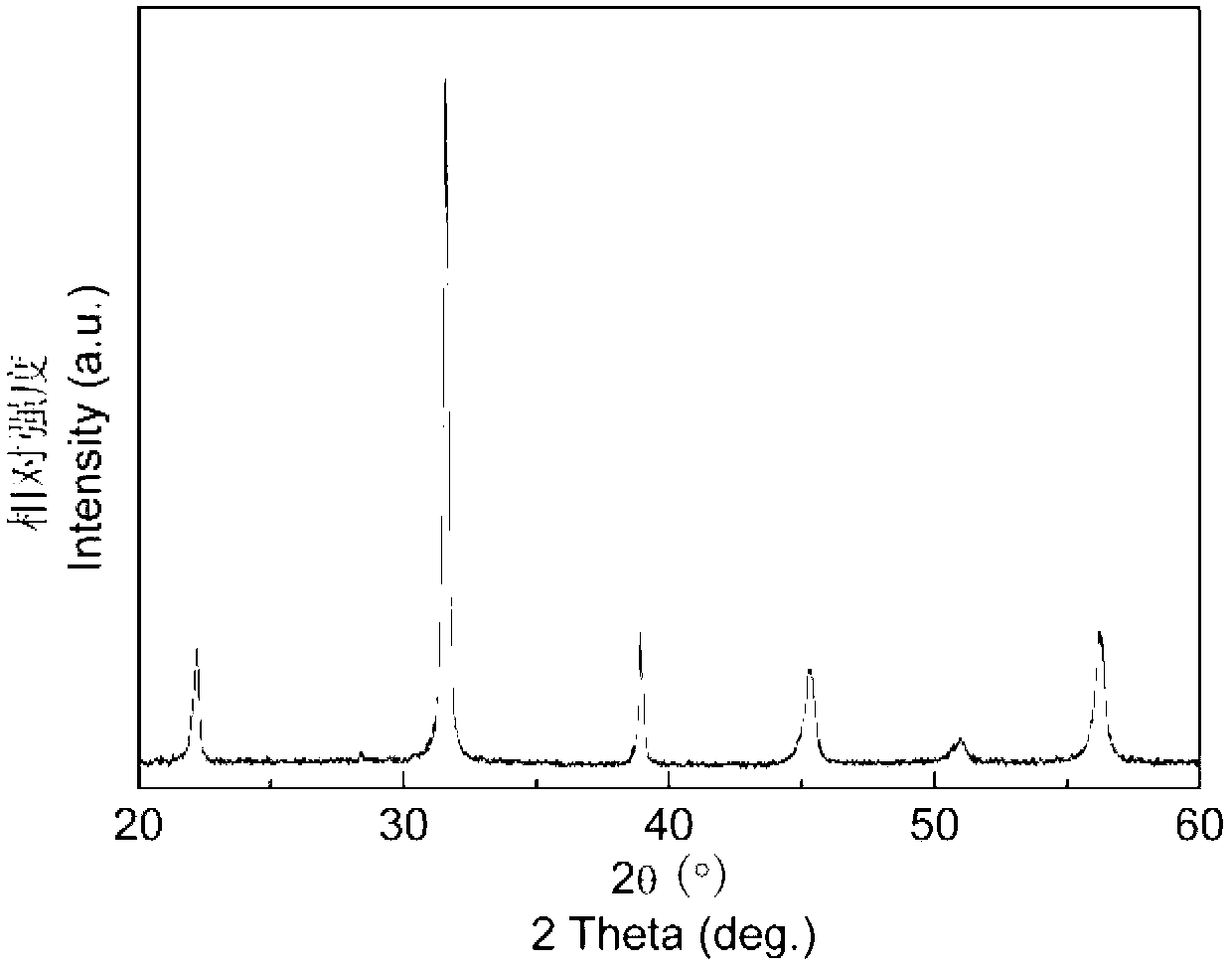

Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof

The invention provides a Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and a preparation method thereof. The method comprises the following steps: preparing a Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 precursor solution from bismuth nitrate, praseodymium nitrate, hydrogen nitrate AE, ferric nitrate and manganous nitrate, wherein AE is Sr, Ca or Ba, and x=0.02-0.05; spinning the precursor solution on a substrate; and then spinning, drying and annealing, so as to obtain the Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film. The Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film is simple in demands on equipment; the experiment condition is easy to achieve; the doping amount is easy to control; the ferroelectric property of the film can be greatly improved; and the prepared Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film is good in uniformity, low in leakage current, and low in coercive field, and has relatively high remanent polarization.

Owner:SHAANXI UNIV OF SCI & TECH

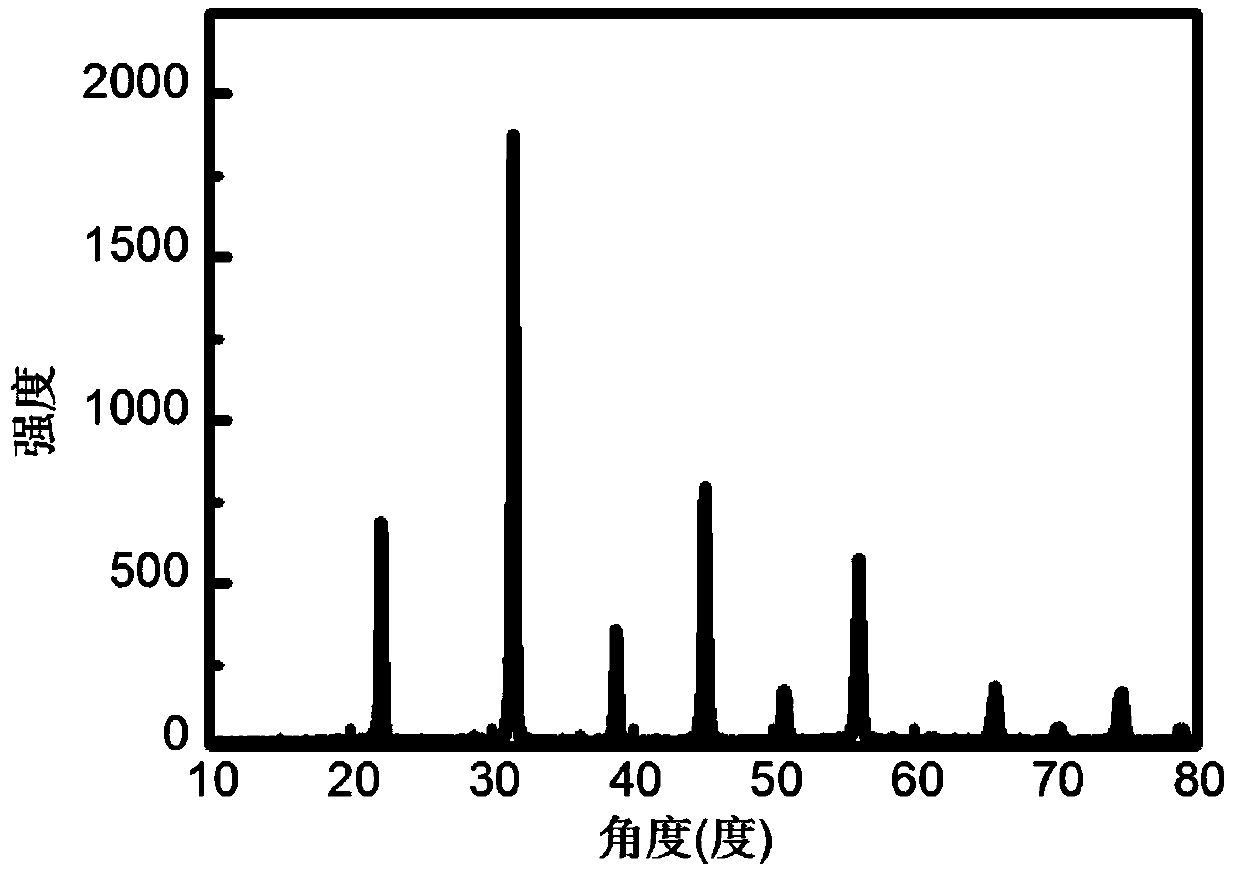

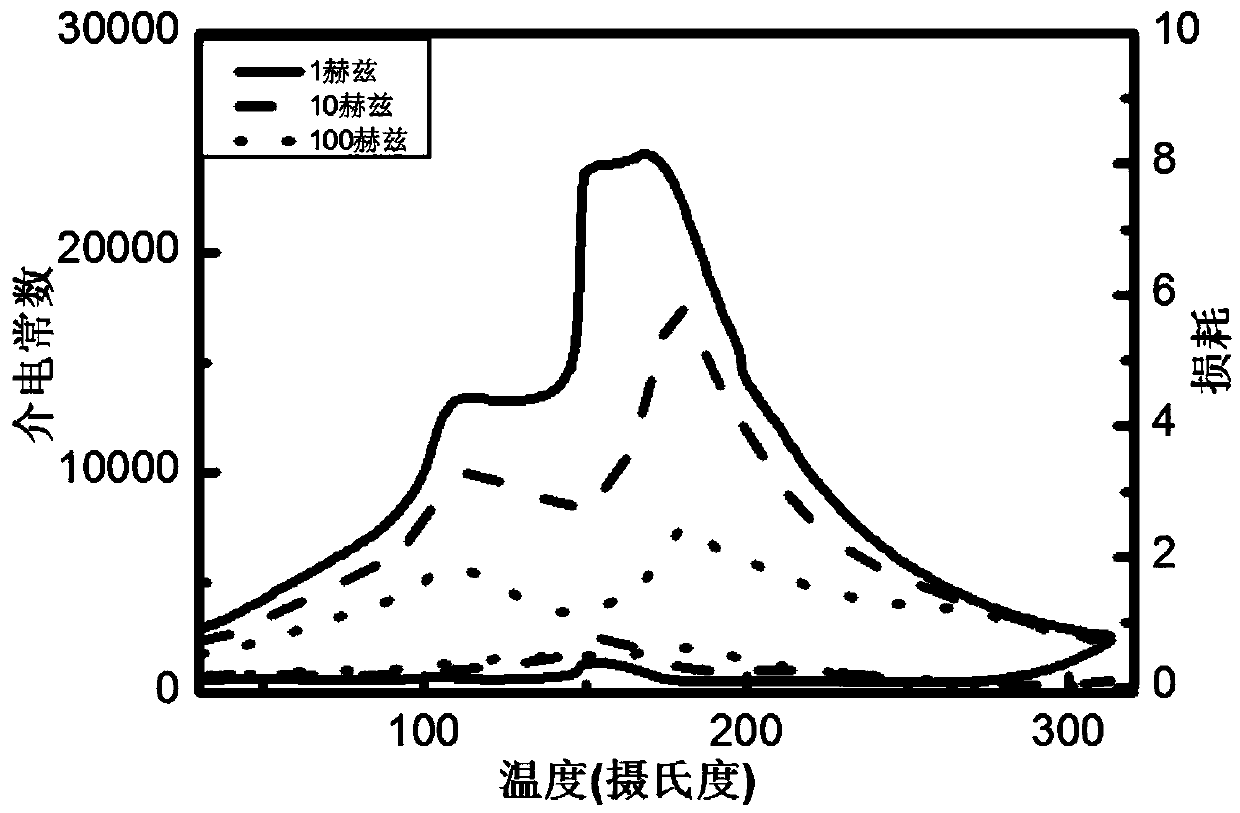

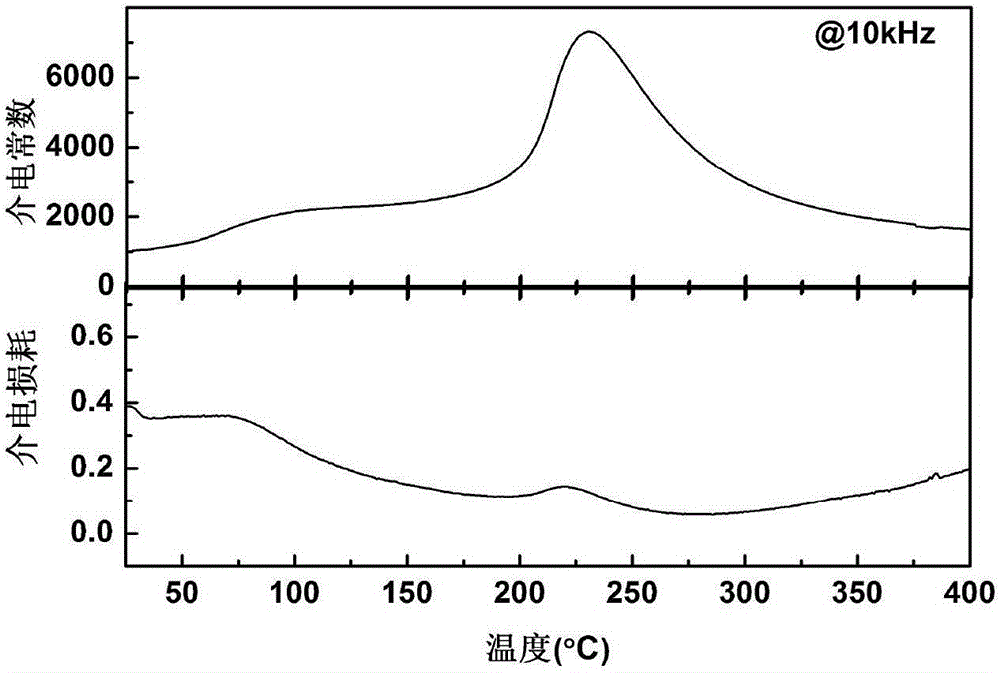

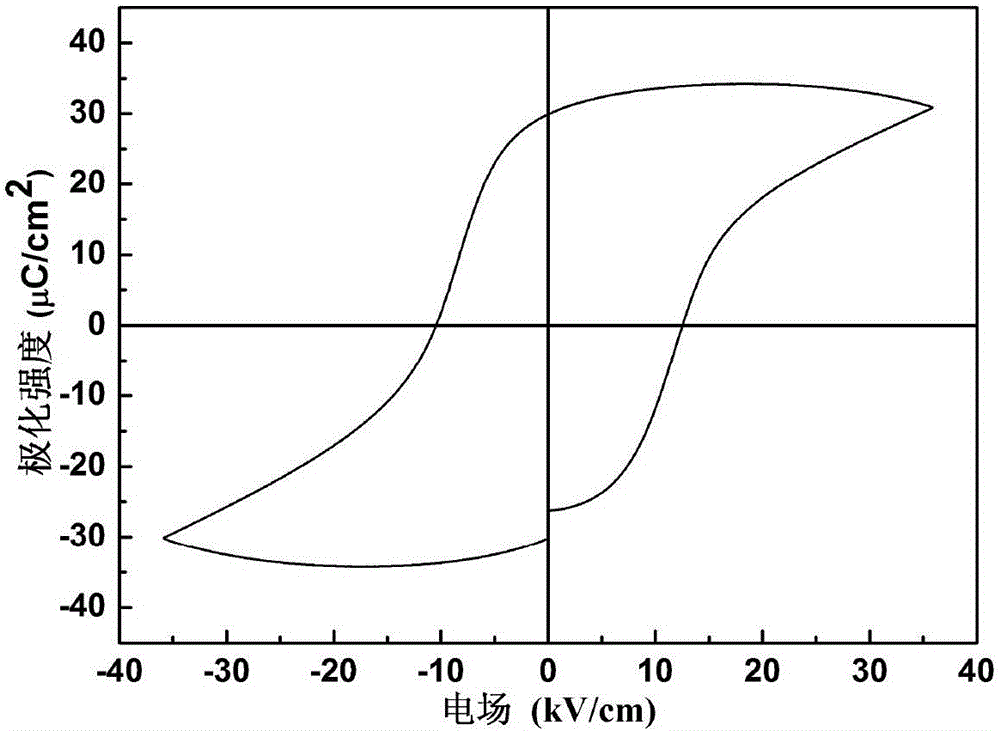

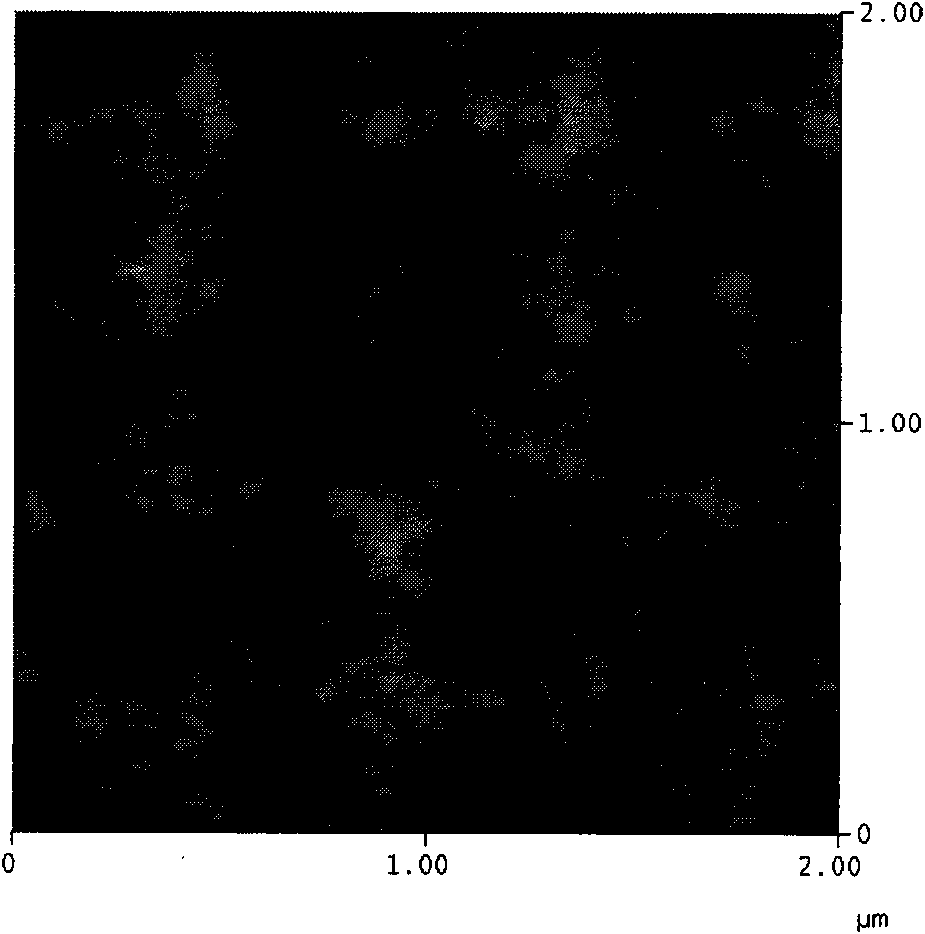

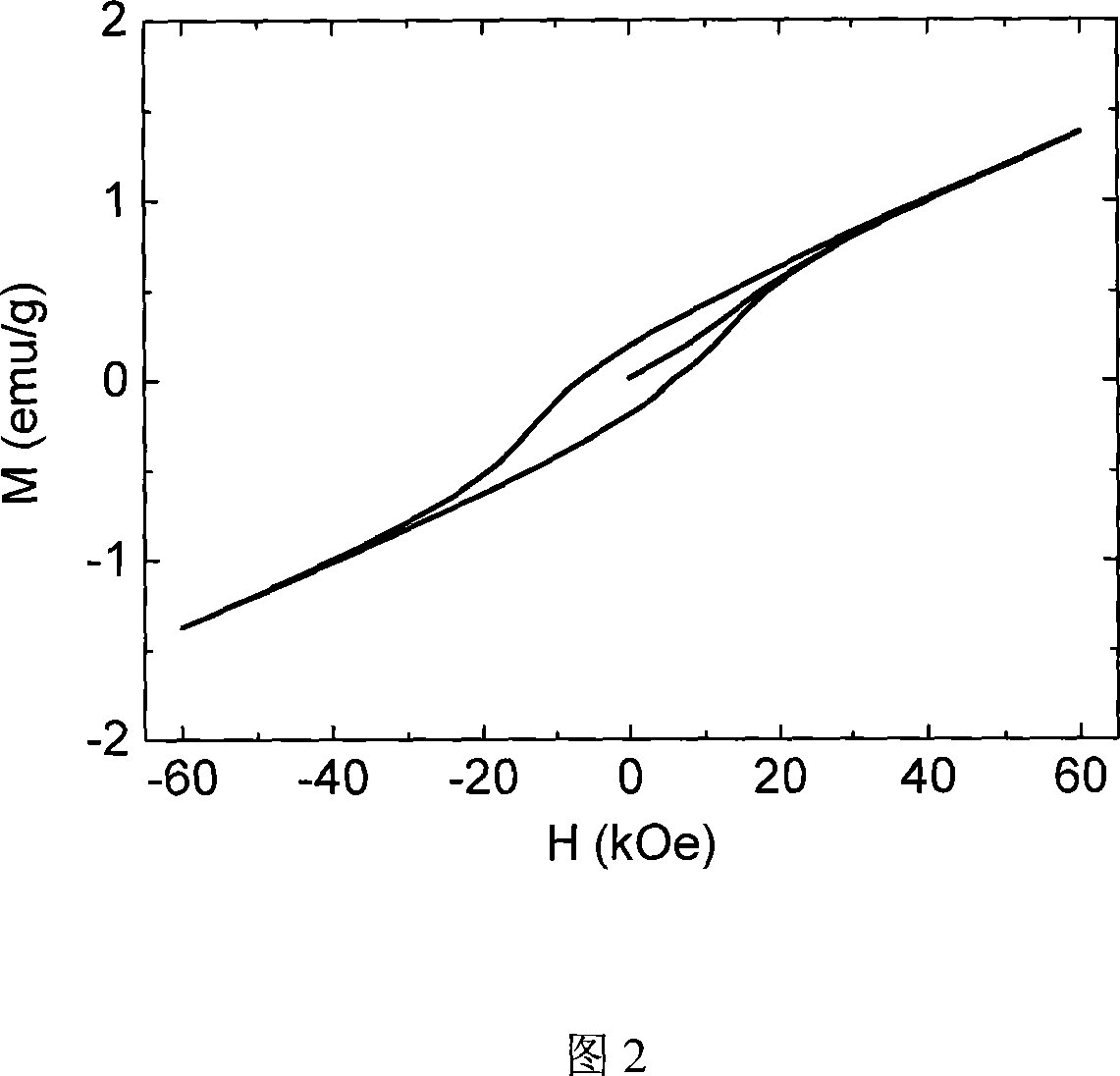

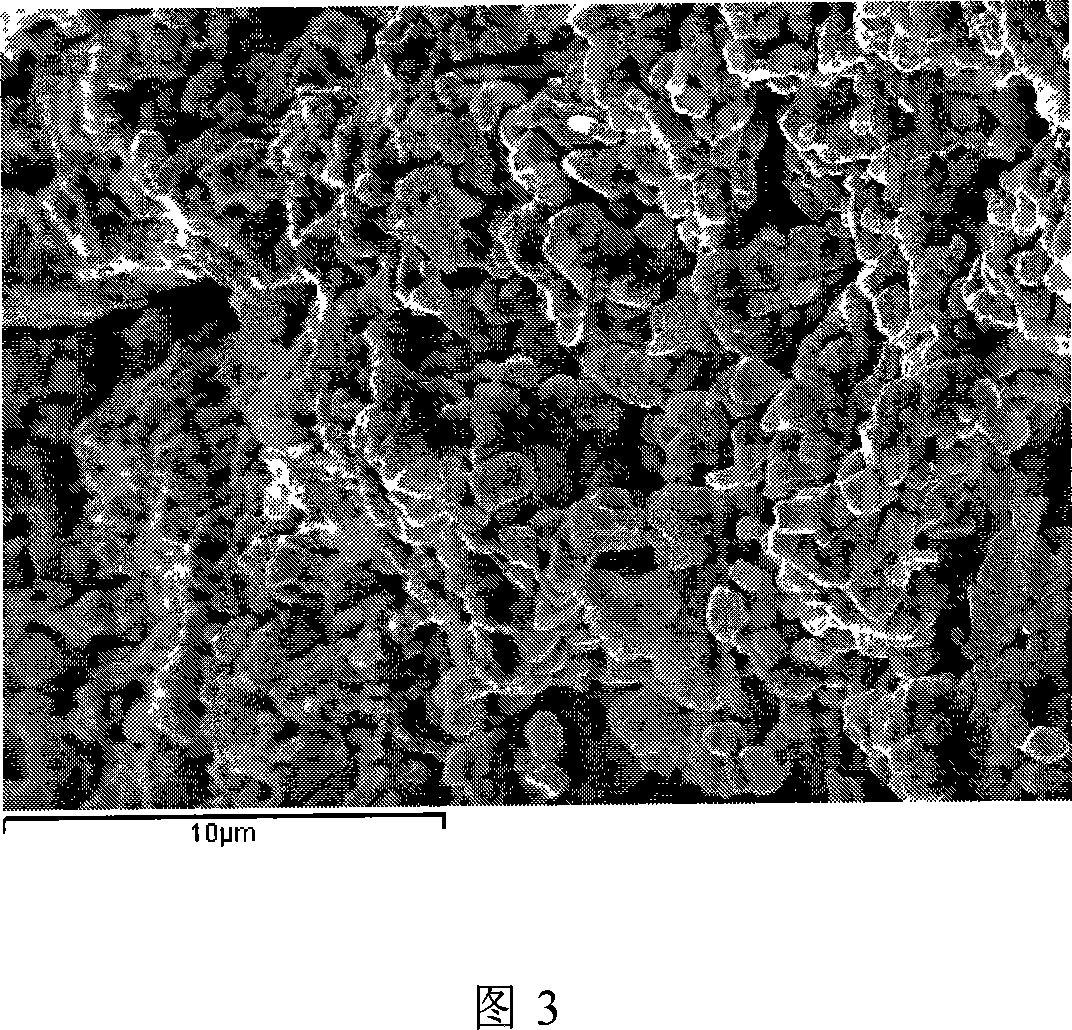

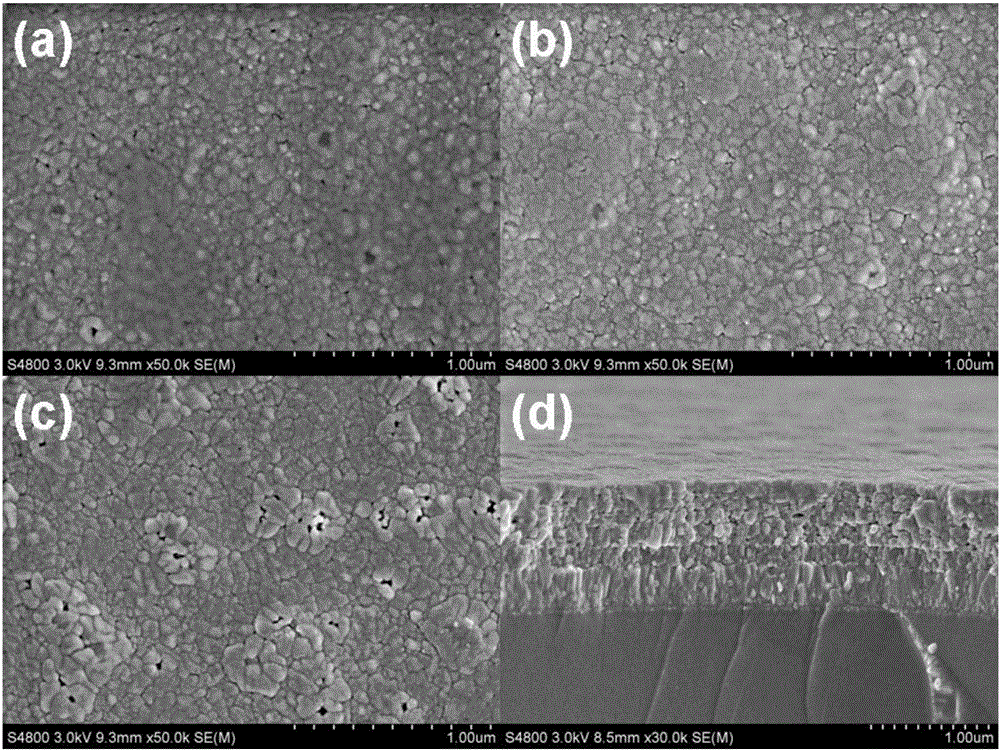

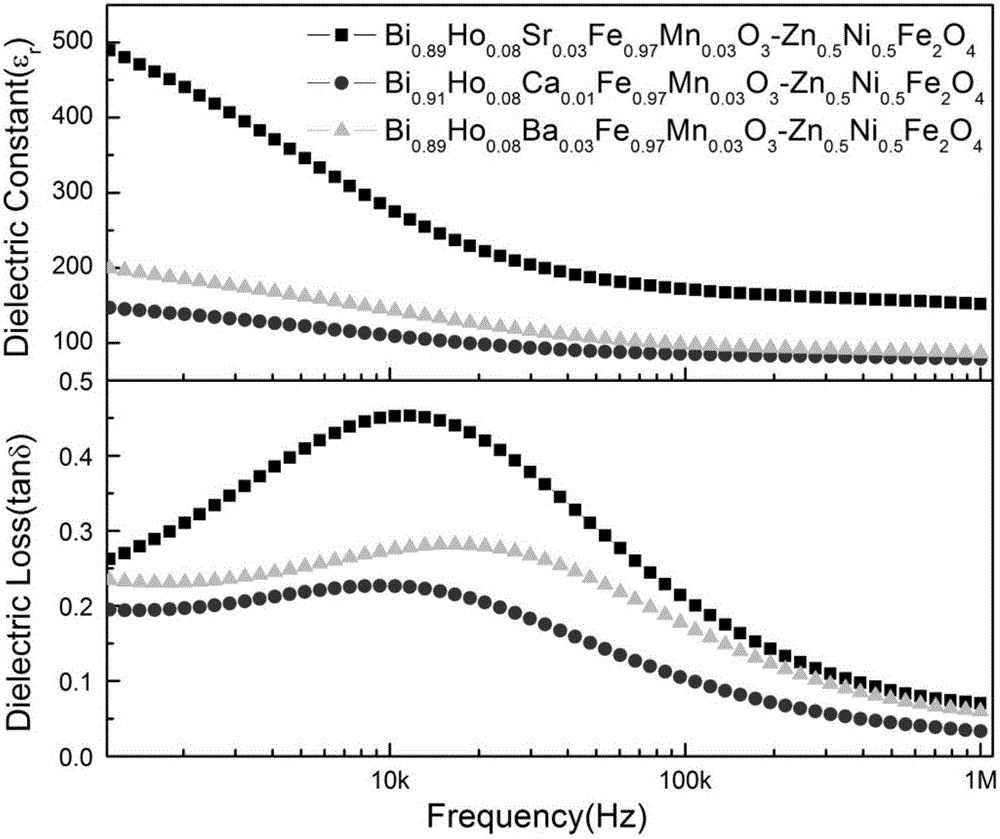

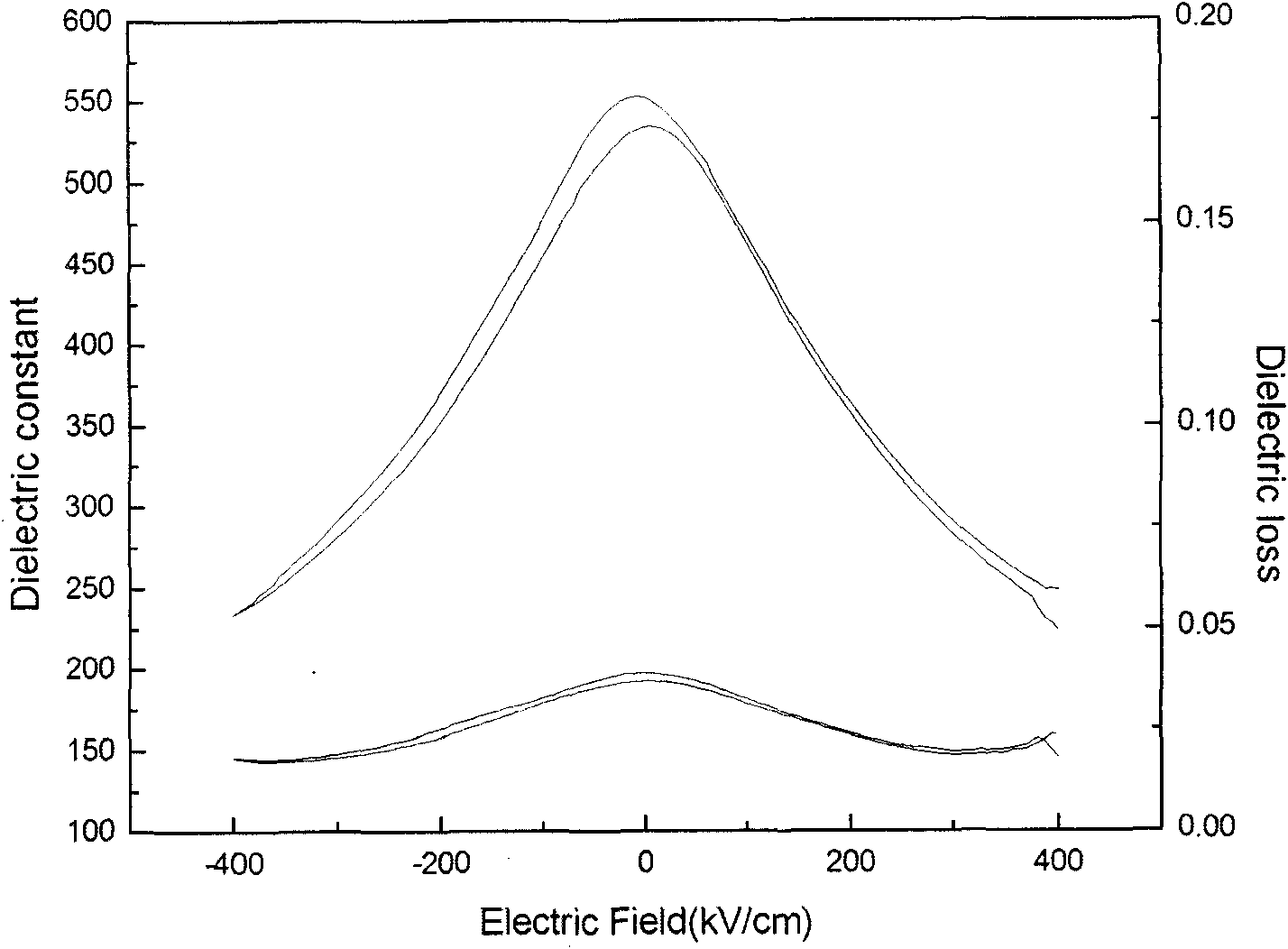

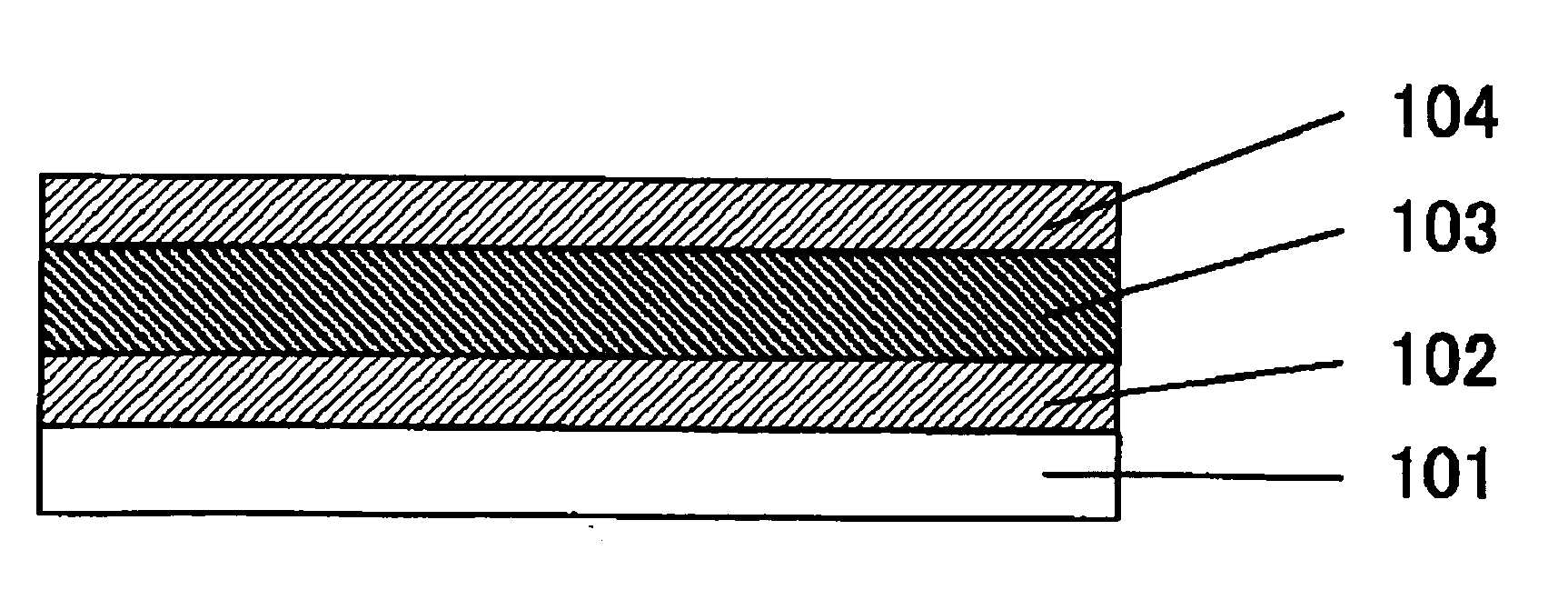

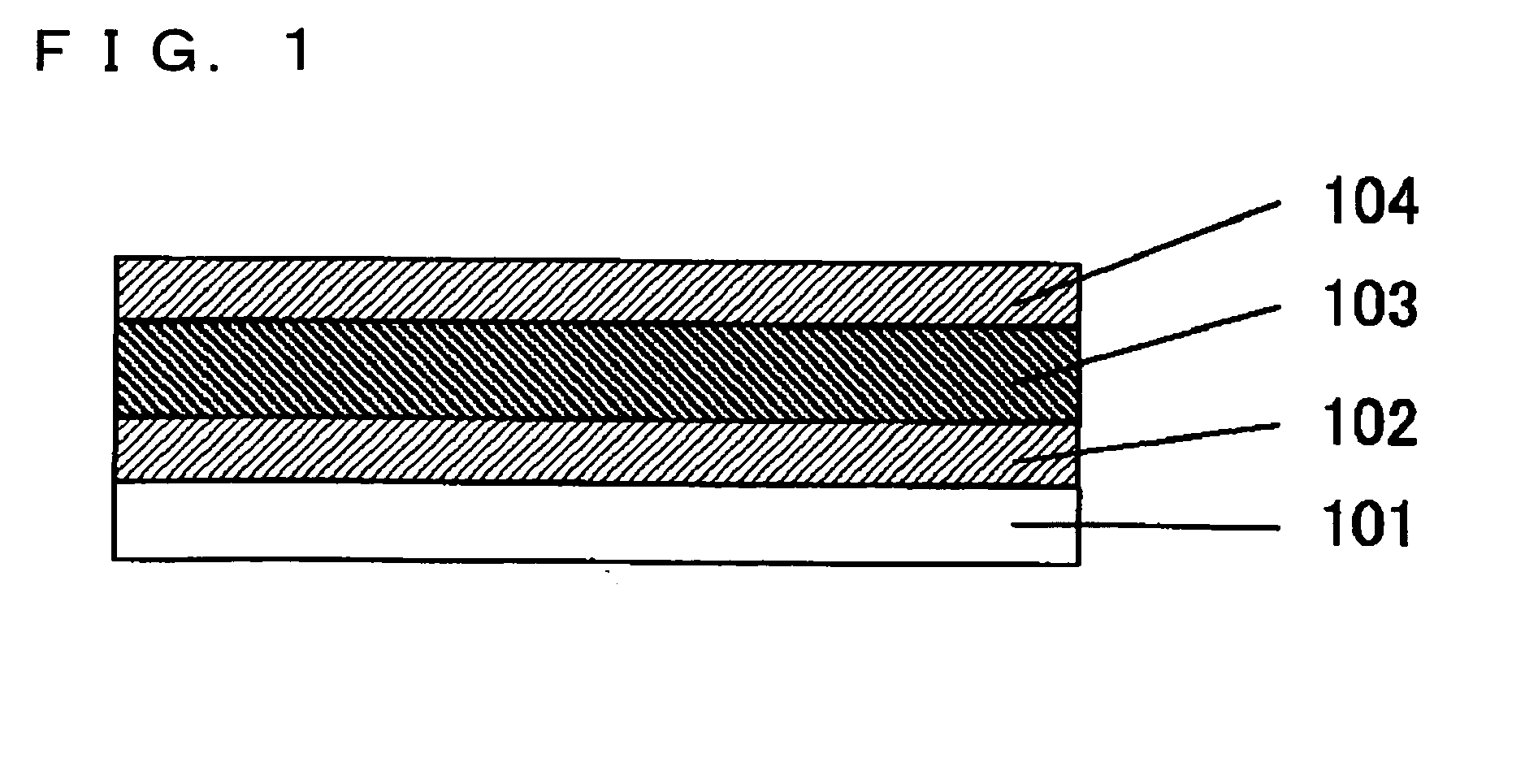

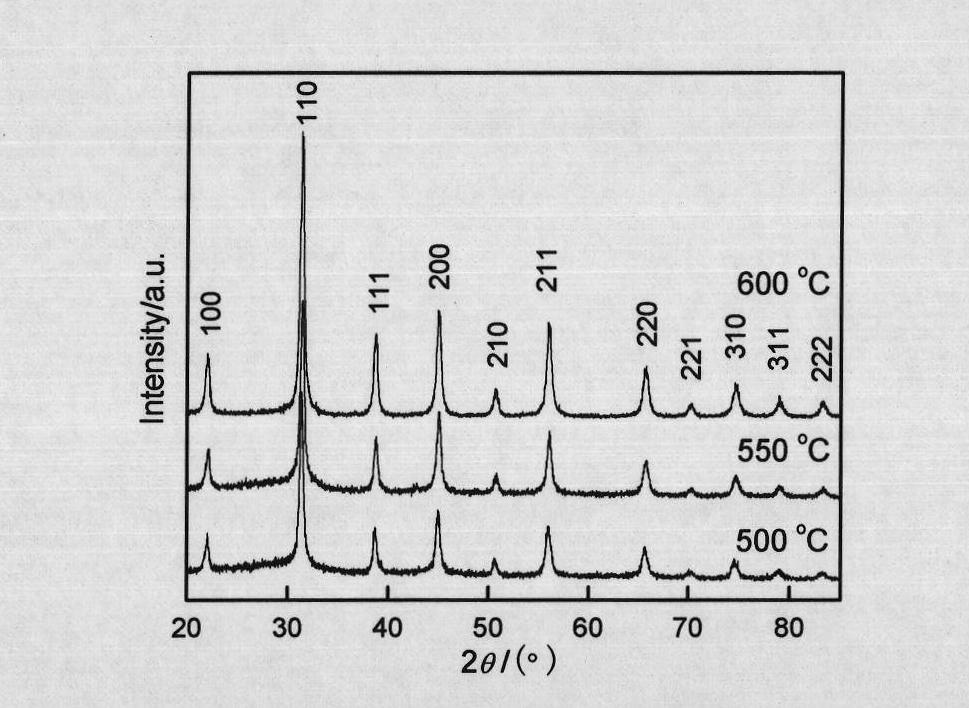

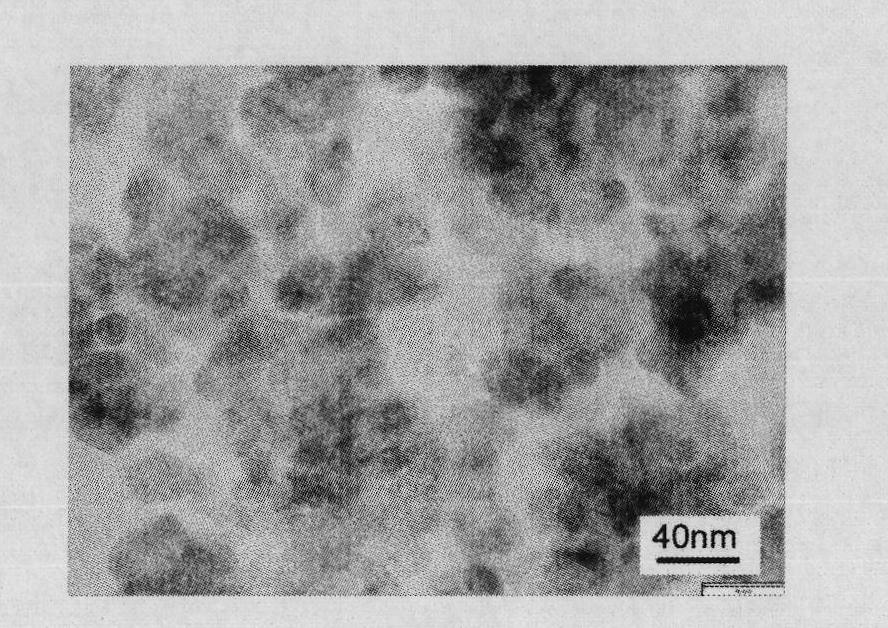

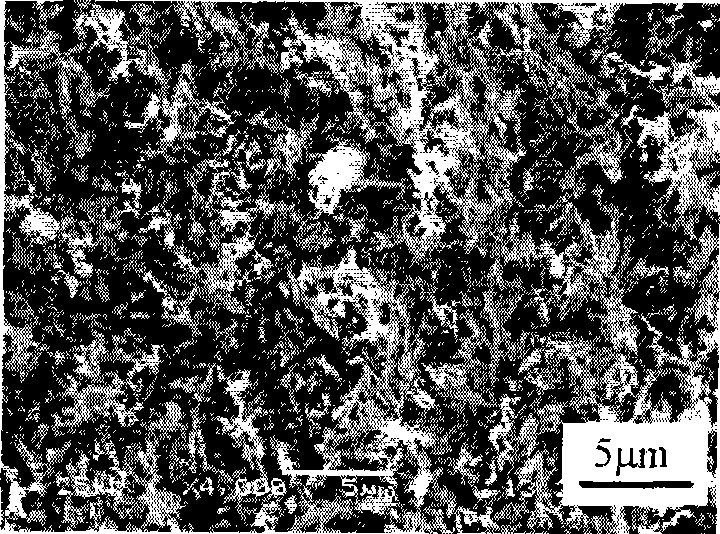

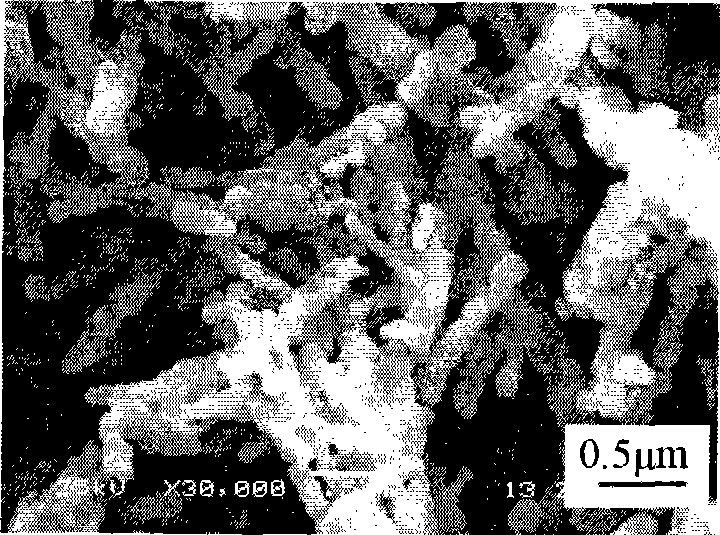

Bi[0.92-x]Ho0.08AExFe0.97Mn0.03O3 multiferroic film and preparation method thereof

InactiveCN104478230AReduce defectsReduce leakage conduction currentCoatingsMANGANESE ACETATEMultiferroics

The invention provides a Bi[0.92-x]Ho0.08AExFe0.97Mn0.03O3 multiferroic film and a preparation method thereof. The method comprises the following steps: preparing a Bi[0.92-x]Ho0.08AExFe0.97Mn0.03O3 precursor solution from bismuth nitrate, holmium nitrate, nitric acid AE, ferric nitrate and manganese acetate, wherein AE is Ca, Ba or Sr, and x=0.01-0.08; spinning the precursor solution on a substrate; and then spinning, drying and annealing, so as to obtain the Bi[0.92-x]Ho0.08AExFe0.97Mn0.03O3 multiferroic film. The Bi[0.92-x]Ho0.08AExFe0.97Mn0.03O3 multiferroic film is simple in demands on equipment; the experiment condition is easy to achieve; the doping amount is easy to control; the ferroelectric property of the film can be greatly improved; and the prepared Bi[0.92-x]Ho0.08AExFe0.97Mn0.03O3 multiferroic film is good in uniformity, low in leakage current and low in coercive field, and has relatively high remanent polarization.

Owner:SHAANXI UNIV OF SCI & TECH

Synthesis method of barium titanate nano-needles

InactiveCN103771501ANot easy to reuniteShape controllableMaterial nanotechnologyTitanium compoundsSynthesis methodsBarium titanate

The invention discloses a synthesis method of barium titanate nano-needles, belonging to the technical field of preparation of nano-materials. The synthesis method comprises the following steps: taking barium acetate and tetrabutyl titanate as raw materials, and taking water as a solvent, wherein the molar ratio of barium acetate to tetrabutyl titanate is 1: 1; uniformly mixing barium acetate, tetrabutyl titanate and water, then placing into a reaction container, sealing, and performing heat preservation at the temperature of 120-180 DEG C for 0.5-24h, wherein the amount of barium acetate and tetrabutyl titanate is not more than 10% of the weight of water, and the amount of barium acetate, tetrabutyl titanate and water is not more than 50% of the filling degree of the container; finally obtaining a barium titanate nano-needle-like white flocculent product. The barium titanate nano-needles synthesized by the synthesis method disclosed by the invention have excellent ferroelectric, dielectric and thermoelectric properties, and can be applied to capacitors, transducers, semiconductor ceramics, ferroelectric and piezoelectric devices and other fields.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Ferroelectric luminescent material and preparation method and application thereof

ActiveCN109575919AExcellent ferroelectricExcellent piezoelectric propertiesPolycrystalline material growthFrom melt solutionsRare-earth elementLuminescent material

The application discloses a ferroelectric luminescent material, which is a perovskite structure ferroelectric oxide material doped with rare earth elements. The material combines the excellent ferroelectric, piezoelectric and electric field-tunable luminescence properties of ferroelectric materials, which makes the material a photoelectric multifunctional material with electric field-tunable luminescence properties. The ferroelectric luminescent material has extremely high application value in photoelectric multifunctional devices.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

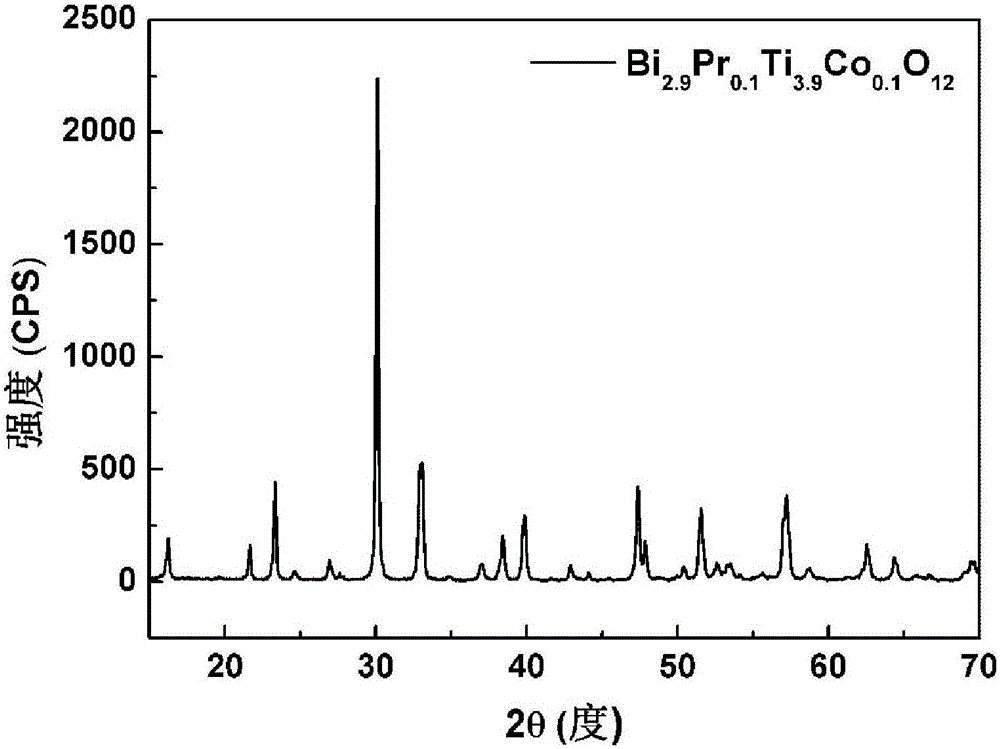

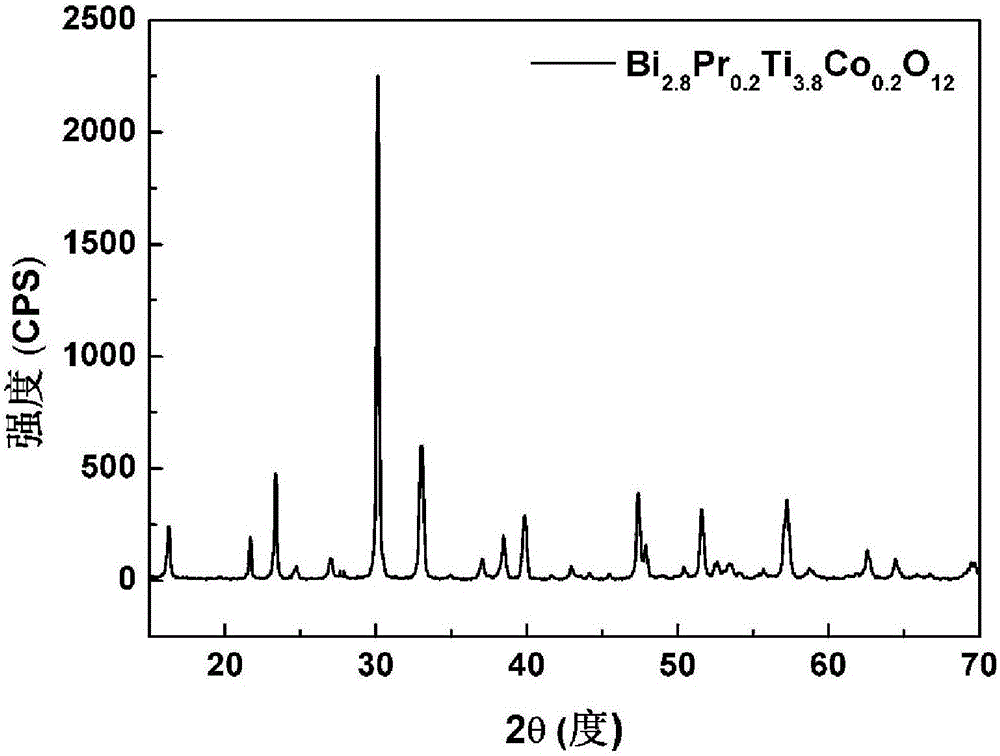

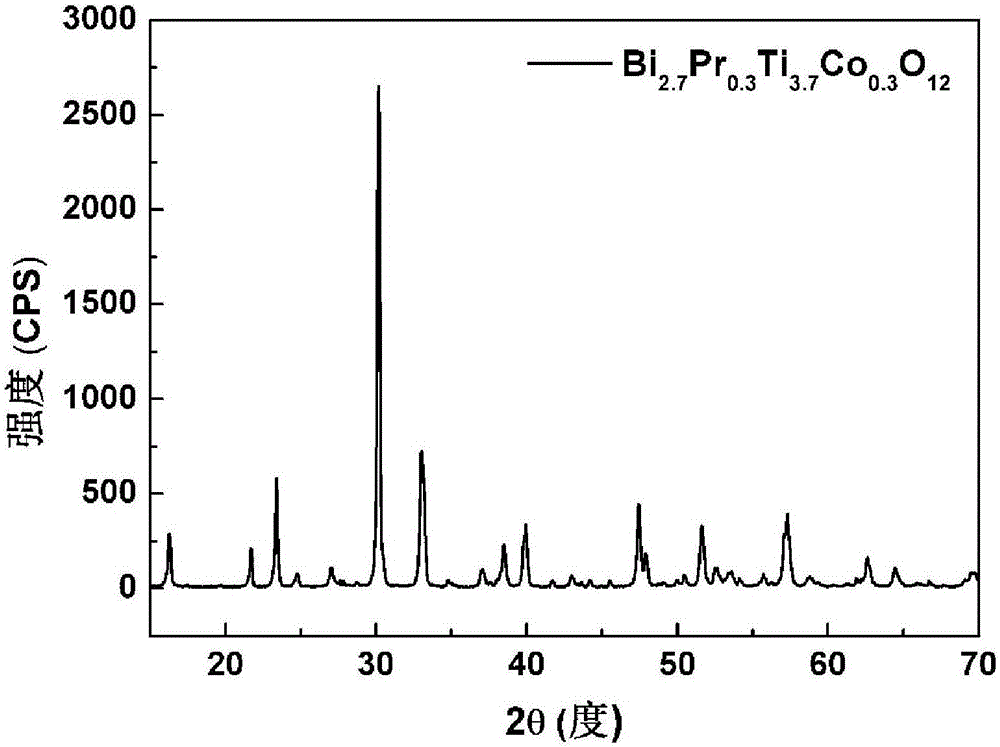

Bismuth titanate Bi4-XPrXTi3-XCoXO12 ceramic material and preparation method thereof

The invention provides a bismuth titanate Bi4-XPrXTi3-XCoXO12 ceramic material and a preparation method thereof. The bismuth titanate Bi4-XPrXTi3-XCoXO12 ceramic material is prepared by the following steps: mixing Bi2O3, TiO2, Pr2O3 and Co3O4 at a mol ratio through a solid-phase method, wherein x is a mole percent of doped ions Pr<3+> and Co<3+> ions; after mixing uniformly, pre-sintering a mixture at 700 DEG C to 800 DEG C for 4h to 8h, and then carrying out secondary ball milling and granulation; pressing and molding the mixture in a mold and discharging a PVC (Polyvinyl Chloride) adhesive; sintering by microwaves at 920 DEG C to 1000 DEG C and keeping the heat for 20min to 40min. By carrying out AB site doping of Pr<3+> and Co<3+> on bismuth titanate, the ferroelectric property is improved and the ferromagnetic property of the material is improved. By adopting a microwave sintering manner, low-temperature and rapid sintering is realized, and the bismuth titanate Bi4-XPrXTi3-XCoXO12 ceramic material with high ferroelectric property and high ferromagnetic property is prepared.

Owner:SHAANXI UNIV OF SCI & TECH

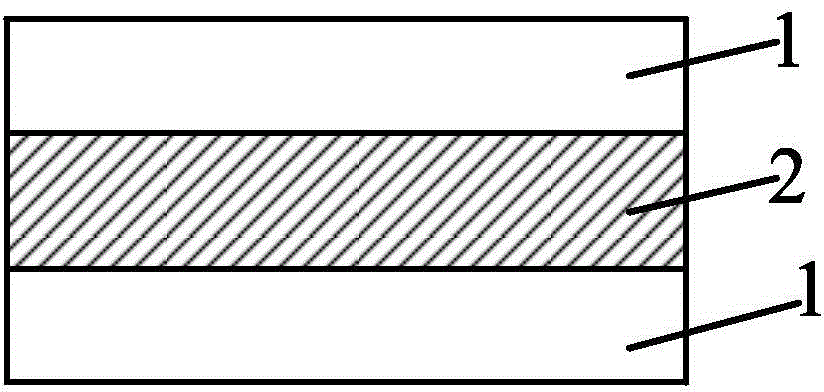

Layered magnetoelectric composite material and preparation method thereof

The invention discloses a layered magnetoelectric composite material and a preparation method thereof. The preparation method comprises the following steps: granulating 0.65BaTiO3-0.35(Na0.5Bi0.5)TiO3 powder and BiY2Fe5O12 powder respectively, then carrying out compression moulding in a mould in a manner of 2-2 composite barrier layer superposition arrangement, then removing a PVA adhesive, and sintering at 1100-1150 DEG C to obtain the layered magnetoelectric composite material. According to the layered magnetoelectric composite material and the preparation method thereof disclosed by the invention, because the 0.65BaTiO3-0.35(Na0.5Bi0.5)TiO3 powder and the BiY2Fe5O12 powder are moulded in the manner of 2-2 composite barrier layer superposition arrangement to co-sinter a ferroelectric phase and a ferromagnetic phase in a layered composite manner, inter-reaction between the two phases can be effectively suppressed, thus keeping the respective characteristics, and enabling the layered magnetoelectric composite material to be good in both ferroelectricity and ferromagnetism.

Owner:SHAANXI UNIV OF SCI & TECH

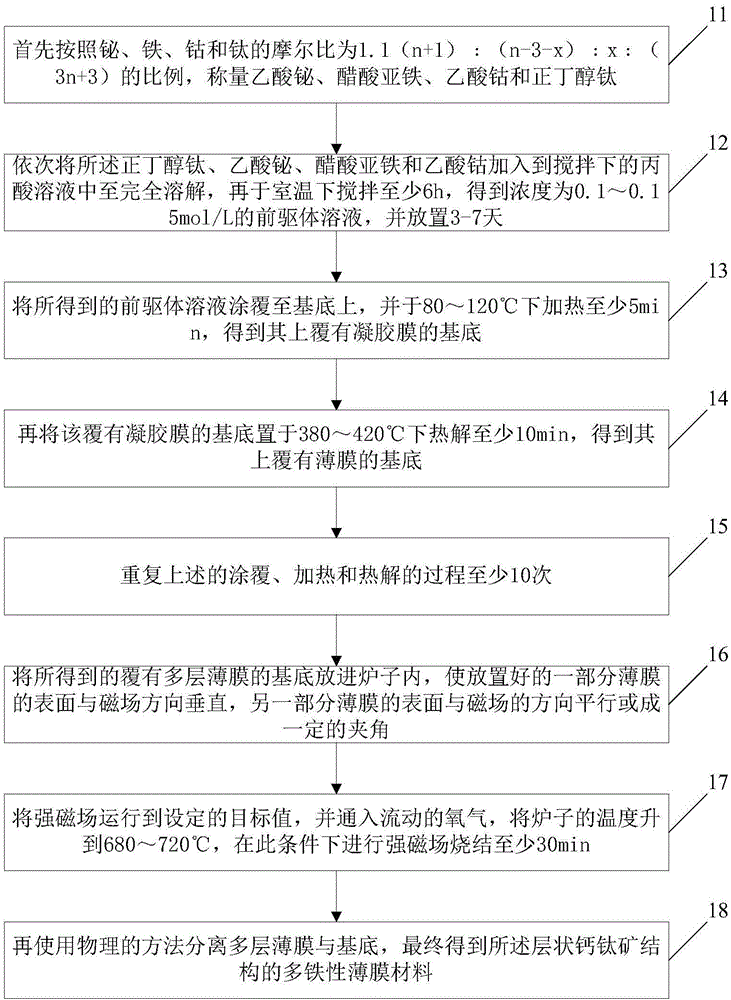

Multiferroic thin-film material of layered perovskite structure and preparation method thereof

The invention discloses a multiferroic thin-film material of a layered perovskite structure and a preparation method thereof. The prepared multiferroic thin-film material is characterized in that bismuth, iron, cobalt, titanium and oxygen elements form a thin film, wherein a chemical formula of the thin film is Bin+1Fen-3-xCoxTi3O3n+3, Bi is bismuth, Fe is iron, Co is cobalt, Ti is titanium, O is oxygen, n is more than or equal to 4, n is an integer, and x is more than 0 and less than or equal to (n-3) / 2; meanwhile, thickness of the multferroic thin-film material is 400-1000nm, the multiferroic thin-film material is composed of platy particles arranged compactly, and the particle sizes of the platy particles are 20-300nm. The multiferroic thin-film material has excellent ferroelectric and ferromagnetic properties, a production process is simple and easy to learn, less equipment is required, a sintering magnetic field is low, a sintering phase formation temperature is low, and the preparation cost is low, so that the multiferroic thin-film material is beneficial to large-scale industrial production.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

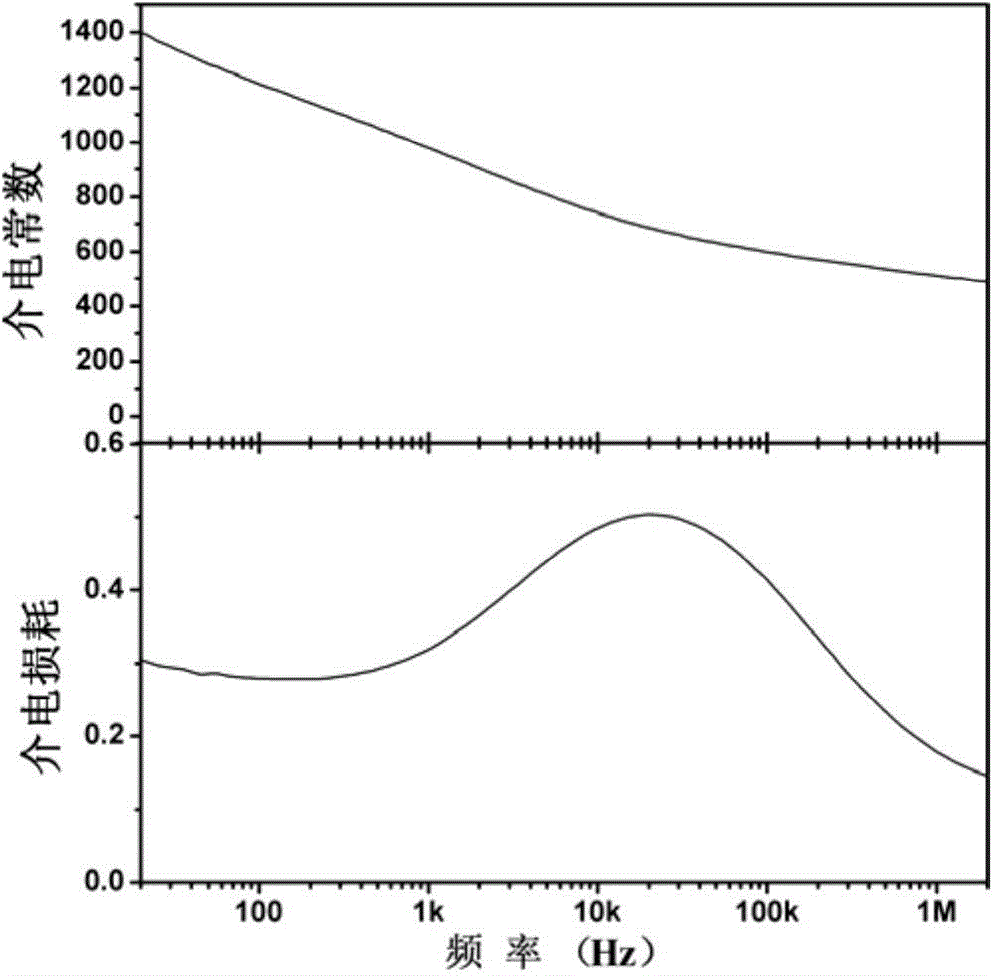

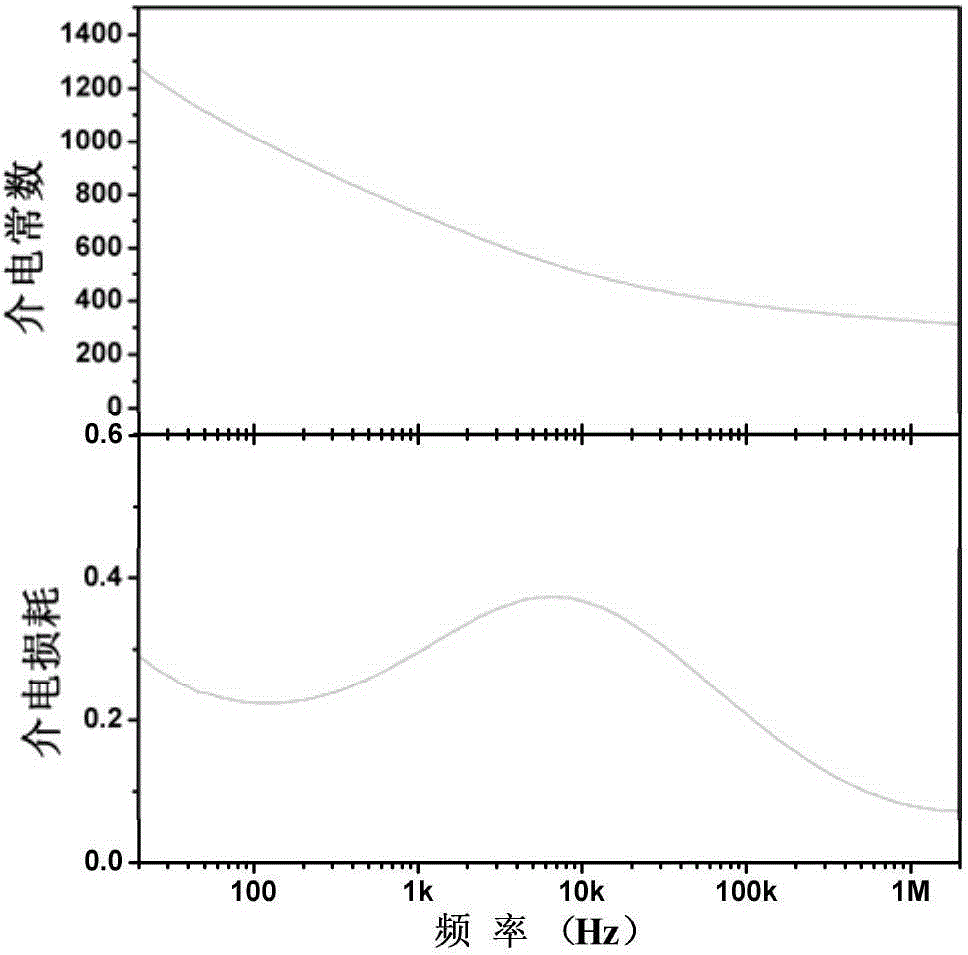

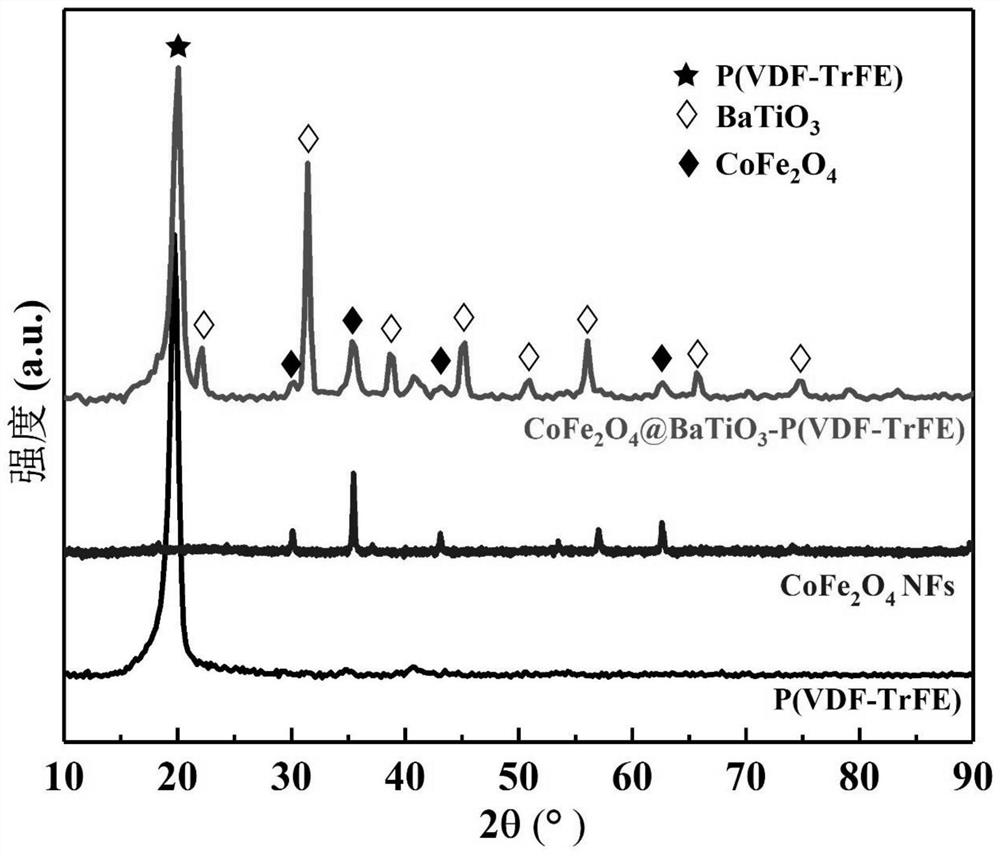

Polymer-based composite medium with ferromagnetic anisotropy and preparation method thereof

ActiveCN111995830AReduce leakage currentUnique application potentialInorganic material artificial filamentsOrganic/organic-metallic materials magnetismPolymer scienceSpinning

The invention discloses a polymer-based composite medium with ferromagnetic anisotropy and a preparation method thereof, and belongs to the technical field of preparation of multiferroic composite media. The invention aims to solve the technical problems that the preparation process of the material structure is complex and the growth condition is harsh and difficult to adjust and control. The preparation method comprises the following steps of: firstly, preparing an inorganic fiber filling phase with a large length-diameter ratio by adopting a sol-gel method and an electrostatic spinning technology; then coating the inorganic fiber filling phase with barium titanate by adopting a hydrothermal synthesis method; and compounding the inorganic fiber filling phas with P(VDF-TrFE), and carryingout hot-pressing treatment so as to obtain the compact high-orientation nanofiber polyvinylidene fluoride flexible multiferroic composite medium with a one-dimensional core-shell structure. Magnetic fields in different directions are applied to the surface of the composite medium, obvious magnetic anisotropy of the composite medium is observed, and the composite medium has higher saturation magnetization intensity and residual magnetization intensity in the fiber direction compared with the direction perpendicular to the fiber direction in the surface. Due to the property, the composite mediumhas a more unique application potential.

Owner:HARBIN UNIV OF SCI & TECH

KNN-based layered magnetoelectric composite and preparation method thereof

InactiveCN106278262AImprove performanceAvoid interactionInorganic material magnetismInductances/transformers/magnets manufactureAdhesiveCurie temperature

The invention discloses a KNN-based layered magnetoelectric composite and a preparation method thereof. The preparation method includes the steps that (K0.45Na0.55)0.98Li0.02(Nb0.77Ta0.18Sb0.05)O3 powder and Ni0.37Cu0.20Zn0.43Fe1.92O3.88 powder are subjected to granulation and then subjected to compression moulding in a mould in a 2-2 composite layer piling and overlying arrangement mode, then a PVA adhesive is discharged, sintering is carried out at 1060-1090 DEG C, and the layered magnetoelectric composite can be obtained. According to the KNN-based layered magnetoelectric composite and the preparation method thereof, a ferroelectric phase and a ferromagnetic phase are co-sintered in a layered composite mode by adopting the 2-2 composite layer piling and overlying arrangement mode for the two kinds of powder, interreaction between the two phases can be effectively inhibited, and accordingly the characteristics of the two phases can be kept, so that the KNN-based layered magnetoelectric composite has a high Curie temperature and good ferroelectricity and ferromagnetism.

Owner:SHAANXI UNIV OF SCI & TECH

Layered magnetoelectric composite material with high Curie temperature and high magnetoelectric coupling performance and preparation method of layered magnetoelectric composite material

A layered magnetoelectric composite material with high Curie temperature and high magnetoelectric coupling performance and its preparation method, comprising Li 0.058 (Na 0.535 K 0.48 ) 0.942 NbO 3 Powder, Co 0.6 Zn 0.4 Fe 1.7 mn 0.3 o 4 After the powder is granulated, it is pressed and formed in a mold according to the stacked arrangement of 2-2 composite barrier layers, and then the PVA binder is discharged, and sintered at 1020-1040°C to obtain a layered magnetoelectric composite material. In the present invention, since Li 0.058 (Na 0.535 K 0.48 ) 0.942 NbO 3 Powder, Co 0.6 Zn 0.4 Fe 1.7 mn 0.3 o 4 The powder is superimposed and arranged in a 2-2 composite barrier layer, and the ferroelectric phase and the ferromagnetic phase are co-fired together in a layered composite manner, so that it has a higher Curie temperature, better ferroelectric properties and magnetic properties. electric effect.

Owner:SHAANXI UNIV OF SCI & TECH

CoFe2O4/BaTiO3-(Na0.5Bi0.5)TiO3 material and preparation method thereof

The invention discloses a CoFe2O4 / BaTiO3-(Na0.5Bi0.5)TiO3 material and a preparation method thereof. The preparation method comprises the following steps: preparing 0.65BaTiO3-0.35(Na0.5Bi0.5)TiO3 powder with barium carbonate, titania, bismuth oxide and sodium carbonate as raw materials, carrying out granulation on CoFe2O4 powder and the 0.65BaTiO3-0.35(Na0.5Bi0.5)TiO3 powder, carrying out compression moulding in a die according to a 2-2 compounding layering staking arrangement mode, discharging rubber, and calcining. According to the CoFe2O4 / BaTiO3-(Na0.5Bi0.5)TiO3 material and the preparation method thereof disclosed by the invention, as a ferroelectric phase and a ferromagnetic phase are co-fired together in a layering compounding mode according to the 2-2 compounding layering staking arrangement mode, mutual reaction between the ferroelectric phase and the ferromagnetic phase can be effectively inhibited so as to keep respective characteristics, and the CoFe2O4 / BaTiO3-(Na0.5Bi0.5)TiO3 material is good in both ferroelectricity and ferromagnetism.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing texture-controllable lead magnesium niobate-lead titanate ferroelectric thin film

InactiveCN101550026AStress reliefMeet the needs of different electrical propertiesNiobiumFerroelectric thin films

A method for preparing texture-controllable lead magnesium niobate-lead titanate ferroelectric thin film relates to a method for preparing lead magnesium niobate-lead titanate ferroelectric thin film. The invention settles the problems of uncontrollable texture and low density in the prior art for preparing lead magnesium niobate-lead titanate ferroelectric thin film. According to the method of the invention, lead acetate is dissolved into a mixed solution of glacial acetic acid and ethylene glycol monomethylether for obtaining a solution A. Then the mixture of magnesium acetate and niobium ethoxide is dissolved into the mixed solution of glacial acetic acid and ethylene glycol monomethylether for obtaining a solution B. Then tetrabutyl titanate is added into the solution B for obtaining a solution C. Finally the solution A and the solution C is mixed and added with stabilizing agent for obtaining PMN-PT precursor sol. Then a spin coater is used for coating the precursor sol on a substrate. The substrate is prebaked after drying. Then the substrate is placed into a fast heat treatment furnace for calcining. Afterwards the substrate is cooled to room temperature. Then the texture-controllable PMN-PT ferroelectric thin film is obtained. The lead magnesium niobate-lead titanate ferroelectric thin film obtained by the invention has the advantages of controllable structure and high density.

Owner:HARBIN INST OF TECH

Highly doped batio3:fe multiferroic thin film material and preparation method thereof

InactiveCN105568265BImprove one-wayUniform and dense surfaceChemical vapor deposition applicationLiquid applicationSpinsRoom temperature

The invention relates to a high-Fe-content doped BaTiO3 multiferroic thin-film material and a preparation method thereof. The molecular formula of the high-Fe-content doped BaTiO3 multiferroic thin-film material is BaTi<1-x>FexO3, wherein x is the atomic ratio of doped components and ranges from 0.01 to 0.4. The preparation method sequentially includes the steps that (1) a precursor is prepared; (2) a substrate is cleaned and pretreated; (3) a highly doped BaTiO3:Fe multiferroic thin film is prepared, specifically, the substrate obtained in the step (2) is spin-coated with the highly doped BaTiO3:Fe sol precursor prepared in the step (1), and then stepped annealing is conducted on the precursor; and (4) the sol coating and annealing processes of the step (3) are repeated, and a thin film sample of a needed thickness is obtained. A precursor solution is clear and transparent and can be stored for a long time; the grown thin film is uniform and compact in surface, good in crystallization property and free of impurity phases, and the grown thin film is good in thickness controllability and high in unipolarity; and the thin-film material has good ferroelectricity and ferromagnetism at the room temperature.

Owner:HENAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d33c2ba5-ceec-44cc-a709-6bfddffa1e71/HDA0000631192430000011.PNG)

![Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d33c2ba5-ceec-44cc-a709-6bfddffa1e71/HDA0000631192430000012.PNG)

![Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d33c2ba5-ceec-44cc-a709-6bfddffa1e71/HDA0000631192430000021.PNG)

![Bi[0.92-x]Ho0.08AExFe0.97Mn0.03O3 multiferroic film and preparation method thereof Bi[0.92-x]Ho0.08AExFe0.97Mn0.03O3 multiferroic film and preparation method thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d995d881-416d-434e-a495-429efc7a0c24/HDA0000631249920000011.PNG)

![Bi[0.92-x]Ho0.08AExFe0.97Mn0.03O3 multiferroic film and preparation method thereof Bi[0.92-x]Ho0.08AExFe0.97Mn0.03O3 multiferroic film and preparation method thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d995d881-416d-434e-a495-429efc7a0c24/HDA0000631249920000012.PNG)

![Bi[0.92-x]Ho0.08AExFe0.97Mn0.03O3 multiferroic film and preparation method thereof Bi[0.92-x]Ho0.08AExFe0.97Mn0.03O3 multiferroic film and preparation method thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d995d881-416d-434e-a495-429efc7a0c24/HDA0000631249920000021.PNG)