Bismuth titanate Bi4-XPrXTi3-XCoXO12 ceramic material and preparation method thereof

A ceramic material, bismuth titanate technology, applied in the field of material science, can solve the problems of deteriorating the ferroelectric properties of materials, reducing the resistivity of materials, etc., and achieve the effects of reduced sintering activation energy, short sintering time, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

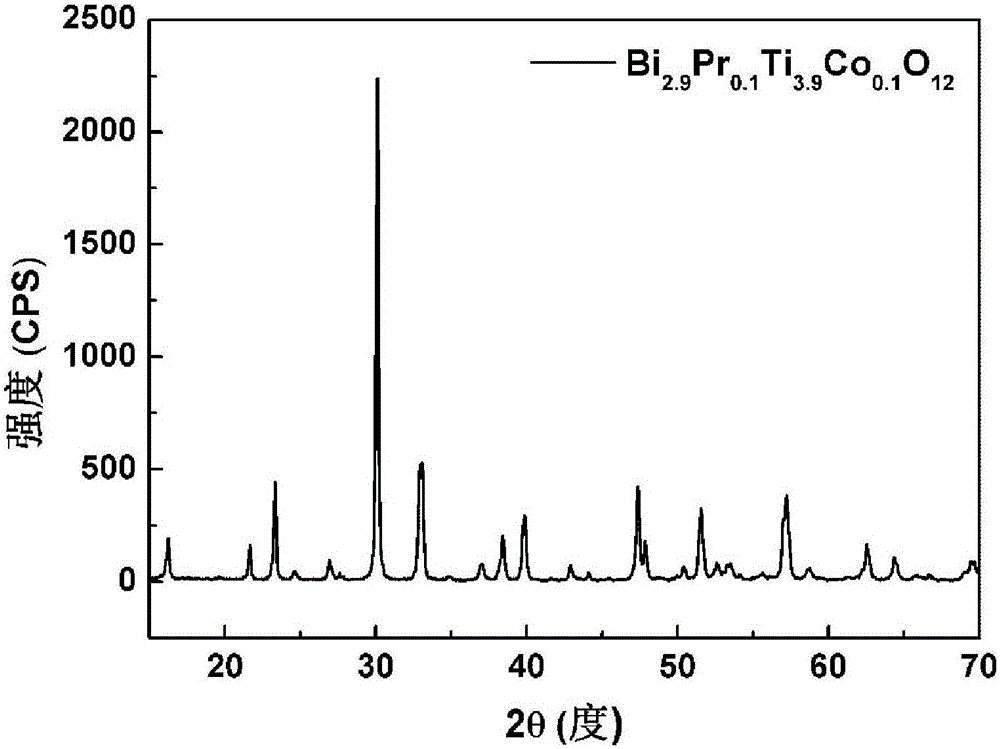

Embodiment 1

[0041] Bismuth titanate Bi with high ferroelectricity and high ferromagnetism 4-x PR x Ti 3-x co x o 12 Ceramic material, the chemical expression is Bi 4-x PR x Ti 3-x co x o 12 , where x is the dopant ion Pr 3+ and Co 3+ Mole percent of ions, and x = 0.1.

[0042] The above Bi 3.9 PR 0.1 Ti 2.9 co 0.1 o 12 A method for preparing a ceramic material, comprising the steps of:

[0043] 1) According to the chemical formula Bi 3.9 PR 0.1 Ti 2.9 co 0.1 o 12 Analytical pure Bi 2 o 3 、TiO 2 、Pr 2 o 3 and Co 3 o 4 After being prepared according to the molar ratio, it was mixed evenly by ball milling, and the ball milling time was 10 hours, and then dried, the drying temperature was 100°C, and the drying time was 8 hours. Sieve, pre-calcined at 800°C for 4 hours, and pass through a 120-mesh sieve after the second ball milling to obtain Bi 3.9 PR 0.1 Ti 2.9 co 0.1 o 12 Powder;

[0044] 2) to Bi 3.9 PR 0.1 Ti 2.9 co 0.1 o 12 Granulate after adding PV...

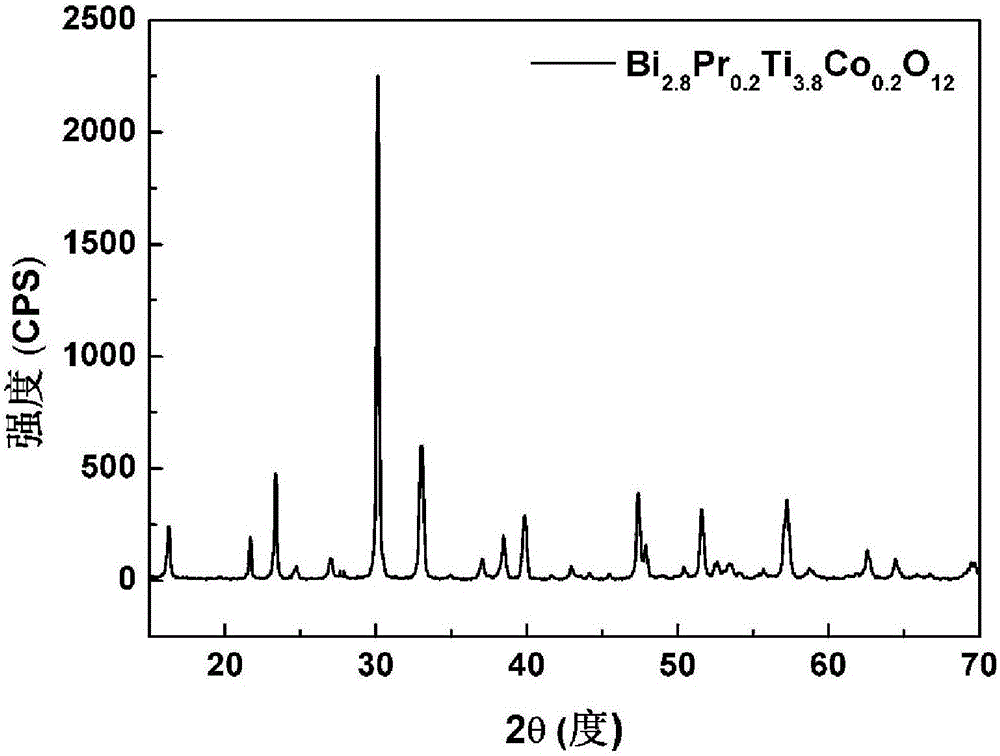

Embodiment 2

[0051] Bismuth titanate Bi with high ferroelectricity and high ferromagnetism 4-x PR x Ti 3-x co x o 12 Ceramic material, the chemical expression is Bi 4-x PR x Ti 3-x co x o 12 , where x is the dopant ion Pr 3+ and Co 3+ Mole percent of ions, and x = 0.2.

[0052] The above Bi 3.8 PR 0.2 Ti 2.8 co 0.2 o 12 A method for preparing a ceramic material, comprising the steps of:

[0053] 1) According to the chemical formula Bi 3.8 PR 0.2 Ti 2.8 co 0.2 o 12 Analytical pure Bi 2 o 3 、TiO 2 、Pr 2 o 3 and Co 3 o 4 After being prepared according to a certain molar ratio, the mixture is uniformly mixed by ball milling, and the ball milling time is 12 hours. Then dry, the drying temperature is 90°C, and the drying time is 10 hours. Sieve, pre-calcined at 750°C for 6 hours, and pass through a 120-mesh sieve after the second ball milling to obtain Bi 3.8 PR 0.2 Ti 2.8 co 0.2 o 12 Powder;

[0054] 2) to Bi 3.8 PR 0.2 Ti 2.8 co 0.2 o 12 Granulate after ...

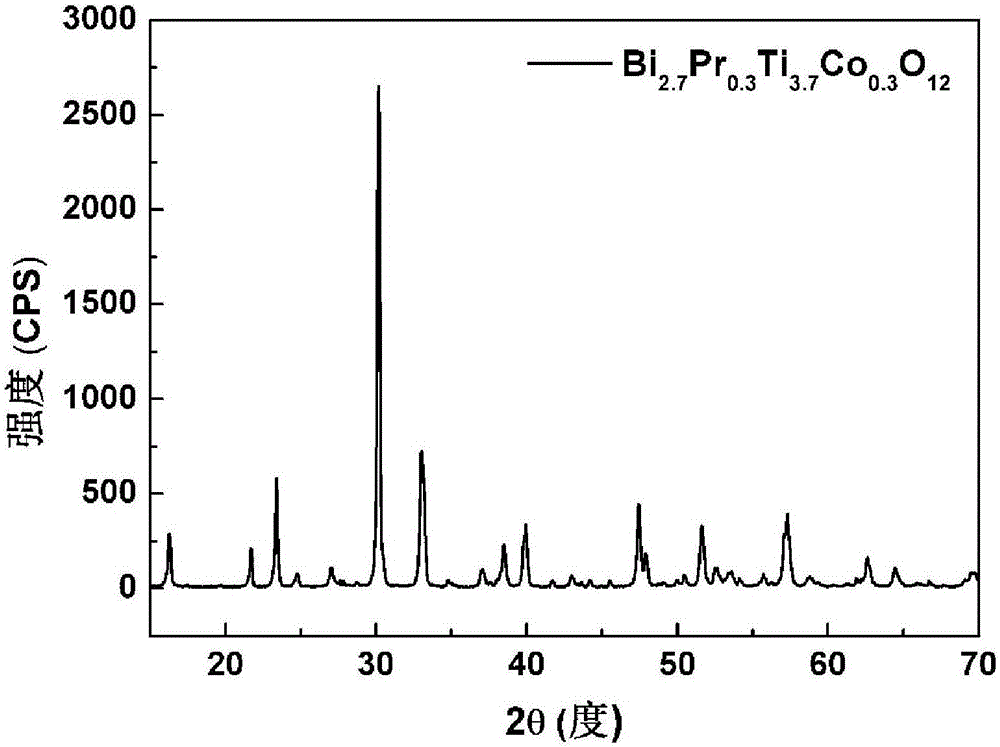

Embodiment 3

[0061] Bismuth titanate Bi with high ferroelectricity and high ferromagnetism 4-x PR x Ti 3-x co x o 12 Ceramic material, the chemical expression is Bi 4-x PR x Ti 3-x co x o 12 , where x is the dopant ion Pr 3+ and Co 3+ Mole percent of ions. And x=0.3.

[0062] The above Bi 3.7 PR 0.3 Ti 2.7 co 0.3 o 12 A method for preparing a ceramic material, comprising the steps of:

[0063] 1) According to the chemical formula Bi 3.7 PR 0.3 Ti 2.7 co 0.3 o 12 Analytical pure Bi 2 o 3 、TiO 2 、Pr 2 o 3 and Co 3 o 4 After being prepared according to the molar ratio, the mixture is uniformly mixed by ball milling, and the ball milling time is 12 hours. Then dry, the drying temperature is 80 ℃, and the drying time is 12 hours. Sieve, pre-calcine at 700°C for 8 hours, pass through a 120-mesh sieve after the second ball milling to obtain Bi 3.7 PR 0.3 Ti 2.7 co 0.3 o 12 Powder;

[0064] 2) to Bi 3.7 PR 0.3 Ti 2.7 co 0.3 o 12 Granulate after adding PVA b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

| saturated polarization | aaaaa | aaaaa |

| saturated polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com