Silver niobate-based lead-free piezoelectric ceramic and preparation method thereof

A technology based on lead-free piezoelectric and piezoelectric ceramics, which is applied in the field of new lead-free piezoelectric ceramics and its preparation, can solve the problems of low piezoelectric performance of AN-based ceramics, difficulty in obtaining AN-based solid solutions, unstable process, etc. The effect of good temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Synthesized in an air atmosphere by a two-step method (Ag 0.64 Li 0.16 Na 0.1 K 0.1 )NbO 3 . First weigh the Ag according to the stoichiometric ratio 2 O. Li 2 CO 3 and Nb 2 o 5 , ball milled in absolute ethanol solution for 12 hours, and the dried powder was calcined at 920°C for 3 hours to synthesize Ag 0.8 Li 0.2 NbO 3 (recorded as ALN); Then take Na by stoichiometric ratio 2 CO 3 、K 2 CO 3 and Nb 2 o 5 , ball milled in absolute ethanol solution for 12 hours, and the dried powder was calcined at 850°C for 3 hours to synthesize (Na 0.5 K 0.5 )NbO 3 (NKN); then according to chemical formula 0.8 (Ag 0.8 Li 0.2 )NbO 3 -0.2 (Na 0.5 K 0.5 )NbO 3 Weigh an appropriate amount of ALN and NKN, ball mill in absolute ethanol solution for 12 hours, and calcinate the dried powder at 900°C for 3 hours to synthesize (Ag 0.64 Li 0.16 Na 0.1 K 0.1 )NbO 3 For solid solution, the calcined samples were ground and analyzed by XRD. From figure 1 It can be see...

Embodiment 2

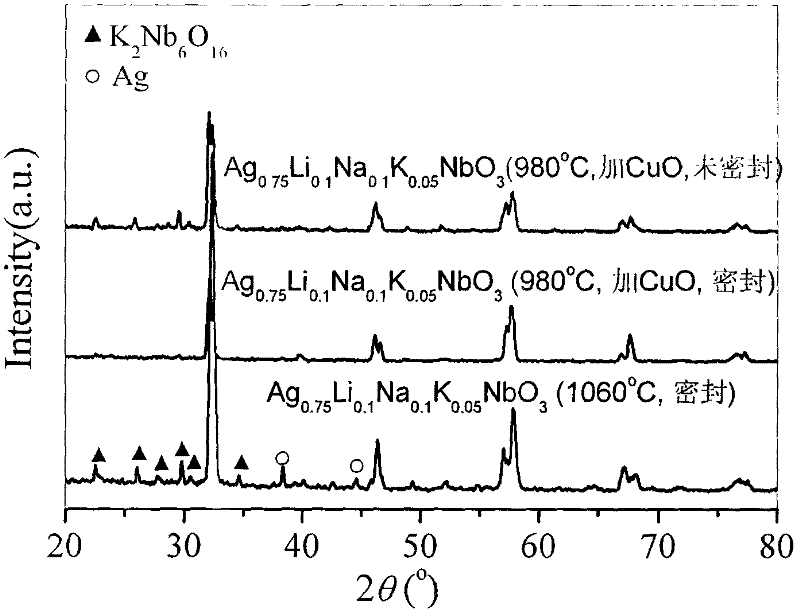

[0023] Synthesized by one-step method under air atmosphere (Ag 0.75 Li 0.1 Na 0.1 K 0.05 )NbO 3 , add 1wt% CuO as a sintering aid, and seal the sintering with a crucible. Weigh Ag according to stoichiometric ratio 2 O. Li 2 CO 3 、Na 2 CO 3 、K 2 CO 3 and Nb 2 o 5 , ball milled in anhydrous ethanol solution for 12 hours, the dried powder was calcined at 900°C for 3 hours, the calcined sample was added with 1wt% CuO and then ball milled for 12 hours, after drying, 10wt% polyvinyl alcohol aqueous solution was added to mix evenly, and the After dry pressing (20MPa) and ejection, seal and sinter at 980°C for 2 hours. The sintered ceramic sheet is covered with a silver electrode, and polarized in silicone oil at 120° C., with a polarizing voltage of 4-5 kV and a polarizing time of 15 minutes. After standing for 24 hours, the Q of the ceramic was measured m = 265, d 33 =50pC / N,k p =20.6%, P r =14.3μC / cm 2 ,E c =3.71kV / mm, T c = 330°C.

[0024] From figure 2 It ...

Embodiment 3

[0032] Synthesized by one-step method under air atmosphere (Ag 0.73 Li 0.12 Na 0.1 K 0.05 )NbO 3 , add 1wt% CuO as a sintering aid, and seal the sintering with a crucible. Weigh Ag according to stoichiometric ratio 2 O. Li 2 CO 3 、Na 2 CO 3 、K 2 CO 3 and Nb 2 o 5 , the rest of the process conditions were consistent with Example 2, and the surface morphology of the ceramic sheet was observed with a scanning electron microscope (SEM). From image 3 It can be seen that the ceramic grain boundary is clear, the sample is dense, the grain size is 1-3 μm, and the volume density reaches more than 95% of the theoretical density. The Q of the ceramics was measured after being placed for 24 hours after polarization m =266,d 33 =54pC / N,k p =18.0%, P r =14.6μC / cm 2 ,E c = 3.56 kV / mm. From Figure 4 It can be seen that the Curie temperature T of the ceramic c up to 340°C, and T c The following have good temperature stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com