Wet chemical prepn process of leadless functional barium titanate ceramic film

A lead-free barium zirconate titanate and functional ceramic technology, applied in liquid chemical plating, piezoelectric/electrostrictive device manufacturing/assembly, coating, etc., can solve the problem of long preparation time, cumbersome process and high preparation cost problem, to achieve the effect of long storage period, good stability and good dielectric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

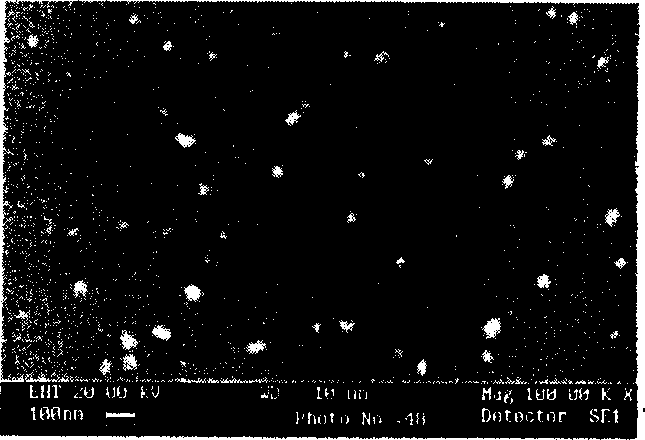

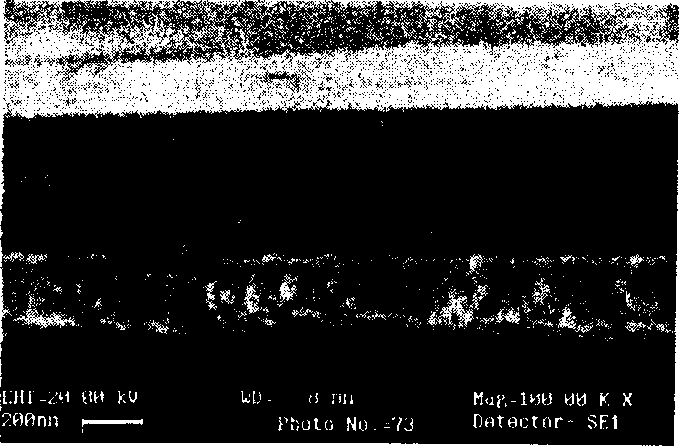

Embodiment 1

[0011] Concentration is 0.3 mol / liter metal ion mol concentration ratio in precursor solution is Ba: Zr: Ti=1: 0.05: 0.95 (abbreviated as BZT5), its preparation method is to dissolve barium acetate in glacial acetic acid, control heating to 70 ℃, Stir for 30 minutes to obtain a clear barium acetate solution; add zirconium propoxide and butyl titanate to ethylene glycol methyl ether respectively, add 10% acetylacetone to stabilize the solution, and stir for 10 minutes. Heat to 70°C according to the above ratio, stir for 30 minutes, and filter out impurities with rapid qualitative filter paper to prepare a precursor solution. Choose Pt / Ti / SiO 2 / Si is the substrate, the glue-spinning speed is 3600 rpm, the time is 30 seconds, the pretreatment temperature is 450° C., the time is 10 minutes, and repeated six times. After annealing at 720°C for 10 minutes in an oxygen atmosphere with a heating rate of 100°C / s, a film with a thickness of 490nm was obtained, with perfect crystalliza...

Embodiment 2

[0013] The concentration of the precursor solution is 0.3 mol / liter, the molar concentration ratio of metal ions is Ba:Zr:Ti=1:0.5:0.5 (abbreviated as BZT50 / 50), the speed of plastic rejection is 3800 rpm, and the time is 30 seconds. 420°C, time 10 minutes, repeated six times, and 730°C, rapid annealing treatment under oxygen atmosphere for 10 minutes to obtain a film with a thickness of 300nm, and a BZT50 / 50 film with perfect crystallization and random orientation. All the other are with embodiment 1.

Embodiment 3

[0015] The concentration of the precursor solution is 0.3 mol / liter, the molar concentration ratio of metal ions is Ba:Zr:Ti=1:1:0 (abbreviated as BZ), the glue-spinning speed is 3000 rpm, the time is 30 seconds, and the pretreatment temperature is 420°C each time , time 10 minutes, repeated six times, after rapid annealing at 730°C for 10 minutes under an oxygen atmosphere, a film with a thickness of 600nm was obtained, and a BZ film with perfect crystallization and random orientation was obtained. All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com