Ferrotitanium bismuth cobaltate ceramic material having layered structure and preparation method thereof

A technology of ceramic material and layered structure, which is applied in the field of layered structure titanium iron cobalt bismuth ceramic material and its preparation, can solve problems such as the inability to meet practical application, and achieve the effect of improving ferroelectricity and ferromagnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

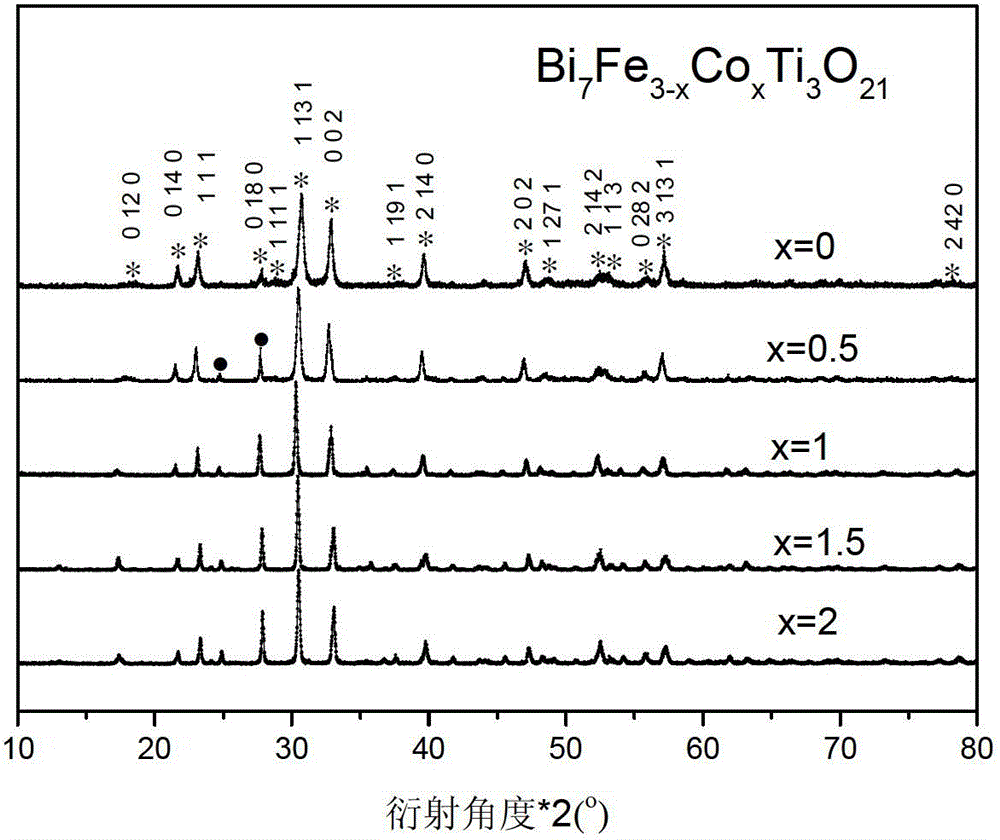

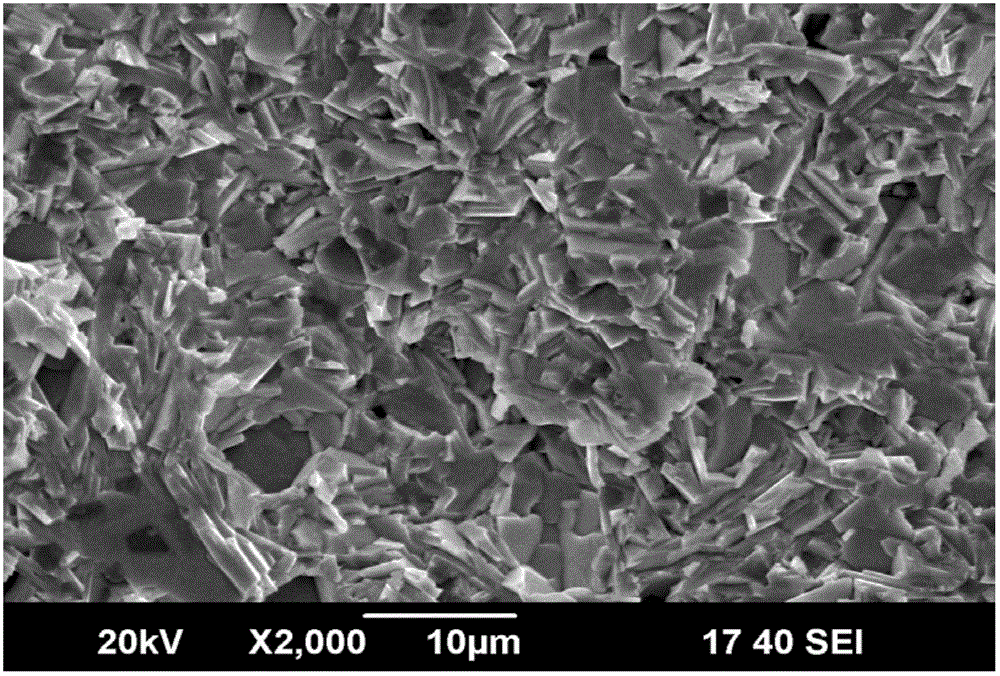

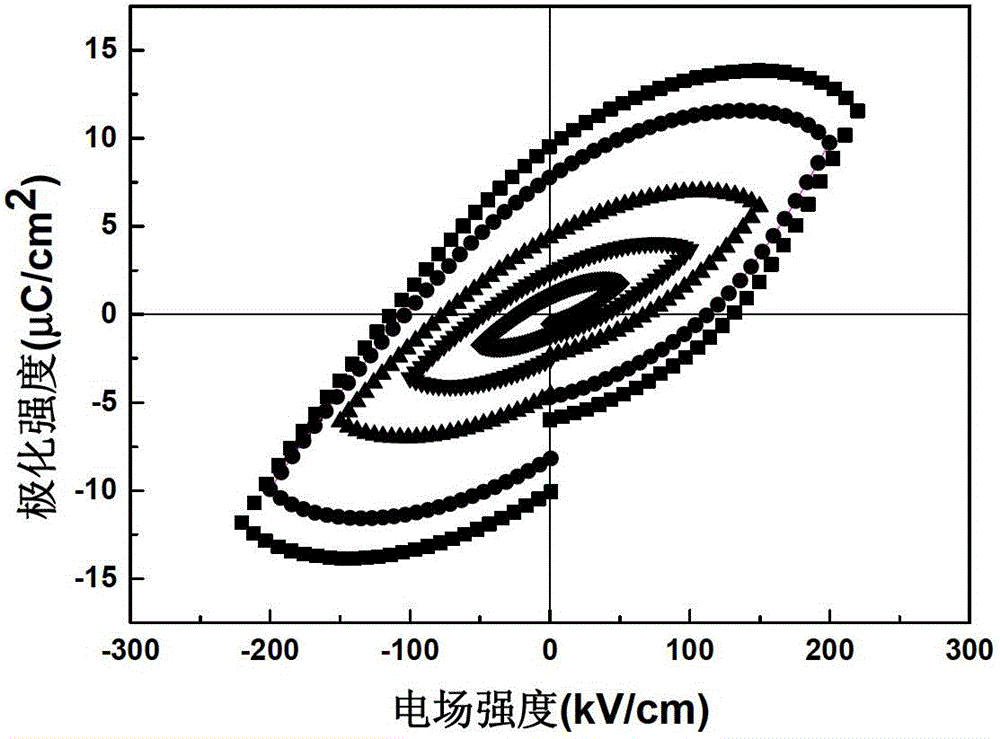

[0047] The purity is 98% n-butyl titanate (C 16 h 36 o 4 Ti) 7.1475g, with a purity of 99% bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) 24.0110g, with a purity of 98.5% iron nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) 7.1062g, with a purity of 99.5% cobalt nitrate hexahydrate (Co(NO 3 ) 3 ·6H 2 O) 1.0354g was dissolved in nitric acid solution, 18.6157g of ethylenediaminetetraacetic acid (EDTA) with a purity of 98% and 19.1227g of citric acid with a purity of 98% were added as complexing agents, and a mixed solution was obtained after stirring. Put the mixed solution in a crucible and evaporate to dryness until burned to obtain a powder, and pre-burn the obtained powder in a muffle furnace at 750°C for 2 hours to remove organic matter to obtain a precursor; A cylindrical sample with a size of Φ12mm×2mm was made, and it was sintered in a muffle furnace at 880°C for 5 hours to obtain a ceramic material, which was Bi 7 Fe 2.5 co 0.5 Ti 3 o 21 .

[0048] Be that ...

Embodiment 2

[0053] The purity is 98% n-butyl titanate (C 16 h 36 o 4 Ti) 7.1475g, with a purity of 99% bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) 24.0110g, with a purity of 98.5% iron nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) 5.6849g, with a purity of 99.5% cobalt nitrate hexahydrate (Co(NO 3 ) 3 ·6H 2 O) 2.0684g was dissolved in nitric acid solution, 18.6157g of ethylenediaminetetraacetic acid (EDTA) with a purity of 98% and 19.1227g of citric acid with a purity of 98% were added as complexing agents, and a mixed solution was obtained after stirring. Put the mixed solution in a crucible and evaporate to dryness until burned to obtain a powder, and pre-burn the obtained powder in a muffle furnace at 750°C for 2 hours to remove organic matter to obtain a precursor; A cylindrical sample with a size of Φ12mm×2mm was made, and it was sintered in a muffle furnace at 880°C for 5 hours to obtain a ceramic material, which was Bi 7 Fe 2 co 1 Ti 3 o 21 .

[0054] Be that the ...

Embodiment 3

[0059] The purity is 98% n-butyl titanate (C 16 h 36 o 4 Ti) 7.1475g, with a purity of 99% bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) 24.0110g, with a purity of 98.5% iron nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) 4.2637g, with a purity of 99.5% cobalt nitrate hexahydrate (Co(NO 3 ) 3 ·6H 2 O) 3.1026g was dissolved in nitric acid solution, 18.6157g of ethylenediaminetetraacetic acid (EDTA) with a purity of 98% and 19.1227g of citric acid with a purity of 98% were added as complexing agents, and a mixed solution was obtained after stirring. Put the mixed solution in a crucible and evaporate to dryness until burned to obtain a powder, and pre-burn the obtained powder in a muffle furnace at 750°C for 2 hours to remove organic matter to obtain a precursor; A cylindrical sample with a size of Φ12mm×2mm was made, and it was sintered in a muffle furnace at 880°C for 5 hours to obtain a ceramic material, which was Bi 7 Fe 1.5 co 1.5 Ti 3 o 21 .

[0060] Structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| remanent polarization | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com