Ocean precipitation process for improving radiation protection performance of metal and iron-based mixture

A radiation and mixture technology, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of unknown influence of adsorbents, and achieve the effects of improving physical properties, improving protection, and stabilizing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

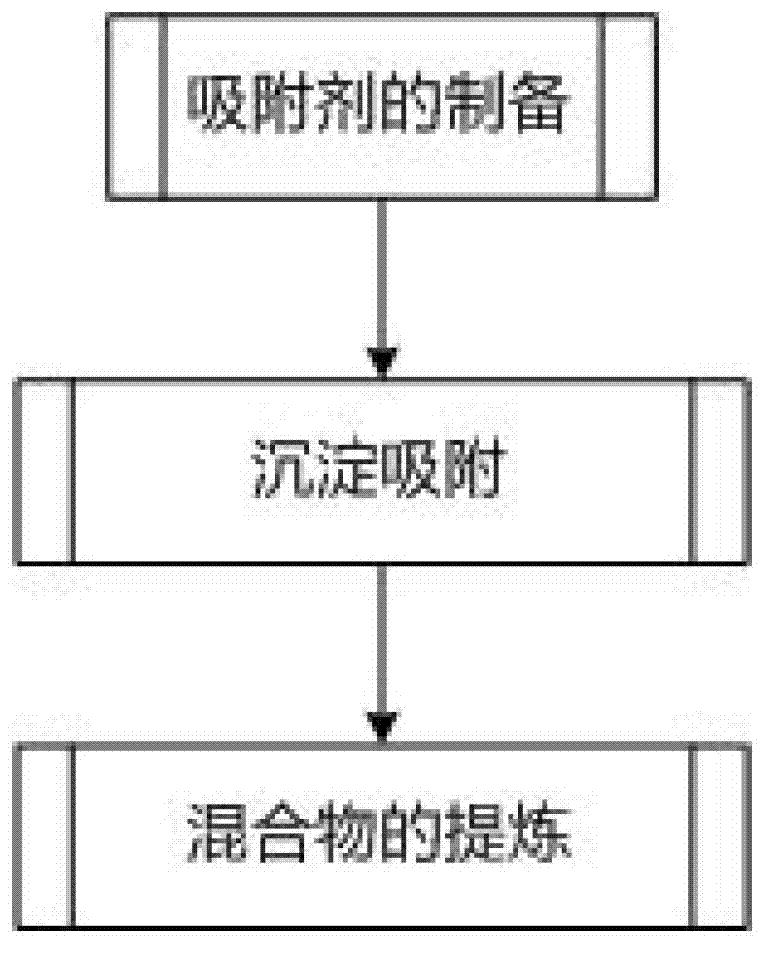

[0059] S101: In percent by mass, sodium oxide: aluminum oxide: silicon oxide: magnesium oxide: calcium oxide: boron oxide = 1: 1.3: 3: 1.6: 0.8: 0.2, take raw materials. Keep the temperature at 900°C to make a molten viscous liquid.

[0060] S102: making iron base, about 99.3% of the iron base, the balance of aluminum, S 3 / V 2 About=1433. To keep the oxygen content of the working environment below 0.1%, add iron to the molten viscous liquid.

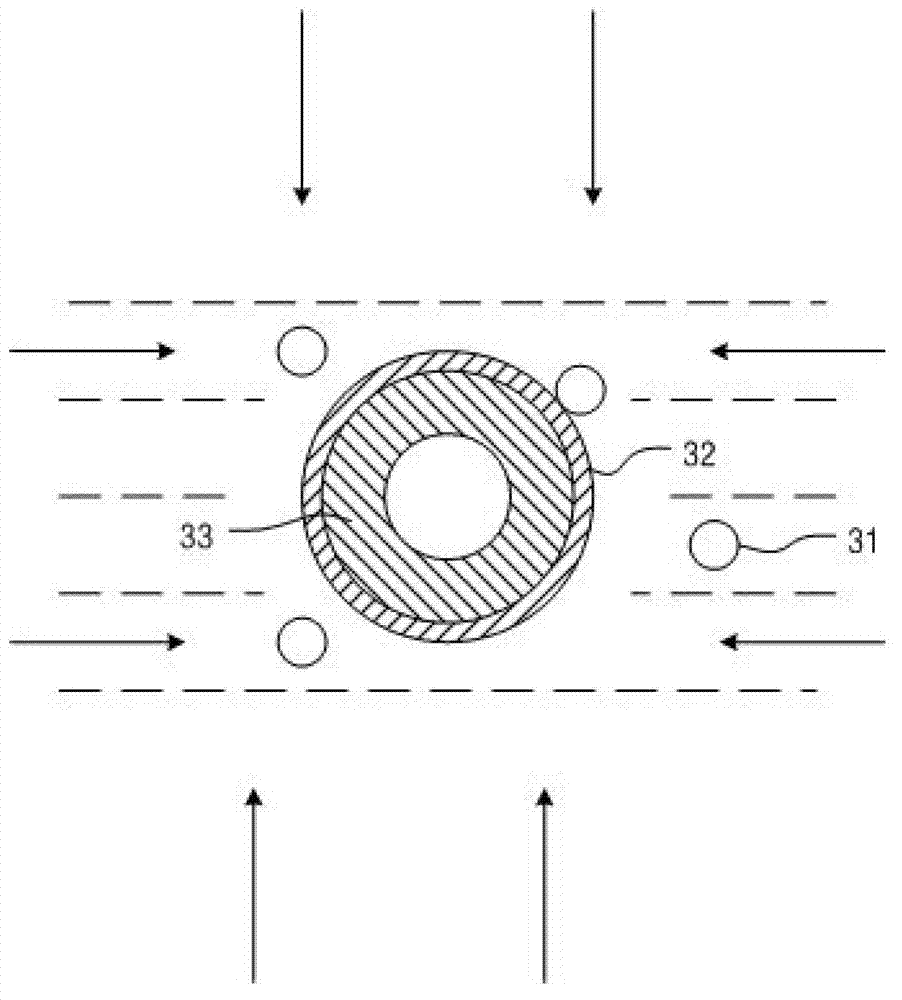

[0061] S103: Gradually cool and draw out, every 5mm, the ambient temperature is lowered by 10°C, and the viscous liquid is gradually scraped off, so that the viscous liquid wraps the iron base, and finally an adsorbent consisting of an amorphous protective film and an iron base is produced. The thickness H of the amorphous protective film satisfies: S / H 2 ≥269.

[0062] S104: Place the adsorbent in an area below 300m from the ground surface and let it stand for 2 years.

[0063] S105: Take out the adsorbent, melt it under the cond...

Embodiment 2

[0068] S201: In terms of mass percentage, sodium oxide: aluminum oxide: silicon oxide: magnesium oxide: calcium oxide: boron oxide = 1: 1.8: 4.6: 2: 2.1: 0.5, take raw materials. Keep the temperature at 1200°C to make a molten viscous liquid.

[0069] S202: making iron base, the purity of the iron base is about 99.89%, S 3 / V 2 =487. To keep the oxygen content of the working environment below 0.1%, add iron to the molten viscous liquid.

[0070] S203: Gradually cool and draw out, every 5mm, the ambient temperature is lowered by no more than 5°C, gradually scrape off the viscous liquid, so that the viscous liquid wraps the iron base, and finally makes an adsorbent composed of an amorphous protective film and an iron base . The thickness H of the amorphous protective film satisfies: S / H 2 ≥857.

[0071] S204: Place the adsorbent in an area below 900m from the ground surface and let it stand for 5 years.

[0072] S205: Take out the adsorbent, melt it under the condition of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com