Method of preparing strong-cubic texture composite base band for coating superconductor by metal powder rolling

A technology of strong cubic texture and metal powder, which is applied in the field of preparation of cubic texture nickel-tungsten-nickel-chromium alloy composite base tape for high-temperature coated superconductors, and can solve problems such as difficulty in realizing large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) The Ni powder with a purity of 99.99% and the W powder with a purity of 99.95% are mixed according to the atomic percentage of W at 8at%; the Ni powder with a purity of 99.99% and the Cr powder with a purity of 99.90% , according to the atomic percentage content of Cr is 13at%; the above two mixed metal powders are mixed evenly in a high-speed inclined horizontal powder mixer; the powder mixing tank is vacuumed, and the vacuum pressure is 8Pa; The barrel speed is controlled at 80 rpm; the powder mixing time is 2 hours;

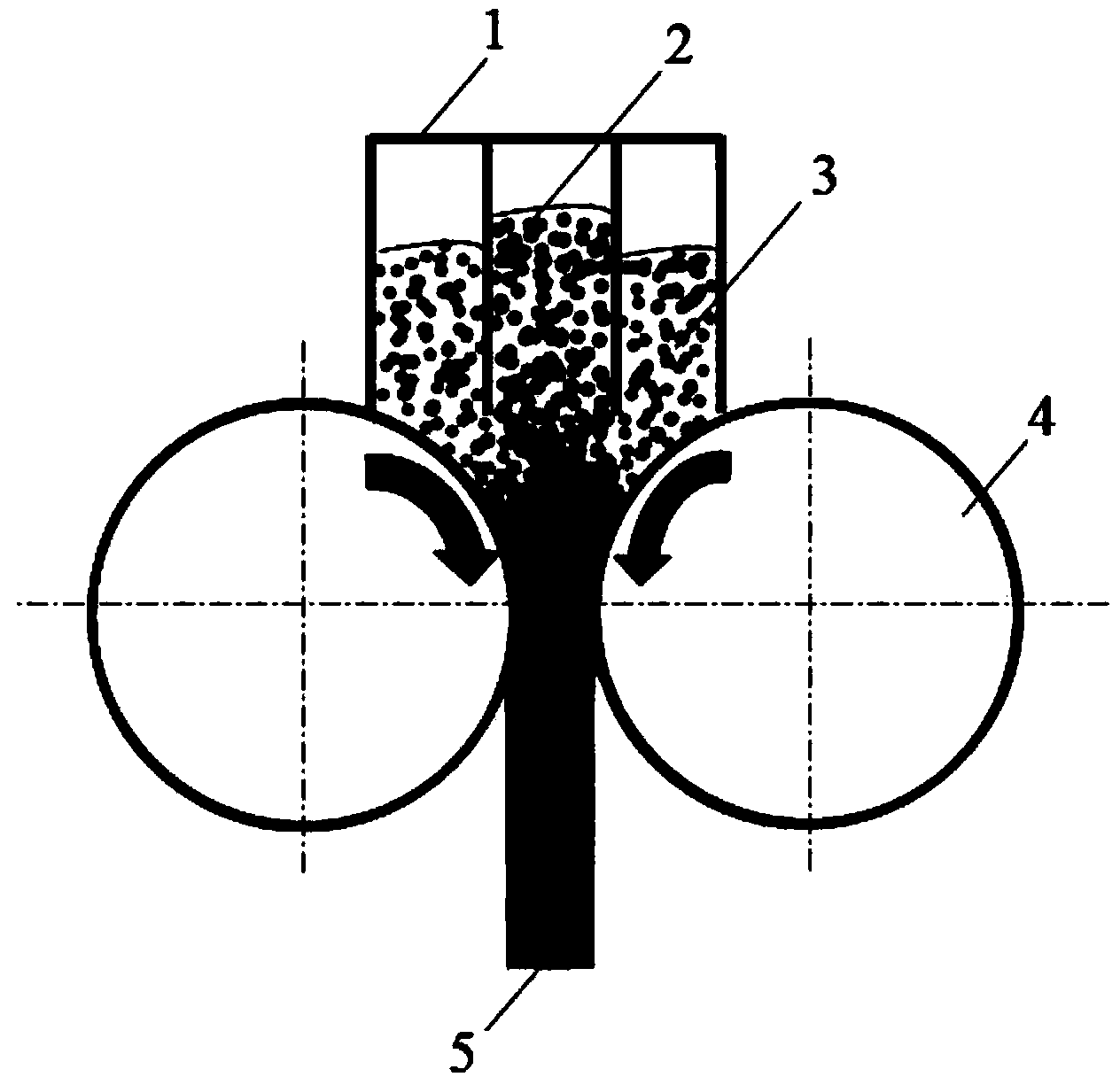

[0028] (2) Pour the uniformly mixed powder into the three adjacent powder storage tanks of the integrated type respectively; the order of powder placement is as follows: the inner powder storage tank is filled with NiCr mixed powder, and the outer two powder storage tanks are filled with NiW mixed powder ;The opening width of the three powder storage tanks is the same, each 30mm wide; the powder storage tank and the roll are placed vertically, the r...

Embodiment 2

[0037] (1) The Ni powder with a purity of 9.99% and the W powder with a purity of 99.95% are mixed according to the atomic percentage of W at 8.5at%; the Ni powder with a purity of 99.99% and the Cr with a purity of 99.90% Powder, according to the atomic percentage content of Cr is 14at%; the above two mixed metal powders are mixed evenly in a high-speed inclined horizontal powder mixer; the powder mixing tank is vacuumed, and the vacuum pressure is 8Pa; The speed of the powder bucket is controlled at 90 rpm; the mixing time is 1.5 hours;

[0038] (2) Pour the uniformly mixed powder into the three adjacent powder storage tanks of the integrated type respectively; the order of powder placement is as follows: the inner powder storage tank is filled with NiCr mixed powder, and the outer two powder storage tanks are filled with NiW mixed powder The opening width of the inner powder storage tank is 50mm, which is twice the opening width of the outer powder storage tank; the powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com