Preparation method of Bi1-xNdxFeO3 rare earth ferrite magnetic wave-absorbing material

A magnetic wave absorbing and ferrite technology, applied in the fields of magnetic field/electric field shielding, electrical components, etc., can solve the problems of limited electromagnetic response, weak ferromagnetism and ferroelectricity, etc., to achieve easy regulation, simple process, and product uniformity. and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

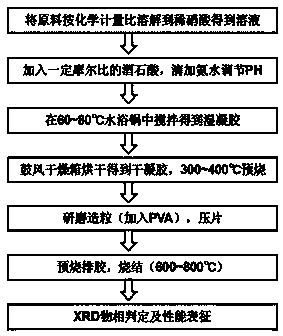

[0036] a Bi 1-x Nd x FeO 3 Preparation method of rare earth ferrite magnetic wave absorbing material, see figure 1 ,Include:

[0037] (1) Analytically pure bismuth nitrate pentahydrate (Bi(NO) 3 ) 3 ·5H 2 O), ferric nitrate nonahydrate (Fe(NO) 3 ) 3 ·9H 2 O) as the ion source of Bi and Fe, according to BiFeO 3 The stoichiometric ratio of the sample is weighed, and ultrasonic dispersion is utilized to dissolve the sample into the dilute nitric acid with a volume ratio of 1:7 to obtain a solution;

[0038] (2) adding the tartaric acid that is 1:1 with the sum molar ratio of the above-mentioned metal ions in the solution, and adjusting pH by dripping ammonia water is 5.0;

[0039] (3) Put the prepared solution in a water bath at 80°C, and stir with a magnetic stirrer for 2 hours until the solution is uniform and in the form of a transparent wet gel;

[0040] (4) drying the wet gel in a drying oven at 100°C for 20 hours to obtain a dry gel;

[0041] (5) put the obtained ...

Embodiment 2

[0052] a Bi 1-x Nd x FeO 3 The preparation method of the rare earth ferrite magnetic wave absorbing material is basically the same as that of Example 1, the difference is:

[0053] In step (1), also added neodymium nitrate hexahydrate (Nd(NO 3 ) 3 ·6H 2 O) as the ion source of Nd, according to Bi 0.95 Nd 0.05 FeO 3 The stoichiometric ratio of the sample is weighed; the volume ratio of each sample and dilute nitric acid is 1:5;

[0054] In step (2), the sum molar ratio of tartaric acid and metal ions is 3:1, and pH is adjusted to 7.0 by dripping ammonia water;

[0055] In step (3), the temperature of the water bath was 70°C, and the stirring time was 3h;

[0056] In step (4), the drying oven temperature is 110°C, and the drying time is 18h;

[0057] In step (5), the pre-burning temperature is 350°C, and the pre-burning time is 5h;

[0058] In step (6), the mass fraction of polyvinyl alcohol glue is 8%, and the pressure is 10.0Mpa;

[0059] In step (7), debonding is ...

Embodiment 3

[0065] a Bi 1-x Nd x FeO 3 The preparation method of the rare earth ferrite magnetic wave absorbing material is basically the same as that of Example 1, the difference is:

[0066] In step (1), also added neodymium nitrate hexahydrate (Nd(NO 3 ) 3 ·6H 2 O) as the ion source of Nd, according to Bi 0.9 Nd 0.1 FeO 3 The stoichiometric ratio of the sample is weighed; the volume ratio of each sample and dilute nitric acid is 1:10;

[0067] In step (2), the sum molar ratio of tartaric acid and metal ions is 2:1, and pH is adjusted to 7.0 by dripping ammonia water;

[0068] In step (3), the temperature of the water bath is 60°C, and the stirring time is 5h;

[0069] In step (4), the drying oven temperature is 100°C, and the drying time is 24h;

[0070] In step (5), the pre-burning temperature is 400°C, and the pre-burning time is 2h;

[0071] In step (6), the mass fraction of polyvinyl alcohol glue is 7%, and the pressure is 10.0Mpa;

[0072] In step (7), debonding is car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com