Method for improving strength of plastic quick-formed parts and equipment for producing special wires

A molding and fast technology, applied in the direction of additive processing, etc., can solve the problems of inability to accurately control the temperature of the heating area, complex mechanical structure, poor equipment reliability, etc., and achieve excellent microwave absorption, good effect, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This method is used to make a rapid prototyping part of the car rearview mirror housing. The material is ABS, the outline size is 220mm×200mm×80mm, and the minimum wall thickness is 2.5mm.

[0031] It is a method for improving the strength of plastic rapid prototyping parts, including the following steps:

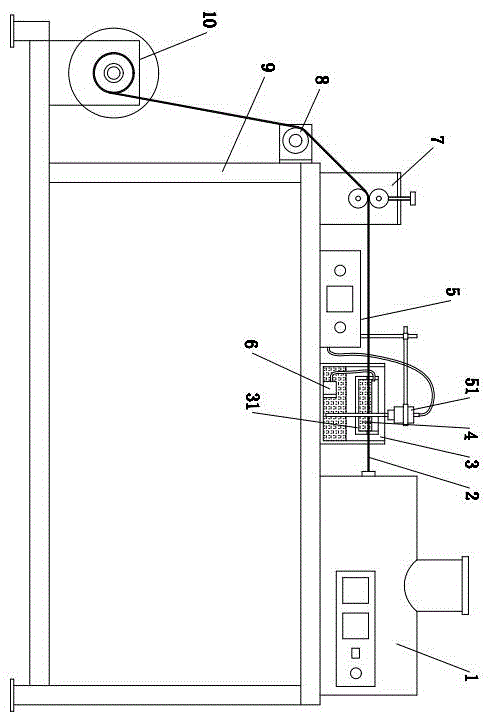

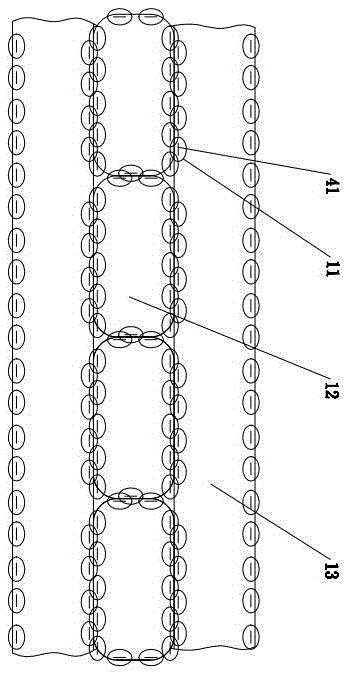

[0032] Step 1: Preparation of plastic wire with graphene microchips adhered to the surface

[0033] Use the plastic extruder 1 to extrude the ABS plastic pellets into a special wire 2 for 3D printers with a diameter of 1.75±0.03mm. The special wire 2 is suitable for the fused deposition molding process (FDM); The hot special wire 2 is cooled and shaped by the cooling tank 3, and the graphene dispersion 4 is installed in the cooling tank 3. The special wire 2 passes through the cooling tank 3 and the graphene microchip is adhered to the back surface; the graphene microchip is to be adhered After the moisture on the surface of the special wire 2 evaporates to dryness, it is ...

Embodiment 2

[0044] This method is used to make rapid prototyping parts of the hair dryer shell, the material is PLA, the outline size is 180mm×160mm×90mm, and the minimum wall thickness is 2mm.

[0045] It is a method for improving the strength of plastic rapid prototyping parts, including the following steps:

[0046] Step 1: Preparation of plastic wire with graphene microchips adhered to the surface

[0047] Use the plastic extruder 1 to extrude the PLA plastic pellets into a 3D printer special wire 2 with a diameter of 3±0.05mmmm. The special wire 2 is suitable for the fused deposition molding process (FDM); The hot special wire 2 is cooled and shaped by the cooling tank 3, and the graphene dispersion 4 is installed in the cooling tank 3. The special wire 2 passes through the cooling tank 3 and the graphene microchip is adhered to the back surface; the graphene microchip is to be attached After the moisture on the surface of the dedicated wire 2 evaporates to dryness, use the winder 10 to wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com